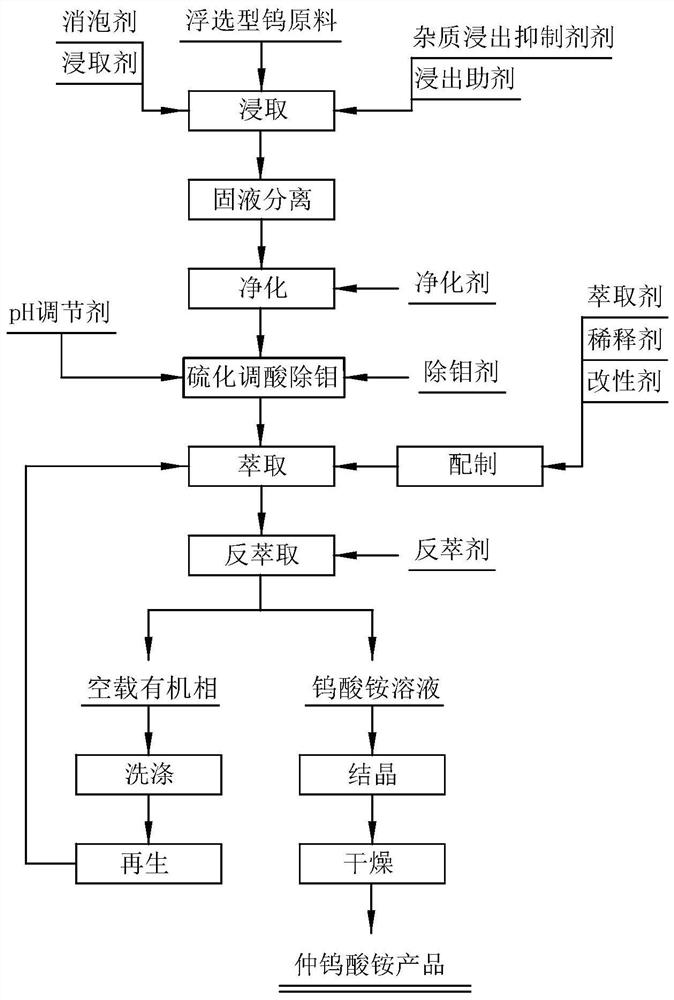

Flotation type tungsten raw material extraction all-wet-process smelting process

A full wet and extraction technology, applied in the field of flotation type tungsten raw material extraction full wet smelting process, can solve the problems of temperature fluctuation, waste of resources, poor economy and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

