Method for rolling wide and thick steel plate by adopting complete negative allowance

A negative tolerance, steel plate technology, used in metal rolling, metal rolling, rolling mill control devices, etc., can solve the problems of control in the range of -0.3~0mm, large thickness tolerance range, short time, etc., to improve the finished product. Rate and thickness of the whole board uniformity, reduce self-weight, increase the effect of load capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with embodiment:

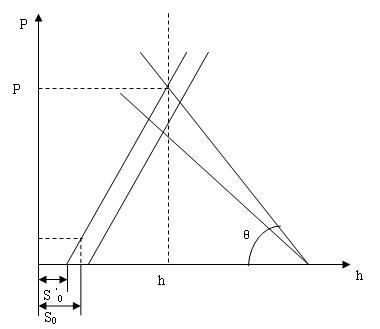

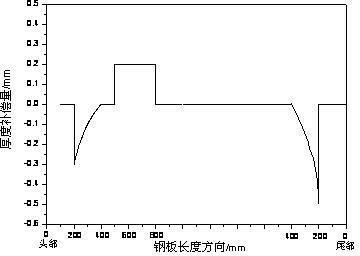

[0017] Taking the rolling of marine steel plates as an example, the steel plate thickness ranges from 12 to 35 mm, and the steel plate width ranges from 1880 to 3650 mm. The production process of this kind of steel plate is: after selecting the appropriate roll and roll shape, make a reasonable rolling plan, then load the steel plate into the furnace, and carry out the hot-rolled billet according to the set thickness of the target under the automatic control system of the thickness of the rolling mill. Rolling, and according to the thickness of the rolling mill exit measured by the online thickness gauge as the feedback of the thickness control system, the thickness compensation is performed on the length direction of the steel plate through the thickness control system to improve the pass rate of the thickness tolerance controlled at -0.3 ~ 0mm.

[0018] (A) Rolling process

[0019...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com