Light durable wood-plastic composite material for trays and preparation method thereof

A wood-plastic composite material and durable technology, applied in the field of wood-plastic composite materials, can solve the problems of wood-plastic materials not having flame retardancy, poor wear resistance and toughness, fire safety hazards, etc., to reduce fire safety hazards, Improved toughness and wear resistance, high safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

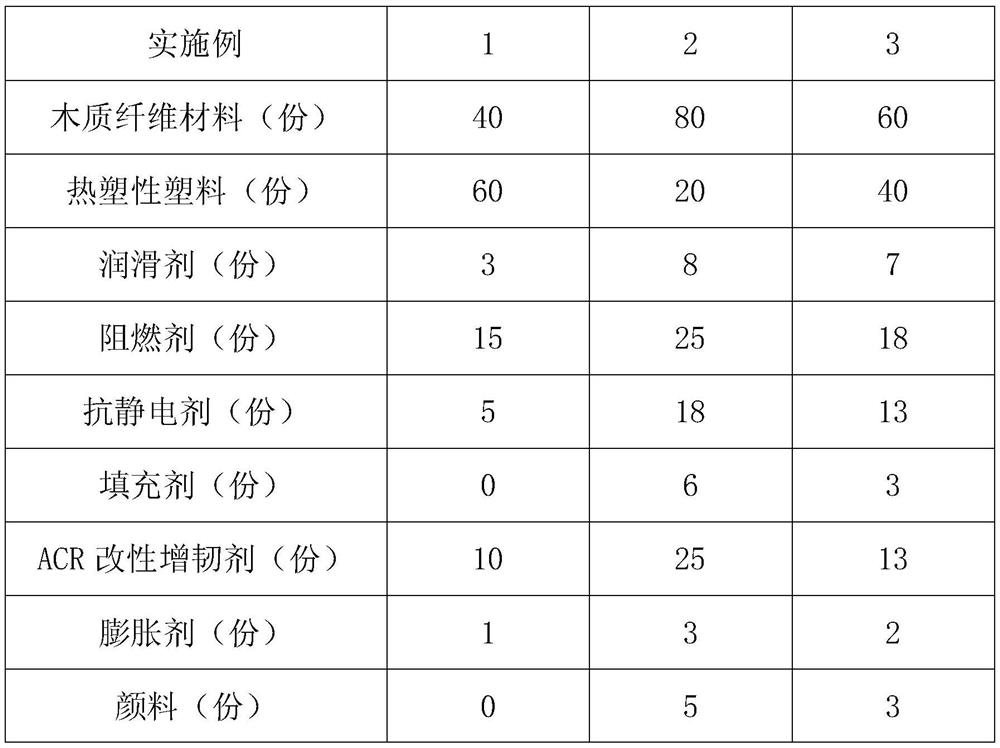

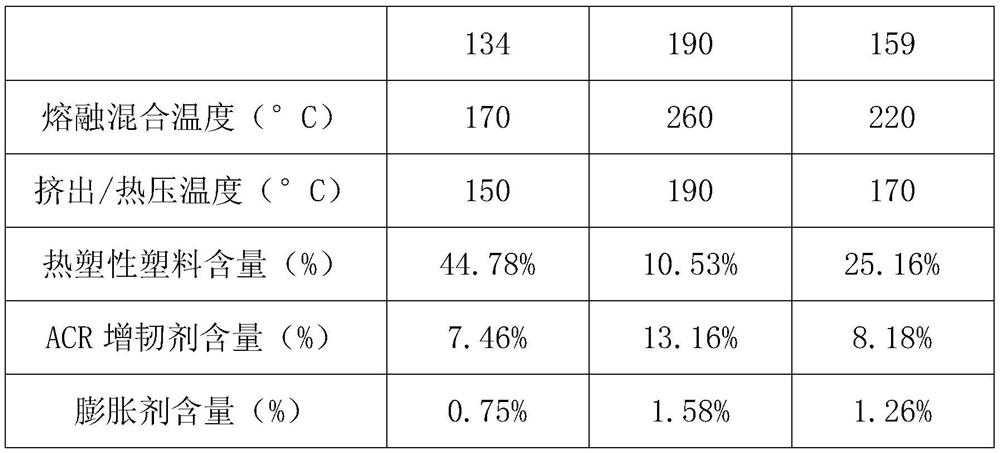

[0023] A light and durable wood-plastic composite material for pallets, the wood-plastic material is formed by mixing components A, B and C, and the A component includes wood fiber materials, thermoplastics and lubricants, The B component includes a flame retardant, an antistatic agent, a filler and an ACR modified toughening agent, and the C component includes an expansion agent and a pigment, and its proportion by weight is as follows: 40 parts of the wood fiber material, 60 parts of thermoplastic, 3 parts of lubricant, 10 parts of flame retardant, 5 parts of antistatic agent, 0 parts of filler, 10 parts of ACR modified toughening agent, 1 part of expansion agent and 0 parts of pigment.

[0024] The lignocellulosic material is woody waste, and the water content of the lignocellulosic material is 5-15%, the thermoplastic is a mixture of high-density polyethylene and waste plastics in any ratio, the lubricant is paraffin, and the The flame retardant is expandable graphite, the...

Embodiment 2

[0031] A light and durable wood-plastic composite material for pallets, the wood-plastic material is formed by mixing components A, B and C, and the A component includes wood fiber materials, thermoplastics and lubricants, The B component includes a flame retardant, an antistatic agent, a filler and an ACR modified toughening agent, and the C component includes an expansion agent and a pigment, and its proportion by weight is as follows: 80 parts of the wood fiber material, 20 parts of thermoplastic, 8 parts of lubricant, 25 parts of flame retardant, 18 parts of antistatic agent, 6 parts of filler, 25 parts of ACR modified toughening agent, 3 parts of expansion agent and 5 parts of pigment.

[0032] The lignocellulosic material is a mixture of wood powder, straw powder and husk powder in any ratio, and the water content of the lignocellulosic material is 5-15%, the thermoplastic is high-density polyethylene, and the lubricant is paraffin wax and polyethylene wax in any ratio, ...

Embodiment 3

[0039] A light and durable wood-plastic composite material for pallets, the wood-plastic material is formed by mixing components A, B and C, and the A component includes wood fiber materials, thermoplastics and lubricants, The B component includes a flame retardant, an antistatic agent, a filler and an ACR modified toughening agent, and the C component includes an expansion agent and a pigment, and its proportion by weight is as follows: 60 parts of the wood fiber material, 40 parts of thermoplastic, 7 parts of lubricant, 18 parts of flame retardant, 13 parts of antistatic agent, 3 parts of filler, 13 parts of ACR modified toughening agent, 2 parts of expansion agent and 3 parts of pigment.

[0040]The lignocellulosic material is a mixture of straw powder and wood waste in any ratio, and the water content of the lignocellulosic material is 5-15%, and the thermoplastic is high-density polyethylene, recycled polyethylene and waste plastics The lubricant is polyethylene wax, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com