Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

213results about How to "Achieve decorative effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A stone-imitating porcelain tile with three-dimensional decoration effects and a producing method thereof

The invention discloses a stone-imitating porcelain tile with three-dimensional decoration effects and a producing method thereof. The method includes A) preparing a porcelain tile blank powder material according to conventional methods, B) preparing a porcelain tile backing material and a surface material, C) preparing a porcelain tile blank, D) drying the blank, E) spraying with the backing material, F) performing digital ink-jet printing, G) coating with the surface material by printing, H) drying the blank coated with the surface material, I) firing and J) performing edge polishing. Beneficial effects of the porcelain tile and the method are that the problems in the prior art due to a high using amount of surface layer pulp and dyeing assistant agents, namely high costs and absence of three-dimensional pattern expression in pattern textures, are overcome; technical problems that porcelain color-penetrated tiles at present are inaesthetic due to bottom exposure caused by slotting, chamfering, and other types of processing are overcome, and the producing method is provided for the porcelain tile that is environmental friendly, economical and richer in decoration effects.

Owner:HANGZHOU NABEL CERAMIC +2

Water-in water type colorful thermal insulation coating and preparation method thereof

InactiveCN102643587AExcellent decorative performance and heat insulation functionAchieve decorative effectReflecting/signal paintsMulticolor effect coatingsThermal insulationEmulsion

The invention discloses a water-in water type colorful thermal insulation coating which comprises the components in parts by weight: 35-50 parts of continuous phase, 30-40 parts of dispersed phase, 15-30 parts of silicone acrylic emulsion and 0.2-5.0 parts of regulator. The heat insulation performance is applied to water-based colorful coating, so that the invention integrates high-grade decoration performance and the heat insulation performance; before the water-in water type colorful thermal insulation coating is used, right amount of water is added into the coating for adjusting the viscosity, and then the coating is sprayed onto a building by a special spray gun, so that the decoration effect of natural stone can be achieved, and the water-in water type colorful thermal insulation coating has reflection heat insulation function.

Owner:深圳市嘉达节能环保科技有限公司

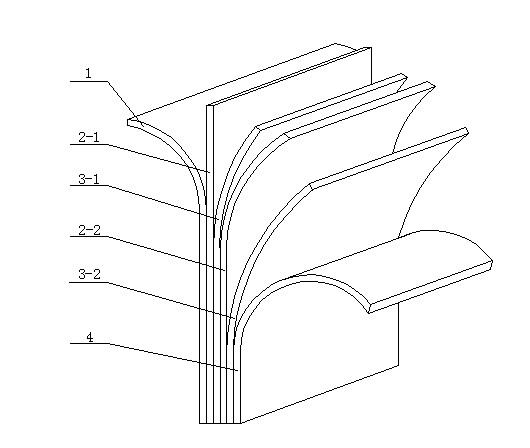

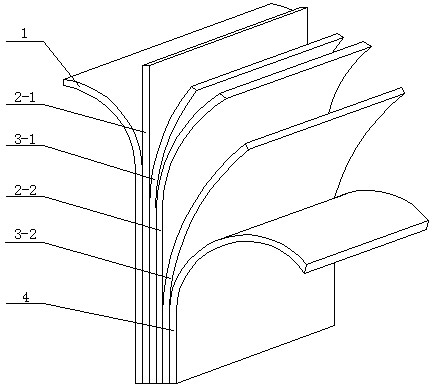

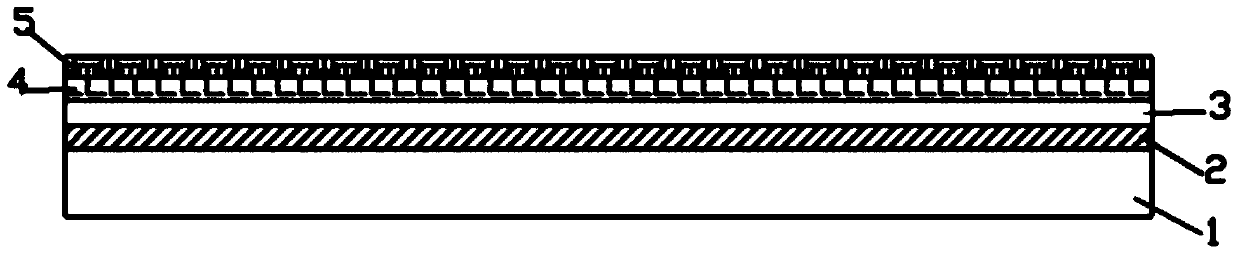

Antifogging agent composition and antifogging colored window film formed by same

ActiveCN102618102AEasy to prepareReduce manufacturing costOther chemical processesSynthetic resin layered productsPolyesterDiamine

The invention relates to an antifogging agent composition and an antifogging colored window film formed by the same. The antifogging agent composition comprises 9-14wt% of hydrophilic resin, 55-76wt% of propylene glycol methyl ether, 3-10wt% of dimethyl methylamine, 1-5wt% of triethylene-diamine, 1-5wt% of leveling agent, 5-26wt% of isopropanol and 5-24wt% of ethanol. The antifogging colored window film comprises an antifogging agent coating layer (1), a first transparent polyester film or transparent polyethylene film substrate (2-1), a dyed acrylic acid adhesive layer (3-1), a second transparent polyester film or transparent polyethylene film substrate (2-2), an acrylic acid adhesive layer (3-2) and a releasing film (4) which are integrally composited, wherein the antifogging agent coating layer (1) is formed by the antifogging agent composition. The antifogging colored window film is antifogging, attractive, transparent and safe.

Owner:CHANGZHOU SANYOU DISSAN PROTECTIVE MATERIAL MFG

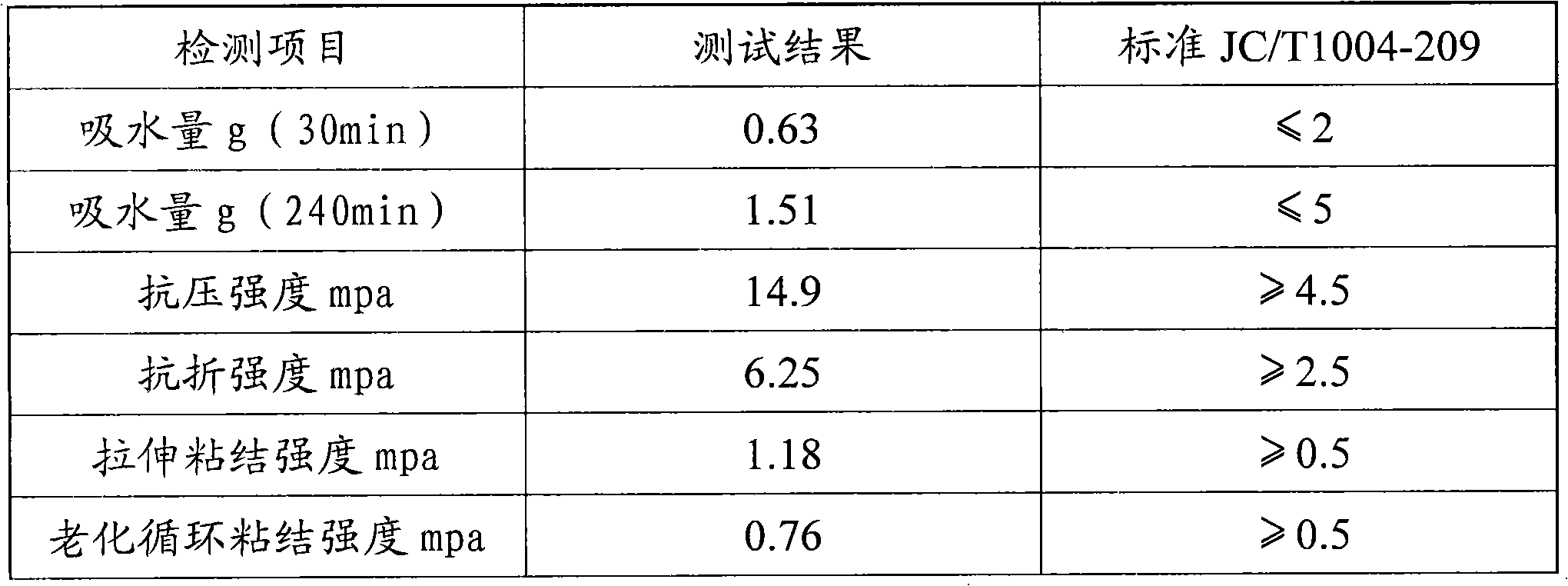

STUCCO wall decoration mortar and construction technology thereof

The invention relates to the field of decoration and protection of inner and outer walls of a building and discloses STUCCO wall decoration mortar. The STUCCO wall decoration mortar comprises the following components: portland cement, quartz sand, redispersible latex powder, ligno-cellulose, cellulose ether, a water repellent and an efforescence inhibitor. The invention also discloses a construction technology of the STUCCO wall decoration mortar, which comprises the following steps of: cleaning a basal plane; leveling the basal plane of a concrete wall by interface treating mortar; preparing the STUCCO wall decoration mortar; troweling the STUCCO wall decoration mortar on the leveled interface treating mortar; and coating protection paint. The invention aims to provide the STUCCO wall decoration mortar and the construction technology thereof. A decorative finish with a consistent decorative effect with poured fair-faced concrete can be very simply and conveniently reconstructed on different basal planes by adopting the STUCCO wall decoration mortar. The construction technology and process of the fair-faced concrete decorative finish are greatly simplified.

