Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

69results about How to "No layering" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Heat-storage medium and its use

InactiveCN1940006ALow toxicityNo supercooling performanceHeat proofingHeat-exchange elementsChemistryMagnesium nitrate

Owner:HUNAN UNIV +1

Special epoxy impregnating compound for basalt fiber and preparation method of special epoxy impregnating compound

The invention discloses a special epoxy impregnating compound for a basalt fiber and a preparation method of the special epoxy impregnating compound. The special epoxy impregnating compound for the basalt fiber is prepared from the following components in percentage by weight: 5.0%-8.0% of an epoxy latex film-forming agent, 0.1%-1% of a lubricant, 0.5%-1.5% of binder, 0.5%-1.5% of plasticizer, 0.2%-1.0% of an antistatic agent, 0.5%-1.0% of a coupling agent and the balance of soft water. The reinforced textile type impregnating compound is suitable for a basalt-reinforced thermosetting phenolic epoxy resin composite material, is good in textile property, and is capable of promoting the binding force of the basalt fiber and the reinforced thermosetting high-molecular polymer.

Owner:成都中玻复合材料有限公司

Optical film with sharpened bandedge

InactiveCN1288520AMelt viscosity reasonably matchedAdequate interfacial adhesionOptical articlesOptical elementsEngineeringRepeat unit

Owner:3M CO

Phosphogypsum high-strength wall brick and its production method

The invention discloses a high-intensity ardealite wall brick and the producing method. And the composition weight ratio of semi-hydrated ardealite to anhydrous ardealite to flyash to coagulant is (70-85) : (12-20 ): (15-20 ): (15-25), where the coagulant is 12-20% silicasol water solution. And the invention uniformly blends them in sprinkling mode, mechanically places the mixture into a mould and shapes in high pressure, mechanically demoulds, and naturally hydrates to make it. And the invention firstly uses large amount of ardealite raw material in building materials, where the synthetic utilization of ardealite is up to 80%; and it is low-cost and saves land resources. After processed, it accords with national stipulated nuclear radiation indexes, has high hardness, reduces equipment investment and reduces cost of product.

Owner:重庆金仓龙新型建材有限公司

Metal piece electroplating method

The invention discloses a metal part electroplating method, which comprises the following: a step of membrane sticking, which is to cover an anti-electroplating membrane coincided with the non-electroplating part of a metal part on the surface of the metal part to be electroplated; a step of electroplating, which is to carry out the electroplating of the metal part covered with the anti-electroplating membrane on the surface; a step of stripping, which is to remove the anti-electroplating membrane on the metal part after electroplating. The metal part electroplating method can avoid unnecessary waste and reduces electroplating cost; moreover, the method greatly increases bonding force when a metal part is glued to other parts or a PCB, and the metal part does not delaminate or fall off even when the metal part is exposed in a high-temperature environment for a long time.

Owner:SHENNAN CIRCUITS

Metal part electroplating method

The invention discloses a metal part electroplating method. The metal part electroplating method includes the steps that a, film pasting is conducted, i.e., the surface of a metal part to be electroplated is covered with an anti-electroplating film coinciding with the portion, not needing electroplating, of the metal part; b, electroplating is conducted, i.e., the metal part with the surface covered with the anti-electroplating film is subjected to electrocoppering, electronickelling and electrogalvanizing, wherein an electrogalvanizing solution for electrogalvanizing is composed of 100-150 mg / L of sodium hydroxide, 5-10 mg / L of ethylenediamine, 25-30 mg / L of triethanolamine, 50-130 mg / L of alkaline tetra-iso-propyl amine, 10-15 mg / L of zinc sulfate, 40-59 mg / L of sodium citrate, 25-39 mg / L of phosphorous acid, 40-55 mg / L of dioctyl sodium sulfosuccinate and 25-67 mg / L of antimony potassium tartrate, and meanwhile electroplating parameters are set; and c, film removal is conducted, i.e., the anti-electroplating film on the metal part is removed after electroplating is completed. By means of the metal part electroplating method, the electroplating cost is reduced and the occurrence rate of hydrogen brittleness is also reduced.

Owner:WUXI QIAOYANG MACHINERY MFG

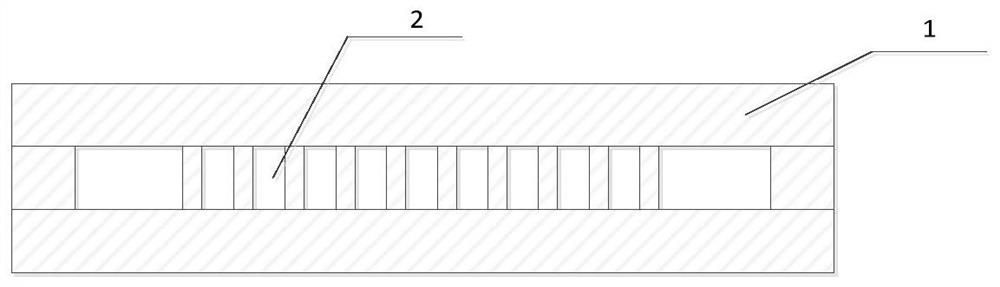

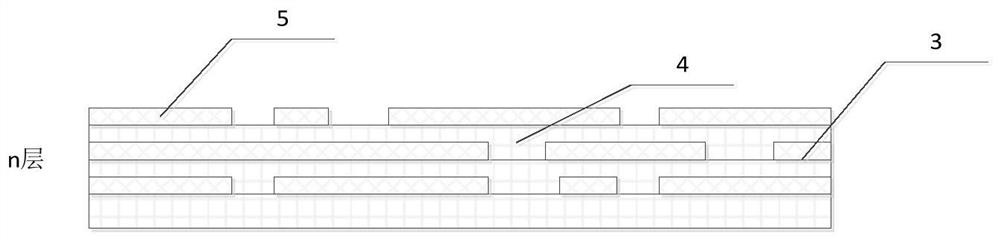

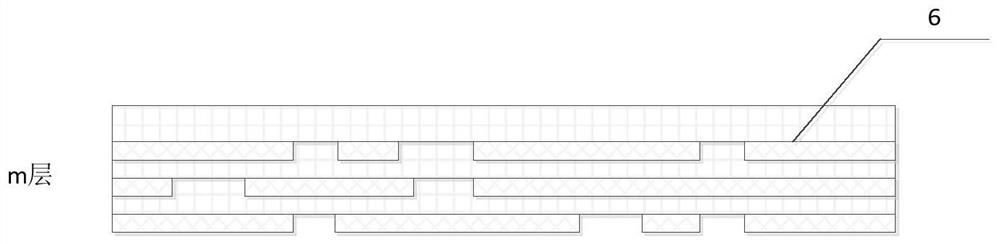

Printed circuit board with embedded micro-channels and preparation method of printed circuit board

ActiveCN113056087AAchieving Density CoolingImprove cooling effectPrinted circuit aspectsPrinted circuit manufactureHigh densityEngineering

The invention discloses a printed circuit board with embedded micro-channels. The printed circuit board comprises an embedded micro-channel metal core plate, wherein the top part of the embedded micro-channel metal core plate is provided with n wiring layers I, the bottom part of the embedded micro-channel metal core plate is provided with m wiring layers II, and the printed circuit board is provided with a liquid inlet and a liquid outlet which are communicated with the micro-channel. The structure has efficient heat dissipation capability, can realize transmission of high-density electrical signals, and meets the application requirements of high-density integrated high-power electronic devices.

