Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

56results about How to "Production process energy saving and environmental protection" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Production process for firing alumina foamed ceramic filter board in roller kiln

The invention relates to the field of the production of foamed ceramic filter boards, and aims to provide a production process for firing an alumina foamed ceramic filter board in a roller kiln. The process comprises the following steps of: weighing according to a formula, performing ball-milling and mixing uniformly to form slurry; cutting sponge, impregnating the sponge and sizing; drying, and guniting; and sintering in the lengthened roller kiln. According to the production process, the alumina foamed ceramic filter board is fired by utilizing the lengthened roller kiln, so the process is small in unit consumption, gas amount required by the roller kiln is little under the condition of producing the same quantity of the filter boards, the amount of discharged flue gas is also reduced greatly, and compared with the conventional technology, the production process has the advantages of energy conservation and environment friendliness; and the quality of the fired foamed ceramic filterboard is more stable.

Owner:HANGZHOU ZHONGYA NEW MATERIALS TECH

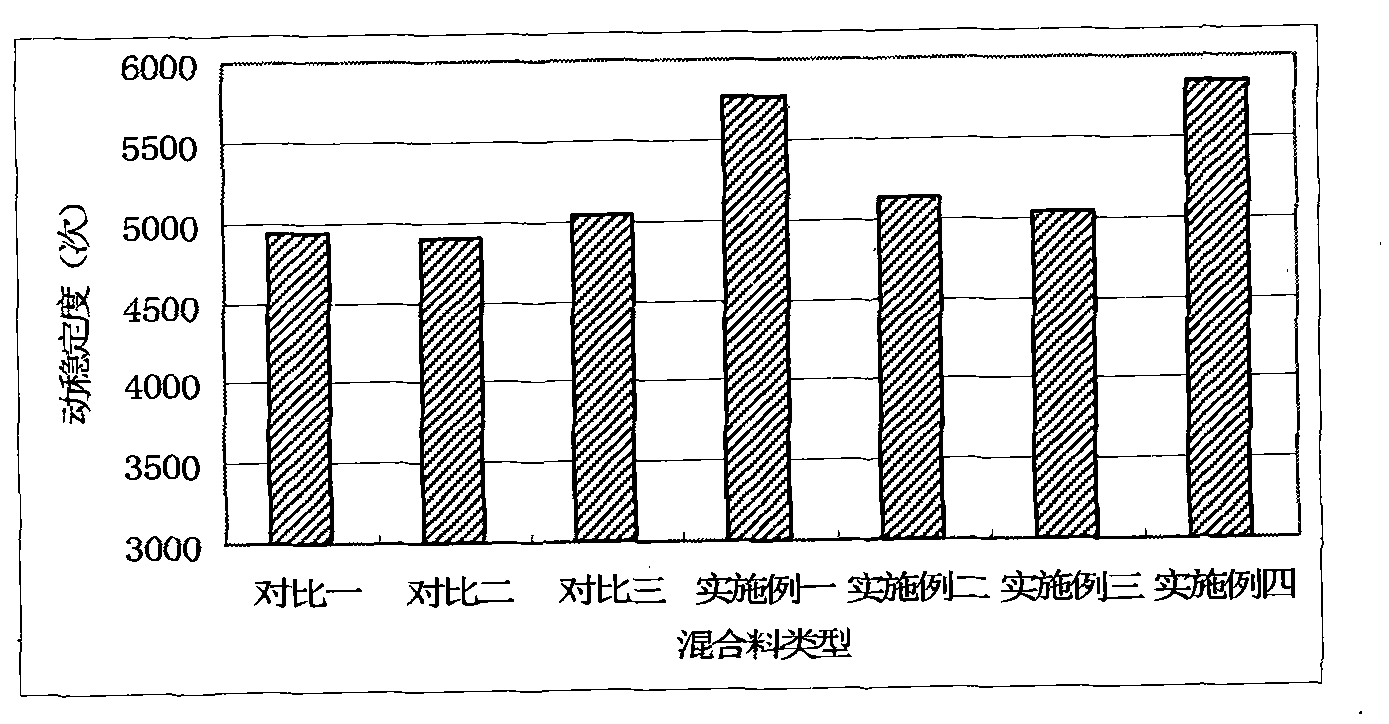

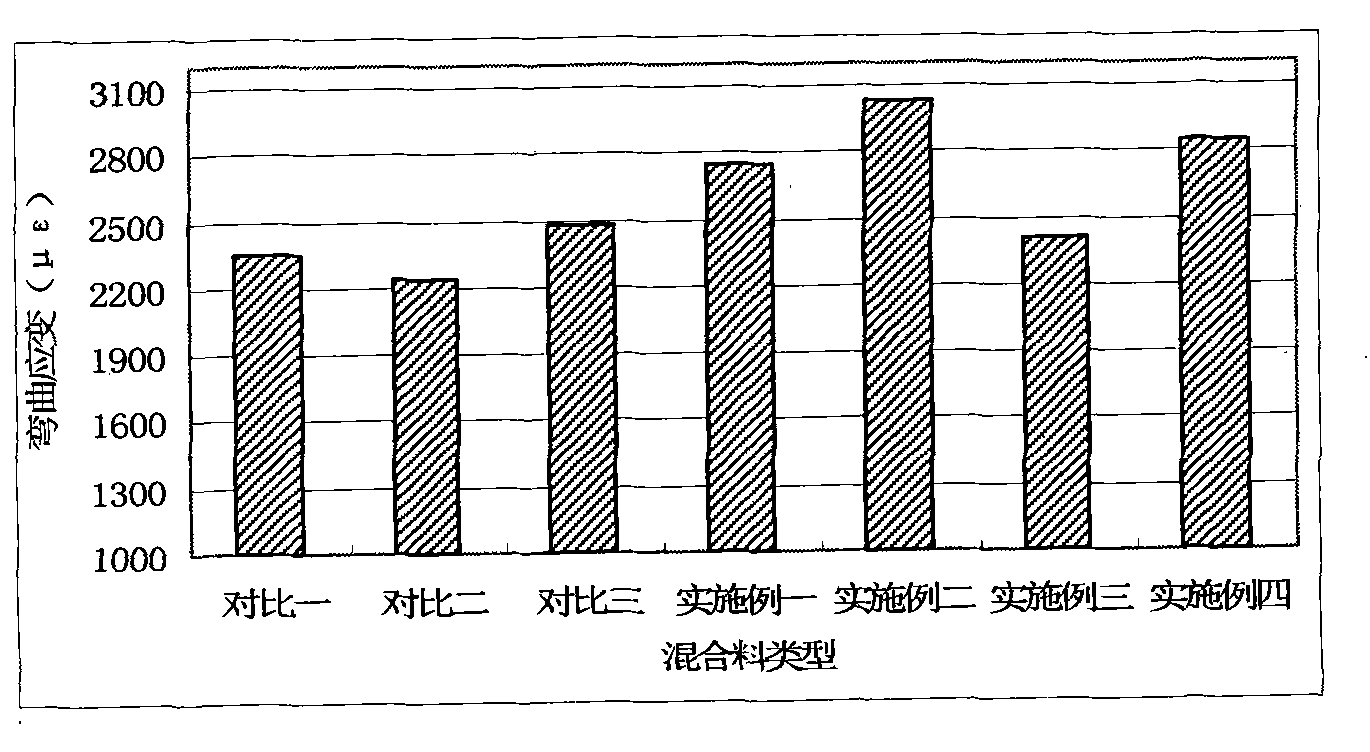

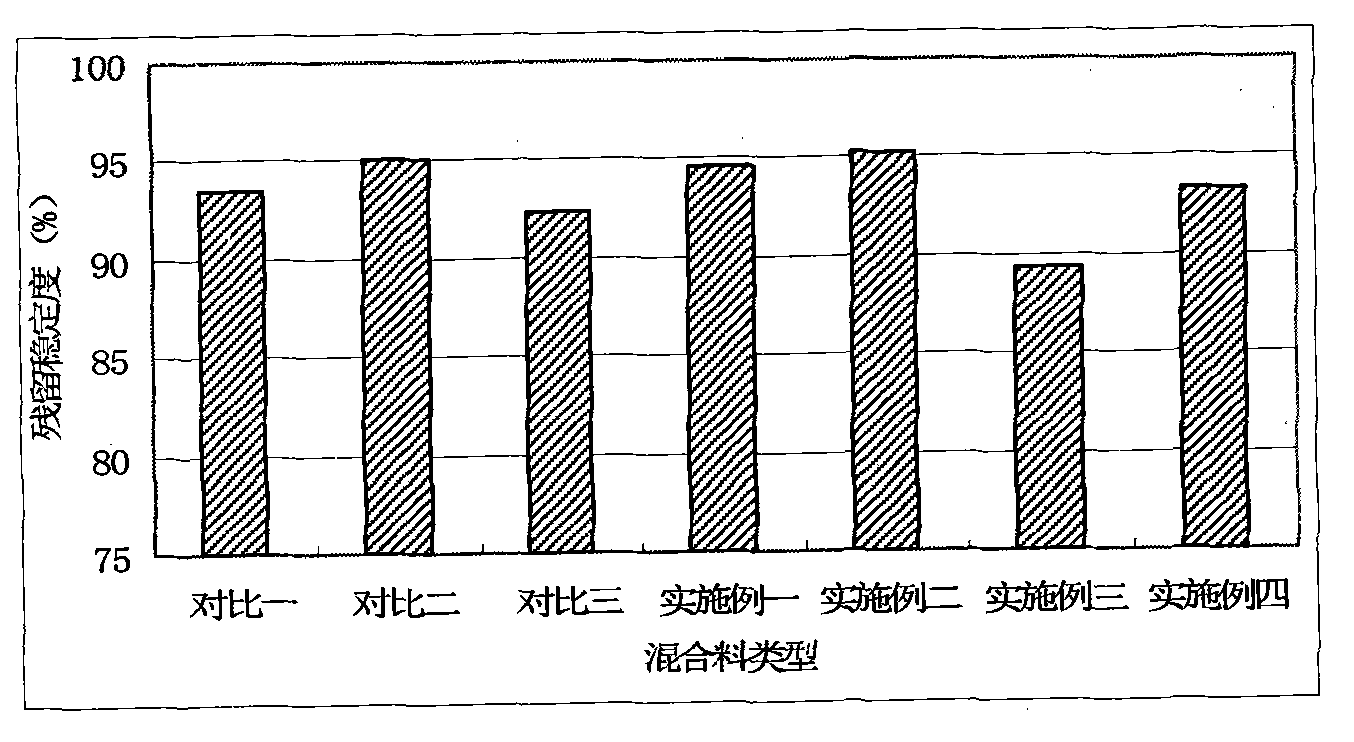

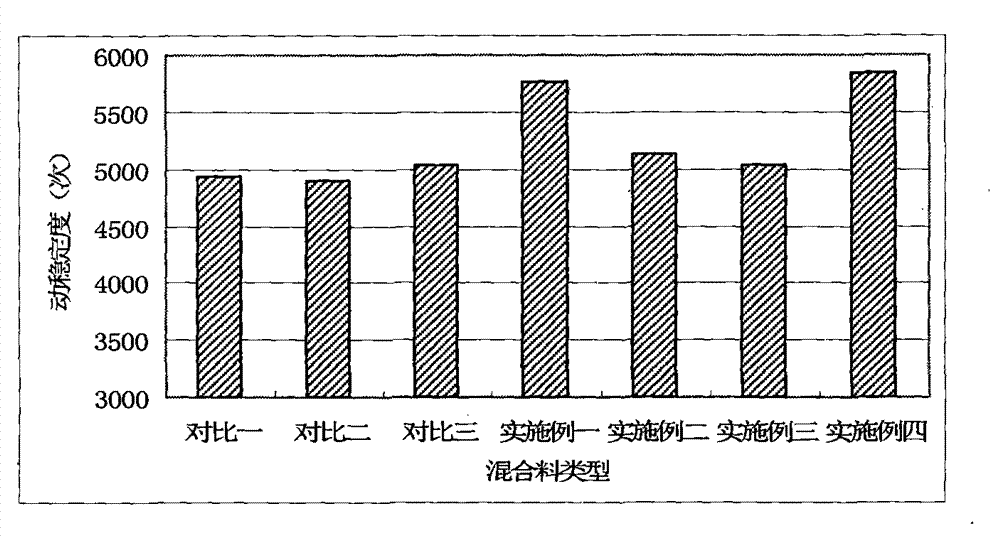

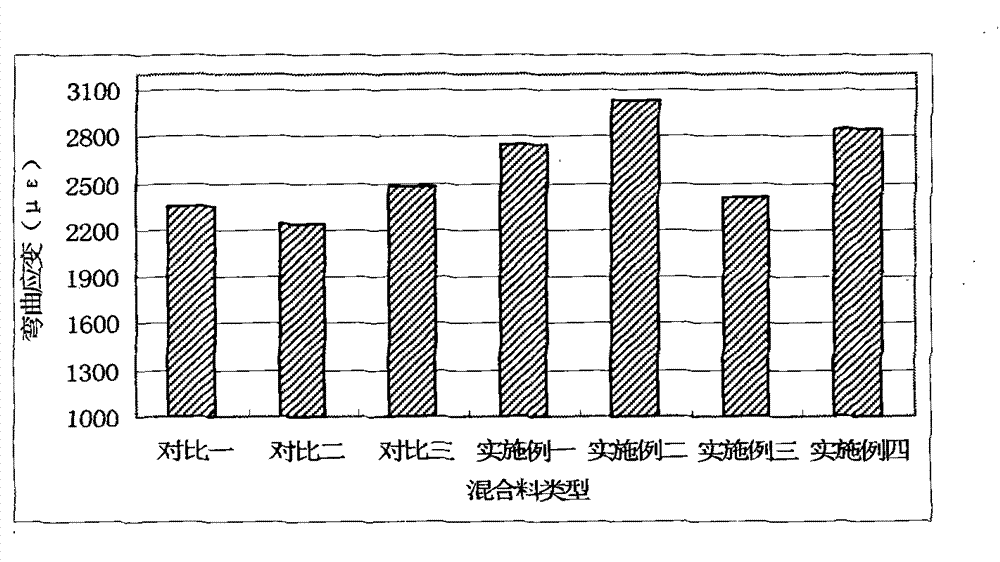

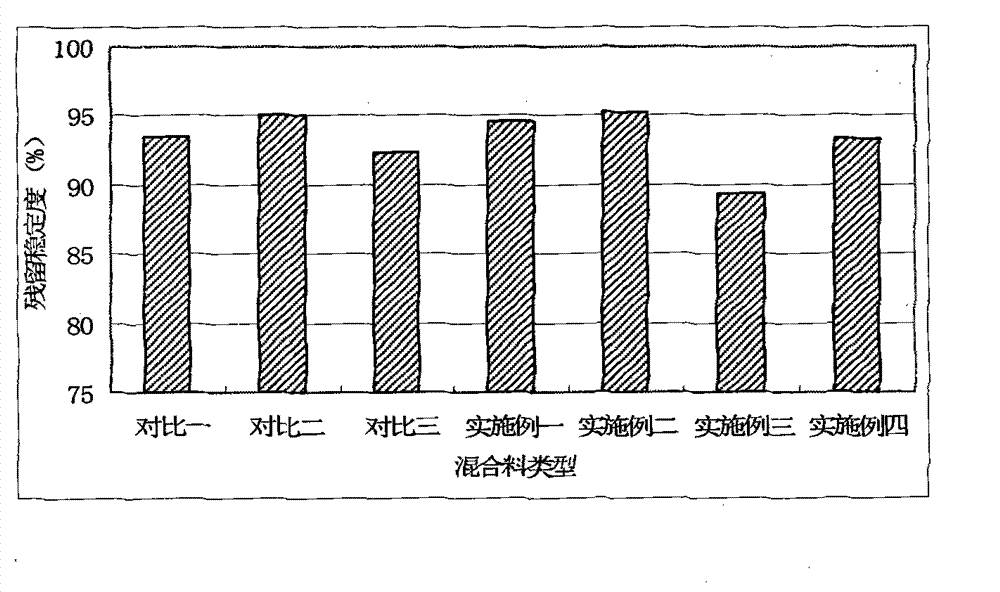

Rubber modified asphalt mixture and preparation and construction methods thereof

The invention relates to a modified asphalt mixture and preparation and construction methods thereof, particularly relates to rubber modified asphalt and preparation and construction methods thereof and belongs to the technical field of engineering. The rubber modified asphalt and the methods solve the construction problem that the mixture is thick and sticky by adding trans-polyoctenamer rubber (TOR) into the asphalt mixture, further reduce the stirring temperature of the rubber asphalt mixture, reduce processing equipment, improve production process, and are favorable for preventing water damage by a design method of continuous dense gradation. The preparation process of the mixture improves the using performance of the rubber asphalt mixture. The rubber modified asphalt and the methodshave the advantages of promoting the comprehensive utilization of waste tires by paving asphalt pavements with waste rubber powder modified asphalt, reducing great environment stress brought by blackpollution, saving resources, improving the pavement performance of the asphalt mixture, improving the service quality of the pavement, prolonging the service life of the pavement, reducing cost, and improving performance of products. Compared with the conventional modified asphalt production process, the preparation and construction methods have the advantages of energy saving and environmental protection and are convenient for construction.

Owner:JIANGSU EASTTRANS INTELLIGENT CONTROL TECH GRP CO LTD

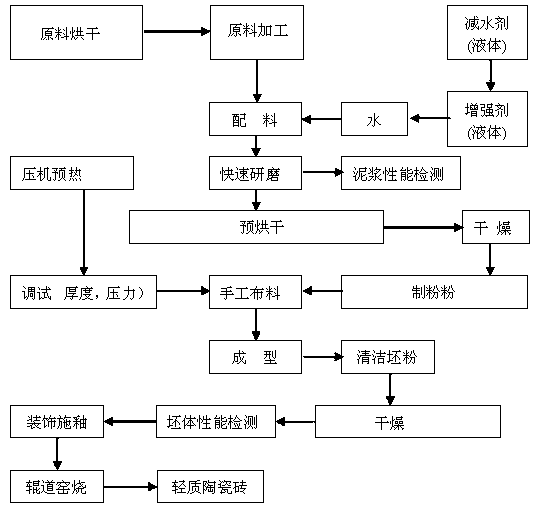

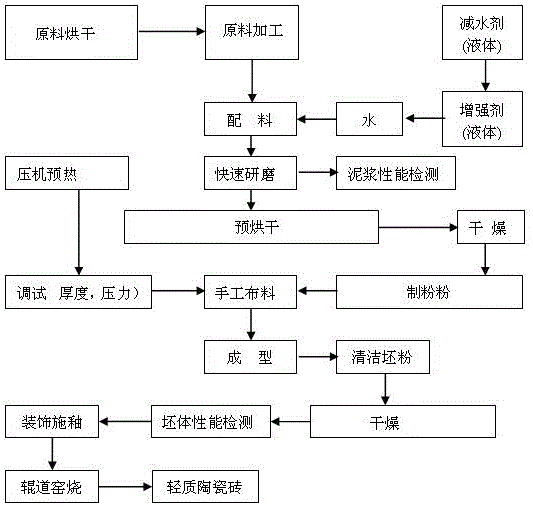

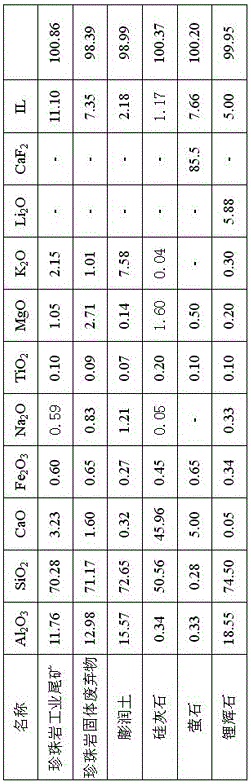

