Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

418results about How to "Play a connecting role" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

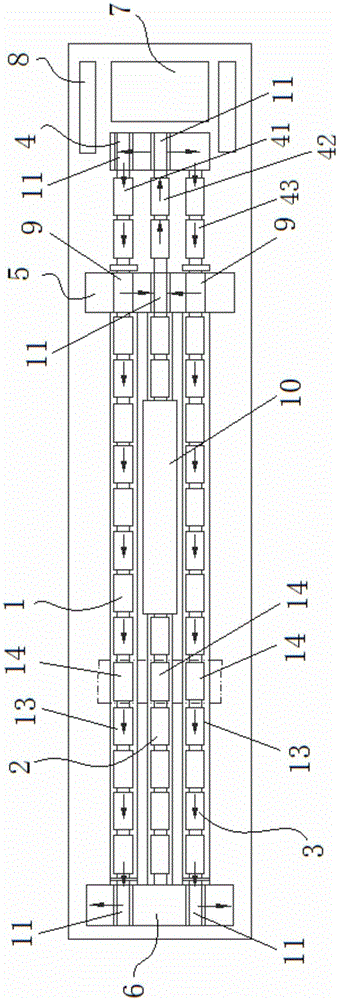

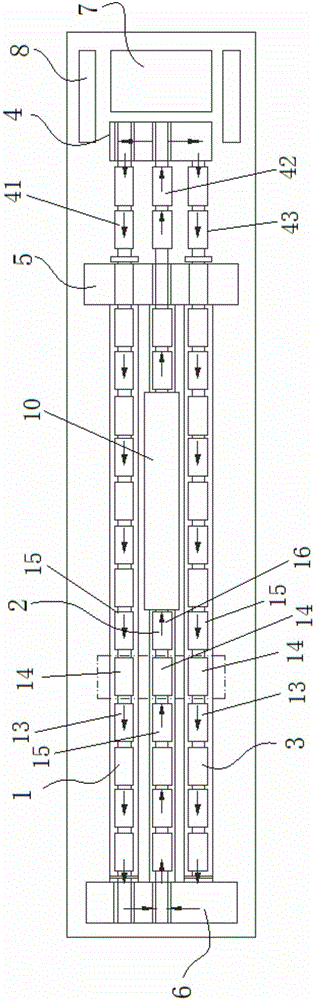

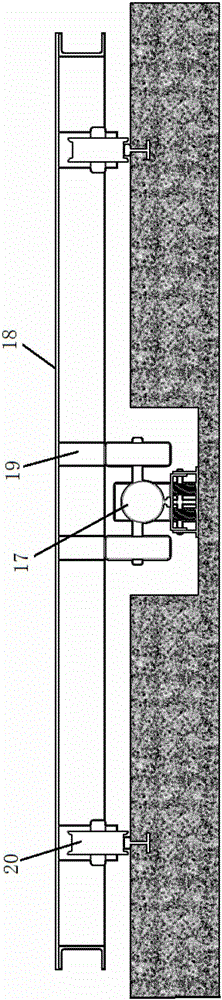

Three-dimensional production system of prefabricated components

ActiveCN105773827AIncreased production flexibilityIncrease productivityCeramic shaping plantsManufacturing engineeringKiln

The invention relates to the field of production of prefabricated components, in particular to a three-dimensional production system of the prefabricated components. The system comprises a prefabricated component production area on the upper layer, a maintenance area on the lower layer and a wheel type mold table; the prefabricated component production area includes a component prefabrication operation area, a component demolding operation area and an edge mold cleaning operation area; the maintenance area is provided with a linear maintenance kiln; the components are borne on a production line in the prefabricated component production area through the wheel type mold table, and move in the linear maintenance kiln in the maintenance area; a mold table ferry transverse moving station is arranged in the prefabricated component production area; a mold table lifting transverse moving device is arranged on the mold table ferry transverse moving station; a special production line and a production secondary line are arranged in the component prefabrication operation area; and the special production line drives the wheel type mold table to transversely move through the mold table lifting transverse moving device so as to connect with the production secondary line in parallel. The system comprehensively improves a prefabricated component production system, can realize multiple production modes, is more flexible in production, and greatly improves the production efficiency.

Owner:国新德

Carbon nano tube strengthening toughening silicon carbide ceramic and preparation method thereof

The invention discloses a carbon nano tube strengthening toughening silicon carbide ceramic. The ceramic is prepared from raw materials comprising silicon carbide powder, boron carbide micro powder, carbon dust, carbon nano tube, agglomerant and dispersing agent of which the weight ratio is 100:0.5-3:1.5-8:0.5-3:3-6:0.2-3.0. Hot pressed sintering or sintering-free process is adopted for preparation. A carbon nano tube strengthening hot pressed sintering silicon carbide material has the high flexural strength of 593MPa, weibull modulus achieves 14.7, reliability is substantially improved compared with general silicon carbide, excellent mechanical property of a carbon nano tube functions in the silicon carbide, and the prepared silicon carbide ceramic has excellent strengthening toughening performance.

Owner:NINGBO VULCAN TECH CO LTD

Biomass coal adhesive and biomass coal prepared by the same

InactiveCN101134920ASimple processRaw materials are easy to getSolid fuelsWaste based fuelChemistryBiomass

The present invention is one kind of biomass briquette adhesive and corresponding biomass briquette producing process. The pale yellow ropy biomass briquette adhesive is produced with crop stalk and through air drying, crushing, soaking in water, adding slaked lime and steaming while stirring. The biomass briquette adhesive has facile cheap material, high efficiency, simple production process and simple composition. The biomass briquette with high biomass adding amount and best utilization of biomass energy of crop stalk is produced through mixing the biomass briquette adhesive and powdered coal in certain ratio and extruding formation. The biomass briquette has high strength, high waterproofing performance, low burning point, high heat value and excellent sulfur fixing effect.

Owner:HENAN POLYTECHNIC UNIV

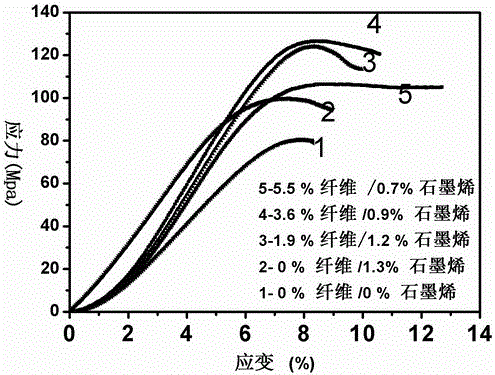

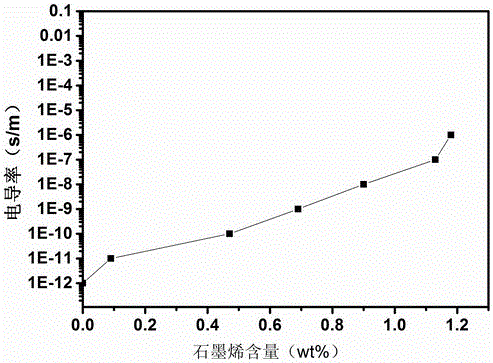

Aramid fiber reinforced 3D graphene/epoxy resin composite material as well as preparation method and application thereof

ActiveCN106832774AHigh compressive strengthImprove conductivityMagnetic/electric field screeningNon-conductive material with dispersed conductive materialEpoxy resin compositeGraphene

The invention relates to an aramid fiber reinforced 3D graphene / epoxy resin composite material and a preparation method thereof. Aramid fibers are uniformly distributed and loaded on 3D graphene, and the composite material has electrical conductivity of 102S / cm or higher and compressive strength of 115MPa or higher. The aramid fiber reinforced 3D graphene / epoxy resin composite material has high comprehensive strength and high electrical conductivity, and can be used as a conducting material or electromagnetic shielding material with good buffering capacity.

Owner:BEIJING UNIV OF CHEM TECH

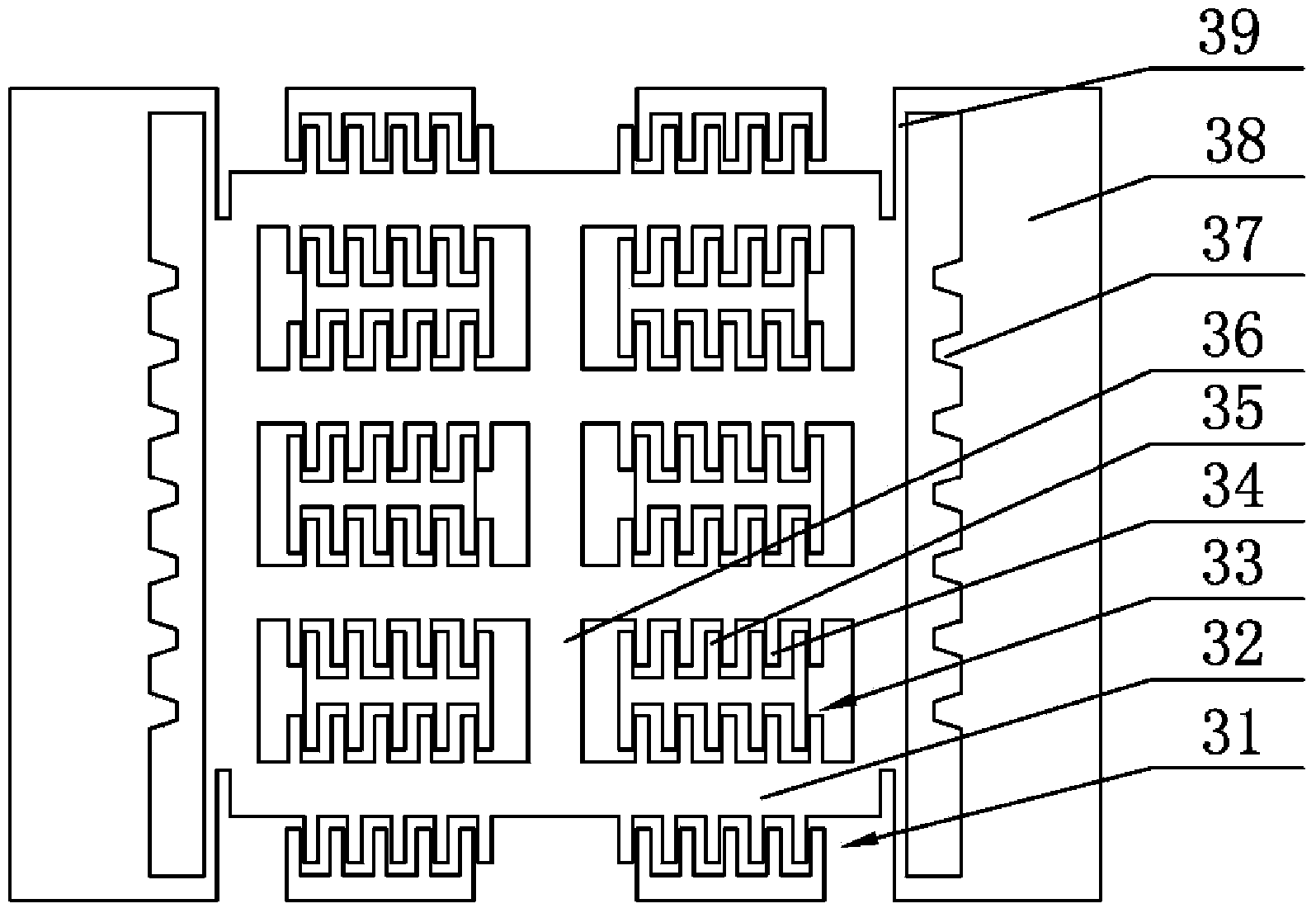

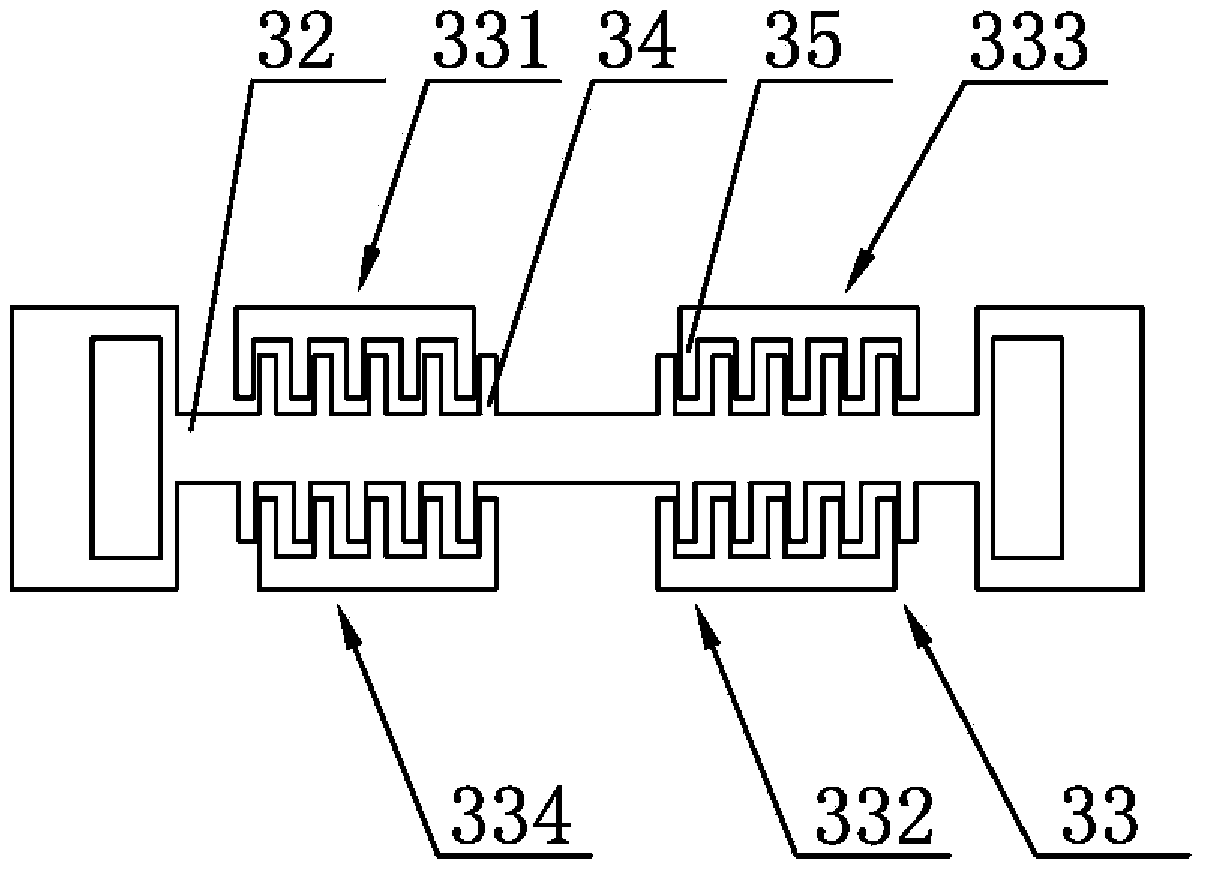

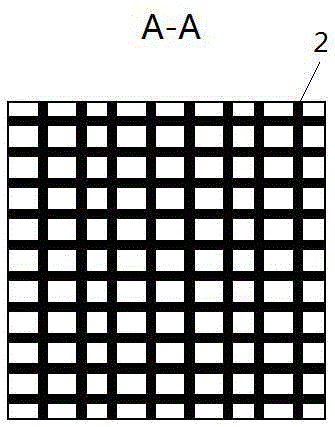

MEMS accelerometer

ActiveCN103954793AAvoid elevationSatisfy invarianceTelevision system detailsAcceleration measurement using interia forcesHysteresisAccelerometer

An MEMS accelerometer comprises a substrate, an acceleration sensitive chip and an integrated circuit, wherein the acceleration sensitive chip and the integrated circuit are arranged on the substrate, a temperature sensor is further arranged on the substrate and is adjacent to the acceleration sensitive chip, and the acceleration sensitive chip comprises a plurality of measurement bodies. Each measurement body comprises a mass block and a comb tooth structure, wherein the comb tooth structure comprises movable comb teeth extending from the mass block and fixed comb teeth, the movable comb teeth and the fixed comb teeth are arranged at intervals and form a difference detection capacitor, the comb tooth structure is divided into multiple groups, the multiple groups of comb teeth structures are divided into a first part and a second part, the variation direction of movable intervals of the comb tooth structure of the first part and the variation direction of movable intervals of the comb tooth structure of the second part are opposite, and one group of the comb tooth structure and one group of the comb tooth structure of the second part respectively output an electric signal. The MEMS accelerometer resolves the problems that a traditional MEMS accelerometer is large in temperature factor and large in temperature hysteresis.

Owner:INST OF GEOLOGY & GEOPHYSICS CHINESE ACAD OF SCI

Scaffold

ActiveCN104372923APlay a connecting roleEasy to buildScaffold connectionsScaffold accessoriesEngineeringFastener

The invention discloses a scaffold which comprises stand columns, long transverse pipes, first connecting fasteners, second connecting fasteners and a bearing plate. The stand columns and the long transverse pipes are all seamless square pipes. The two ends of each long transverse pipe are provided with through holes. The first connecting fasteners are of a coaxial dual-hinge structure. Each second connecting fastener is of a dual-bole connection hinge structure. A base is fixed to the side edge of each hinge structure, wherein the base extends in the axial direction of the hinge structure to form a protrusion. The protrusions are matched with the through holes in size. The bearing plate is of a flat plate structure, and the upper portions of the two side edges of the bearing plate extend and protrude downwards to form hooks. According to the scaffold, each first connecting fastener is used for connecting two corresponding stand columns conveniently and rapidly, and materials are saved; then the second connecting fasteners are utilized for fixing the long transverse pipes to the stand columns; the bearing plate is used for being hung on the long transverse pipes to play a bearing role and a connection role for the scaffold as well, and therefore scaffold construction is convenient and easy.