Owner:SOUTHWEST CHINA RES INST OF ELECTRONICS EQUIP

Low-speed rotating original taste extrusion juicer

The invention provides a low-speed rotating original taste extrusion juicer and aims at providing a juicer small in occupied space, high in juice yield, light in weight, small in noise and convenient to dismantle and clean. The technical scheme is that at least three coarse pitch spiral blade teeth (20) extending to the front end of a cylinder along the circumferential bus direction and a rotating body head (15) forming a cone spiral with the front-end cylinder are arranged on the cylinder of a spiral propeller (5) positioned on an induction direct current motor spindle, and a turbine spiral tooth communicated with a spiral blade tooth channel is arranged at the shaft end of the rotating body head. The low-speed rotating original taste extrusion juicer is provided with a spiral extrusion port (19) and a mesh structure, residues of fruits and vegetables are discharged to a juicer hood (9) outside the juicer, wall knives (17) arranged around the extrusion port spiral surface equidistantly are arranged on an inner wall of the juicer hood (9), every wall knife extends towards a ring of the spiral surface (18) symmetrically, a frustum is formed in the axial direction, and a residue outlet with a residue discharging hole is inserted into a feeding barrel through a rotating clamping hook to be buckled so as to be connected to be a whole.

Owner:JOIN ONE ELECTRIC SHENZHEN

Anti-static and high-toughness oil absorbent roll

InactiveCN105478090AHigh strengthGood dimensional stabilityOther chemical processesNon-woven fabricsFiberSorbent

The invention discloses anti-static and high-toughness oil absorbent roll. The oil absorbent roll comprises a PE leakage-proof layer and an oil sorbent layer. The PE leakage-proof layer is compounded and fixed along the periphery of the oil sorbent layer. The oil sorbent layer is formed on the surface of the PE leakage-proof layer. The surface and the inside of the oil sorbent layer are in a spongy shape. Taper holes are formed in the surface of the oil absorbent roll. The oil sorbent layer forms a fiber web through warp direction embedding or warp direction and weft direction embedding weaving of filament formed by oil sorbent high molecular fiber and heat bonding fiber, needling on the fiber web is performed, the content of the heat bonding fiber in the filament is 5%-25%, the diameter ratio of the oil sorbent high molecular fiber to the heat bonding fiber is 5:1-7:1, and the length of the heat bonding fiber is below 1 / 5 that of the oil sorbent high molecular fiber. The anti-static and high-toughness oil absorbent roll effectively avoids secondary pollution caused by oil leakage because of compression in the utilization process and has anti-static performance. The taper holes are formed in the surface of the oil sorbent layer, so that the oil sorbent rate is improved greatly, and blocking conditions on the surface of the oil sorbent layer do not occur easily.

Owner:SUZHOU BD ENVIRONMENTAL PROTECTION

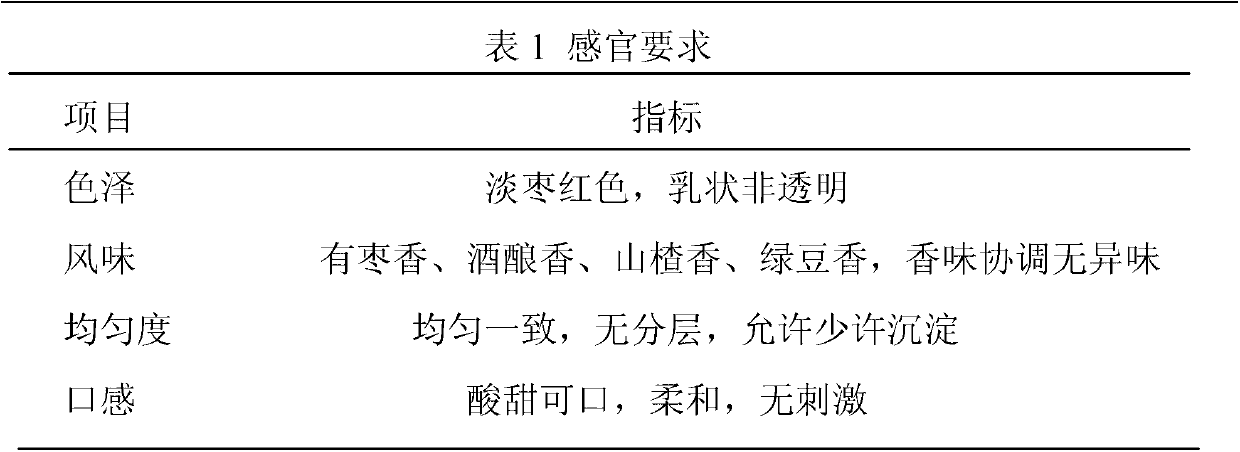

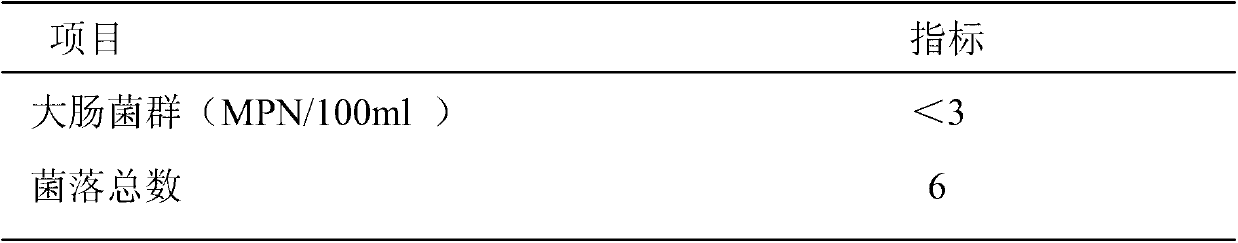

Grain and fruit compounding beverage and preparation method thereof

The invention relates to a grain and fruit compounding beverage and a preparation method thereof. The beverage comprises, by weight, 20-30% of Chinese date juice, 10-25% of hawthorn juice, 10-25% of mung bean emulsion, 10-30% of glutinous rice fermentation juice and 0.2-0.5% of a stabilizer. The preparation steps include (1) preparing the mung bean emulsion, the glutinous rice fermentation juice, the Chinese data juice and the hawthorn juice beverages; (2) evenly mixing the raw material juice and adding accessories for even mixing; and (3) homogenizing, filling and sterilizing to obtain the grain and fruit compounding beverage. The beverage has the advantages of healthcare such as air supply, greening blood, enhancing immunity of the organism, invigorating the stomach and digestion, dredging toxin in the human body, checking the diarrhea, strengthening the spleen and reducing the blood fat; and additionally, the beverage is thick, tasty and refreshing, delamination-free, not easy to generate sedimentation and easy to absorb.

