Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

48results about How to "Reduce internal voids" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

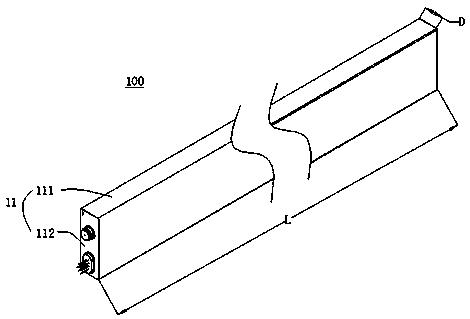

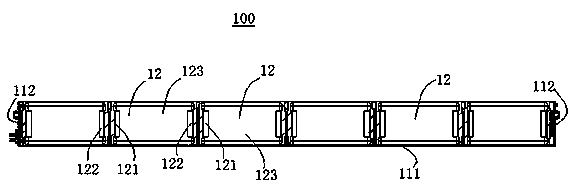

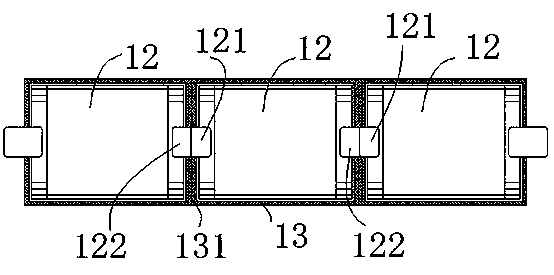

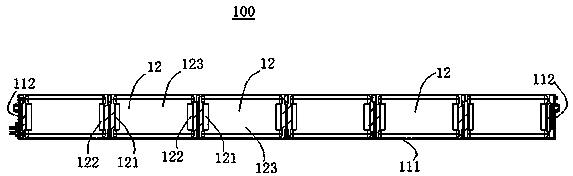

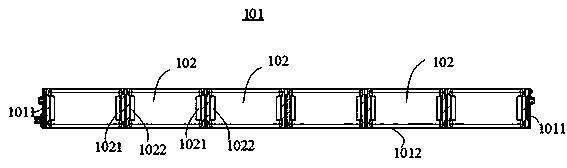

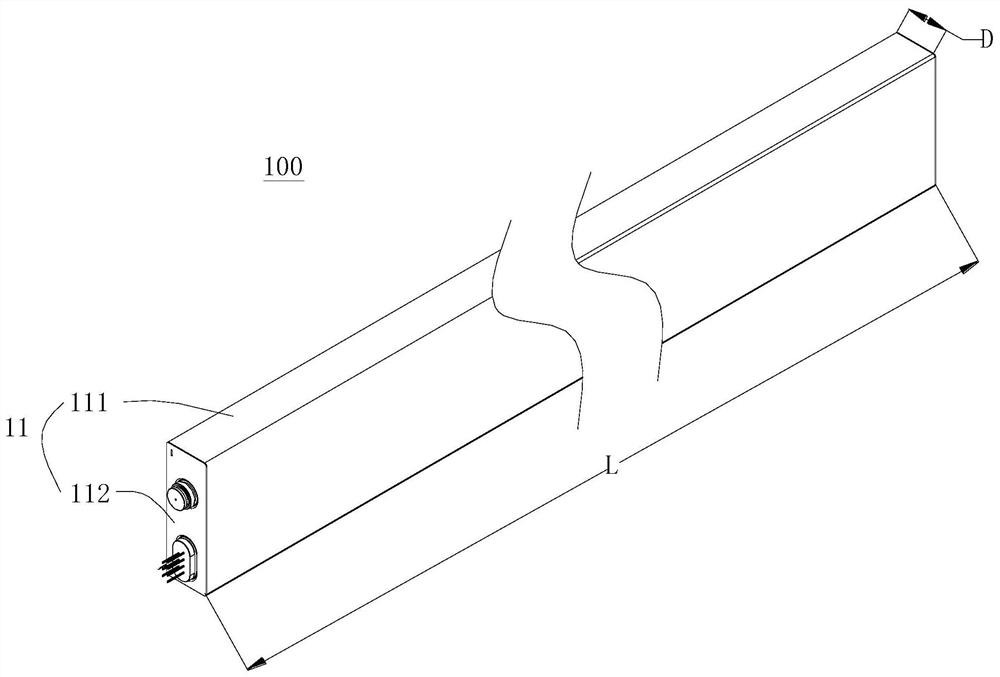

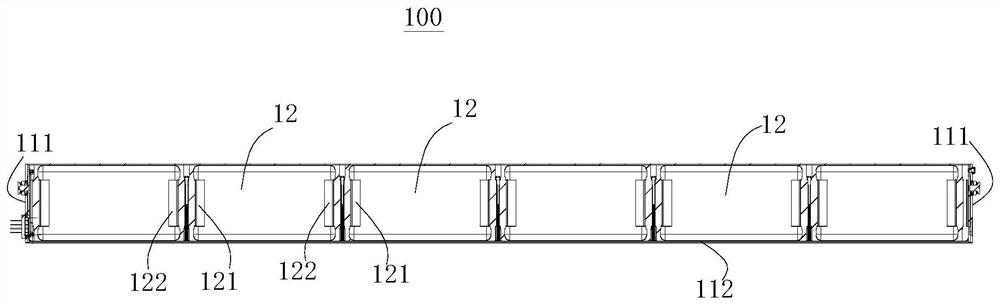

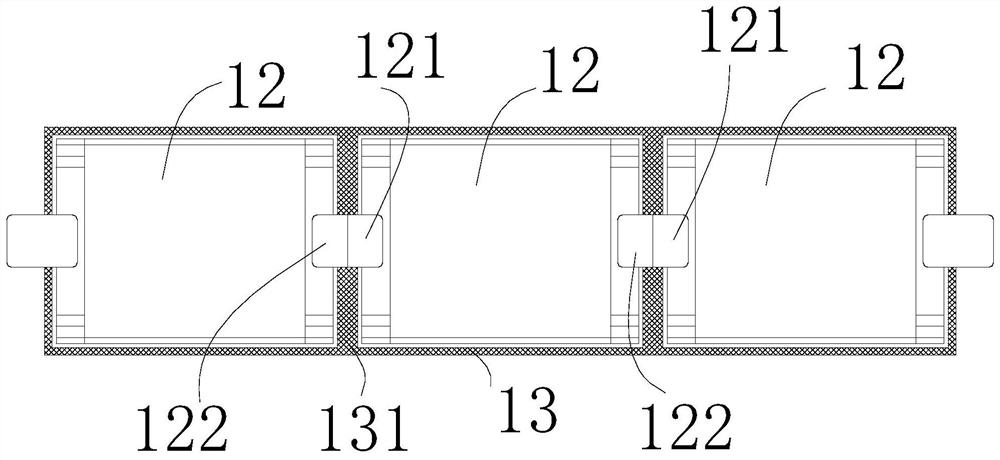

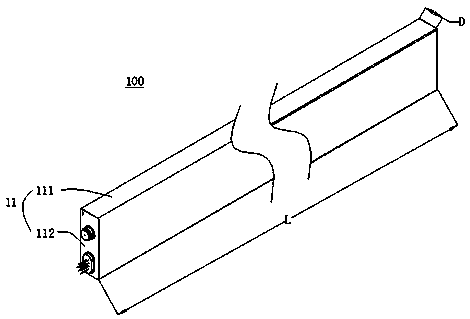

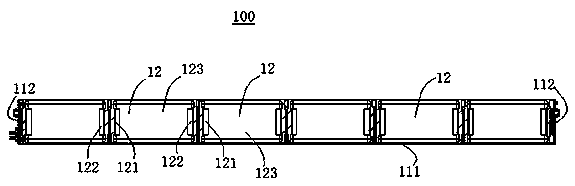

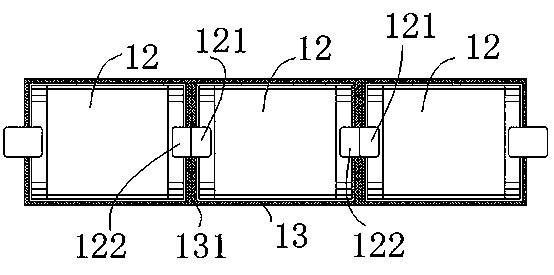

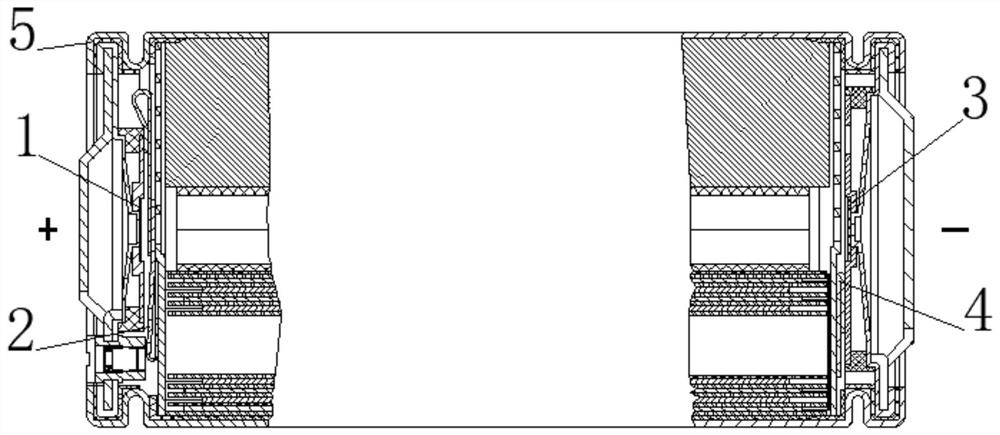

Battery, battery module, battery pack and electric vehicle

ActiveCN110828717AHigh mechanical strengthExtended service lifeVent arrangementsElectrolyte accumulators manufactureElectric carsElectric vehicle

The invention provides a battery, a battery module, a battery pack and an electric vehicle. The battery comprises a metal casing body and a plurality of pole core strings packaged in the metal casingbody. The plurality of pole core strings are arranged along a second direction and connected in series with one another. Each pole core string comprises a plurality of pole core groups which are arranged along a first direction and connected in series with one another. Each pole core group comprises at least one pole core. Each pole core group is packaged in a packaging film. The air pressure between the metal casing body and packaging films is lower than the air pressure outside the metal casing body. According to the invention, the sealing effect and the strength of the battery are improved.

Owner:BYD CO LTD

Battery, battery module, battery pack and electric vehicle

ActiveCN110828745AHigh mechanical strengthExtended service lifeLarge-sized flat cells/batteriesBattery isolationElectric carsElectric vehicle

The invention provides a battery, a battery module, a battery pack and an electric vehicle. The battery comprises a metal casing body and a plurality of pole core groups which are successively arranged and packaged in the metal casing body. The pole core groups are connected in series with one another. Each pole core group comprises at least one pole core. Each pole core group is packaged in a packaging film. The air pressure between the metal casing body and packaging films is lower than the air pressure outside the metal casing body. The air pressure in the packaging films is lower than theair pressure between the metal casing body and the packaging films. According to the invention, the sealing effect and the strength of the battery are improved.

Owner:BYD CO LTD

Battery pack and electric vehicle

ActiveCN110828746AHigh mechanical strengthExtended service lifeSynthetic resin layered productsBattery isolationElectric carsElectric vehicle

The invention provides a battery pack and an electric vehicle. The battery pack comprises a battery sequence which comprises a plurality of single batteries. The thickness of each single battery extends along a first direction, and the plurality of single batteries are sequentially arranged along the first direction to form the battery sequence. At least one single battery comprises a metal casingbody and a pole core packaged in the metal casing body. The air pressure in the metal casing body is lower than the air pressure outside the metal casing body. A gap is formed between at least two adjacent single batteries, and the proportion range of the gap to the thickness of the single batteries is 0.001 to 0.15. The battery pack provided by the invention is relatively high in energy density,and the safety performance is greatly improved.

