Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

37results about How to "No recrystallization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

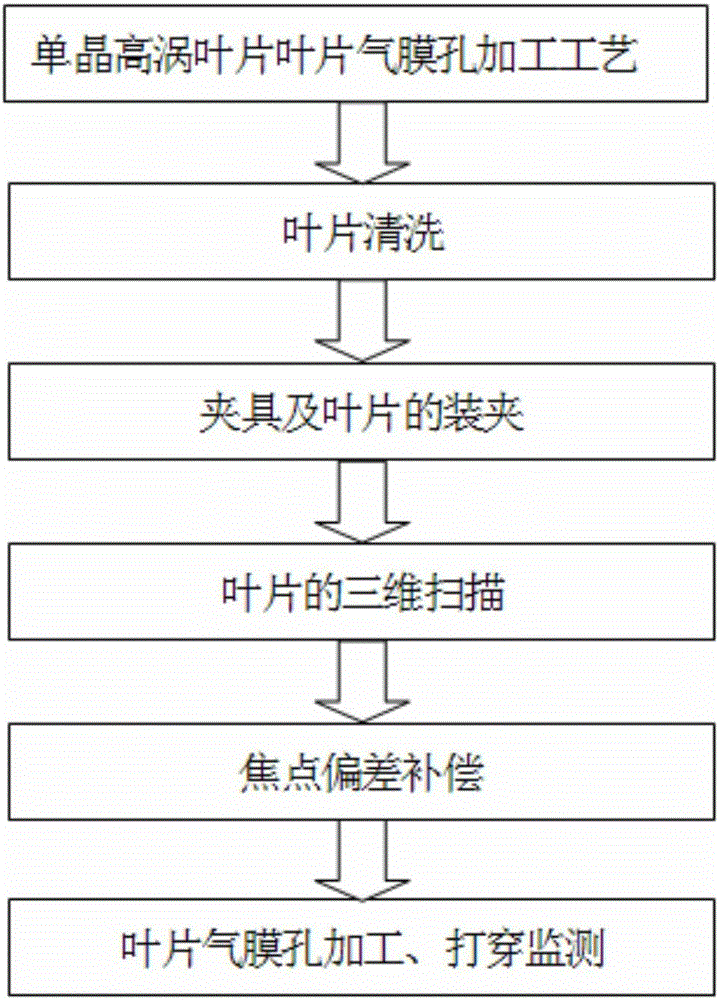

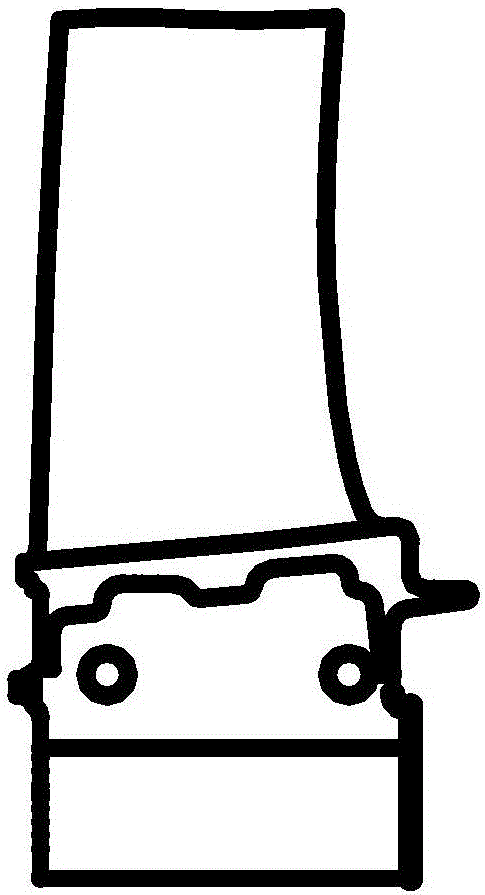

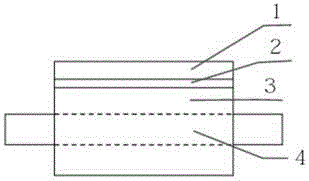

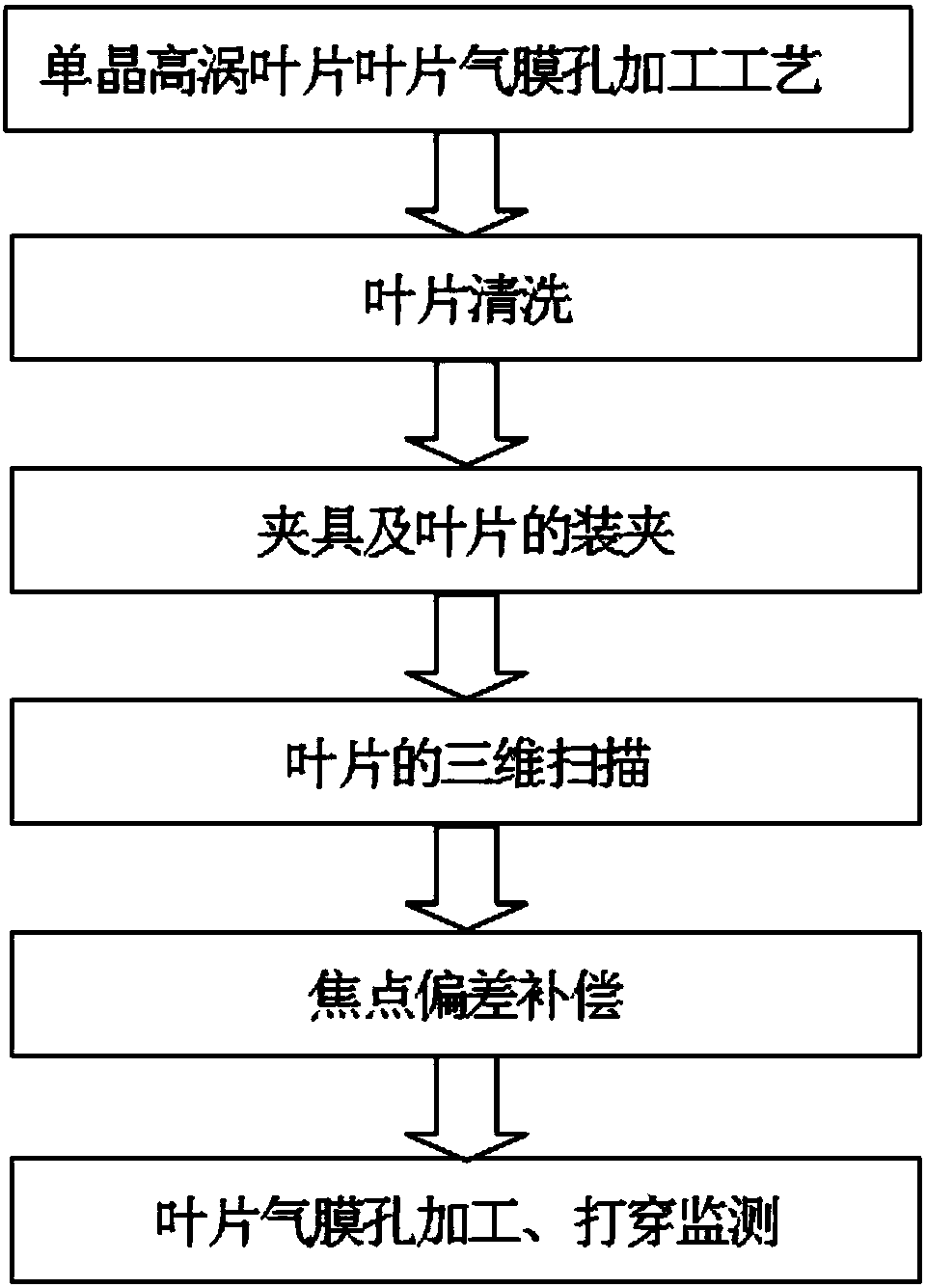

Low-damage processing method of film holes in single crystal high-pressure-turbine hollow blade of aircraft engine

ActiveCN106583949AExtend the life cycleExtended processing cycleLaser beam welding apparatusAviationEngineering

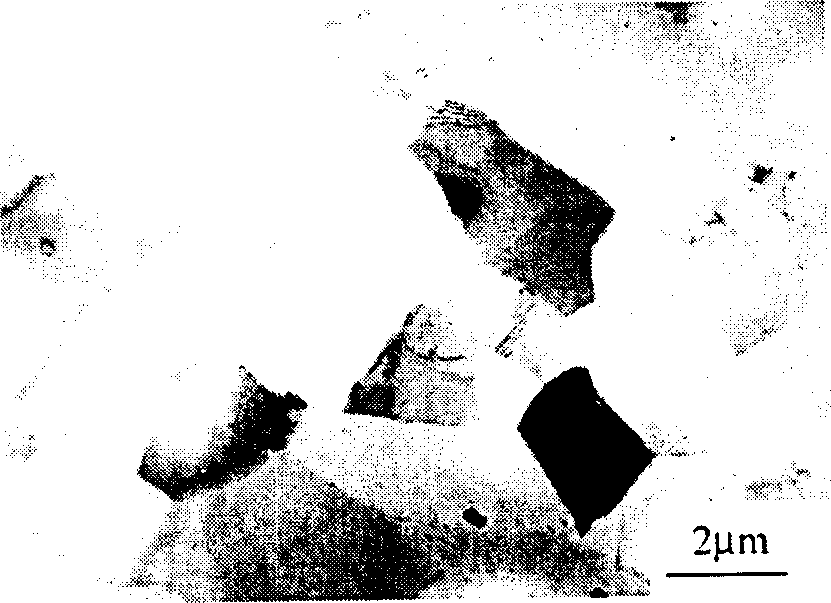

The invention provides a low-damage processing method of film holes in a single crystal high-pressure-turbine hollow blade of an aircraft engine. The low-damage processing method comprises the following steps: wiping the surface of the blade through degreasing cotton with absolute alcohol; transferring into a drying box to dry; arranging a clamp on a machine table, and aligning; assembling the dried blade on the clamp and locking; presetting scanning system parameters; scanning the blade; saving axis moving coordinate value of each hole to be processed under an automatically-generated machine coordinate system as a *.xls file; importing and generating a hole position file; performing compensative correction on the deviation value of a focus position of the hole to be processed; and setting the optimized laser processing technological parameters through a main processing interface. With the adoption of the low-damage processing method, the processed hole is outstanding in quality; a remelting layer, microcacks and recrystallization can be avoided after the single crystal material is processed, so that subsequent processing can be saved, and as a result, the fatigue life and the processing cycle of the blade can be prolonged and improved; the ablation threshold of the single crystal material can be effectively reduced; the recrystallization of the single crystal material can be avoided.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

