Electrochemical battery packaging material

A packaging material, electrochemical technology, applied in the direction of battery box/sleeve material, battery pack components, battery box/jacket, etc. problems, to achieve the effect of increasing electrolytic resistance, ensuring no delamination, and increasing weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

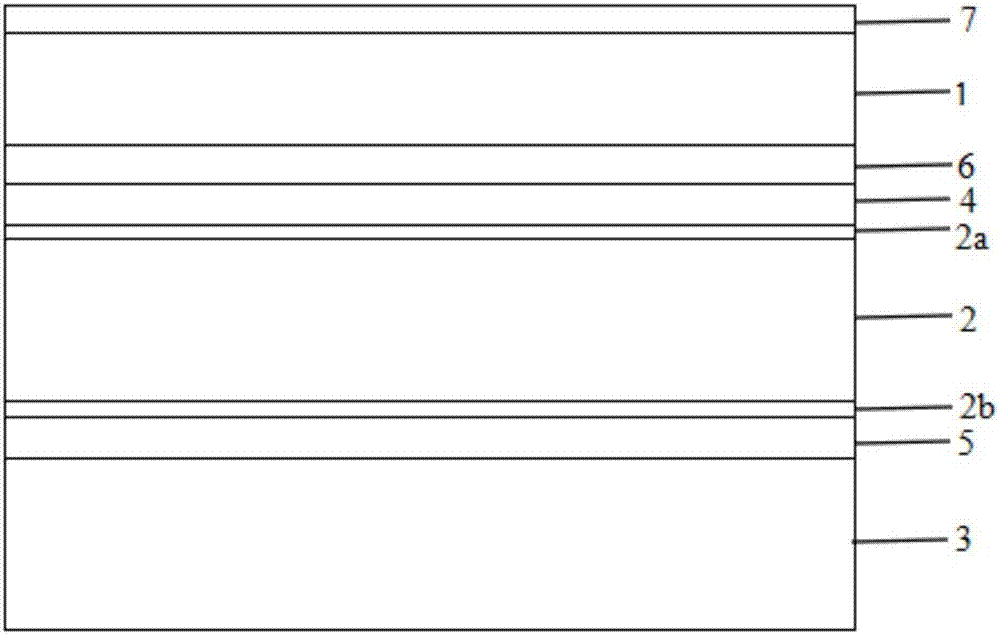

[0026] This embodiment provides a packaging material for electrochemical cells, which includes a thermoplastic resin layer 3, a second adhesive layer 5, a metal foil layer 2, a first adhesive layer 4, a protective layer 1, and a metal foil layer 2 stacked in sequence. It has a first chemical treatment layer 2a in contact with the first adhesive layer 4 and a second chemical treatment layer 2b in contact with the second adhesive layer 5, and it also includes a layer formed on the protective layer 1 and the first adhesive layer. The color coating 6 between the layers 4 and the matt layer 7 formed on the outer surface of the protective layer 1; its preparation can be done in a conventional manner, as follows:

[0027] (a) Coating a chromate treatment solution (about 3% solid mass fraction) on the inner and outer surfaces of the metal foil layer 2 with a thickness of 30 μm, and drying in an oven at 150° C., thereby forming on both surfaces of the metal foil layer 2 Chromium conten...

Embodiment 2

[0034] This embodiment provides a packaging material for electrochemical cells, which is consistent with the raw material and structure in Embodiment 1, except that in step (b), carbon black with an average particle diameter of 1.5 μm: polyester polyol: ethyl acetate The ester is mixed evenly with sodium polyacrylate dispersant under the condition of mass fraction of 2:60:38 to obtain the main agent mixture of the colored coating. The mass fraction solid (including carbon black and polyester polyol) content rate of the above-mentioned colored coating main ingredient mixture is 20%, and the mass fraction solid content rate of the colored pigment (carbon black) is 10%.

Embodiment 3

[0036] This embodiment provides a packaging material for electrochemical cells, which is consistent with the raw material and structure in Embodiment 1, except that in step (b), carbon black with an average particle diameter of 1.5 μm: polyester polyol: ethyl acetate The ester is mixed evenly with sodium polyacrylate dispersant under the condition of mass fraction of 4:53.3:42.7 to obtain the main agent mixture of the colored coating. The mass fraction solid (including carbon black and polyester polyol) content rate of the above-mentioned colored coating main ingredient mixture is 20%, and the mass fraction solid content rate of the colored pigment (carbon black) is 20%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com