Owner:BYD CO LTD

Multi-layer anti-flaming textile cloth and manufacturing method thereof

ActiveCN103361987AImprove flame retardant performanceIncreasing the thicknessSynthetic resin layered productsWoven fabricsSurface layerEmulsion

The invention relates to multi-layer anti-flaming textile cloth and a manufacturing method thereof. The multi-layer anti-flaming textile cloth comprises at least three surface layers which are adhered through anti-flaming emulsion; the surface layers are interwoven of warps and wefts up and down; before being woven, the warps and the wefts are soaked in a specific anti-flaming chemical medicinal solution; the warps comprise textile metal fibers, polyester cotton, polyamide filaments and 20D chinlon matt fully drawn yarn (FDY) filaments; the wefts comprise cotton, hemp, furs and 20D chinlon matt FDY filaments; the cross sections of all the warps and wefts are flat rectangular; the firmness of the cloth can be improved; the warps and the wefts are soaked in the anti-flaming chemical medicines, so that effects of retarding flames and preventing fire from spreading are achieved; hexa-bromine water media and deca-bromine-antimonous oxide are coated on the surface of the cloth; furthermore, the cloth is tightly woven and is low in ventilating property, so that the anti-flaming effect of the cloth can be enhanced; the manufacturing method for the cloth is simple; a plurality of warps or wefts are combined, so that the firmness and the air permeability of the cloth are improved.

Owner:陕西秦塬纺织有限公司

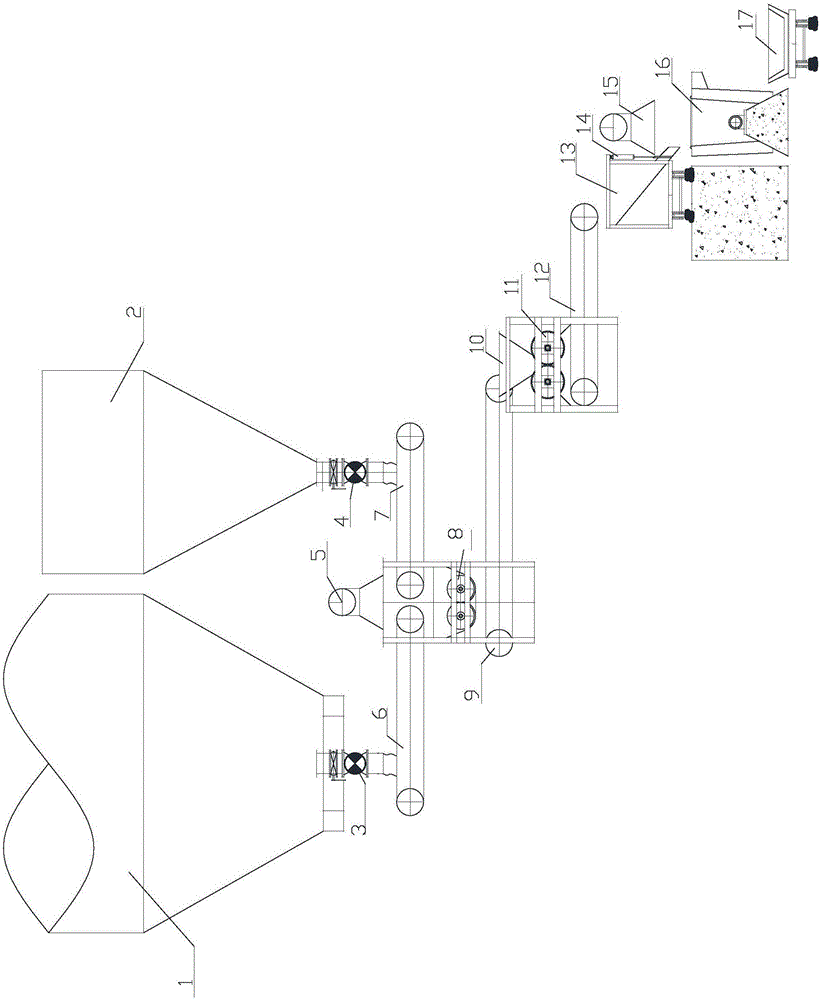

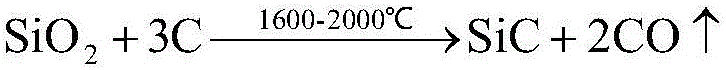

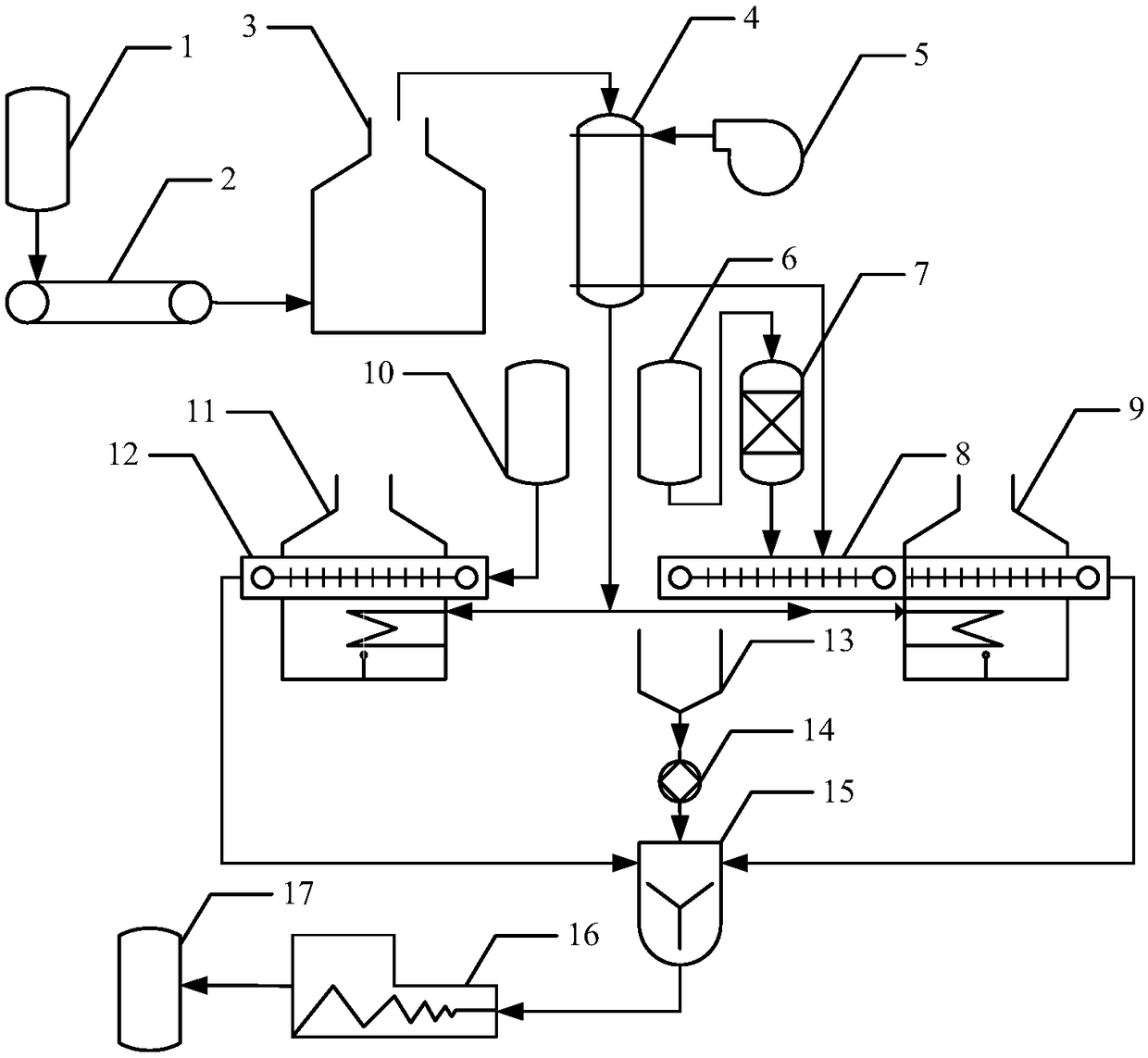

Method for utilizing industrial waste silica fume to prepare industrial silicon and production system

ActiveCN106219550ALower iron levelsImprove qualitySilicon compoundsMixed materialsToxic industrial waste

The invention relates to a method for utilizing industrial waste silica fume to prepare industrial silicon. The method includes the following steps that S1, encryption treatment is conducted on industrial waste silica fume, then the industrial waste silica fume is mixed, blended and stirred with a reducing agent to obtain a mixed material; S2, water is added to the mixed material, stirring is performed, pelletizing treatment is performed after stirring to obtain silica fume pellets; S3, the silica fume pellets are subjected to reduction smelting at the temperature of 1600-2000 DEG C for 19-21 minutes, and industrial silicon can be obtained. The invention further comprises a production system for utilizing waste silica fume to prepare industrial silicon. The system comprises a silica fume storage and encryption bin, a reducing agent storage bin, a double-auger stirring and mixing machine, an opposite-roller compression and pelletizing machine and a reducing smelting furnace. The reduced and smelt main raw materials can be wholly waste silica fume, the recovery rate of the silica fume is above 85%, the problems of low comprehensive utilization degree of silica fume and environmental pollution are solved, and higher-purity industrial silicon products are also produced.

Owner:刘成成

Method for improving performance of gypsum powder

A method for improving the performance of gypsum powder belongs to the field of gypsum powder application, and comprises the following steps: 1, selecting a coating agent capable of tightly combiningwith gypsum crystal; 2, adding a liquid coating agent to the gypsum powder; and 3, sending the gypsum powder into which the liquid coating agent is added to a coating device for coating. The method has the characteristics of greatly improving the strength, water resistance and the like of the gypsum powder.

Owner:ZHENGZHOU SUNDY BUILDING TECH

Biomass briquette and preparation method thereof

InactiveCN107033980AImprove adhesionHigh calorific valueBiofuelsSolid fuelsAluminum silicateBiomass briquettes

The invention discloses a biomass briquette. The biomass briquette is prepared from the following raw materials by weight: 30 to 45 parts of straw, 25 to 35 parts of wood chips, 15 to 25 parts of rice husks, 10 to 15 parts of corncob, 5 to 10 parts of anthracite, 1 to 3 parts of quicklime and 6 to 9 parts of magnesium aluminum silicate hydrate. The invention also discloses a preparation method for the biomass briquette. According to the invention, the biomass briquette and the preparation method thereof can effectively utilize biomass raw materials and have the advantages of simple processing technology, low cost, small density, high calorific value, low ash content, full combustion, etc.

Owner:湖南双晟科技信息咨询有限公司

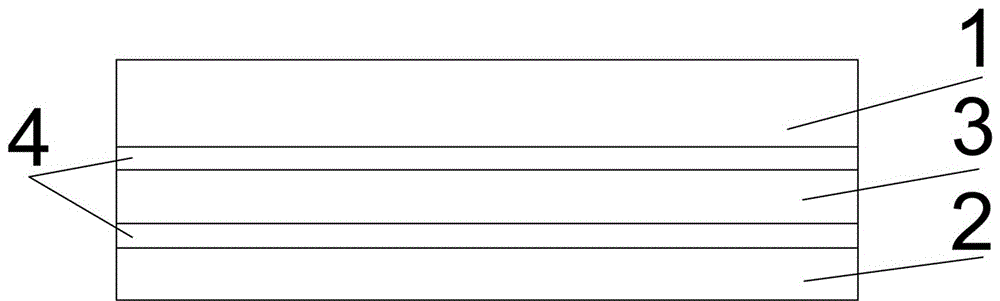

Sound insulating PVB (polyvinyl butyral) laminated glass and preparation method thereof

ActiveCN106003922AStrong sound insulationReduce internal voidsSynthetic resin layered productsLaminationPolyvinyl butyralPolystyrene

The invention relates to sound insulating glass and a preparation method thereof, in particular to sound insulating PVB (polyvinyl butyral) laminated glass and a preparation method thereof. The sound insulating PVB laminated glass comprises a first glass substrate, a second glass substrate, a PVB film between the first glass substrate and the second glass substrate as well as polystyrene films located between the first glass substrate and the PVB film as well as between the second glass substrate and the PVB film, wherein the first glass substrate and the second glass substrate are arranged vertically. The preparation method of the sound insulating PVB laminated glass comprises the following steps: (1) cleaning of the glass substrate; (2) preparation of the polystyrene films; (3) combining operation: the PVB film is arranged in a combining chamber for combination of the glass substrates, the PVB film and the polystyrene films; (4) prepressing for exhausting; (5) high-pressure molding. The prepared PVB laminated glass has good mechanical property, impact resistance and good sound insulating effect, the PVB film cannot fall off the glass when the laminated glass meets external impact or the external environmental temperature changes acutely, and the service life is long.

