Tungsten copper module for high thermal load part of fusion device as well as preparation method thereof

A tungsten-copper, high-heat technology, applied in the field of tungsten-copper modules and its preparation, can solve the problems of not being able to find the experimental process and parameters, and cannot exceed the recrystallization temperature, and achieve the effects of low cost, high efficiency, and strong reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

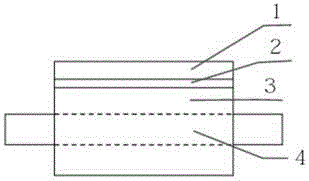

[0032] A method for preparing a tungsten-copper module used for high thermal load parts of a fusion device, specifically comprising the following steps:

[0033] Step 1. Select suitable sized tungsten, oxygen-free pure copper and chrome-zirconium copper heat sink materials for the preparation of tungsten-copper modules. Among them, tungsten is industrially produced tungsten with a size of 40mm×40mm and a thickness of 5mm; the adaptive layer is made of tungsten with a thickness of 1mm Oxygen-free pure copper; chrome-zirconium-copper alloy heat sink adopts a material with a size of 45mm×45mm and a thickness of 25mm;

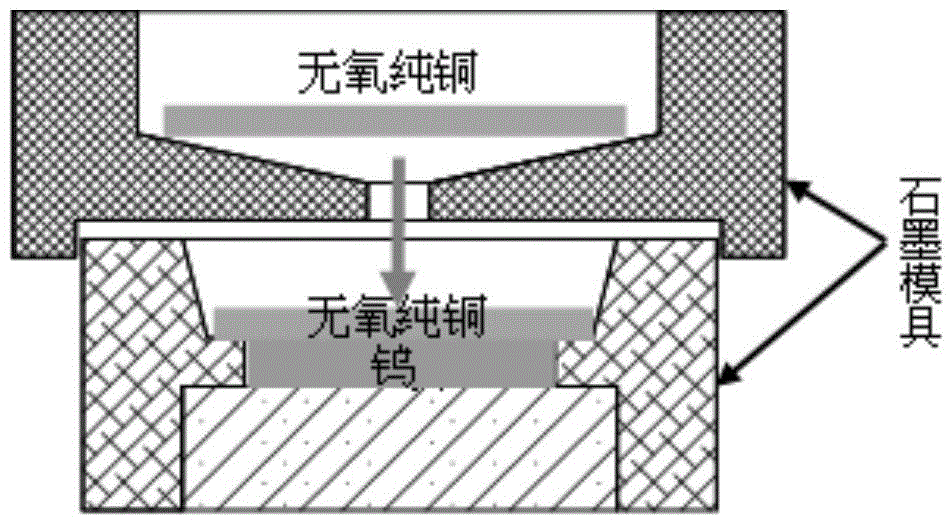

[0034] Step 2. Vacuum casting of oxygen-free pure copper on the surface of tungsten;

[0035] Step 2.1, pretreating the surface of tungsten and oxygen-free pure copper;

[0036] Pretreatment of tungsten and oxygen-free pure copper surface to remove impurities, oil stains and oxide film on the surface: put pure tungsten and chromium-zirconium copper alloy into acet...

Embodiment 2

[0048] A method for preparing a tungsten-copper module used for high thermal load parts of a fusion device, specifically comprising the following steps:

[0049] Step 1. Select suitable sized tungsten, oxygen-free pure copper and chrome-zirconium copper heat sink materials to prepare tungsten-copper modules. Among them, the tungsten is industrially produced tungsten with a size of 30mm×30mm and a thickness of 8mm; the adaptive layer is made of tungsten with a thickness of 2mm. Oxygen-free pure copper; chrome-zirconium-copper alloy heat sink adopts a material with a size of 35mm×35mm and a thickness of 25mm;

[0050] Step 2. Vacuum casting of oxygen-free pure copper on the surface of tungsten;

[0051] Step 2.1, pretreating the surface of tungsten and oxygen-free pure copper;

[0052] Pretreatment of tungsten and oxygen-free pure copper surface to remove impurities, oil stains and oxide film on the surface: put pure tungsten and chromium-zirconium copper alloy into acetone sol...

Embodiment 3

[0064] A method for preparing a tungsten-copper module used for high thermal load parts of a fusion device, specifically comprising the following steps:

[0065] Step 1. Select suitable sized tungsten, oxygen-free pure copper and chrome-zirconium copper heat sink materials for the preparation of tungsten-copper modules. Among them, tungsten is selected from industrially produced tungsten with a size of 60mm×60mm and a thickness of 10mm; the adaptive layer is selected from tungsten with a thickness of 3mm Oxygen-free pure copper; chrome-zirconium-copper alloy heat sink adopts a material with a size of 65mm×65mm and a thickness of 30mm;

[0066] Step 2. Vacuum casting oxygen-free pure copper on the surface of tungsten;

[0067] Step 2.1, pretreating the surface of tungsten and oxygen-free pure copper;

[0068] Pretreatment of tungsten and oxygen-free pure copper surface to remove impurities, oil stains and oxide film on the surface: put pure tungsten and chromium-zirconium copp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com