Owner:WUXI SAFETY SCAFFOLDING

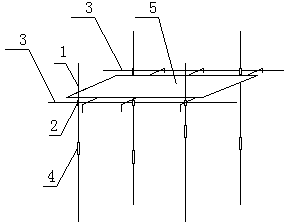

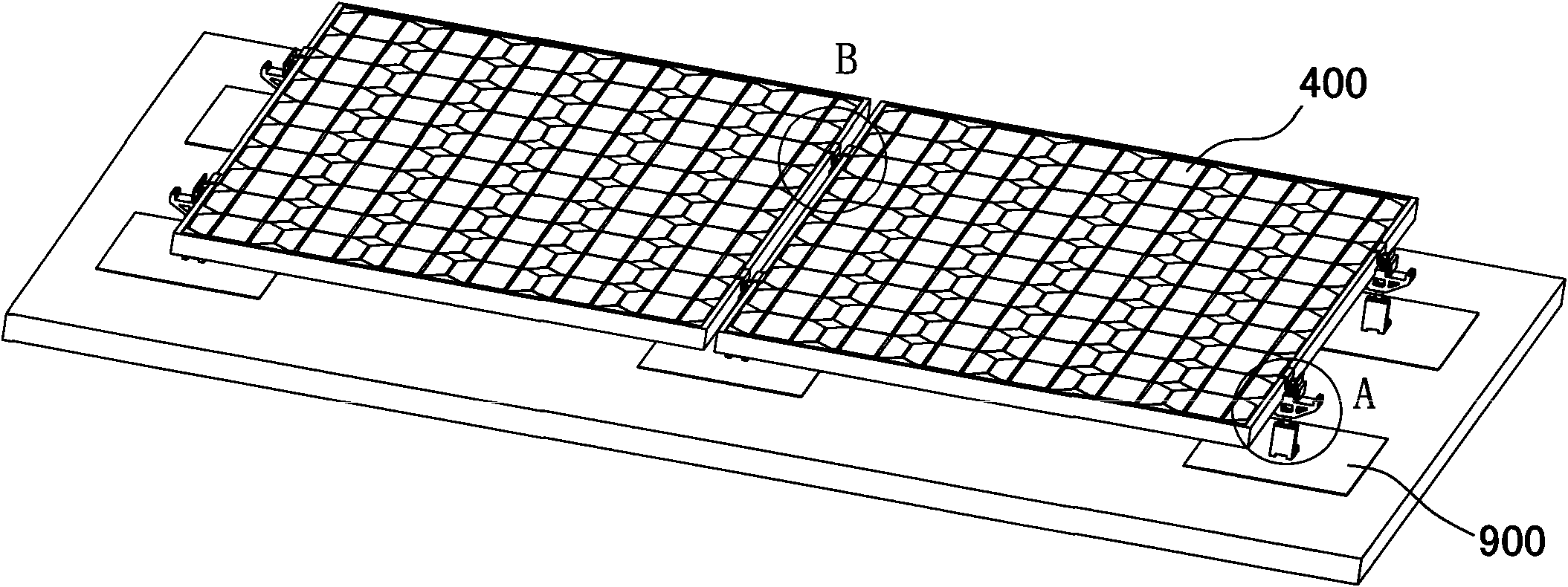

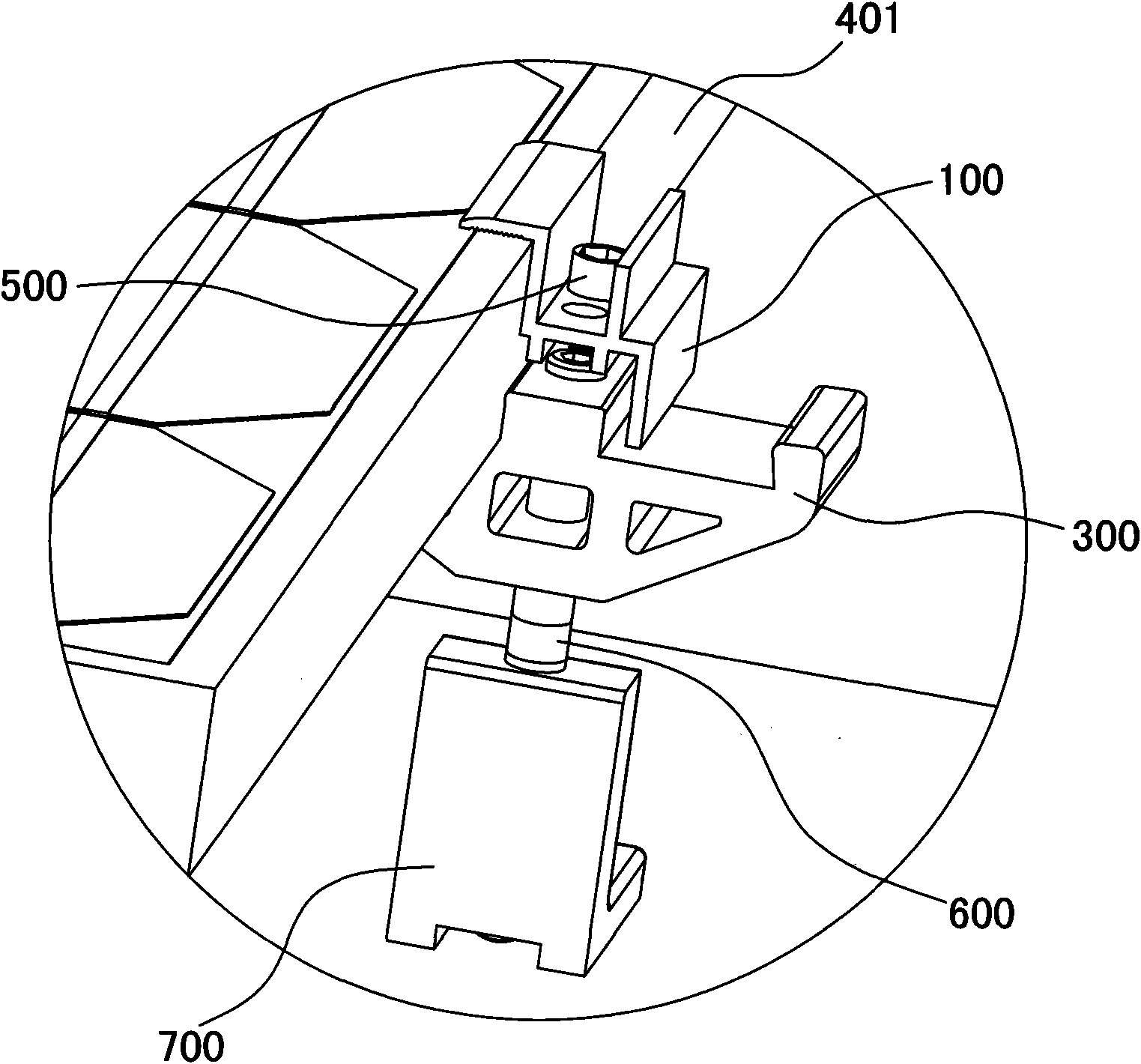

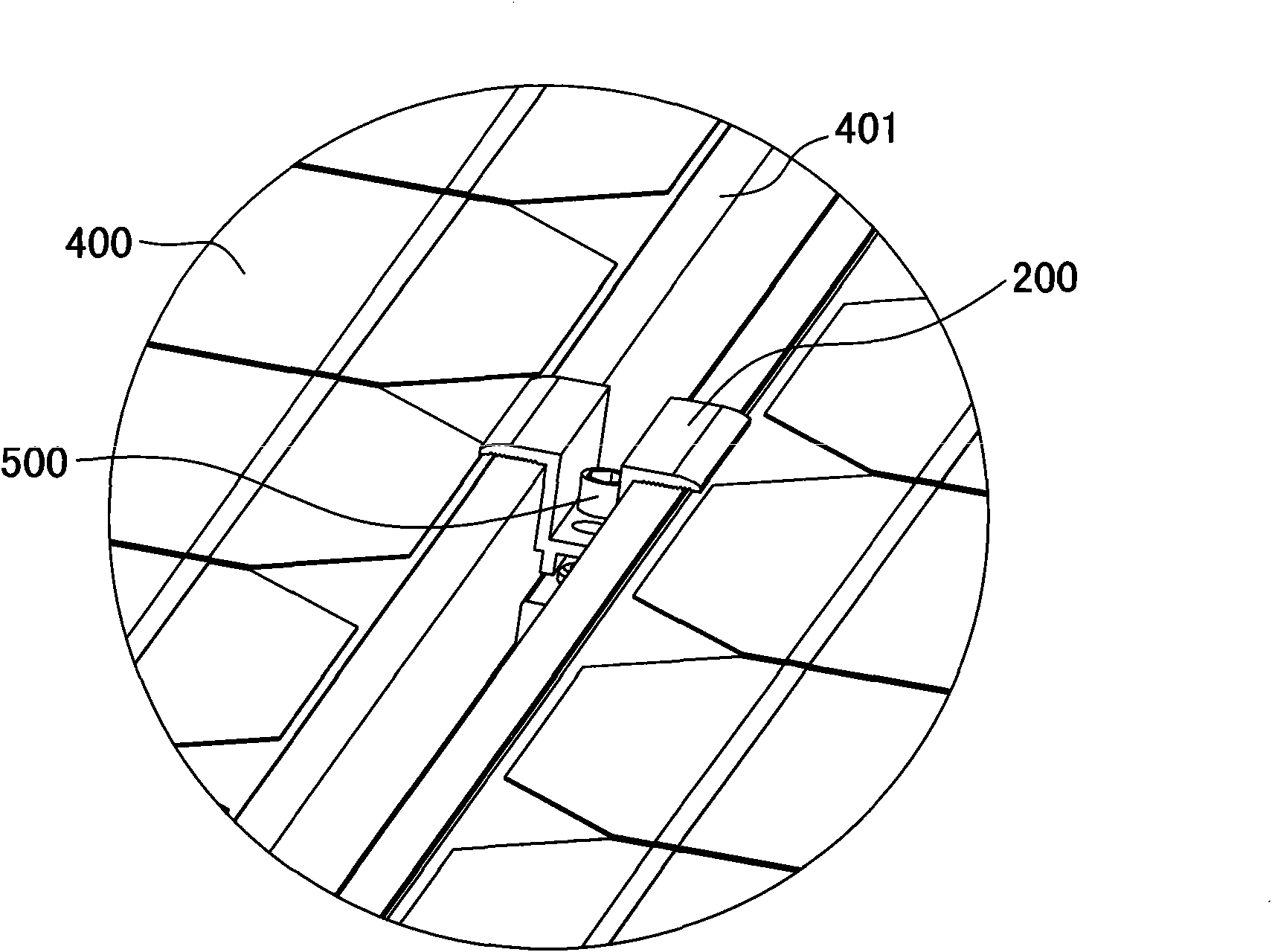

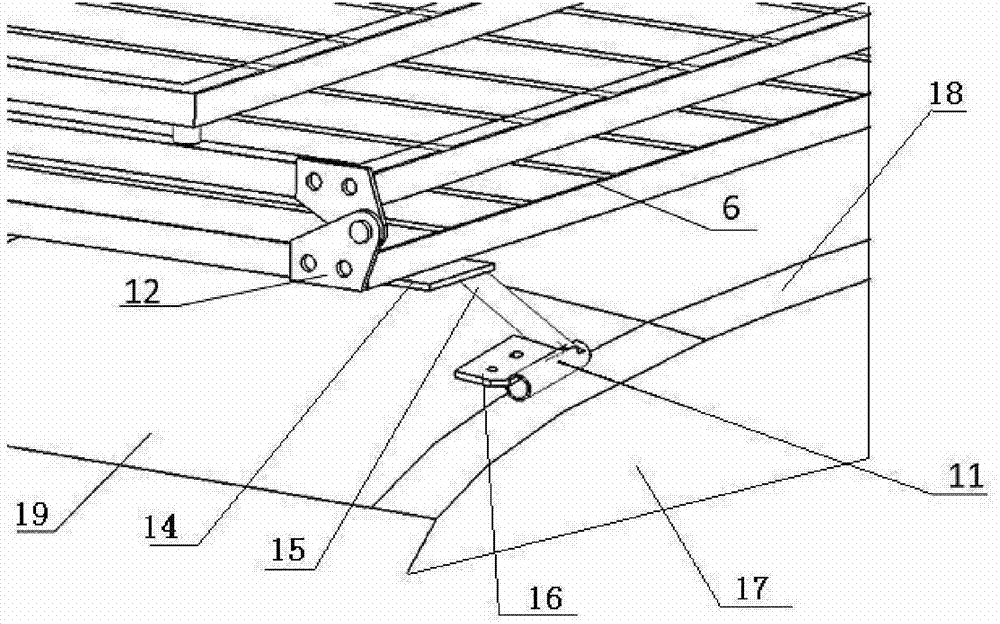

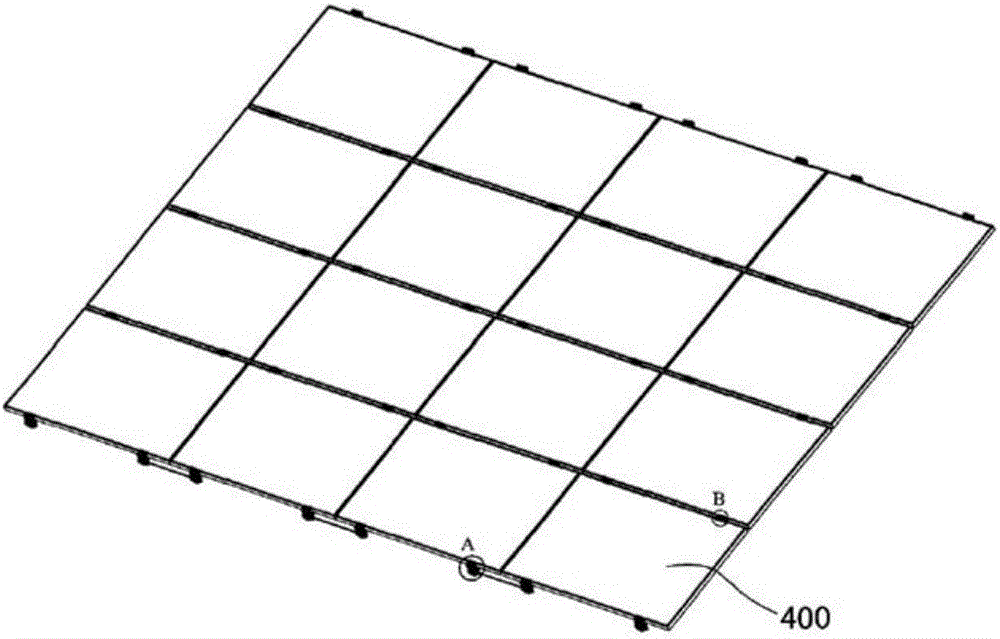

Roof photovoltaic power generation system

InactiveCN102005977AEasy to installNeatly installedPhotovoltaic supportsRoof covering using slabs/sheetsPetroleum engineeringPhotovoltaic power generation

The invention discloses a roof photovoltaic power generation system. The system comprises a solar photovoltaic module, an edge card, a middle card, an adjusting block, an adjusting rod and a footing, wherein the adjusting rod is provided with an upper external thread and a lower external thread between which a polish rod part is connected and which have opposite turning directions; the top of the adjusting rod is provided with a turning structure, the bottom of the adjusting rod is provided with a second connecting section with an external thread, and the diameter of the second connecting section is smaller than that of the adjusting rod; the footing is arranged under the adjusting block and is connected with the adjusting block through the adjusting rod; the upper thread of the adjusting rod is connected with an adjusting screw hole of the adjusting block in a matching mode, and the lower thread of the adjusting rod is connected with a second adjusting screw hole of the footing in the matching mode; and the second connecting section of the adjusting rod is provided with a nut which is clamped in a through hole below the second adjusting screw hole of the footing. By the roof photovoltaic power generation system, the photovoltaic module can be adjusted up and down, the installation surface of the photovoltaic module has a consistent height, and the normal generating efficiency of the photovoltaic module is ensured.