Owner:HUZHOU XINFU NEW MATERIALS CO LTD

Assembled sandwich panel with metal surface insulation for building and its installation method

InactiveCN102296772AWith flame retardant functionAchieve flame retardant functionCovering/liningsInsulation layerThermal bridge

The invention discloses an assembled sandwich panel with metal surface heat insulation for construction and an installation method, which comprises a metal shell and a thermal insulation layer uniformly filled and bonded in the metal shell, and the upper and lower ends of the metal shell are provided with movable The ribs and grooves cooperate with each other, the ribs are provided with through holes along the width direction, the middle part of the splicing surface around the metal shell is provided with an opening extending along the length direction, and the inner side of the opening is provided with relatively independent left and right support frames. 1. The right support frame is supported between the thermal insulation layer and the metal shell, and is connected at the opening through a silicon rubber pad. The opening can effectively block the thermal bridges on the inner and outer end faces of the metal shell, improving the heat preservation and heat insulation effects, and the bolt connection improves the overall seismic performance of the assembly. It is suitable for packaging and decoration of building exterior walls under various environmental conditions.

Owner:李明宙

Method for preparing biomass briquetting fuel from sisal hemp residues

The invention discloses a method for preparing biomass briquetting fuel from sisal hemp residues. Sisal hemp residue powder, magnesium oxide, manganese ore slag, starch, cerous sulfate, sodium carboxymethylcellulose mucilage and epoxy asphalt with the weight ratio of 100:(8-12):(5-10):(10-15):(2-4):(10-15):(5-8) are adopted as raw materials, and the biomass briquetting fuel is prepared through the procedures of smashing, forming, drying and the like. The method has the advantages that the preparation process is simple, energy consumption is low, production efficiency is high, the forming rate is high, and cost is low, the prepared biomass fuel is low in density, high in heat value, low in ash content, not prone to looseness, good in moisture resistance, capable of being saved for a long time and suitable for industrial production, and internal gaps of the product are small.

Owner:GUANGXI NANNING SHENGQIAN TECH DEV CO LTD

Preparation method of biomass solid fuel

The invention discloses a preparation method of biomass solid fuel. The method includes the steps of adding cassava lees into a smashing machine to be smashed to be 40-60 mesh to obtain cassava lee powder, adding the cassava lee powder, magnesium oxide, acetylene sludge, attapulgite and pucherite into a stirring device, adding a proper amount of water to be stirred into paste, putting the paste into a muffle furnace to be sintered for 3-5 h at a temperature of 500-600 DEG C to obtain carbide, evenly mixing the carbide with polyurethane rubber and polyurethane asphalt, conveying the obtained mixed materials to a forming machine to be press-formed at a temperature of 120-140 DEG C and pressure of 60-80 MPa to obtain formed fuel, drying the formed fuel, cooling the fuel to the room temperature, and packaging the fuel to obtain the biomass solid fuel. The method has the advantages of being simple in preparation process, low in energy consumption, high in production efficiency, high in forming rate, low in cost and the like; the prepared biomass solid fuel is low in density, high in heat value, small in ash content, small in production internal gap, free of loosening, good in humidity resistance, capable of being stored for a long time and suitable for industrial production.

Owner:GUANGXI NANNING SHENGQIAN TECH DEV CO LTD

Low-energy consumption and high-calorific value formed fuel processing device and method thereof

PendingCN108373940AReduce energy consumptionHigh calorific valueBiofuelsSolid fuelsProcess engineeringHeating furnace

The invention discloses a low-energy consumption and high-calorific value formed fuel processing device and a method thereof. The device comprises a first-stage straw storage bin, a second-stage strawstorage bin, a coffee ground storage bin, a first fuel heating furnace, a second fuel heating furnace and a pregelatinized starch tank, wherein the first-stage straw storage bin is connected with a biomass gasifying furnace, and an outlet of the biomass gasifying furnace is connected with the first fuel heating furnace and the second fuel heating furnace, respectively; the second-stage straw storage bin is connected with the first fuel heating furnace through a first chain grate stoker; the coffee ground storage bin is connected with the second fuel heating furnace through a second chain grate stoker; and the fuel heating furnace, the second fuel heating furnace and the pregelatinized starch tank are connected with an extrusion forming machine through the same mixing stirrer, and an outlet of the extrusion forming machine is connected with a formed fuel storage bin. According to the device, a low-energy consumption and high-calorific value solid formed fuel can be obtained, so that the utilization cost of a biomass energy source is lowered, and the development and the application of a biomass utilization technique are promoted.