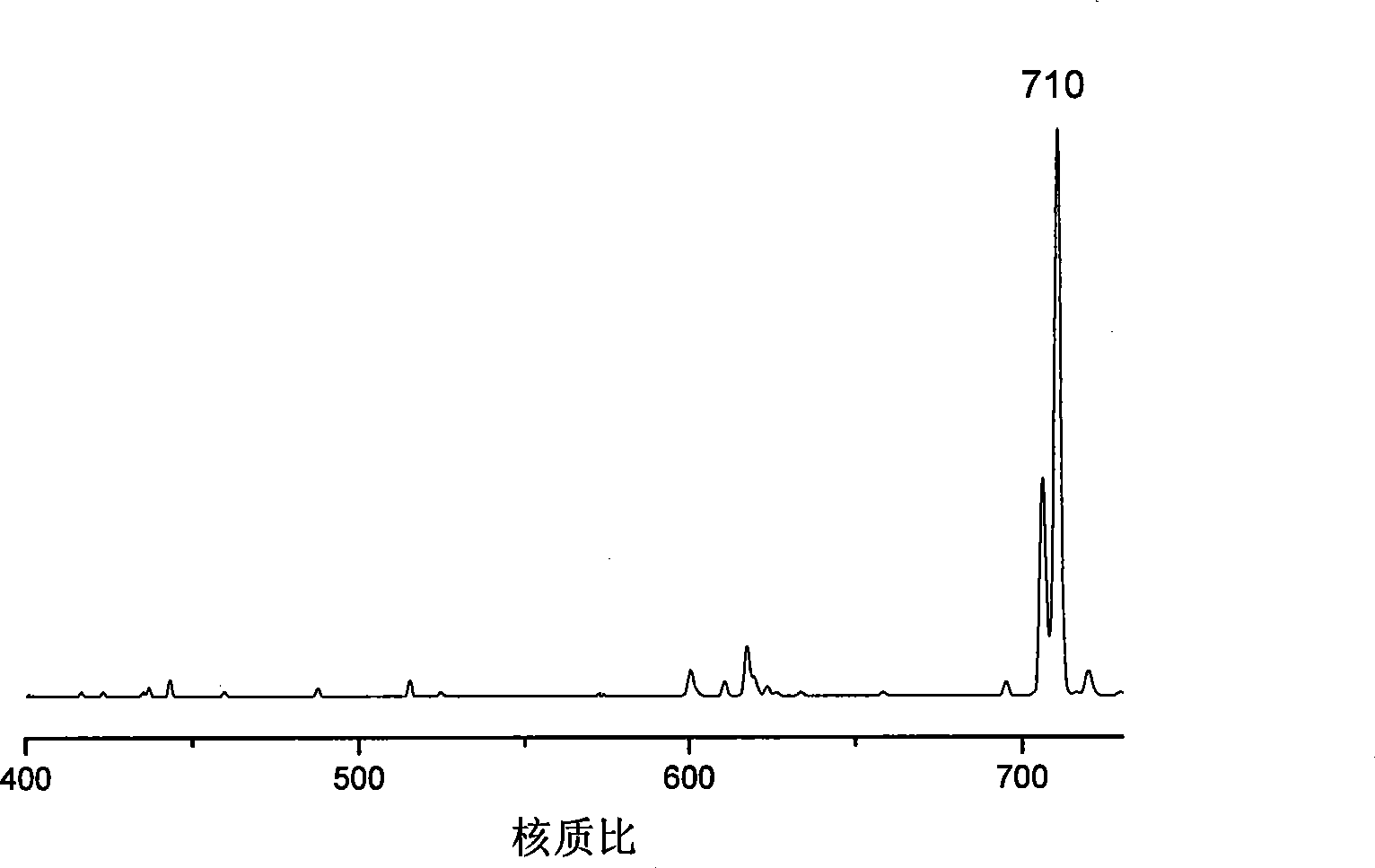

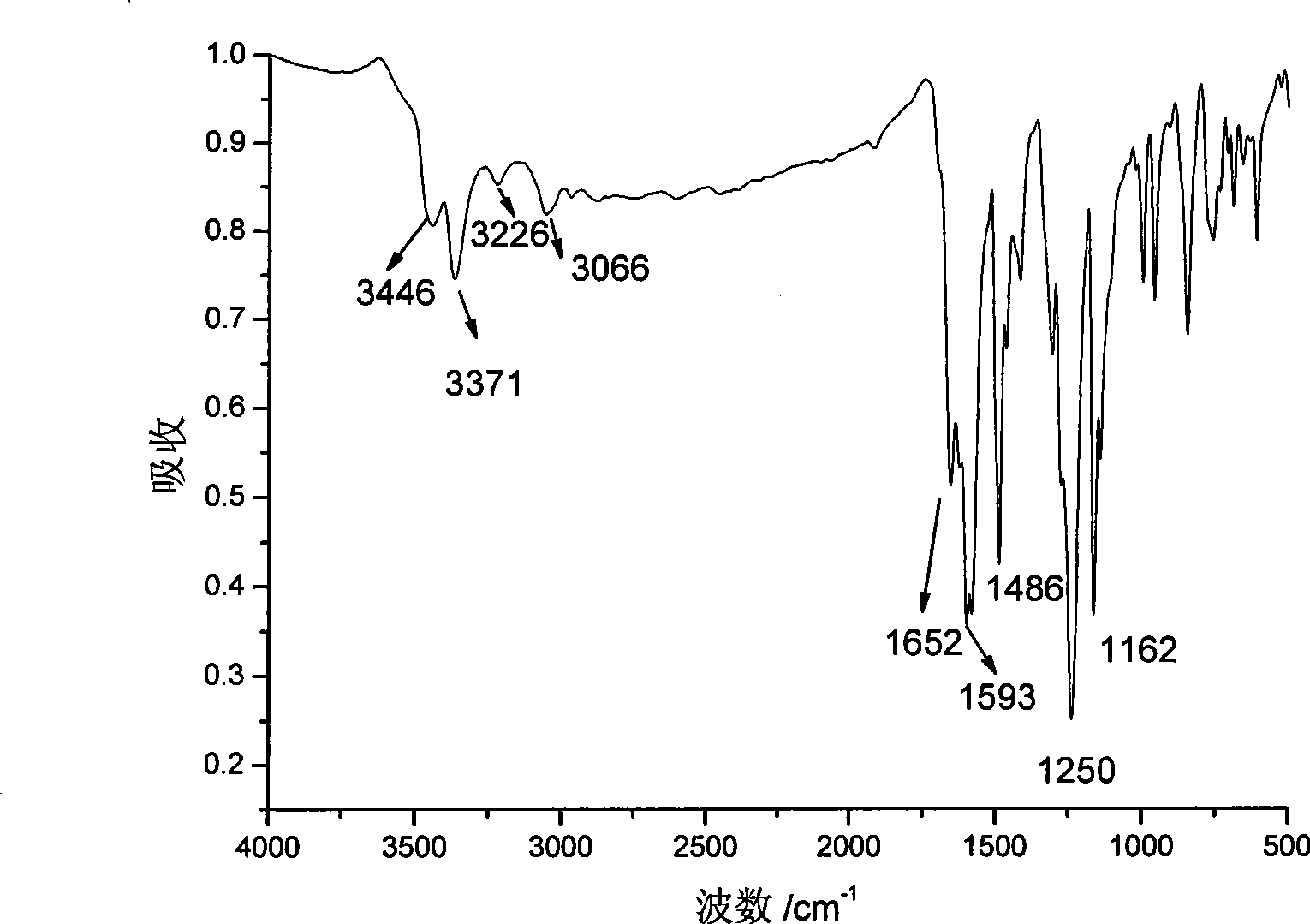

Prepn process of beta-hydroxyl-beta-methyl butyric calcium (HMB-Ca)

InactiveCN1417190ASimple preparation processHigh purityCarboxylic acid salt preparationIsobutanolHaloform reaction

The present invention belongs to an organic compound preparing technology. Beta-hydroxyl-beta-methyl butyric calcium (HMB-Ca) is prepared using 4-methyl-4-hydroxy-2-propione as raw material and wateras solvent and through haloform reaction in water solution of NaOBr, acidification, isobutanol extraction, reaction of HMB acid in isobutanol extract with Ca(OH)2 to produce salt HMB-Ca. The said process has high product purity and less environmental pollution. The product HMB-Ca may be used in promoting the growth of muscles, strengthening immunity, reducing cholesterin and low-density lipoprotein level, preventing coronary heart disease and cardiac vascular disease, strengthening body's nitrogen-fixing capacity and maintaining body's protein level.

Owner:MANTE SHANGHAI BIAOLOGICAL SCI TECH

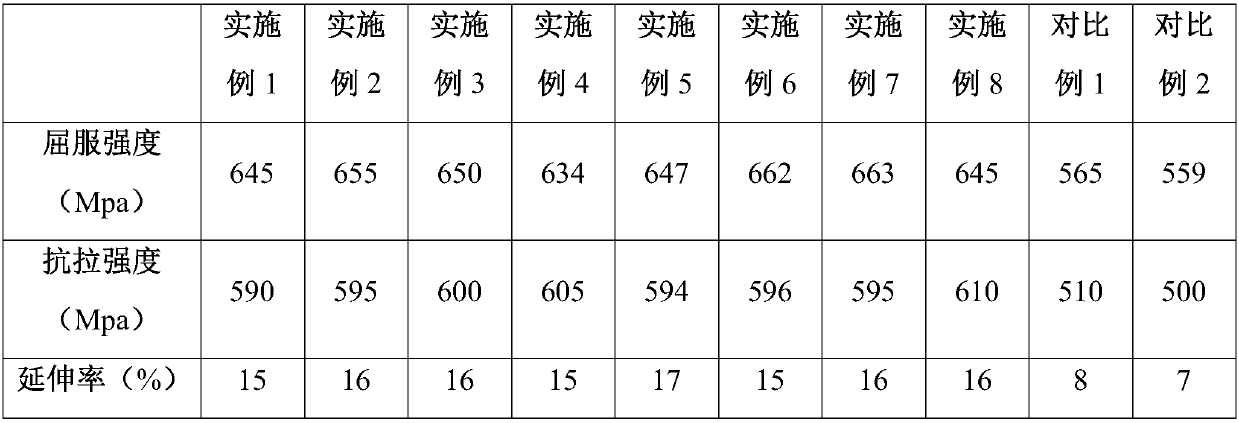

Two-stage forced solution treatment method for high strength deformed aluminum alloy

This invention discloses a double-stage forced solutionizing method for manufacturing a high-strength flexible alumina alloy. The method comprises the steps of: (1) performing a first stage solutionizing method at 430-460 deg.C for 1-3 h; and (2) performing a second stage solutionizing method at 460-500 deg.C for 1-3 h. The method can ensure the remelting of the precipitated phase during performing and hot-pressing processes, while recystallization and crystal grain growth can be avoided. Therefore, the precipitated phase can be uniform and fine during the subsequent aging treatment. The alumina alloy manufactured by this method has improved ultimate tensile strength and yield strength (by 3-10%), elongation percentage (by 1-5%), fracture ductility, fatigue resistance and stress corrosion resistance.