Owner:CSI SOLAR POWER GROUP CO LTD +1

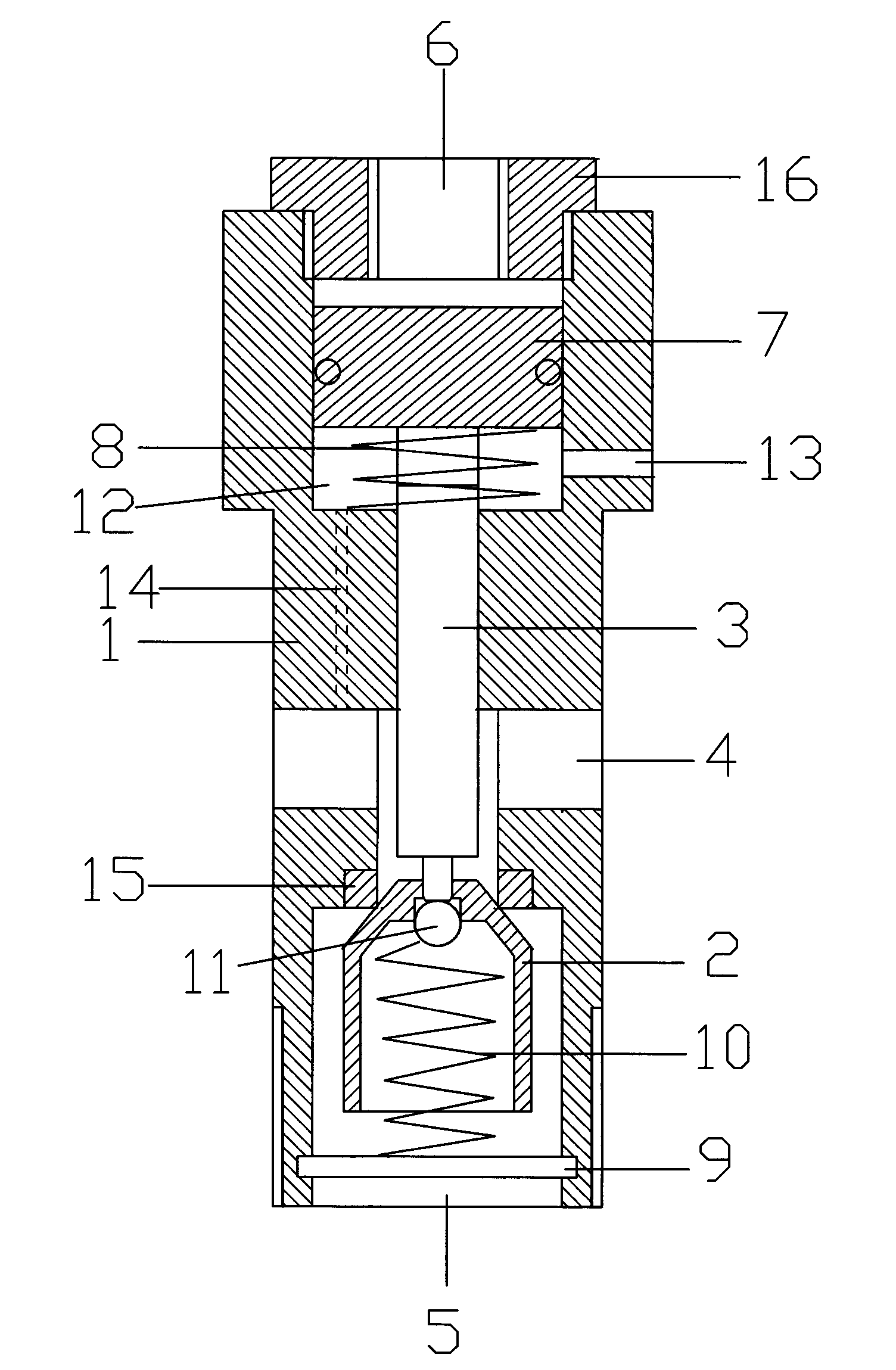

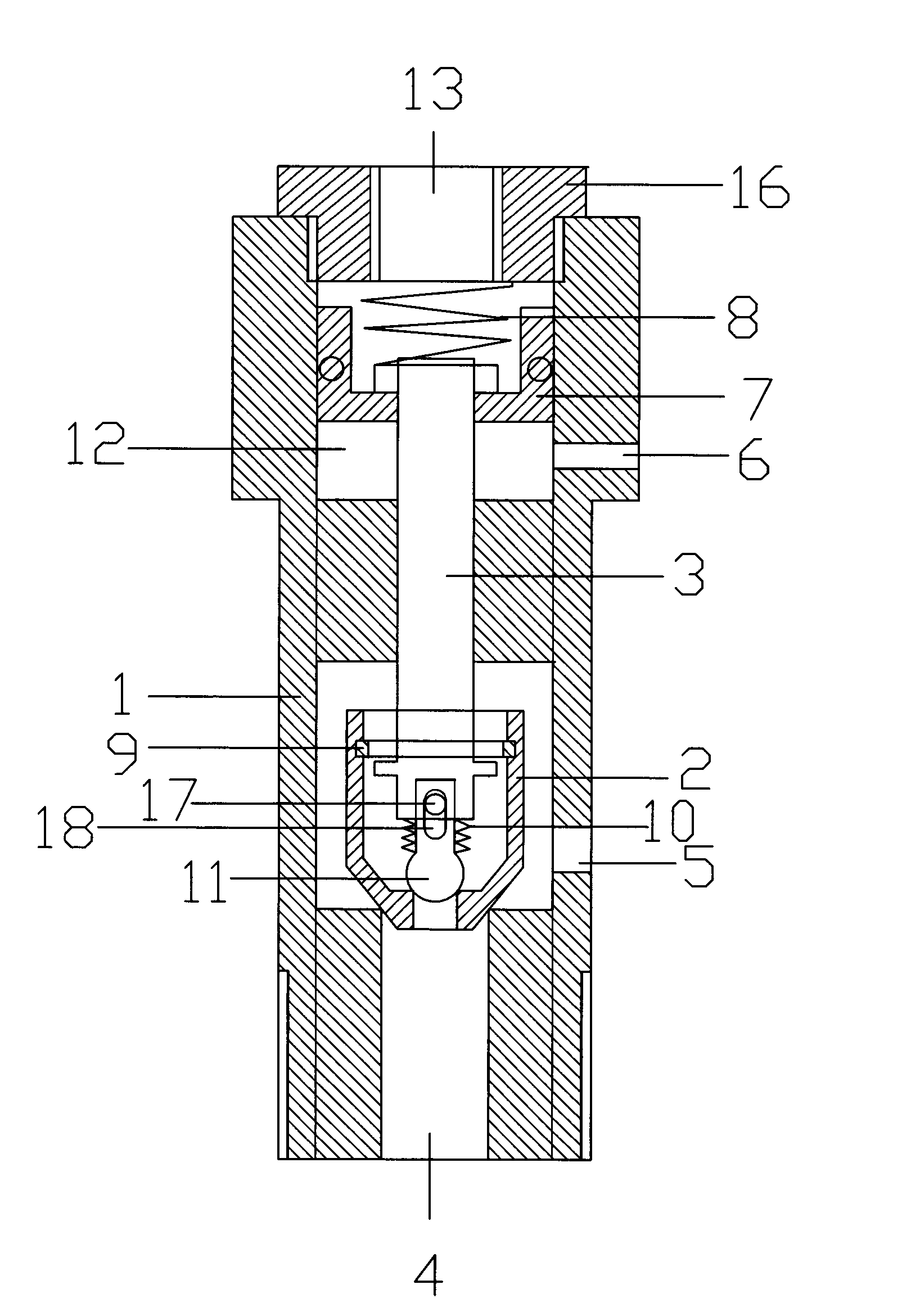

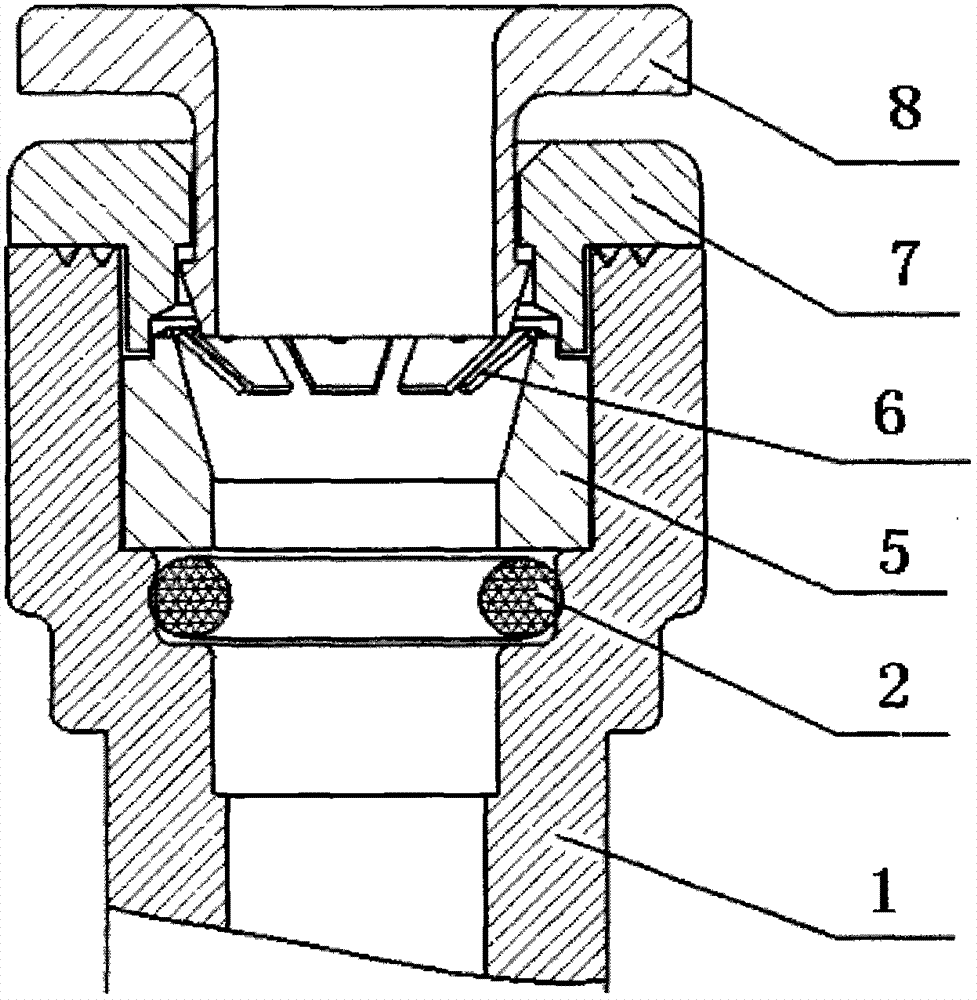

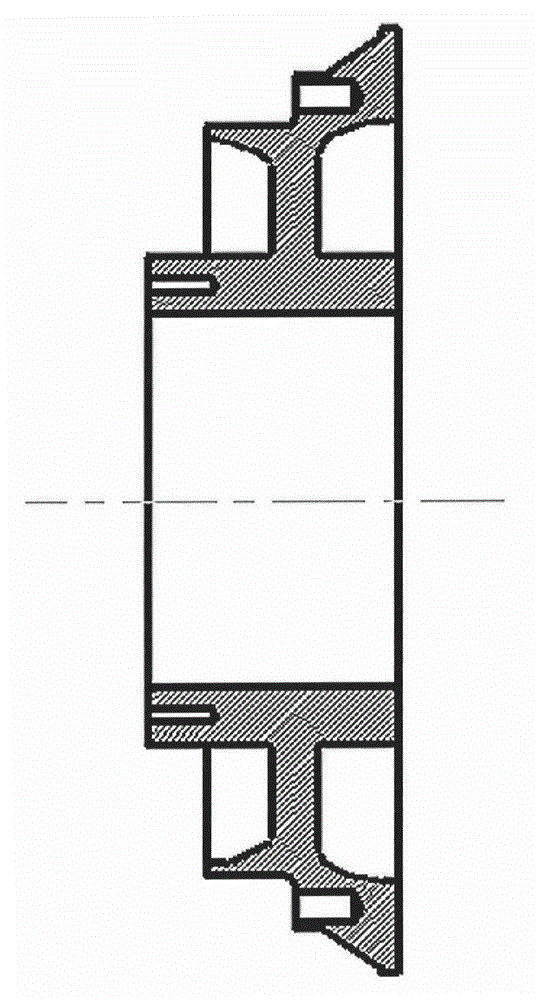

Hydraulic one-way valve

ActiveCN102102689APlay a connecting roleControl switchServomotor componentsCheck valvesEngineeringScrew thread

The invention discloses a hydraulic one-way valve which comprises a valve body (1), a main valve plug (2) and a top rod (3), wherein the valve body (1) is provided with a liquid inlet (4), a liquid outlet (5), a control liquid inlet (6) and a liquid discharge channel; the main valve plug (2) and the top rod (3) are arranged in the valve body (1); the outer diameter of the upper end head part of the valve body (1) is greater than the outer diameter of the part below the head part; the part below the head part of the valve body (1) is provided with outer screw threads; the valve wall of the part below the head part of the valve body is provided with a plurality of transverse channels; the valve body is through up and down; the upper part of the top rod (3) is provided with a control piston (7); the control piston is also provided with a spring II (8); and one end of the spring II is fixed on the control piston (7), and the other end of the spring II is fixed on the valve body (1). By adopting the hydraulic one-way valve provided by the invention, the hydraulic components and pipelines can be connected, thus an articulated bolt and the hydraulic one-way valve can be integrated.

Owner:林友根

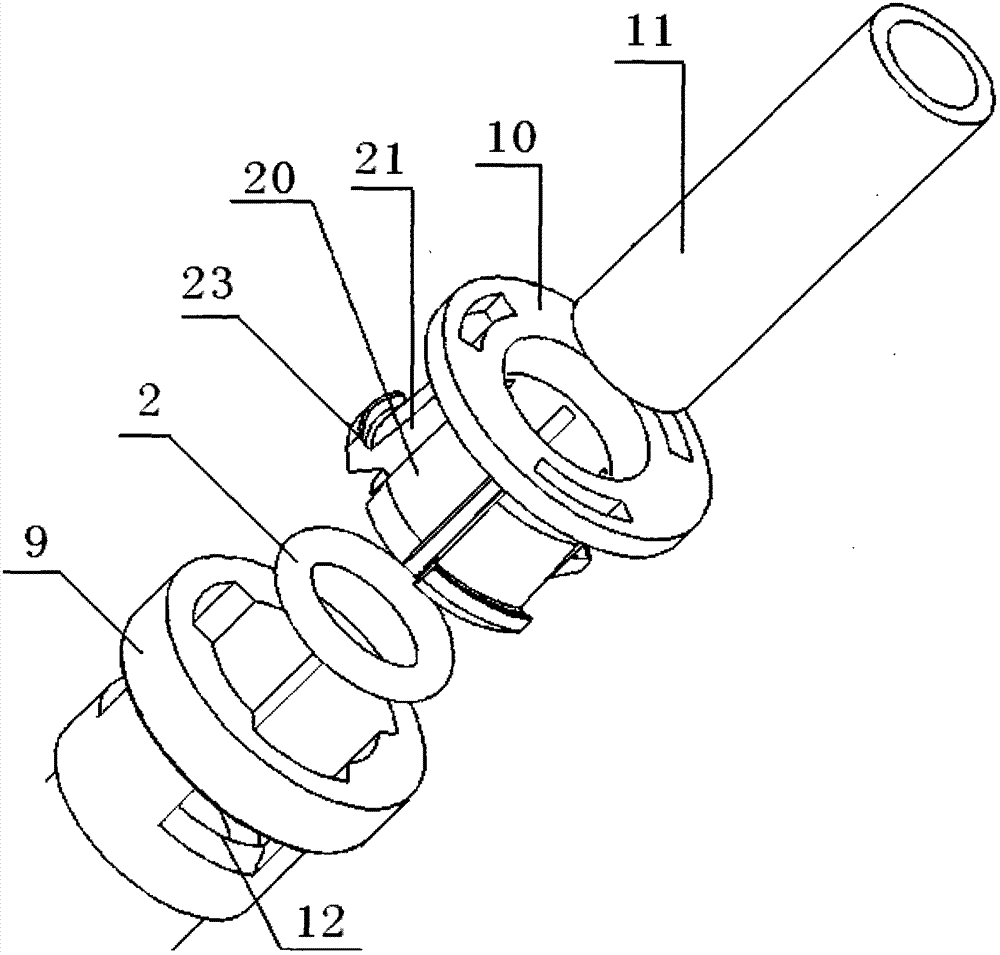

Quick coupling

InactiveCN102927392AEasy to install and disassembleSimple structureCouplingsCouplingAssembly disassembly

The invention belongs to the field of pipe connection, and particularly relates to a rapid coupling which is applied to the connection pipes and valves of fluids such as gas and liquid. The quick coupling comprises three components, namely a connection body, a sealing ring and a multifunctional movable sleeve; the three components can be freely assembled, disassembled and changed; the sealing ring is arranged between a ring-shaped boss in the connection body and a fixed limiting pin of the multifunctional movable sleeve and only moves in the range of the sealing wall of the connection body; the quantity of square side through holes of the connection body is equal to the quantity of elastic arm barb claws on the multifunctional movable sleeve; the elastic arm barb claws are correspondingly arranged and hooked on the hook walls of the square side through holes; and the inclined planes of the square side through holes of the connection body are staggered away from the inclined planes of the barb claws of the multifunctional movable sleeve. The quick coupling provided by the invention has the effects of overcoming the defects of the conventional quick couplings, enabling the mounting and dismounting between the connection pipes as well as between the connection pipes and the valves to be convenient and quick, being simple in structure, simple in manufacturing process and high in production efficiency, reducing the production cost and having wide application.

Owner:史在恒

Tent installed on roof panel

ActiveCN103089060APlay a supporting roleEliminate the risk of collapseTents/canopiesAdhesiveEngineering

The invention relates to a tent, in particular to a foldable tent installed on a roof panel. The tent installed on the roof panel comprises a tent body and a mounting seat. The mounting seat comprises a tent connecting end, a vehicle connecting end and a supporting piece. The supporting piece is respectively connected with the two ends of the mounting seat. The supporting piece is provided with a supporting end, the supporting end abuts against a weld joint adhesive tape, the weld joint adhesive tape is located between a lateral enclosing plate and the roof panel, and gravity of the tent body is transmitted to the weld joint adhesive tape through the tent connecting end and the supporting end sequentially. The mounting seat enables the tent body to be connected with a vehicle, wherein the tent connected end of the mounting seat and the vehicle connected end mainly play a role in connecting, and the supporting pieces place a role in supporting. The supporting end abuts against the weld joint adhesive tape, and the gravity of the tent body is transmitted to the weld joint adhesive tape through the tent connecting end, the supporting piece and the supporting end sequentially, and therefore collapse risks caused by the fact that load bearing of the roof panel is too large are avoided.

Owner:HANGZHOU BRANCH ZHEJIANG GEELY AUTOMOBILE RES INST +2

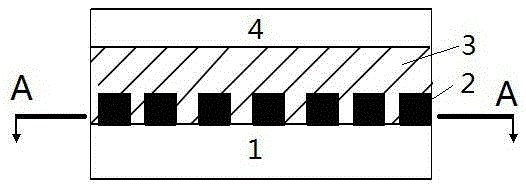

Production and separation method for flexible substrate

ActiveCN105428312AImprove stabilityWide range of applicationsSolid-state devicesSemiconductor/solid-state device manufacturingMesh gridManufacturing engineering

The invention discloses a production and separation method for a flexible substrate. The method comprises: preparing a combination layer composed of a connection layer and a grid-shaped continuous frame layer between a rigid substrate and a flexible substrate, wherein the continuous frame layer is stable under the preparation condition of subsequent corresponding devices or film layers and is decomposed by specific treatment; changing a reaction condition to realize decomposition or morphologic change of the continuous frame layer; and forming a grid-shaped gas passage in the connection layer to remove the connection layer in a plasma atmosphere so as to finish the separation of the flexible substrate. According to the separation method, not only can the stripping of the substrate be finished on the premise of ensuring the intact substrate but also a mature glass substrate based film layer preparation process and a matching device can be fully utilized, so that the method has promotional values.