Owner:SHENZHEN SIMON BUILDING MATERIAL

Colored STUCCO wall decoration mortar and construction process thereof

The invention discloses colored STUCCO wall decoration mortar, relating to the field of building interior and exterior wall decoration and protection. The colored STUCCO wall decoration mortar comprises the components of: silicate cement, aluminate cement, anhydrite, quartz sand, re-dispersible latex powder, lignocellulose, cellulose ether, a moisture repellent and ferric oxide series pigments. The invention also discloses a construction process of the colored STUCCO wall decoration mortar, which comprises the following steps of: cleaning the wall base surface; leveling the wall base surface by using interface mortar; preparing the colored STUCCO wall decoration mortar; flatly spreading the colored STUCCO wall decoration mortar on the leveled interface mortar; and coating a protective paint. The invention aims at providing the colored STUCCO wall decoration mortar and the construction process thereof. Colored fair-faced concrete layers can be simply and conveniently constructed on different base surfaces by using the colored STUCCO wall decoration mortar, and no high-alkaline environment can be caused by the concrete pouring process to damage cement color.

Owner:SHENZHEN SIMON BUILDING MATERIAL

Bi-component epoxy caulking agent and preparation method thereof

Bi-component epoxy caulking agent comprises a component A and a component B and is characterized in that the component A comprises, by weight percent, 13.5-33.5% of waterborne epoxy resin, 25.5-68.5% of quartz sand, 0.5-2.5% of propylene glycol, 1-5% of glitter powder, 1-5% of propylene glycol leveling agent and 1-31% of talcum powder; and the component B comprises, by weight percent, 90-95% of waterborne epoxy hardener and 5-10% of phenol. The prepared component A and component B are packaged separately. The weight ratio of the component A to the component B is 10:1-4. The component A and the component B are mixed well according to a given proportion to obtain the bi-component caulking agent. The bi-component caulking agent has functions of caulking and decorating for mosaic or ceramic tiles. The bi-component caulking agent not only can be used as cement replacement for caulking the mosaic or ceramic tiles and the like, but is safe, efficient and free of side effects. The bi-component caulking agent is applicable to caulking and decorating of mosaic or ceramic tiles and the like.

Owner:刘伟

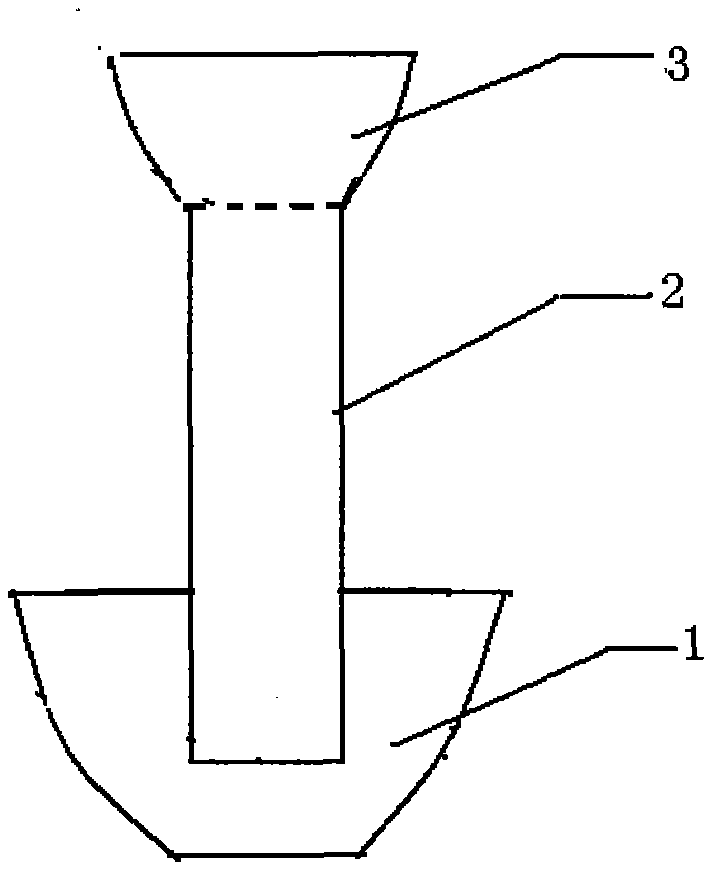

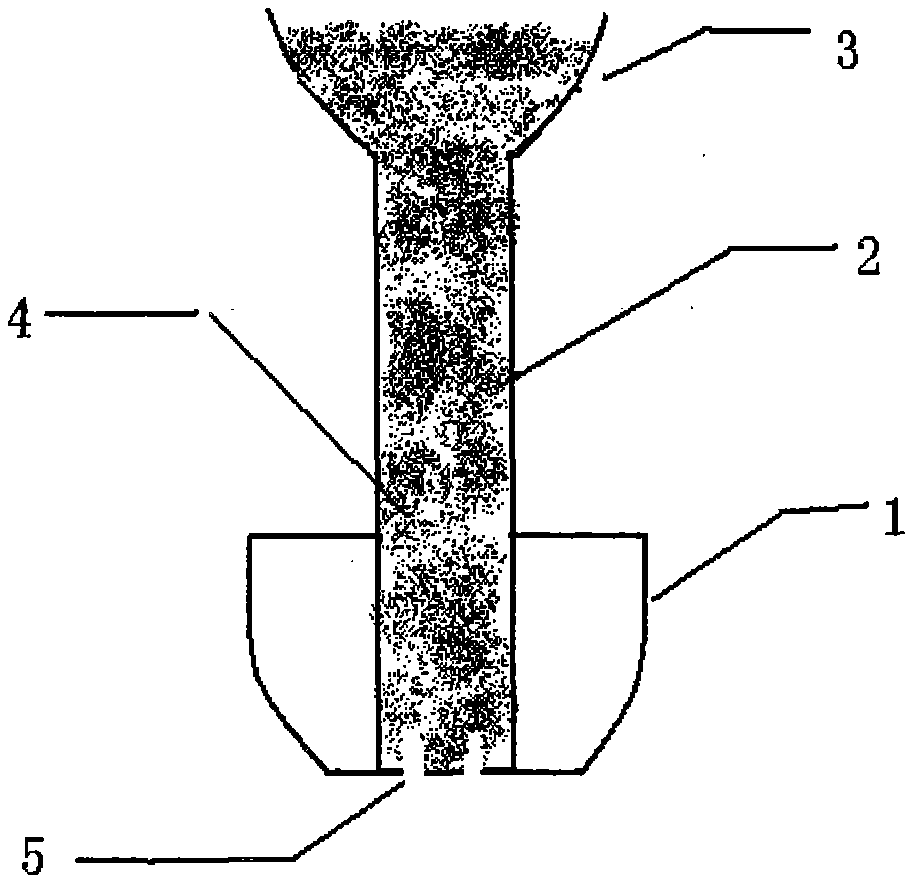

Vertical type flowerpot

InactiveCN104206199AImprove the decorative effectAchieve decorative effectSelf-acting watering devicesAgriculture gas emission reductionPlant cultivationEngineering

The invention provides a novel vertical type flowerpot which aims to solve the problems that watering and fertilization of an existing hanging plant cultivation flowerpot are inconvenient, and the decoration modeling is single. According to the technical scheme, the vertical type flowerpot comprises a hollow tube and a base. The vertical type flowerpot is characterized in that the lower end of the hollow tube is fixed on the base, and the upper end of the hollow tube is connected with a planting hopper. The vertical type flowerpot can be used for traditional soil cultivation and also can be used for soil-less cultivation, the soil-less cultivation can be either substrate culture or water culture, the vertical type flowerpot is further suitable for self-water absorption cultivation, and thus the problems that watering and fertilizer applying of indoor flower culture are troublesome, insanitary and the like can be well solved. By means of the vertical type flowerpot, various modelings can be added, and therefore the decorative effect of flowers is greatly enriched.

