Ultra-thick high temperature-resistant steel for pressure vessel and preparation method thereof

A technology for pressure vessels and high temperature resistance, applied in temperature control, metal rolling, manufacturing tools, etc., can solve the problems of high alloy content, poor welding performance, high carbon equivalent, etc., and achieve good heat strength and large rolling process window , the effect of high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

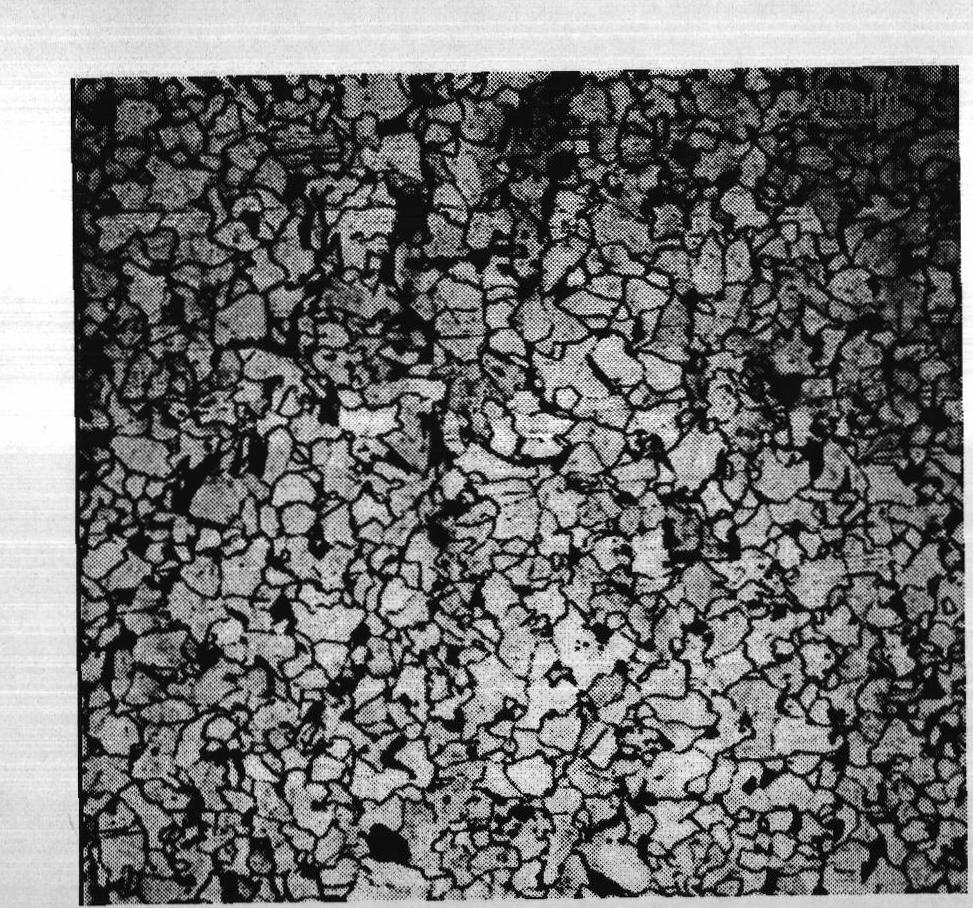

Image

Examples

Embodiment 1

[0033] An extra-thick high-temperature-resistant pressure vessel steel, wherein the chemical composition of the steel is: C 0.10%, Si 0.25%, Mn 0.60%, Cr 0.95%, V 0.25%, Mo 0.30%, P 0.011%, S 0.005 %, the remaining content is Fe and unavoidable inclusions.

[0034] The preparation method of the above-mentioned extra-thick high-temperature-resistant pressure vessel steel is as follows: including smelting, heating, rough rolling, finish rolling, normalizing, and tempering processes, wherein the basicity of the refining slag is controlled at 3.0, and the long nozzle for ladle pouring is protected by an Ar seal. The submerged nozzle of the tundish is fully protected with Ar sealing, and the superheat of the tundish is controlled at 21°C; the billet is heated in a heating furnace with a heating temperature of 1200°C and a heating time of 4.5 hours. The steel billet comes out of the furnace, and after being descaled by the pre-descaler, it enters the rough rolling mill for rolling. ...