Owner:SHANGHAI UNIV

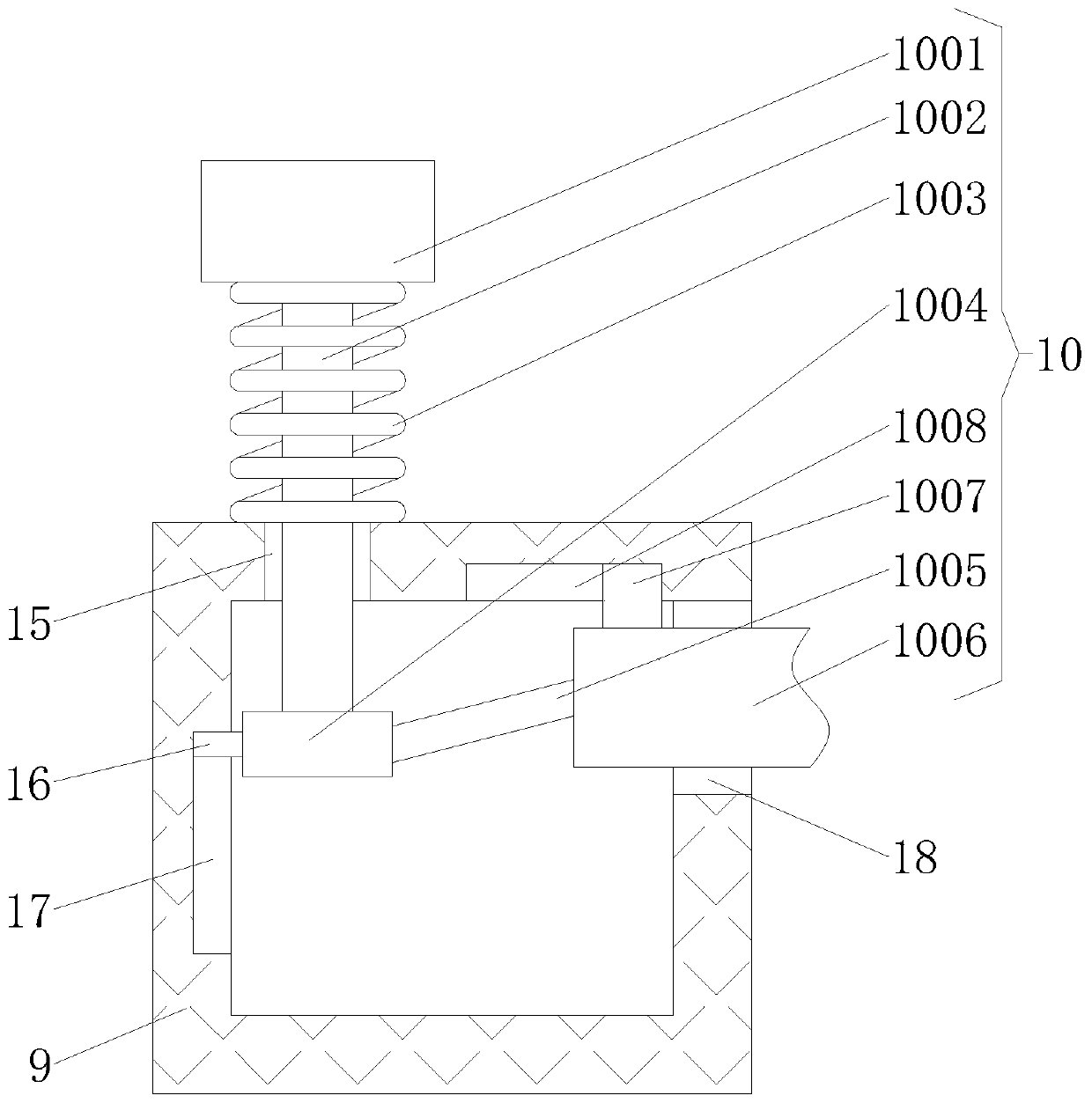

Steel structure correcting and lifting system and construction technology thereof

ActiveCN108824720APrevent problems such as poor installation effectPositioningBuilding material handlingStairwaysAutomatic controlEngineering

The invention relates to a steel structure correcting and lifting system and a construction technology thereof. The steel structure correcting and lifting system comprises a supporting base plate, supporting push rods, a placing plate, rotary rollers, a position adjusting device and a positioning device. The supporting push rods are uniformly mounted on the top of the right side of the supportingbase plate, the placing plate is installed on the tops of the supporting push rods, a square groove is formed in the middle of the right end of the placing plate, and rotary rollers are symmetricallymounted at the front and rear ends of the top of the placing plate. The position adjusting device is mounted on the top of the right side of the supporting base plate, and the positioning device is mounted on the top of the left side of the supporting base plate. The steel structure correcting and lifting system can solves the problems that when an existing steel structure stair is mounted, stairplacing angles need to be corrected manually, the manual moving of a steel structure stair is more difficult, the steel structure stair is lifted with human assistance, the stair cannot be fixed whenlifting the steel structure, a stair lifting angle cannot be controlled automatically, and wounding hidden danger happens when the stair is lifted.

Owner:鹤山市建筑设计院有限公司

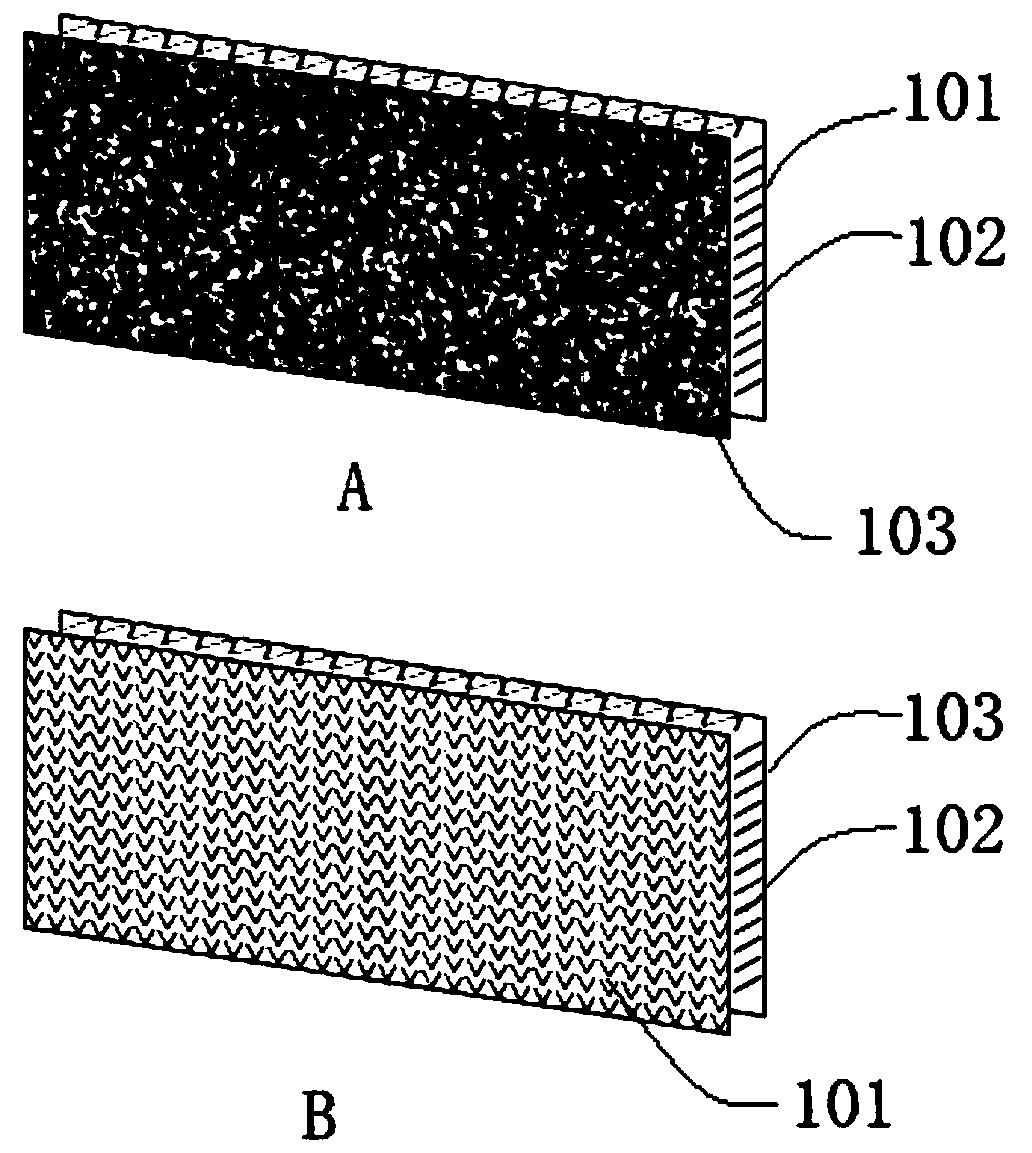

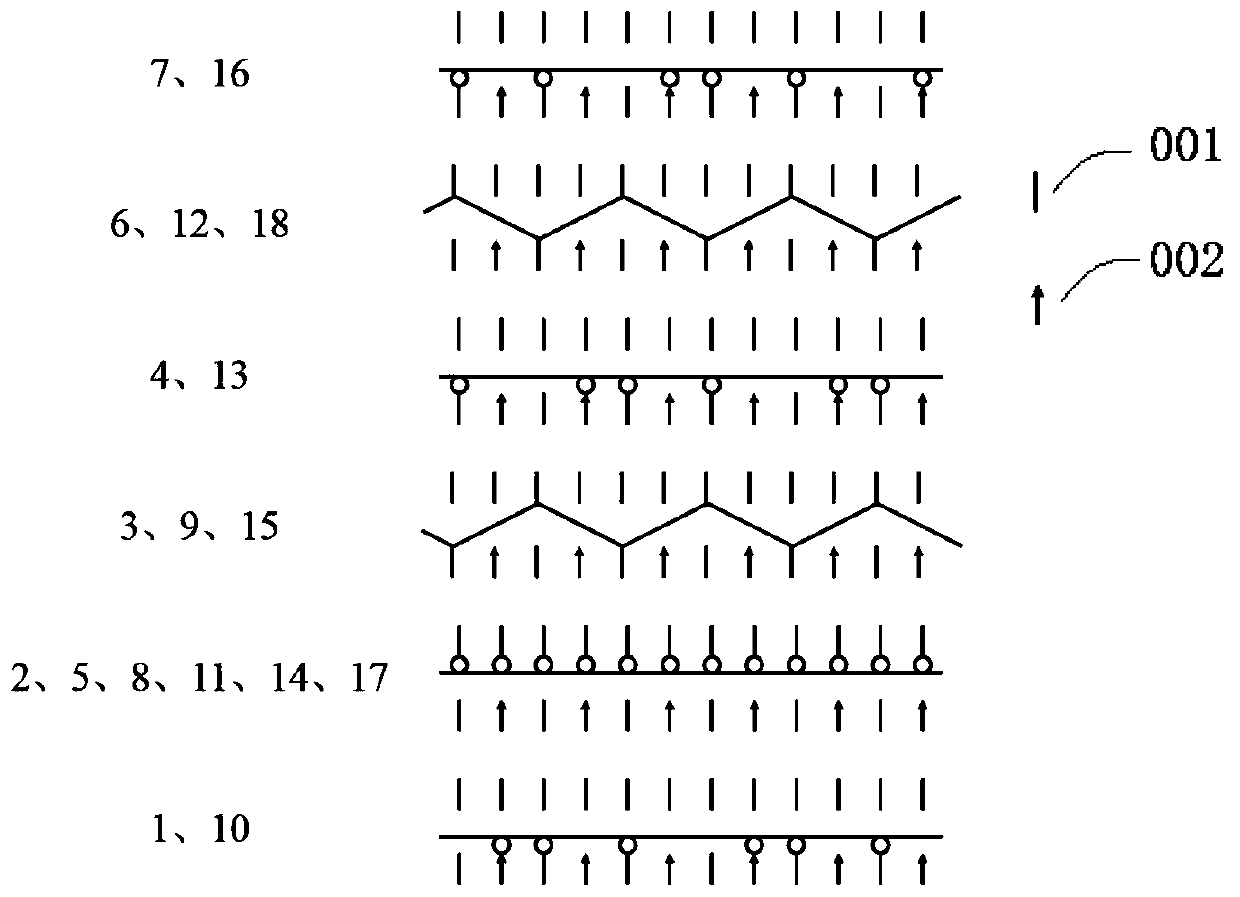

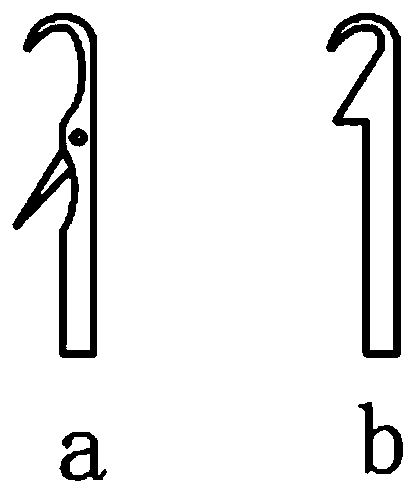

Two-sided weft-knitted cut-pile knitted fabric and knitting method thereof

ActiveCN110760980AReduce the problem of hair sheddingOmit the link of fleece treatmentCircular knitting machinesYarnStructural engineering

The invention discloses a two-sided weft-knitted cut-pile knitted fabric and a knitting method thereof. The fabric comprises a piled layer, a flat layer and a connection layer, the connection layer isconnected with the flat layer and the piled layer, and loop formation and loop cutting for pile formation of the piled layer are completed in one step. The weft-knitted cut-pile knitted fabric is knitted by a circular weft knitting machine, cylinder needles include knife needles and latch needles, dial needles include latch needles, and accordingly front and back faces of the fabric can be different in loop density, and the loop density of the flat layer of the fabric is larger than that of the piled layer; due to one-step completion of loop formation and cutting of the piled layer, production cost is saved, and production efficiency is improved; owing to the connection layer, fixation and isolation effects on the flat layer and the piled layer are achieved, dimensional stability of the fabric is improved, and exposure of pile yarns or connection yarns of the fabric is reduced. By adoption of the knitting method, procedures of a fabric compounding process are avoided, safety of the fabric is guaranteed, and the method has a promising application prospect in garment fabrics, home textile fabrics, industrial fabrics and the like.

