Dedicated quenching device of steel plate spring

A technology for leaf springs and quenching equipment, applied in quenching devices, heat treatment equipment, furnaces, etc., can solve the problems that the cooling curve cannot be accurately controlled, the material structure and properties cannot be obtained, and the digital monitoring cannot be achieved. The effect of improving carbon control indicators, reducing labor consumption, and good practical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

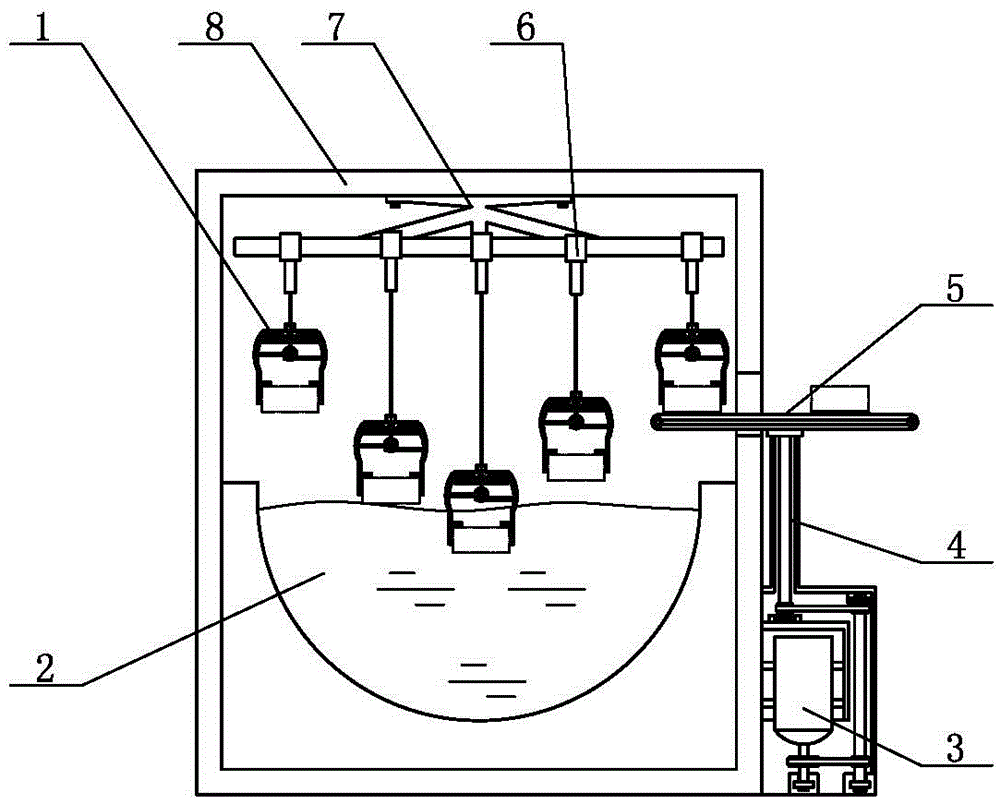

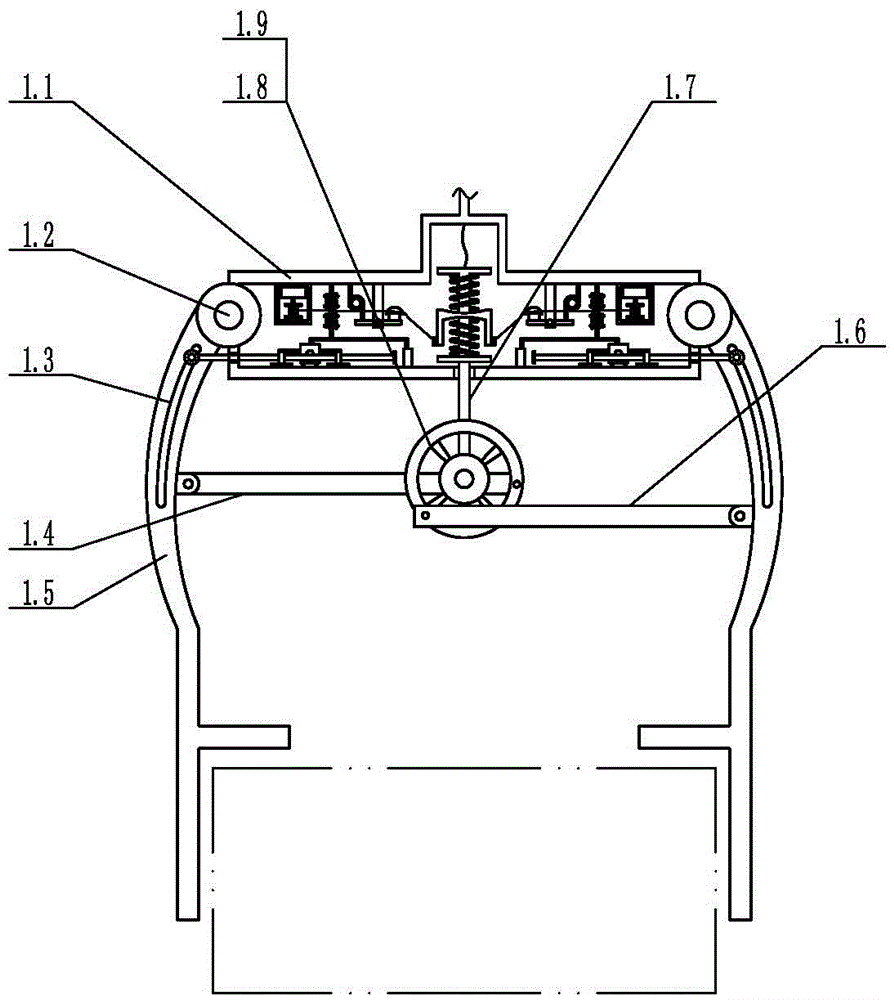

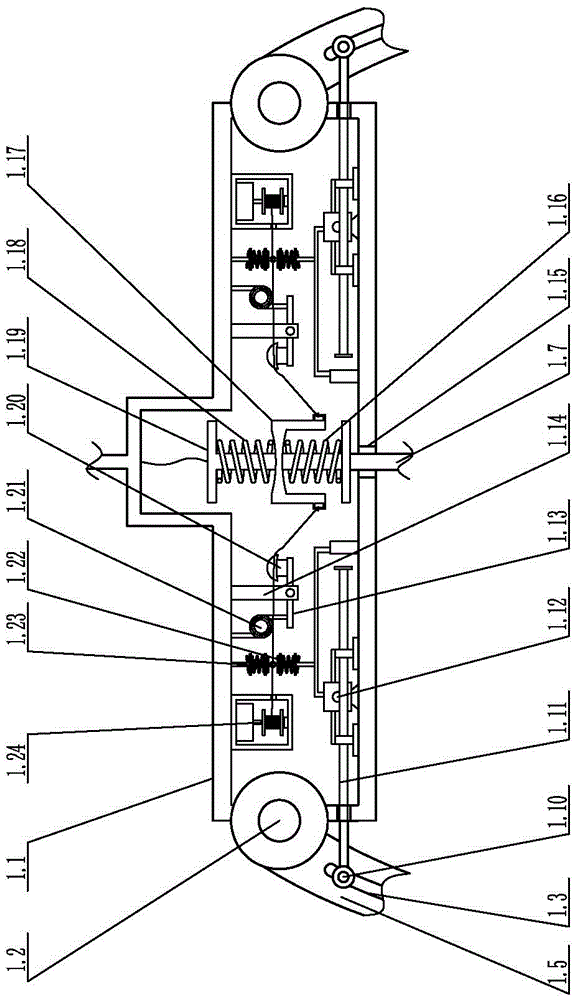

[0028] Such as figure 1 As shown, the special quenching equipment for a leaf spring of the present invention includes a quenching box, a quenching pool, an electric runner, a hoisting device and a manipulator; the quenching pool is arranged at the bottom of the quenching box; the electric runner is installed on On the top wall of the quenching box, more than three manipulators are installed on the electric runner through the lifting equipment. The electric runner can drive the hoisting equipment and the manipulator to rotate above the quenching pool. Automatically loosen or clamp the leaf spring, and under the driving of the hoisting equipment, immerse the leaf spring into and out of the quenching pool; the quenching box is provided with a feed inlet and more than three discharge outlets, and the feed inlet passes through the inlet The feeding conveyor belt is connected to the silo, and the outlet is connected to different cooling bins; the feeding conveyor belt is installed o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com