Owner:GENERAL RESEARCH INSTITUTE FOR NONFERROUS METALS BEIJNG

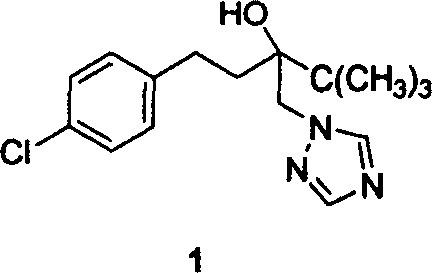

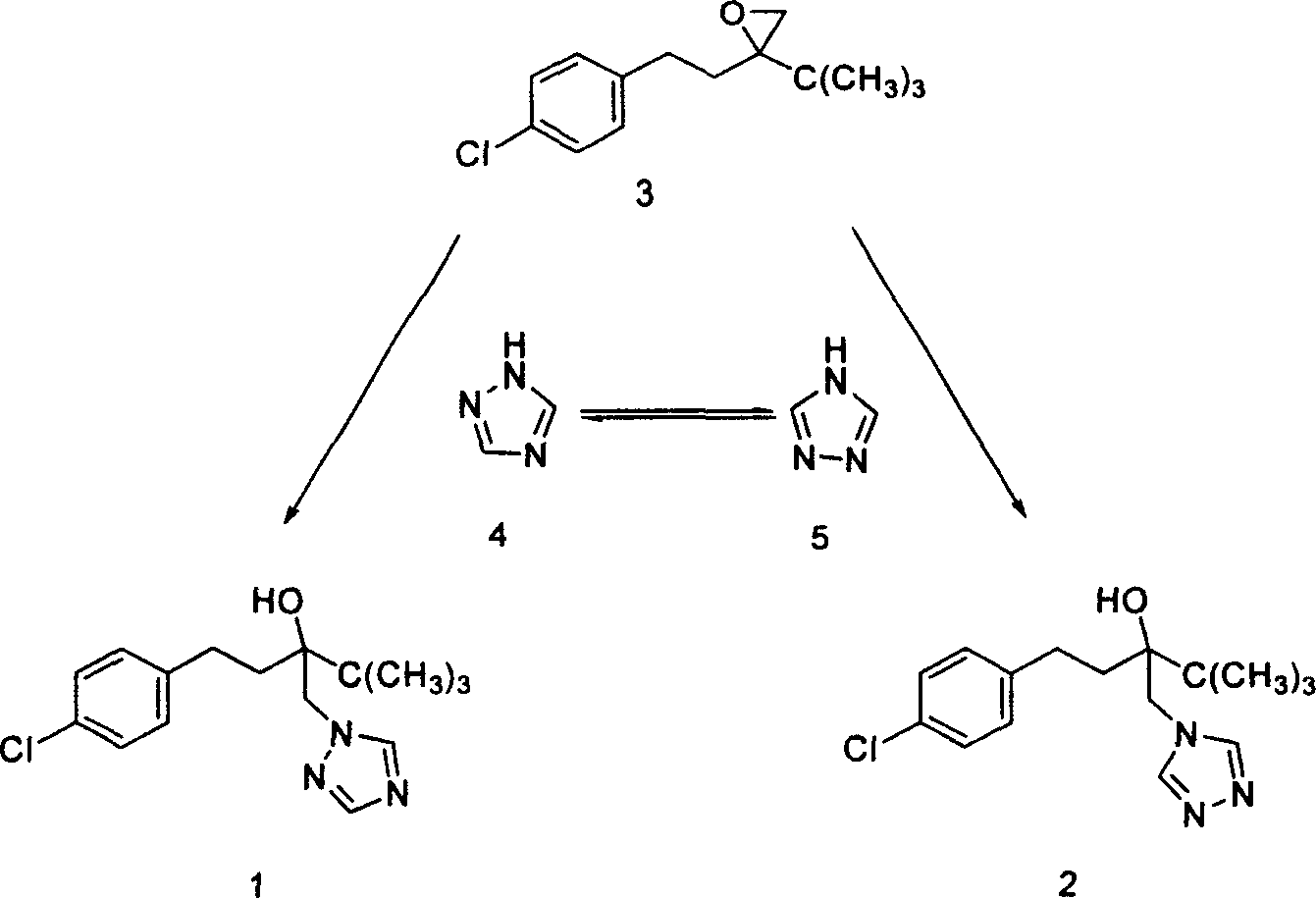

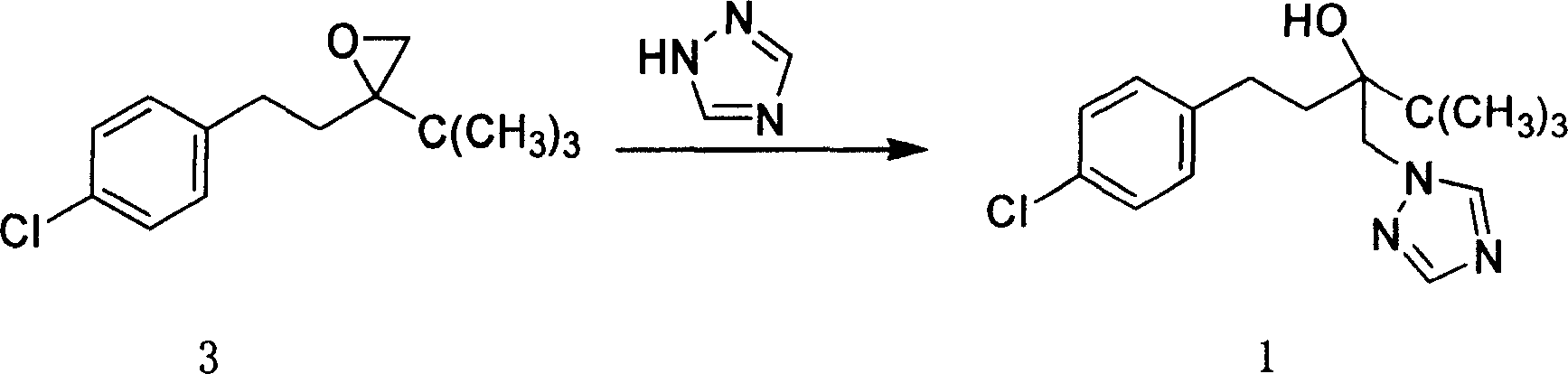

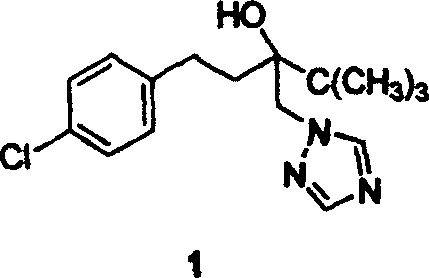

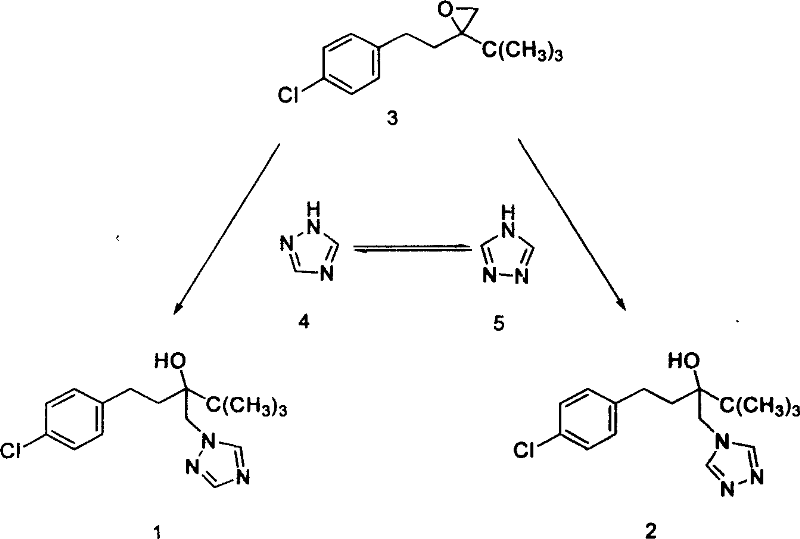

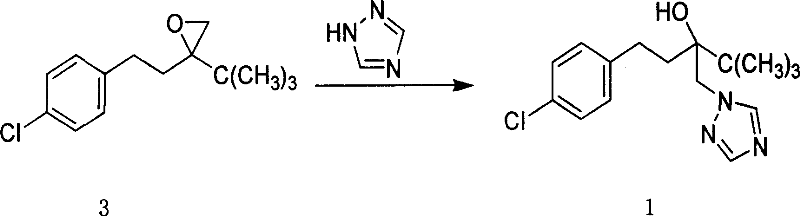

Method for preparing Tebucomazole in high purity

A process for preparing high-purity pentazolol features the reaction between 1-(4-chlorphenylethyl)-1-tert-butyl-1, 2-epoxy ethane and 1,2,4-triazole in organic polar solvent under existence of alkali while adding catalyst chosen from N,N-dimethyl-4-aminopyridine, N,N-dimethylphenylamine, methylphrrolidone, dimethyl formamide, methanol sodium, ethanol sodium, potassium hydroxide and sodium hydroxide. Its advantages are high output rate and high purity.

Owner:HUNAN CHEM RES INST +1

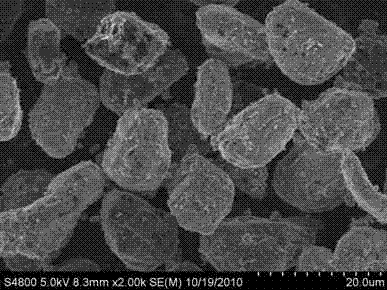

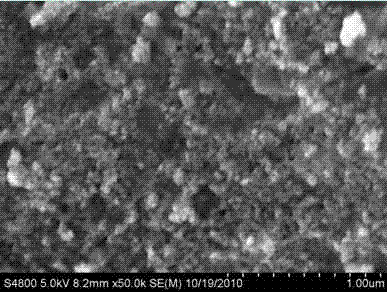

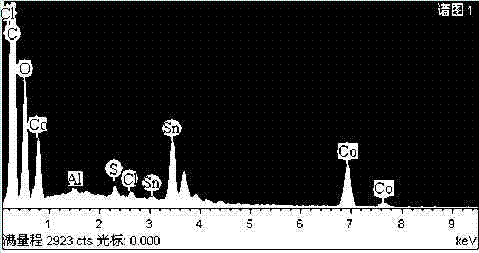

Preparation method for lithium ion battery anode active material

ActiveCN102544444AIncrease capacity and cycle performanceImprove adhesionCell electrodesSolventLarge capacity

The invention provides a preparation method for a lithium ion battery anode active material. The preparation method comprises the following steps of: 1) uniformly dispersing acidified graphite in an organic polymer to obtain a mixed system; 2) adding an organic metal salt solution into the mixed system with stirring, wherein the solute of the organic metal salt solution contains organic tin and organic cobalt, and the solvent of the organic metal salt solution is an organic solvent; and 3) drying the mixed system, and sintering the mixed system at 500 to 900 DEG C to obtain the lithium ion battery anode active material. The preparation method for the lithium ion battery anode active material is simple in process; and a battery adopting the anode active material has high capacity and high cycling performance.

Owner:BYD CO LTD

Aluminum alloy profile for aviation and production technology thereof

InactiveCN107675044AImprove mechanical propertiesOmit the steps of manual validationAviationRare-earth element

The invention belongs to the field of aluminum alloy profile production, and relates to an aluminum alloy profile for aviation and a production technology thereof. The aluminum alloy profile includes,by mass, no more than 0.25% of Si, no more than 0.4% of Fe, no more than 0.25% of Mn, 5-20% of Zn, no more than 15% of Mg, no more than 8% of Cu, no more than 1% of Zr, no more than 1% of Ti, 0.01-1.0% of Sr and the balance Al. By adding a proper amount of rare earth element Sc into a composition of 7xxx series aluminum alloy, the prepared aluminum alloy profile can be fine and uniform in grain and have good thermal processing formability, and a recrystallization phenomenon does not exist in the process of hot extrusion and solid solution aging heat treatment, so that grain refining, segregation reduction and more uniform texture of the prepared aluminum alloy profile are achieved.

Owner:CHINA ZHONGWANG

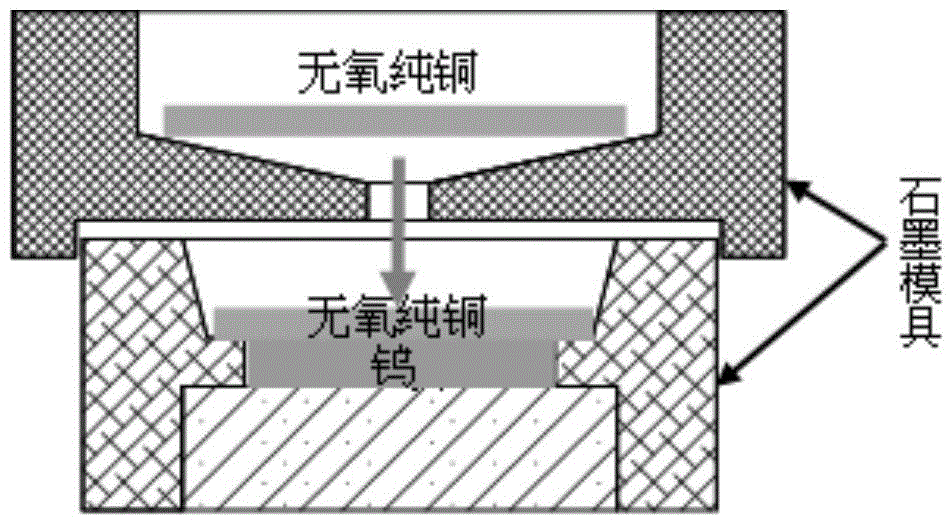

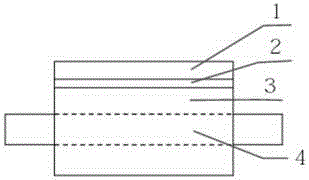

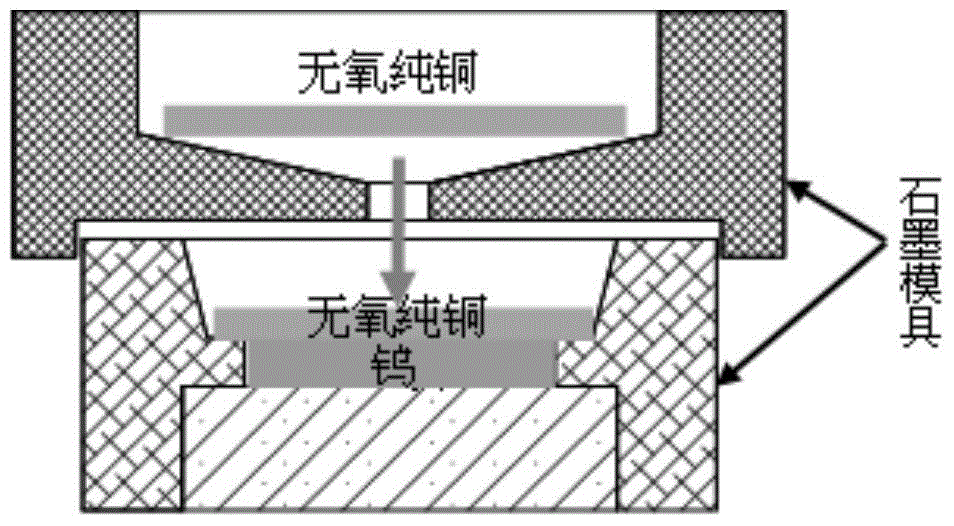

Tungsten copper module for high thermal load part of fusion device as well as preparation method thereof

ActiveCN104416973AReduce defects such as holesReduce defectsLamination ancillary operationsLaminationPre treatmentHeat sink

The invention relates to the technical field of connection of heterogeneous materials and particularly relates to a tungsten copper module for a high thermal load part of a fusion device as well as a preparation method thereof. The method comprises the following steps: 1) selecting tungsten, anaerobic pure copper and a chromium zirconium copper alloy heat sink material in appropriate size; 2.1) pre-treating surfaces of tungsten and anaerobic pure copper; 2.2) carrying out vacuum-casting on the anaerobic pure copper on the surface of tungsten; 3.1) pre-treating the surface of the anaerobic pure copper in a tungsten / anaerobic pure copper block and a to-be-welded face of a chromium zirconium copper alloy; 3.2) welding the tungsten / anaerobic pure copper block and the chromium zirconium copper alloy in a vacuum hot pressed furnace; and 3.3) machining a welded tungsten / anaerobic pure copper / chromium zirconium copper alloy compound block to form the required tungsten copper module. The preparation method of the tungsten copper module is low in cost, high in efficiency and high in reliability and the tungsten copper module can bear a steady state thermal load which is greater than 5MW / m<2>.