Owner:JIANGNAN UNIV

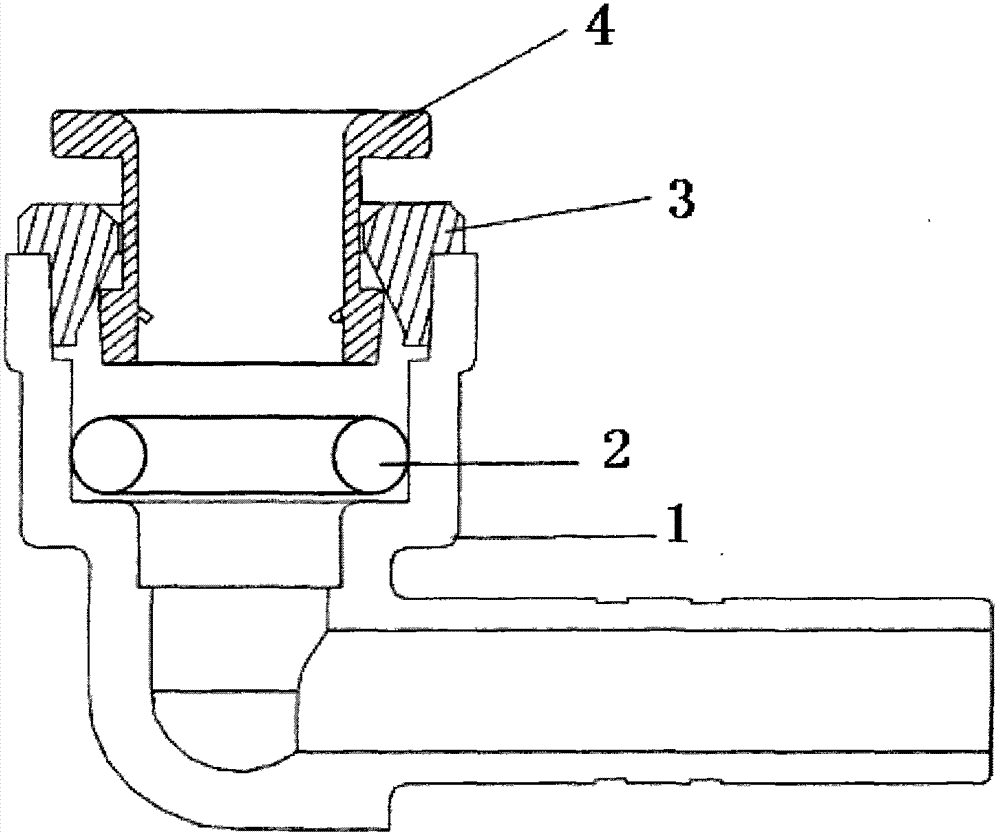

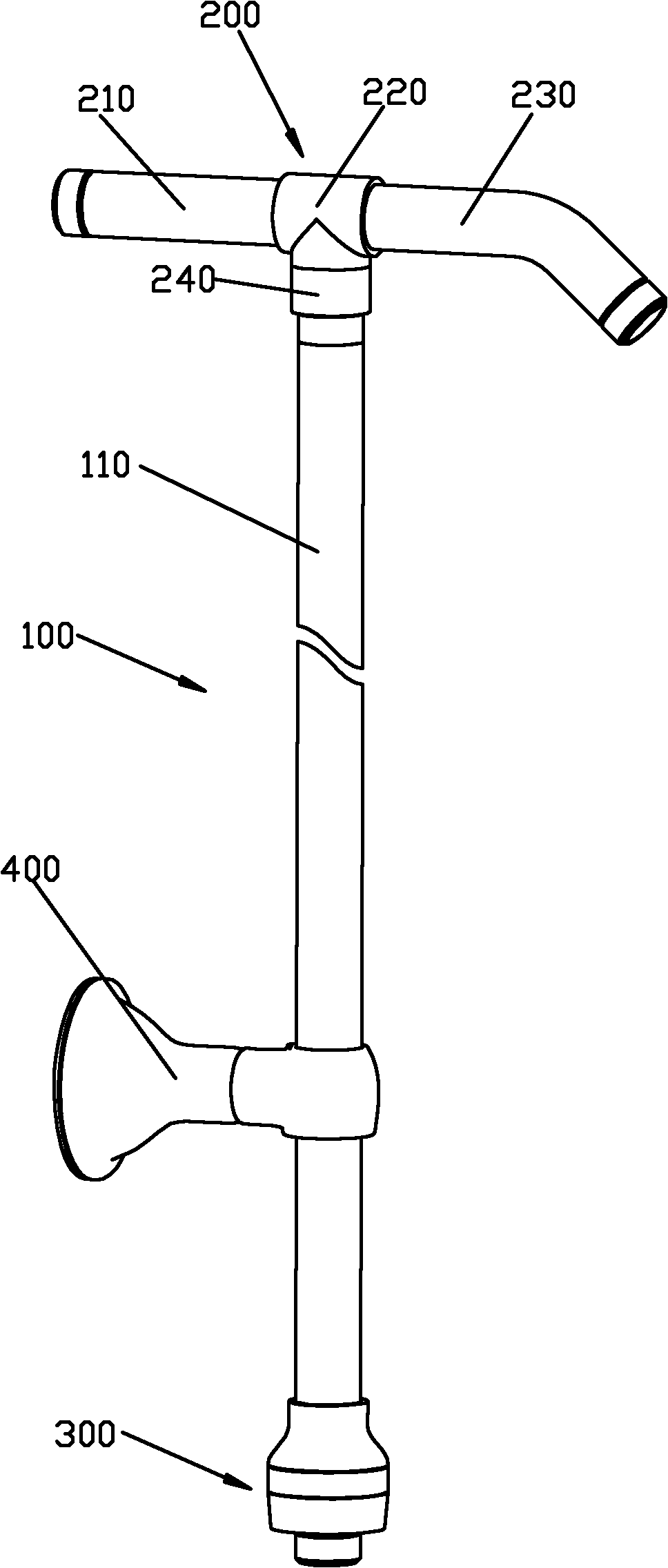

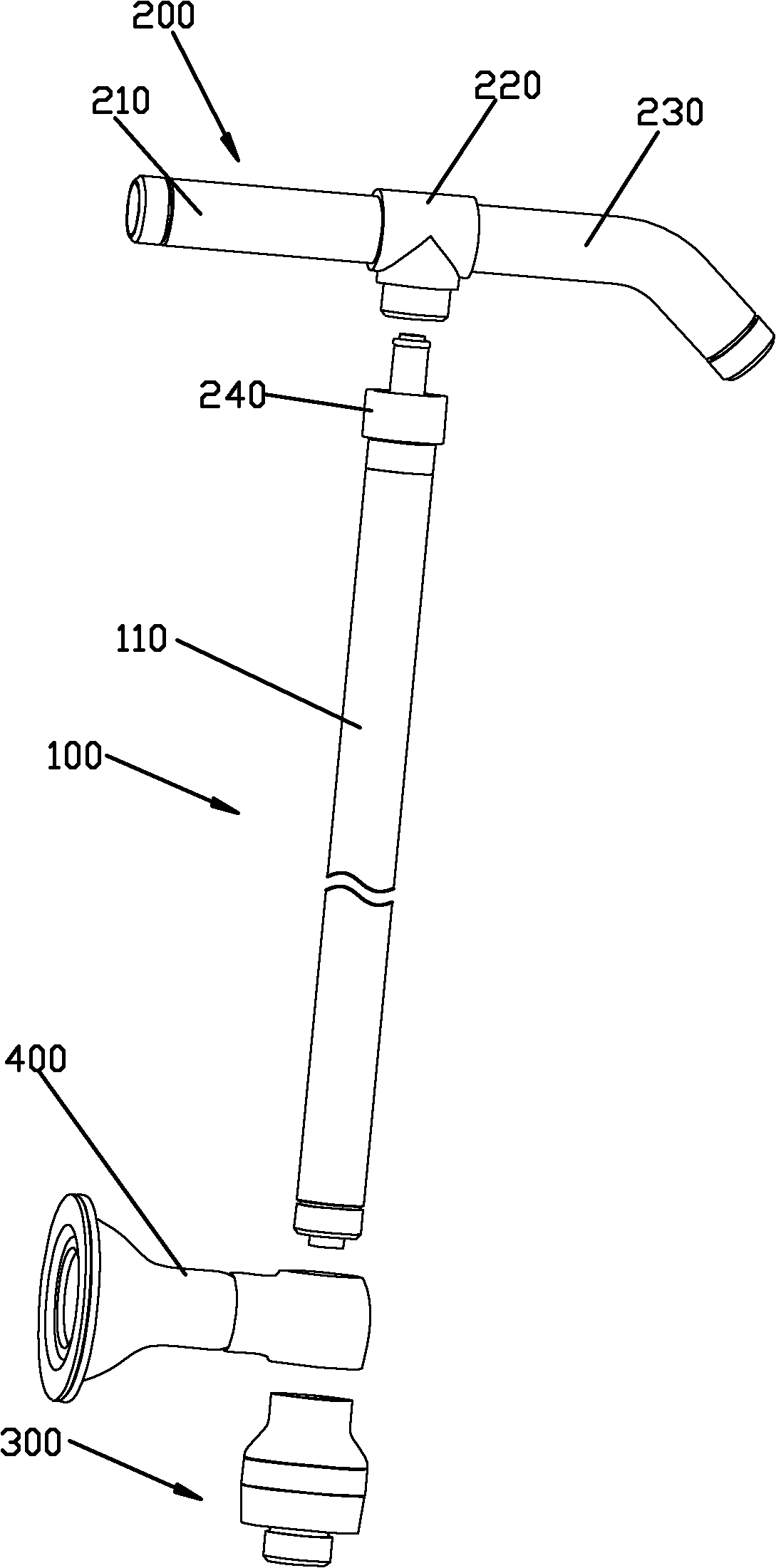

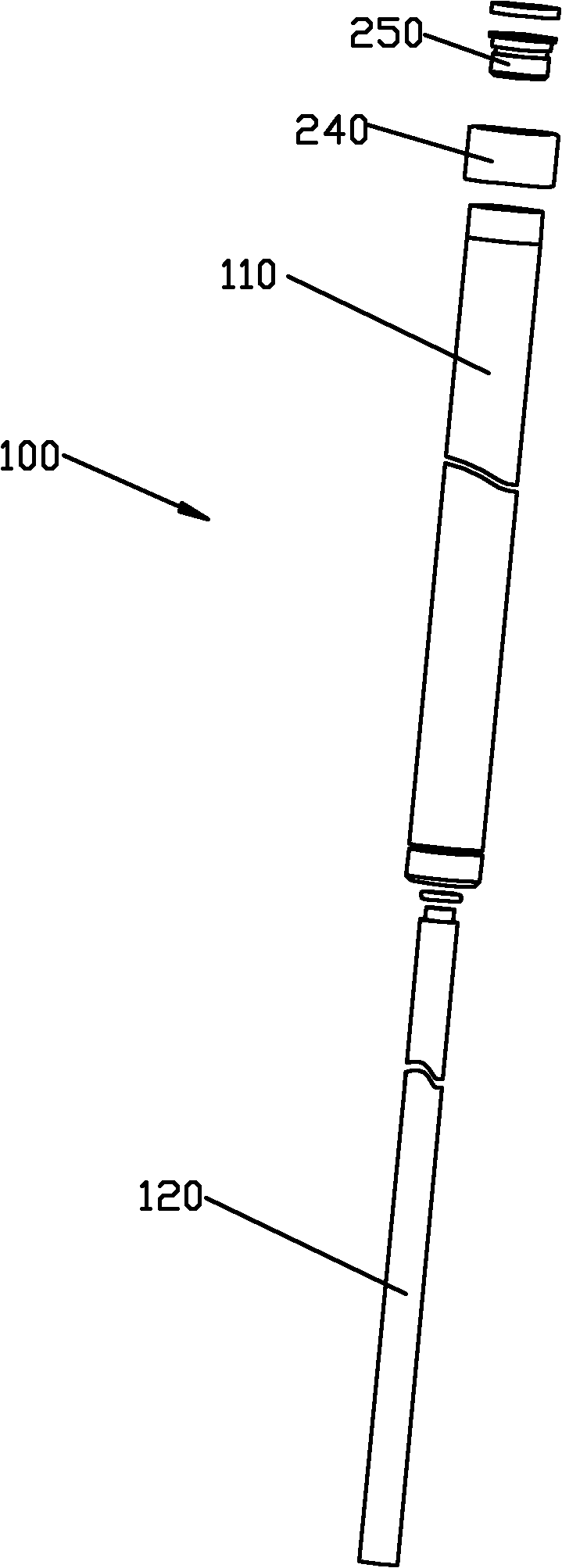

Bottom rotary switching mechanism

InactiveCN101852301AEasy to operateErgonomicPipe supportsMultiple way valvesInlet channelEngineering

The invention discloses a bottom rotary switching mechanism, comprising a tubular assembly and a switching device, wherein the tubular assembly comprises an outer tube and an inner tube which are mutually sleeved; a water inlet channel is formed between the outer tube and the inner tube; a first water path is formed in the inner tube; the switching device comprises a fixed unit, a sealing unit and a rotating sleeve; the fixed unit is fixedly connected with the outer tube and the inner tube and is provided with an adapting cavity and a second water path which are communicated with the water inlet channel; and the first water path and the second water path are respectively provided with an inlet. The sealing unit is movably connected in the adapting cavity. The switching of the first water path and the second water path can be realized by the movement of the sealing unit. The rotating sleeve is rotatably connected outside the fixed unit and connected the sealing unit in a driving way; and the sealing unit moves by rotating the rotating sleeve.