Glass-ceramic decoration face light ceramic composite brick and preparation method thereof

ActiveCN103993718APromote sustainable developmentWith heat insulation and sound insulation performanceCovering/liningsCeramic layered productsCeramic compositeBrick

The invention discloses a glass-ceramic decoration face light ceramic composite brick and a preparation method thereof. The glass-ceramic decoration face light ceramic composite brick comprises a heat-preserving base layer and a decorating wear-resisting layer arranged on the heat-preserving base layer. The heat-preserving base layer is a blind hole foaming ceramic layer, the thickness ranges from 4 mm to 60 mm, and the volume density ranges from 230 Kg / m<3> to 980 Kg / m <3>; the decorating wear-resisting layer is a glass-ceramic layer, the thickness ranges from 2 mm to 4 mm, and the volume density ranges from 2000 Kg / m<3> to 3000 Kg / m <3>; a bottom material of the heat-preserving base layer and a face material of the decorating wear-resisting layer are formed by secondary material distribution and one-time formation through a pressing machine and one-time firing through a roller kiln. The base layer of the composite brick has the heat-preserving, heat-insulating and sound-insulating performance, the decorating glass-ceramic layer has the wear-resisting property, the anti-skid property, shock resistance and the like, is excellent in decoration performance, and can be widely applied to heat-preserving decoration of external wall lower layers, indoor wall faces and indoor grounds, while existing heat-preserving materials and decoration materials do not have the properties and the application; solid waste generated by exploiting and processing perlite is adopted, the production process saves energy and is environmentally friendly, and sustainable development of perlite industries can be promoted.

Owner:安徽瑞蒙科技有限公司

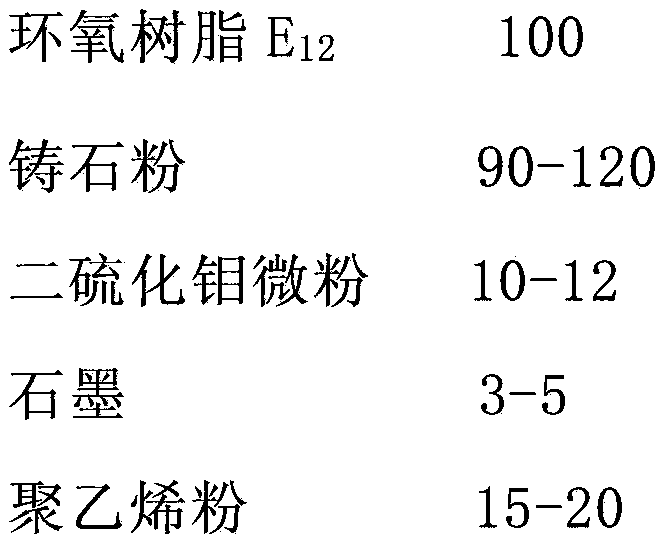

Production method of wear-resistant anti-corrosion inner-coating oil pipe

ActiveCN104069999AImprove bindingHigh tensile strengthAnti-corrosive paintsSpecial surfacesEpoxyFriction reduction

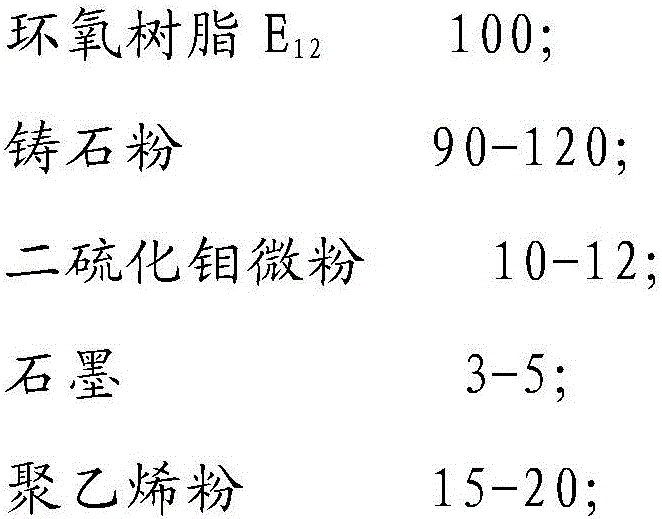

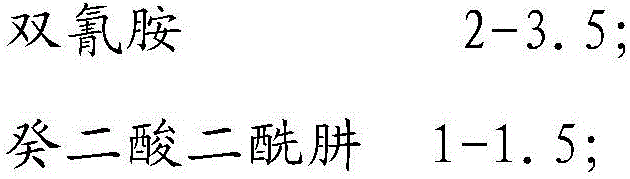

The invention relates to a production method of a wear-resistant anti-corrosion inner-coating oil pipe. The coating of the oil pipe comprises, by weight, 100 parts of epoxy resin E12, 90-120 parts of glass-ceramic powder, 3-5 parts of graphite; 10-12 parts of molybdenum disulfide micro powder, 15-20 parts of polyethylene powder, 2-3.5 parts of dicyandiamide and 1-1.5 parts of sebacic acid dihydrazide. The production method includes: deoiling and sand blasting, mixing, preheating, static spraying, curing, forming, polishing, inspecting, powder recycling and the like. By the method which is short in curing time, friction coefficient between a sucker rod and the inner wall of the oil pipe can be lowered evidently, friction reduction and abrasion resistance are achieved, the anti-corrosion performance of the inner wall of the oil pipe can be increased evidently, the inner diameter of the oil pipe is unchanged, pipe wall scaling and paraffin precipitation are restrained, and the oil pipe is good in high temperature resistance, long in service life, and the like.

