Titanium microalloyed Q355B structural steel plate and recrystallization controlled rolling process method thereof

A Q355B, micro-alloying technology, applied in the field of medium and heavy plate production, can solve problems such as large power consumption and electrode consumption, adverse effects on internal quality, affecting rolling rhythm, etc., to achieve low manufacturing costs and suppress grain growth. Large, fast-paced effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

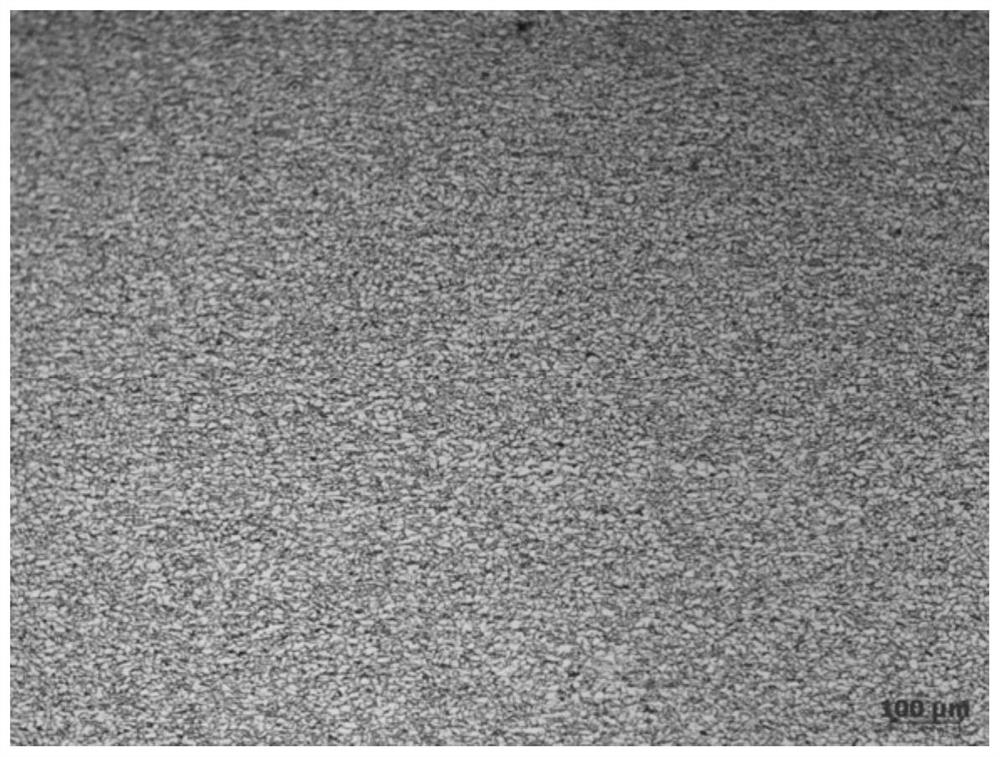

Image

Examples

Embodiment 1

[0039] The chemical composition of the steel plate in this example is C: 0.18%, Si: 0.19%, Mn: 0.72%, P: 0.017%, S: 0.008%, Als: 0.028%, Ti: 0.059%, Ceq: 0.30%.

[0040] According to above-mentioned chemical composition range, the technological process of the present embodiment is as follows:

[0041] After the iron ore is smelted into molten iron in the blast furnace, the molten iron is pre-desulfurized so that the S in the molten iron is ≤0.006%;

[0042] Blowing in a 120t converter, the end temperature of the converter is 1658°C, the LF entry temperature is 1540°C, 220 meters of aluminum wire is fed, after adding ferro-titanium 3.2Kg / t steel, the soft blowing time is 8 minutes and 21 seconds, and the calcium wire is fed 200m, the exit temperature is 1560°C, the exit Ti content is 0.063%, and the S content is 0.007%;

[0043]The temperature of the molten steel continuous casting tundish is 1537°C (liquidus line is 1515°C), the superheat of the tundish is controlled between ...

Embodiment 2

[0054] The chemical composition of the steel plate in this example is C 0.17%, Si 0.23%, Mn 0.78%, P 0.016%, S 0.005%, Als 0.039%, Ti 0.067%, Ceq 0.29%.

[0055] According to above-mentioned chemical composition range and technological process, the technological process of the present embodiment is as follows:

[0056] After the iron ore is smelted into molten iron in the blast furnace, the molten iron is pre-desulfurized so that the S in the molten iron is ≤0.006%;

[0057] Blowing in a 120t converter, the end temperature of the converter is 1651°C, the LF entry temperature is 1538°C, the aluminum wire is fed 220 meters, after adding titanium iron 3.2Kg / t steel, the soft blowing time is 8 minutes and 24 seconds, and the calcium wire is fed 200m, the exit temperature is 1556°C, the exit Ti content is 0.071%, and the S content is 0.004%;

[0058] The temperature of the molten steel continuous casting tundish is 1534°C (liquidus line is 1515°C), the superheat of the tundish is ...

Embodiment 3

[0068] The chemical composition of the steel plate in this example is C: 0.18%, Si: 0.20%, Mn: 0.82%, P: 0.012%, S: 0.004%, Als: 0.032%, Ti: 0.062%, Ceq: 0.32%.

[0069] According to above-mentioned chemical composition range and technological process, the technological process of the present embodiment is as follows:

[0070] After the iron ore is smelted into molten iron in the blast furnace, the molten iron is pre-desulfurized so that the S in the molten iron is ≤0.006%;

[0071] Blowing in a 120t converter, the end temperature of the converter is 1658°C, the LF entry temperature is 1545°C, the aluminum wire is fed 225 meters, after adding ferro-titanium 3.1Kg / t steel, the soft blowing time is 8 minutes and 17 seconds, and the calcium wire is fed 200m, the exit temperature is 1562°C, the exit Ti content is 0.068%, and the S content is 0.004%;

[0072] The temperature of the molten steel continuous casting tundish is 1538°C (liquidus line is 1515°C), the superheat of the tu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com