Self-bearing fire-resistant flame-retardant coaxial high-voltage cable and manufacturing method thereof

A fire-resistant, flame-retardant, high-voltage cable technology, applied in the direction of coaxial cables/analog cables, cable insulation structures, insulated cables, etc., can solve the problems of burning space, large gaps in cables, poor flame retardant effect, etc., and achieve increased contact Larger area, longer service life, good support effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

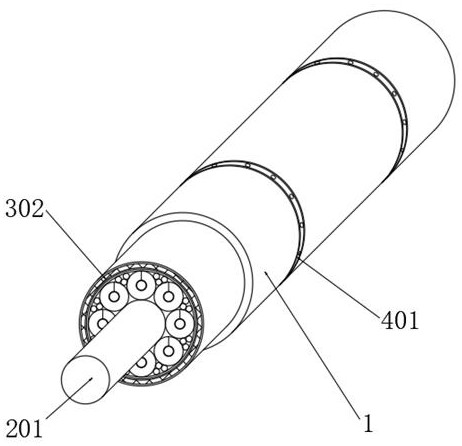

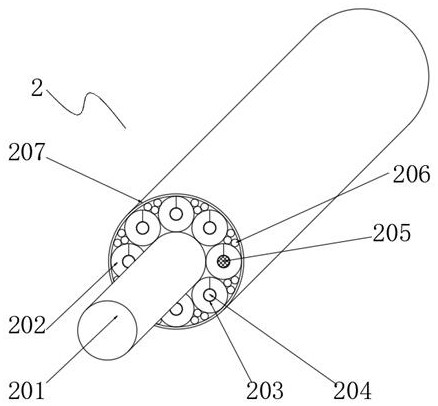

[0041] Embodiment 1: as Figure 1-5 As shown, the present invention provides a technical solution, including a coaxial cable substrate 1, a central assembly 2, an inner conductor 201, an insulating strip 202, a through hole 203, an air bag 204, carbon dioxide 205, a flame-retardant wire 206, and an inner heat-sealing film 207 ,

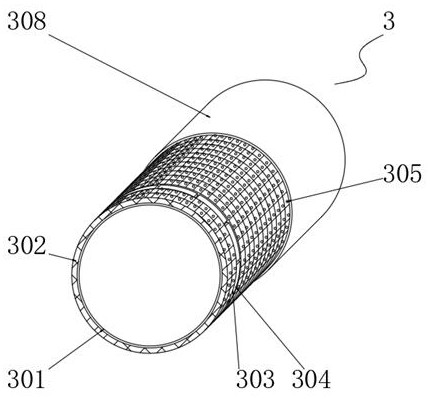

[0042] Middle layer component 3, insulating rubber pad 301, metal braiding layer 302, inlay groove 303, barrier ring 304, iron powder 305, deformation groove 306, anti-slip groove 307, outer heat sealing film 308,

[0043] Outer layer component 4, aluminum alloy ring 401, heat conducting groove 402, insulating block 403, rubber ring 404, connection hole 405, heat conducting wire 406, insulating layer 407, heat dissipation groove 408 are provided with a central component 2 inside, and the central component 2 includes inner wires 201, insulating strip 202, through hole 203, air bag 204, carbon dioxide 205, flame retardant silk 206 and inner heat sealin...

Embodiment 2

[0049] Embodiment 2: as Figure 6 Shown, a kind of manufacturing method of self-supporting refractory flame-retardant coaxial high voltage cable comprises the following steps:

[0050] S1: Central component assembly: the inner wire is used as the central axis, and several insulating strips are hinged on the outside of the inner wire, and the flame-retardant wire fills the gap between the insulating strips and then wraps the inner heat-sealing film.

[0051] S2: Assembly of the middle layer components: put the central component into the extruder, wrap the insulating rubber on the outside of the inner heat-sealing film, and then cover the outside with a metal braid layer, evenly cover the barrier rings, and sprinkle the gap between the barrier rings Iron powder, wrapped with heat-sealing film.

[0052] S3: Assembly of outer layer components: the aluminum alloy ring is sleeved on the outside of the outer heat-sealing film, and then the cable is placed in the extruder, and the me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com