Owner:NANJING FORESTRY UNIV

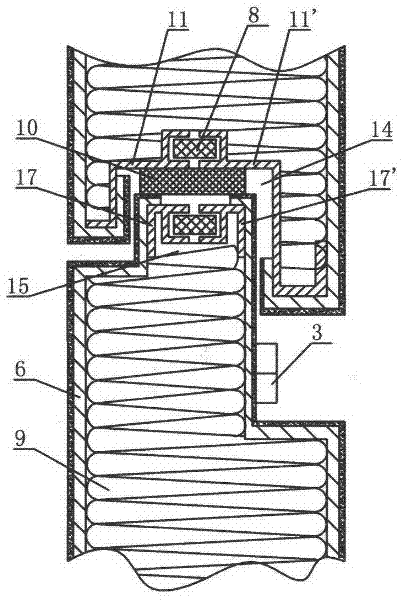

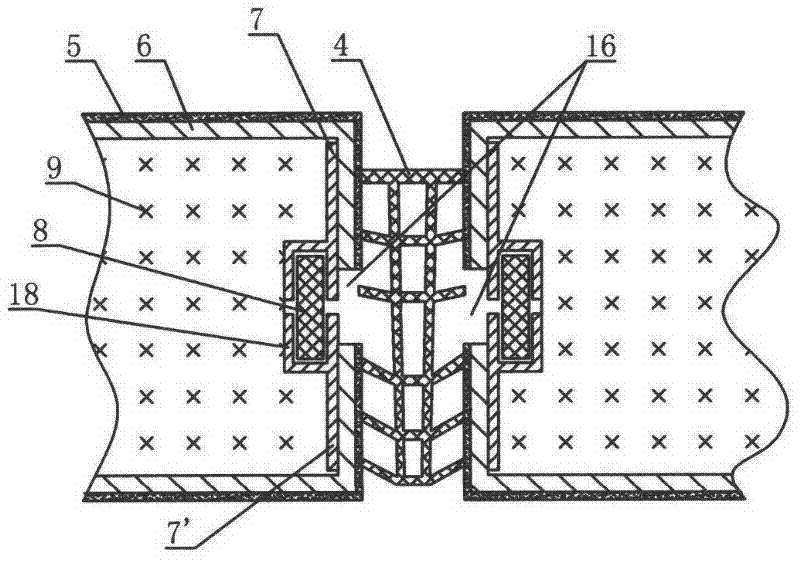

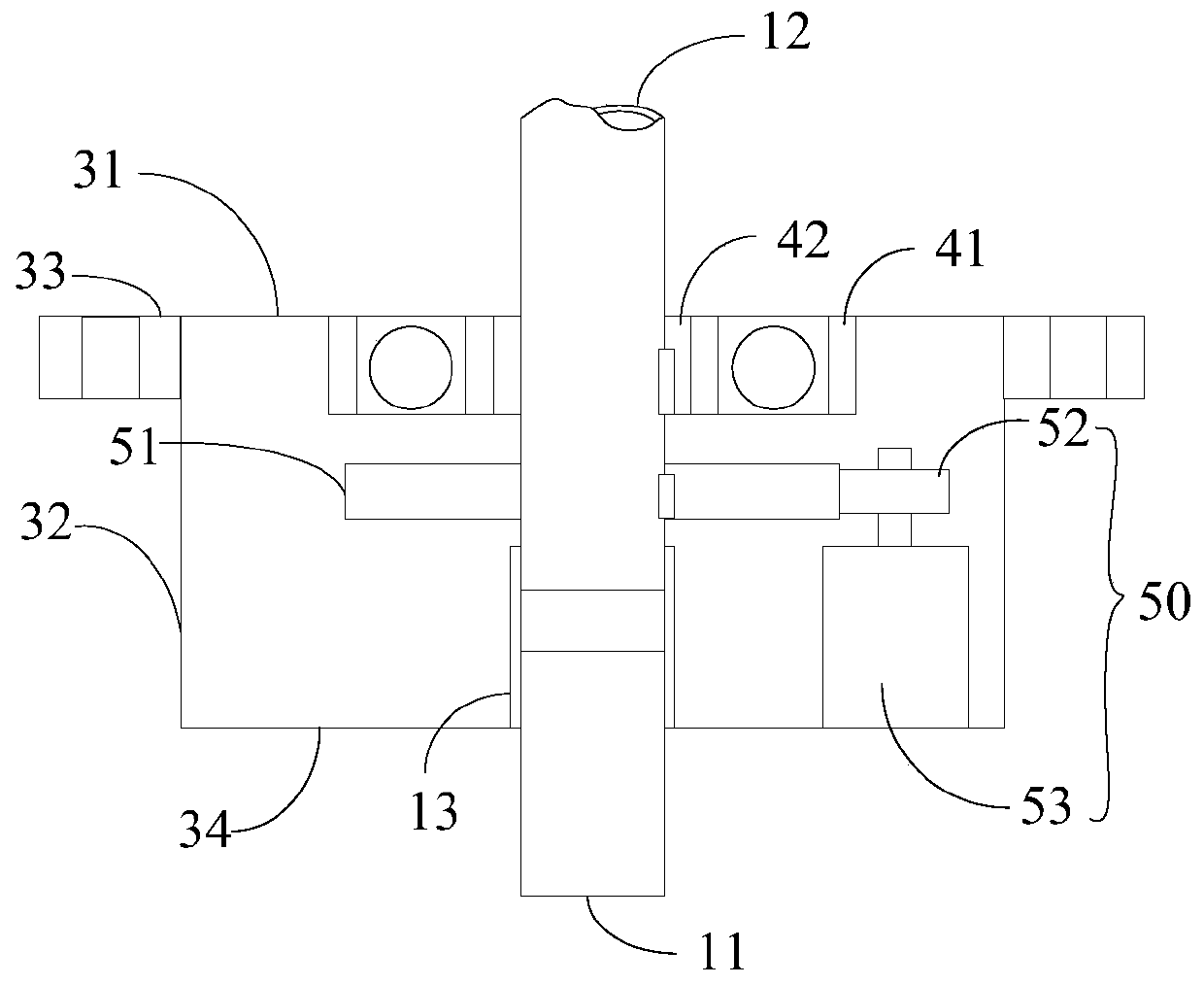

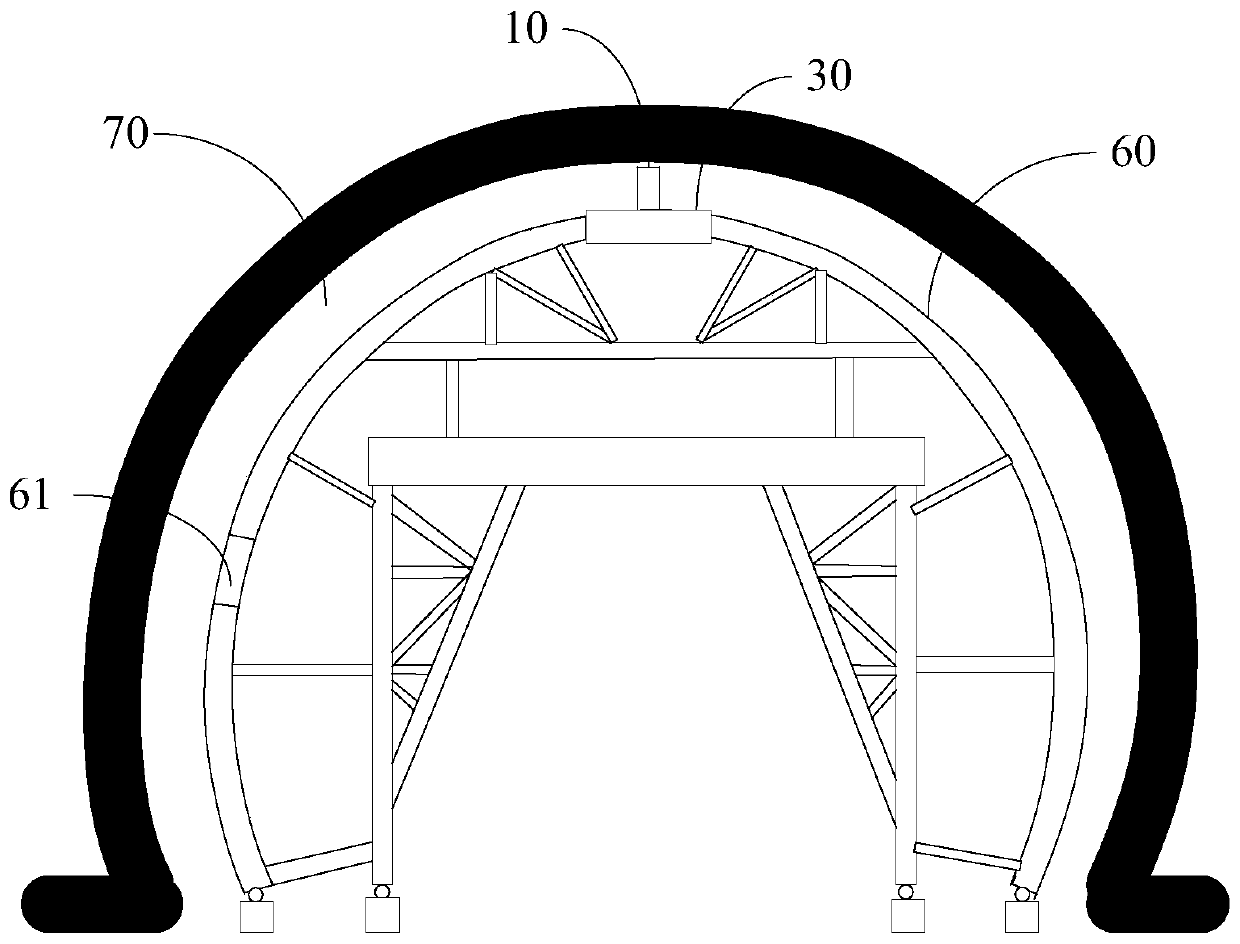

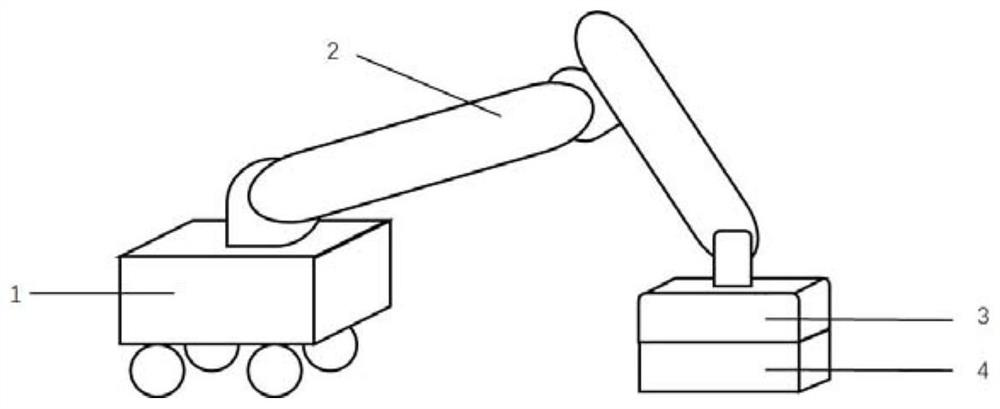

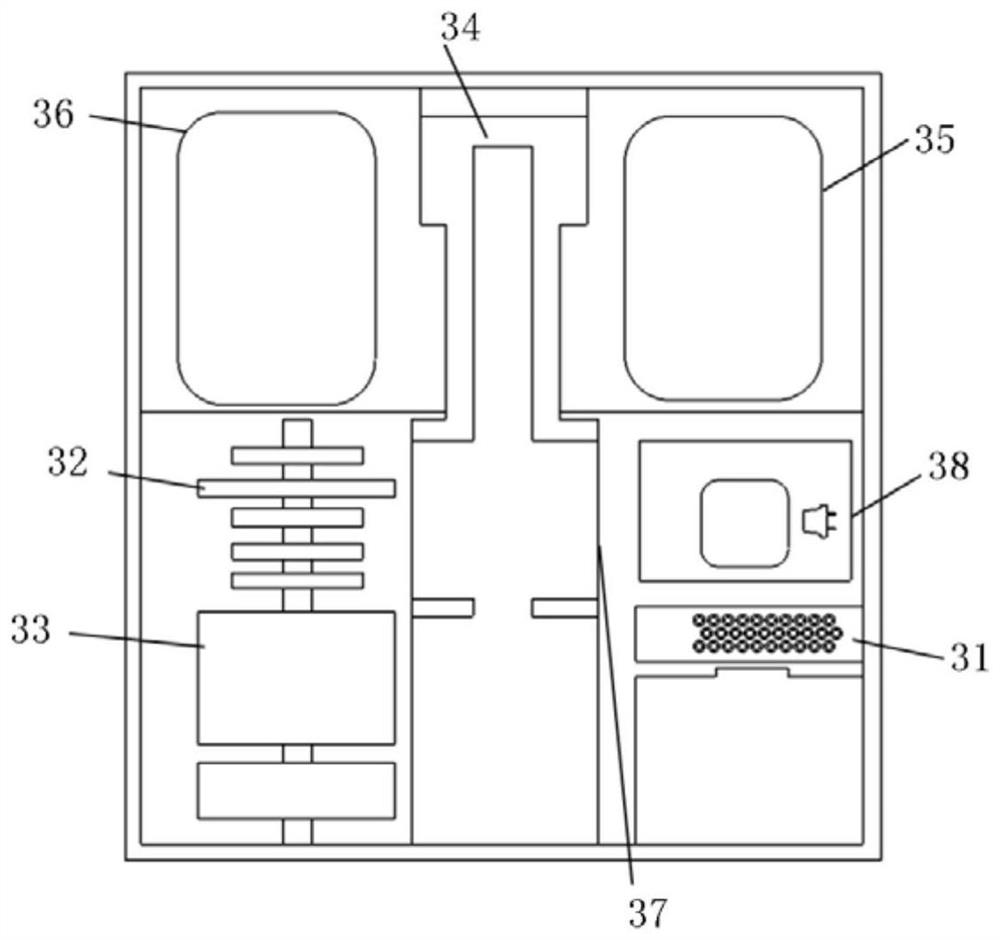

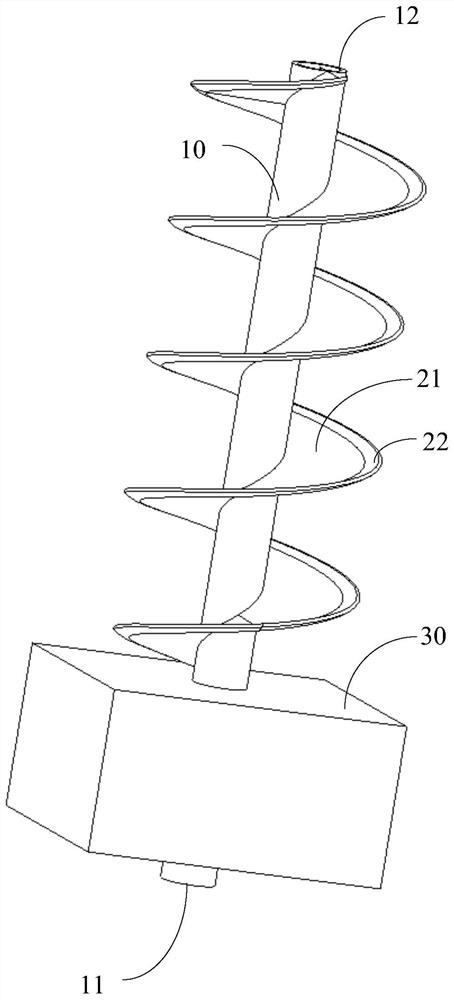

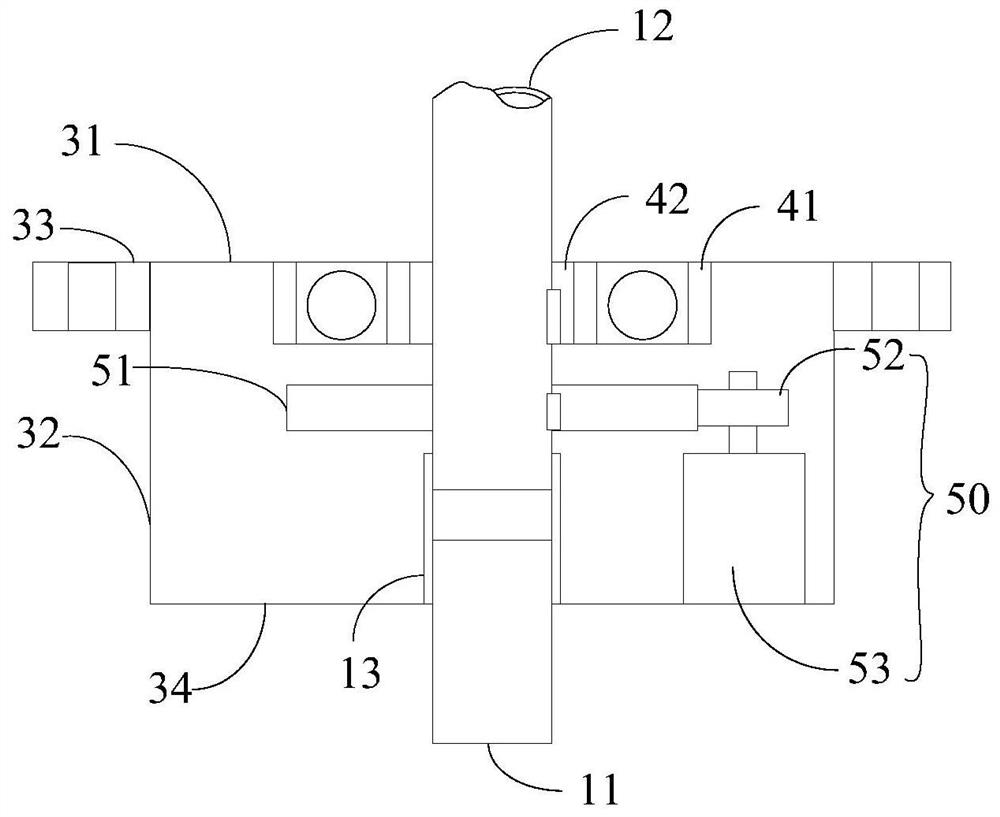

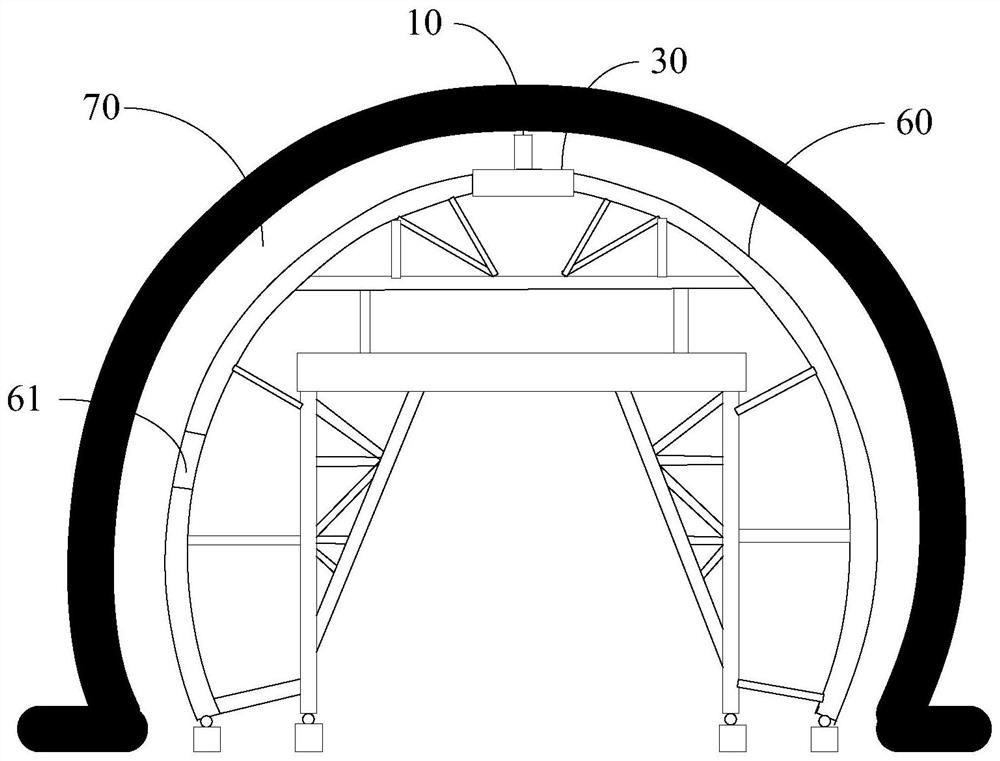

Pouring device, lining trolley and pouring technology

ActiveCN110645017AReduce internal voidsAvoid voidsUnderground chambersHydro energy generationStructural engineeringPipe

The invention discloses a pouring device applied to a lining trolley. The lining trolley comprises an arc template. A pouring window is formed in the arc template. The pouring device comprises a fixing base matched with the pouring window, a pouring pipe arranged on the fixing base, a spiral sheet arranged on the periphery of the pouring pipe and a drive assembly driving the spiral sheet to rotate. The pouring device solves the problem about empty disengaging during existing vault part concrete pouring.

Owner:湖南帝星智能科技有限公司

Preparation method of novel biomass briquette fuel

The invention discloses a preparation method of a novel biomass briquette fuel. The preparation method comprises the following steps: adding wood chips to a crusher, and crushing the wood chips to 40-60 meshes to obtain wood chip powder; adding the wood chip powder, magnesium oxide, manganese mine slag, mica powder and cerium nitrate to a stirrer, adding a proper amount of water, stirring above added materials and water to form a paste; taking the paste, putting the paste in a muffle furnace, and roasting the paste at 700-800DEG C for 2-3h to obtain carbide; uniformly mixing the carbide with petroleum resin and sodium carboxymethylcellulose adhesive slurry, conveying the obtained mixture to a molding machine, and carrying out extrusion molding at 120-140DEG C under 60-80Mpa to obtain a briquette fuel; and drying the briquette fuel, cooling the dried briquette fuel to room temperature, and packaging the cooled briquette fuel to obtain the biomass briquette fuel. The method has the advantages of simple preparation technology, low energy consumption, high production efficiency, high molding rate and low cost; and the prepared biomass fuel has the advantages of small density, high calorific value, less ash, small internal gap, no looseness, good moisture resistance, realization of long-term preservation, and suitableness for industrial production.

Owner:GUANGXI NANNING SHENGQIAN TECH DEV CO LTD

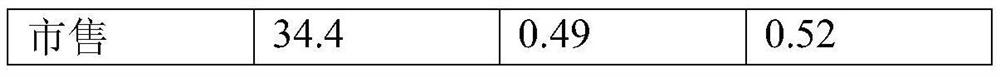

High-efficiency biomass solid pellet fuel

The invention discloses a high-efficiency biomass solid pellet fuel. The high-efficiency biomass solid pellet fuel is prepared from corncobs, magnesium oxide, calcium carbide slag, starch, lanthanum oxide, petroleum resin and polyurethane asphalt according to a weight ratio of 100:5-10:5-8:6-10:3-5:5-8:4-6 through crushing, molding and drying processes. The calorific value of the prepared biomass solid pellet fuel product is 24-28MJ / kg, the ash content of the product is 2.5-4.0%, the water absorption rate of the product is 8-10%, and all performances of the product are better than those of current commercial products. A preparation method of the biomass solid pellet fuel has the advantages of simple process, low energy consumption, low production efficiency, high molding rate and low cost.

Owner:GUANGXI NANNING SHENGQIAN TECH DEV CO LTD

Method for preparing efficient biomass briquettes

The invention discloses a method for preparing efficient biomass briquettes. The method comprises the steps of adding peanut shells into a pulverizer to obtain 40-60-mesh peanut shell powder through pulverizing; adding the peanut shell powder, magnesium oxide, red mud and cobalt carbonate into a stirrer, then adding a proper amount of water, and conducting stirring to obtain paste; placing the paste in a muffle furnace for roasting lasting 3-4 h at 600-800 DEG C, so that a carbide is obtained; evenly mixing the carbide with sodium carboxymethylcellulose mucilage and epoxy asphalt to obtain a mixture, and conveying the mixture to a forming machine for extrusion forming at 110-130 DEG C under the pressure of 60-80 Mpa, so that briquette fuel is obtained; drying the briquette fuel, reducing temperature to room temperature, and conducting packaging to obtain the biomass briquettes. The biomass briquettes have a calorific value of 25-30 MJ / kg, ash content of 2.5-4.0% and water absorption of 8-10%, and various performances are all higher than those of products currently available in the market.

Owner:GUANGXI NANNING SHENGQIAN TECH DEV CO LTD

Preparation of composite biomass fuel

InactiveCN106047440AExtensive sources of raw materialsLow priceBiofuelsSolid fuelsMuffle furnacePulverizer

