Thin strip continuous casting cloth ladle liquid level detection method and device

A liquid level detection and liquid level technology, applied in the field of metallurgy, can solve the problems of low measurement accuracy, high cost, and unstable industrial application of liquid level detection of thin strip continuous casting cloth ladle, so as to improve the measurement accuracy, reduce the difficulty and Cost, effect of improving control stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Hereinafter, the present invention will be described in detail with reference to the drawings and examples. It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other.

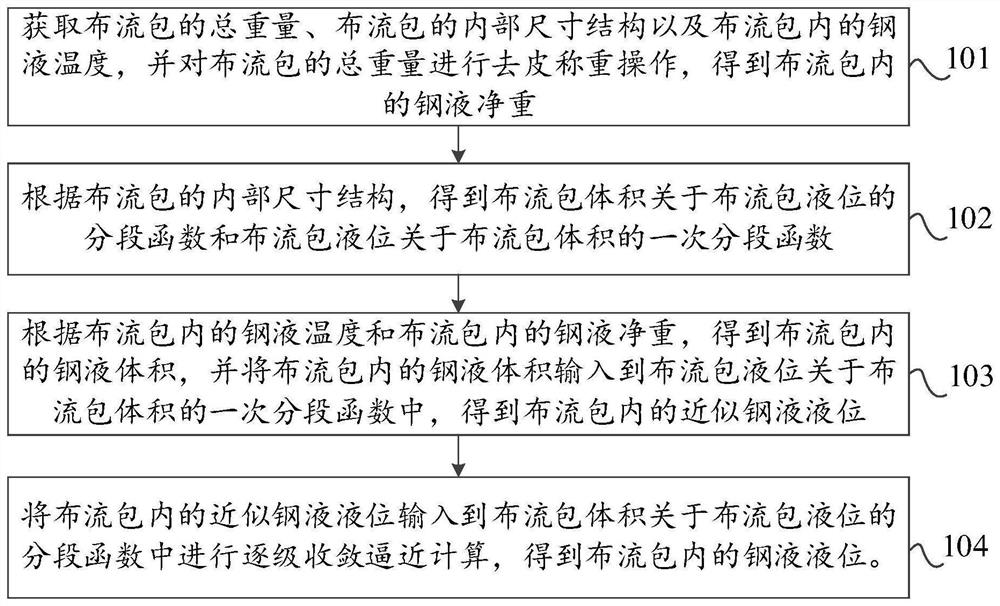

[0034] In one embodiment, such as figure 1 As shown, a thin strip continuous casting cloth ladle liquid level detection method is provided, and the application of this method to PLC controllers and other computer equipment is used as an example to illustrate, including the following steps:

[0035] 101. Obtain the total weight of the flow bag, the internal size and structure of the flow bag, and the temperature of the molten steel in the flow bag, and perform peeling and weighing operations on the total weight of the flow bag to obtain the molten steel in the flow bag net weight.

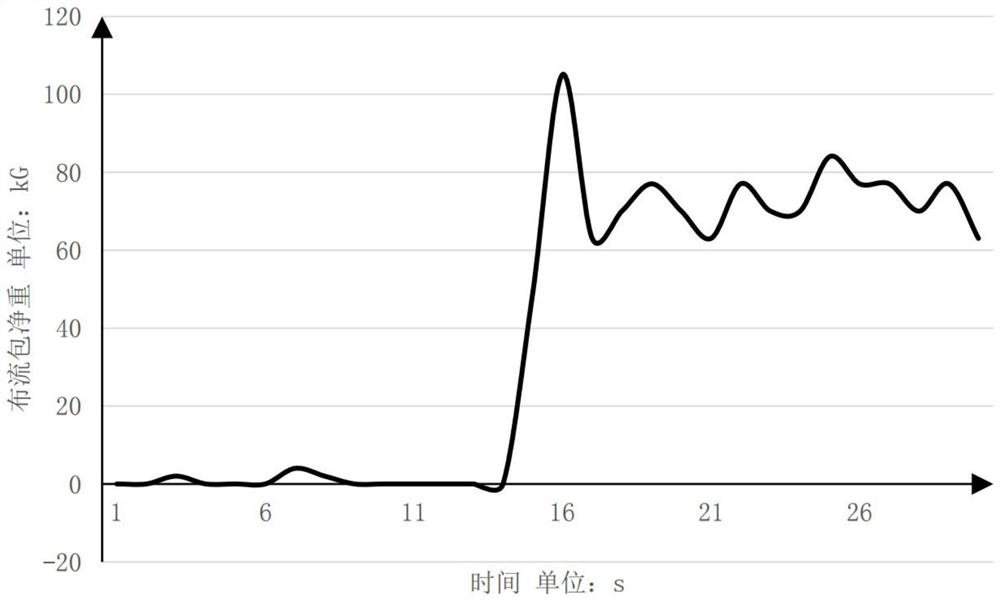

[0036] Specifically, the computer equipment can use detection elements such as rail scale sensors and continuous tempe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com