Ladle refining furnace electrode adjusting system

A ladle refining furnace and electrode adjustment technology, applied in furnaces, electric furnaces, furnace types, etc., can solve the problems that cannot meet the needs of optimal operation of power circuits, three-phase electrodes cannot be adjusted independently, and are prone to shaking during use, etc., to achieve lifting Highly accurate, reduced size, less prone to shaking effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

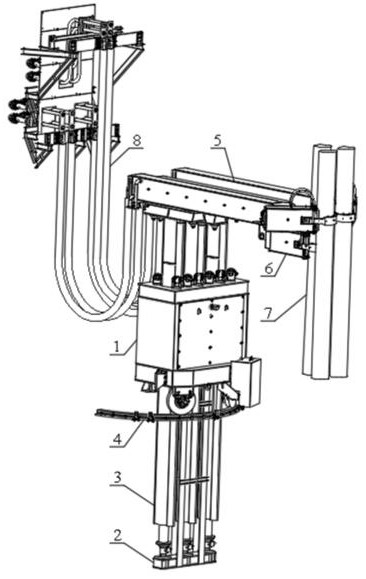

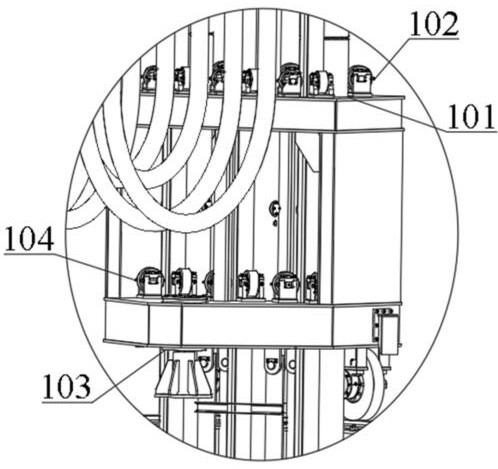

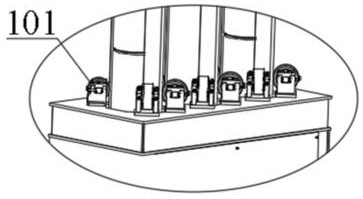

[0056] Such as Figure 1 to Figure 3 As shown, the electrode adjustment system of the ladle refining furnace includes a rotating base frame 1, a base 2, a lifting device 3, a station adjustment device 4, a cross arm 5 and a clamping device 6, wherein: the rotating base frame 1 is rotatable as a load-bearing body The base platform is installed on the foundation platform, the foundation platform is a cement structure or a frame base, three upper through holes 101 are opened on the load-bearing plate of the rotating base frame 1, and a plurality of upper guide wheels 102 are arranged symmetrically around the upper through holes 101, and the rotating base frame The lower bearing plate of 1 is correspondingly provided with three lower through holes 103, and a plurality of lower guide wheels 104 are arranged symmetrically around the lower through holes 103. Specifically, the upper through hole 101 and the lower through hole 103 are correspondingly provided for vertically installing ...

Embodiment 2

[0058] Such as figure 1 with Figure 4 As shown, the base 2 is arranged on the bottom of the rotating base frame 1 and is used for installing the lifting device 3. The base 2 includes two sets of double-headed hinged seats 201, four sets of mounting arms 202 and a horizontal mounting base 203. The head hinged seat 201 is parallel and symmetrically installed on the bottom of the rotating base frame 1. One end of the mounting arm 202 is hinged on the double-headed hinged seat 201, and the other end of the mounting arm 202 is fixed on the horizontal mounting seat 203. There are reinforcing beams 204, four mounting arms 202 and a horizontal mounting seat 203 to form a swingable frame structure, which is used to eliminate errors in the installation process and avoid movement interference. At the same time, it ensures that the horizontal mounting seat 203 is always horizontal and And it can rotate along with the rotating base frame 1 .

Embodiment 3

[0060] Such as Figure 5 to Figure 8 As shown, the lifting device 3 includes three groups of lifting cylinders 301, lifting platform 302, lifting column 303, lifting sleeve 304 and connecting seat 305. Specifically, the lifting cylinder 301 is controlled by a hydraulic valve, and the bottom of the lifting cylinder 301 is fixed at a horizontal On the mounting base 203, the lifting platform 302 is arranged on the telescopic rod of the lifting cylinder 301, the lifting platform 302 can move with the telescopic rod, the lifting column 303 is coaxially arranged inside the lifting sleeve 304, and the bottom of the lifting column 303 is installed through a flange On the lifting platform 302, the top of the lifting column 303 is hinged. Specifically, the top of the lifting column 303 is provided with a connecting platform 3031, and the connecting platform 3031 is rotatably installed in the hinge hole 3041 of the lifting sleeve 304 through the hinge shaft 3032. When the lifting oil cyl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com