Owner:陈泽伟

LED ceiling lamp

InactiveCN104763952ALower the altitudeSmall packaging and transportation volumePoint-like light sourceLighting heating/cooling arrangementsLighting systemEngineering

The invention discloses an LED (light-emitting diode) ceiling lamp. The ceiling lamp comprises a lamp holder, a power supply module, a positioning expansion lamp housing, a radiator, an LED light-emitting component and a light transmission cover, wherein the positioning expansion lamp housing comprises a first shell and a second shell, and the first shell and the second shell relatively position and slide in the axial direction of the lamp holder and cannot relatively rotate on the vertical surface of the axis of the lamp holder; the lamp holder is connected with the top of the first shell, the radiator is in a hat-shaped structure with brims, the outer surface of a hat top is fixedly connected with the bottom of the second shell, the inner surface of the hat top is connected with the LED light-emitting component, and the brims are close to a corresponding embedded ceiling down lamp socket; the outer edge of the light transmission cover is connected with the inner surface of the radiator to cover the LED light-emitting component. According to the ceiling lamp, the disadvantage occurred by replacing a traditional illuminating system of an embedded ceiling down lamp with a current LED illuminating product is solved, and thus the ceiling lamp is long in service life, convenient to install and good in decoration effect, and has the significant meaning to energy conservation and environment protection.

Owner:FUJIAN YDJ LIGHT

Furniture and wood door adhered with veneers on surfaces and manufacturing method thereof

InactiveCN102450875ALabor intensiveReduce production efficiencyWood working apparatusDoor leavesPulp and paper industry

The invention relates to furniture and wood door adhered with veneers on the surfaces and a manufacturing method thereof. Each of the furniture and the wood door comprises a wood inner blank, an upper veneer, a base coat and a top coat, and the well sand-ground base coats are pre-coated on the veneers before the veneers containing concave-down or convex-up or curved arc-shaped surface and other special-shaped surface members or parts are bonded with the wood inner blanks. Therefore, the problems of large labor intensity of artificial manual sand-grinding of the special-shaped surfaces, low production efficiency and series dust pollution are solved, the production efficiency of such type of the furniture and the wood doors is greatly improved and the application prospects are significant.

Owner:唐善学

Preparation method and application of functional water-based heat-radiative color paint

ActiveCN103421394AAchieve decorative effectWith radiant heat functionMulticolor effect coatingsWater basedMetallurgy

The invention discloses water-based color paint having the function of heat radiation. The paint comprises 10-40 parts of disperse phase and 60-90 parts of continuous phase. The heat radiation is imparted to the water-based color paint, so that the paint can have the functions of decorating, heat radiating and cooling; the paint is applicable to blade coating, brush coating and spray coating with special guns, and is also applicable to industrial insulation inner surfaces and building exterior surfaces.

Owner:MARINE CHEM RES INST

Double-ingredient epoxy seam beautifying glue

InactiveCN106381117AEasy to operateSafe and non-toxicNon-macromolecular adhesive additivesMacromolecular adhesive additivesEpoxyCrack resistance

The invention relates to seam beautifying glue, in particular to double-ingredient epoxy seam beautifying glue. An ingredient A is prepared from the following ingredients in percentage by weight: 60 to 90 percent of epoxy resin, 0 to 30 percent of plasticizers, 0 to 3 percent of anti-freezing agents, 0 to 15 percent of glitter powder, 1 to 10 percent of thixotropic agents, 0.01 to 1 percent of antifoaming agents and 0 to 20 percent of filling materials; an ingredient B is prepared from the following ingredients in percentage by mass: 65 to 95 percent of curing agents, 1 to 20 percent of thixotropic agents, 0 to 30 percent of plasticizers and 0 to 15 percent of glitter powder. The ingredient A and the ingreeinet B are respectively packaged after the preparation; the ingredient A and the ingredient B can be used after being uniformly mixed according to the weight ratio of 1:1. The construction operation is convenient; the advantages of safety, non-toxicity, wear resistance, waterproof performance, mildewproof performance, stain prevention, chemical medicine resistance, anti-cracking performance, fine crack resistance, yellowing resistance, rich color and the like are realized; the seam beautifying glue can be used as the seam beautifying glue by replacing the existing cement and can be used for performing color matching on ceramic tiles in different colors so as to achieve the decoration effect.

Owner:三友(天津)高分子技术有限公司

Material distributing equipment for whole body marble and production technology for whole body marble

InactiveCN106335128ASolve the difficult problem of adding slurry to milling and changing productionSolve the difficult problem of production transferFeeding arrangmentsAuxillary shaping apparatusCompression moldingWhole body

The invention discloses material distributing equipment for whole body marble and a production technology for the whole body marble. By the adoption of the material distributing equipment and the production technology, a toner is controlled effectively, the requirement for a toner cylinder is lowered, and the waste caused by cleaning of the toner cylinder is reduced. The material distributing equipment comprises toner hoppers, a material distributing belt, a powder transfer hopper, a grid and a press. The toner hoppers are arranged above the material distributing belt. The material distributing belt corresponds to the lower sides of the toner hoppers. The powder transfer hopper is connected with the tail end of the material distributing belt. A discharging opening corresponds to the grid. The grid is arranged below the powder transfer hopper and connected with the press. The production technology comprises the following steps of A, taking raw materials, ball-milling the raw materials into slurry according to a formula and performing sieving; B, performing atomizing and draining, obtaining powder and conveying the powder to a powder bin for staling; C, taking the color materials, adjusting the ratio, embossing the materials through the grid, conveying the materials into the press and performing compression molding; D, drying the molded materials and performing glazing and ink jetting; and E, conveying the materials into a kiln for firing, performing polishing, and then obtaining the whole body marble.