Owner:吐鲁番金澳果业有限公司 +1

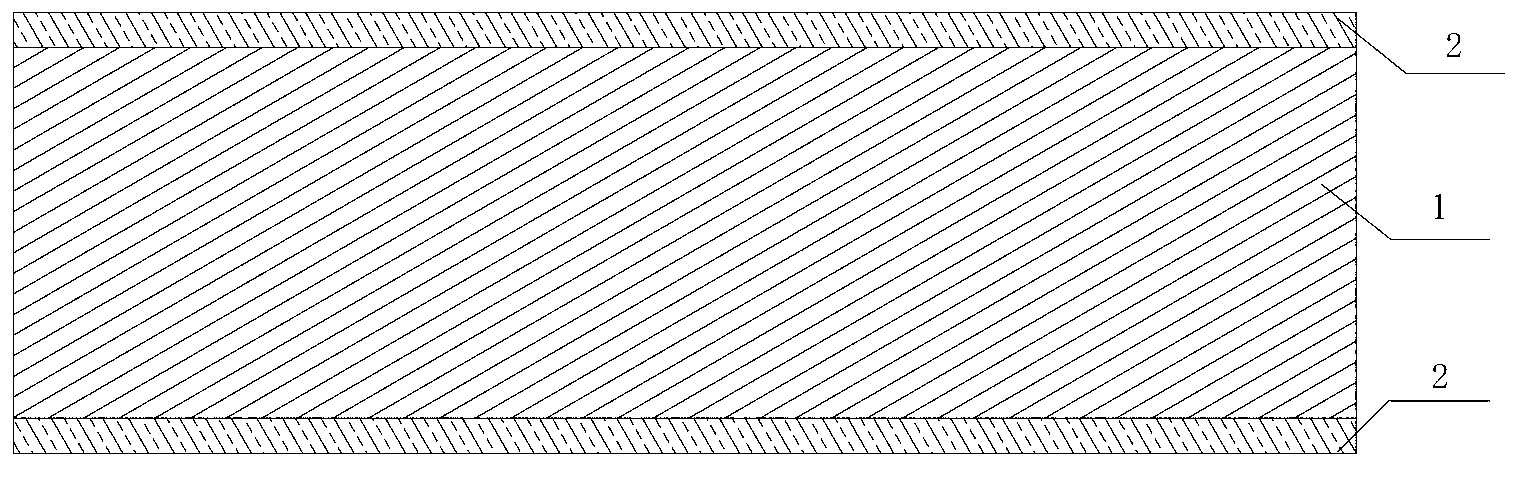

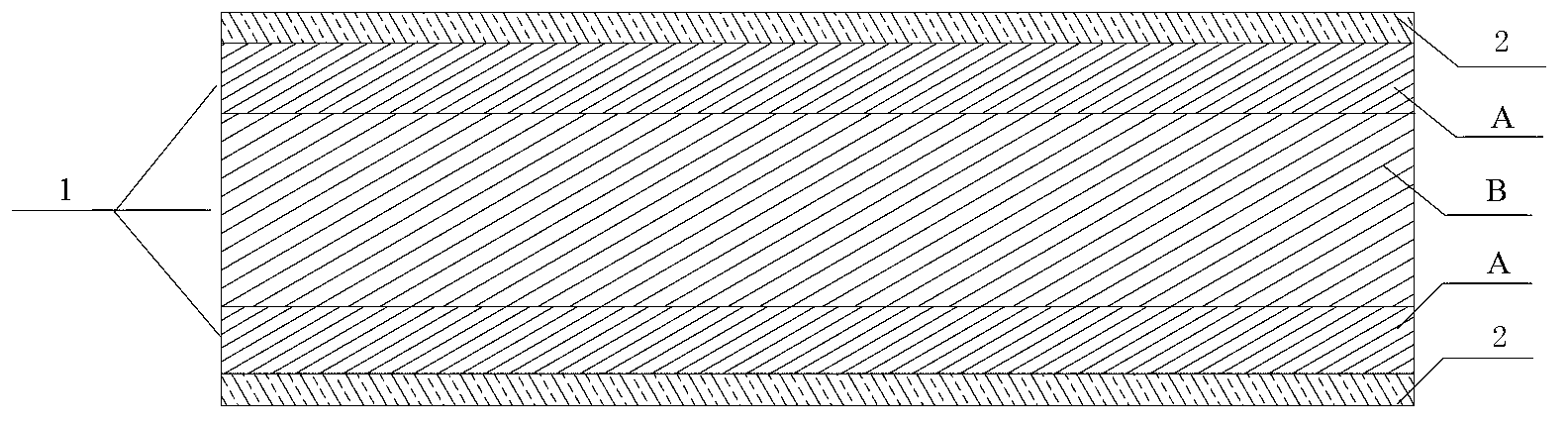

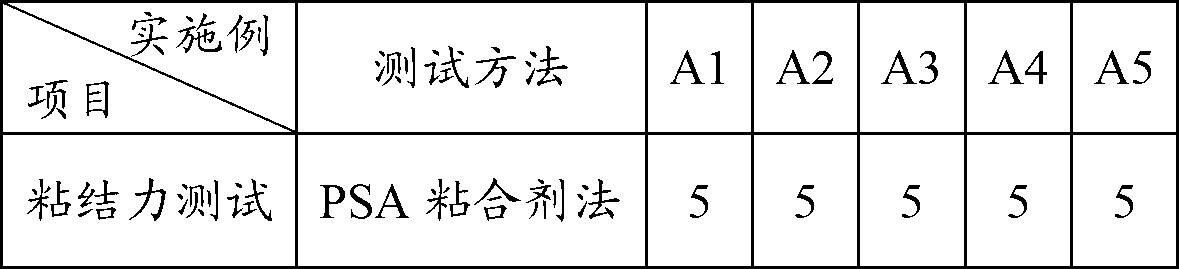

High-cohesiveness polyester film, method for preparing same as well as solar cell back panel

ActiveCN103013369ANo layeringWon't fall offFilm/foil adhesivesEster polymer adhesivesPolyester(Hydroxyethyl)methacrylate

The invention relates to the technical field of polyester films, and in particular relates to a high-cohesiveness polyester film, a method for preparing the same and a solar cell back panel. In order to solve the defect of layering or falling off of the conventional solar back film, the invention provides the high-cohesiveness polyester film, the method for preparing the same and the solar cell back panel. The polyester film comprises a base layer, wherein the two sides of the base layer are respectively adhered with a high cohesive layer, and a high cohesive layer material is a copolymer of maleic anhydride and hydroxyethyl methacrylate. The high-cohesiveness polyester film provided by the invention has good cohesiveness, and the method for preparing the same is simple in technology and is easy to operate. The solar cell back panel which is prepared from the polyester film cannot layer or fall off.