The invention discloses preparation of composite biomass fuel. The preparation comprises: drying mulberry twigs in the sun and adding the dried mulberry twigs in a pulverizer for pulverization to obtain mulberry twig powder having the size in a range of 40-60 mesh; adding mulberry twig powder, magnesium oxide, manganese slag, perlite and cerium nitrate in a stirrer and adding a proper amount of water for stirring to obtain paste; putting the paste in a muffle furnace and performing roasting in a temperature range of 600-800 DEG C for 2-3h to obtain a carbide; uniformly mixing the carbide with a petroleum resin and epoxy asphalt to obtain a mixture, conveying the mixture to a forming machine, and performing extrusion forming in a temperature range of 120-140 DEG C at the pressure of 80-100 Mpa to obtain formed fuel; and drying the formed fuel, cooling the formed fuel to the room temperature, and performing packaging to obtain the biomass fuel. The preparation has advantages of simple technology, low energy consumption, high production efficiency and forming rate, and low cost. The obtained biomass fuel is small in density, high in calorific value, less in ash, small in inner gap and good in moisture resistance, is not loose, and can be stored for a long time. The preparation is suitable for industrial production.

Owner:GUANGXI NANNING SHENGQIAN TECH DEV CO LTD

Battery, battery module, battery pack and electric vehicle

ActiveCN113193270AHigh mechanical strengthExtended service lifeVent arrangementsCell sealing materialsElectric carsElectric vehicle

The invention provides a battery, a battery module, a battery pack and an electric vehicle. The battery comprises a metal shell and a plurality of pole core strings packaged in the metal shell; the plurality of pole core strings are arranged along a second direction and are connected in series; each pole core string comprises a plurality of pole core groups which are arranged along a first direction and are connected in series; each pole core group comprises at least one pole core; the pole core groups are packaged in a packaging film; the air pressure between the metal shell and the packaging film is lower than the air pressure outside the metal shell, and so that the sealing effect and the strength of the battery can be improved through the above mode.

Owner:BYD CO LTD

Rigid polyurethane foam plastic and preparation method thereof

The invention provides a rigid polyurethane foam plastic, which is prepared from the following raw materials: isocyanate, high-functionality polyester polyol, a nano microsphere reinforcing agent, a foaming agent, an organic silicon foam stabilizer, a cross-linking agent, a catalyst and a compound filler. The method has the advantages of simple process, easy industrial production, no generation ofthree wastes in the whole process, meeting of environmental protection requirements, and strong practicality.

Owner:广州珈鹏科技有限公司

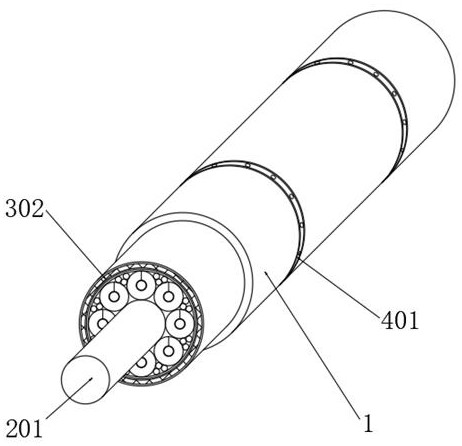

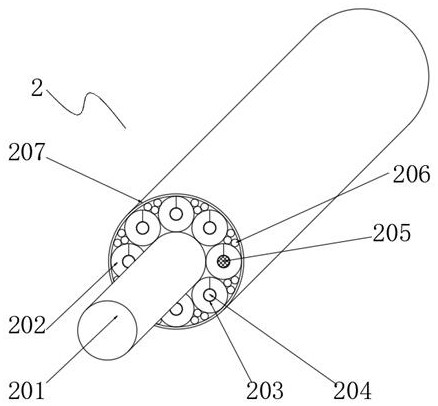

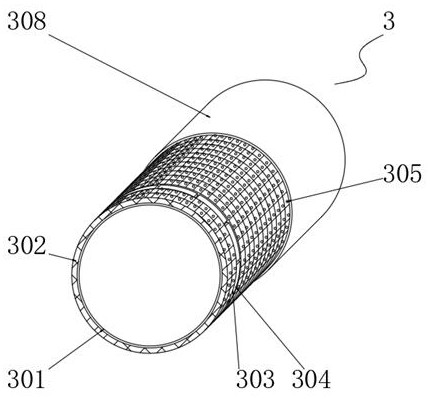

Self-bearing fire-resistant flame-retardant coaxial high-voltage cable and manufacturing method thereof

InactiveCN112071501AScientific and reasonable structureEasy to useCable insulation constructionInsulated cablesRubber ringCoaxial cable

The invention discloses a self-bearing fire-resistant flame-retardant coaxial high-voltage cable and a manufacturing method thereof. A central assembly is arranged in a coaxial cable base body; the outer side of an inner wire is uniformly wrapped with insulating strips; the outer side of an inner heat-sealing film is provided with a middle-layer assembly; the outer side of an insulating rubber padis sleeved with a metal braided layer; iron powder is uniformly distributed between adjacent blocking rings; an outer layer assembly is arranged on the outer side of an outer heat-sealing film; heatconduction grooves are evenly formed in the outer side of an aluminum alloy ring; and rubber rings are bonded to the two sides of the aluminum alloy ring. According to the invention, the central assembly is used as an inner core of the cable; the cooperation between the insulating strips and flame-retardant wires improves flame-retardant effect, and the flexibility of the plurality of hinged insulating strips is better; iron powder of a middle-layer assembly absorbs oxygen and water vapor in a gap to prevent the metal braided layer from being oxidized and corroded; the aluminum alloy ring andheat conducting wires of the outer layer assembly dissipate heat; and a blocking ring and the aluminum alloy ring serve as a supporting framework and are matched with the central assembly to improve the overall strength of the cable, so the cable is more convenient to use.