Owner:广东博华陶瓷有限公司

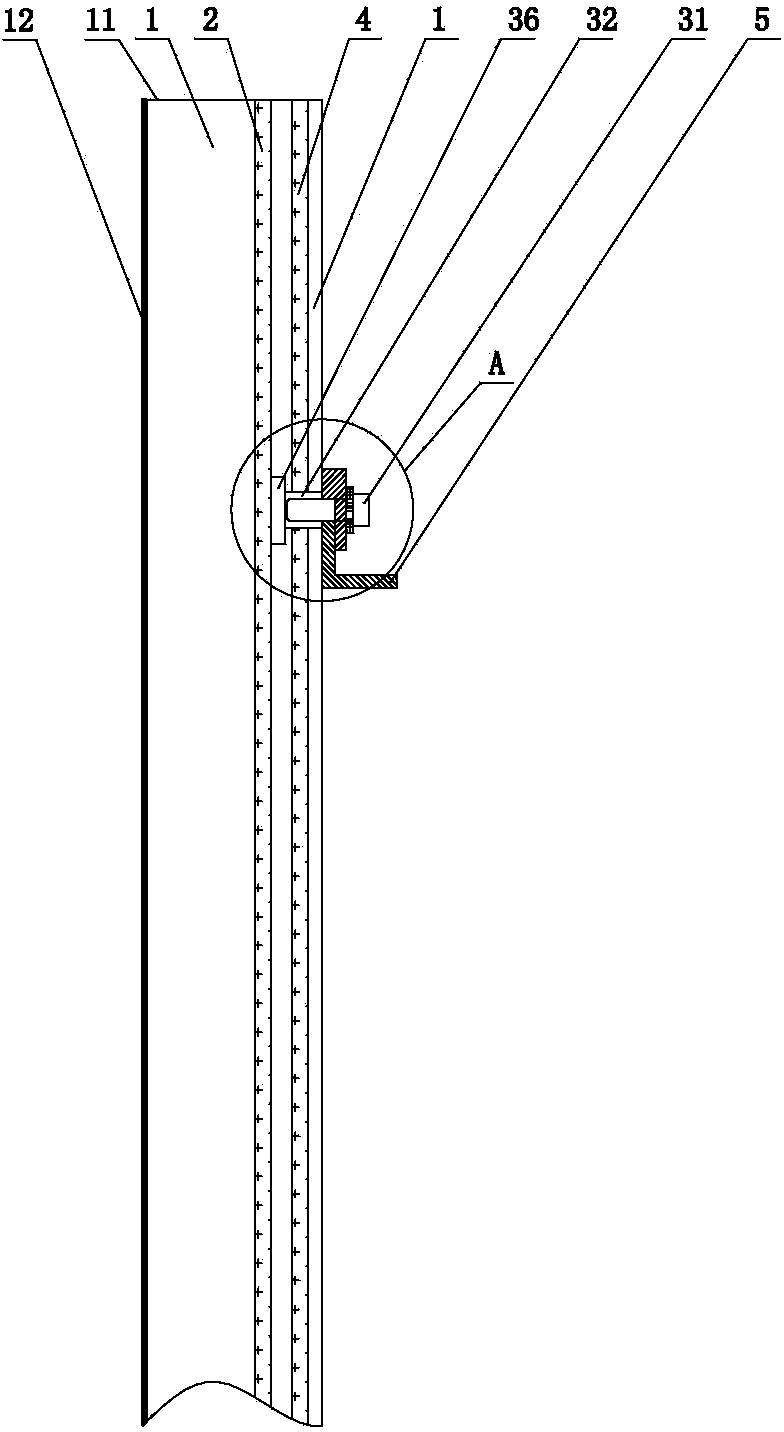

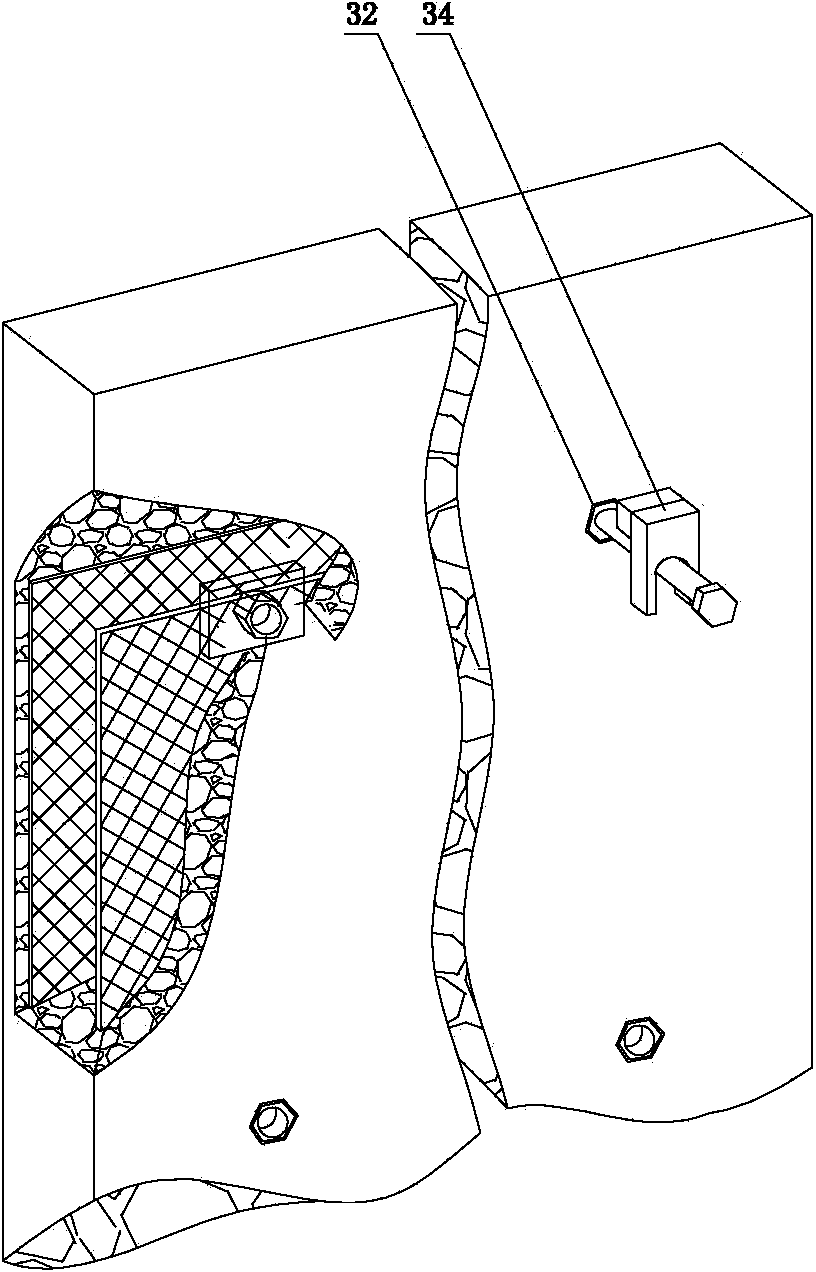

Artificial stone plate and curtain wall thereof

InactiveCN104110092AHas a large damagePollutedConstruction materialWallsEnvironmental resistanceSocial benefits

The invention relates to an artificial stone plate and a curtain wall thereof. The artificial stone plate comprises a stone plate made of a concrete material. Two layers of steel wire meshes are embedded in the stone plate; two rows of fastening nuts are embedded in a back surface of the stone plate; inner ends of the fastening nuts are connected to a strip plate between the two layers of the steel wire meshes; the fastening nuts penetrate through one layer of the steel wire meshes; and the outer ends of the fastening nuts reach the back surface of the stone plate. The artificial stone plate has the advantages of light weight, low cost, and convenient and fast installation, overcomes the disadvantages of high cost of stone installation framework, and complex program and high labor cost for stone slotting, punching and fixed installation; the surface of the stone is treated by a plurality of surface treatment methods, thereby achieving a decoration effect of natural stone completely; and a hydrophobic layer can effectively prevent phenomena of water seepage, discoloration and efflorescence. The artificial stone plate is synthesized by using regenerated resources, overcomes the disadvantages of large disruption to the environment and radiation pollution in stone exploration, has the advantages of low cost and environment protection, and has very good economic benefits and social benefits.

Owner:钟兵

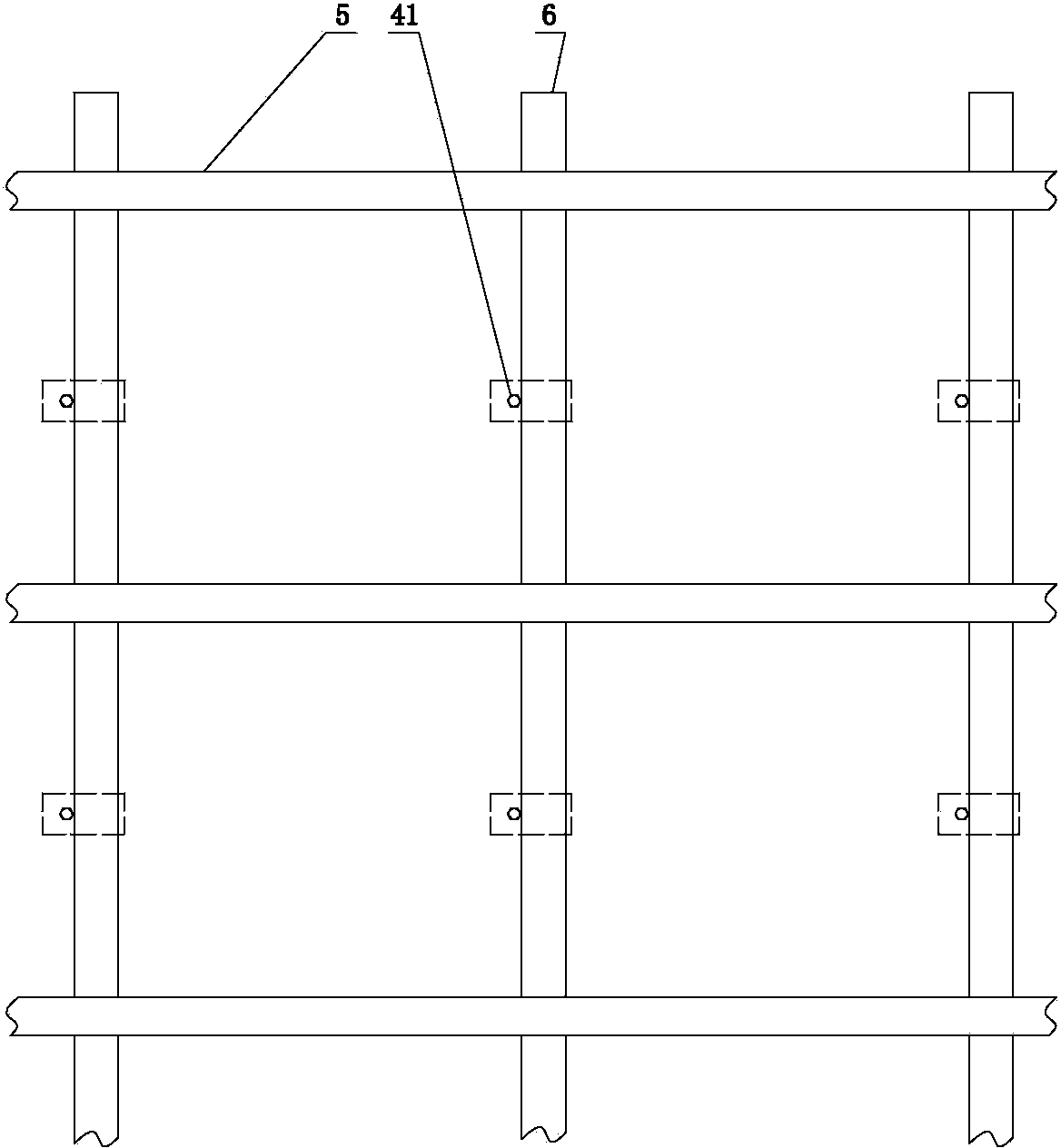

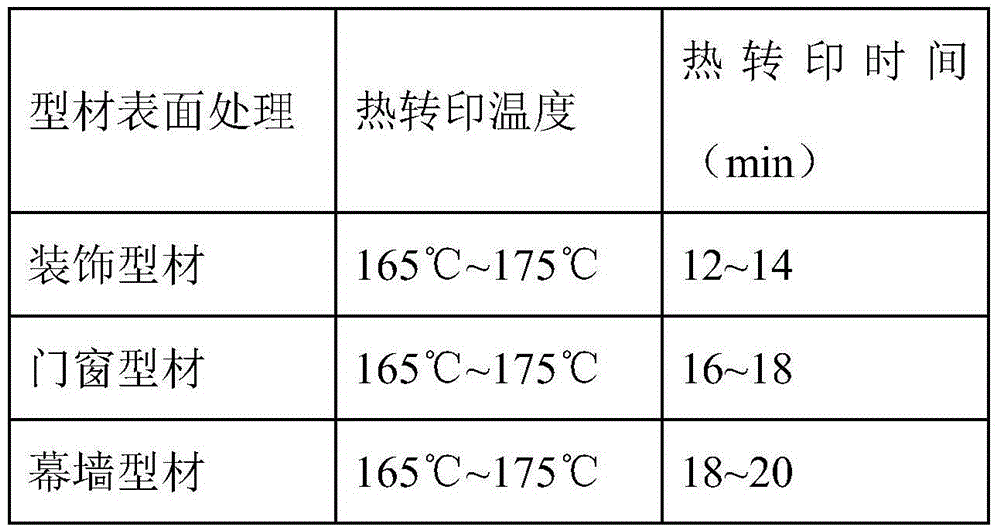

Production process of aluminum profile with 4D (Four-dimensional) wood grain surface