Owner:SOUTHWESTERN INST OF PHYSICS

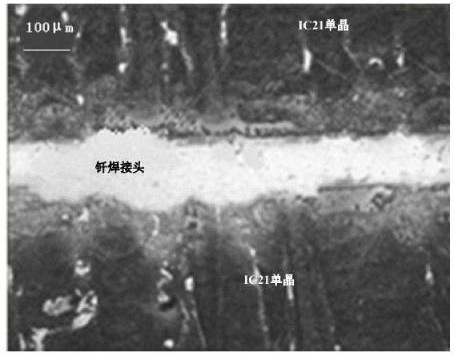

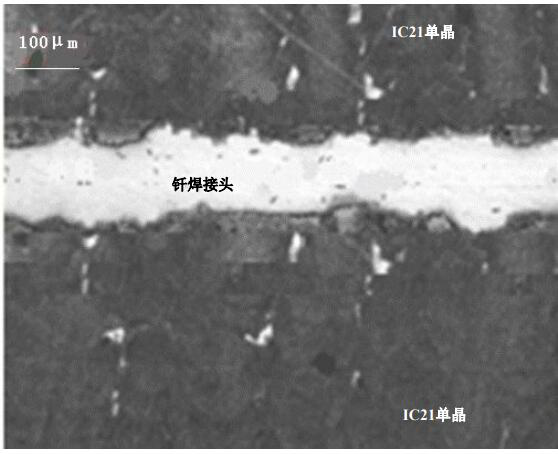

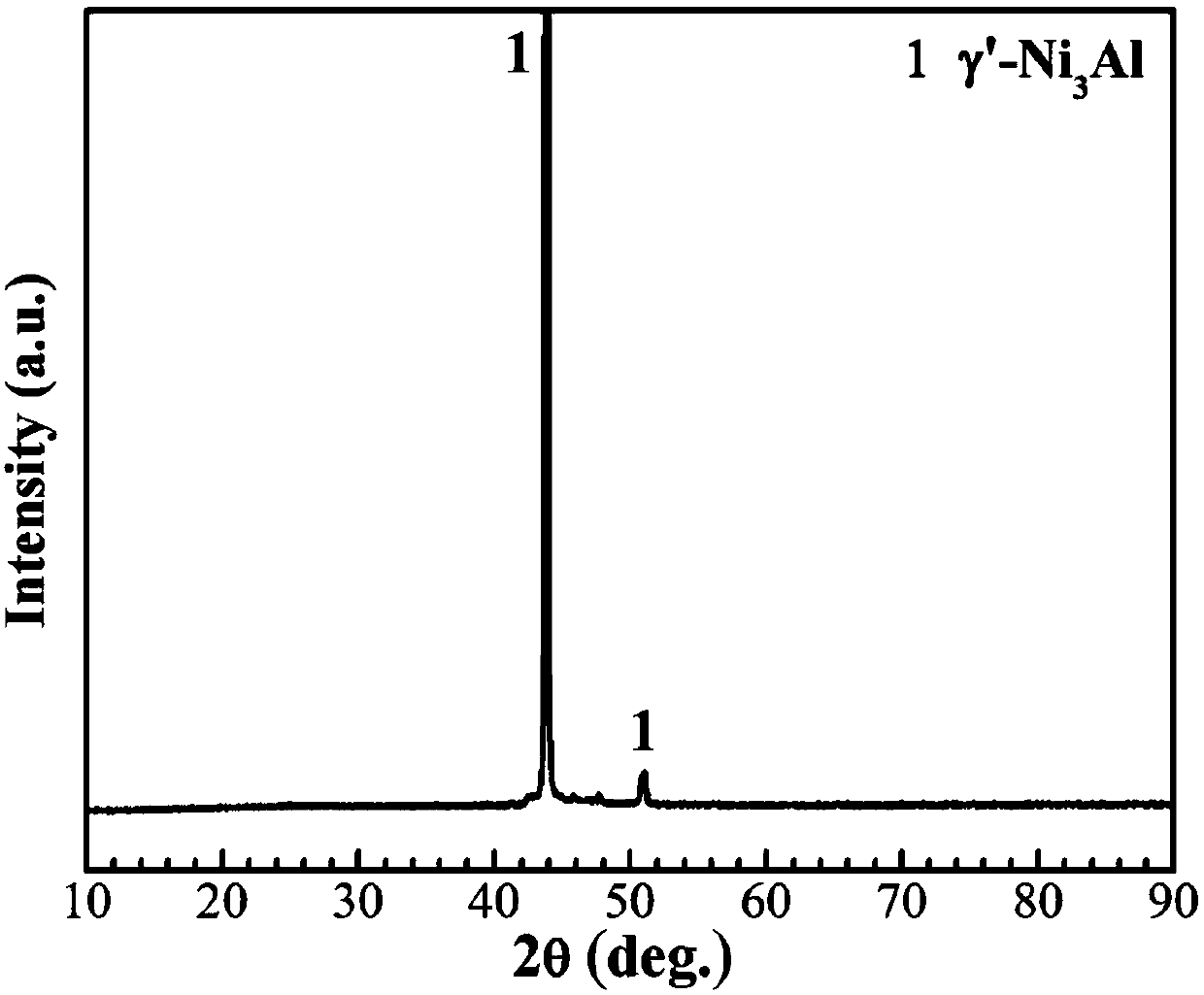

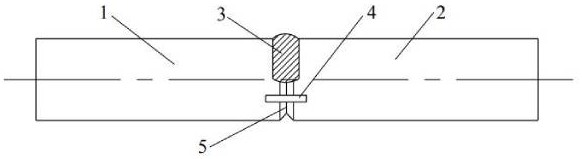

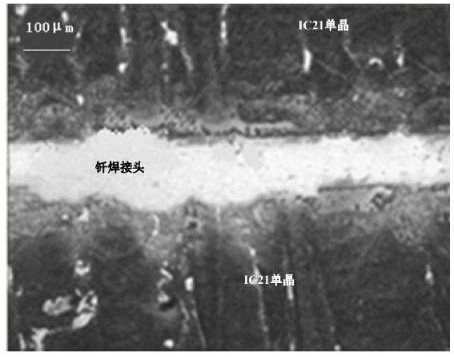

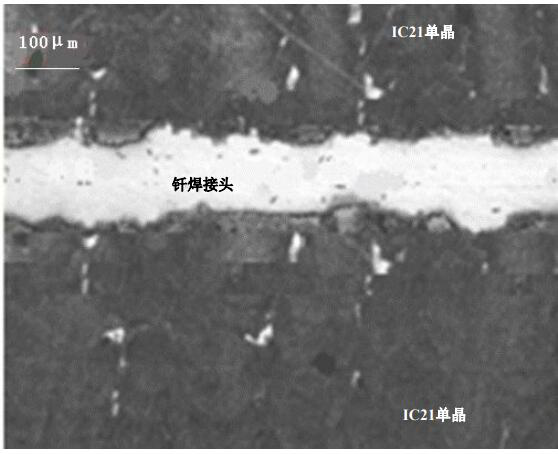

High-performance brazing method for Ni3Al-based single crystal alloy

ActiveCN112008180AWell organized interfaceMechanical properties up to standardWelding/cutting media/materialsSoldering mediaWelding defectMechanical properties of carbon nanotubes

The invention belongs to the technical field of welding, and particularly relates to a high-performance brazing method for a Ni3Al-based single crystal alloy. A novel high-temperature-resistant Ni-Cr-W-Mo-Si brazing filler metal is applied, and a brazing process suitable for the brazing filler metal and the Ni3Al-based single crystal alloy is provided. The brazing process mainly includes the stepsof cleaning before brazing, assembling and positioning, brazing filler metal presetting, vacuum brazing, and heat treatment after welding. By means of the brazing filler metal and the process, an excellent brazed joint structure can be obtained; a brazing seam and a base metal interface are well combined; meanwhile, the brazing seam is free of welding defects and low in melting point phase; and aNi3Al-based single crystal alloy brazed joint brazed according to the process has the high mechanical property meeting the using requirement.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

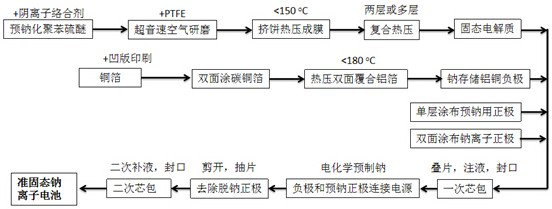

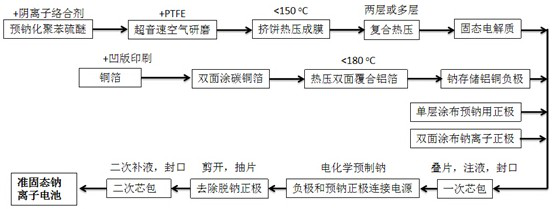

Manufacturing method of high-energy-density quasi-solid-state sodium ion battery

ActiveCN112290081AImprove thermal stabilityNon-flammableSolid electrolytesFinal product manufactureSolid state electrolyteElectrolytic agent

The invention relates to the field of new energy and discloses a manufacturing method of a high-energy-density quasi-solid-state sodium ion battery, and the method comprises two main technological processes of pre-preparing sodium and removing secondary packaging of a positive electrode for pre-preparing sodium. According to the pre-preparing sodium process, under the action of an electric field,a positive electrode for sodium prefabrication is subjected to single-layer coating, and uniform sodium plating is formed on the surface of a porous aluminum foil by compounding a sodium ion polyethylene and polyphenylene sulfide-based composite solid electrolyte, so that nucleation and growth of metal sodium are uniform, and dendritic crystal generation is inhibited. The sodium-ion polyethylene polyphenylene sulfide-based composite solid electrolyte can be tightly adhered to a sodium storage aluminum-copper negative electrode after sodium is prefabricated, and can be easily separated from a single-layer coated positive electrode for pre-sodium, the positive electrode for pre-sodium after sodium removal is taken out, the internal damage of a battery cell cannot be caused, and secondary vacuumizing and sealing are performed. The battery manufactured by the method has good flame retardant property and good thermal stability, the electrolyte injection amount is reduced, combustibles in the battery are also reduced, and the safety performance of the battery is improved.