Owner:安迈森(福建)线缆有限公司

Feldspar waste concrete and preparation method thereof

The invention is applicable to the technical field of concrete, and provides feldspar waste concrete and a preparation method thereof. The feldspar waste concrete is prepared from, by weight, 80-100 parts of feldspar waste, 40-60 parts of cement, 20-40 parts of nanometer aluminum oxide powder, 10-30 parts of coal ash, 40-60 parts of coarse aggregate, 20-40 parts of medium sand, 10-30 parts of argil, 10-12 parts of modifier and 8-10 parts of water, wherein the modifier is prepared from triethoxyvinylsilane and a beta naphthalene sulfonic acid sodium formaldehyde condensate. According to the concrete disclosed by the invention, internal gaps of the concrete can be reduced to a certain extent by adding the nano aluminum oxide powder and the fly ash, and meanwhile, the impact toughness of theconcrete is improved; by adding the modifier, internal gaps of the concrete can be effectively reduced, so the concrete disclosed by the invention has good later strength.

Owner:梁水明

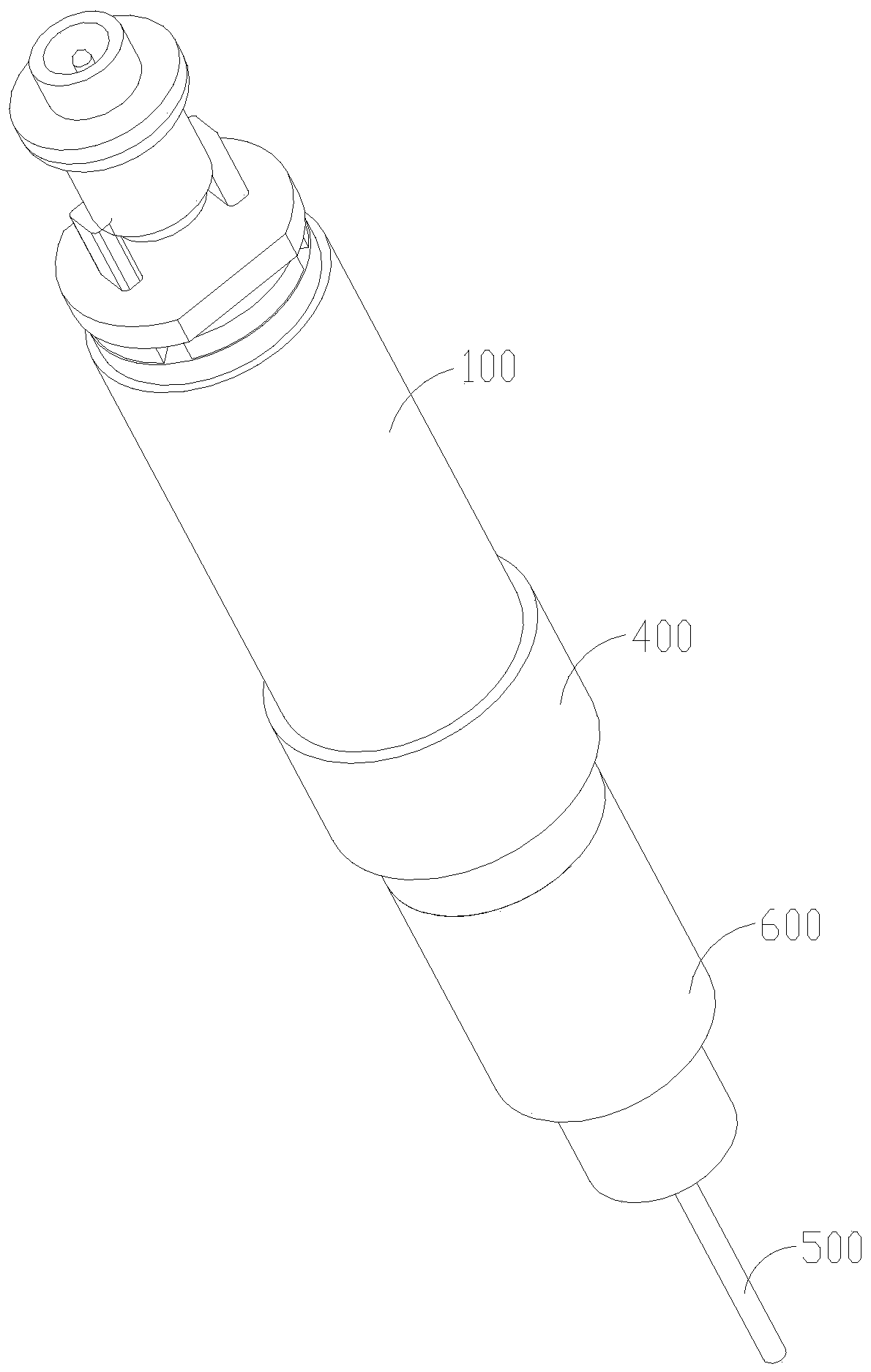

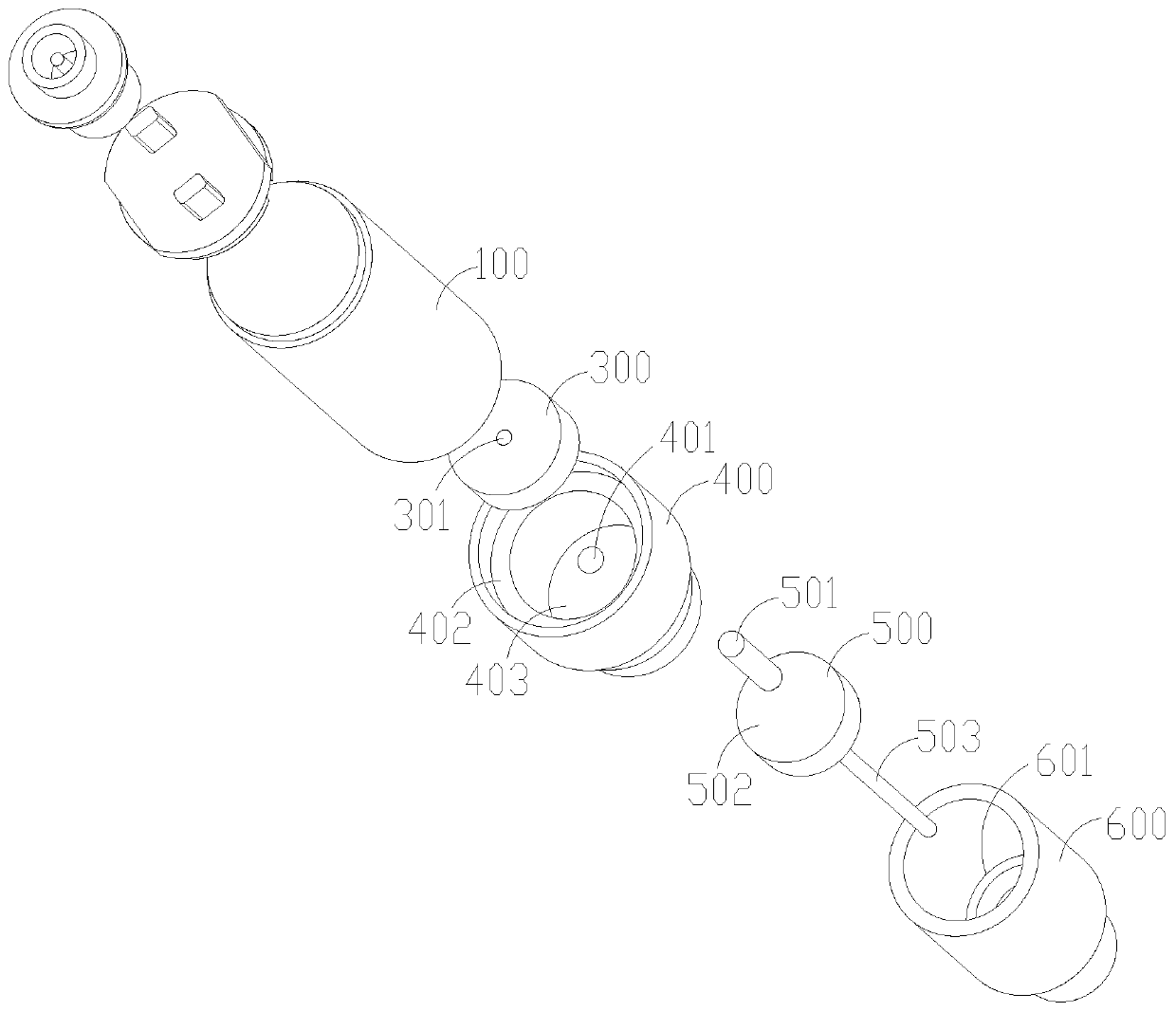

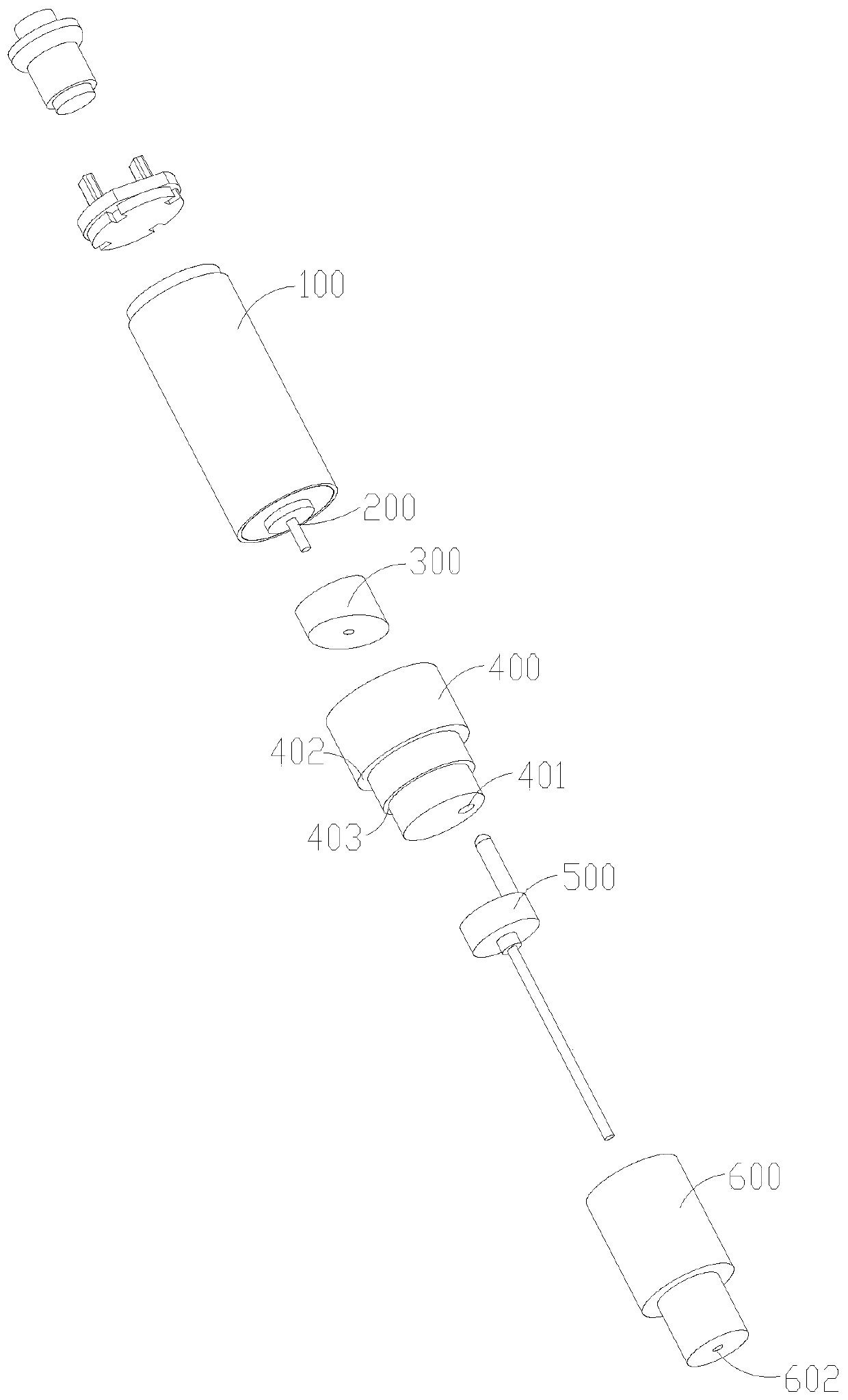

Telescopic device for tattooing instrument

PendingCN111135452ACompact structureReduce internal voidsMedical devicesEngineeringMechanical engineering