ActiveCN104549972AGood wood effectAchieve decorative effectDecorative surface effectsPretreated surfacesPaper sheetCorrosion

The invention relates to a production process of an aluminum profile with a 4D (Four-dimensional) wood grain surface. The production process comprises the following steps of pre-processing the profile; powdering and graining; corroding grains; washing; spraying base powder; carrying out heat transfer printing on the wood grains. The pre-processing of the aluminum profile comprises the following steps of pre-processing and placing the profile; acid pickling; chromizing; drying. The powdering and graining comprises the following steps of graining; powdering through a grain plate to form the wood grains, wherein the speed of a conveyor belt is controlled to be 2.6-2.8m / s; solidifying. The grains corrosion comprises the following steps of placing the profile in alkali bath liquid, corroding the surface part of the profile without the grains, and remaining the part protected by the powder. The washing comprises the following steps of water washing; chromizing; draying. The spraying of base powder comprises the following steps of spraying; solidifying at high temperature. The heat transfer printing of the wood grains comprises the following steps of cutting paper; sticking paper; covering with a high-temperature bag; tidying and vacuumizing; putting the vaccumized profile covered with the plastic bag into a furnace so as to be subjected to wood grain heat transfer printing; cooling and removing the bags. According to the production process of the aluminum profile with the 4D wood grain surface, the concave-convex wood grains are formed, and the wood grain effect is good.

Owner:GUANGDONG YAOYINSHAN ALUMINUM

Aqueous paint capable of generating chromatic pattern and preparation method thereof

The invention provides a water paint which can produce colorful patterns, and is made from color gel granules, protecting glue, and water. The constituents by weight proportions are 25-35 portions of gel granules, 45-55 portions of protecting glue; the rest is water. The constituents making up the color gel granules are 11-22 portions of pigment slurry, 45-70 portions of cellulose ether solution, 1-5 portions of film forming addition agent, and 0.5-1.5 portions of fungicides, and 1-7 portions of antifreeze. The preparing method includes 1, obtaining color gel granules, 2, obtaining protecting glue, and 3, obtaining the paint with color patterns. The invention has the advantages that the color gel granules is in a relatively stable state in the protecting glue; the paint can be sprayed on the surface of an object to form various separate three-dimensional color patterns, has excellent anti-aging performance, is innoxious and harmless, can replace wallpaper, can be sprayed on wooden furniture, metal, plastic and other objects, has excellent wear resistance and long service life.