Owner:XIAMEN SOLEX HIGH TECH IND CO LTD

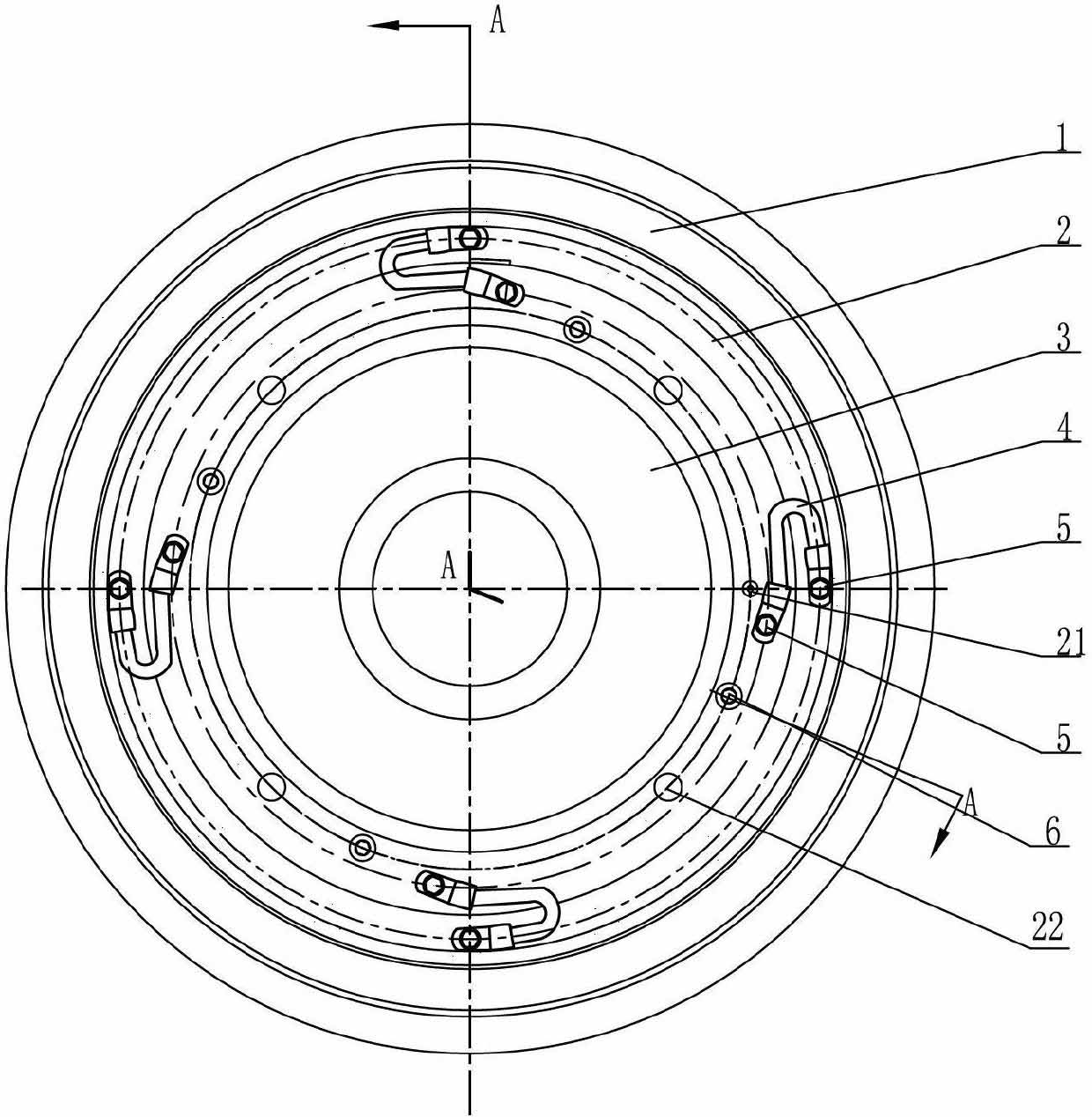

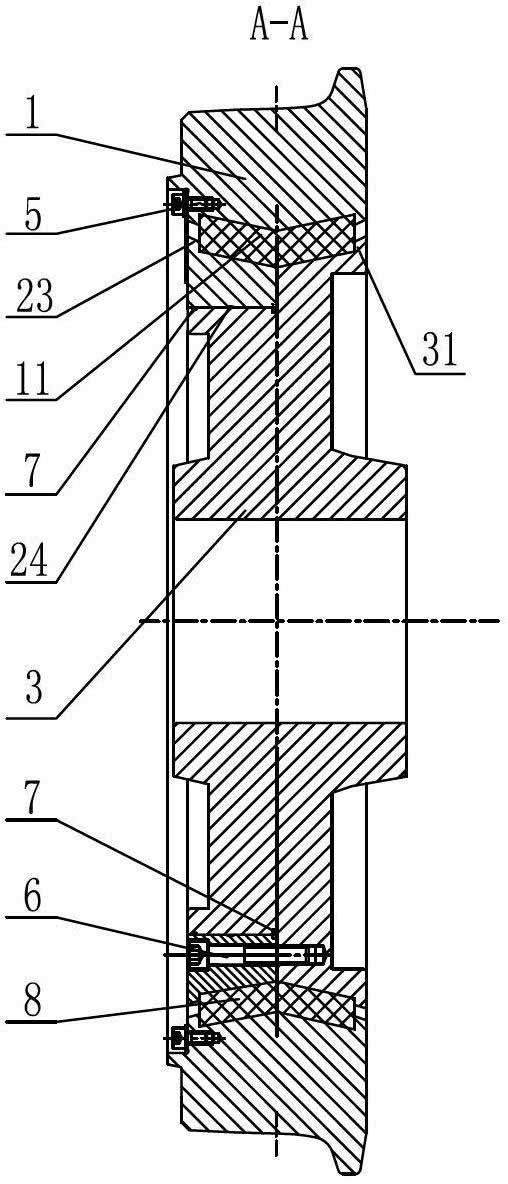

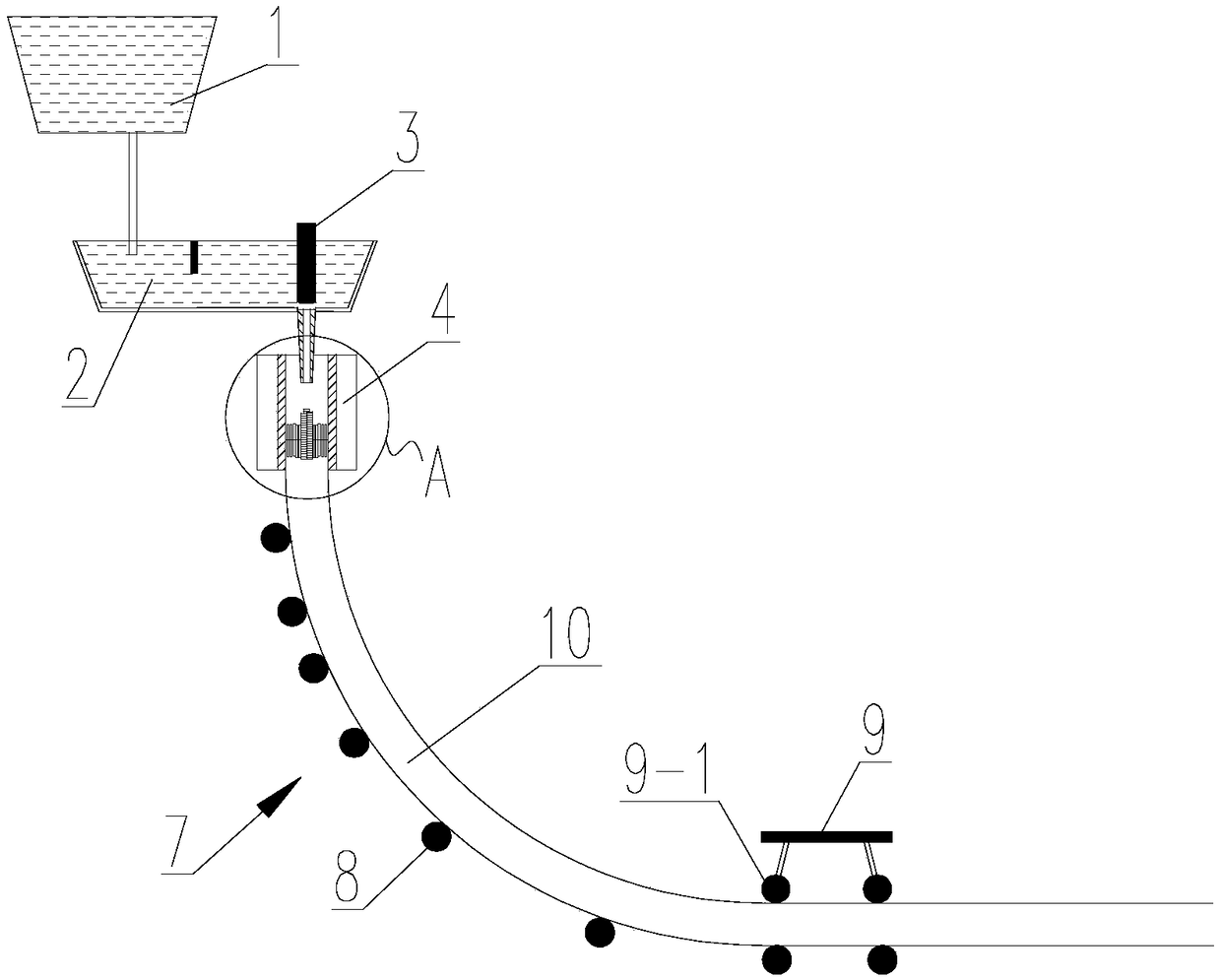

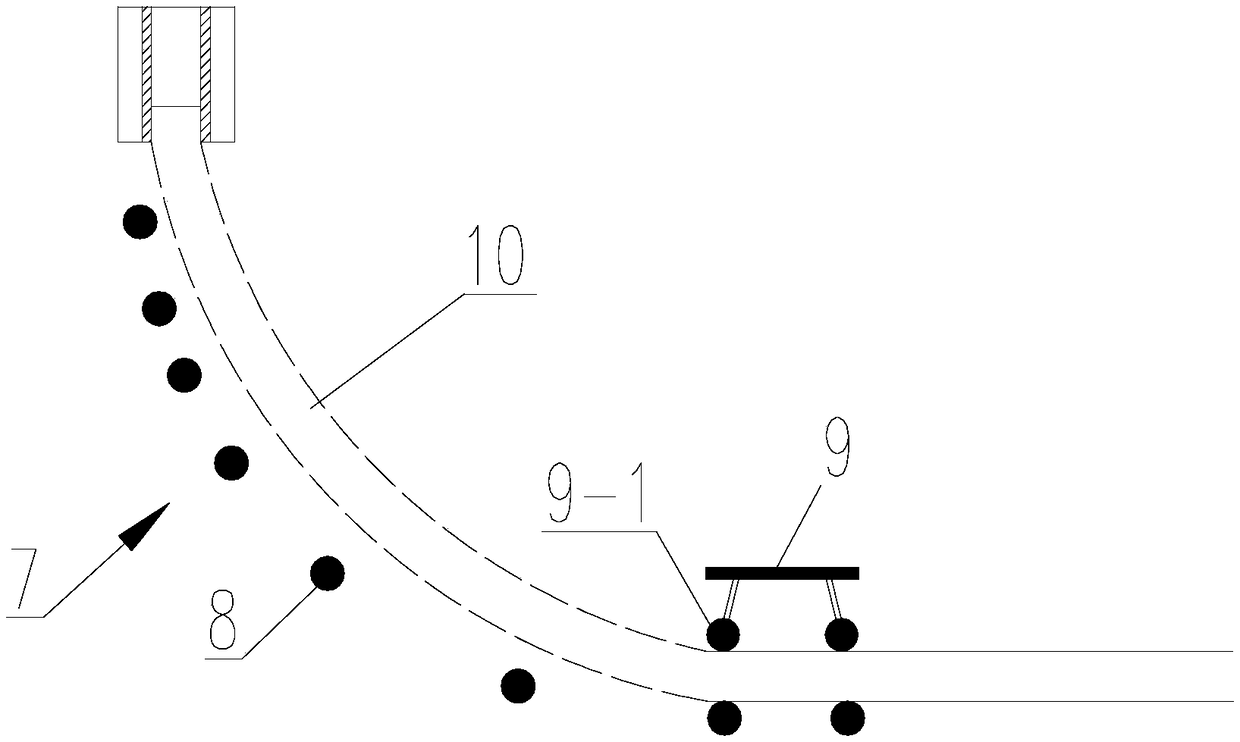

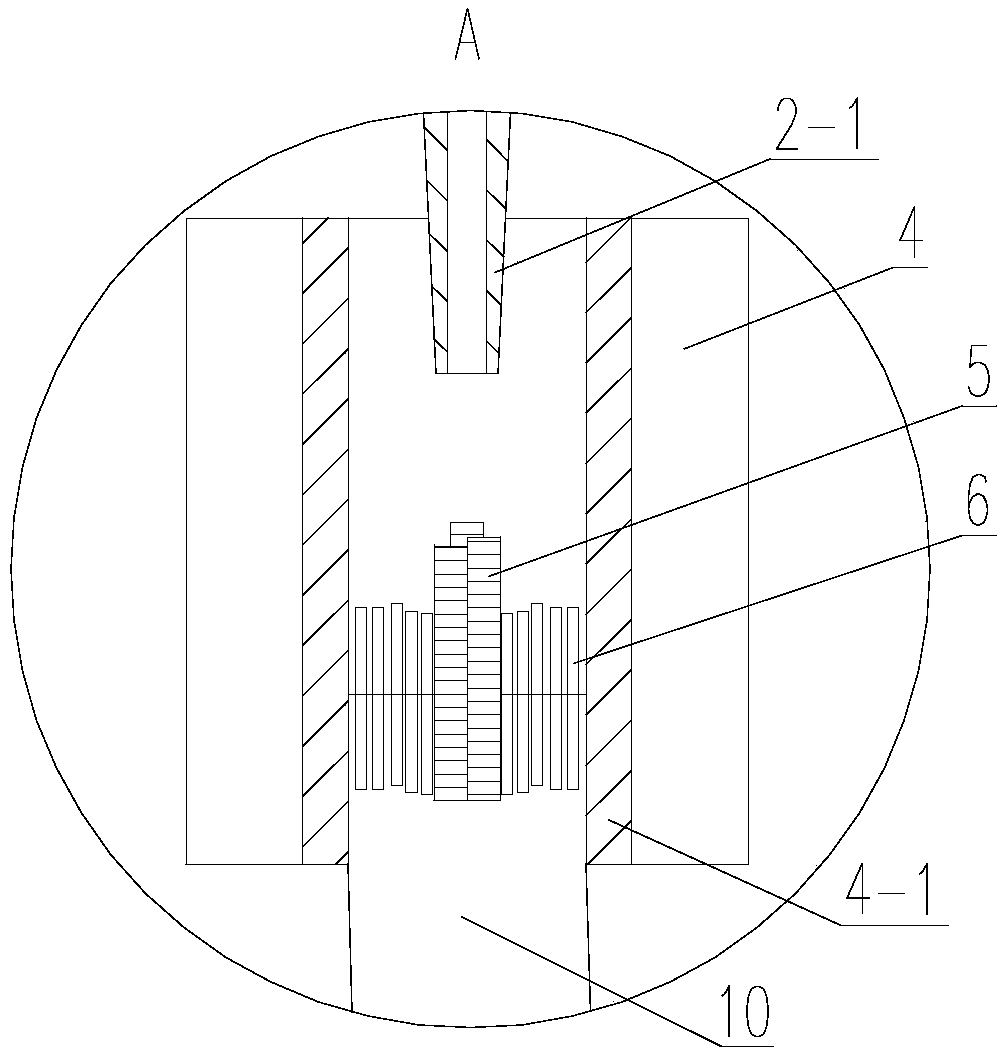

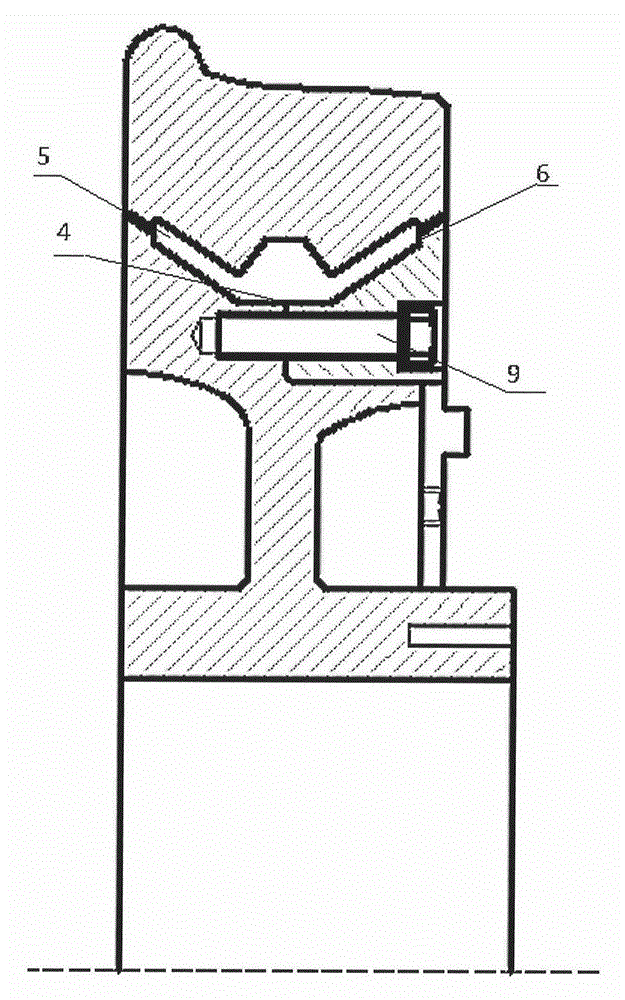

Compression-shear compound elastic wheel for rail vehicles

The invention relates to a compression-shear compound elastic wheel for rail vehicles. The elastic wheel comprises a hub, a wheel center, a compression ring and V-shaped elastic elements. More than two elastic elements are arranged among the hub, the wheel center and the compression ring, two ends of the elastic elements are respectively connected with two end faces of a hub ring groove and beadings on the compression ring and the wheel center, the compression ring is mounted on the wheel center in a press assembling mode, more than three threaded holes are distributed evenly along the circumference of the compression ring, more than three threaded holes are arranged correspondingly in the wheel center, and more than three connection fastening pieced are connected onto the threaded holes in the compression ring and the wheel center in a rotary mode; more than two jacking threaded holes for mounting jacking bolts are arranged on the compression ring, an annular oil groove is mounted on an inner hole wall of the compression ring and communicated with an oil filling hole in an end face of the compression ring, and sealing rings are mounted on two sides of the annular oil groove of the wheel center on the inner wall of the compression ring. The compression-shear compound elastic wheel for rail vehicles has the advantages of being reasonable in structure, capable of improving security performances, and convenient to mount and dismount and maintain.

Owner:CRRC CHANGZHOU TECH MARK IND CO LTD +1

Method for increasing fast replacement success rate by decreasing drawing speed through continuous casting machine

The invention relates to the technical field of steelmaking, in particular to a method for increasing the fast replacement success rate by decreasing the drawing speed through a continuous casting machine. According to the method for increasing the fast replacement success rate by decreasing the drawing speed through the continuous casting machine, the drawing speed is decreased when a tundish isreplaced, the time of passing of a casting blank through a secondary cooling chamber is prolonged, and thus the cooling strength of the casting blank is improved; the temperature of the casting blankis lower before the fast replacement drawing speed returns to zero, in this way, the relative deformation quantity of the casting blank staying in the secondary cooling chamber is smaller in the period that the fast replacement drawing speed returns to zero and casting is started again, it is ensured that when a new tundish starts to be cast, the casting blank can be normally drawn out of a crystallizer under the current pressure of straightening rollers, straightening cracks are avoided, the success rate of fast replacement and casting starting is increased, the quality of the casting blank is guaranteed, and operation is easy; and in addition, when casting is started again, connecting rods are utilized as a connector, after high-temperature molten steel flowing into a copper pipe in thecrystallizer makes contact with the connecting rods, heat of the molten steel is absorbed, the molten steel is solidified while the connecting rods are smelted, thus the connecting effect is achieved,the breed-out situation is avoided, and successful casting starting is guaranteed.

Owner:ZENITH STEEL GROUP CORP

W-shaped rubber ring elastic wheel

InactiveCN105034686AImprove securityImprove the safety of useRail-engaging wheelsWheel protectionRubber ringInterference fit

The invention discloses a W-shaped rubber ring elastic wheel which comprises a rim, a wheel core, a jump ring and an elastic element with a W-shaped cross section. The jump ring is mounted on the wheel core through press fit. Twelve cylindrical countersunk holes are uniformly distributed on the jump ring along the circumference. The wheel core is provide with twelve threaded holes correspondingly. Twelve connecting fasteners penetrate the cylindrical countersunk holes on the jump ring and are connected with the threaded holes of the wheel core in threaded connection. The elastic element is mounted in a gap among the rim, the wheel core and the jump ring. Furthermore two ends of the elastic element are respectively connected with two end surfaces of a rim annular groove and a crossette on the jumper ring and a crossette on the wheel core, thereby preventing wheel derailing when an elastic component fails, and improving wheel safety in driving, wherein interference fit is realized between the elastic element, the rim, the wheel core and the jump ring. According to the W-shaped rubber ring elastic wheel, under a precondition that high performance of the elastic wheel is ensured, the mass under a wheel spring is reduced as possible, thereby facilitating mounting, detachment and maintenance, and furthermore realizing purposes of reducing vibration and noise.

Owner:XIAN TECH UNIV

Roof photovoltaic module support

InactiveCN106059453AEasy installationSave installation timePhotovoltaic supportsSolar heating energyPhotovoltaic power generationPhotovoltaics

The invention discloses a roof photovoltaic module support, which comprises solar photovoltaic modules, roof fixing parts, side clips and middle clips. The roof photovoltaic module support has the beneficial effects that the support is easily installed, and the neat and quick installation of a roof photovoltaic power generation system is realized; during an installation process, the support, the roof fixing parts and the side clips are matched and installed together, and the second module can be inserted into a clamping groove of the roof fixing part at the side of the first module in the subsequent installation process, so that the modules can be directly installed one by one, and the calculation of the position of each roof fixing part is not needed, and thus the installation time is greatly saved, and meanwhile, the support is convenient for installation and the production efficiency is improved.

Owner:JIANGSU POWERTECH ELECTRICAL EQUIP

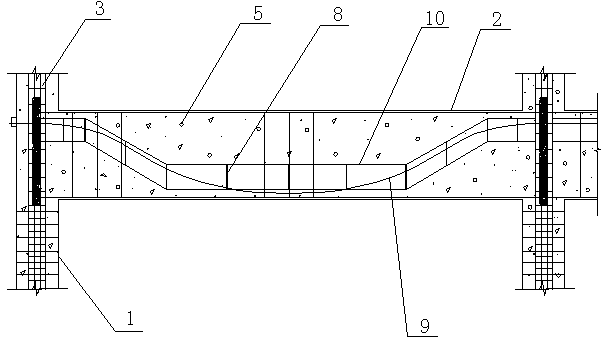

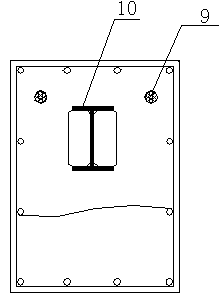

Combination column and combination beam frame with internally-arranged high-strength concrete core columns and construction method thereof

InactiveCN103967128AReduce section sizeReduce workloadBuilding constructionsPre stressControl theory

The invention relates to a combination column and combination beam frame with internally-arranged high-strength concrete core columns and a construction method of the combination column and combination beam frame. The special strong combination column and combination beam frame with the internally-arranged core columns is provided with internally-arranged asymmetric steel rib or plastic rib prestressed concrete combination beams and reinforcing bar concrete combination columns with the internally-arranged core columns, the combination beams are horizontally arranged between the combination columns, and the combination beams are connected with the combination columns at intersections through joints. The core columns are formed by pouring longitudinal ribs, stirrups and concrete together, the longitudinal ribs are distributed around the core columns and are wrapped by the stirrups, and the core columns are placed in the reinforcing bar concrete columns. Transverse stiffening ribs are arranged on steel ribs or plastic ribs in the combination beams, the steel ribs or the plastic ribs at the midspan positions are arranged on the lower portions of the combination beams, the steel ribs or the plastic ribs on supports are arranged on the upper portions of the combination beams, and prestressed ribs are arranged in the combined beams in the length direction. The prestressed ribs on the beam and column joints penetrate through two sides of the core columns, and are tensioned and anchored at the ends of the combination columns. The section size of the columns can be obviously reduced, too wide columns are prevented from existing in a system, and the prestressed ribs in the combination beams can generate evenly-distributed counterforce to eliminate part of external loads.

Owner:NORTHEAST GASOLINEEUM UNIV

Thermoformable fire-proof sponge and preparation method thereof

The invention relates to the technical field of sponge, in particular to a thermoformable fire-proof sponge. The thermoformable fire-proof sponge is composed of the following raw materials in part by weight: 5 to 20 parts of PPG (Polypropylene Glycol), 60 to 95 parts of POP (Polyether Polyol), 1 to 9 parts of TDI (Toluene-2,4-diisocyanate), 1 to 3 parts of MDI (Diphenyl-methane-diisocyanate), 0.5 to 2 parts of H2O, 0.3 to 0.8 parts of SI (Silicon), 0.01 to 0.05 parts of A-1, 1.1 to 1.5 parts of A-33, 1.1 to 1.5 parts of catalyst, 0.5 to 5 parts of white carbon black, 10 to 30 parts of calcium carbonate, 8 to 10 parts of openings agent, 5 to 20 parts of fire-proofing agent, and 2 to 6 parts of flame composite agent. According to the invention, the thermoformable fire-proof sponge has the advantages of safety, environmental protection and high hardness; and the adhering tension is stronger, the structure is stable, and the compressive forming effect is good. The preparation method of the thermoformable fire-proof sponge is carried out under a normal pressure, so that the requirements on equipment and energy consumption are low; the production and manufacture time is shortened; and the process cost is low.