The invention discloses a telescopic device for a tattooing instrument. A motor works to drive a single-surface oblique circular table to rotate, a first connecting shaft penetrates through a first through hole, props against one side of an oblique plane of the single-surface oblique circular table under the effect of a spring, the single-surface oblique circular table extrudes the first connecting shaft to do a rectilinear motion in the first through hole, and the first connecting shaft drives a second connecting shaft to do a rectilinear motion. The telescopic device has the advantages thatthe outer diameter of the single-surface oblique circular table is accordant with the inner diameter of a second shell on a second step surface, and the outer diameter of a middle circular table is accordant with the inner diameter of a third shell on a third step surface, so that the integral structure can be configured to be more compact, internal gaps are less, the bulk density is higher, and the texture is better; situations of excessive deformation, louder noise and larger vibration caused by a larger extrusion force of the first connecting shaft during high-speed rotation are avoided; and the telescopic speed is smooth.

Owner:郑录安

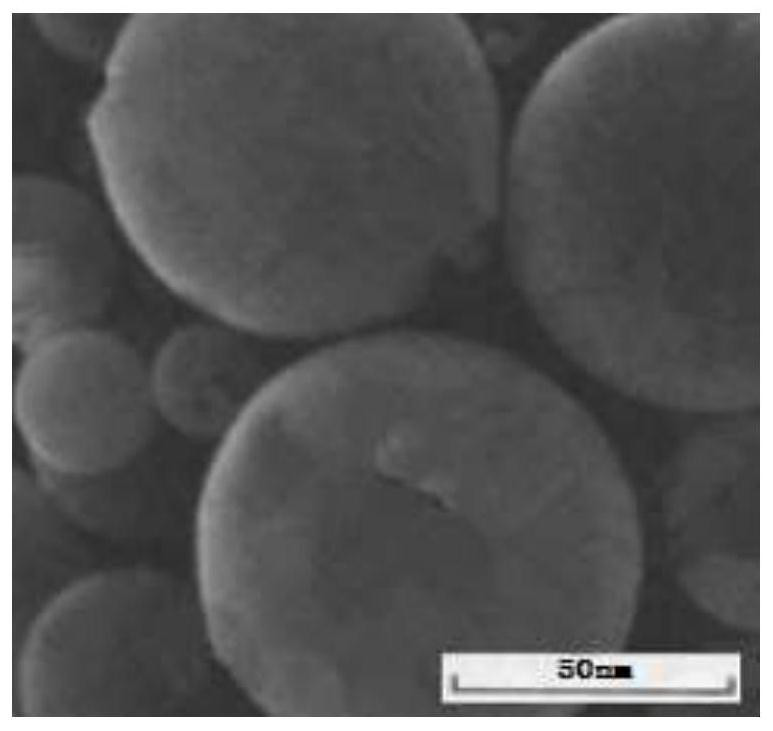

Moon-based landing platform and construction method thereof

The invention relates to a moon-based landing platform and a construction method thereof, in particular to a platform used when a spacecraft lands on the moon and a construction method of the platform, and belongs to the technical field of deep space exploration of the moon. According to the invention, the microwave sintering molding of the multi-component simulated lunar soil material with small particles, light weight and large specific surface area in the aerospace field is realized, the molding precision and density requirements of a spacecraft landing platform are met, a technical basis is provided for subsequent lunar base construction and lasting operation, and good economic benefits and social benefits are achieved.

Owner:BEIJING SATELLITE MFG FACTORY

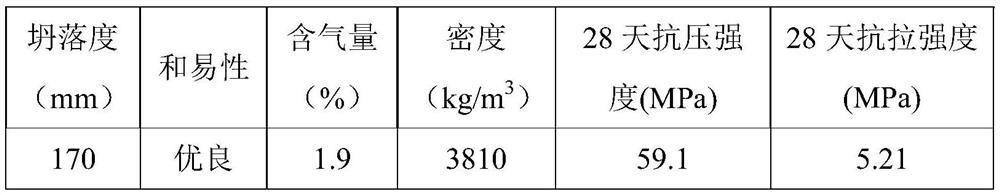

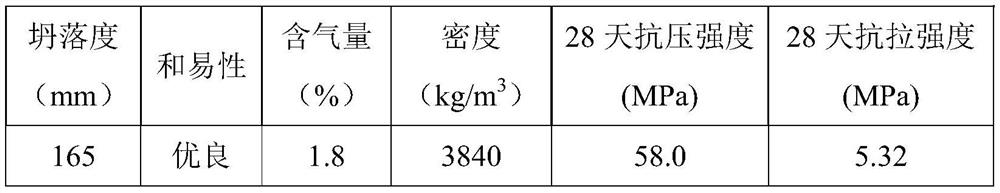

Anti-radiation hematite brick, anti-radiation hematite mortar and method for constructing shielding wall by using the two

InactiveCN112645661AIncrease slumpReduce porosityWallsBuilding material handlingBrickPhysical chemistry

The invention discloses an anti-radiation hematite brick, anti-radiation hematite mortar and a method for constructing a shielding wall by using the anti-radiation hematite brick and the anti-radiation hematite mortar. The anti-radiation shielding wall breaks through the mode of pouring the shielding wall by using concrete for a long time; the hematite brick is prepared by stirring raw materials to required slump in a fixed place according to a specific mixing ratio of the raw materials, injecting the mixture into a mold, performing vibrating, compacting and hardening and removing the mold; the hematite mortar is prepared by mixing and stirring the raw materials according to a specific mixing ratio; and the shielding wall is manufactured by lofting, watering, wire suspension and laying the hematite bricks. The bricklaying method comprises the following steps of: implanting reinforcing steel bars for fixing at proper positions between newly-built hematite brick wall bricks and an old wall ; and during construction, filling the hematite mortar between the hematite bricks and the bricks. A proper amount of fly ash is added into the hematite bricks and the hematite mortar, so that the workability is better, and the construction is more convenient; the hematite bricks are detachable and reusable, construction is simplified, production cost is reduced, and the wall is high in density, high in anti-radiation shielding capacity and particularly suitable for being used in narrow space parts.

Owner:CHINA NUCLEAR IND HUAXING CONSTR +1

A battery, a battery module, a battery pack and an electric vehicle

ActiveCN110828745BHigh mechanical strengthExtended service lifeLarge-sized flat cells/batteriesSynthetic resin layered productsElectric carsElectric vehicle

The present application provides a battery, a battery module, a battery pack, and an electric vehicle. The battery includes a metal case and a plurality of pole core groups packaged in the metal case and arranged in sequence, and the pole core groups are connected in series , the pole core group contains at least one pole core; the pole core group is packaged in a packaging film, the air pressure between the metal casing and the packaging film is lower than the air pressure outside the metal casing, and the inside of the packaging film The air pressure is lower than the air pressure between the metal casing and the packaging film, and the above method is beneficial to improve the sealing effect and strength of the battery.

Owner:BYD CO LTD

Casting device, lining trolley and pouring process

ActiveCN110645017BReduce internal voidsAvoid voidsUnderground chambersHydro energy generationSpiral bladeStructural engineering

The invention discloses a pouring device, which is applied to a lining trolley. The lining trolley includes an arc-shaped formwork, and a pouring window is arranged on the arc-shaped formwork, and the pouring device includes a fixing device adapted to the pouring window. a seat, a pouring pipe arranged on the fixed seat, a spiral blade arranged on the outer periphery of the pouring pipe, and a driving component for driving the spiral plate to rotate. The invention solves the problem of voids existing in concrete pouring at the existing arch top position.

Owner:湖南帝星智能科技有限公司

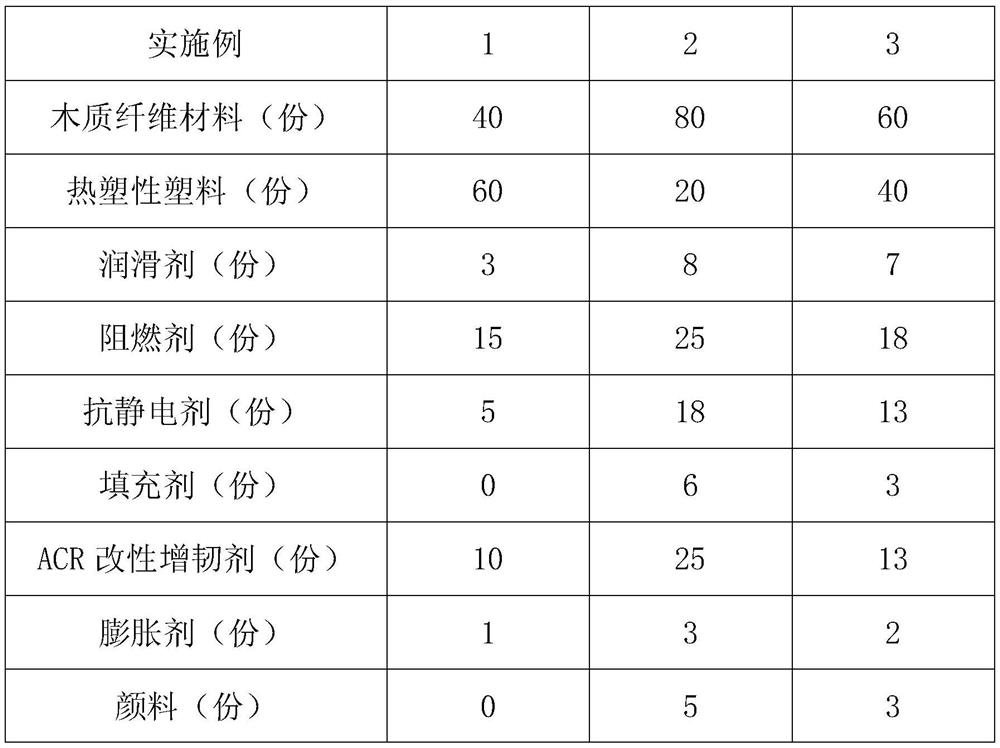

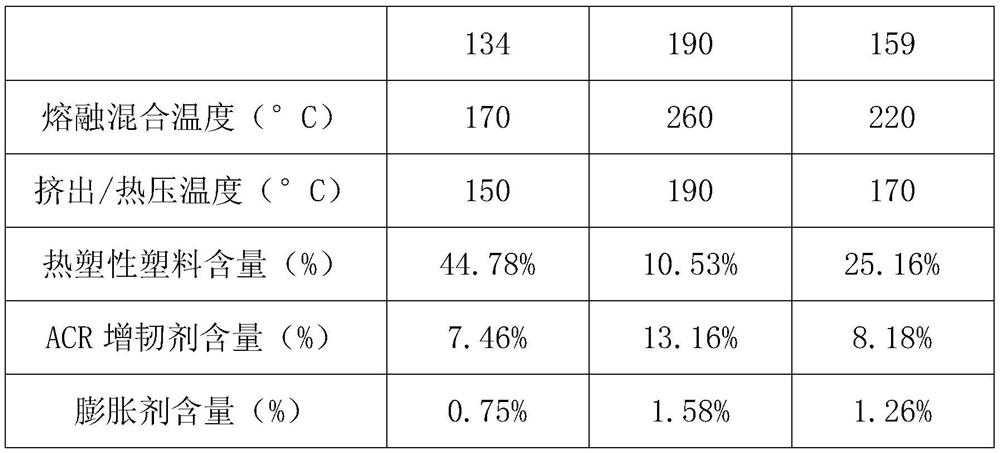

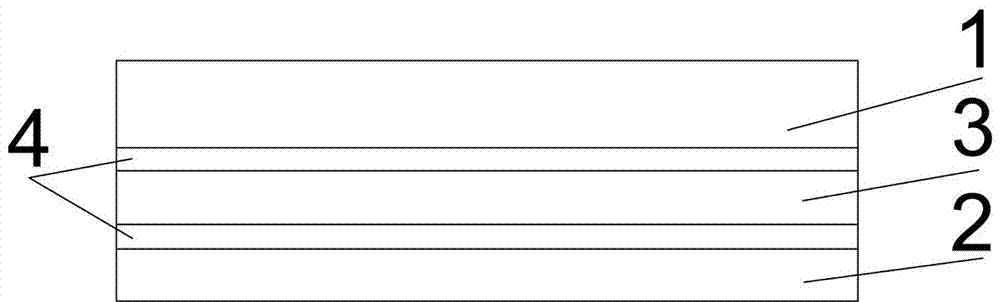

Light durable wood-plastic composite material for trays and preparation method thereof