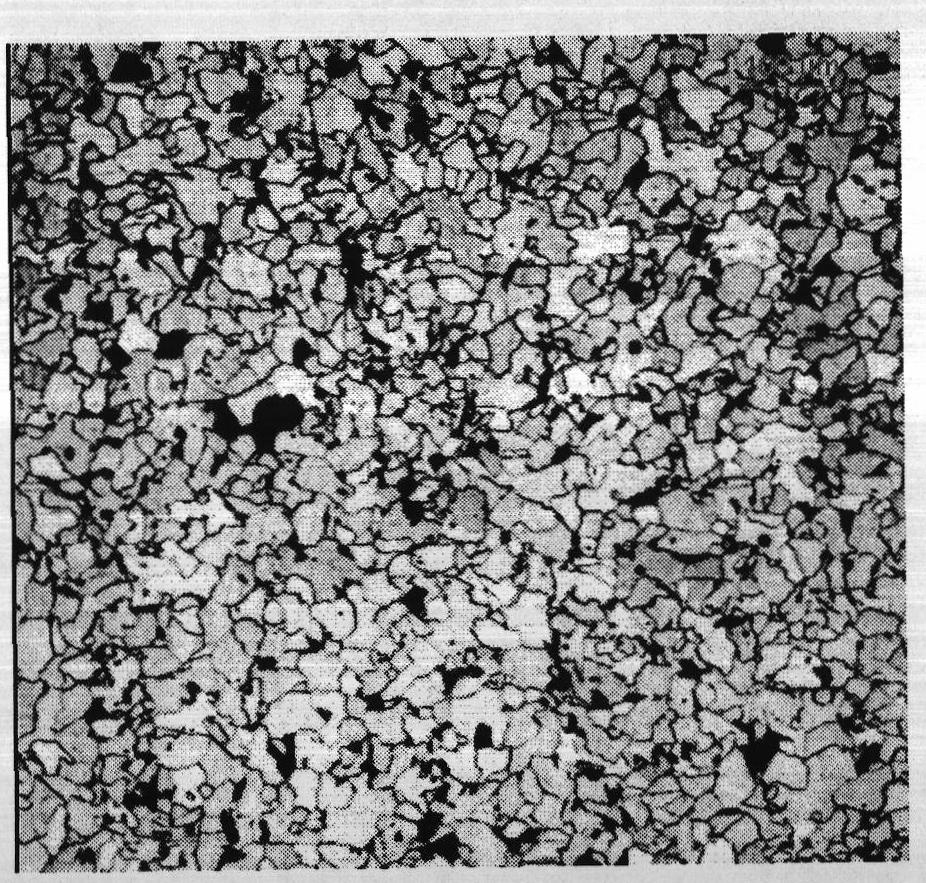

Embodiment 2

[0036] Steel composition is the same as in Example 1. The preparation method of the extra-thick high-temperature resistant pressure vessel steel is as follows: including smelting, heating, rough rolling, finish rolling, normalizing, and tempering processes, wherein the basicity of the refining slag is controlled at 3.5, and the long nozzle for ladle pouring is protected by an Ar seal. 1. Fully protected pouring with submerged nozzle and Ar seal in the tundish, the superheat of the tundish is controlled at 21°C; put the billet into the heating furnace for heating, the heating temperature is 1200°C, and the heating time is 4.5 hours. The steel billet comes out of the furnace, and after being descaled by the pre-descaler, it enters the rough rolling mill for rolling. The rolling temperature is 1171°C, and 6 passes of rolling are carried out. The reduction rates of each pass are: 9.47%, 7.93%, 6.84%, respectively. 13.64%, 13.27%, 11.73%, the total reduction rate is 48.7%, and the ...