Owner:PETROCHINA CO LTD

Fly ash composite admixture for concrete and preparation method of admixture

ActiveCN103435287ASolve storage problemsSolve problems such as land occupationSolid waste managementSlagBall mill

The invention relates to a fly ash composite admixture for concrete, and a preparation method of the admixture, and belongs to a building material for building, and a preparation method of the building material. The fly ash composite admixture and the preparation method mainly solve the technical problems that the existing mineral admixture is too large in slump, larger in chemical shrinkage and self-shrinkage, and high in use cost. The fly ash composite admixture for the concrete adopts the technical scheme that the fly ash composite admixture is prepared by taking 20-30wt% of slag, 4-15wt% of stone chips, 58-73wt% of fly ash and 1-4wt% of desulphurization gypsum as raw materials. The preparation method comprises the following steps that the fly ash is smashed into ultrafine fly ash by ultrafine smashing equipment; the slag, the stone chips and the desulphurization gypsum are mixed uniformly and ball-milled into powder; the ultrafine fly ash and the ball-milled powder are mixed and homogenized; and the fly ash composite admixture for the concrete is prepared.

Owner:SHUOZHOU JUGUANG BUILDING MATERIAL DEV CO LTD +1

Phenyl-containing MT type resin and preparation method thereof

ActiveCN102875810AImprove mechanical propertiesTroubleshooting Refractive Index MismatchesSilanesRoom temperature

The invention relates to phenyl-containing MT type resin and a preparation method thereof. The weight-average molecular weight of the phenyl-containing MT type resin is 800-8000. The preparation method of the phenyl-containing MT type resin includes the steps: (1) dissolving acid catalysts into solvent, increasing the temperature to 50-90 DEG C, dropwise adding a mixture of phenyl tri-alkoxy silane and monofunctional alkoxy silane and reacting for 3-8 hours; (2) decreasing the temperature of a reaction mixture to the room temperature, neutralizing the reaction mixture to neutrality, filtering and washing; and (3) removing the solvent so that the phenyl-containing MT type resin is obtained. The phenyl-containing MT type resin prepared by the method has the weight-average molecular weight of 800-8000 and can be applied to high-refraction liquid silicone rubber.

Owner:ZHONGHAO CHENGUANG RES INST OF CHEMICALINDUSTRY CO LTD

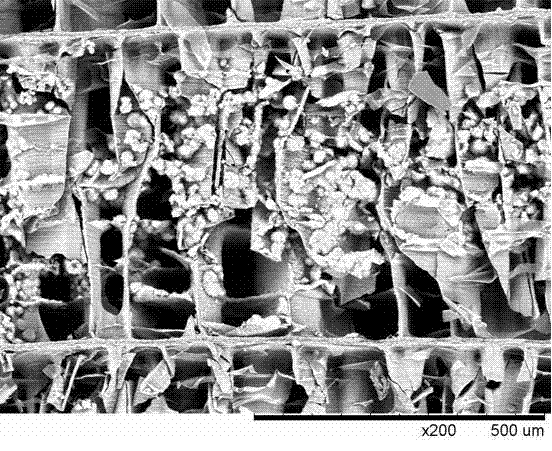

Cuttlebone transformation series porous composite bio-ceramic, its preparation method and application

The invention relates to the technical field of medical material production and aims to provide a cuttlebone transformation series porous composite bio-ceramic, which contains at least two organic components in human bone mineral. According to the ceramic, cuttlebone's exquisite three-dimensional intercommunicated mesh structure, effective mechanical structure--truss structure and crystal form of cuttlebone biological self assembly ceramic and connection of crystals are remained. The ceramic provided by the invention has high porosity and ideal aperture, and simultaneously has good mechanical strength and biocompatibility. As a precursor, a cuttlebone porous bone mineral scaffold is transformed to form the cuttlebone transformation series porous composite bio-ceramic by the addition of phosphoric acid in a first-stage wet process or by the addition of soluble phosphatic and phosphoric acid in a second-stage wet process. The cuttlebone transformation series porous composite bio-ceramic at least contains two components from the following human bone mineral components of: calcium carbonate, dihydrate calcium hydrogen phosphate, anhydrous calcium hydrogen phosphate, calcium dihydrogen phosphate, tricalcium phosphate, octacalcium phosphate, hydroxyapatite and carbonated hydroxyapatite.

Owner:李亚屏

Production equipment and production technology for healthy rice

ActiveCN101611846AIngenious designHigh in nutrientsSaving energy measuresFood preparationNutrient contentPower consumption

The invention relates to a production equipment and production technology for healthy rice. The production equipment comprises a steamer which can be loaded in a steaming box, a plurality of water tanks, a plurality of piers on which a steaming cabinet is placed, a conveyer belt being capable of conveying the steamer which can be drawn out from the steaming cabinet to a drying room to be processed and a rice mill; wherein unhulled rice after being washed and sieved is put into the steaming box of the steamer, the steamer loaded with the unhulled rice is sequentially placed into the water tanks for soaking the unhulled rice and the steaming cabinet for steaming the unhulled rice, the conveyer belt conveys the steamer after the unhulled rice is steamed to the drying room for drying, and the dried steamed unhulled rice becomes rice by milling of the rice mill. The production equipment of the invention has low power consumption, low equipment cost and high yield, can meet heavy demand of the people on the novel healthy rice, and can promote good health and a long life of human. The production equipment of the invention for healthy rice is smart in design, favourable in performance and is convenient and practical. The production technology of the invention is easy to operate, is energy saving and environmentally friendly, can strengthen self nutrient of the rice, can improve the nutrient content of the rice to the utmost extent, and especially can greatly improve content of vitamins B and E.