Owner:LUOYANG DAYU IND

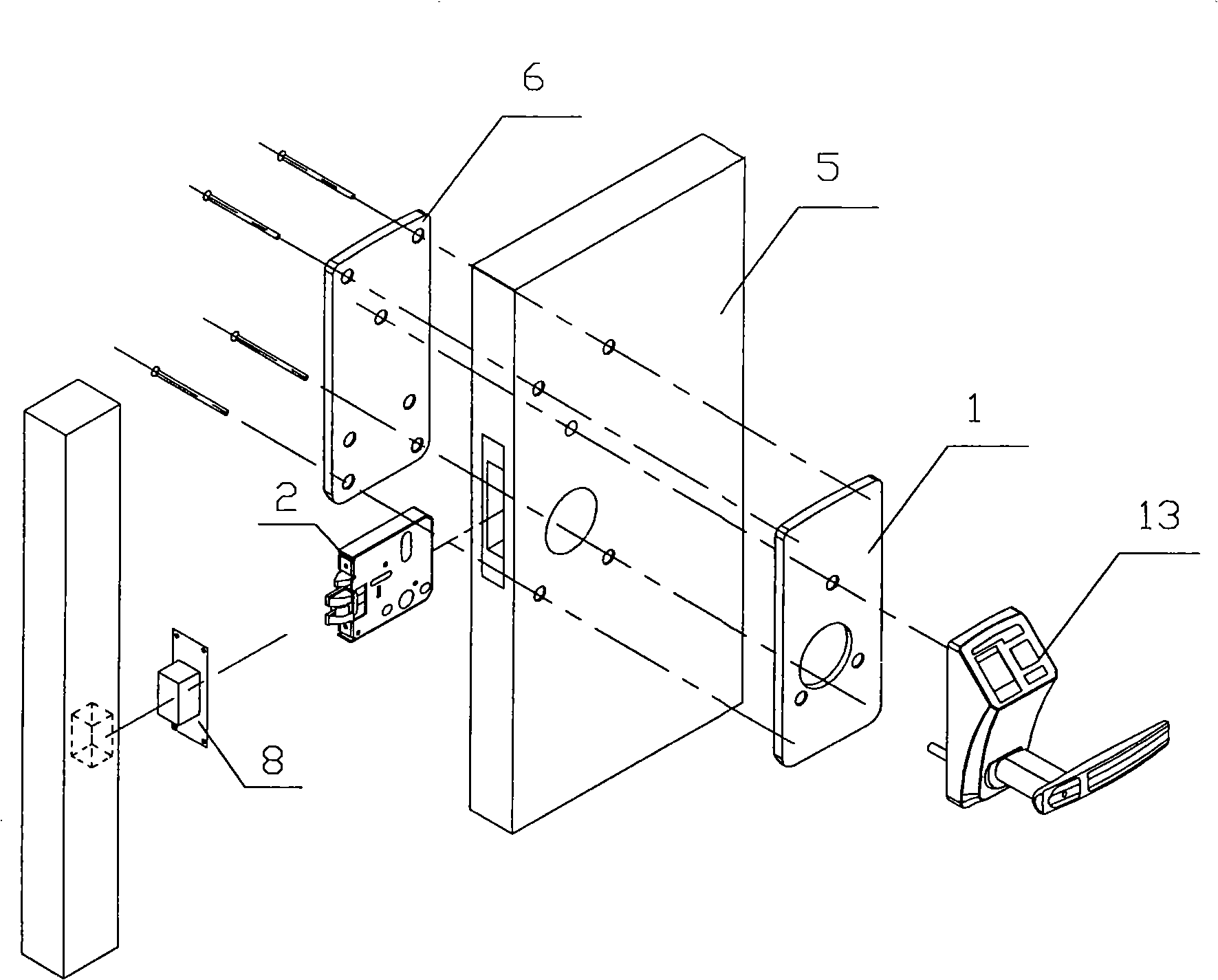

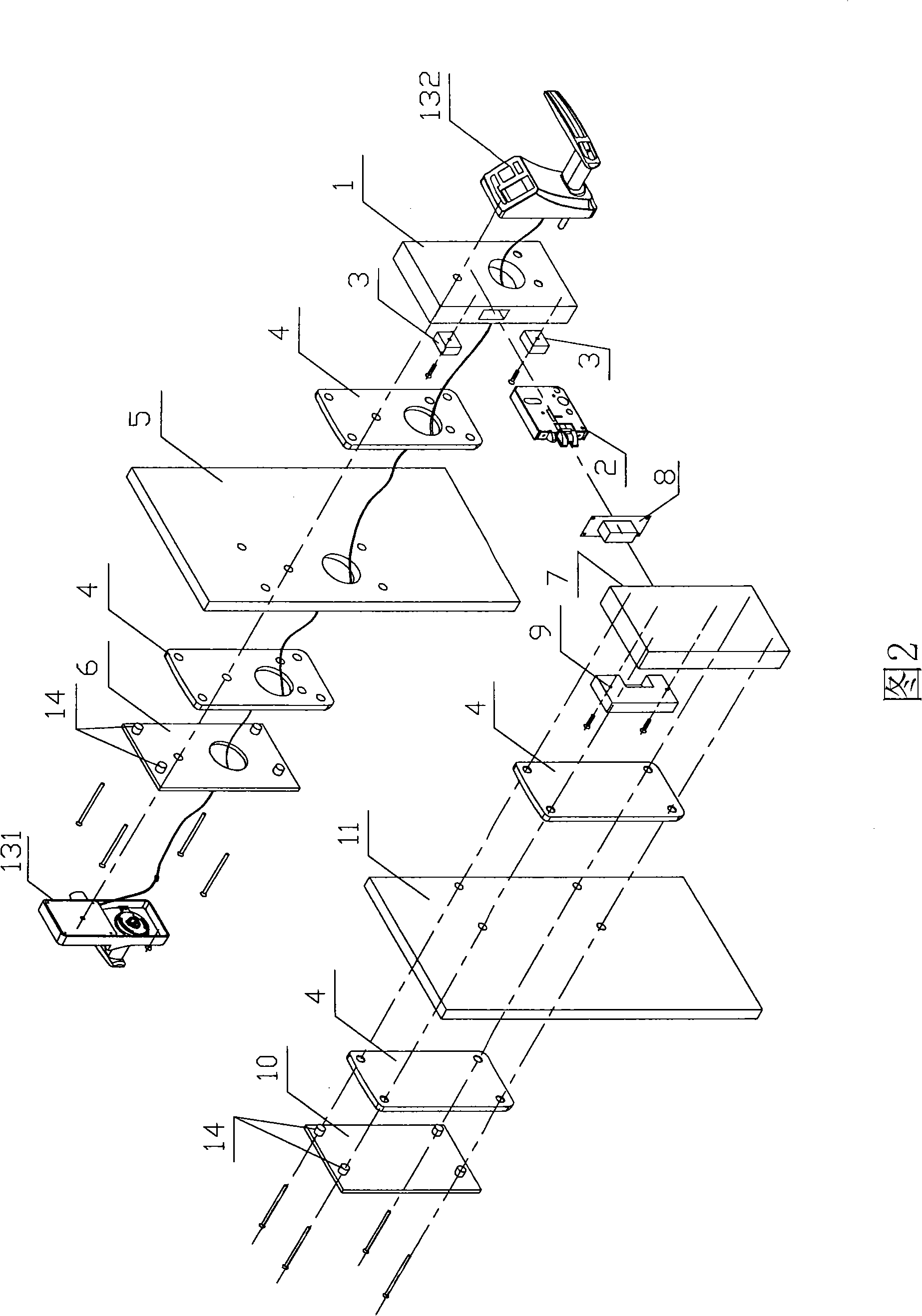

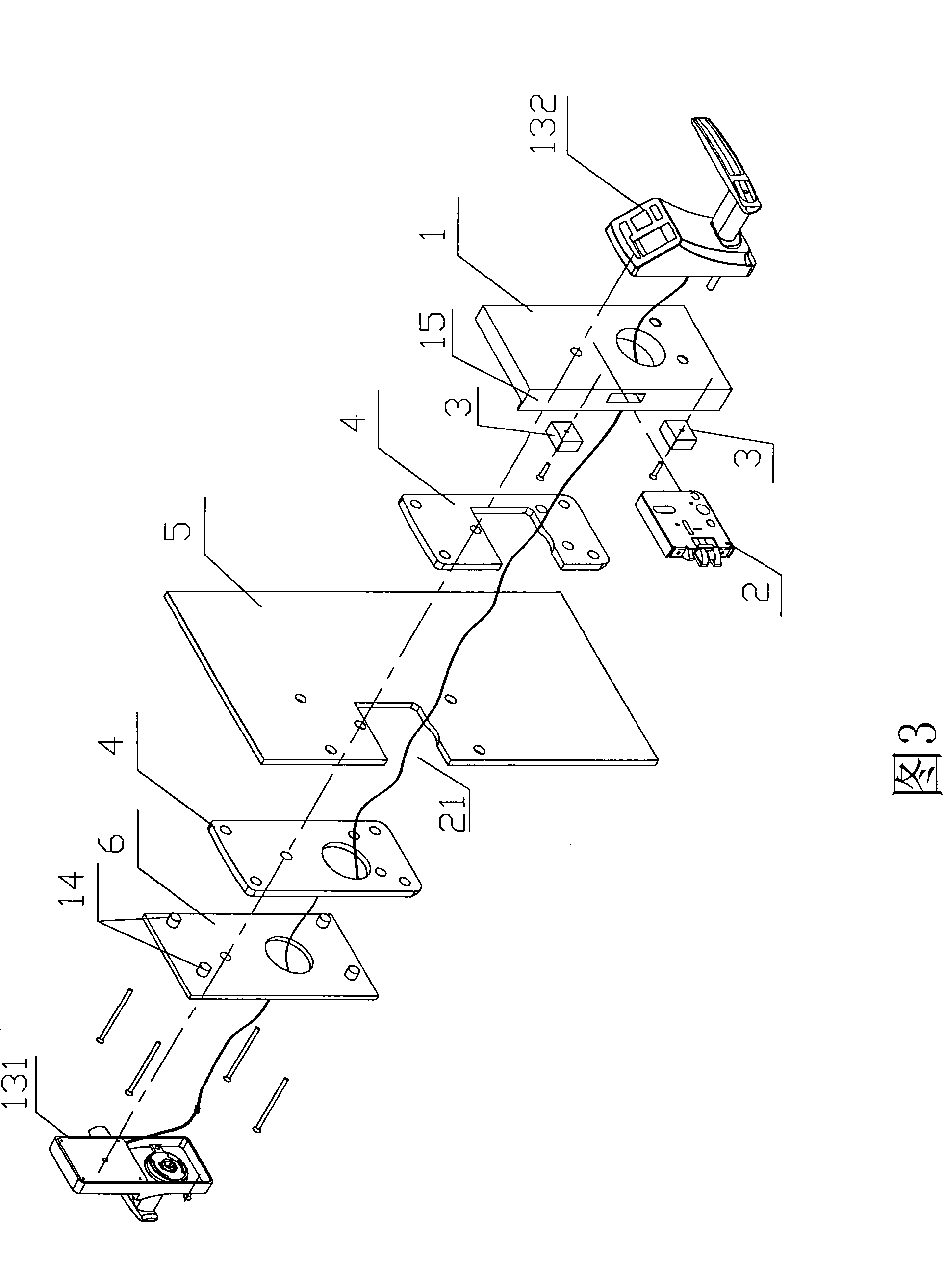

Installation structure of electronic lock

InactiveCN101255777ANeat appearanceReduce complexityElectric permutation locksSoftware engineeringFastener

The present invention discloses an installation structure of an electronic lock which comprises an electronic control unit box. The invention is characterized in that the structure also comprises two separated inner fixing plate and external fixing plate. The inner fixing plate and the external fixing plate can traverse the door leaf through the fastener and are oppositely installed and fixed on two sides of the door leaf. The electronic control unit box is detachably fixed on the external surface of the external fixing plate or the inner fixing plate. The invention has the characteristics of simple structure, convenient and reliable installation, wider installation range of the electronic lock and the like. The invention is widely applied on the installation of the electronic lock in various kinds of door, the installation of traditional core inserting door lock and the improvement and change of the old lock.

Owner:曹湛斌

Manufacturing method of glazed brick and product thereof

The invention relates to a manufacturing method of a glazed brick and a product thereof. The method includes: A) a step of blending raw materials, performing ball milling, performing spray granulation, pressing to form a green brick, drying the green brick and spraying a base glaze on the green brick; B) a step of printing patterns on the green brick after the A) step, and spraying a transparent glaze; C) a step of printing patterns on the green brick after the B) step, drying, spraying a transparent glaze again and drying; D) a step of spraying a transparent glaze on the green brick after the C) step and drying; and E) a step of kilning the green brick in the D) step, polishing with an inelastic module, packaging and putting the brick into storage. When the product is exposed to light, the ray of light is subjected to two times of transmission and refraction, so that the patterns are strong in stereoscopic effects, add radiance and beauty to each other, are natural and grand, and can achieve decorative effects similar to that of natural stone.

