Fault treatment method of dust remover valve for steelmaking system

A fault handling method and dust collector technology, applied in the manufacture of converters, etc., can solve problems such as abnormal operation of double pendulum valves, dust stuck in double pendulum valves, abnormal detection, etc., to achieve low self-cost and operating costs, avoid explosion venting, The effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

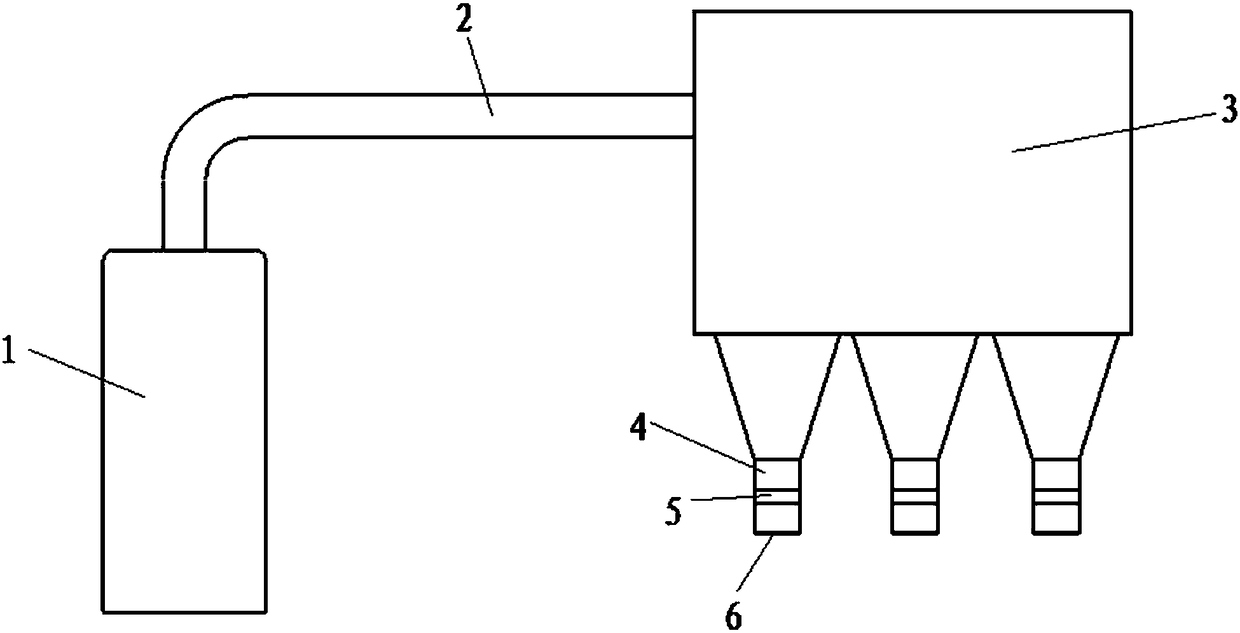

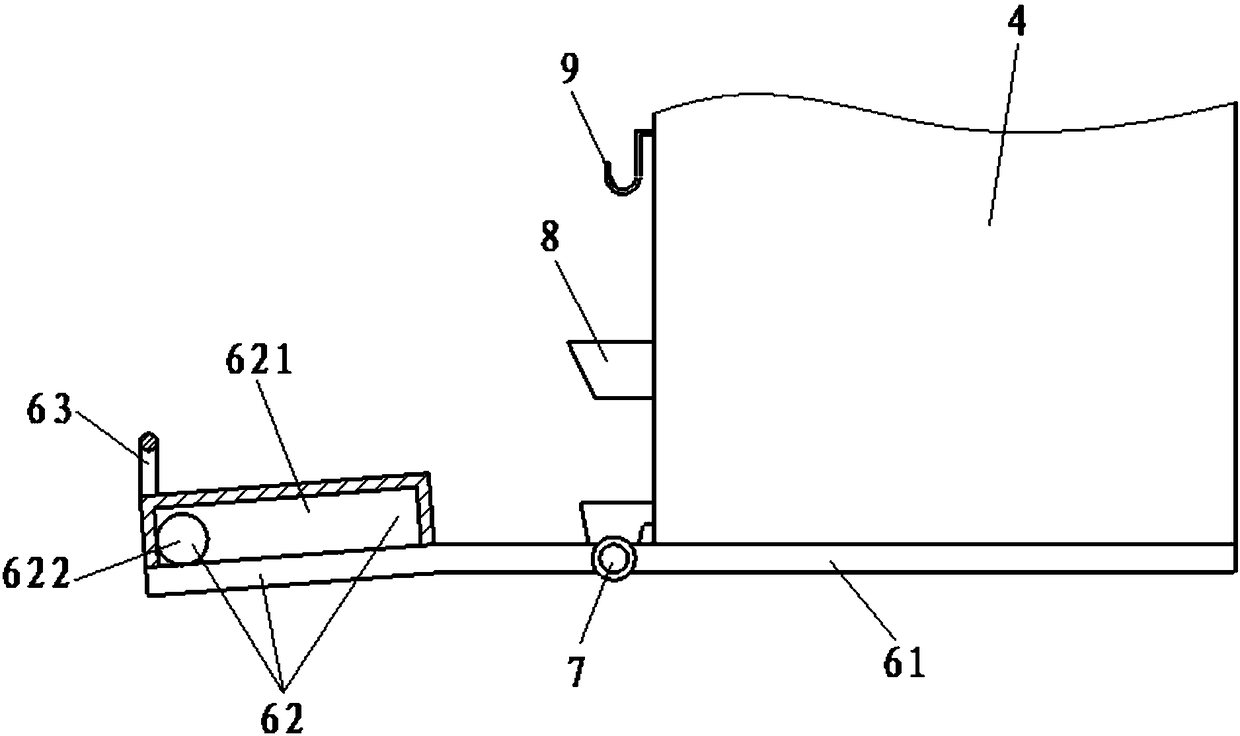

[0015] The troubleshooting method for the valve failure of the dust collector in the steelmaking system is as follows: set a temporary valve 6 on the dust discharge pipe 4 of the dust collector and below the valve 5 of the dust collector; when the valve 5 of the dust collector fails, keep the steelmaking system running normally The valve 5 is adjusted to normally open, and the temporary valve 6 is activated; the temporary valve 6 and the ash discharge pipe 4 of the dust collector are hinged through the rotating shaft 7, and the temporary valve 6 includes the ash discharge pipe cover 61 on one side of the rotating shaft 7 and the Gravity control structure 62; Gravity control structure 62 comprises gravity ball 622 and slideway 621, and gravity ball 622 is positioned at slideway 621 and can move along slideway 621 so that the distance of gravity b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com