Shoe insole material with natural light transmission and preparation method thereof

A light-transmitting and natural technology, applied in the field of shoe manufacturing, can solve the problems of limited preparation process, single particle appearance, low cost performance, etc., and achieve the effects of green environmental protection, simple process and broad application prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

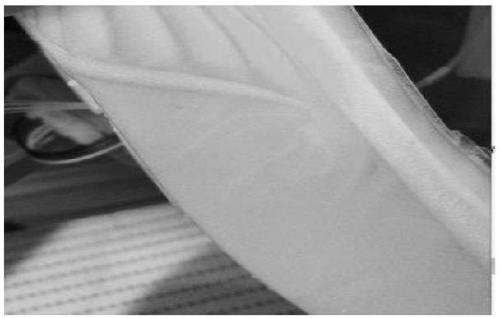

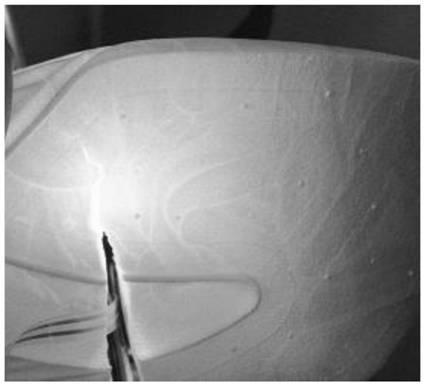

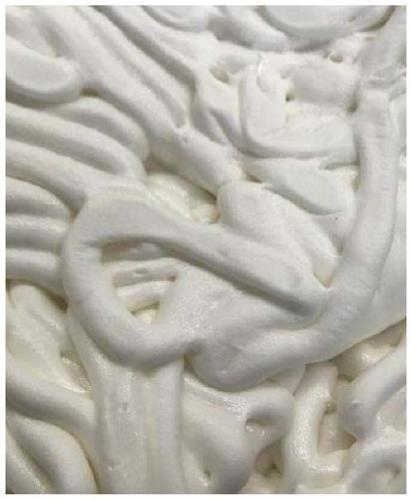

Image

Examples

preparation example Construction

[0045] The present invention also provides a method for preparing a shoe midsole material with natural light transmission described in the above technical solution, comprising the following steps:

[0046] a) After premixing the components in the thermoplastic polyurethane elastomer mixture, drying and dehumidifying to obtain a premix;

[0047] b) The premixed material obtained in step a) is sequentially subjected to extrusion foaming, injection foaming and molding, and after adding air holes, a shoe midsole material with natural light transmission is obtained; the extrusion foaming method is super Critical foaming.

[0048] In the invention, firstly, each component in the thermoplastic polyurethane elastomer mixture is premixed, and then dried and dehumidified to obtain the premix. In the present invention, the thermoplastic polyurethane elastomer mixture material is the same as that in the above technical solution, and will not be repeated here.

[0049] In the present inv...

Embodiment 1

[0059] (1) The composition of the thermoplastic polyurethane elastomer mixture:

[0060] TPU main material (WANHUA85105): 100 parts by weight;

[0061] Nucleating agent: 1.5 parts by weight;

[0062] Flow agent: 1 part by weight;

[0063] Anti-yellowing agent: 0.5 parts by weight;

[0064] Foaming agent: 1.2 parts by weight;

[0065] Among them, the nucleating agent is nano-titanium dioxide, the flow agent is erucamide lubricant, the anti-yellowing agent is ultraviolet light absorber VSU; the foaming agent is C.

[0066] (2) Preparation method:

[0067] Weigh each component in the above-mentioned thermoplastic polyurethane elastomer mixture in parts by weight as a raw material; after premixing the weighed raw materials, pour them into the lower barrel of the extruder for drying and dehumidification, and set the temperature of the dehumidifier to The temperature is 180°C, the drying temperature of the lower barrel is 80°C, and the time is 120min to obtain a premix; then th...

Embodiment 2

[0070] (1) The composition of the thermoplastic polyurethane elastomer mixture:

[0071] TPU main material (LUBRIZOL58135): 100 parts by weight;

[0072] Nucleating agent: 1.3 parts by weight;

[0073] Flow agent: 1 part by weight;

[0074] Anti-yellowing agent: 0.5 parts by weight;

[0075] Foaming agent: 1.3 parts by weight;

[0076] Among them, the nucleating agent is nano-titanium dioxide, the flow agent is erucamide lubricant, the anti-yellowing agent is ultraviolet light absorber VSU; the foaming agent is C.

[0077] (2) Preparation method:

[0078] Weigh each component in the above-mentioned thermoplastic polyurethane elastomer mixture in parts by weight as a raw material; after premixing the weighed raw materials, pour them into the lower barrel of the extruder for drying and dehumidification, and set the temperature of the dehumidifier to The temperature is 180°C, the drying temperature of the lower barrel is 80°C, and the time is 120 minutes to obtain the premix...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| foaming ratio | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com