Owner:广东富利时实业有限公司

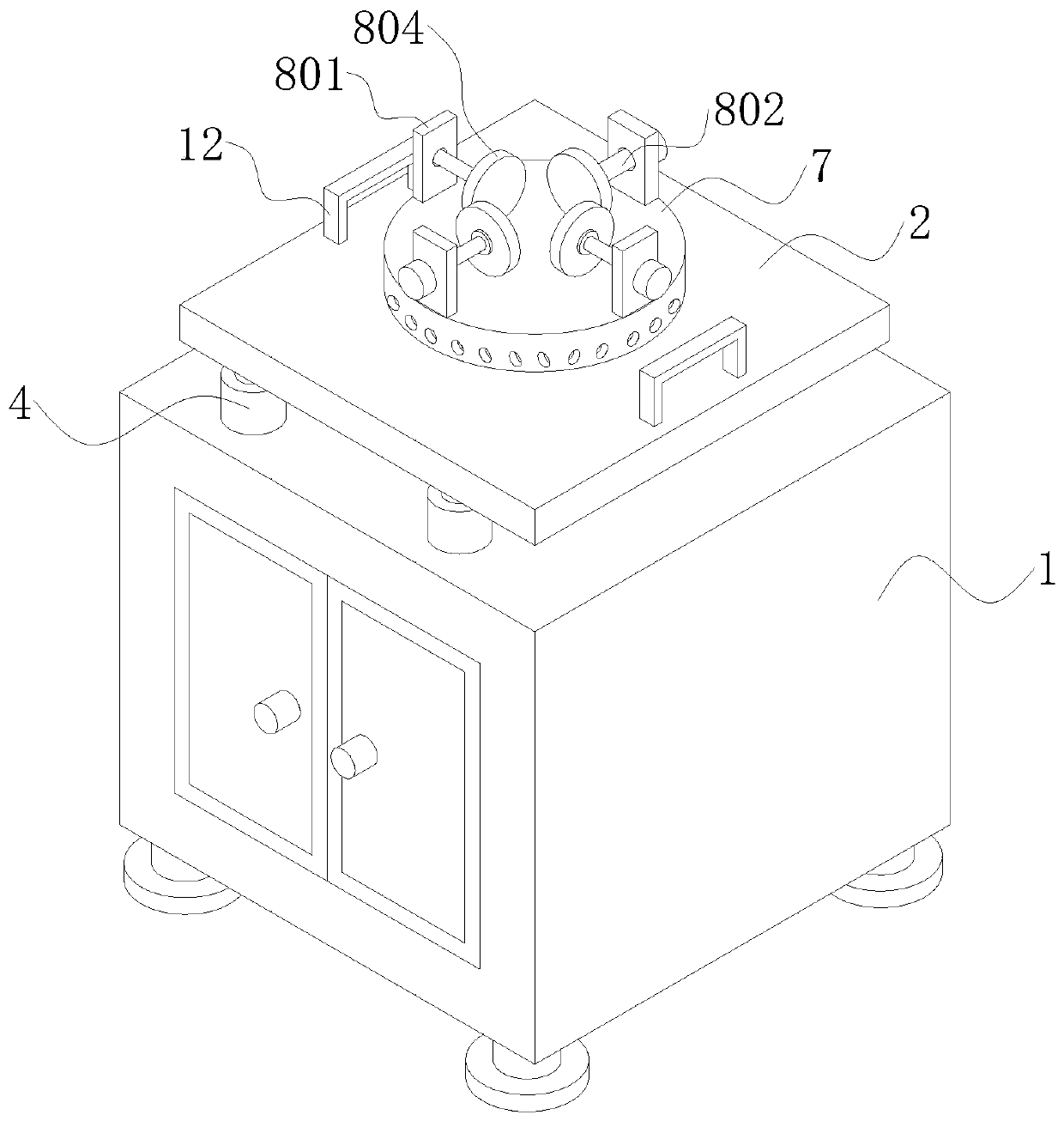

Mold machining device achieving precise locating

InactiveCN111515879AEasy to useUse, solve the problem that the existing mold processing device is not convenient to useWork holdersWork benchesWorkbenchMachining

The invention discloses a mold machining device achieving precise locating. The mold machining device comprises a workbench. A fixed plate is arranged at the top of the workbench. Locating blocks arefixedly connected to the bottom of the fixed plate. The bottoms of the locating blocks are sleeved with locating sleeves. Locating grooves used in cooperation with the locating blocks are formed at the tops of the locating sleeves. According to the mold machining device, through cooperative use of the workbench, the fixed plate, the locating blocks, the locating sleeves, the locating grooves, a moving rod, a moving plate, fixed mechanisms, a shell, a locating mechanism, a clamp groove, a handle, a moving wheel, an annular groove, a through hole, a limiting block, a limiting groove and a through opening, the problems that an existing mold machining device is inconvenient for users to use, the position of a mold needs to be fixed multiple times in the use process, a large quantity of time and energy of users are consumed, consequently, use of users is influenced, and the work efficiency of users is reduced are solved; and the mold machining device achieving precise locating has the advantage of being convenient for users to use and is worthy of popularization.

Owner:宁波引智信息科技有限公司

Super-high flow return-oil defoamer

ActiveCN102410285AGuaranteed sealing performanceReduce flow rateFluid-pressure actuator componentsStreamflowNational pipe thread

The invention relates to a super-high flow return-oil defoamer, in particular relates to a heavy mining dumper, and belongs to the hydraulic field. The defoamer is characterized in that a base is provided with a connecting hole and is fixedly connected with one end of a shell; the other end of the shell is fixedly connected with a bottom plate, and the bottom plate is provided with a hole; and a cross-shaped partition plate is arranged in the shell and is provided with an oil hole. The super-high flow return-oil defoamer is of an integral cylindrical structure, wherein the base is connected with an oil return pipe in an oil tank through an internal 6''NPT (national pipe thread) so as to play a role in connection and ensure the airtightness of the joint; the shell, the bottom plate and the cross-shaped partition plate are provided with oil passing holes, and the flow rate of the hydraulic oil is reduced so as to prevent air bubbles from occurring when hydraulic oil passes through the oil passing holes; and a baffle is arranged at the bottom side of the hydraulic oil tank so as to prevent the high-flow hydraulic oil from washing away the dirt precipitated on the bottom of the oil tank.

Owner:INNER MONGOLIA NORTH HAULER

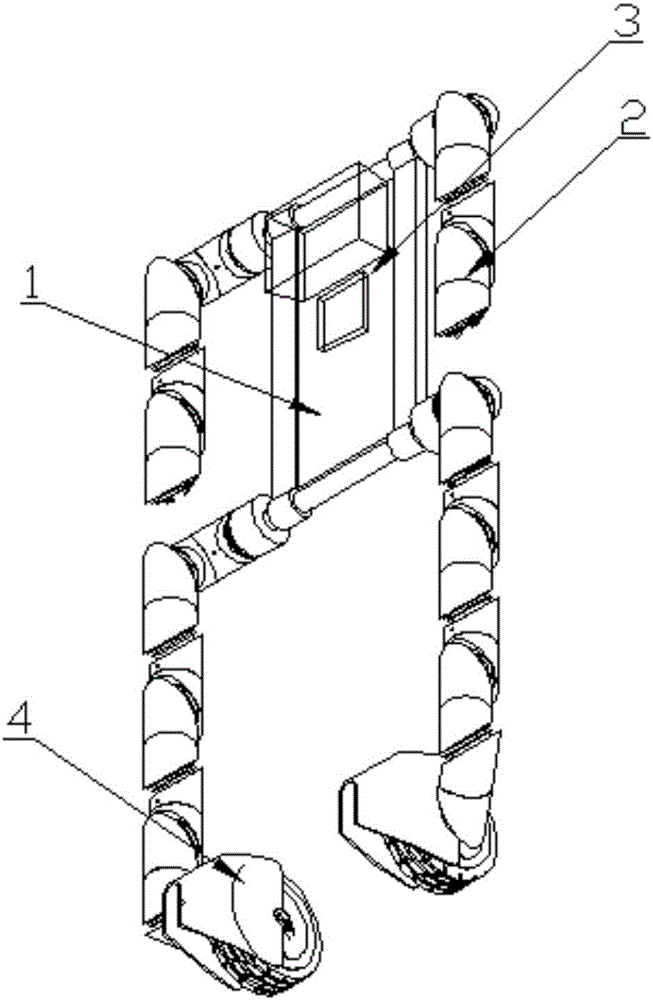

Modular reconfigurable robot

ActiveCN106272387AGuaranteed stabilityPlay a connecting roleProgramme-controlled manipulatorModularitySpecific function

The invention discloses a modular reconfigurable robot. The modular reconfigurable robot is composed of a bracket module, joint modules, a control module, wheel foot modules and auxiliary modules. The bracket module is used for overall supporting the robot. The joint modules are used for achieving the effect of connecting all the modules of the robot. A motor is designed in each joint module and provides power drive. The auxiliary modules are modules, for example, foot modules for a hexapod robot, designed special for robots with specific functions. The wheel foot modules are used for achieving the supporting and movement functions of a walking or wheeled robot. The control module is used for achieving the autonomous control function of the robot. According to the modular reconfigurable robot, a legged human-shaped robot, a wheeled vehicle-shaped robot, a bionic hexapod robot and robots of other structures are reconfigured mainly by the modules according to the task requirements, and modularization and reconfiguration of the robot structure are achieved.

Owner:ANHUI UNIVERSITY

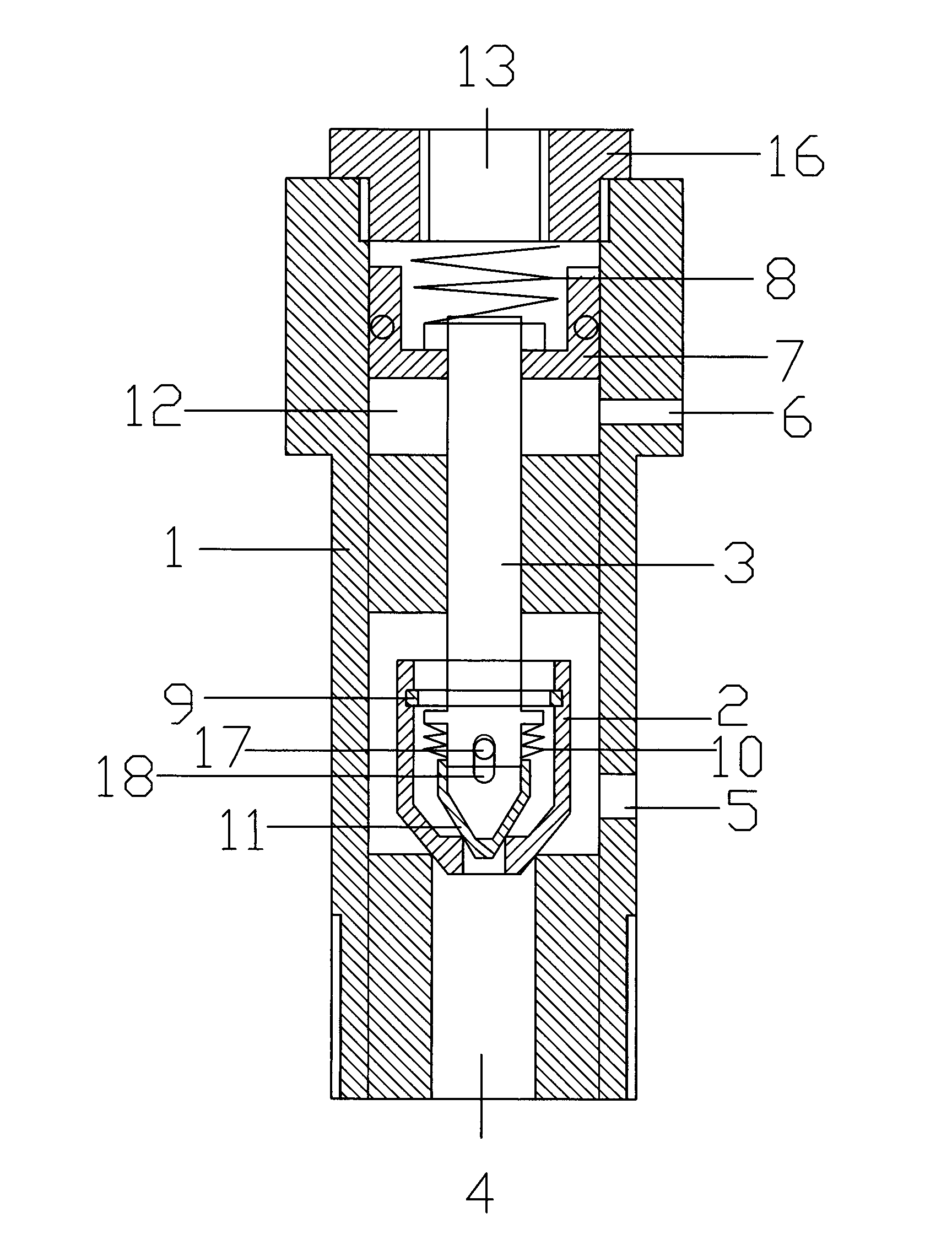

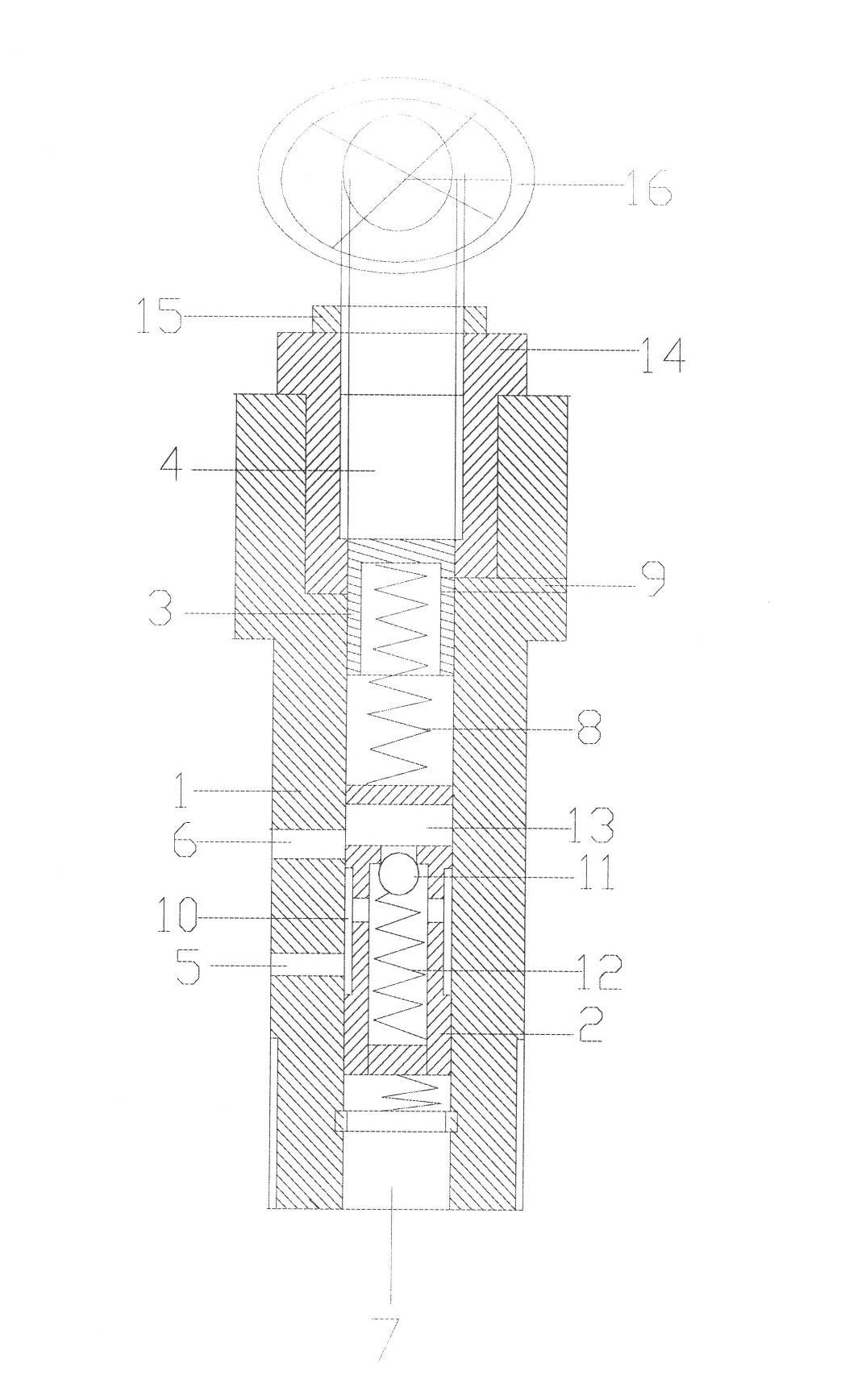

Direct-acting externally piloted one-way sequence valve

InactiveCN102563183APlay a connecting roleReasonable layoutOperating means/releasing devices for valvesValve housingsBiomedical engineeringHydraulic pressure

The invention discloses a direct-acting externally piloted one-way sequence valve, which comprises a valve body (1), a main valve spool (2) and a reset spring (8). A liquid inlet (5), a liquid outlet (6) and a control liquid inlet (7) are arranged on the valve body (1), the main valve spool (2) is arranged in the valve body (1), the outer diameter of the head at the upper end of the valve body (1) is larger than that of a portion below the head, an external thread is arranged on the portion below the head of the valve body (1), one end of the reset spring (8) is connected onto the main valve spool (2), the other end of the reset spring (8) is fixed onto the valve body, the head at the upper end of the valve body is closed, and a cavity between the main valve spool (2) and the upper end of the valve body is communicated with the outside through a drainage channel (9). The external shape of the valve body is equivalent to that of a hinged bolt, a hydraulic part and a pipeline can be connected by the valve body, and the hinged bolt and the direct-acting externally piloted one-way sequence valve are integrated.

