Preparation method of high-strength non-fading imitation wood plank

A high-strength, imitation wood technology, applied in the field of preparation of building decoration materials, can solve the problems of physical strength, simulated life cycle, poor weather resistance, unsustainable impact effect, high material bonding strength, etc., to broaden the scope of use , long service life, high material bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

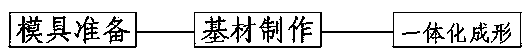

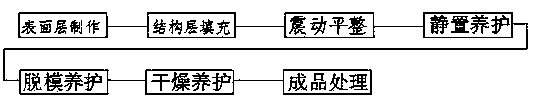

[0034] The production process of a high-strength non-fading imitation wood board of the present invention includes a mold preparation stage, a base material production stage, and an integrated forming stage;

[0035] The mold preparation stage adopts the following process steps:

[0036] a. Select silicone rubber with strong replication ability, good alkali resistance and high tensile strength as the molding material. The performance parameters of the silicone rubber are selected with a viscosity of 39000mPa·s, a hardness of Shore 33, and an elongation of 450%. ;

[0037] b. Select the wood with the required texture as the matrix of the mould, and the wood requires no repeated texture within 3 square meters;

[0038] c. Using the above-mentioned silicone rubber as a raw material, cooperate with the above-mentioned wood as the mold matrix to make a mold.

[0039] In particular, the silicone rubber stirring, pouring and forming maintenance in the above step c requires a space ...

Embodiment 2

[0056] The production process of a high-strength non-fading imitation wood board of the present invention includes a mold preparation stage, a base material production stage, and an integrated forming stage;

[0057] The mold preparation stage adopts the following process steps:

[0058] a. Select silicone rubber with strong replication ability, good alkali resistance and high tensile strength as the molding material. The performance parameters of the silicone rubber are selected with a viscosity of 40000mPa·s, a hardness of Shore 30, and an elongation of 400%. ;

[0059] B, select the wood of required texture as the parent body of mould, described wood does not appear repeated texture within 5 square meters;

[0060] c. Using the above-mentioned silicone rubber as a raw material, cooperate with the above-mentioned wood as the mold matrix to make a mold.

[0061] In particular, the stirring, pouring, and forming maintenance of the silicone rubber in the above step c requires...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com