Owner:东莞奥创能源科技有限公司

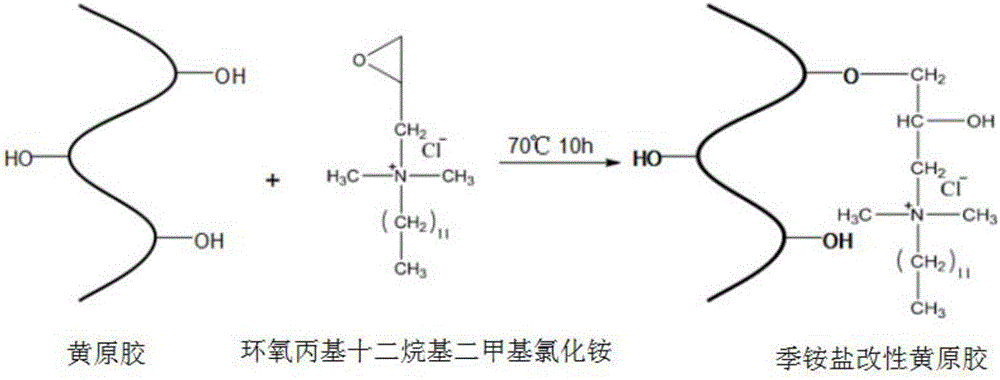

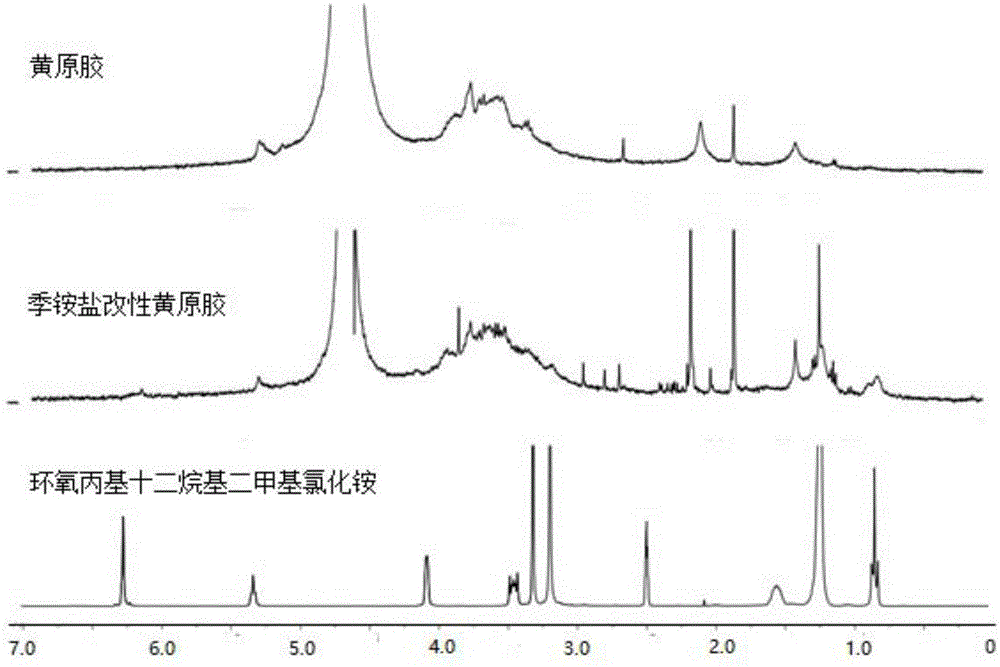

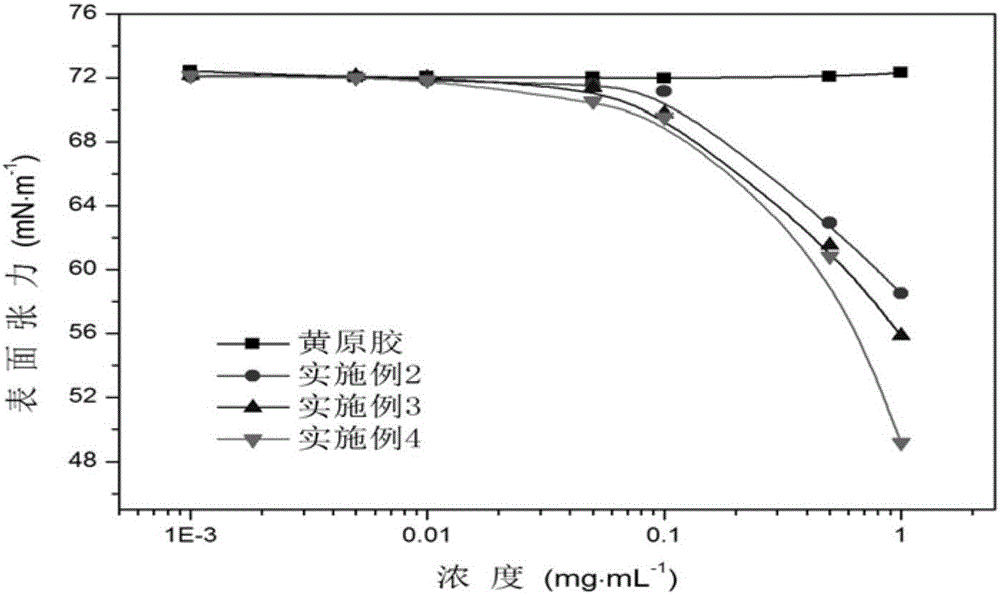

Hydrophobic associative cationic xanthan gum preparation method

Owner:SHANDONG UNIV

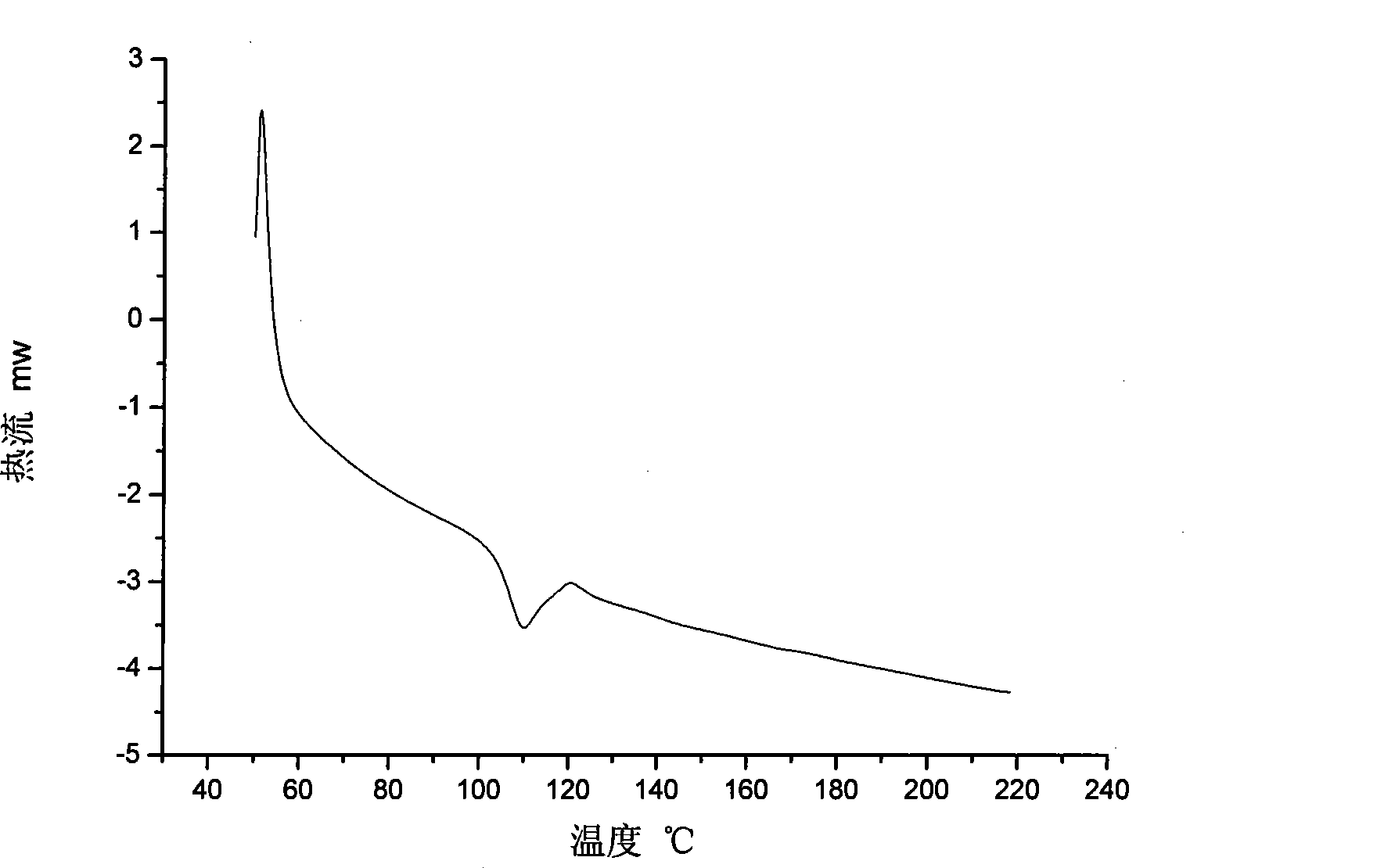

Functional film prepared from functionalized organic powder, low-temperature damage-free manufacturing method and application

ActiveCN111004404AHigh strengthImprove toughnessOrganic-compounds/hydrides/coordination-complexes catalystsFinal product manufactureOrganic filmMicron scale

The invention provides a functional film prepared from functionalized organic powder, a low-temperature damage-free manufacturing method and application. The organic powder film material is composed of the functionalized organic powder and polytetrafluoroethylene (PTFE), polytetrafluoroethylene molecular chains are opened through preheated supersonic airflow, the functionalized organic powder is bonded, air in the powder is extruded to form a continuous cake shape, the powder forms a film through a low-temperature hot-pressing process, and then the film material with low porosity and uniform thickness is formed through a multi-layer film hot-pressing compounding process. According to the method, micron-sized organic films can be continuously prepared in a roll-to-roll mode, the physical and chemical properties of the organic powder can be brought into play to the maximum extent, and performance damage caused by high temperature or introduction of a solvent for film formation or anisotropy caused by recrystallization is prevented. No solvent is introduced in the manufacturing process, and the problems of environmental pollution, high energy consumption, uneven film material densityand the like caused in the solvent drying process are avoided.