Owner:林友根

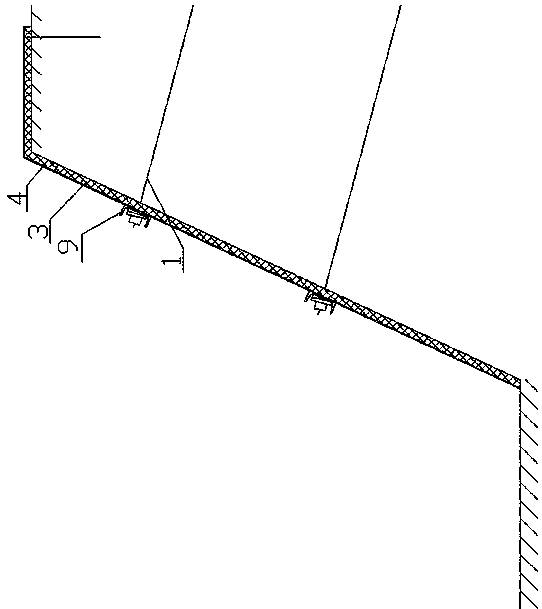

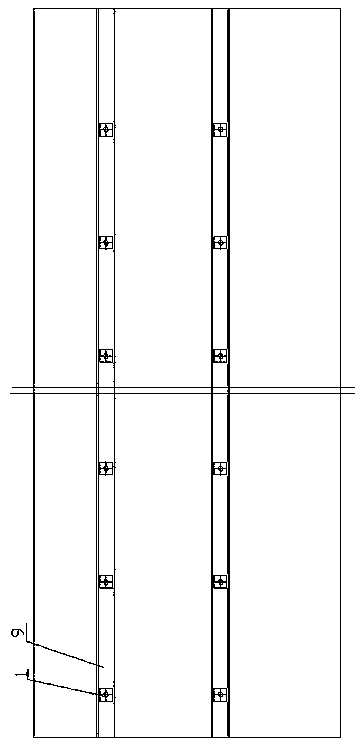

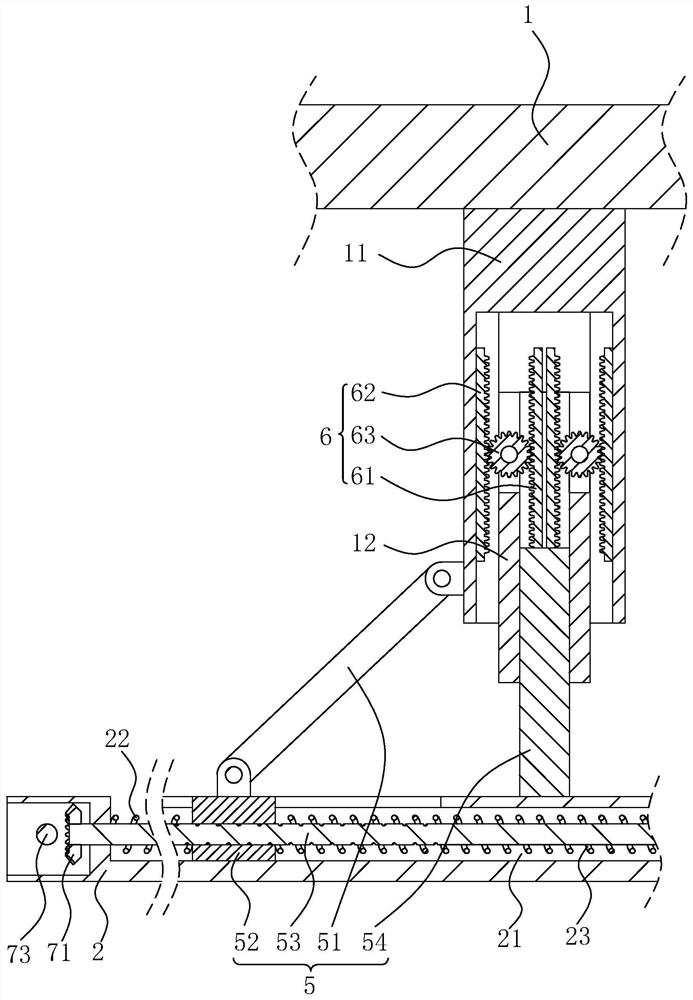

Fabricated temporary support device and application thereof

PendingCN108867659AImprove connection strengthRealize prefabricated connectionExcavationsUltimate tensile strengthComputer engineering

The invention discloses a fabricated temporary support device and application thereof, comprising a lining covered on the side surface of the support, an anchor bar (1) arranged on the side surface ofthe support, an article skeleton arranged between the anchor bar (1) and the lining, wherein the side surface of the support is fixed through the lining; a fixed mount point is formed on the side surface of the support through the anchor bar (1); the connection intensity of the lining is improved through the article skeleton, the anchor bar (1) is connected with the lining and the article skeleton, so that the fabricated connection on the side surface of the support is achieved, and the working efficiency is improved.

Owner:TAIAN DAIZHONG ELECTROMECHANICAL TECH DEV CO LTD

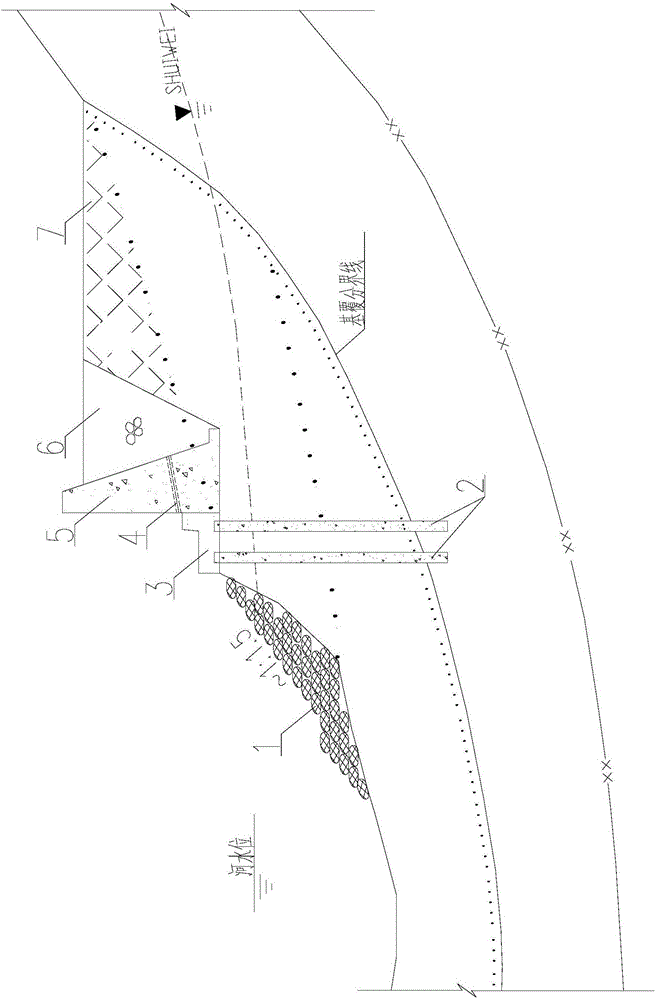

Comprehensive side-slope treatment structure for preventing river channel erosion and construction method thereof

ActiveCN106400744AEasy constructionImprove integrityCoastlines protectionWater flowStructural engineering

The invention relates to a comprehensive side-slope treatment structure for preventing river channel erosion and a construction method thereof. The comprehensive side-slope treatment structure aims at preventing the phenomenon that a river channel covering layer at the downstream position of a flood releasing structure is thick and is frequently scoured by water flow, and therefore side slopes at both shores and a river channel are comprehensively treated, and stability and safety of the side slopes and buildings near the side slopes are ensured. According to the technical scheme, the comprehensive side-slope treatment structure for preventing river channel erosion is characterized in that concrete guard walls are arranged on the river channel side slopes at the downstream position of a flood releasing structure, two to three rows of cement cast-in-place piles stretching into the bed rock surface are arranged on the side, close to a river channel, of each concrete guard wall, and the space between each concrete guard wall and the corresponding river bank is backfilled with rock ballast; concrete foundations connected with the corresponding concrete guard walls are arranged at the tops of the cement cast-in-place piles, and a structural joint is arranged between each concrete foundation and the corresponding concrete guard wall; and alloy net stone bags which are connected in series and extend to the bottom of a riverbed are arranged on the side, close to the river channel, of each concrete foundation.

Owner:POWERCHINA HUADONG ENG COPORATION LTD

Adjustable light steel keel suspended ceiling structure

The invention relates to the field of indoor decoration, in particular to an adjustable light steel keel suspended ceiling structure. The structure comprises a plurality of transverse keels arranged in parallel and longitudinal keels fixedly arranged between the adjacent transverse keels and perpendicular to the transverse keels; ceiling plates are installed in rectangular spaces formed between the adjacent transverse keels and the longitudinal keels; two fixing rods fixedly connected with a roof are arranged above the transverse keels; adjusting assemblies are arranged between the two fixingrods and the transverse keels; each adjusting assembly comprises an adjusting rod, a sliding block, and a two-way lead screw; one end of each adjusting rod is hinged to the corresponding fixing rod; the other end of each adjusting rod is hinged to the corresponding sliding block; the sliding blocks are slidably connected with the transverse keels in the length direction of the transverse keels; the length direction of the two-way lead screws is the same as the length direction of the transverse keels; the two-way lead screws are rotationally connected with the transverse keels; and the two sliding blocks are arranged at the two ends of the two-way lead screws in a sleeving mode respectively and are in threaded connection with the two-way lead screws. The adjustable light steel keel suspended ceiling structure has the effect that the height of the transverse keels and the height of the longitudinal keels can be adjusted.

Owner:上海临河建设有限公司

Absorption type cold-hot integrated machine

InactiveCN101280982AProtect the natural environmentImprove energy efficiencyClimate change adaptationEnergy efficient heating/coolingEvaporationEngineering

The invention relates to an absorption type integrative machine, comprising a high evaporation temperature cooling loop, a low evaporation temperature cooling loop and a heat retriever; the high evaporation temperature cooling loop comprises a generator, a condenser and a first evaporator and a solution heat exchanger; the generator is driven by external heat source, one end of the generator is connected with the condenser, another end is connected with the solution heat exchanger; the heat retriever is in series connection between the generator and the condenser. The absorption type cool-heat integrative machine of technical proposal of the invention, because including two respectively independently cooling loops, the high evaporation temperature cooling loop and the low evaporation temperature cooling loop with different evaporation temperatures, can efficiently use the remaining heat, the waste heat, the solar energy, the gas and the power energy as energy to cool, and at the same time of generating sanitary hot water, can provide refrigeration below zero DEG C, cool storage above zero DEG C and the air-conditioner refrigeration, thus improving the energy consumption efficiency at the same time of protecting the natural environment of earth.

Owner:SHENZHEN POLYTECHNIC

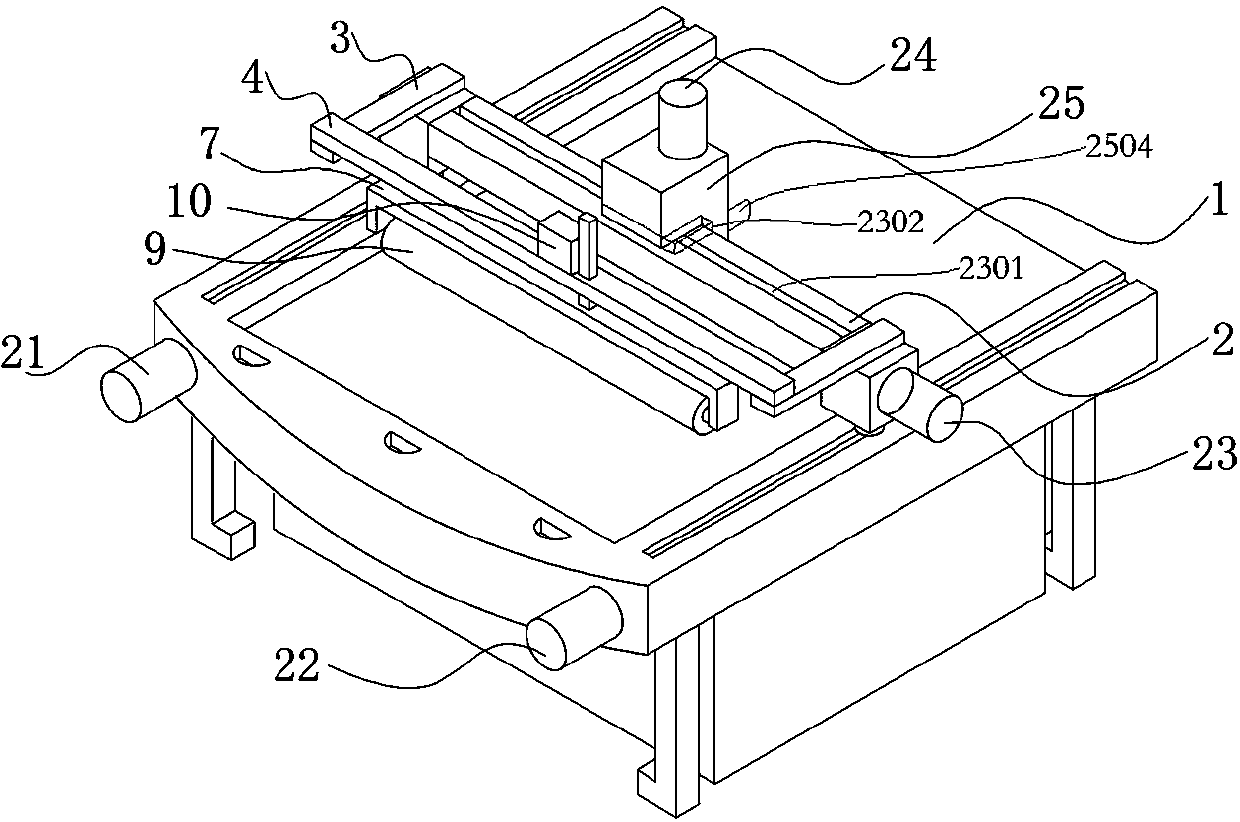

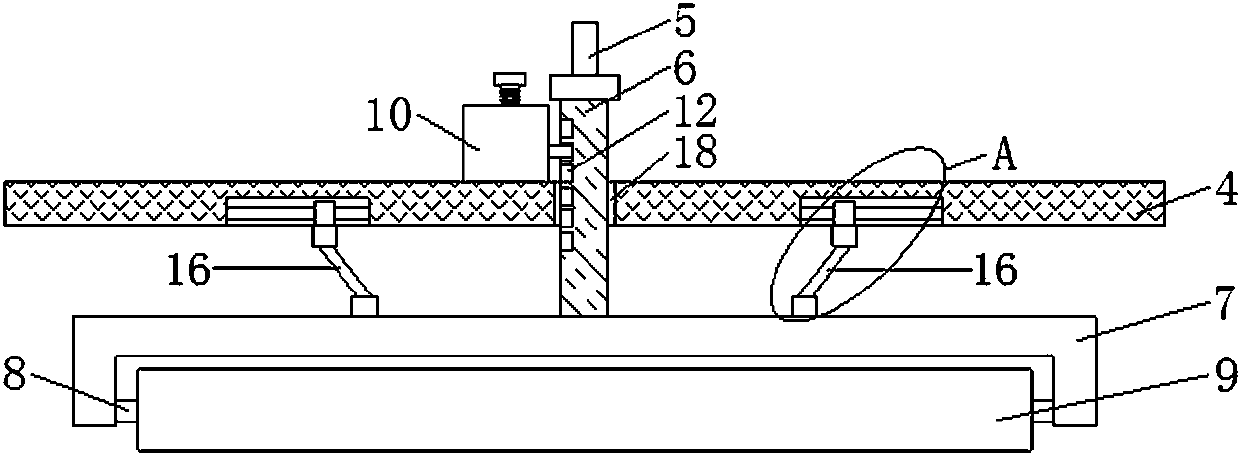

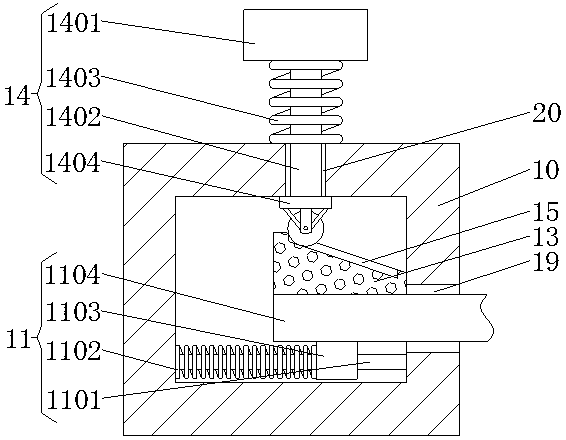

Car foot mat cutting machine with adjusting function

ActiveCN111409123AWith adjustment functionAvoid inconvenienceMetal working apparatusElectric machineryMachine

The invention belongs to the technical field of car trims, and particularly relates to a car foot mat cutting machine with an adjusting function. The car foot mat cutting machine comprises a workbench, a cutting device, a cutting transmission mechanism, a pull ring, fixed plates, a support, a connecting plate, a fixed roller, a shell, a fixed mechanism, a clamp block, an adjusting mechanism and astabilization mechanism. The cutting transmission mechanism comprises a portal frame, a first portal frame transmission motor, a first transmission lead screw, a first transmission nut, a first sliding block, a first guide rail, a second portal frame transmission motor, a second transmission lead screw, a second transmission nut, a second sliding block and a second guide rail. The cutting device comprises a tool apron, a tool apron guide rail, a tool apron sliding block, a tool apron transmission lead screw, a nut, a tool apron transmission motor, a tool holder lifting motor, a cutter holder lifting lead screw, a nut, a cutting tool holder, a cutting tool and a cutting tool transmission motor. Fixed plates are fixedly connected to the two sides of the top of the portal frame. The surface of a connecting rod is sleeved with the fixed roller. The fixed mechanism used in cooperation with the connecting rod is arranged at the bottom of an inner cavity of the shell.

Owner:苏州言诺信息科技有限公司

Transverse plate spring type independent suspension structure

PendingCN106585312AReduce weightPlay a guiding roleResilient suspensionsEngineeringMechanical engineering

The invention provides a t transverse plate spring type independent suspension structure. The transverse plate spring type independent suspension structure comprises a knuckle pivot assembly, an upper fork arm assembly, a steering gear assembly, a tie rod assembly, a front vibration damper assembly and a transverse plate spring assembly. Since a transverse plate spring scheme is employed, a transverse plate spring replaces left and right lower swing arms and also has the effect of a transverse stabilization rod, an inclined pull bar structure is omitted, a guide effect is exhibited, one component has multiple functions, the structure is simpler, the weight of a front suspension structure is greatly reduced, the rigidity of the plate spring assembly is enhanced through a corresponding clamping structure, a reed is not offset back and forth when the structure handles impact from the front side of an automobile, the structure especially reduces the dimension of the front suspension structure in a height direction, and the structure is suitable for a miniaturized motor vehicle and a miniaturized electric vehicle.

Owner:北京宏瑞汽车科技股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com