Owner:NINGBO CHANGYANG TECH

Water-based ink for negative ion decorative paper and preparation method therefor

The invention provides a water-based ink for negative ion decorative paper. Every 100 parts of the ink consist of the following components in parts by weight: 50-60 parts of negative ion color paste, 20-30 parts of a modified casein liquid, 0.5-2 parts of a thickening agent, 0.1-0.5 part of an antifoaming agent A, 1-3 parts of ethanediol A, 1-3 parts of alcohol, 0.1-0.5 part of a mildewproof agent A, and the balance of water A. According to the water-based ink, negative ions can be sustainably released to the air without additionally adding energy resources and the concentration of the negative ions in indoor air reaches the level of that in suburb and fields. The ink is fine and smooth, is not precipitated or layered, and has the characteristics of good storage stability, full coating and the like.

Owner:HANGZHOU HIWETECH CHEM TECH CO LTD

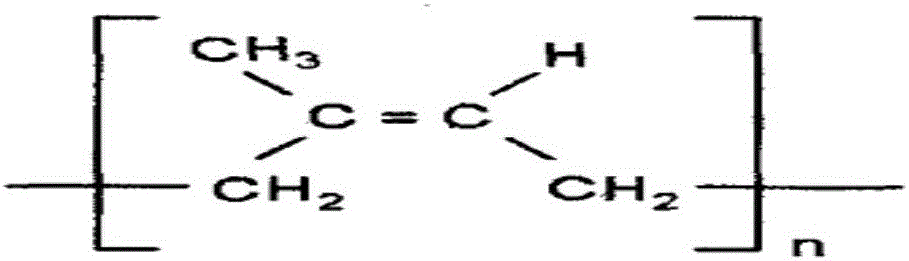

Rubber and ceramic composite material and preparation method thereof

The invention provides a rubber and ceramic composite material and a preparation method thereof. The rubber and ceramic composite material is prepared from the following components in percentage by weight: 50 percent to 55 percent of natural rubber and 50 percent to 45 percent of nano powder; the total mass is 100 percent. The nano powder is prepared from the following components in parts by weight: 40 to 45 parts of nano silicon dioxide, 35 to 40 parts of nano aluminum sesquioxide, 1 to 1.5 parts of nano molybdenum dioxide, 0.8 to 1 part of nano graphene, 1.5 to 2 parts of a silane coupling agent and 10 to 10.5 parts of an auxiliary material. According to the composite material provided by the invention, four types of dispersed nanoparticles are uniformly embedded into a rubber macromolecular grid to form a grid core and are mutually matched, so that the wearing resistance and anti-ageing performance of the composite material are effectively improved and the service life is prolonged.

Owner:胡连刚

Hair composition containing marine bio-active substance

ActiveCN108324591AReduce flakingRelieve inflammationCosmetic preparationsHair cosmeticsCuticlePiroctone olamine

The invention discloses a hair composition containing a marine bio-active substance. Specifically, the hair composition consists of D-glucosamine hydrochloride, marine shellfish peptide, fish proteinpeptide, algal polysaccharides and piroctone olamine, and furthermore, the hair composition can be assisted by olive oil and panthenol. The hair composition provided by the invention can serve as a hair shampoo, such as an anti-dandruff shampoo, having a special dandruff removal function; and after the use of the hair composition, a scalp cuticle structure and a normal barrier function can be repaired. The hair composition has multiple functions such as taking a lasting moisturizing effect, balancing oil secretion, inhibiting bacteria, diminishing inflammation, removing dandruff, relieving itching and the like; and in addition, the hair composition can also obviously improve hair quality, reduce furcation and relieve alopecia, and the hair composition can simultaneously conduct dandruff removing and hair nourishing.

Owner:FOSHAN ANAN BEAUTY & HEALTH PRODS +2

Electrochemical battery packaging material

ActiveCN107170915AResistant to electrolyteWear-resistantSynthetic resin layered productsJackets/cases materialsChemical treatmentPolyurethane adhesive

The invention relates to an electrochemical battery packaging material. The electrochemical battery packaging material comprises a thermoplastic resin layer, a second bonding layer, a metal foil layer, a first bonding layer and a protective layer, wherein the metal foil layer is provided with a first chemical treatment layer contacted with the first bonding layer and a second chemical treatment layer contacted with the second bonding layer, and the electrochemical battery packaging material also comprises a coloring coating formed between the protective layer and the first bonding layer and a matte layer formed on the outer surface of the protective layer. Therefore, the coloring coating is not directly printed on the protective layer, but coloring pigments are added into a polyurethane adhesive and coated on the protective layer, so that adhesion is enhanced; and the chemical treatment layers are formed at the inner layer and the outer layer of the metal foil layer, and the chemical treatment layers can enhance electrolysis resistance of the packaging material and also can enhance weather resistance of the packaging material, so that no layering of the packaging material in high temperature and high humidity environments is guaranteed.

Owner:SUZHOU FIRST PV MATERIAL CO LTD

Manufacturing method of multi-layer soft-and-hard-plate combined printed board with impedance requirement

InactiveCN104320929AQuality assuranceGuaranteed reliabilityMultilayer circuit manufactureCopper foilEngineering

Owner:双鸿电子(惠州)有限公司

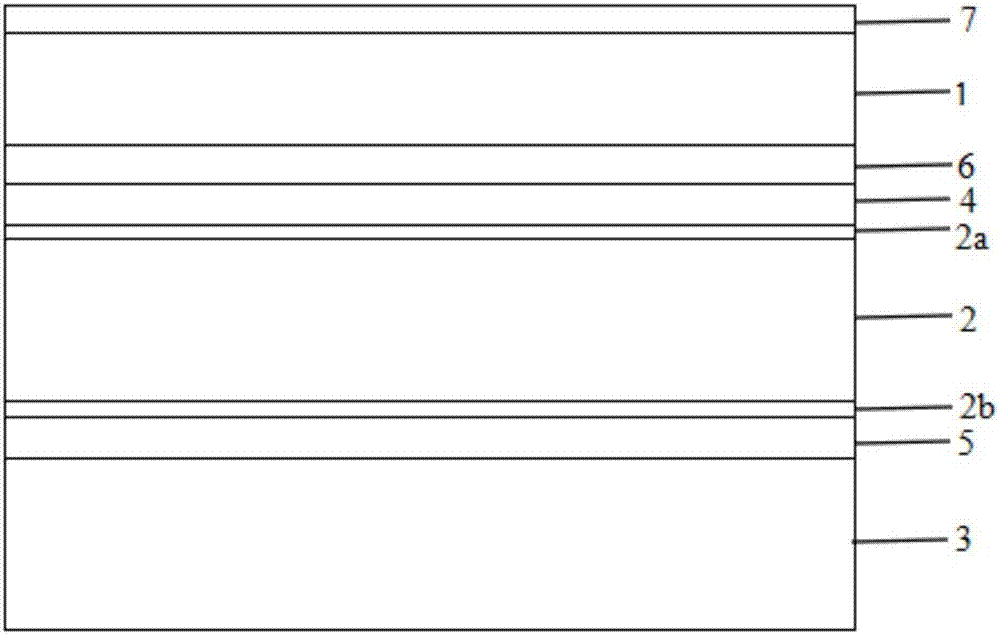

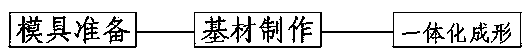

Preparation method of high-strength non-fading imitation wood plank

ActiveCN103660425AGuaranteed decorative effectOvercome longevityWater-setting substance layered productCellulosePolymer modified