Owner:东莞奥创能源科技有限公司

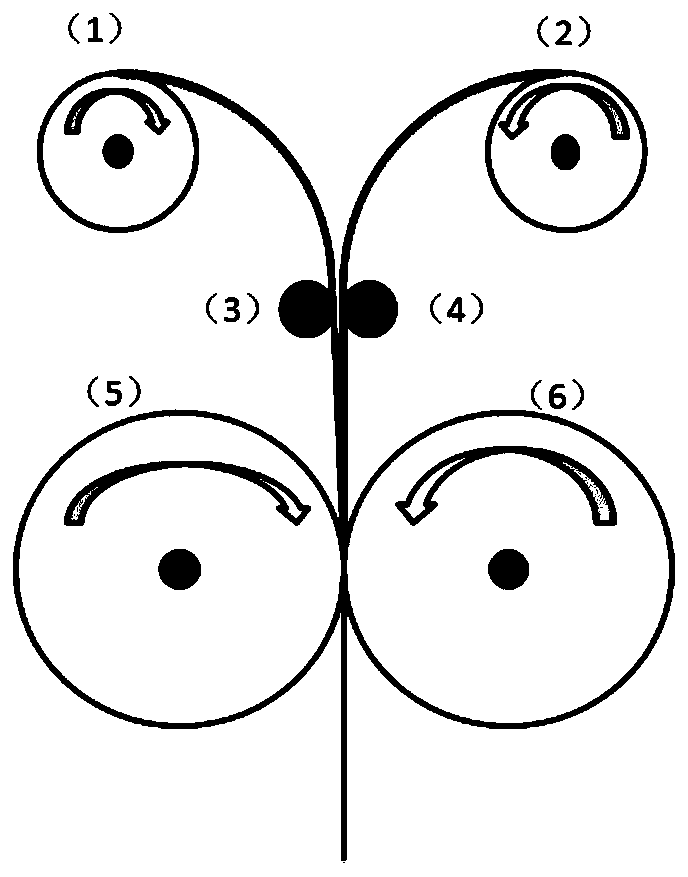

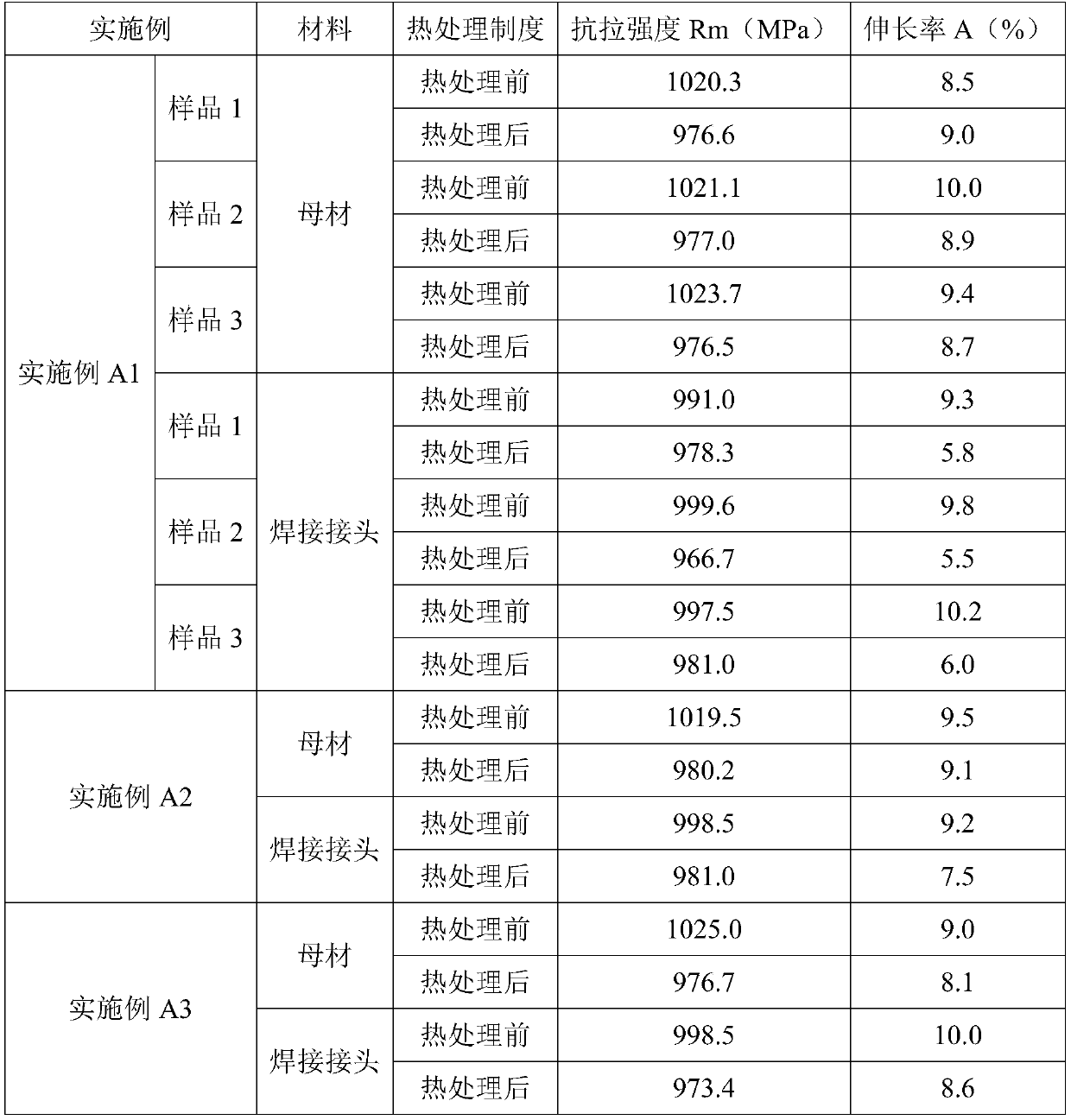

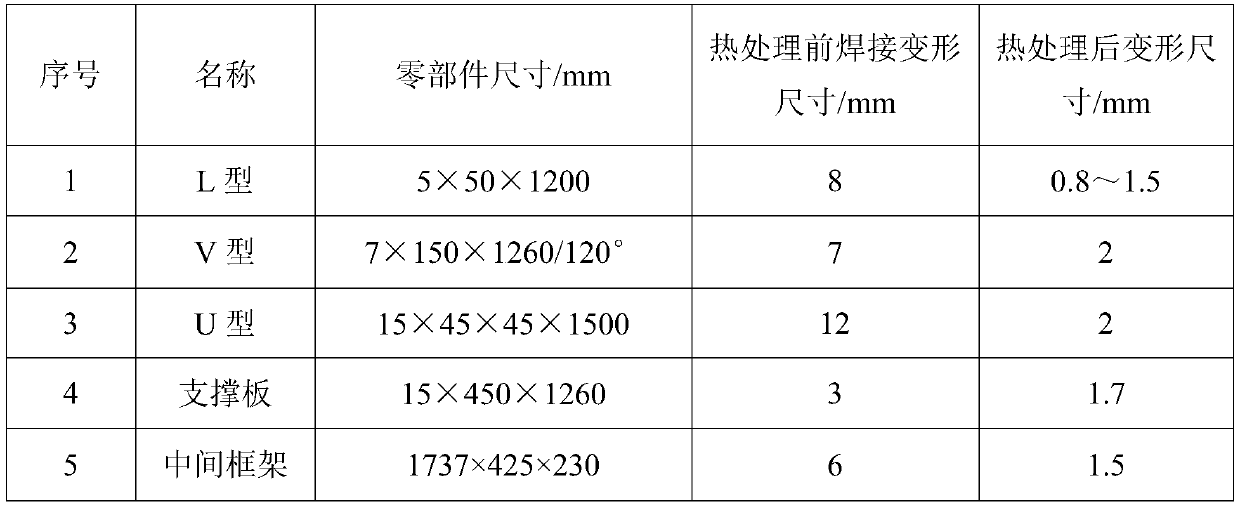

Technological method for heat treatment to titanium alloy welded component

The invention relates to a technological method for heat treatment to a titanium alloy welded component. The technological method comprises the following step (1) of removing oil stain from the surface of the titanium alloy welded component to be treated; the step (2) of adding a little water to high temperature anti-oxidation coatings for dilution, and mixing the water and the coatings uniformlyto obtain high temperature anti-oxidation coating aqueous solutions, and coating the aqueous solutions on the surface of the titanium alloy welded component to be treated; the step (3) of clamping andfixing the titanium alloy welded component to be treated with a tool after drying the high temperature anti-oxidation coating aqueous solutions; the step (4) placing the titanium alloy welded component clamped and fixed with the tool properly into a resistance furnace, and setting heat treatment process parameters, wherein the annealing temperature Tm is 500-600 DEG C, the temperature rise time tis 1.5-2.0 h, and the holding time tm is 2.0-2.5 h; cooling the titanium alloy welded component in the furnace to 200 DEG C and below, taking out the titanium alloy welded component from the furnace,and air-cooling the titanium alloy welded component to room temperature; and the step (5) of cleaning the coatings on the surface of the titanium alloy welded component. Compared with the prior art,the technological method has the advantages of convenient operation, and high economy and adaptability.

Owner:CHINA WEAPON SCI ACADEMY NINGBO BRANCH

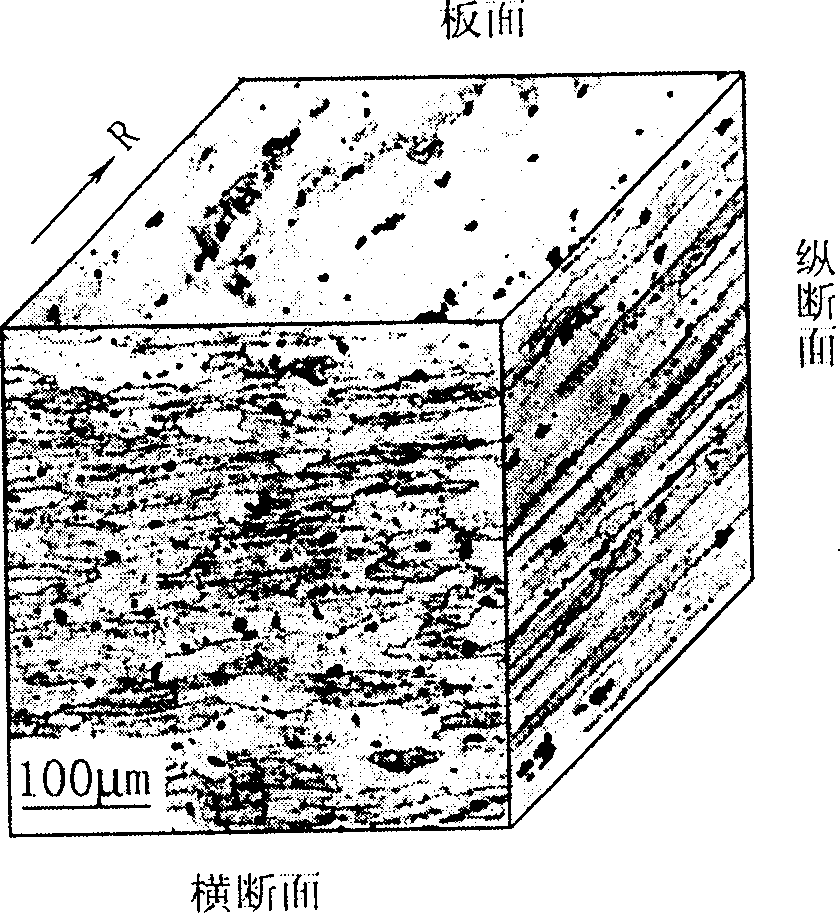

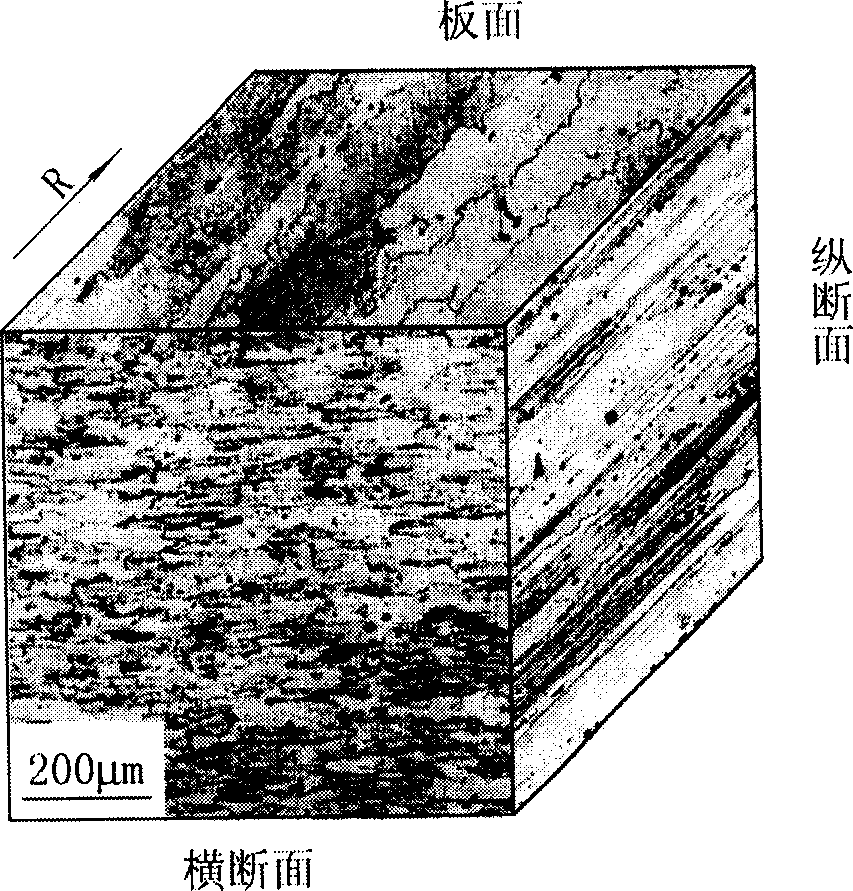

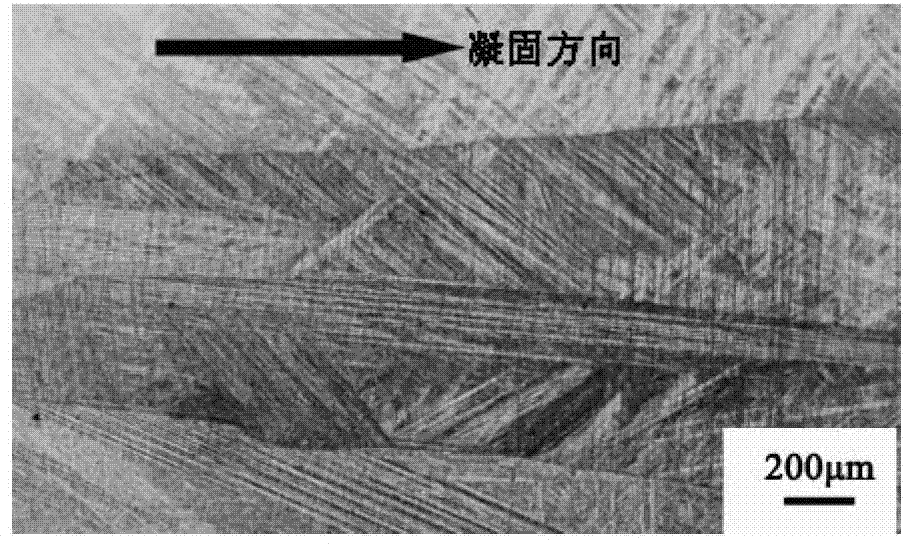

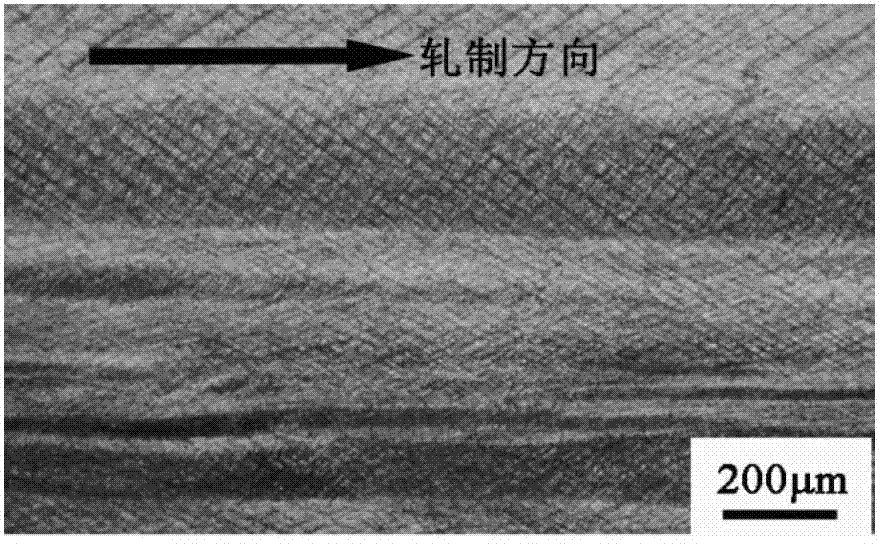

Efficient rolling technology for continuous columnar crystal structure high-aluminum bronze sheet material

