Low-cost non-quenched and non-tempered crankshaft steel 48MnV-C and production method thereof

A production method, 48mnv-c technology, applied in the direction of furnace type, furnace, heat treatment furnace, etc., can solve the problems of affecting the performance of steel mills, high cost, and increased energy and medium consumption, and achieve the control of dimensional accuracy and effective Benefits to production organization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

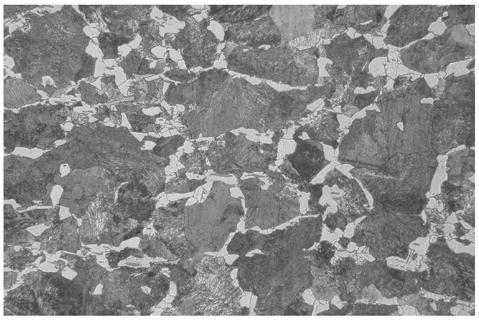

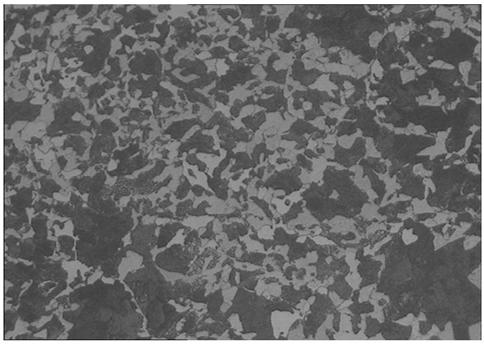

Image

Examples

Embodiment 1

[0023] Simultaneously according to another aspect of the present invention, a kind of production method of low-cost non-quenched and tempered crankshaft steel 48MnV-C is provided: comprising the steps of converter-RH refining-LF refining-continuous casting, wherein,

[0024] 1) During the RH vacuum treatment, nitrogen is used as the lifting gas, and the vacuum is pre-evacuated. After the vacuum slide valve is opened, the minimum vacuum degree is quickly reached, and the degassing process is performed. During the degassing process, the vacuum pressure is required to be less than 100pa and the holding time is ≥ 15min. Take component samples when RH starts to circulate for 5 minutes. According to the reported values of components, C, Si, Cr, and V elements are adjusted according to the lower limit value of refining components, and the amount of alloy added in LF furnace should be reduced as much as possible to make full use of the degassing of RH. Features. The RH cycle time is...

Embodiment 2

[0030] Simultaneously according to another aspect of the present invention, a kind of production method of low-cost non-quenched and tempered crankshaft steel 48MnV-C is provided: comprising the steps of converter-RH refining-LF refining-continuous casting, wherein,

[0031] 1) During the RH vacuum treatment, nitrogen is used as the lifting gas, and the vacuum is pre-evacuated. After the vacuum slide valve is opened, the minimum vacuum degree is quickly reached, and the degassing process is performed. During the degassing process, the vacuum pressure is required to be less than 100pa and the holding time is ≥ 15min. Take component samples when RH starts to circulate for 5 minutes. According to the reported values of components, C, Si, Cr, and V elements are adjusted according to the lower limit value of refining components, and the amount of alloy added in LF furnace should be reduced as much as possible to make full use of the degassing of RH. Features. The RH cycle time is...

Embodiment 3

[0037] Simultaneously according to another aspect of the present invention, a kind of production method of low-cost non-quenched and tempered crankshaft steel 48MnV-C is provided: comprising the steps of converter-RH refining-LF refining-continuous casting, wherein,

[0038] 1) During the RH vacuum treatment, nitrogen is used as the lifting gas, and the vacuum is pre-evacuated. After the vacuum slide valve is opened, the minimum vacuum degree is quickly reached, and the degassing process is performed. During the degassing process, the vacuum pressure is required to be less than 100pa and the holding time is ≥ 15min. Take component samples when RH starts to circulate for 5 minutes. According to the reported values of components, C, Si, Cr, and V elements are adjusted according to the lower limit value of refining components, and the amount of alloy added in LF furnace should be reduced as much as possible to make full use of the degassing of RH. Features. The RH cycle time is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com