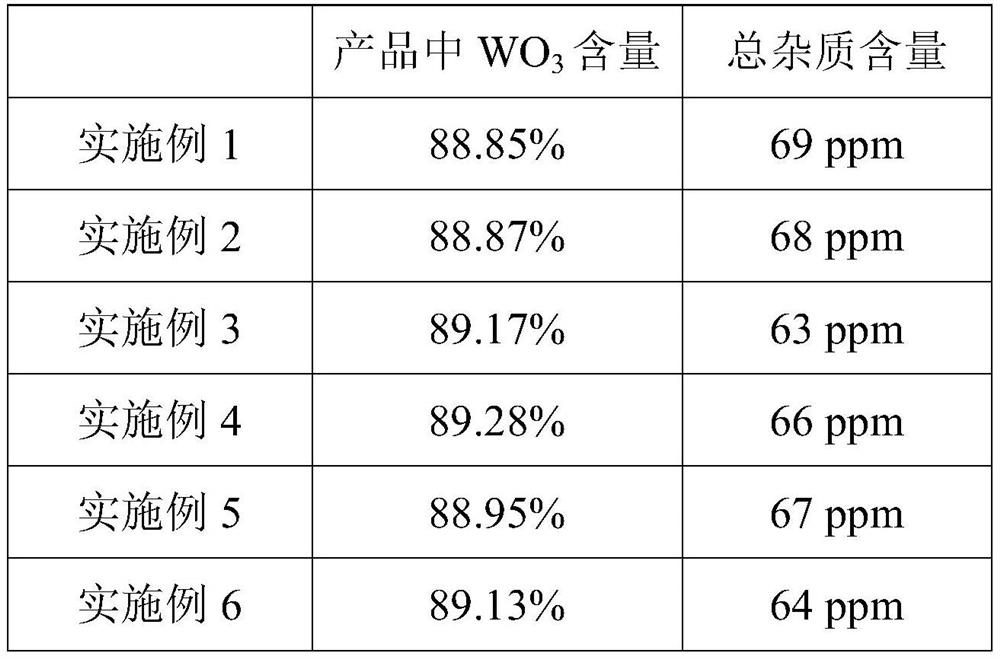

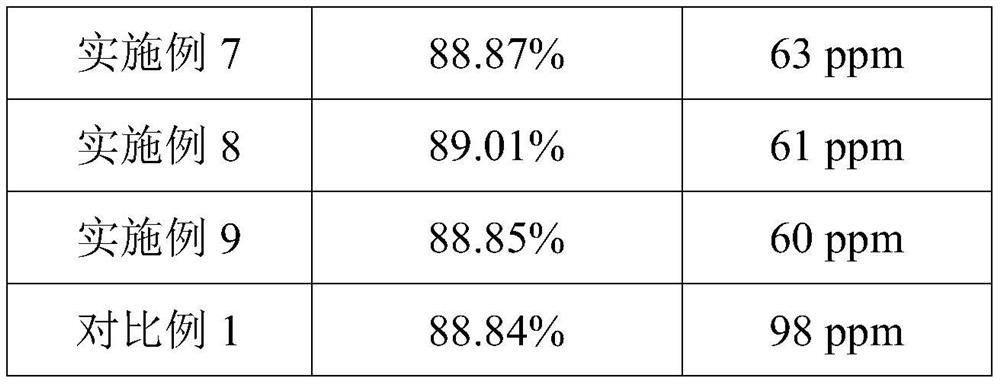

Examples

Embodiment 1

[0098] A flotation type tungsten raw material extraction full wet smelting process, according to the above process and method to produce ammonium paratungstate products, wherein:

[0099] Leaching process: the leaching agent is sodium carbonate, and the defoaming agent is SXP, which is obtained by fractionation or cracking of petroleum. 10 ~C 18 Alkane product (the mass ratio of defoamer to flotation type tungsten raw material is 1:1×10 9 ), leaching for 8 hours at 100°C.

[0100] Solid-liquid separation process: adopt filter press separation method.

[0101] Purification process: the purifying agent is magnesium sulfate.

[0102] Sulfurization acid adjustment and molybdenum removal process: the molybdenum removal agent is sodium sulfide.

[0103] Extraction process: two-stage countercurrent extraction, the extracted organic phase includes 8 parts of tertiary amine (N235), 78 parts of high boiling point hydrocarbons, C 10 8 parts of primary alcohol, 6 parts of secondary o...

Embodiment 2

[0107] A flotation type tungsten raw material extraction full wet smelting process, according to the above process and method to produce ammonium paratungstate products, wherein:

[0108] Leaching process: the leaching agent is sodium hydroxide, and the defoaming agent is castor oil (the mass ratio of the defoaming agent to the flotation type tungsten raw material is 1:1×10 8 ), leaching for 7 hours at 120°C.

[0109] Solid-liquid separation process: vacuum filtration separation method is adopted.

[0110] Purification process: The purifiers are magnesium sulfate and magnesium oxide, which are returned to the leaching process before purifying the slag.

[0111] Sulfurization acid adjustment and molybdenum removal process: the molybdenum removal agent is sodium sulfide and sodium hydrosulfide.

[0112] Extraction process: two-stage countercurrent extraction, the extracted organic phase includes 6 parts of tridecylamine, 80 parts of high boiling point hydrocarbons, C 12 10 pa...

Embodiment 3

[0116] A flotation type tungsten raw material extraction full wet smelting process, according to the above process and method to produce ammonium paratungstate products, wherein:

[0117] Grinding and crushing process of flotation-type tungsten raw materials: use mechanical crushing method to grind and crush tungsten mineral raw materials until the mass percentage of mineral particle size ≤ 45 microns is ≥ 95%.

[0118] Leaching process: the leaching agent is sodium fluoride, the defoamer is oleic acid (the mass ratio of defoamer to flotation type tungsten raw material is 1:1×10 7 ), leaching at 150°C for 6 hours,

[0119] Solid-liquid separation process: adopt filter press separation method.

[0120] Adding defoamer process: Add trioctylamine and octanol defoamer (amount of 75mg / L) with a mass ratio of 1:1 to the obtained sodium tungstate solution, and make the defoamer in sodium tungstate by stirring dispersed in the solution.

[0121] Purification process: the purificati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com