The invention provides a preparation method of a high-strength non-fading imitation wood plank. The preparation method comprises a mold preparation stage, a substrate manufacturing stage and an integrally forming stage, wherein the substrate manufacturing stage comprises the steps as follows: manufacturing of a surface coloring layer substrate: cement used for manufacturing the surface coloring layer substrate is taken as a cementing material, an iron oxide pigment, an acrylic emulsion and hard calcium are combined, cement-based polymer modified color paste is prepared, and all component materials are required to be mixed and stirred uniformly into dilute paste; and manufacturing of a structure packing layer substrate: the structure packing layer takes cement as a cementing material, river sand, macadam, a superplasticizer, cellulose, an iron oxide pigment, an acrylic emulsion and hard calcium are combined, all component materials of the structure packing layer substrate are required to be mixed and stirred uniformly, and high-performance filling concrete is prepared. An imitation wood plank finished product prepared with the preparation method of the imitation wood plank is high in strength and imitation degree and good in weather resistance, the finished product cannot layer or strip, and the performance of an obtained material is excellent.

Owner:广东崀玉新材料科技股份有限公司

High-strength colorfast faux-wooden plate material

ActiveCN103693903AGuaranteed decorative effectLarge design spaceWater-setting substance layered productCellulosePolymer modified

The invention provides a high-strength colorfast faux-wooden plate material including a surface colored layer and a structure filled layer. The surface colored layer adopts a cement-based polymer modified color paste, and the structure filled layer adopts high-performance filling concrete. The cement-based polymer modified color paste is prepared from the following components: 45 to 65 parts by weight of cement, 8 to 30 parts by weight of calcium stearate, 2 to 20 parts by weight of an iron oxide pigment, 10 to 30 parts by weight of an acrylic emulsion, and 10 to 35 parts by weight of water. The high-performance filling concrete is prepared from the following components: 15 to 35 parts by weight of cement, 15 to 35 parts by weight of river sand, 35 to 65 parts by weight of gravel, 0.3 to 1 part by weight of a high-range water reducing agent, 0.2 to 1 part by weight of cellulose, and 0.1 to 8 parts by weight of an iron oxide pigment. The faux-wooden plate material finished product is not delaminated and peeled off, has good weather resistance, high degree of simulation and more durable color, is more wear-resistant, and is easy to maintain.

Owner:广东崀玉新材料科技股份有限公司

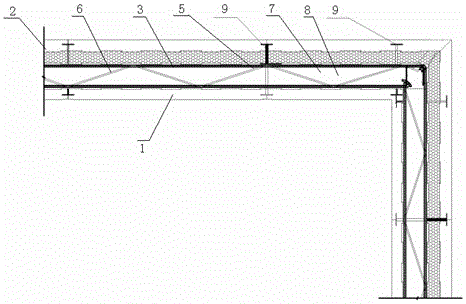

Building insulation precast block and modular reinforcement cast-in-place construction method thereof

ActiveCN105019593AAvoid damageLow costConstruction materialSolid waste managementWater savingArchitectural engineering

The invention relates to a fixing device of a building insulation precast block and a building insulation modular reinforcement cast-in-place construction method. The building insulation precast block comprises a plurality of precast block bodies which are spliced, the precast block bodies comprise inner plates and outer plates, reticular three-dimensional frames penetrate among the inner plates and the outer plates, the reticular three-dimensional frames comprise a plurality of interspersed transverse reinforcement frames and vertical reinforcement frames, the transverse reinforcement frames and the vertical reinforcement frames have the same structure and respectively comprise two parallel main reinforcements, diagonal bracing web reinforcements which are in zigzag arrangement along the length direction of the two main reinforcements are arranged between the two main reinforcements, the diagonal bracing web reinforcements comprise a plurality of diagonal reinforcements which are sequentially connected end to end, two ends of the diagonal reinforcements are welded on the main reinforcements, building waste rock and mortar are filled between the inner plates and the outer plates, and four adjacent inner plates or four adjacent outer plates are connected into a whole through pulling supports. The building insulation precast block has the advantages of water saving, emission reduction, environmental protection, waste utilization, multiple functions and normalization, realizes industrialization and modular building, and realizes functions of reticular reinforcements and pulling supports.

