Technological method for heat treatment to titanium alloy welded component

A technology of welding components and process methods, applied in the field of heat treatment and annealing, can solve the problems of increasing manpower, material resources, heat treatment temperature and heat treatment furnace temperature inconsistency, long cycle, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment A1

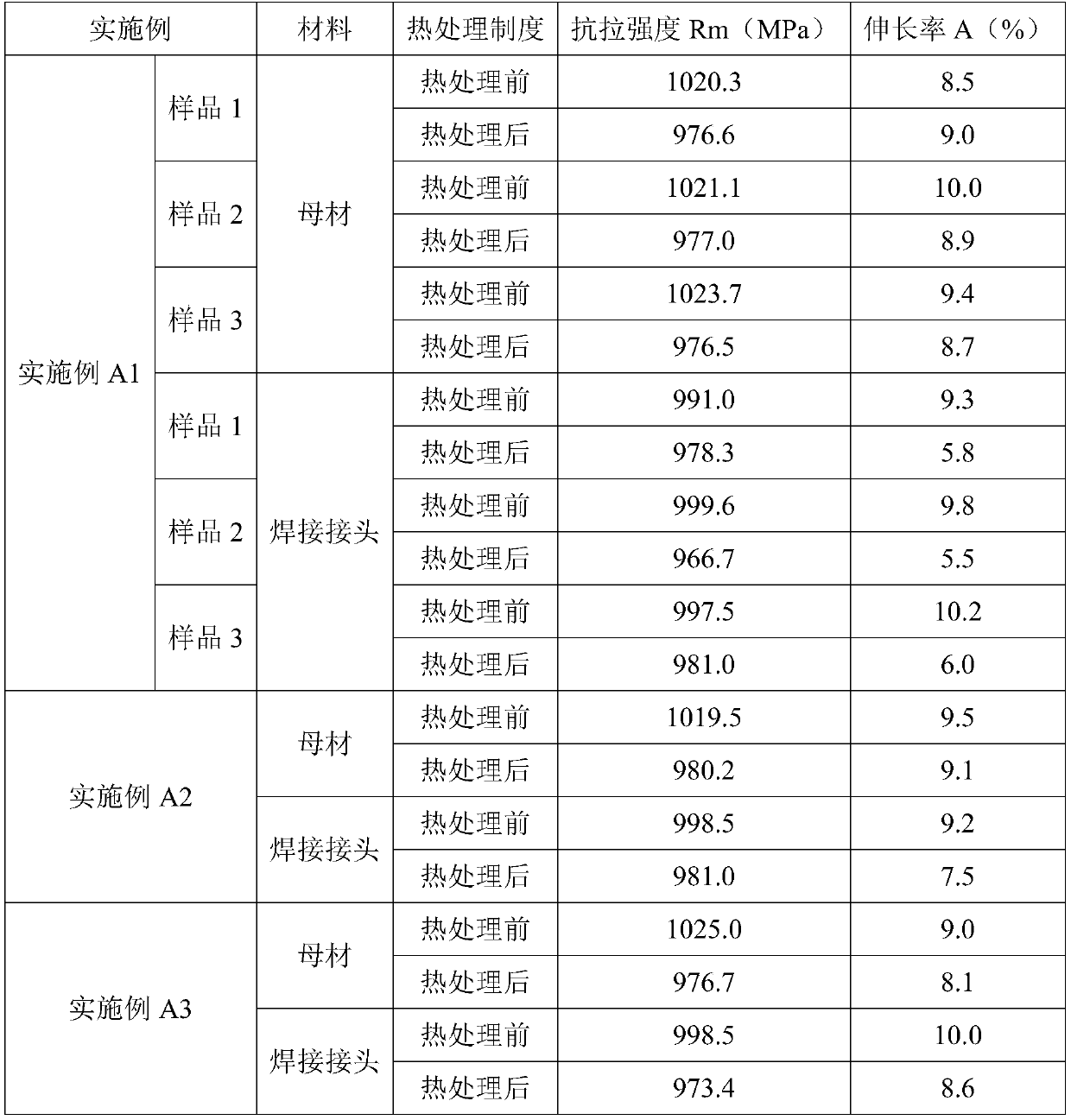

[0027] Prepare three samples of titanium alloy welded components, clean the surface of titanium alloy welded components with acetone, dilute the paint containing water-soluble borosilicate glass enamel with a small amount of water and stir it evenly, and then apply a layer of it with a brush. On the surface of the component, after the first layer of paint dries naturally, another layer of paint is applied, and after the second layer of paint dries naturally, the component to be treated is put into a resistance furnace, and the heat treatment process parameter is set as the annealing temperature T m =500°C, heating time t 升 = 1.5h, holding time t m =2.0h, after cooling down to below 200°C with the furnace, take it out of the furnace, air cool to room temperature, and use a wire brush to clean the surface coating of the components.

[0028] After the heat treatment is completed, the surface of the titanium alloy test plate changes from silvery white to silvery white mixed with ...

Embodiment A2

[0030] Clean the surface of the titanium alloy welded component with alcohol, dilute the paint containing water-soluble borosilicate glass enamel with a small amount of water and stir it evenly, then apply a layer on the surface of the component by spraying method, and dry the first layer of paint at 80°C After that, apply another layer of paint. After the second layer of paint is dried at 80°C, put the component to be treated into the resistance furnace, and set the heat treatment process parameter as the annealing temperature T m =550°C, heating time t 升 : 1.7h, holding time t m = 2.2h, after cooling down to below 200°C with the furnace, take it out of the furnace, air cool to room temperature, and use a high-pressure water gun to clean the surface coating of the components.

[0031] After the heat treatment was completed, the surface of the titanium alloy test plate changed from silvery white to silvery white mixed with light blue, and then the mechanical properties of the...

Embodiment A3

[0033] Clean the surface of the titanium alloy welded component with acetone, dilute the paint containing water-soluble borosilicate glass enamel with a small amount of water and stir it evenly, then apply a layer on the surface of the component with a brush, and wait for the first layer of paint to naturally After drying, apply another layer of paint. After the second layer of paint dries naturally, put the component to be treated into the resistance furnace, and set the heat treatment process parameter as the annealing temperature T m =600°C, heating time t 升 =2.0h, holding time t m =2.5h, after cooling down to below 200°C with the furnace, take it out of the furnace, air cool to room temperature, and use a wire brush to clean the coating on the surface of the component.

[0034] After the heat treatment was completed, the surface of the titanium alloy test plate changed from silvery white to silvery white mixed with light blue, and then the mechanical properties of the bas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com