Application method of vacuum ion sputtering coating in IML technology

A technology of ion sputtering and application method, applied in the application field of vacuum ion sputtering coating in IML process, can solve the problems of cracking, instability, immature process method, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

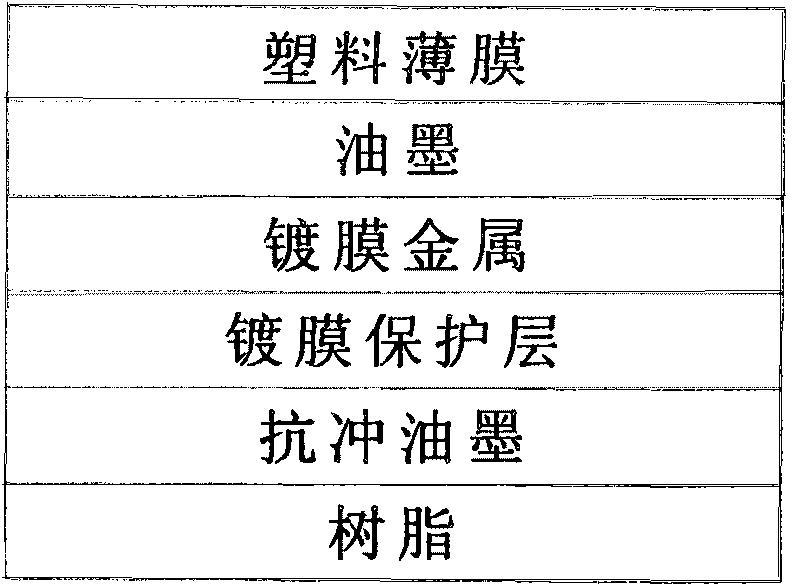

[0015] Such as figure 1 The IML fault structure is shown, and the processed IML product process is: printing on the reverse side of the plastic film, hollowing out the icon area, depositing non-conductive metal and protective layer on the ink, subsequent printing, high pressure forming, punching, and injection molding.

[0016] In order to achieve a good insulation effect by vacuum coating, the thickness of the film layer must be effectively controlled, and the appropriate coating process and coating material must be selected to have both a metallic texture and a nano-insulation thickness.

[0017] Choose a beautiful and pollution-free vacuum coating process, deposit a layer of nano-film on the plated sheet, make full use of the vacuum deposition characteristics of insulating materials, and choose metal In and Sn alloy (ratio 3:7) with a wide bandwidth as the coating material Base layer, the thickness is controlled between 30 and 60 nanometers, and the vacuum degree is control...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com