ActiveCN102962252AImprove processing efficiencyImprove rolling performanceMetal rolling arrangementsCrystal structureWater cooling

An efficient rolling technology for continuous columnar crystal structure high-aluminum bronze sheet material belongs to the technical field of plastic processing of metal materials. The specific technology comprises the steps as follows: firstly, a blank is subjected to single-pass high-temperature rolling at the temperature range of 600 DEG C to 850 DEG C, and the rolling deformation is 60%-90%; water cooling is carried out after rolling; the subsequent warm rolling processing for 3 to 11 passes is carried out at the temperature range of 200 DEG C to 400 DEG C, and the deformation for each pass is controlled to be within 5%-20%. The total amount of finish for the sheet material is more than 95%, and the high-aluminum bronze sheet material does not contain a fragile precipitated phase after formation, is no longer recrystallized and has a continuous sheet-shaped crystal structure. The efficient rolling technology has the advantages that the processing technology with the combination of the single-pass hot rolling and multi-pass warm rolling is adopted, the alloy is no longer recrystallized, and the high-orientation structure is kept; the temperature for the first-pass rolling is high (600 DEG C to 850 DEG C), the pass deformation is large, and the processing efficiency is high; and the high-aluminum bronze sheet material subjected to subsequent warm rolling does not contain the fragile precipitated phase, has the continuous sheet-shaped crystal structure, and also has excellent mechanics, physical and chemical properties.

Owner:UNIV OF SCI & TECH BEIJING

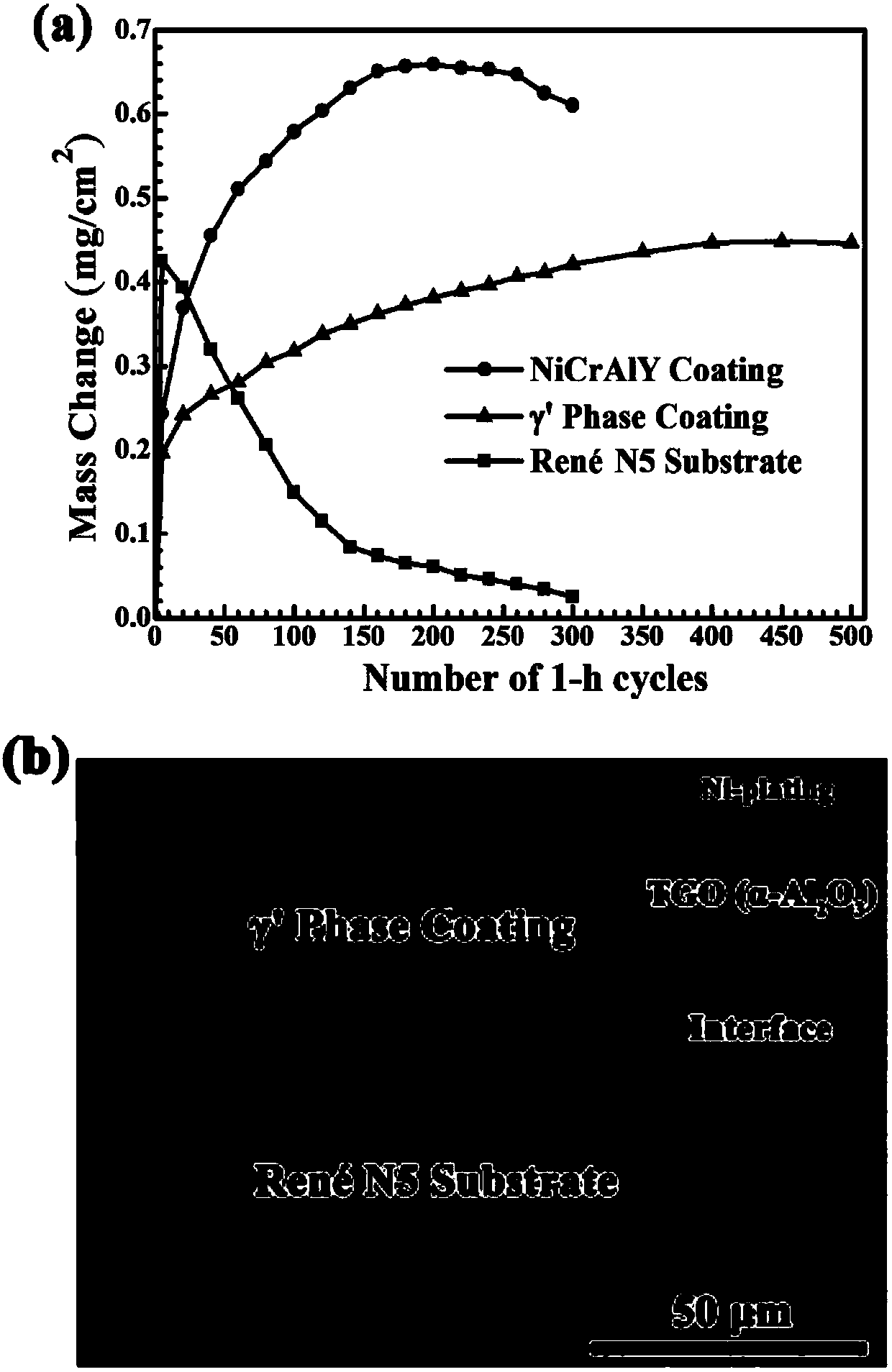

High temperature protective coating material suitable for single crystal nickel-based superalloy blades

ActiveCN110396623AGood high temperature oxidation resistanceSolve the problem of damaging the mechanical properties of single crystal matrixVacuum evaporation coatingSputtering coatingChemical compositionSingle crystal substrate

The present invention provides a high temperature protective coating material suitable for single crystal nickel-based superalloy blades. The high temperature protective coating material is prepared from 1.5-10.0 wt.% of Cr, 3.0-12.0 wt.% of Co, 8.0-12.0 wt.% of Al, 0-3.0 wt.% of Re, 0-6.0 wt.% of W, 0-2.0 wt.% of Mo, 0.5-7.0 wt.% of Ta, 0.01-0.2 wt.% of Hf, 0.1-0.3 wt.% of Y, and the balance Ni;and the high temperature protective coating material has a phase equilibrium structure of gamma' phase at 1050 DEG C. The high-temperature oxidation performance of a coating prepared from the high-temperature protective coating material is superior to that of an MCrAlY (M is Ni, Co, or NiCo) coating and a beta-NiAl coating, and comparable to that of a NiPtAl coating. The coating forms metallurgical bond with a substrate, but not like the MCrAlY coating, the beta-NiAl coating or the NiPtAl coating which forms a secondary reaction zone with a single crystal substrate, so that the problem that the coating damages the mechanical property of the single crystal substrate is avoided. The coating prepared from the material can be used as an independent high-temperature-resistant corrosion-resistant coating, and can also be used as a bonding layer of a thermal barrier coating, and the prepared thermal barrier coating has better thermal shock resistance life than a NiPtAl / YSZ thermal barrier coating.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI +1

Sun-screening agent spray

InactiveCN109431826AEconomic savingsPrevent intrusionCosmetic preparationsToilet preparationsCooling effectAgricultural engineering

The invention discloses sun-screening agent spray. Sun-screening components with strong light sensitivity, an emollient, a solvent, a cooling agent, and the like are stored into an aerosol tank in anisolating mode through a bag, and a propellant is charged between the aerosol tank and the bag, wherein the cooling agent is preferably trans-1-chloro-trifluoropropene. The spray disclosed by the invention is cool, quick-drying and free of unpleasant smell. According to the invention, in use of a spray tank, a spray valve which can be rotated by 360 degrees is adopted to the operation and use of the sun-screening agent spray, and the sun-screening agent spray is safe (non-combustible), environmentally friendly (low-GWP and low-VOC), efficient and convenient, can effectively protect the effectiveness of a sun-screening agent within a quality guarantee period, and has cooling effect. The sun-screening agent spray disclosed by the invention is easy to carry, easy to use, easy to store, and safe and reliable, and has very excellent application performance.

Owner:ZHONGSHAN TIANTU FINE CHEM CO LTD

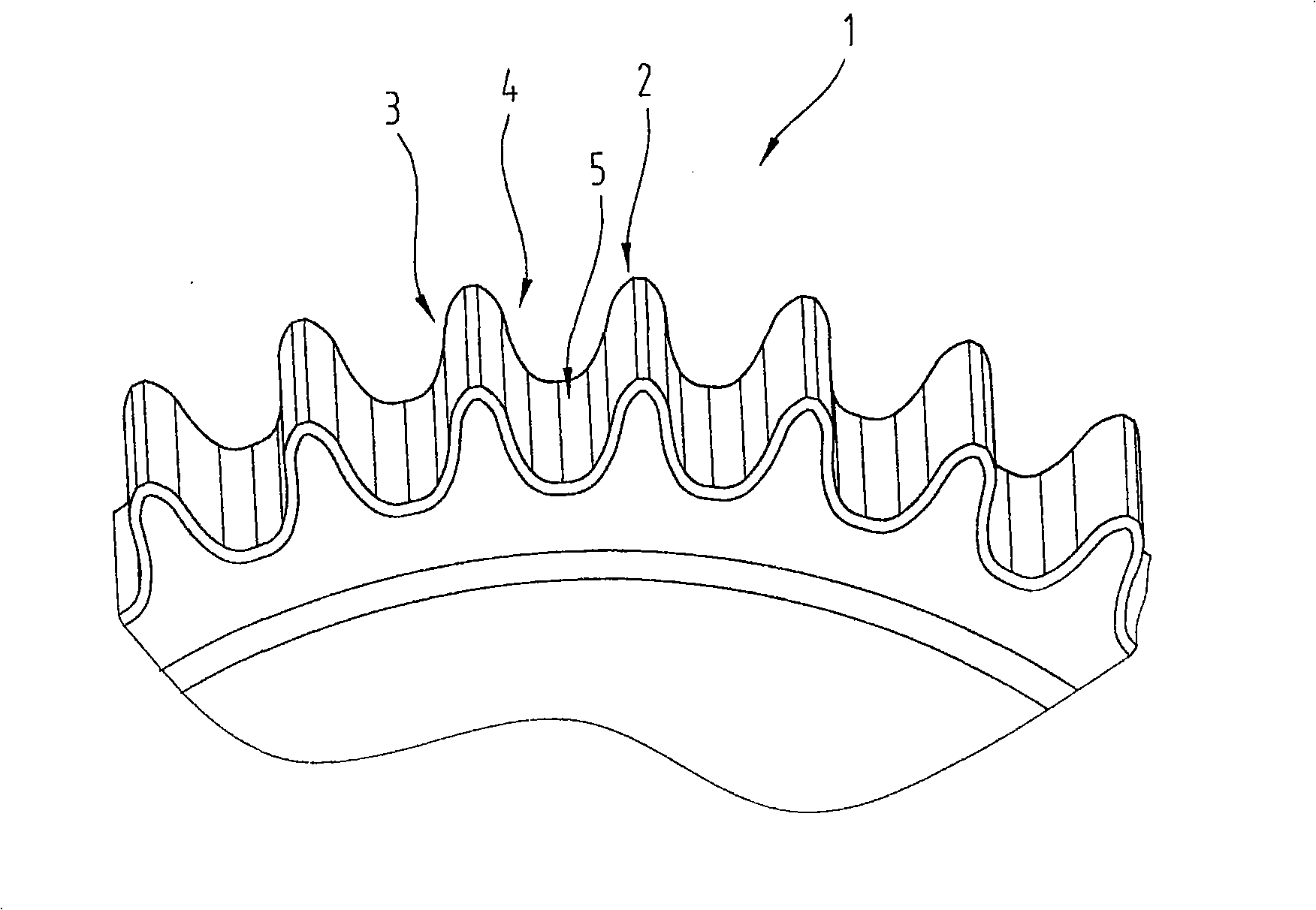

Sintered gear

InactiveCN101514744AHigh mechanical strengthReduce porosityPortable liftingThin material handlingLower limitSurface roughness

The invention relates to a sintered gear (1) with teeth (2), between which a tooth base (5) is respectively formed. The tooth base (5) has a surface which is subjected to a thermo-mechanical finishing process and a surface roughness with an arithmetical mean roughness value Ra, measured in accordance with DIN EN ISO 4287, selected fr om a range with a lower limit of 0.2 .mu.m and an upper limit of 2.0 .mu.m.