Owner:刘广胜

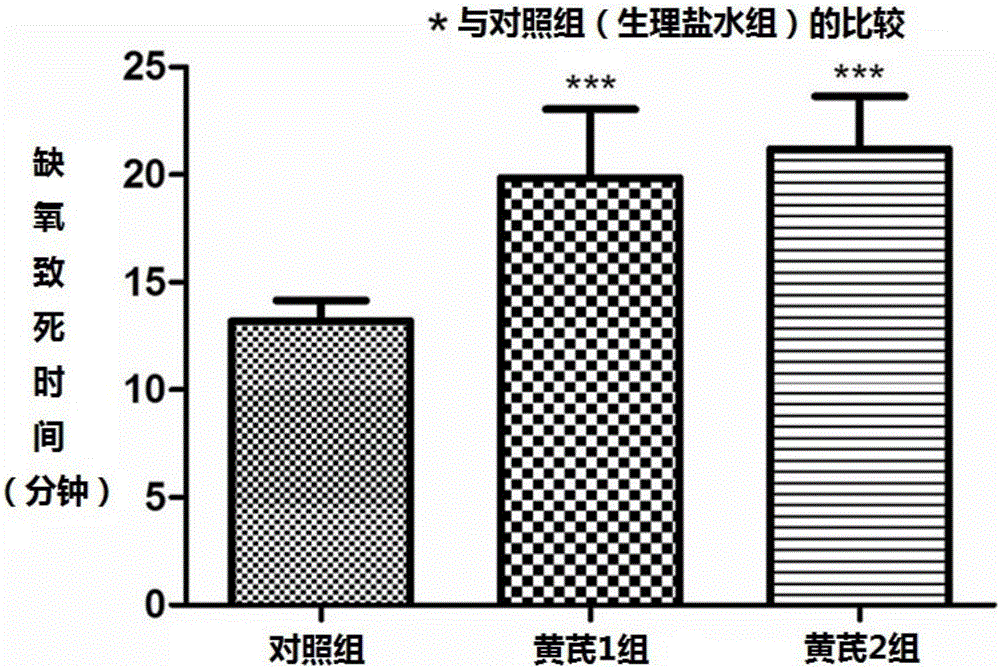

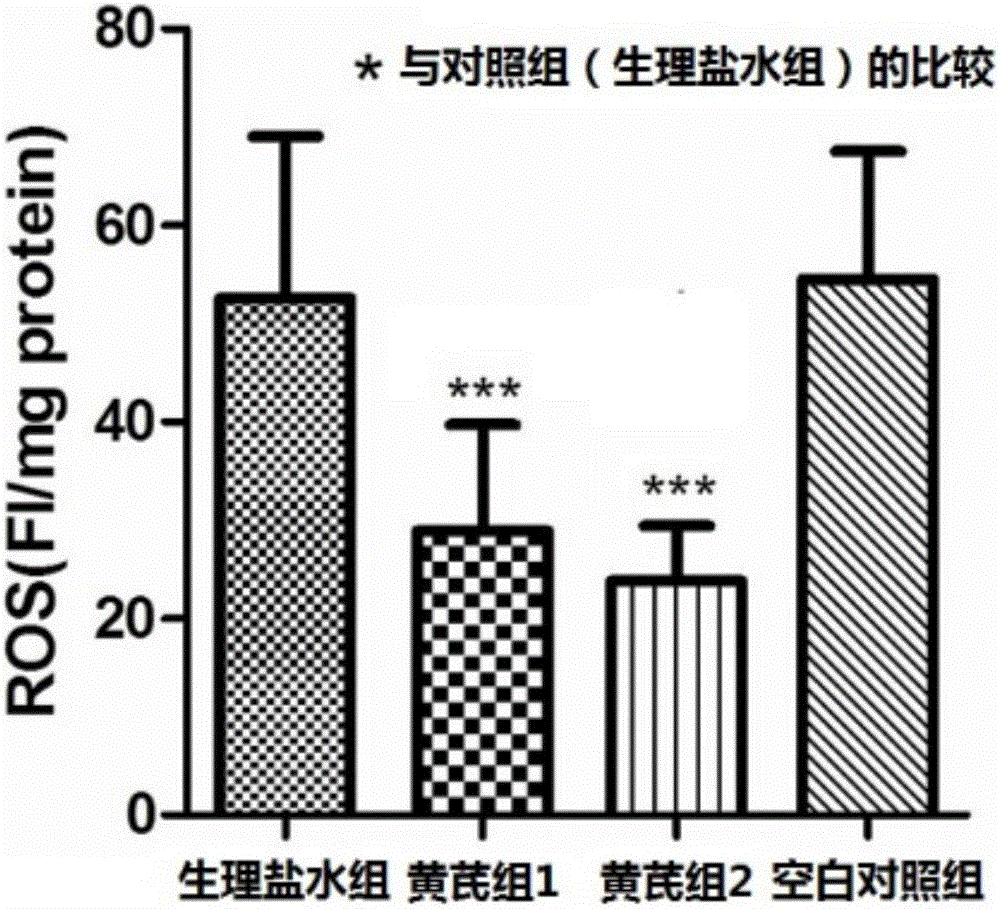

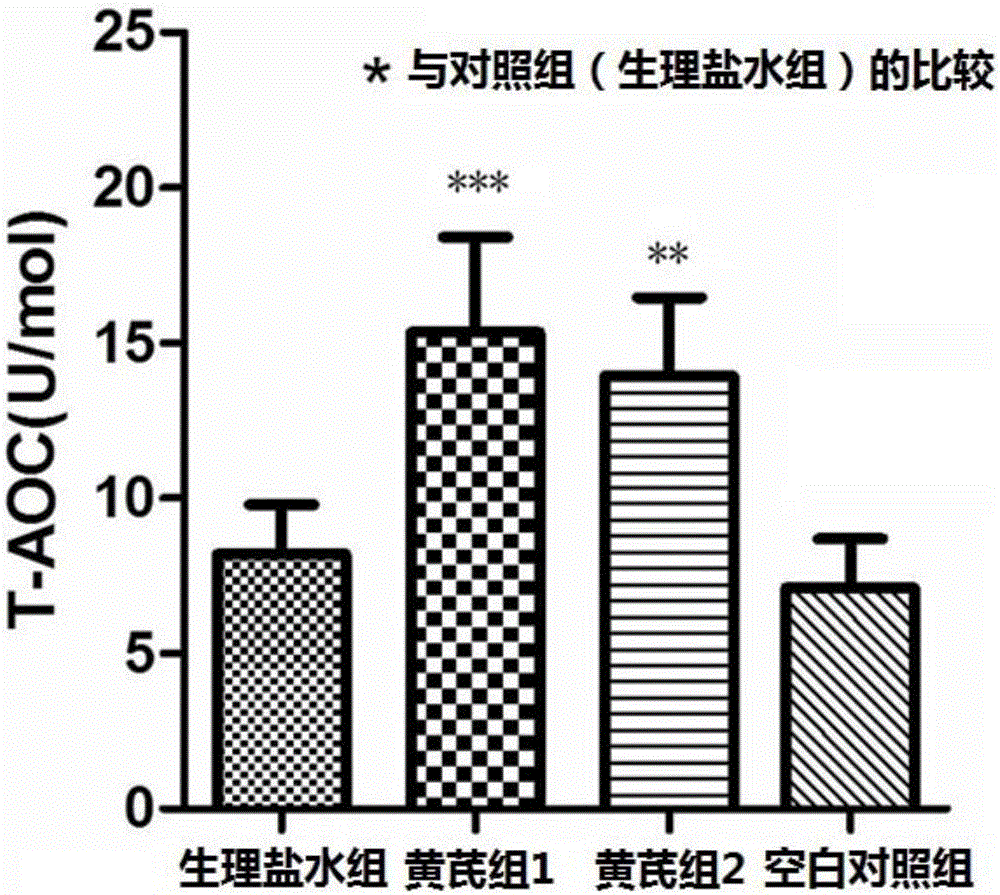

Functional astragaluspolysaccharide drink with functions of immunity enhancement and fatigue resistance and preparation technology of functional astragalus polysaccharide drink

InactiveCN105995354AHigh transparencyGreat tasteNatural extract food ingredientsFood ingredient functionsSuspended particlesAdditive ingredient

The invention relates to a functional astragalus polysaccharide drink with functions of immunity enhancement and fatigue resistance and a preparation technology of the functional astragalus polysaccharide drink. The preparation method comprises steps as follows: a dry astragalus root is cleaned, dried in air and then smashed into astragalus powder; purified water is added for reflux extraction; ethanol is used for polysaccharide precipitation, a precipitate is dried, purified water is added to dissolve the precipitate, and then a clarifying agent is added for standing and clarification; centrifugation is performed for obtaining supernatant, and the supernatant is a concentrated liquid of astragalus polysaccharide; the concentrated liquid of the astragalus polysaccharide is evenly mixed with drink additives and purified water, wherein the drink per kg contains 200-400 mg of the astragalus polysaccharide, 4.5-6 g of lysine, 1-1.5 g of inositol, 8-32 g of citric acid, 10-20 mg of nicotinamide, 260-390 mu g of folic acid, 1.4-2.1 mg of vitamin B6, 2.4-3.6 mu g of vitamin B12, 0.02-0.1 mg of lactic acid, 20-60 g of a sweetening agent and the balance of purified water. The functional astragalus polysaccharide drink tastes comfortable without medicine flavor, is golden yellow, has high transparency with no suspended particles or sediment, has health-care function and good effect and has a single characteristic ingredient.

Owner:GANSU HEBO LONG PHARMA TECH CO LTD

High density building member and manufacturing method thereof

The invention discloses a high density building member. The building member comprises the following raw materials in part by weight: 70 to 80 parts of base stock of more than 350 meshes, 10 to 20 parts of coarse aggregate of between 10 and 40 meshes, 10 to 20 parts of asphalt powder or cement, 7 to 10 parts of plant glue solution prepared by boiling corn and sticky rice with water, 1 to 2 parts of citric acid curing agent and the like. A method for manufacturing the high density building member comprises the following steps of: mixing coarse and fine base stocks; taking the boiled plant glue solution as a coagulant; and after a blank is formed under a high pressure, solidifying and shaping the building member by microwave heating. The base stock can be prepared by smashing industrial solid waste, building rubbish, tailings, weathered granite and the like by ball milling and screening the smashed product. Screened particles can be taken as the coarse aggregate. A process for manufacturing the building member is energy saving and environmental-friendly, and a product has the advantages of high density, high intensity, water resistance, freezing resistance, high temperature resistance and the like.

Owner:王发东

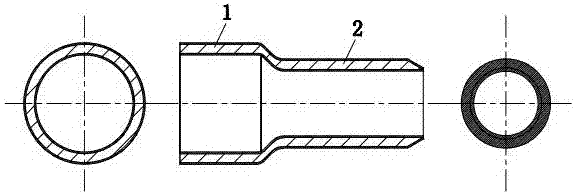

Production technology for connecting pipe of compressor

InactiveCN107009101ARealize environmentally friendly manufacturingImprove assembly stabilityEnvironmental resistancePunching

The invention relates to the technical field of connecting pipes of compressors, in particular to a production technology for a connecting pipe of a compressor. The production technology for the connecting pipe of the compressor includes the steps that firstly, material selecting is conducted; and secondly, continuous multistage punching stretching forming or pipe machining technology forming is adopted, wherein firstly continuous multistage punching stretching forming is adopted includes the first step of blanking, the second step of multistage stretching, the third step of trimming, the fourth step of punching and the fifth step of shaping, and secondly, pipe machining technology forming is adopted; thirdly, polishing cleaning is conducted; and fourthly, drying is conducted. The production technology for the connecting pipe of the compressor has the beneficial effects of environment friendliness and energy conservation, due to the fact that the end portion of a diffusionless pipe end portion is covered with a red copper plate layer, assembling stability and sealing performance of the connecting pipe of the compressor can be improved, deformation of pump body parts can be reduced, the production efficiency can be greatly improved, and the quality reject ratio is greatly reduced.

Owner:DONGGUAN JINRUI HARDWARE PROD

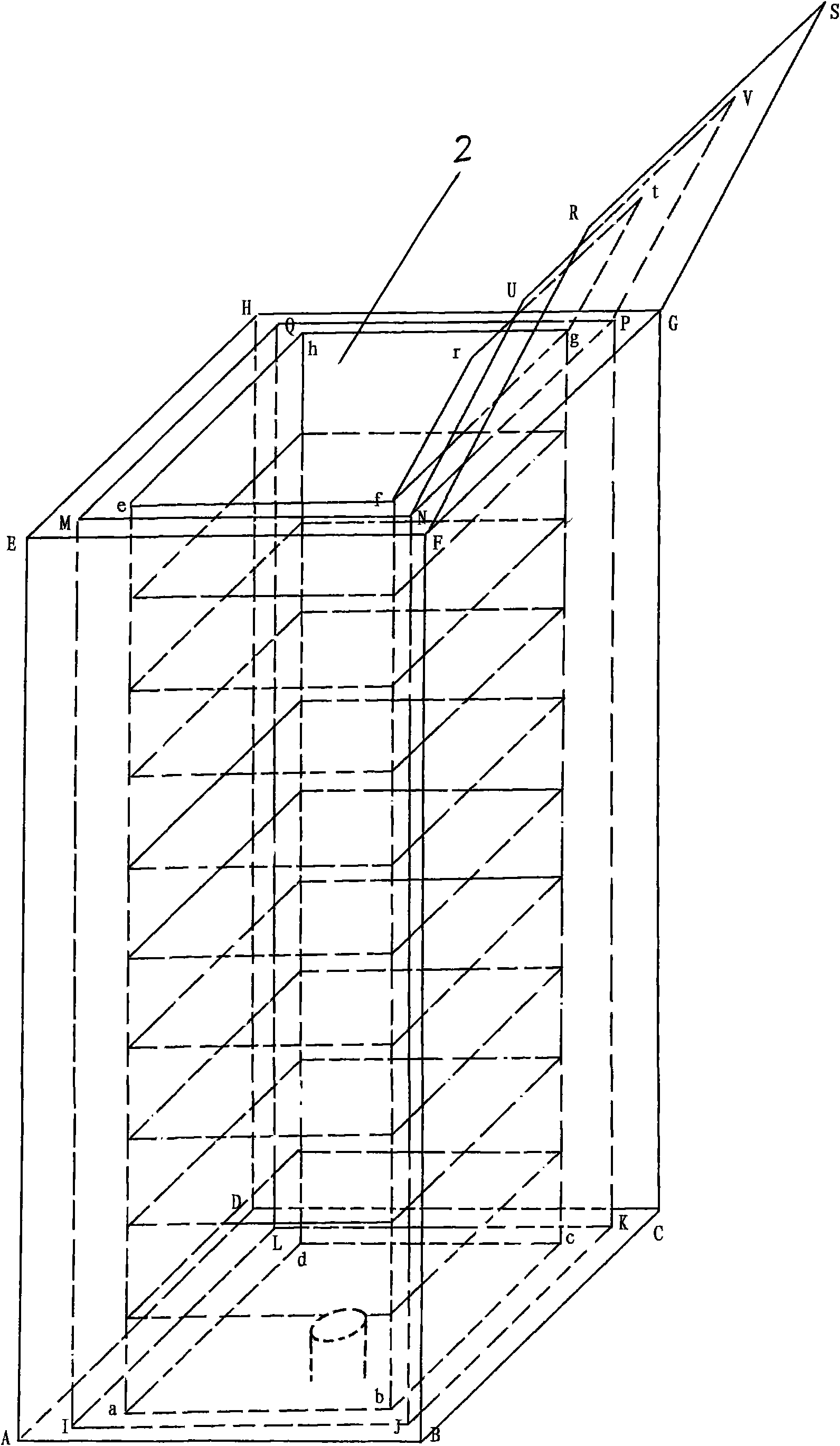

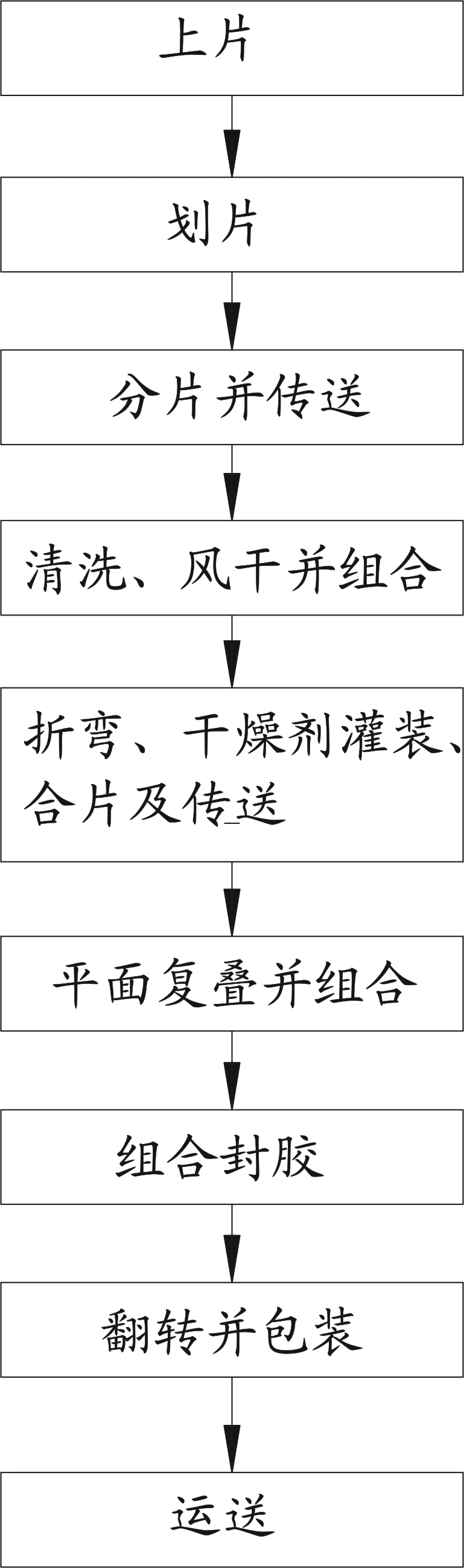

Process for producing hollow glass

The invention relates to the technical field of processing of glass, in particular to a process for producing hollow glass. The process for producing the hollow glass comprises the following steps of: loading, scribing, fragmenting and transmitting, cleaning and air-drying, bending and filling a drying agent, laminating and transmitting, performing plane overlying and combining, performing combined sealing, turning, packaging and transporting. The invention provides the low-carbon and environment-friendly process for producing the hollow glass, which is high in production efficiency and quality.