Owner:中建三局科创产业发展有限公司

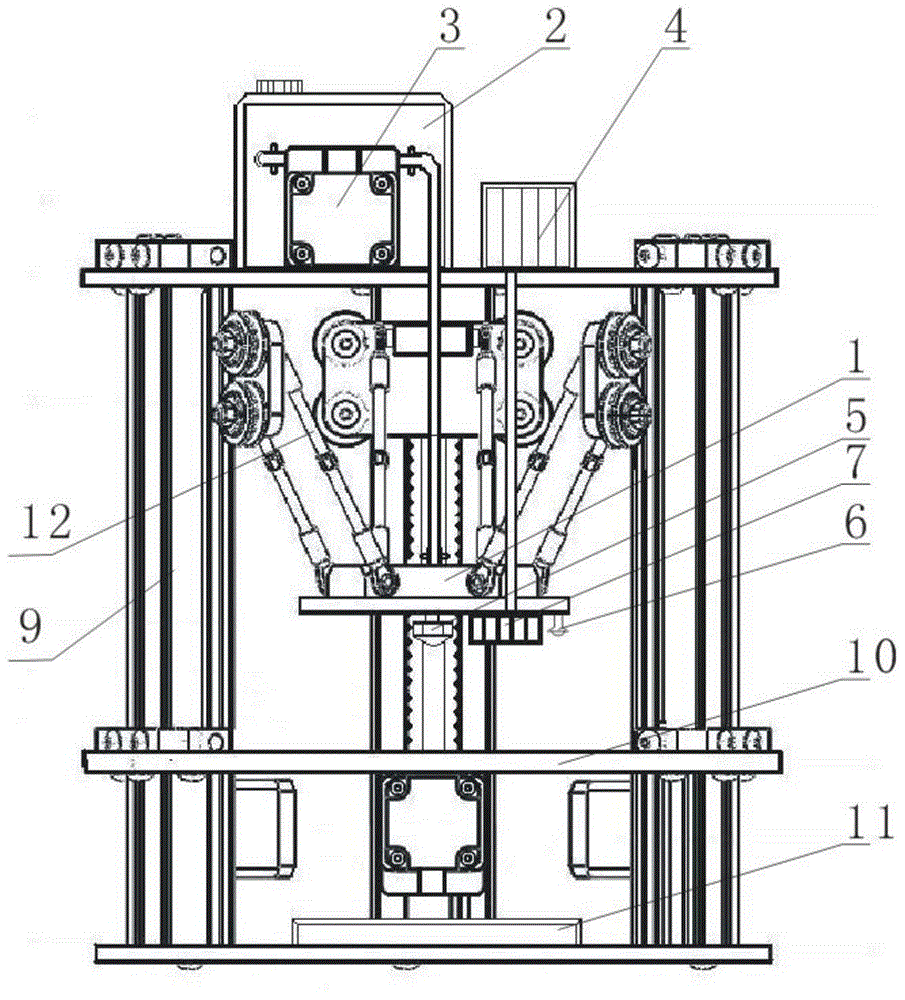

Catalytic curing type 3D printing technology and printer

InactiveCN105014972AHigh densityNot easy to damageAdditive manufacturing apparatusMulti materialVolumetric Mass Density

Owner:朱沫

Manufacturing method for double polylactic acid (PLA) laminated paper cup

The invention discloses a manufacturing method for a double polylactic acid (PLA) laminated paper cup. A prepared clear, transparent and sticky liquid is poured into a heating groove. The temperatureof the heating groove is controlled between 200 DEG C and 210 DEG C. Stirring is conducted through a gum application wheel arranged above the heating groove and a layer of PLA is rolled up by the gumapplication wheel. The temperature of the gum application wheel is controlled between 190 DEG C and 200 DEG C. The rolled-up layer of PLA is scraped to 0.20-0.65 Mu in thickness by a comma scraper arranged on one side of the gum application wheel. Paper is pressed to be attached to the gum application wheel by a pressing roller. At the moment, laminating (intermolecular connection) is conducted onthe PLA rolled up by the gum application wheel and the paper. Finally, the paper laminated with PLA is taken away through a rotation wheel, and paper laminated with PLA is prepared. According to themanufacturing method for the double PLA laminated paper cup, the paper laminated with PLA does not need to be dipped in a PLA solution; only the heating groove, the gum application wheel and an oven need electricity in the manufacturing technological process of the paper cup, and other parts do not need electricity; the cost is lowered greatly; the density of the paper cup is excellent; a liquid does not permeate into the inner wall of the paper cup from the outer wall of the paper cup; the production process is free of pollution; and a discarded paper cup can completely decompose into CO2 andH2O.

Owner:上海馨星环保科技有限公司

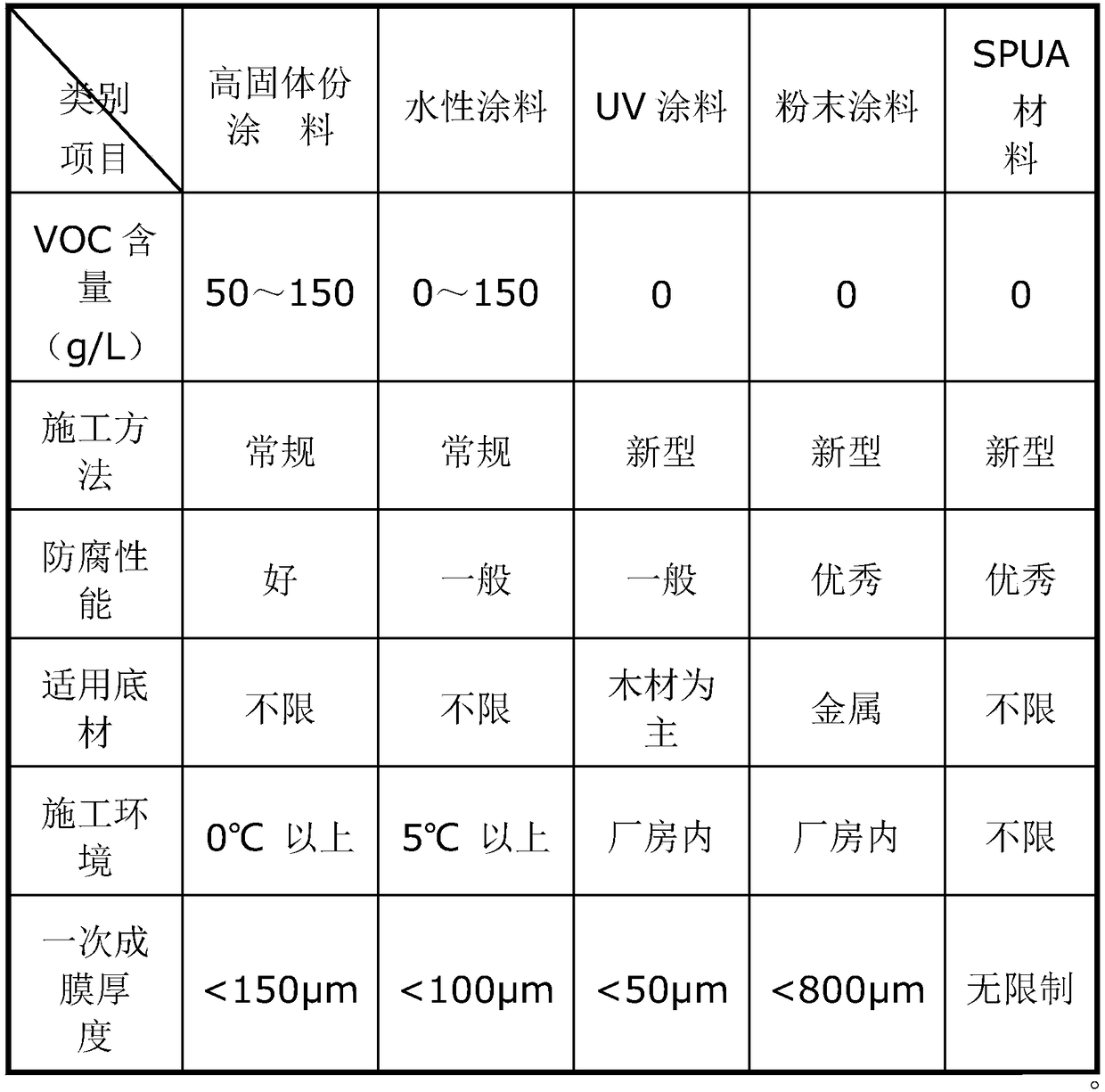

Coated polyurea material and coated polyurea material plate and preparation method

InactiveCN109439159AFast curingIncrease productivityFireproof paintsLiquid surface applicatorsHigh pressureVarnish

The invention belongs to the technical field of building materials and discloses a coated polyurea material and a coated polyurea material plate and a preparation method. The coated polyurea materialconsists of components of a polyurea coating and a polyether material, wherein the mass ratio of the polyurea coating to the polyether material is 1:1. The preparation method of the coated polyurea material comprises the following steps: heating the polyurea coating and the polyether material to 60 DEG C, and carrying out high-temperature high-pressure coating molding by using special polyurea equipment; placing a foamed sculptured plastic bottom plate on a coated polyurea material plate, and coating the foamed sculptured plastic bottom plate by a waterproof polyurea coating layer, a repairinglayer, a modified polyurea coating, a colored drawing layer and an anti-ultraviolet vanish layer from top to bottom in sequence. By adopting the coated polyurea material, the shapes of EPS (ExpandedPolystyrene), EVA (Ethylene Vinyl Acetate) and a soft body are not easily damaged, ultraviolet rays can be prevented when the coated polyurea material is used outdoor, the structure of a product can be changed, the service life of the product can be prolonged, and the attractiveness of the product can be improved.