Owner:FOSHAN DONGPENG CERAMIC +2

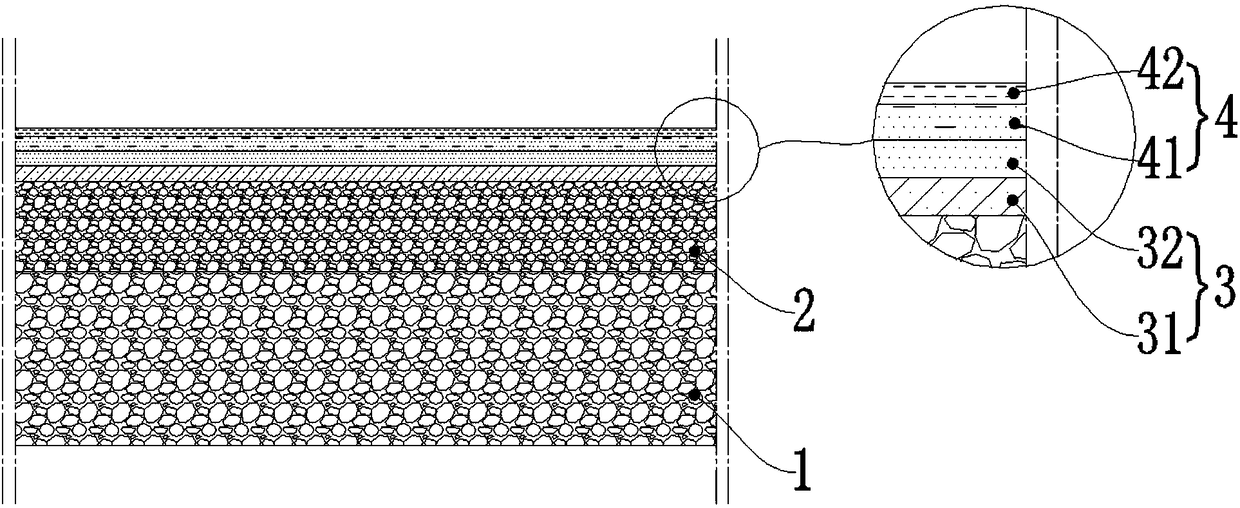

Once-firing multi-density composite foamed ceramic decorative board and preparation method thereof

The invention discloses a once-firing multi-density composite foamed ceramic decorative board. The once-firing multi-density composite foamed ceramic decorative board comprises a first foamed layer, asecond foamed layer, a sealing layer and a surface decorative layer arranged in order from bottom to top, wherein the density of the second foaming layer is less than the density of the first foaminglayer; the first foaming layer, the second foaming layer, the sealing layer and the surface decorative layer are fired once; the sealing layer is used for sealing a hole in the surface of the secondfoaming layer; the sealing layer is an engobe layer, or the sealing layer is a non-foamed ceramic slurry layer and an engobe layer, and the non-foamed ceramic slurry layer is located between the foamed layer and the engobe layer; the surface decorative layer is a glazed layer. Correspondingly, the invention also discloses a preparation method of the decorative board. The sealing layer can improvethe flatness of the product and improve the decorative effect of the product. The foamed ceramic decorative board is easy to clean. The foamed layers, the sealing layer and the surface decorative layer are fired once, and the layers are firmly bonded.

Owner:GUANGDONG KITO CERAMICS GROUP CO LTD +1

One-time-coating enamel and preparation method

The invention discloses one-time-coating enamel and a preparation method thereof. The one-time-coating enamel comprises the following components in part by weight: 42 to 45 parts of silica, 4 to 6 parts of aluminum oxide, 7 to 9 parts of sodium oxide, 2 to 3 parts of potassium oxide, 2 to 3 parts of lithium oxide, 17 to 19 parts of diboron trioxide, 5 to 6 parts of titanium dioxide, 1 to 2 parts of calcium oxide, 3 to 4 parts of zirconium dioxide, 1 to 2 parts of sodium hexafluoroaluminate, 2 to 3 parts of strontium oxide, 3 to 4 parts of phosphorus pentoxide, 4 to 5 parts of cobalt oxide, 4 to 5 parts of nickel oxide, 4 to 5 parts of ferric oxide, 1 to 3 parts of potassium nitrate, 1 to 3 parts of sodium nitrate, 1 to 3 parts of boric acid, 1 to 3 parts of lithium fluoride and 1 to 3 parts of strontium carbonate. The preparation method comprises the following steps of: weighing all the components respectively; uniformly mixing the cobalt oxide, the nickel oxide and the nitrate; fully stirring all materials till the uniformity is more than or equal to 98 percent; smelting the mixture in a smelting furnace at the temperature of between 1,200 and 1,300 DEG C, taking a thread sample out and discharging the sample, wherein each meter of the sample is divided into 2 to 3 segments; pressing an enamel tablet by a tablet press till the thickness is less than 2mm; and cooling and smashing the obtained product. When the one-time-coating enamel is coated and enameled on the surface of steel sheets and cast irons, the bottom enamel unifying effect can be achieved at one time, so that the technical problem of one-time enameling is solved.

Owner:梁梦林

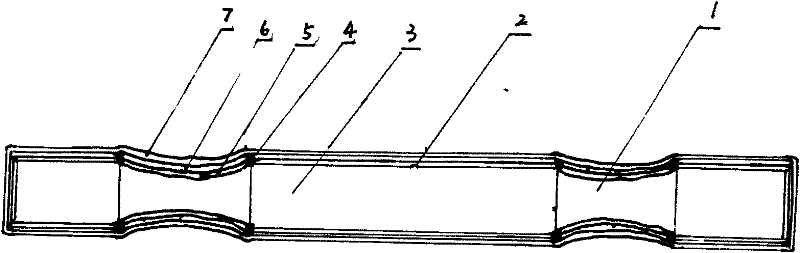

Flexible extruded plastic profile, especially plastic tube and method for producing the same

InactiveUS20060070870A1Avoid damageEasy to depositPipe laying and repairLiquid surface applicatorsThin membraneEngineering

A method for making the plastic profile comprising depositing an inner thin film with a metallic appearance onto the surface of the flexible extruded plastic profile depositing an outer protective cover layer that is at least partially transparent onto the inner thin film wherein the inner thin film and the outer protective cover layer form a layer system to cover the flexible extruded plastic profile.

Owner:REHAU AG & CO

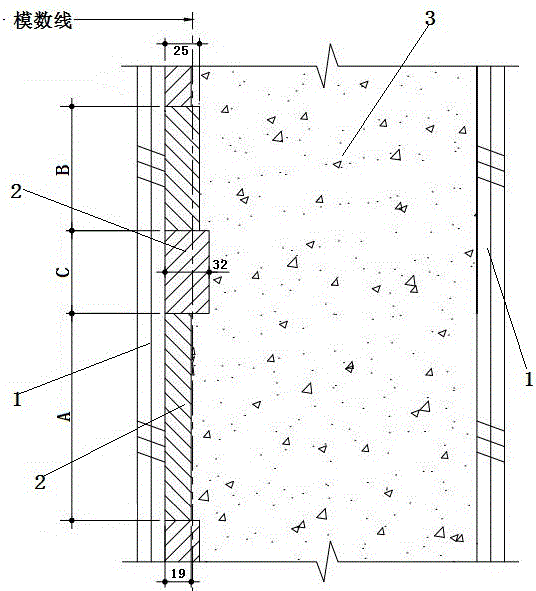

Formwork and construction process for fabricating concavo-convex wood-grain fair-faced concrete wall

InactiveCN106836793AEliminate seamsCreate wholenessForms/shuttering/falseworksForming/stuttering elementsSolid woodWood plank

The invention discloses a template and a construction process for making a concave-convex wood-grain fair-faced concrete wall. The template includes: an inner and outer double-layer template, wherein the inner layer is a rubbing board made of solid wood, and the outer layer is a base plate with a complete plane , characterized in that the rubbing board is fixed on the complete plane of the substrate, the rubbing board is formed by splicing wood boards of at least one thickness, and each thickness of wood boards includes several pieces. The construction process includes the following steps: (1) splicing several wooden boards on the base plate to form an inner and outer double-layer structure formwork; (2) setting several pieces of said formwork on the side of the wall that needs to form a concave-convex wood grain wall surface effect, and using One side of the rubbing board faces the wall; (3) pour fair-faced concrete and perform concrete curing for several days; (4) remove the formwork after curing and repair the defects on the wall.

Owner:SUZHOU HUAZAO ARCHITECTURAL DESIGN CO LTD

Preparation method of shell and shell prepared by method

InactiveCN102076185ABeautiful appearanceImprove surface propertiesDecorative surface effectsVacuum evaporation coatingMetalInorganic sulfide

The invention provides a preparation method of a shell and the shell prepared by the method. The preparation method of the shell comprises the following steps: providing a plastic substrate which is prepared from polyphenylene sulfide; performing plasma surface treatment to the surface of the plastic substrate; and formed a non-conductive metal film on the treated surface of the plastic substrate. The shell contains the plastic substrate and the non-conductive metal film formed on the surface of the plastic substrate, wherein the plastic substrate prepared from polyphenylene sulfide and the adhesive strength of the non-conductive metal film on the surface of the plastic substrate is above 3B.

Owner:SHENZHEN FUTAIHONG PRECISION IND CO LTD

Display window cover assemblies and electronic devices and methods using the same

InactiveCN101336165AImplement featuresAchieve decorative effectGlass/slag layered productsSynthetic resin layered productsEngineeringDisplay device

An electronic device has a display window and includes a composite display window cover assembly and a display device. The composite display window cover assembly is disposed in the display window. The composite display window cover assembly includes a glass panel and a plastic panel secured to the glass panel. The display device is positioned to be viewed through the display window and the composite display window cover assembly.

Owner:SONY ERICSSON MOBILE COMM AB

Novel adsorptive material for treating air pollution and its preparing method

InactiveCN1748858AEasy to useIncrease profitOther chemical processesDispersed particle separationCalcium hypochloriteActive carbon

The novel adsorptive material for treating polluted air consists of active carbon or charcoal 50-100 weight portions and additive 0-50 weight portions, and the additive may be silicon colloid, calcium hopochlorite, anhydrous cup sulfate, anhydrous calcium chloride or calcium oxide. The preparation process includes first reinforced activation of active carbon or charcoal, the subsequent mixing with additive, and final vacuum packing. The present invention can adsorb, digest and degrade toxic matter in air effectively, and inhibit and kill virus in air. It is safe, efficient, low in power consumption, healthy, environment friendly, multifunctional and excellent in technological performance.