Owner:浙江潜能贸易有限公司

Anti-oxidation and anti-fatigue astragalus root functional drink and preparation process thereof

InactiveCN106107340AComfortable tasteNo smell of medicineNatural extract food ingredientsFood ingredient functionsSuspended particlesAdditive ingredient

The invention relates to an anti-oxidation and anti-fatigue astragalus root functional drink and a preparation process thereof. The preparation process comprises the following steps: cleaning and air-drying dry astragalus roots, and then grinding the dry astragalus roots into astragalus root powder; adding purified water for reflux extraction, and then adding a clarifying agent for standing and clarifying; centrifuging supernatant liquid to obtain an astragalus root extracting solution; and uniformly mixing the astragalus root extracting solution with drink additives and purified water. Each 1kg of the drink contains 20-50mg of total saponins of astragalus roots, 4.5-6g of lysine, 1-1.5g of inositol, 10-40mg of citric acid, 10-20mg of nicotinamide, 260-390mu g of folic acid, 1.4-2.1mg of vitamin B6, 2.4-3.6mu g of vitamin B12, 0.02-0.07mg of lactic acid, 20-60g of a sweetening agent and the balance of purified water. The prepared astragalus root functional drink has comfortable taste, is free of medicine smell, has an amber color and high transparency, is free of suspended particles or precipitates, has health-care functions and good effects, and contains a single symbolic ingredient.

Owner:GANSU HEBO LONG PHARMA TECH CO LTD

A glass-ceramic facing lightweight ceramic composite brick and its preparation method

ActiveCN103993718BPromote sustainable developmentWith heat insulation and sound insulation performanceCovering/liningsCeramic layered productsBrickCeramic composite

Owner:安徽瑞蒙科技有限公司

Process for producing rock/slag wool products by using iron-making blast furnace hot slag and electric-arc furnace

InactiveCN110540360AMelting fastMeet quality requirementsGlass making apparatusElectric arc furnaceSlag

The invention provides a process for producing rock / slag wool products by using iron-making blast furnace hot slag and an electric-arc furnace. The process comprises the following steps of: adding quartz sand tailings during slag receiving of a slag ladle, and partially melting quartz sand by using impact force in slag tapping and heat of blast furnace slag; conveying fly ash into electric furnaceslag by using a gas injection method, and carrying out rapid melting; adding quartz sand and a small amount of a magnesium hardening and tempering material; increasing the current of the electric arcfurnace, and carrying out stirring by using high-current and nitrogen stirring so as to allow the hardening and tempering material to be fully melted and homogenized; pouring slag in the slag ladle into the electric arc furnace, and allowing the slag just poured into the electric arc furnace and the slag provided in the furnace body to be fully molten through nitrogen stirring; and increasing thecurrent and carrying out stirring through a current loop generated by the current of the electric arc furnace so as to realize further homogenization of the slag. The process provides a new way for utilizing the blast furnace slag, increases the additional value of the utilization of blast furnace slag, and realizes high-additional-value utilization of fly ash.

Owner:潍坊奥华环保新材料科技有限公司

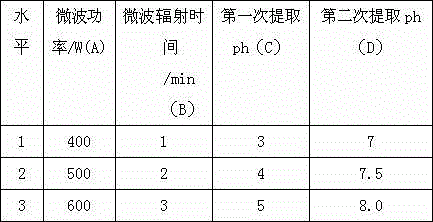

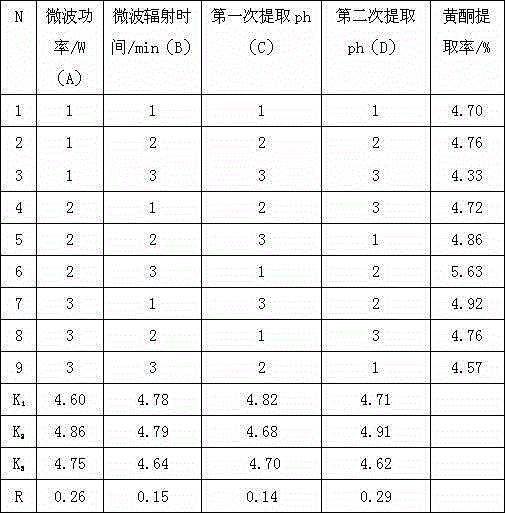

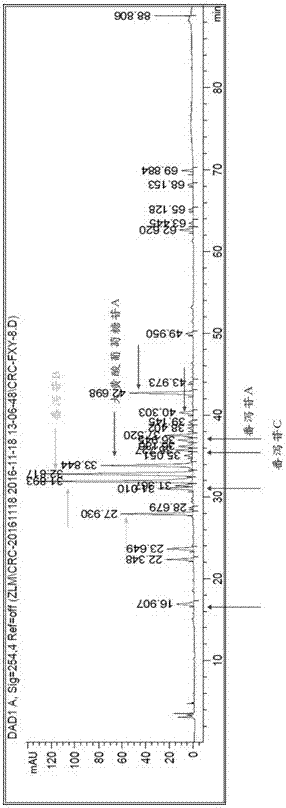

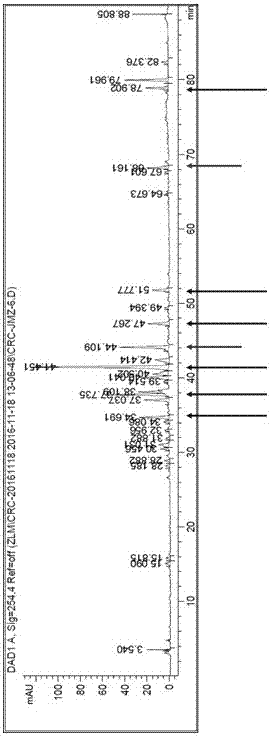

Technology for extracting flavone of peanut shells

ActiveCN103875909BHigh extraction rateLow costAnimal feeding stuffMicrowave methodProcess engineering

Owner:山东金胜粮油食品有限公司

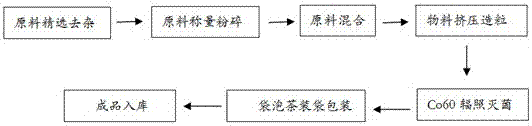

Pure herbal weight losing tea bag health-care food and preparation method thereof

InactiveCN107136245AAll-around mild flavorCompatibility is reasonablePre-extraction tea treatmentMetabolism disorderMedicineFood technology

The present invention discloses pure herbal weight losing tea bag health-care food and a preparation method thereof, and relates to the technical field of health-care food. The health-care food is prepared from the following Chinese herbal medicines in parts by weight: 20-50 parts of folium sennae, 10-40 parts of green tea, 10-30 parts of cassia seeds, 10-20 parts of lotus leaves and 10-20 parts of rhizoma alismatis. The 5 herbal raw materials are directly crushed, the crushed raw materials are mixed evenly according to a certain ratio, the mixed medicinal materials are subjected to a ring die extrusion and granulation, and the granulated raw materials are sub-packaged into 2.0 g-5.0 g / bag using a teabag machine. The technology all uses physical methods, does not add any technological accessory materials, and is free of waste water, waste gas and waste residue pollutions. The health-care food is simple, convenient and highly efficient, and energy saving and environmentally friendly.

Owner:BEIJING AOTE SHUER HEALTH PROD DEV

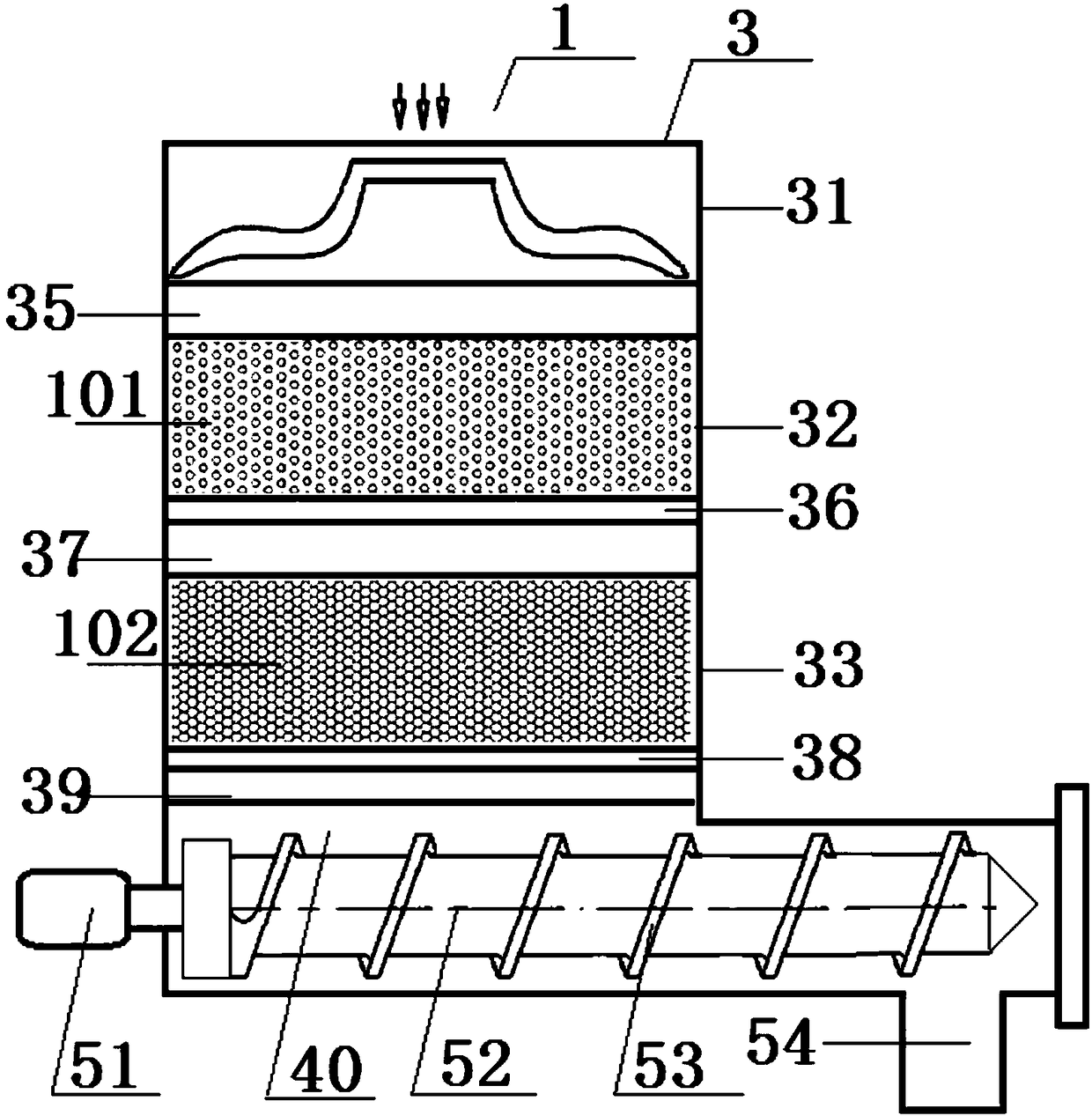

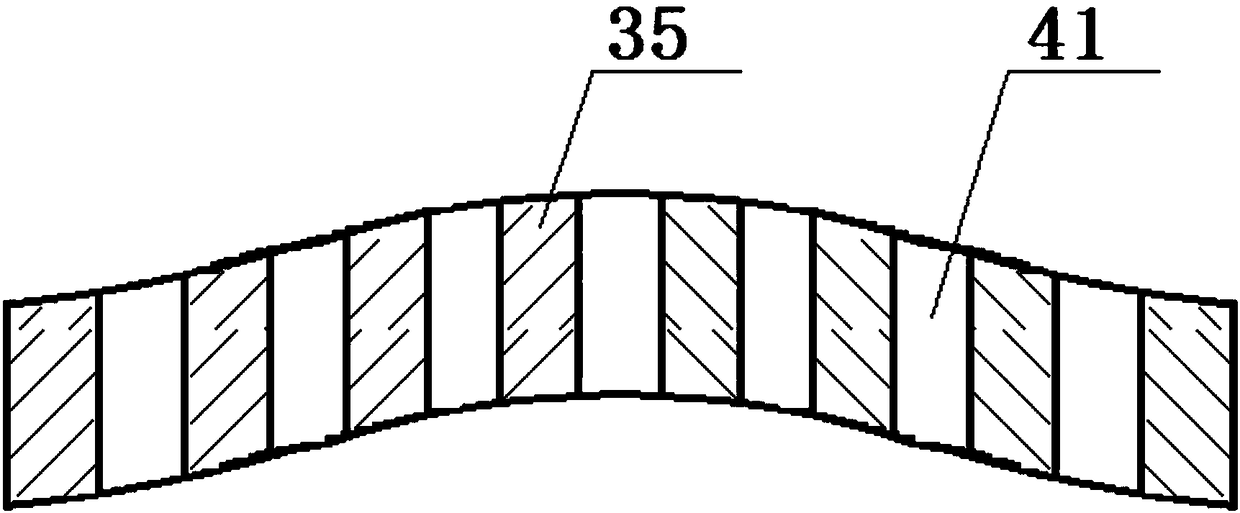

Filtering and regeneration system for waste non-woven fabric

ActiveCN108315826ARealize recyclingBeneficial effects achieved: the present invention can realize regeneration and recyclingSpinning solution de-aeratingFilament forming substance formingDrive motorWaste management