Owner:MIBA SINTER AUSTRIA

Chemical method for removing remelted layer on monocrystal nickel-base high-temperature alloy surface

The invention belongs to surface treatment technology and relates to an improved method for removing a remelted layer on a monocrystal nickel-base high-temperature alloy surface. The method comprises the following steps of: removing oil from the part surface; preparing a remelted layer removing solution; removing the remelted layer; and cleaning the part. The invention can not cause recrystallization on the monocrystal nickel-base high-temperature alloy surface and ensure that the performance of the part is free from adverse effects. Meanwhile, the invention enhances the work efficiency and reduces the cost.

Owner:AECC AVIATION POWER CO LTD

Metal ceramic material

The invention discloses a metal ceramic material, and belongs to the technical field of metal ceramic materials. The metal ceramic material comprises, by weight, 60-80 parts of a principal phase, 16-20 parts of a binding phase, 5-10 parts of carbide, 3-10 parts of an additive, 5-10 parts of whiskers and 5-10 parts of auxiliaries. SiC and / or TiC serve / serves as the whiskers, and carbon nano tubes serve as the auxiliaries. Through adding of the whiskers Sic and / or TiC and the auxiliary carbon nano tubes, the strength of the metal ceramic material is high, toughness is enhanced, and the application range of a metal ceramic cutter manufactured through a powder metallurgy manner is wide.

Owner:自贡市希力数控工具有限公司

Manufacturing process of metal ceramic material for numerical control cutter

InactiveCN110064760AGood dispersionGrind evenlyTransportation and packagingMetal-working apparatusPorosityNumerical control

The invention discloses a manufacturing process of a metal ceramic material for a numerical control cutter, and belongs to the technical field of numerical control cutter materials. The manufacturingprocess comprises the steps of (1), mixing raw materials, and filtering after wet grinding to obtain mixed slurry; (2), carrying out spray drying granulation on the mixed slurry through a closed-circuit solvent recovery spray drying tower; (3), pressing the mixed granules obtained in the step (2) into a green body by adopting an extrusion method; and (4), placing the prepared green body into a degreasing and pressurizing integrated sintering furnace, vacuumizing and filling argon into the sintering furnace before heating, filling hydrogen to completely replace the argon after heating, fillingthe argon again to completely replace the hydrogen when the temperature is continuously heated to 500-600 DEG C after glue discharging is completed, vacuumizing with a pump, continuously heating to 1,350-1,550 DEG C, keeping the temperature for 8-12 minutes before refilling with the argon, keeping the temperature for more 40-60 minutes, and naturally cooling to room temperature after reducing thetemperature to 900 DEG C by de-energizing. The manufactured material has zero porosity, high toughness, uniform structure, excellent mechanical property and durability.

Owner:自贡市希力数控工具有限公司

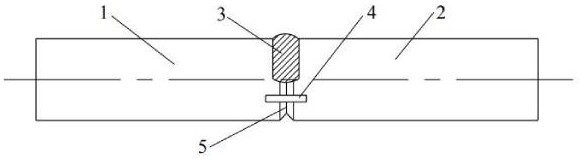

A low-temperature joining method of tzm and wre dissimilar alloys

ActiveCN107081517BEfficient connectionLow connection temperatureWelding/soldering/cutting articlesNon-electric welding apparatusRoom temperatureAlloy

The invention provides a low-temperature connecting method of a TZM and WRe dissimilar alloy. Ti powder is adopted as an activated middle layer, a TZM alloy and a WRe alloy are subjected to diffusion welding at the temperature lower than the recrystallization temperature of base metal through the spark plasma sintering technology, and a connecting part of the TZM alloy and the WRe alloy is obtained. By means of the welding method, it can be guaranteed that the base metal is not recrystallized, meanwhile, the TZM / WRe dissimilar alloy connecting part high in strength and good in forming is obtained, and the room temperature shear strength of a connector can reach 263 MPa.

Owner:HEFEI UNIV OF TECH

Functional film prepared by functionalized organic powder, low-temperature non-damaging manufacturing method and application

ActiveCN111004404BHigh molecular weightEfficient exclusionOrganic-compounds/hydrides/coordination-complexes catalystsFinal product manufactureOrganic filmHigh energy

The invention provides a functional membrane prepared by using functionalized organic powder, a low-temperature non-damaging manufacturing method and its application. The organic powder membrane material is composed of functionalized organic powder and polytetrafluoroethylene (PTFE). The heated supersonic airflow opens the polytetrafluoroethylene molecular chain, bonds the functionalized organic powder, and extrudes the air in the powder to form a continuous cake. Layer-film hot-pressing composite process forms a low-porosity, uniform-thickness film. This method can continuously roll-to-roll to produce micron-sized organic membranes, which can maximize the physical and chemical properties of organic powders and prevent performance damage or anisotropy caused by recrystallization due to high temperature or introduction of solvents into the film. . No solvent is introduced in the manufacturing process, which avoids the problems of environmental pollution, high energy consumption and uneven density of membrane materials caused by the solvent drying process.

Owner:东莞奥创能源科技有限公司

High energy density quasi-solid-state sodium-ion battery manufacturing method

ActiveCN112290081BImprove thermal stabilityNon-flammableSolid electrolytesFinal product manufactureSolid state electrolyteElectrolytic agent

Owner:东莞奥创能源科技有限公司

Chemical method for removing remelted layer on monocrystal nickel-base high-temperature alloy surface

The invention belongs to surface treatment technology and relates to an improved method for removing a remelted layer on a monocrystal nickel-base high-temperature alloy surface. The method comprises the following steps of: removing oil from the part surface; preparing a remelted layer removing solution; removing the remelted layer; and cleaning the part. The invention can not cause recrystallization on the monocrystal nickel-base high-temperature alloy surface and ensure that the performance of the part is free from adverse effects. Meanwhile, the invention enhances the work efficiency and reduces the cost.

Owner:AECC AVIATION POWER CO LTD

Compound emulsifier for cake and preparation method of compound emulsifier

InactiveCN109984158AInhibition of recrystallizationGood water solubilityDough treatmentGlycerolPhospholipid

The invention discloses a compound emulsifier for a cake. The compound emulsifier for the cake is prepared from, by weight, 0.1-60 parts of a d-sorbitol solution, 0.1-50 parts of glycerin, 0.1-8 partsof glycerin monostearate, 0.1-4 parts of Tween 80, 0.1-4 parts of phospholipid, 0.1-8 parts of triglyceride monostearate and 0.1-10 parts of vegetable oil. The invention further discloses a preparation method of the compound emulsifier for the cake. The compound emulsifier for the cake and the preparation method of the compound emulsifier for the cake can effectively avoid the problem of starch retrogradation.

Owner:DONGGUAN HUAMEI FOOD

Novel phenylacetylene end capacity capped polyimide prepolymer and preparation method thereof

The invention belongs to the field of polymer materials, and in particular relates to a performed polyimide polymer of two novel phenylacetylene sealed ends and a preparation method thereof. The preparation method is to use diamine 1, 3-di(3, aminobenzene oxyl-4'-formacyl) benzene and triamine 1, 3, 5-tri(3- aminobenzene oxyl-4'-formacyl) benzene respectively with an end-capping reagent - phenylacetylene anhydride to prepare performed polyimide polymer powder of the phenylacetylene sealed ends by the acetone method, the one-step method and the two-step method. The method for preparing the performed polyimide polymer has the advantages of high yield, good quality, high purity and no necessity of performing recrystallization. The performed polyimide polymer of the phenylacetylene sealed ends can be used for preparing high-performance crosslinking materials and has a wide processing window.

Owner:JILIN UNIV

A high-performance brazing method for ni3al-based single crystal alloys

ActiveCN112008180BNo recrystallizationAntioxidant-enhancing elementsWelding/cutting media/materialsSoldering mediaSingle crystalWelding defect

The invention belongs to the technical field of welding, in particular to a Ni 3 High performance brazing method for Al-based single crystal alloys. A new type of high temperature resistant Ni-Cr-W-Mo-Si solder was applied and a suitable for the solder and Ni 3 The brazing process of Al-based single crystal alloy mainly includes the steps of pre-welding cleaning, assembly positioning, presetting solder, vacuum brazing, and post-welding heat treatment. Using the solder and technology used in the present invention can obtain excellent brazing joint structure, the brazing seam and the base metal interface are well combined, and the brazing seam has no welding defects and low melting point phases simultaneously, and the Ni brazed according to the technology 3 Al-based single crystal alloy brazed joints have high mechanical properties that meet the requirements of use.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

Potassium decaborate sodium salt fertilizer and preparation method thereof

InactiveCN103265336ANo precipitationNo recrystallizationAdditivesWelding/cutting media/materialsAgricultural engineeringPotassium hydroxide

The invention relates to a preparation of instant potassium decaborate sodium salt. The compound refers to potassium decaborate sodium salt prepared through high-temperature and high-pressure polymerization reaction of sodium decaborate, potassium hydroxide and boric acid. The potassium decaborate sodium salt fertilizer can be dissolved completely at a high dissolving speed, and can be widely applied to industry and agriculture.

Owner:安徽省农望农业科技开发有限公司

Method for preparing Tebucomazole in high purity

A process for preparing high-purity pentazolol features the reaction between 1-(4-chlorphenylethyl)-1-tert-butyl-1, 2-epoxy ethane and 1,2,4-triazole in organic polar solvent under existence of alkali while adding catalyst chosen from N,N-dimethyl-4-aminopyridine, N,N-dimethylphenylamine, methylphrrolidone, dimethyl formamide, methanol sodium, ethanol sodium, potassium hydroxide and sodium hydroxide. Its advantages are high output rate and high purity.

Owner:HUNAN CHEM RES INST +1

A low-damage processing method for air film holes in single-crystal high-vortex hollow blades of aero-engines

ActiveCN106583949BExtend the life cycleExtended processing cycleLaser beam welding apparatusAlcoholLaser processing

The invention provides a low-damage processing method of film holes in a single crystal high-pressure-turbine hollow blade of an aircraft engine. The low-damage processing method comprises the following steps: wiping the surface of the blade through degreasing cotton with absolute alcohol; transferring into a drying box to dry; arranging a clamp on a machine table, and aligning; assembling the dried blade on the clamp and locking; presetting scanning system parameters; scanning the blade; saving axis moving coordinate value of each hole to be processed under an automatically-generated machine coordinate system as a *.xls file; importing and generating a hole position file; performing compensative correction on the deviation value of a focus position of the hole to be processed; and setting the optimized laser processing technological parameters through a main processing interface. With the adoption of the low-damage processing method, the processed hole is outstanding in quality; a remelting layer, microcacks and recrystallization can be avoided after the single crystal material is processed, so that subsequent processing can be saved, and as a result, the fatigue life and the processing cycle of the blade can be prolonged and improved; the ablation threshold of the single crystal material can be effectively reduced; the recrystallization of the single crystal material can be avoided.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

Tungsten-copper module for high thermal load parts of fusion device and preparation method thereof

ActiveCN104416973BReduce defects such as holesNot brittleLamination ancillary operationsLaminationCopperHeat sink

The invention relates to the technical field of connection of heterogeneous materials and particularly relates to a tungsten copper module for a high thermal load part of a fusion device as well as a preparation method thereof. The method comprises the following steps: 1) selecting tungsten, anaerobic pure copper and a chromium zirconium copper alloy heat sink material in appropriate size; 2.1) pre-treating surfaces of tungsten and anaerobic pure copper; 2.2) carrying out vacuum-casting on the anaerobic pure copper on the surface of tungsten; 3.1) pre-treating the surface of the anaerobic pure copper in a tungsten / anaerobic pure copper block and a to-be-welded face of a chromium zirconium copper alloy; 3.2) welding the tungsten / anaerobic pure copper block and the chromium zirconium copper alloy in a vacuum hot pressed furnace; and 3.3) machining a welded tungsten / anaerobic pure copper / chromium zirconium copper alloy compound block to form the required tungsten copper module. The preparation method of the tungsten copper module is low in cost, high in efficiency and high in reliability and the tungsten copper module can bear a steady state thermal load which is greater than 5MW / m<2>.

Owner:SOUTHWESTERN INST OF PHYSICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com