A shoe midsole material with natural light transmission and its preparation method

A light-transmitting and natural technology, applied in the field of shoe manufacturing, can solve the problems of difficult light-transmitting breakthrough, single particle appearance, low cost performance, etc., and achieve the effect of increasing diversity, simple process and broad application prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0063] The present invention also provides a method for preparing a shoe midsole material with natural light transmission described in the above technical solution, comprising the following steps:

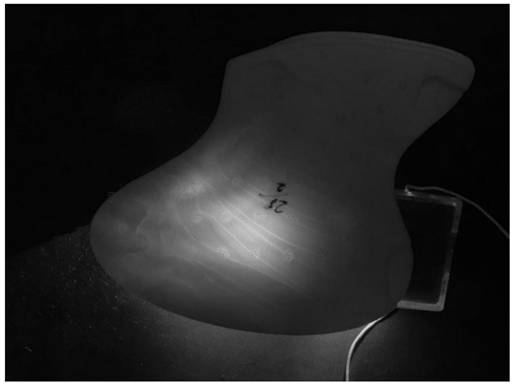

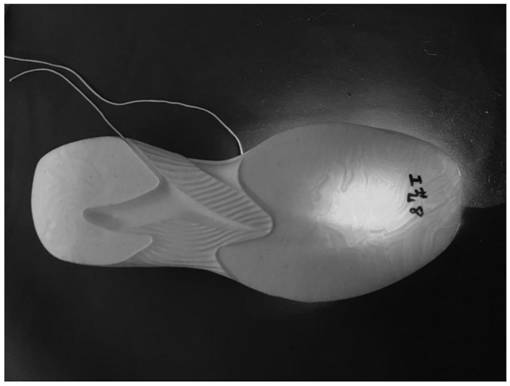

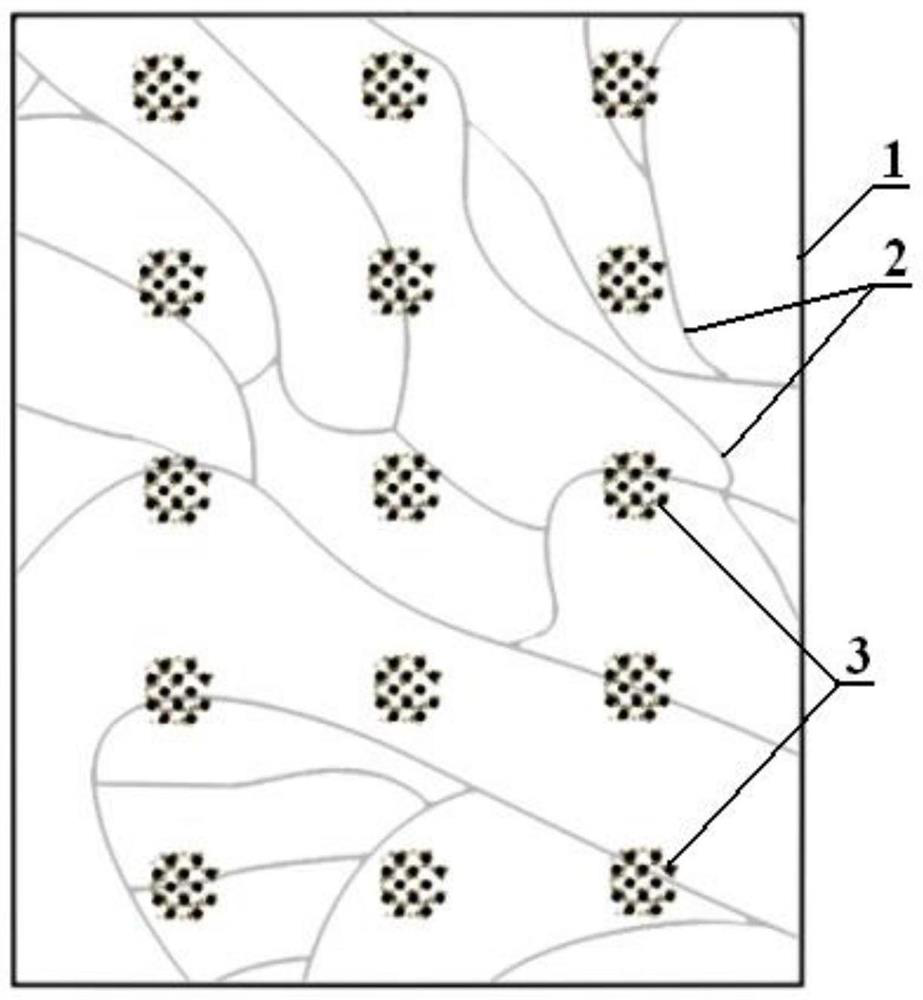

[0064] a) performing supercritical extrusion molding on the thermoplastic polyurethane elastomer mixture material to obtain a shoe midsole body with a light-transmitting texture;

[0065] b) Air holes are added to the main body of the shoe midsole with light-transmitting texture obtained in step a), to obtain a shoe midsole material with natural light transmission.

[0066] In the invention, firstly, the thermoplastic polyurethane elastomer mixture material is subjected to supercritical extrusion molding to obtain a shoe midsole main body with light-transmitting texture. In the present invention, the thermoplastic polyurethane elastomer mixture material is the same as that in the above technical solution, and will not be repeated here.

[0067] In the present invention, the proces...

Embodiment 1

[0081] (1) The composition of the thermoplastic polyurethane elastomer mixture:

[0082] TPU main material (WANHUA85105): 100 parts by weight;

[0083] Nucleating agent: 1.5 parts by weight;

[0084] Flow agent: 1 part by weight;

[0085] Anti-yellowing agent: 0.5 parts by weight;

[0086] Foaming agent: 1.2 parts by weight;

[0087] Among them, the nucleating agent is nano-titanium dioxide, the flow agent is erucamide lubricant, the anti-yellowing agent is ultraviolet light absorber VSU; the foaming agent is C;

[0088] After mixing, a thermoplastic polyurethane elastomer compound material is obtained.

[0089] (2) Preparation method:

[0090] Pour the thermoplastic polyurethane elastomer mixture into the lower barrel of the extruder for drying and dehumidification. The temperature of the dehumidifier is set at 180°C, the drying temperature of the lower barrel is 80°C, and the drying time is 120min to obtain the premixed material; then The obtained premixed material is ...

Embodiment 2

[0093] (1) The composition of the thermoplastic polyurethane elastomer mixture:

[0094] TPU main material (LUBRIZOL58135): 100 parts by weight;

[0095] Nucleating agent: 1.3 parts by weight;

[0096] Flow agent: 1 part by weight;

[0097] Anti-yellowing agent: 0.5 parts by weight;

[0098] Foaming agent: 1.3 parts by weight;

[0099] Among them, the nucleating agent is nano-titanium dioxide, the flow agent is erucamide lubricant, the anti-yellowing agent is ultraviolet light absorber VSU; the foaming agent is C;

[0100] After mixing, a thermoplastic polyurethane elastomer compound material is obtained.

[0101] (2) Preparation method:

[0102] Pour the thermoplastic polyurethane elastomer mixture into the lower barrel of the extruder for drying and dehumidification. The temperature of the dehumidifier is set at 180°C, the drying temperature of the lower barrel is 80°C, and the drying time is 120min to obtain the premixed material; then The obtained premixed material i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| foaming ratio | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com