The invention relates to a filtering and regeneration system for a waste non-woven fabric. The system comprises a filtering assembly and a material conveying assembly. The filtering assembly comprisesa housing, a top cover is arranged on the housing, a primary filtering segment and a fine filtering segment are arranged in an inner cavity of the housing in sequence, a conical panel with first communication holes is disposed between the top cover and the primary filtering segment, a clapboard is disposed between the primary filtering segment and the fine filtering segment and made by stacking apartition net and a corrugated partition plate from top to bottom, second communication holes are formed in the corrugated partition plate, and partition net holes are formed in the partition net. Asealing baseplate made by stacking a baseplate body and a bottom net with third communication holes is arranged at the bottom, and the third communication holes are formed by connecting conical guideholes with through holes. The material conveying assembly includes a material conveying bin, a material conveying screw rod and a driving motor. An upper end opening of the material conveying bin is connected to a lower end opening of the housing, the bottom of the material conveying bin is provided with a discharge opening, an inner cavity of the material conveying bin is provided with the horizontally placed material conveying screw rod, and one end of the material conveying screw rod is connected with the driving motor.

Owner:LIMING VOCATIONAL UNIV

Production and preparation method of 2-methyl-4-isopropylaniline

InactiveCN112694407AReduce pollutionProduction process energy saving and environmental protectionOrganic compound preparationAmino compound preparationIsopropylNitration

The invention discloses a production and preparation method of 2-methyl-4-isopropylaniline. The method comprises the following steps: using isopropyl benzene as a starting raw material, carrying out homogeneous nitrification in a concentrated sulfuric acid medium to obtain a nitroisopropyl benzene mixture; and reducing and separating the reaction mixture by iron powder to obtain p-isopropylaniline with the content of more than or equal to 97%. The nitration yield of the reaction is 72.4%, and the reduction yield is 92.3%; the separation yield is 93.6%, and the total yield is 62.6%. Compared with the prior art, the method has the beneficial effects that the novel production process is energy-saving, environment-friendly, small in environmental pollution and suitable for large-scale production.

Owner:HUAIAN SHUANGYANG CHEM

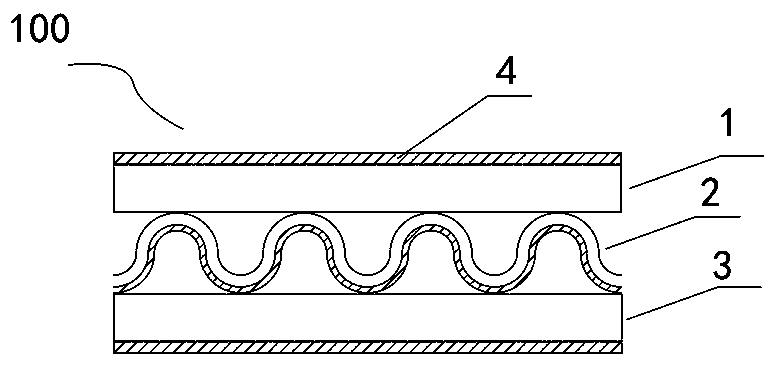

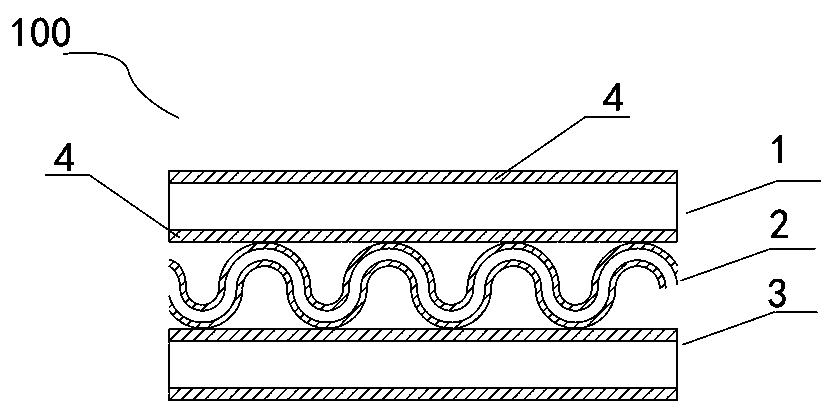

Energy-saving and environment-friendly corrugated paperboard production technology

ActiveCN110978643AHigh strengthProduction process energy saving and environmental protectionMechanical working/deformationSpecial paperFiberCellulose

The invention discloses an energy-saving and environment-friendly corrugated paperboard production technology. The technology includes the following steps of S1, paint preparation, S2, raw paper mounting, S3, paint spraying, S4, raw paper preheating, S5, core paper forming, S6, gluing and compounding, S7, drying and shaping, and S8, forming. According to the technology, reinforcing coatings are sprayed on the surface of surface paper, the surface of core paper and the surface of inner paper respectively, and then gluing and compounding are carried out to obtain a corrugated paperboard. Under the combined action of active ingredient cationic starch and nanocrystalline cellulose of the reinforcing coatings, the strength of the obtained corrugated paperboard is higher than that of corrugatedpaperboard which has the same gram weight and is not processed with the reinforcing coatings, and therefore the mechanical strength of the raw paper large in recycled fiber amount is well improved. The consumption of recycled fiber is increased, the consumption of new fiber materials is reduced, meanwhile, paint in use is water-based paint, components come from renewable plant raw materials, and therefore the production technology of the corrugated paperboard saves more energy and is more environmentally friendly.

Owner:厦门世凯威包装工业有限公司

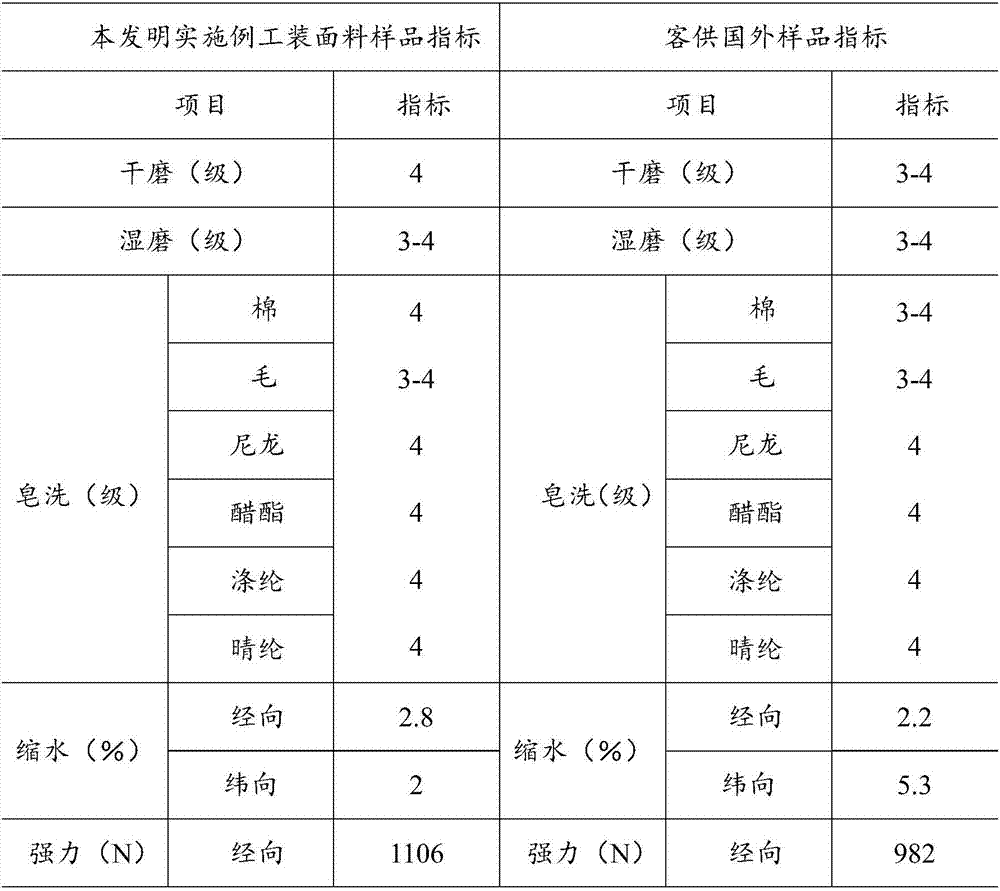

Workwear fabric and production technology thereof

InactiveCN107447398AProduction process energy saving and environmental protectionRealize continuous mass productionSingeingHeating/cooling textile fabricsAfter treatmentEngineering

The invention discloses a workwear fabric and a production technology thereof, and relates to the field of textiles. According to the production technology, by selecting proper pretreatment desizing, bleaching, singeing, sizing and mercerizing technologies, the process saves more energy and is more environmentally friendly, and elastic loss of spandex is decreased. By selecting proper dyes and auxiliaries and controlling technological conditions, dye uptake is high, and elastic loss of the spandex is low. By the aid of after-treatment procedures, the final workwear fabric can achieve both hand feeling and pilling resistance. Therefore, the workwear fabric and the production technology thereof have the advantage of production continuity, the energy is saved, environments are protected, and the produced environment-friendly workwear fabric is balanced and excellent in various performances, presents strong market competitiveness and has a wide market prospect.

Owner:四川川棉印染有限公司

Manufacturing method of low sizing amount environment-friendly plywood

ActiveCN105818225BImprove qualityReduce manufacturing costElectric wood treatmentWood treatment detailsFiberAdhesive

The invention relates to a method for manufacturing an environmentally friendly plywood with low sizing amount, and belongs to the technical field of wood-based panel manufacturing. The process is to cut wood sections into 1-3mm wooden veneers, dry them to adjust the moisture content to 2-15%, and carry out atmospheric pressure and low-temperature plasma modification treatment on both sides of the veneers. Through the synergistic effect of ultrasound and cyclone, the The adhesive is atomized into particles with a diameter of less than 40 μm and sprayed on the tight surface of the veneer. The amount of adhesive applied on one side is controlled at 10-80g / m2, and the fiber texture directions of adjacent layers of veneer are perpendicular to each other. Pressed to obtain low-sizing environment-friendly plywood. The performance of the product prepared by this method meets the requirements of the national standard for plywood, the amount of formaldehyde released reaches the requirements of E0 level, and the amount of adhesive is reduced by 30-70% compared with the amount of the traditional glue coating method, the product quality is significantly improved, and the production cost is significantly reduced. In addition, the production process of this method is energy-saving and environmentally friendly, and the production equipment is easy to operate, high in efficiency, good in controllability, and can be continuously automated.

