Method for increasing fast replacement success rate by decreasing drawing speed through continuous casting machine

A continuous casting machine and pulling speed technology, which is applied in the field of steelmaking, can solve the problems of the liquid level overflow accident of the mold 4, reduce the success rate of the heat transfer of the tundish, and the casting billet 10 is easy to detach, so as to improve the success rate of quick change, Improve the success rate and avoid the effect of straightening cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

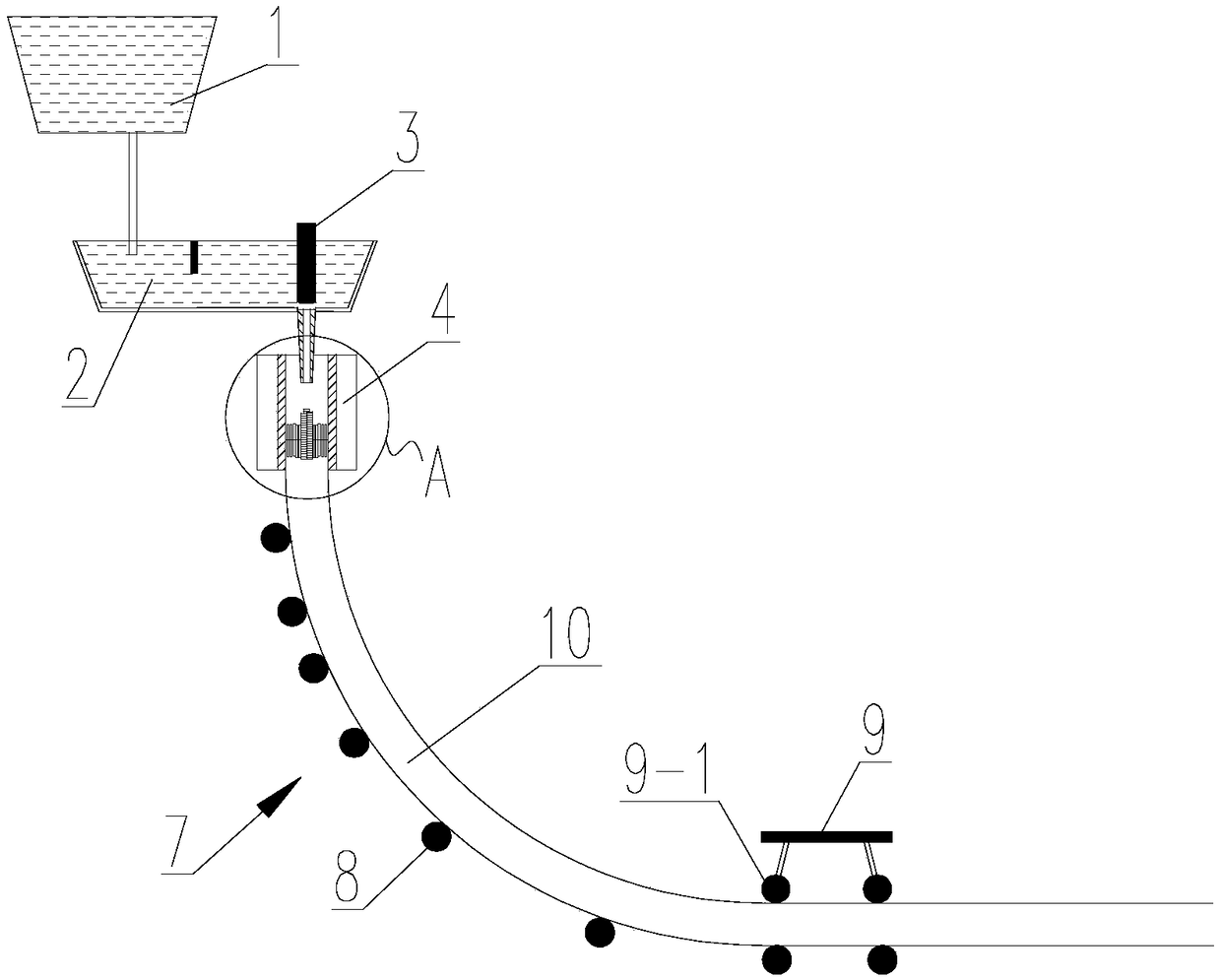

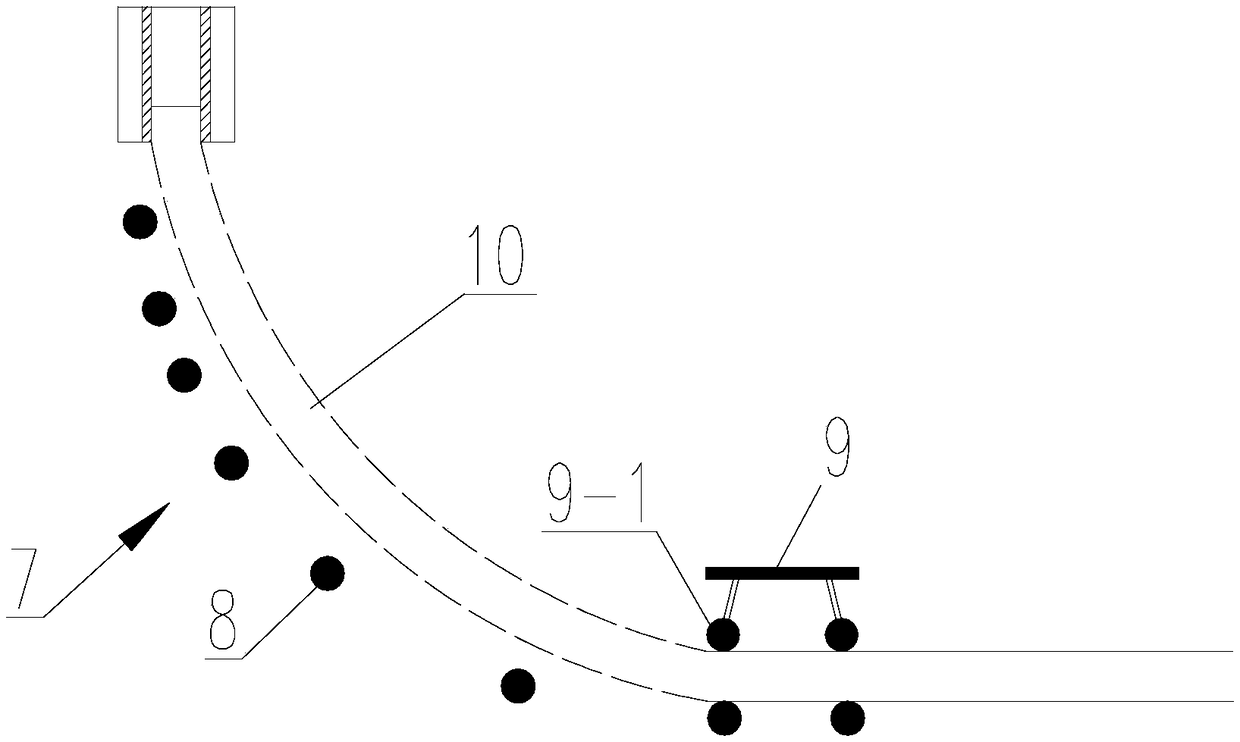

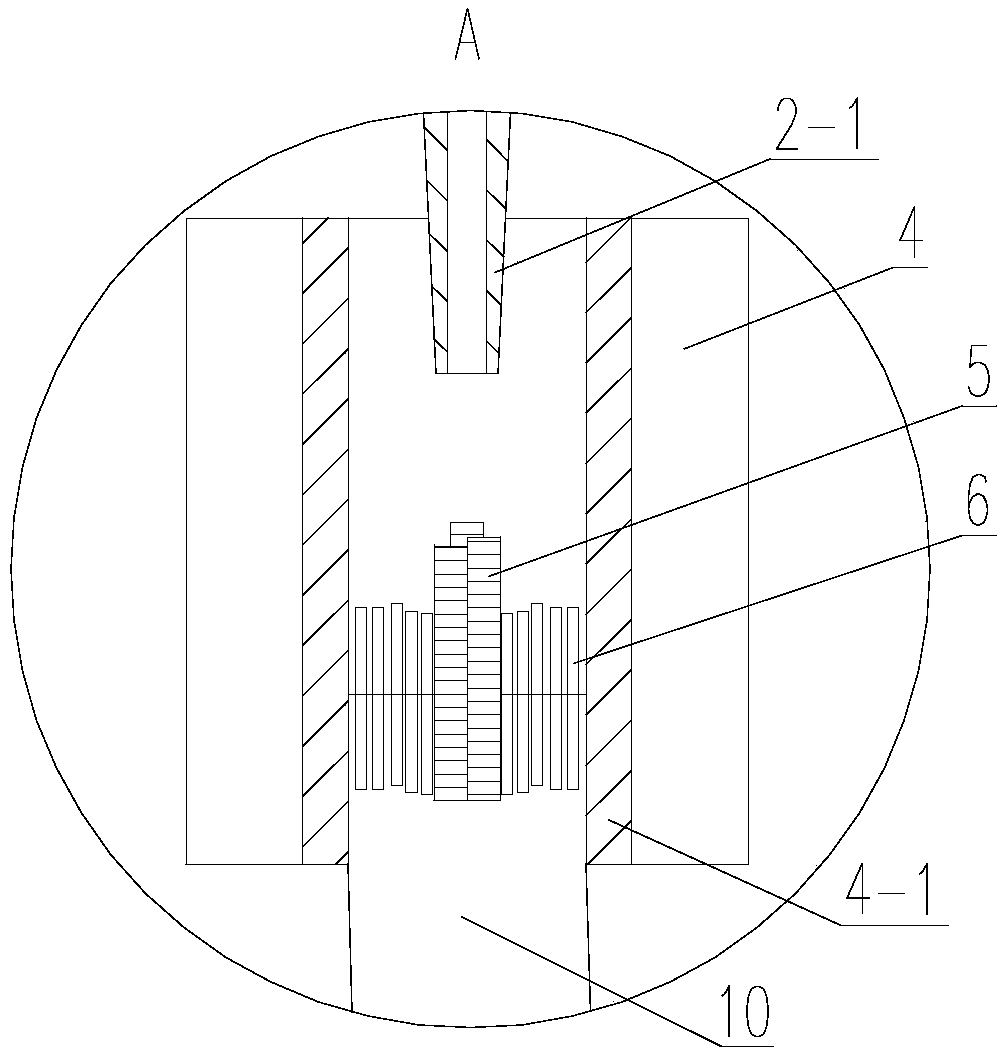

[0036] Such as figure 2 and 3 As shown, in this embodiment, the radius of the continuous casting machine is a 10-unit, 10-stream double tundish continuous casting machine with an arc of 10 m, and the tundish is filled with a liquid level height of 800 mm, and the length of the copper tube 4-1 in the crystallizer 4 is 904 mm. The cross-section of the copper tube 4-1 in the device 4 is 160mm*160mm, the target casting speed is 2.1m / min, the molten steel flows from the ladle 1 to the tundish 2, and then flows from the nozzle 2-1 of the tundish 2 to the crystallizer 4 in the copper pipe 4-1, forming the casting slab 10, the casting slab 10 then reaches the secondary cooling chamber 7, and solidifies into a circular arc shape and sticks to the secondary cooling support roll 8, and the straightening roll 9 of the tension straightening machine 9 The casting strand 10 is pulled out under the pressure of -1; the specific implementation steps are as follows:

[0037] S1: The pouring o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com