Owner:黎伯忠

Thick self-leveling mortar

The invention relates to self-leveling mortar and in particular relates to thick self-leveling mortar. The mixture of the thick self-leveling mortar disclosed by the invention before use comprises the following components: 5-10 mass parts of sulfate aluminum cement, 20-25 mass parts of Portland cement, 5-10 mass parts of heavy calcium powder, 0.05-0.08 part of tartaric acid, 0.08-0.1 mass part of lithium carbonate, 0.2-0.3 mass part of a polycarboxylate superplasticizer, 0.05-0.08 mass part of cellulose with the viscosity of 400mPa*s and 0.1-0.15 mass part of a dry powder antifoaming agent. The thick self-leveling mortar disclosed by the invention can be rapidly dried to reach a usage state and is not cracked when the construction thickness is large.

Owner:罗来兵

Magnetic suspension anion air purifier

InactiveCN106765653ANew experienceAchieve purification effectMechanical apparatusSpace heating and ventilation safety systemsPower flowAir purifiers

The invention provides a magnetic suspension anion air purifier. The magnetic suspension anion air purifier is characterized in that the air purifier comprises a base and a purifier body; the base comprises electromagnets, electromagnet coils, transmitting coils and a main control panel A; and the purifier body comprises a ventilation chamber, a main control panel B, an anion generator, anion emitters, a support, receiving coils, permanent magnets and a draught fan. Compared with the prior art, the magnetic suspension anion air purifier has the beneficial effects that the effect that a magnetic field is generated after each electromagnet is powered on and the principle that same polarities of every two permanent magnets repel each other and different polarities of every two permanent magnets attract each other are utilized, and therefore the purifier body can be suspended above the base; and meanwhile, magnetic flux variation generated in the transmitting coils inside the base is inducted by the receiving coils in the purifier body, and after passing through the main control panel B, a generated alternating current supplies power to the anion generator and other devices in the purifier body, so that the effects of air purification, LED backlight decoration and the like are achieved.

Owner:陆汉明

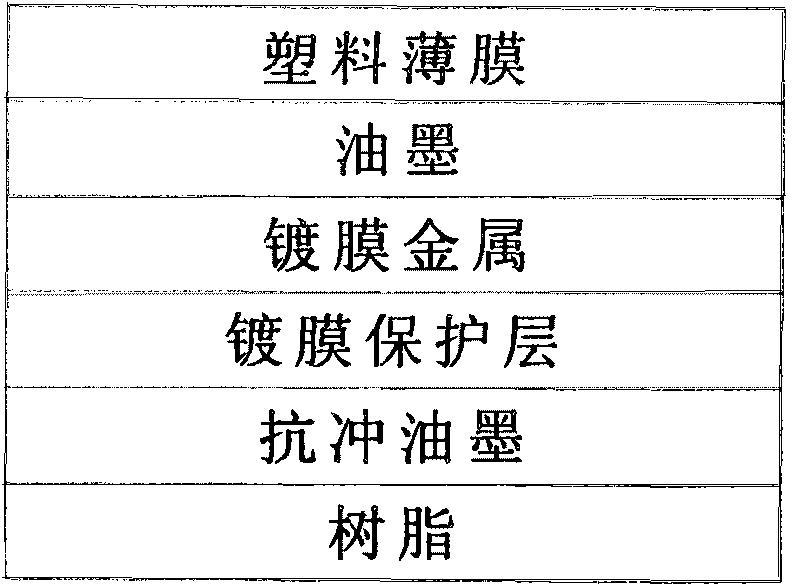

Application method of vacuum ion sputtering coating in IML technology

InactiveCN101698935AAchieve decorative effectPlay a semi-permeable functional roleVacuum evaporation coatingSputtering coatingAlloyHigh pressure

The invention relates to an application method of vacuum ion sputtering coating in an IML technology, which selects In-Sn alloy of which metals have wide bandwidths as substrate of a coating material, wherein the ratio of In to Sn is 3:7, thus the coated film layer has beautiful metal texture. Two insulation protection layers of Al2O3 and SiO2 are matched with the surfaces of In and Sn, and the thicknesses of the Al2O3 and SiO2 insulation protection layers are respectively controlled to 30-40 nanometers and 60-70 nanometers. By using the technology of first coating metals and then coating metal protection layers, a coating zone can resist the erosion of ink and tension in the forming process, and the key part has the metal texture of the coating film and also the insulating non-conductive property. The invention solves the technical problem that in the machining process of mobile phone molding parts, such as printing an anti-impact ink layer, performing high-pressure forming and injection molding, the coating film is eroded, cracks and the like, thereby realizing large-scale popularization and application of the coating technology in ornaments of mobile phone shells.

Owner:TIANJIN ZHONGHUAN HI TECH

In-mold decoration (IMD) production technology for switch panel

InactiveCN103117181AStrong (solvent) resistanceVibrant and long-lasting colorElectric switchesEngineeringWear resistance

The invention provides an in-mold decoration (IMD) production technology for a switch panel and relates to the production technology for the switch panel. A traditional production technology is reformed. The IMD technology is applied to production of the switch panel and a socket panel. Various patterns and characters are printed on a sheet, and the sheet coated with a membrane is conveyed to an injection molding main machine hand for in-mold coating and injecting. The patterns on the surface of the switch panel produced by adoption the technology are good in wear resistance, rich and bright in color, and strong in third dimension.

Owner:刘 志勇

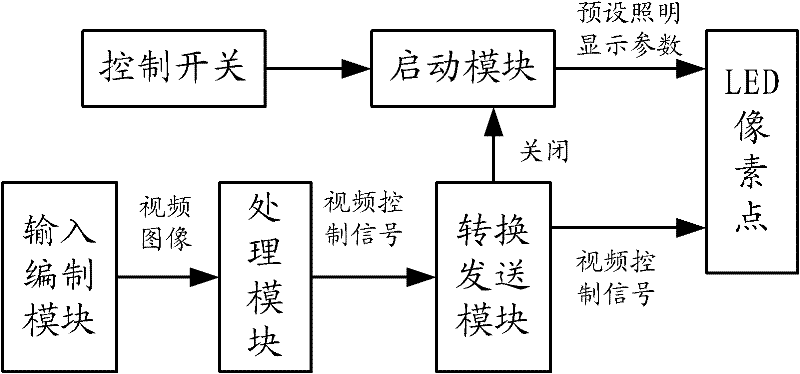

An indoor lighting display system

InactiveCN102287633AAchieve lighting effectsImprove lighting effectsPoint-like light sourceElectric circuit arrangementsControl signalEffect light

The invention discloses an indoor lighting display system which comprises a lighting display device, a heating panel, a mounting rack and a control unit, wherein the lighting display device is provided with a plurality of LED ( light emitting diode) pixel points, a scatter plate, a control switch and a starting module; the control switch is used for disconnecting or communicating the power of the lighting display unit; the starting module is used for automatically transmitting one preset lighting display parameter to each LED pixel points when the control switch is switched on; the control unit comprises a formation module and a processing module; the formation module is used for inputting formation so as to complete the input of each video image according to the operation, the processing module is used for processing video images so as to generate video control signals, the starting module is closed when the starting module receives the video control signals, and simultaneously the video control signals are sent to a transformation transmitter module which is used for displaying each LED pixel point. The display system provided by the invention integrates the functions of lighting, decoration, display; and the display system provided by the invention has the advantages of simple mounting structure and good heat dissipation and lighting display effects.

Owner:佛山市南海区先创光电设备有限公司

Fire prevention, thermal insulation and decoration integrated board and making method thereof

ActiveCN105418029AHigh strengthLow thermal conductivityHeat proofingFire proofingCelluloseInsulation layer

The invention relates to a fire prevention, thermal insulation and decoration integrated board and a making method thereof. The fire prevention, thermal insulation and decoration integrated board comprises an insulating layer and a decorating layer. The insulating layer is made from glass beads, cement, rubber powder, cellulose and polypropylene fibers. The decorating layer is made from mullite, cement, glass beads, rubber powder, cellulose, pigments and water-proofing agents. According to the fire prevention, thermal insulation and decoration integrated board, the mullite is used for making the fireproof decorating layer, and the incombustible material glass beads are adopted for the insulating layer at the same time, so that two fireproof lines are provided, and the fireproofing grade reaches grade A. Meanwhile, compared with existing fire prevention, thermal insulation and decoration integrated boards, the fire prevention, thermal insulation and decoration integrated board is simple in production process, relatively low in manufacture cost and quick and convenient to construct.

Owner:HEBEI INSTITUTE OF ARCHITECTURE AND CIVIL ENGINEERING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com