Bottom rotary switching mechanism

A switching mechanism and waterway switching technology, applied in the direction of mechanical equipment, engine components, pipe supports, etc., can solve the problems of inconvenient switching, achieve the effect of convenient switching, ensure the guiding performance, and increase the switching machine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

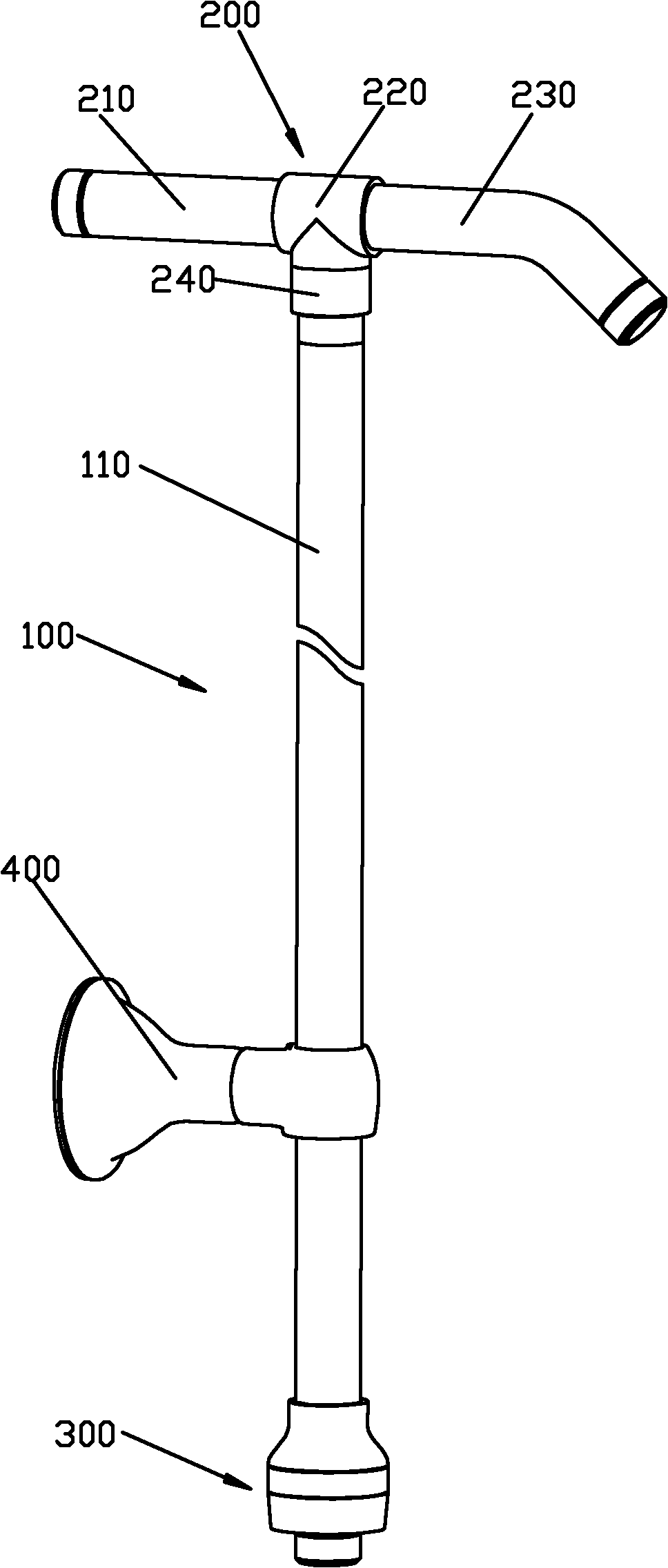

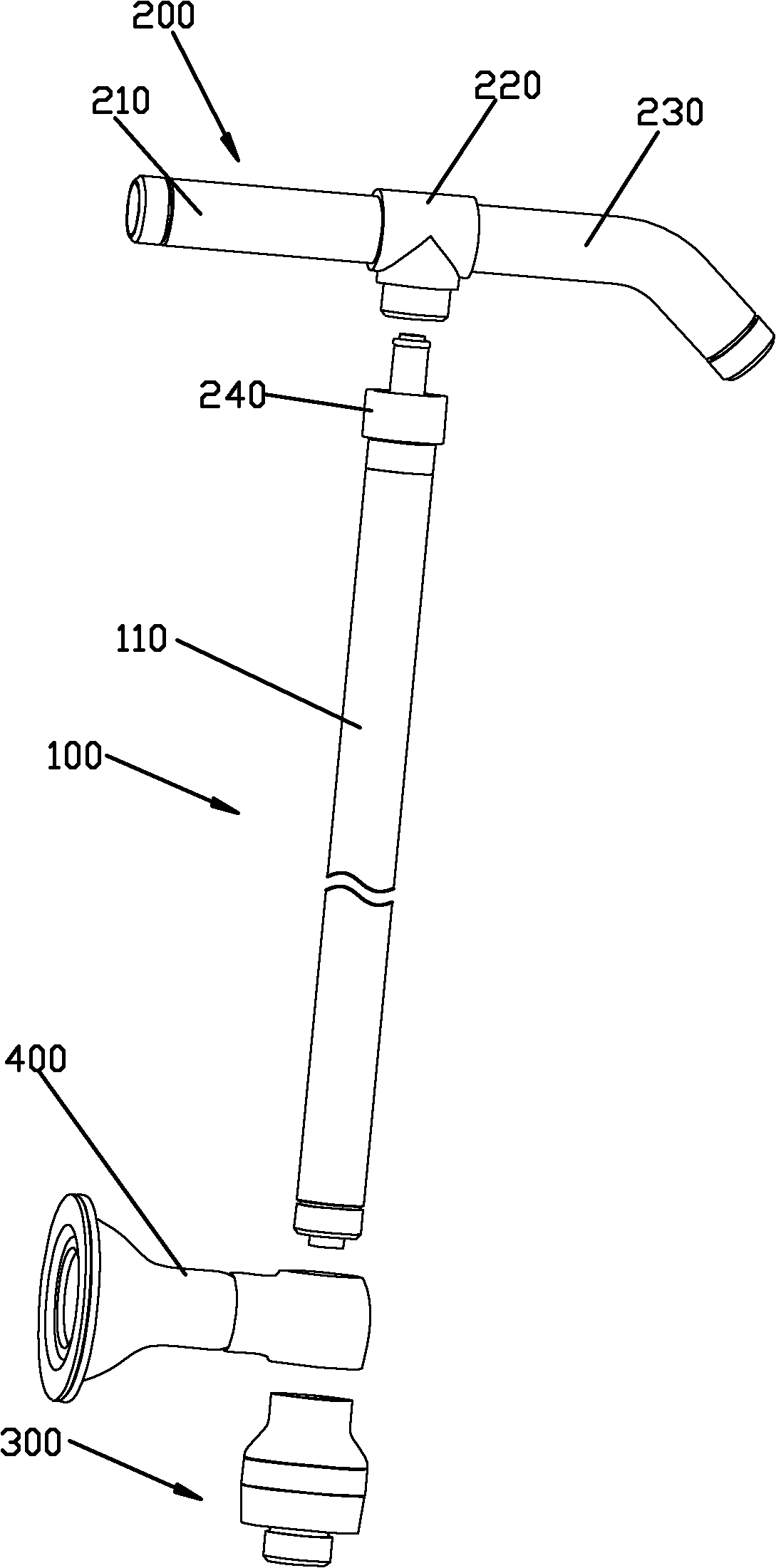

[0073] Please check Figure 1 to Figure 13 , the bottom rotation switching mechanism, which includes a tube assembly 100 , an arm assembly 200 , a switching device 300 and a suction cup assembly 400 .

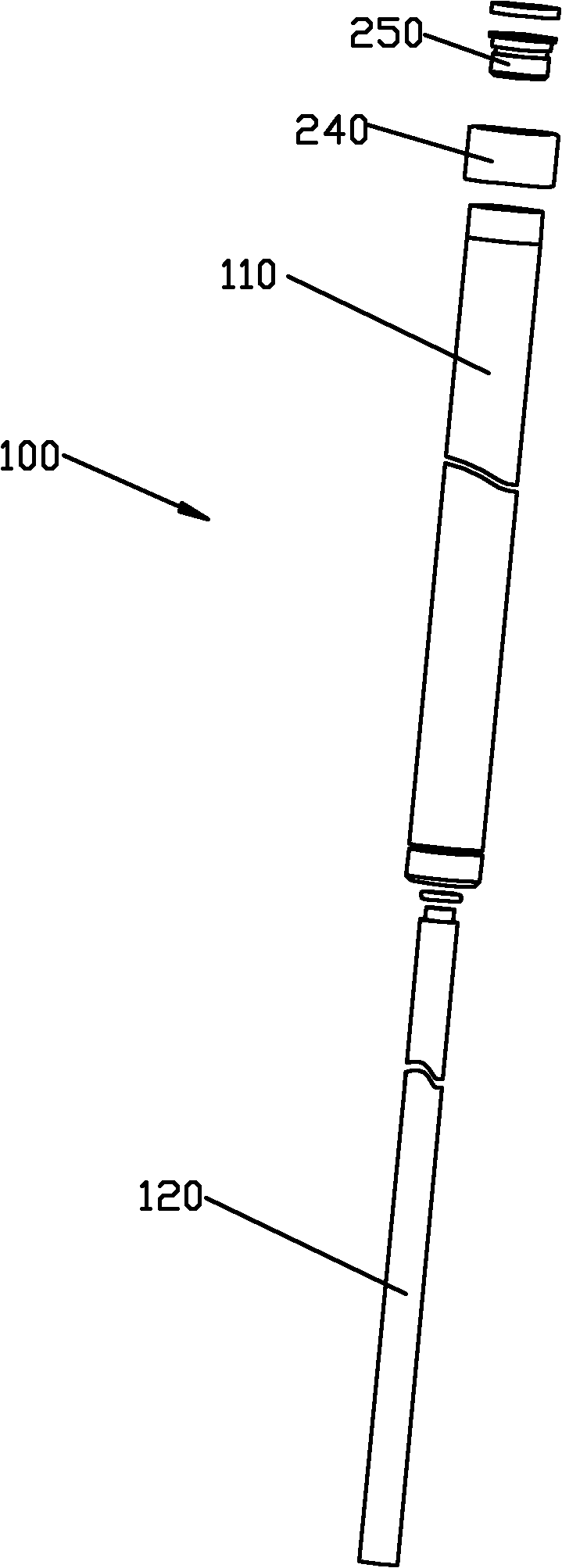

[0074] Please check Figure 1 to Figure 4 , the tube assembly 100, which includes an outer tube 110 and an inner tube 120 that are nested in each other, a water inlet channel 130 is formed between the outer tube 110 and the inner tube 120, and a first water channel 140 is formed between the inner tubes 120 .

[0075] Please check Figure 1 to Figure 4 , the arm assembly 200, which includes a rear pipe 210 connected to a water source, a fixed head 220 and a front pipe 230. The fixed head 220 is fixedly connected to the front pipe 230, the rear pipe 210, the outer pipe 110 and the inner pipe 120, and makes the rear pipe 210 connected to the water inlet channel 130 between the outer pipe 110 and the inner pipe 120, so that the The front pipe 230 is connected to the first water...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com