Owner:惠州市祯华化工有限公司

Static-resistant high-density oil absorbing cotton

InactiveCN105498725AHigh densityGood resistance to multiple bendingOther chemical processesNeedling machinesFiberHigh density

The invention discloses a static-resistant high-density oil absorbing cotton. The oil absorbing cotton comprises a PE leakage-resistant layer and an oil absorbing layer. The PE leakage-resistant layer is compounded and fixed along the periphery of the oil absorbing layer; the oil absorbing layer is formed on the surface of the PE leakage-resistant layer, and the oil absorbing layer is formed in the mode that filaments formed by oil absorbing polymeric fibers and heat bonding fibers are subjected to warp mosaic weaving or warp-weft mosaic weaving to form a fiber web, and the fiber web is acupunctured; the content of high shrinkage fibers in the filaments is 10%-45%, the diameter ratio of the oil absorbing polymeric fibers to the high shrinkage fibers is 1:1-3:2, and the length of the high shrinkage fibers is 2 or more times that of the oil absorbing polymeric fibers. According to the oil absorbing cotton, as the acupuncture production technology is combined, good static resistance and the good oil absorbing performance are achieved, the strength, the toughness and the abrasive resistance of the oil absorbing cotton are improved, and the oil absorbing cotton is free of hair slipping, layering and falling.

Owner:SUZHOU BD ENVIRONMENTAL PROTECTION

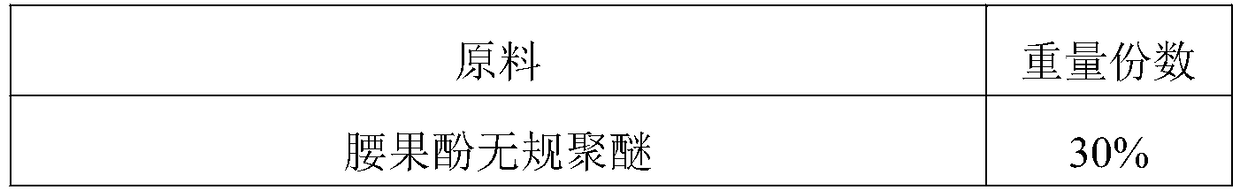

Universal spandex compounded emulsifier and preparation method thereof

The invention discloses a universal spandex compounded emulsifier and a preparation method thereof. The universal spandex compounded emulsifier is composed of 30-50 parts of anacardol polyether, 20-40parts of fatty alcohol-polyoxyethylene ether, 5-15 parts of sorbitan fatty acid ester, 3-5% of aliphatic alcohol phosphate polyoxyethylene ether potassium salt, 3-5% of fatty alcohol-polyoxyethyleneether potassium salt, 5-12% of silicone phosphate and 5-20% of silicone resin. Compared with the prior art, the universal spandex compounded emulsifier has the advantages of being similar in emulsifying property to nonylphenol polyoxyethylene ether and prior in low-temperature fluidity to fatty alcohol-polyoxyethylene ether, stable in performance and less prone to layering; anacardol is extractedfrom natural cashew nut shell oil and accordingly is wide in source and low in price; through the silicone phosphate and the silicone resin, the prepared universal spandex compounded emulsifier can eliminate static electricity, avoid adhesion and increase the strength of formed oil films, and further during application, can be good in fiber forming and smooth in backing-off.

Owner:TONGXIANG HENGLONG CHEM CO LTD

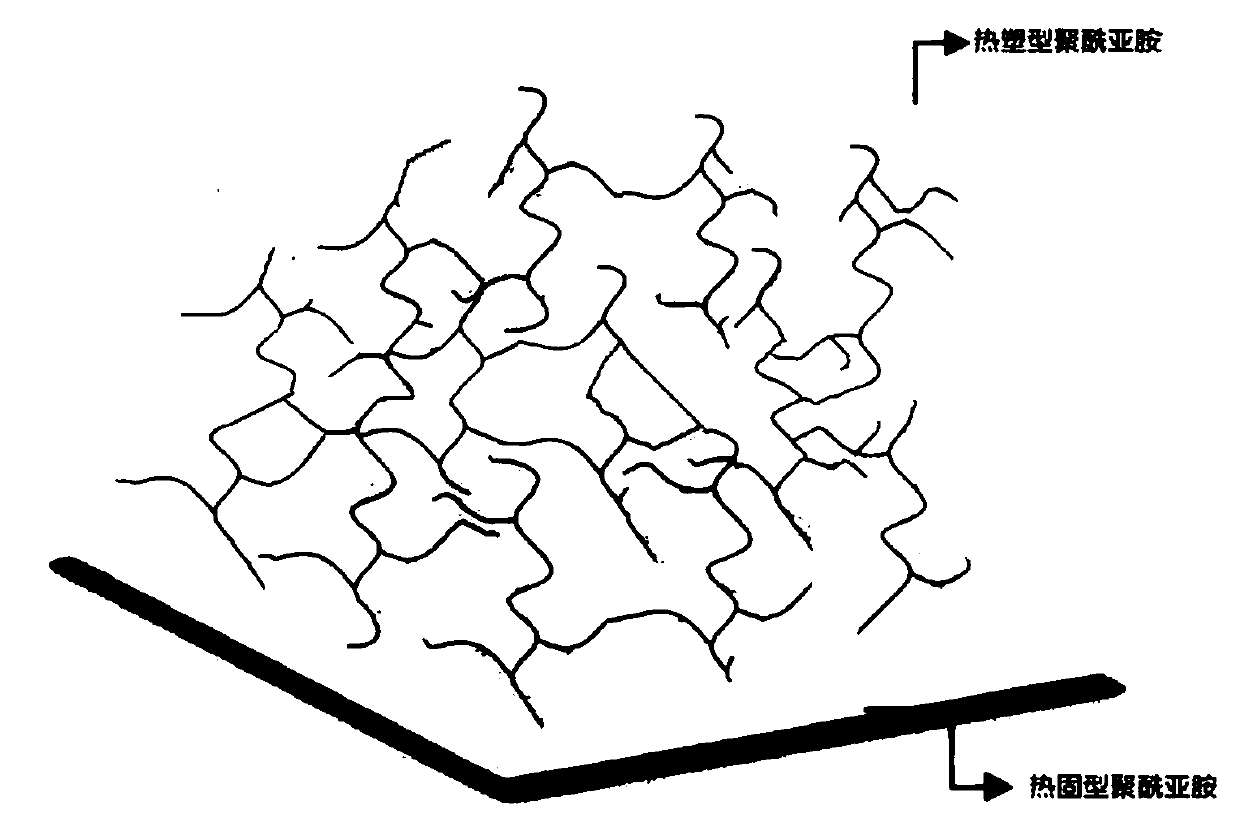

Preparation method of non-interface thermoplastic thermosetting polyimide composite film

