Oxygen-enriched decomposition process of tungsten raw material

A raw material and oxygen-enriched technology, applied in the field of metallurgy and chemical industry, can solve the problems of waste of resources, loss of tungsten mineral raw materials, and high energy consumption, and achieve the effects of energy saving and environmental protection in the production process, industrialization, and good economic benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

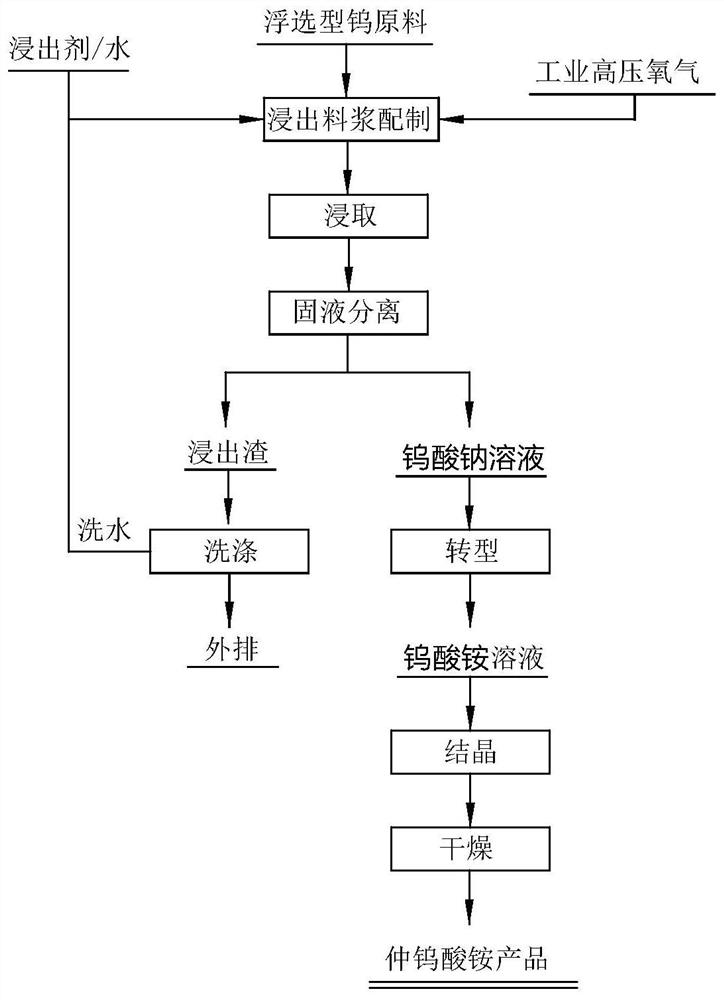

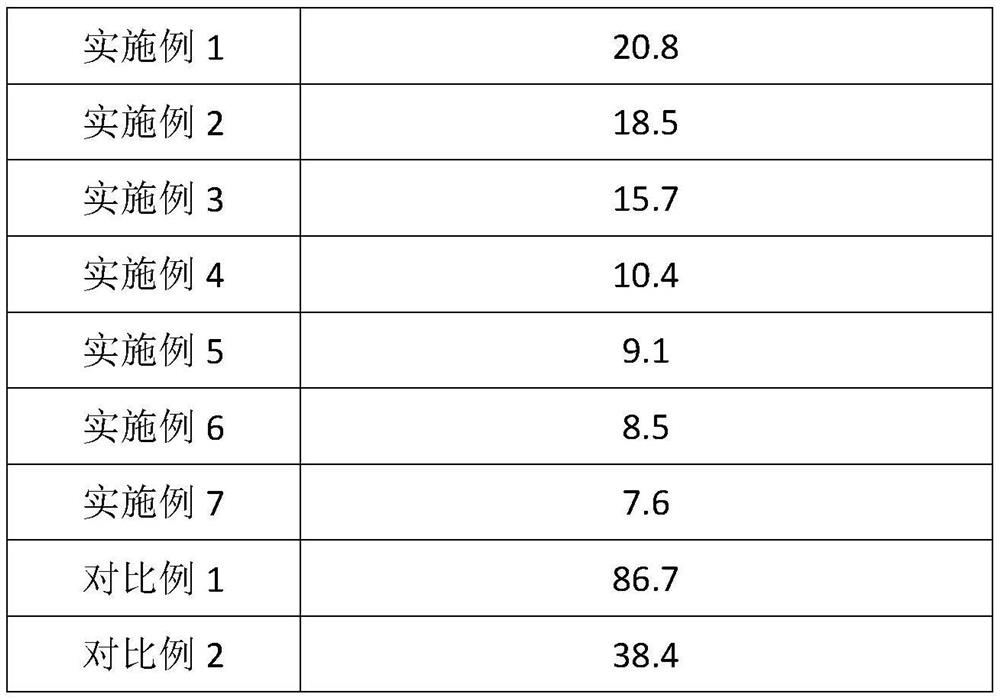

[0042] An oxygen-enriched decomposition process for tungsten raw materials, comprising the following steps:

[0043] S1. Preparation of leaching slurry: crush the scheelite ore by mechanical crushing until more than 98% of the mineral particle size is ≤45 μm, and add the crushed scheelite, leaching agent, and water into the leaching reactor at a mass ratio of 1:1:3 , mix uniformly to obtain leaching slurry; wherein, the ratio of the volume of the leaching slurry to the effective volume of the leaching reactor is 0.9; the leaching agent is sodium carbonate.

[0044] S2. Leaching: Pass oxygen-enriched gas into the leaching reactor until the pressure in the leaching reactor is 0.1Mpa; the oxygen-enriched gas is air with an oxygen volume percentage of 20.9%; at a reaction temperature of 100°C, the leached material The slurry and oxygen-enriched gas were reacted in the leaching reactor for 8 hours to obtain a mixed slurry of sodium tungstate solution and leaching residue.

[0045]...

Embodiment 2

[0053] An oxygen-enriched decomposition process for tungsten raw materials, comprising the following steps:

