Compression-shear compound elastic wheel for rail vehicles

A rail transit vehicle and elastic wheel technology, which is applied in the field of compression-shear composite elastic wheels for rail transit vehicles, can solve the problems of low loading and unloading efficiency, increased processing procedures, hidden safety hazards, etc., achieve convenient assembly and disassembly operations, and improve use Safety, safe and reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

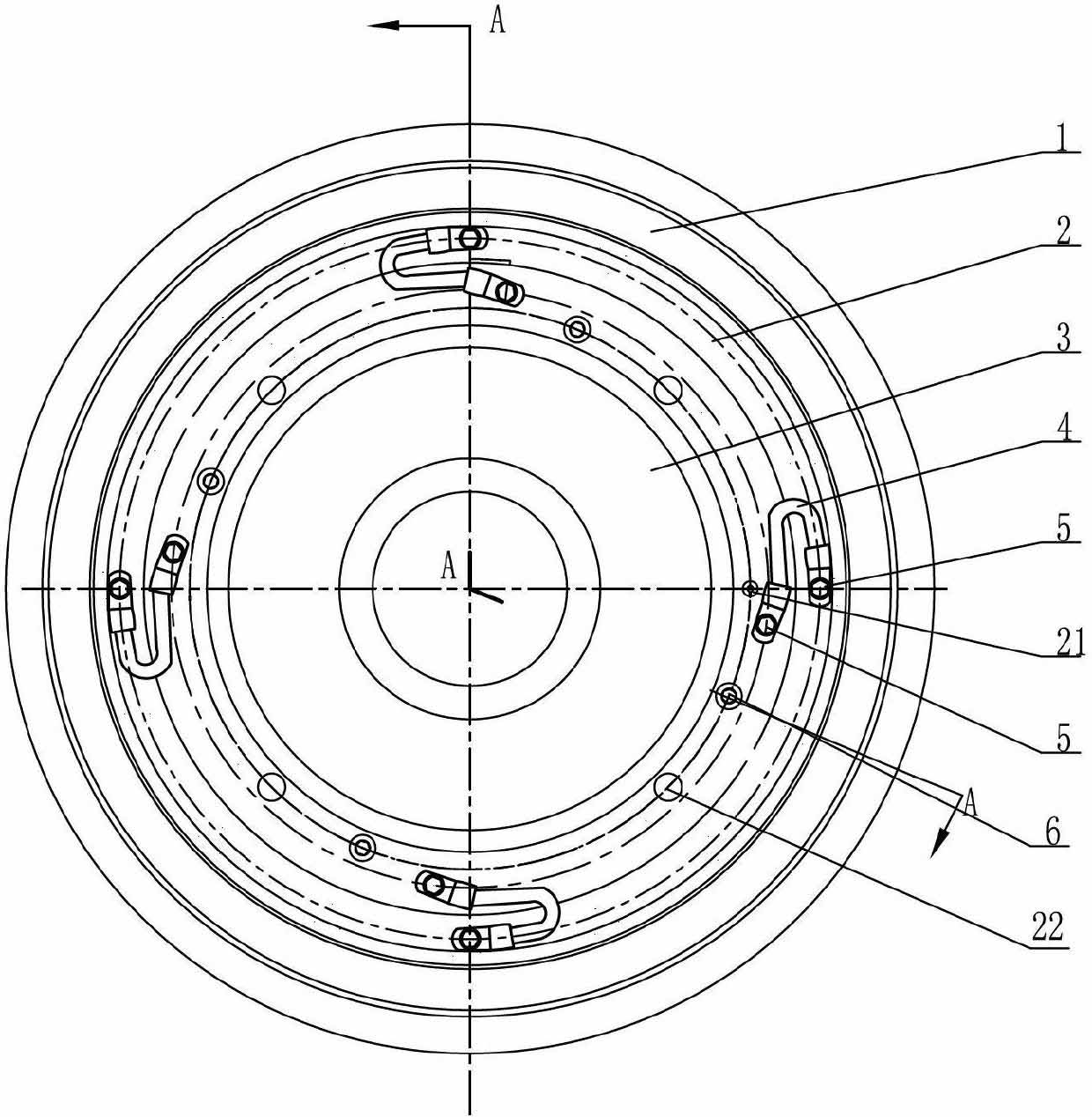

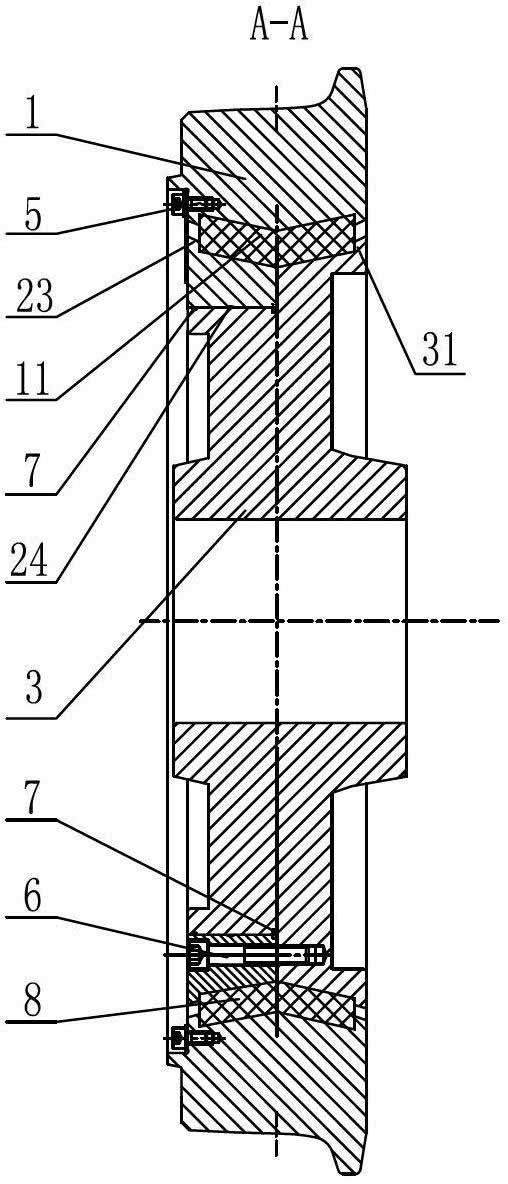

[0014] See Figure 1-5 As shown, the compression-shear composite elastic wheel for rail transit vehicles of the present invention comprises a tire 1, a wheel center 3, a pressure ring 2 and a V-shaped elastic element 8, and more than two elastic elements 8 are arranged between the tire 1 and the Between the wheel center 3 and the tire 1 and the pressure ring 2, and the two ends of the elastic element 8 are respectively connected to the two ends of the ring groove 11 of the tire 1 and the shoulder 23 on the pressure ring 2 and the shoulder 31 on the wheel center 3 The connection can prevent the wheel from derailing when the elastic element 8 fails, so as to improve the driving safety performance of the wheel. The elastic element 8 of the present invention is composed of 2 to 40 V-shaped rubber blocks. The elastic element 8 is made of rubber material, or the elastic element 8 is made of rubber material with a metal skeleton inside, or the elastic element 8 is equipped with Made...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com