Assembled sandwich panel with metal surface insulation for building and its installation method

A sandwich panel and metal surface technology, which is applied in construction, building structure, covering/lining, etc., can solve the problem that the installation quality and installation effect are not easy to guarantee, can not meet the needs of energy saving and environmental protection, and the consumption of materials and energy is large, etc. problems, to achieve good decorative effect, improve fire prevention effect, and stable use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The central idea of the present invention is to increase the assembly speed of exterior wall decoration and reduce the assembly cost. safety and reliability.

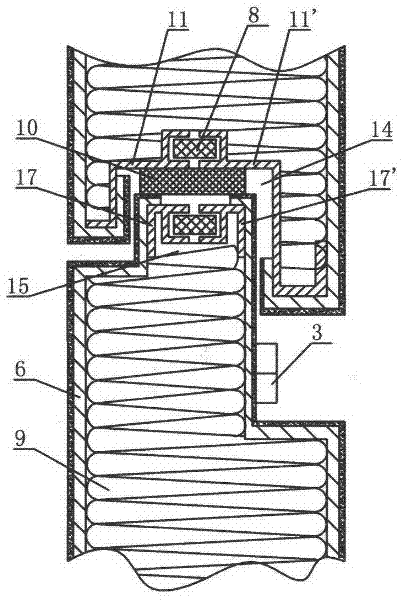

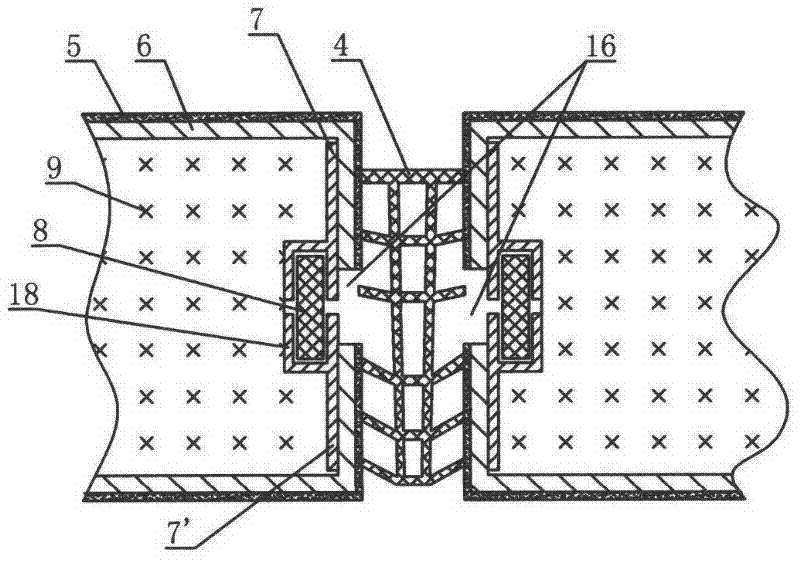

[0026] Attached below figure 1 , figure 2 , image 3 The present invention is further described:

[0027] The metal-faced heat-insulating assembled sandwich panel of the present invention includes a rectangular metal shell 6 and a thermal insulation layer 9 uniformly filled and bonded in the metal shell 6 . The metal shell 6 is made of galvanized sheet, which is stable in structure, anti-corrosion and anti-rust. In order to increase the surface decoration and durability, the surface of the metal shell 6 is covered with a fluorocarbon coating 5. The fluorocarbon coating 5 has a strong ability to prevent ultraviolet radiation and waterproof performance, and can effectively protect the inner metal shell 6. The color of the layer is usually a variety of metallic colors to improve the decorative effect of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com