Owner:NANJING FORESTRY UNIV

Production process of feed-grade liquid-state natural lutein product

PendingCN109965105AProduction process energy saving and environmental protectionSimple and safe operationAccessory food factorsWorking-up animal fodderColor effectLutein

The invention relates to a production process of a feed-grade liquid-state natural lutein product. The production process includes specific production steps: preparing natural lutein extract saponification liquid and emulsification powder, adding the emulsification powder into the natural lutein extraction saponification liquid, and stirring. The product is safe, healthy, long in emulsification stable quality guarantee period, low and economical in production cost, convenient and flexible to use and operate and outstanding and efficient in coloring effect, and the production process is energy-saving and environment-friendly.

Owner:广州品悦生物科技有限公司

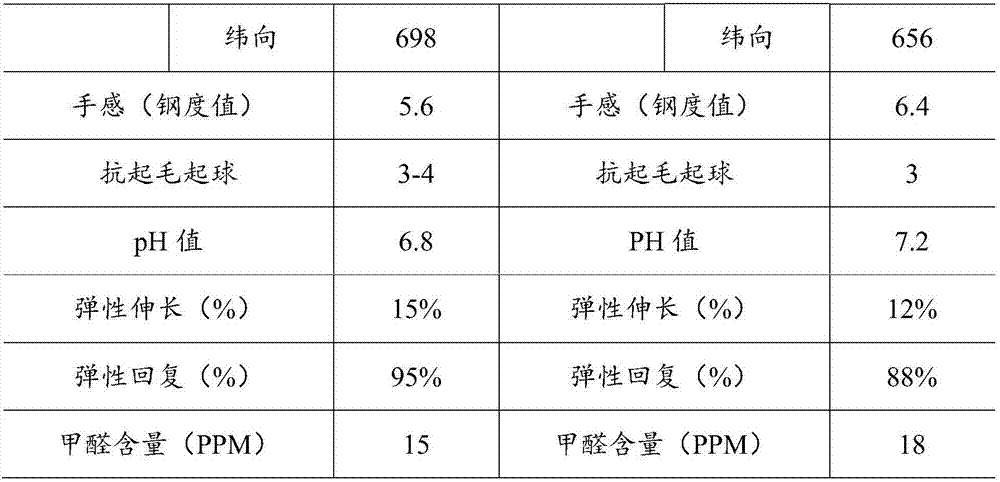

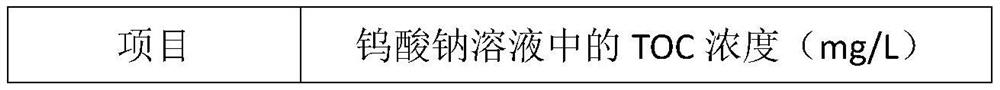

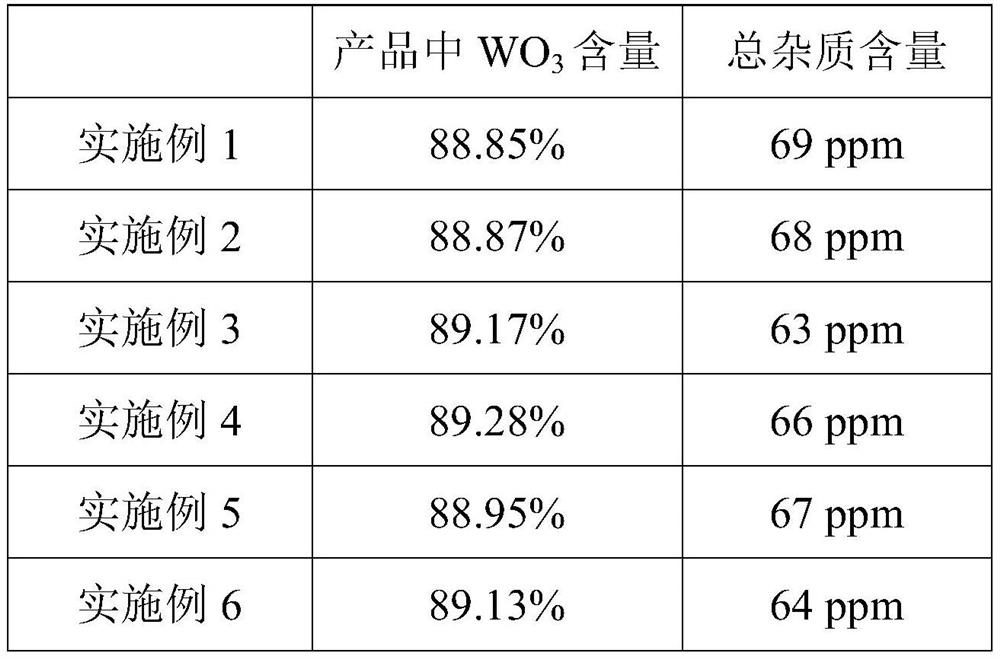

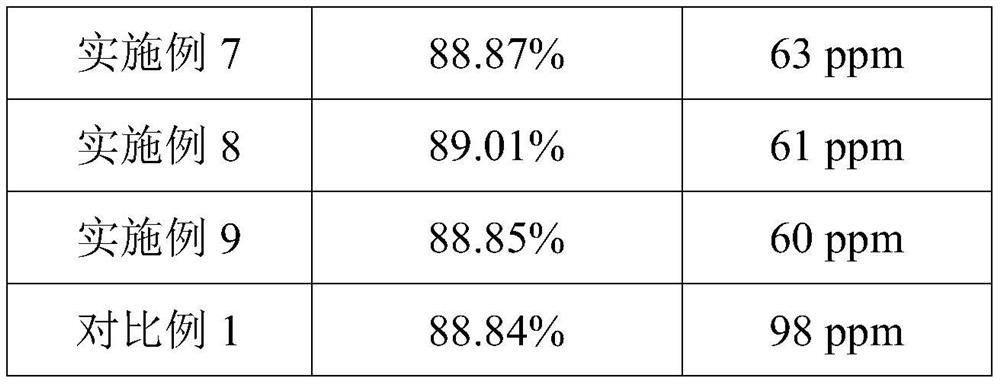

Oxygen-enriched decomposition process of tungsten raw material

PendingCN113060765AImprove qualityProduction process energy saving and environmental protectionTungsten compounds preparationAmmonium paratungstateWash water

The invention discloses an oxygen-enriched decomposition process of a tungsten raw material, and relates to the technical field of ammonium paratungstate .The oxygen-enriched decomposition process comprises the following steps: S1, mixing a flotation type tungsten raw material, a leaching agent, water and / or washing water to obtain leaching slurry; and S2, introducing oxygen-enriched gas into the leaching slurry, wherein the oxygen-enriched gas and the leaching slurry react, and after the reaction is finished, obtaining mixed slurry of a sodium tungstate solution and leaching residues, wherein the oxygen-enriched gas is gas with the oxygen volume percent content being greater than 20.9%. The method has the beneficial effects that the oxygen-enriched gas is added in the leaching process, so that the surfactant in the raw materials can be effectively removed in the leaching process, the influence of the surfactant on the production process is overcome, the production process is energy-saving and environment-friendly, the economic benefit is good, industrialization is extremely easy to realize, and the quality of ammonium paratungstate can be improved.

Owner:江钨世泰科钨品有限公司

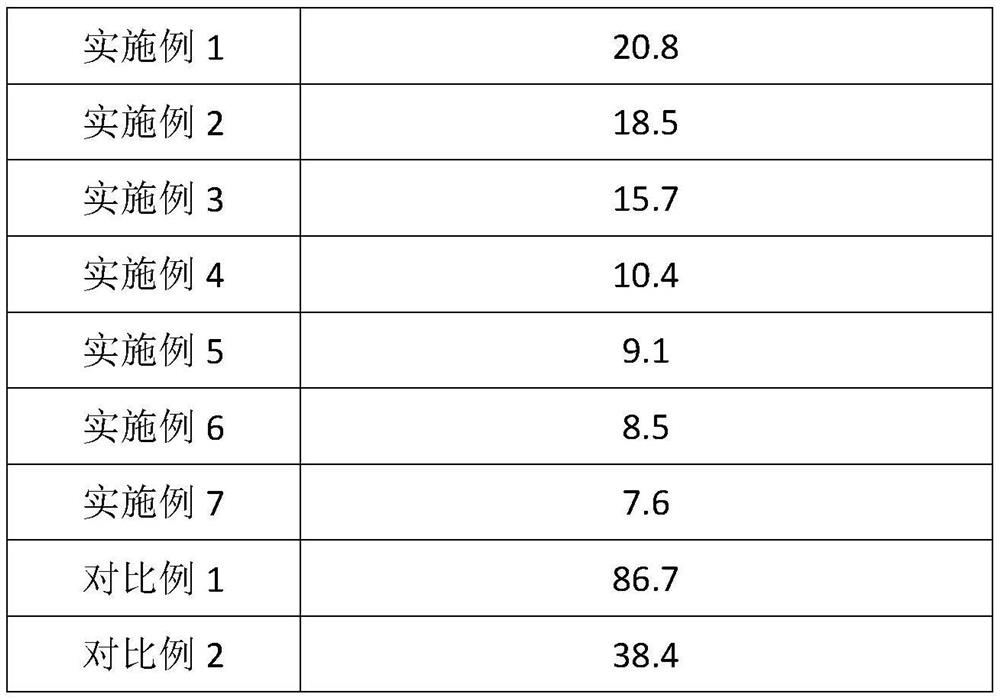

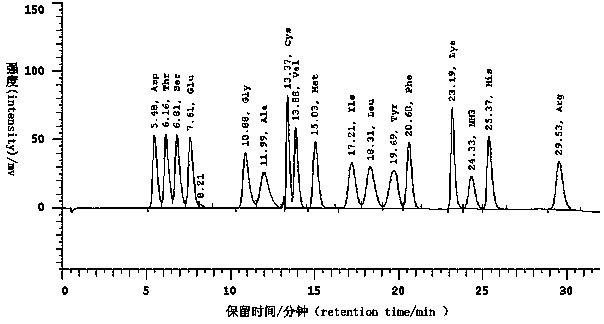

Method for preparing amino acid liquid fertilizer by hydrolyzing animal proteins with multiple acids and application of amino acid liquid fertilizer

ActiveCN103058749BEmission reductionReduce manufacturing costFertilizer mixturesPhosphoric acidPollution

The invention discloses a method for preparing an amino acid liquid fertilizer by hydrolyzing animal proteins with multiple acids and application of the amino acid liquid fertilizer. The method comprises the following steps: by using waste animal proteins (hair, skin, horns and the like) as raw materials, sequentially adding hydrochloric acid, phosphoric acid and sulfuric acid solutions with proper mass percentage into the animal proteins according to proper mass ratio; and after hydrolyzing the animal proteins, adding cheap alkaline matters (ammonia water, lime and magnesium oxide) for neutralization, filtering the neutralized acidolysis solution, and concentrating to obtain the amino acid liquid fertilizer. The liquid fertilizer contains 17 amino acids, and has high contents of N, P, Ca and Mg. The fertilizer efficiency test indicates that when being applied onto foliage, the amino acid liquid fertilizer can obviously increase the yield of pakchoi and obviously enhance the quality of vegetables, thereby having good economic benefits. The invention has the advantages of simple preparation technique and low production cost, is easy to implement, and is a high-quality fertilizer for producing no-pollution agricultural products.