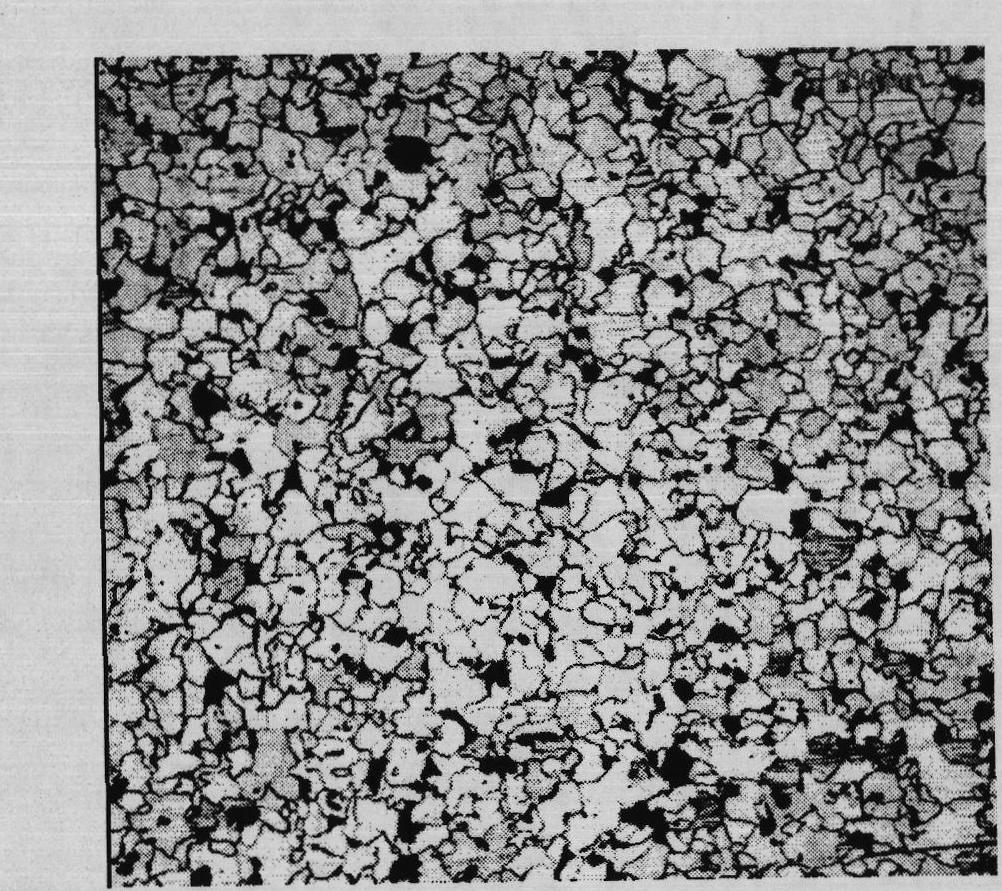

Embodiment 3

[0038] An extra-thick high-temperature-resistant pressure vessel steel, wherein the chemical composition of the steel is: C 0.09%, Si 0.30%, Mn 0.55%, Cr 1.00%, V 0.0.20%, Mo 0.27%, P 0.008%, S 0.002%, the rest is Fe and unavoidable inclusions.

[0039] The preparation method of the above-mentioned extra-thick high-temperature-resistant pressure vessel steel is as follows: including smelting, heating, rough rolling, finish rolling, normalizing, and tempering processes, wherein the basicity of the refining slag is controlled at 4.5, and the long nozzle for ladle pouring is protected by an Ar seal. The submerged nozzle of the tundish is fully protected with Ar sealing, and the superheat of the tundish is controlled at 21°C; the billet is heated in a heating furnace with a heating temperature of 1200°C and a heating time of 4.5 hours. The steel billet comes out of the furnace, and after being descaled by the pre-descaler, it enters the rough rolling mill for rolling. The rolling ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com