The invention discloses a light durable wood-plastic composite material for trays. The wood-plastic composite material is prepared by mixing a component A, a component B and a component C. The component A comprises a wood fiber material, thermoplastic plastic and a lubricant; the component B comprises a flame retardant, an antistatic agent, a filler and an ACR modified toughening agent; and the component C comprises an expanding agent and a pigment. According to the light durable wood-plastic composite material for the trays and the preparation method of the light durable wood-plastic composite material, a preparation process is simple, raw material cost is low, environmental protection is achieved, the flame retardance and the antistatic property of the material are good, potential safetyhazards of fire disasters are reduced, potential safety hazards caused by static electricity to human bodies and other aspects are reduced, and high safety is realized; the ACR modified toughening agent is added for modification and toughening, so the toughness and wear resistance of the material are improved, the wear resistance is optimized, the service life is prolonged; and by using the expanding agent, the defects of internal gaps, cavities and surfaces are reduced, internal pressure is maintained, the material is expanded while the performance of the material is ensured, and the weightof the material is reduced.

Owner:WUHU ASIA PACIFIC GENERAL TRAY PACKING CO LTD

A kind of pvb sound insulation laminated glass and preparation method thereof

ActiveCN106003922BStrong sound insulationReduce internal voidsSynthetic resin layered productsLaminationPolystyreneHigh pressure

The invention relates to sound insulating glass and a preparation method thereof, in particular to sound insulating PVB (polyvinyl butyral) laminated glass and a preparation method thereof. The sound insulating PVB laminated glass comprises a first glass substrate, a second glass substrate, a PVB film between the first glass substrate and the second glass substrate as well as polystyrene films located between the first glass substrate and the PVB film as well as between the second glass substrate and the PVB film, wherein the first glass substrate and the second glass substrate are arranged vertically. The preparation method of the sound insulating PVB laminated glass comprises the following steps: (1) cleaning of the glass substrate; (2) preparation of the polystyrene films; (3) combining operation: the PVB film is arranged in a combining chamber for combination of the glass substrates, the PVB film and the polystyrene films; (4) prepressing for exhausting; (5) high-pressure molding. The prepared PVB laminated glass has good mechanical property, impact resistance and good sound insulating effect, the PVB film cannot fall off the glass when the laminated glass meets external impact or the external environmental temperature changes acutely, and the service life is long.

Owner:HUZHOU XINFU NEW MATERIALS CO LTD

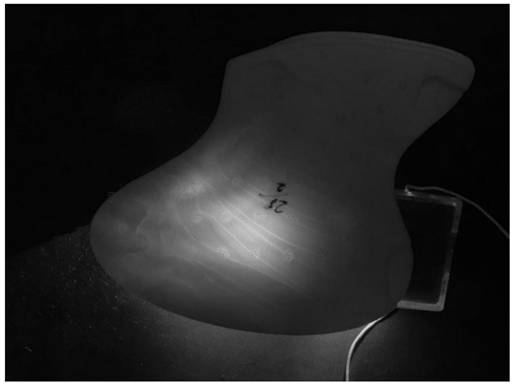

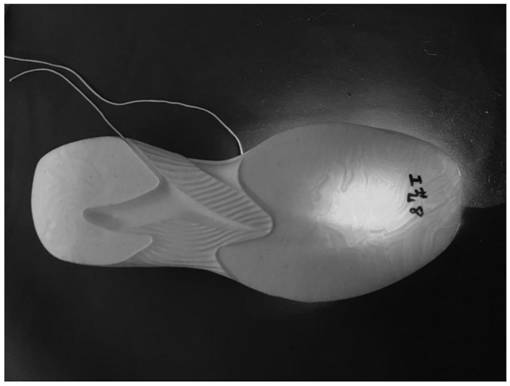

A shoe midsole material with natural light transmission and its preparation method

ActiveCN111602925BWith natural light transmissionReduce internal voidsSolesDomestic articlesThermoplastic polyurethaneLight perception

The invention provides a shoe midsole material with natural light transmission, comprising: a shoe midsole body with a light-transmitting texture; air holes evenly distributed on the shoe midsole body; the shoe with a light-transmitting texture The midsole body is made of thermoplastic polyurethane elastomer mixture through supercritical extrusion molding. Compared with the prior art, the shoe midsole material with natural light transmission provided by the present invention adopts supercritical extrusion molding to obtain the shoe midsole body with light-transmitting texture, and then arranges evenly distributed air holes to reduce the internal cavity of the product. The material is more stable and will not collapse; on the basis of good cushioning and resilience, the product also has natural light transmission, can obtain irreplaceable appearance lines and strange landscapes under light perception, and is cost-effective.

Owner:ANTA CHINA

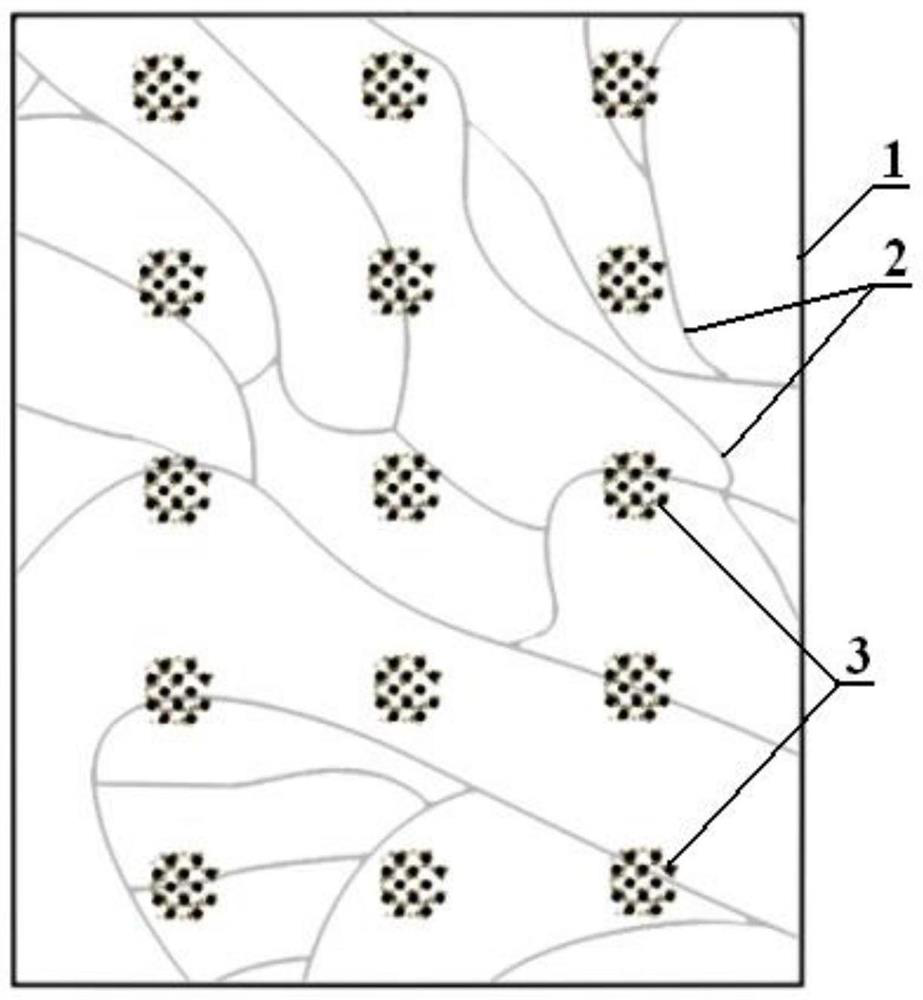

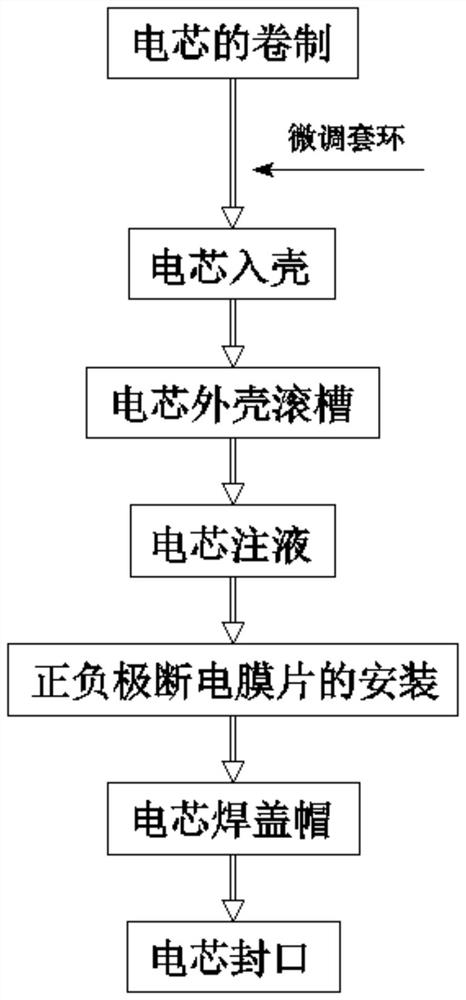

An assembly process of inner fine-tuning cylindrical battery core

ActiveCN111009693BForce densificationForce densityFinal product manufactureSecondary cellsElectrolytic agentThermodynamics

The invention discloses an assembly process of an internal fine-tuning cylindrical battery cell, which belongs to the technical field of lithium batteries. An internal fine-tuning cylindrical battery cell assembly process can be configured by setting a fine-tuning collar between the battery core and the inner wall of an external casing, so that the The large internal uneven adjustment block inside can provide greater support for the concave part of the cell, so that the force of the cell in this part becomes denser, the internal gap is reduced, and the fuller part is aligned with the smaller part. The internal unevenness adjustment block or the part without the internal unevenness adjustment block makes this part less supported by the fine-tuning collar compared with the concave part, which effectively compensates for the tightness of the plump part itself and the small gap, which leads to the infusion process. In the middle, the infiltrated electrolyte is less, which makes the electrolyte infiltrated in the whole cell uneven, so as to achieve the effect of adjusting the uniformity of the electrolyte infiltrated in the cell as a whole, thereby effectively improving the quality of the lithium battery obtained in the later stage and effectively prolonging the life of the lithium battery. Lithium battery life.

Owner:南京中比新能源科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com