Owner:湖南杜高生物科技有限公司

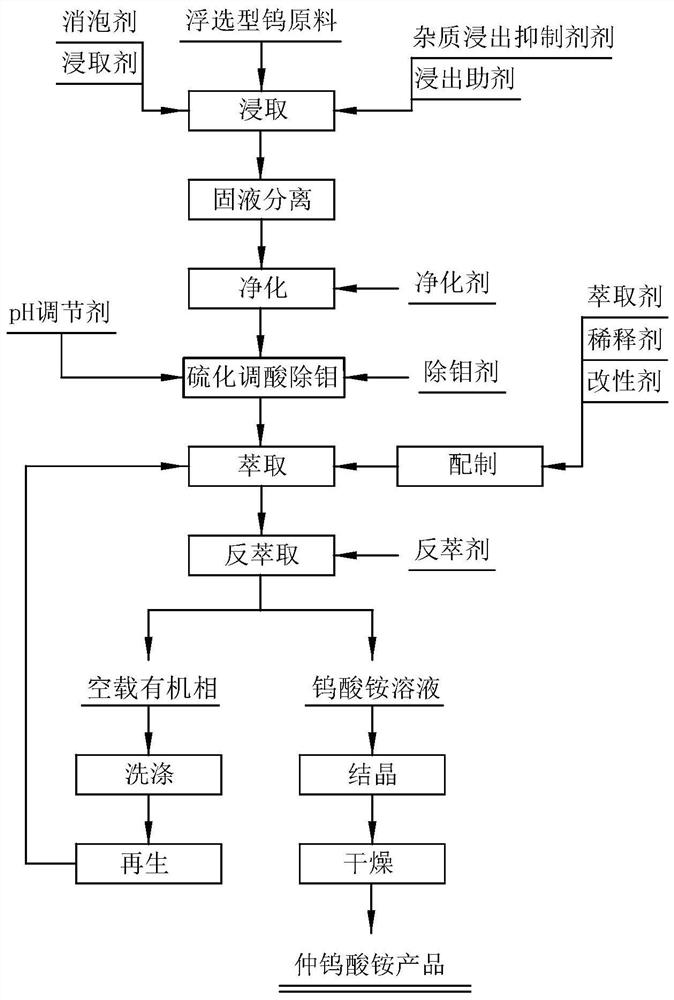

Flotation type tungsten raw material extraction all-wet-process smelting process

PendingCN113073212AShorten delivery timeImprove purification effectProcess efficiency improvementFoam dispersion/preventionChemical industryAmmonium paratungstate

The invention relates to the technical field of metallurgical chemical industry, and provides a flotation type tungsten raw material extraction all-wet-process smelting process. The process comprises the steps of leaching, solid-liquid separation, purification, sulfuration, acid regulation and molybdenum removal, extraction, reextraction and crystallization to produce an ammonium paratungstate product, wherein the leaching process comprises the following steps of uniformly mixing the flotation type tungsten raw material with a leaching agent, water and / or washing water and a defoaming agent in a leaching reactor, and leaching for 0.1-8 hours at the temperature of 100-250 DEG C to obtain mixed slurry of a sodium tungstate solution and leaching residues; and the defoaming agent comprises one or more of an organic silicon defoaming agent, castor oil, aldehydes, alcohols, ketones, kerosene and tertiary amine. The defoaming agent is added in the leaching process, so that the influence of a surfactant in the sodium tungstate solution on the production process can be effectively inhibited, the feed liquid conveying time is effectively shortened, a better solution purification effect is obtained, a high-quality ammonium paratungstate product is obtained, and production accidents can be reduced.

Owner:江钨世泰科钨品有限公司

Rubber modified asphalt mixture and preparation and construction methods thereof

ActiveCN101967048BSolve thick and sticky construction problemsImprove low temperature performanceRoads maintainenceWaste rubberRoad surface

The invention relates to a modified asphalt mixture and preparation and construction methods thereof, particularly relates to rubber modified asphalt and preparation and construction methods thereof and belongs to the technical field of engineering. The rubber modified asphalt and the methods solve the construction problem that the mixture is thick and sticky by adding trans-polyoctenamer rubber (TOR) into the asphalt mixture, further reduce the stirring temperature of the rubber asphalt mixture, reduce processing equipment, improve production process, and are favorable for preventing water damage by a design method of continuous dense gradation. The preparation process of the mixture improves the using performance of the rubber asphalt mixture. The rubber modified asphalt and the methods have the advantages of promoting the comprehensive utilization of waste tires by paving asphalt pavements with waste rubber powder modified asphalt, reducing great environment stress brought by black pollution, saving resources, improving the pavement performance of the asphalt mixture, improving the service quality of the pavement, prolonging the service life of the pavement, reducing cost, and improving performance of products. Compared with the conventional modified asphalt production process, the preparation and construction methods have the advantages of energy saving and environmental protection and are convenient for construction.

Owner:JIANGSU EASTTRANS INTELLIGENT CONTROL TECH GRP CO LTD

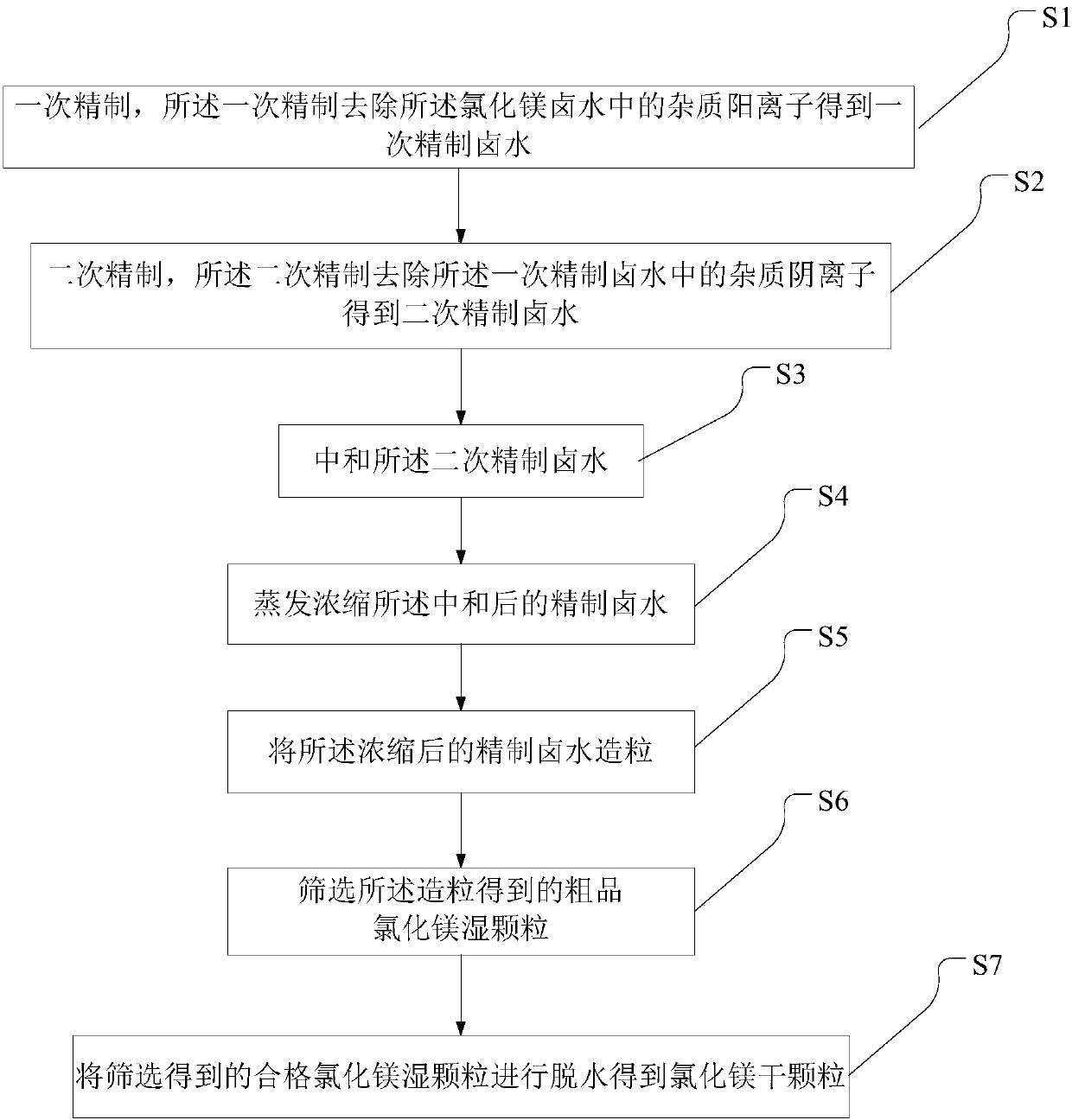

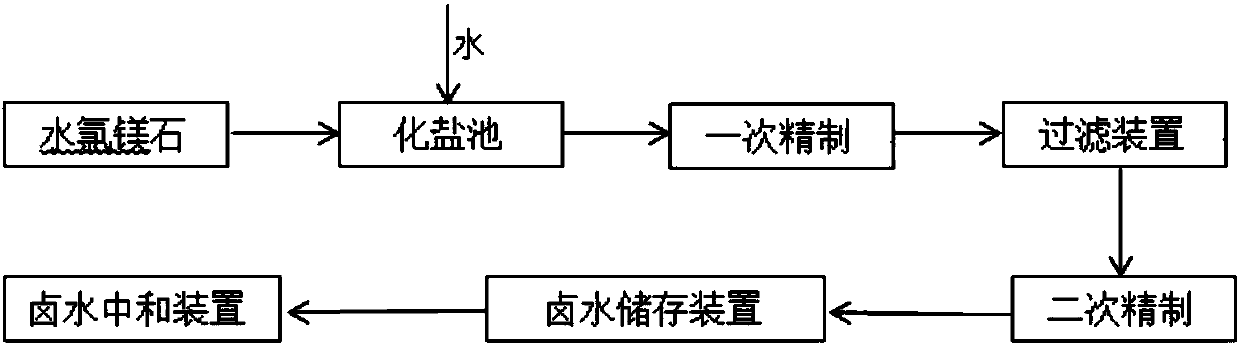

Method of using waste aged brine to prepare magnesium chloride particles

The invention discloses a method of using waste aged brine to prepare magnesium chloride particles. A tail liquid of the water aged brine after production of potassium fertilizer is used as a raw material for tedding in a salt field to precipitate bischofite. The method comprises the following steps of primary refining, wherein impurity cations in the magnesium chloride brine are removed to obtainprimary refined brine; secondary refining, wherein secondary refining is carried out to remove impurity anions in the primary refined brine to obtain secondary refined brine; neutralizing, wherein the secondary refined brine is neutralized; evaporating and concentrating, wherein the neutralized refined brine is evaporated and concentrated; granulating, wherein the concentrated refined brine is granulated; screening, wherein crude magnesium chloride wet particles obtained by granulation are screened; dewatering, wherein the qualified magnesium chloride wet particles obtained by screening are dewatered to obtain dry magnesium chloride particles. The method of using the waste aged brine to prepare the magnesium chloride particles is simple in process, energy-saving and environmentally friendly, the prepared magnesium chloride particles have good quality and high recoverability rate, and industrialized production can be easily achieved.

Owner:QINGHAI SALT LAKE IND

Manufacturing process of low volatile organic compound (VOC) polyurethane automobile instrument board

InactiveCN109535381AReduce volatilityImprove environmental performanceVegetable oilAutomobile market

The invention belongs to the technical field of high polymer materials, and particularly relates to a manufacturing process of a low volatile organic compound (VOC) polyurethane automobile instrumentboard. The polyurethane soft automobile instrument board is manufactured by taking a material A and a material B as raw materials, wherein the material A is composed of polyether polyol, vegetable oil, a tertiary amine catalyst, silicon oil, a chain extender and water, and the material B is composed of liquefied methylene diphenyl diisocyanate (MDI) and crude MDI. The low-volatile and reaction-type raw materials are selected for the polyurethane composition provided by the invention. The production method is simple, is easy to implement, and has the advantages of environmental friendliness, nopollution and the like. The content of volatile organic compounds of the prepared instrument board is reduced on the premise that other performance is not influence, and requirements of a medium-high-end automobile market on polyurethane low-VOC automobile instrument boards are met.

Owner:SHANGHAI INST OF TECH

A production method of wear-resistant and anti-corrosion inner coating oil pipe

ActiveCN104069999BImprove bindingHigh tensile strengthAnti-corrosive paintsSpecial surfacesEpoxyPresent method

The invention relates to a production method of a wear-resistant and anti-corrosion inner coating oil pipe; the coating formula is: epoxy resin E 12 100, cast stone powder 90‑120, graphite 3‑5, molybdenum disulfide powder 10‑12, polyethylene powder 15‑20, dicyandiamide 2‑3.5, sebacic acid dihydrazide 1‑1.5, the production process includes oil removal Sandblasting, mixing, preheating, electrostatic spraying, curing, forming, grinding and polishing, inspection and powder recovery are eight steps. This method can significantly reduce the friction coefficient between the sucker rod and the inner wall of the tubing, and has anti-friction and anti-wear properties. Double function, can significantly improve the corrosion resistance of the inner wall of the oil pipe, has the advantages of short curing time, no change in the inner diameter of the oil pipe, good high temperature resistance, inhibition of scaling and waxing on the pipe wall, and long service life.

Owner:PETROCHINA CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com