InactiveCN109867804AComprehensive performance application requirements to meetImprove performanceCoatingsComposite filmPolymer science

The invention relates to a preparation method of a thermoplastic thermosetting polyimide composite film, and belongs to the technical field of special engineering plastic films. The invention aims toprovide a preparation method of a thermoplastic thermosetting polyimide composite film. The preparation method comprises the following steps: (1) preparing thermosetting polyamide acid glue A; (2) preparing thermoplastic polyamide acid glue B; (3) performing casting film formation on the polyamide acid glue A on the surface of a mirror annular stainless steel strip through a precision die head, performing initial baking so as to obtain a glue film A, and performing corona or plasma treatment on the surface of the glue film A; (4) coating the polyamide acid glue B to both sides of the glue filmA, and performing initial baking; (5) performing synchronous or stepwise two-way stretching, performing chemical or thermal imidization, and performing coiling so as to obtain the polyimide compositefilm. The preparation method can be industrialized, the prepared polyimide composite film has the performance advantages of no interface delamination, high peeling stability, high dimensional stability and the like.

Owner:NINGBO EXCITON TECH

Making method of oyster normal juice seasoning

InactiveCN106490572AUniform colorImprove extraction efficiencyFood ingredientsFood dryingChemistryBrowning reaction

The invention discloses a making method of oyster normal juice seasoning. The making method includes the following steps that pretreatment is carried out firstly, pulping is carried out, primary cell disruption and secondary superfine cell disruption are carried out, a Maillard reaction is carried out, materials enter a high-pressure homogenizer for particle refinement and homogenization, cooled oyster normal juice sauce is spray-dried, pure oyster powder is obtained, an oyster mixture is prepared according to the formula, and finally pelletizing and packaging into the finished product are carried out. After primary cell disruption, secondary superfine cell disruption and high-pressure homogenization are carried out, oyster meat is refined to be 0.05-0.1 micrometer, original nutritional ingredients and flavor of oysters can be saved, any part of the oyster meat cannot be wasted, the color and luster are more uniform, settling or layering cannot be generated, the fishy smell of the oysters can be removed through the Maillard reaction, and the good flavor of the boiled oysters is provided. In addition, the making method has the advantages of being simple in process, low in extraction cost and environmentally friendly and saving energy.

Owner:泉州喜博生物保健食品有限公司

Aqueous epoxy resin colloid and preparation method thereof

ActiveCN106947359AEasy to operateLow reaction temperatureEmulsion paintsEpoxy resin coatingsAcetic acidEpoxy

The invention relates to a preparation method of an aqueous epoxy colloid, and belongs to the field of paint industry. The aqueous epoxy resin colloid comprises the following components in percentage by weight: 20 to 30 wt% of epoxy resin, 20 to 30 wt% of epoxy diluent, 5 to 10 wt% of diethanolamine, 1 to 5 wt% of acetic acid, and 30 to 40 wt% of deionized water. The preparation method comprises the following steps: at first, diluting epoxy resin by an active diluent until the epoxy resin becomes uniform and transparent, adding diethanolamine at a controlled temperature of 80 to 85 DEG C, carrying out reactions for 1 to 1.5 hours at a constant temperature, adding acetic acid to carry out neutralization, and dropwise adding deionized water under stirring to obtain transparent and uniform aqueous epoxy colloid. Compared with a conventional chemical modification method, the operation is simple, the reaction temperature is low, the reaction time is short, and nearly no VOC is discharged. The size of colloid particles reaches the nano level. The stability is good, the hydrophilic property is excellent, and the viscosity is low.

Owner:HARBIN INST OF TECH AT WEIHAI

Phosphogypsum high-strength wall brick and its production method

The invention discloses a high-intensity ardealite wall brick and the producing method. And the composition weight ratio of semi-hydrated ardealite to anhydrous ardealite to flyash to coagulant is (70-85) : (12-20 ): (15-20 ): (15-25), where the coagulant is 12-20% silicasol water solution. And the invention uniformly blends them in sprinkling mode, mechanically places the mixture into a mould and shapes in high pressure, mechanically demoulds, and naturally hydrates to make it. And the invention firstly uses large amount of ardealite raw material in building materials, where the synthetic utilization of ardealite is up to 80%; and it is low-cost and saves land resources. After processed, it accords with national stipulated nuclear radiation indexes, has high hardness, reduces equipment investment and reduces cost of product.

Owner:重庆金仓龙新型建材有限公司

A method for manufacturing a printed board with multi-layer soft and hard boards and impedance requirements

InactiveCN104320929BQuality assuranceGuaranteed reliabilityMultilayer circuit manufactureCopper foilMechanical engineering

The invention relates to a manufacturing method of a multi-layer soft-and-hard-plate combined printed board with an impedance requirement. The manufacturing method comprises the steps that an inner soft plate circuit is manufactured, and cover films are pressed on the two faces of a manufactured soft plate; PP sheet processing and copper foil and soft plate surface processing are carried out; the soft plate, the processed PP sheet and the copper foil are overlaid, and a false attaching machine is used for carrying out pre-pressing locating; a press-fit machine is used for pressing the soft plate, the processed PP sheet and the copper foil; an outer circuit is manufactured, and outer copper foil where circuits do not need to be manufactured is removed through etching. By means of the manufacturing method, the product yield can be greatly improved through process control and can reach more than 90%, and the product rejection rate is lowered to about 8%.

Owner:双鸿电子(惠州)有限公司

Method for producing lightweight artificial culture stone product by adopting high-humidity sludge

ActiveCN105152590AImprove structural strengthHigh degree of simulationSolid waste managementHigh humidityWeather resistance

The invention relates to a method for producing a lightweight artificial culture stone product by adopting high-humidity sludge, and aims to provide the method capable of achieving effective digestion of the high-humidity sludge and environmental protection. The lightweight artificial culture stone product produced with the method has the characteristics of high structural strength, good weather resistance and excellent overall performance. According to the technical scheme, the method for producing the lightweight artificial culture stone product by adopting the high-humidity sludge comprises steps as follows: 1), preparation of raw materials including high-humidity sludge, washed-out sand sludge, special cement, waste foam particles or waste plastic particles, lightweight aggregate, a sludge modifier and an appropriate amount of water; 2), slurry preparation; 3), molding; 4), surface treatment; accordingly, the lightweight artificial culture stone product is obtained.

Owner:杭州临安晨熙水利科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com