Manufacturing method of high-energy-density quasi-solid-state sodium ion battery

A sodium ion battery, high energy density technology, applied in the direction of secondary battery, solid electrolyte, final product manufacturing, etc., can solve the problem of no industrialization solution, etc., achieve high safety, good thermal stability, non-combustible Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

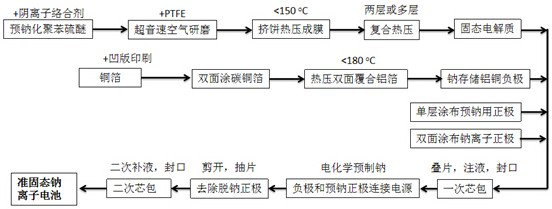

Method used

Image

Examples

Embodiment approach 1

[0047] (1) Preparation of isotropic sodium ion polyethylene-polyphenylene sulfide (PE-PPS) composite solid electrolyte

[0048] N-methylpyrrolidone (NMP), lithium sulfide Na 2 S. Lithium hydroxide NaOH, according to the material ratio of 4:1:0.2, placed in a high-pressure reactor with stirring function, and heated to 220 °C for 4 hours to obtain a dehydration system; secondly, cool the dehydration system To 90°C, add 1,4-dichlorobenzene (p-DCB), p-DCB is the same as Na 2 The molar ratio of S to substance is 1:1. React at 230°C for 120 minutes to obtain a mixed slurry. Again, drop the same amount of HCl as NaOH in the mixed slurry to just neutralize NaOH, and remove NMP and H in the mixed slurry by evaporation or sublimation. 2 O, to obtain dry mixed powder A. The mixed powder A was sheared and pulverized with a frozen alloy blade at -40°C to obtain a mixed powder B with D50=5 μm. In the pulverized mixed powder B, calixarone (the added calixarone The amount of the substanc...

Embodiment approach 2

[0061] (1) Preparation of isotropic sodium ion polyethylene-polyphenylene sulfide (PE-PPS) composite solid electrolyte

[0062] N-methylpyrrolidone (NMP), lithium sulfide Na 2 S. Lithium hydroxide NaOH, according to the material ratio of 5:2:0.3, put it in a high-pressure reactor with stirring function, and heat it up to 210 °C for 5 hours to dehydrate at a high temperature to obtain a dehydration system; secondly, cool the dehydration system To 80 ℃, add p-DCB, p-DCB with Na 2 The molar ratio of S to substance is 1:1. React at 230°C for 120 minutes to obtain a mixed slurry. Again, drop the same amount of HCl as NaOH in the mixed slurry to just neutralize NaOH, and remove NMP and H in the mixed slurry by evaporation or sublimation. 2 O, to obtain dry mixed powder A. Put the mixed powder A at -40°C by using a frozen impact jet mill plus a classification system and a vibrating sieve machine to prepare a mixed powder B with D50=10 μm, and add caliximidazole to the pulverized ...

Embodiment approach 3

[0073] (1) Preparation of isotropic sodium ion polyethylene-polyphenylene sulfide (PE-PPS) composite solid electrolyte

[0074] N-methylpyrrolidone (NMP), lithium sulfide Na 2 S. Lithium hydroxide NaOH, according to the material ratio of 4.5:1.5:0.3, placed in a high-pressure reactor with a stirring function, and heated to 210 ° C for 5 hours to obtain a dehydration system; secondly, cool the dehydration system To 80°C, add 1,4-dichlorobenzene (p-DCB), p-DCB is the same as Na 2 The molar ratio of S to substance is 1:1. The reaction was carried out at 240° C. for 150 minutes to obtain a mixed slurry. Again, drop the same amount of HCl as NaOH in the mixed slurry to just neutralize NaOH, and remove NMP and H in the mixed slurry by evaporation or sublimation. 2 O, to obtain dry mixed powder A. Put the mixed powder A at -40°C by using a frozen impact jet mill plus a classification system and a vibrating sieve machine to prepare a mixed powder B with D50=15 μm, and add 2-aminot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com