[0054] S1. Preparation of leaching slurry: crush the scheelite ore by mechanical crushing until more than 98% of the mineral particle size is ≤45 μm, and add the crushed scheelite, leaching agent, and water into the leaching reactor at a mass ratio of 1:2:4 , mix uniformly to obtain leaching slurry; wherein, the ratio of the volume of leaching slurry to the effective volume of the leaching reactor is 0.8; the leaching agent is sodium hydroxide and sodium fluoride with a mass ratio of 1:1.

[0055] S2. Leaching: Pass oxygen-enriched gas into the leaching reactor until the pressure in the leaching reactor is 0.3Mpa, and the oxygen-enriched gas is air with an oxygen volume percentage of 30%; at a reaction temperature of 125°C, the leaching The slurry and oxygen-enriched gas were reacted in the leaching reactor for 7 hours to obtain a mixed slurry of sodium tungstate solut...

Embodiment 3

[0058] An oxygen-enriched decomposition process for tungsten raw materials, comprising the following steps:

[0059] S1. Preparation of leaching slurry: crush the scheelite ore by mechanical crushing until more than 98% of the mineral particle size is less than or equal to 45 μm, and add the crushed scheelite, leaching agent, and water into the leaching reactor at a mass ratio of 1:3:5 , mix uniformly to obtain leaching slurry; wherein, the ratio of the volume of leaching slurry to the effective volume of the leaching reactor is 0.7; the leaching agent is sodium phosphate, sodium monohydrogen phosphate and sodium dihydrogen phosphate with a mass ratio of 1:1:1 .

[0060] S2. Leaching: Pass oxygen-enriched gas into the leaching reactor until the pressure in the leaching reactor is 0.5Mpa, and the oxygen-enriched gas is air with an oxygen volume percentage of 40%; at a reaction temperature of 150°C, the leaching The slurry and oxygen-enriched gas were reacted in the leaching re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com