Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

95results about How to "Soak fast" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Sintered water permeable brick and preparation method thereof

ActiveCN106087631AImprove water permeabilityLittle tortuousnessSingle unit pavingsPaving detailsBiomass fuelsSurface layer

The invention discloses a sintered water permeable brick and a preparation method thereof, and belongs to the technical field of sintered ceramics. According to the water permeable brick, structural pug in a surface layer is composed of, by weight, 45-65% of structural fine aggregates, 20-30% of plastic high-temperature binders and 15-25% of water, pore forming pug in the surface layer is composed of, by weight, 20-50% of pore forming agent aggregates, 45-80% of plastic pore adding binders and 0-5% of biomass fuel internal combustion catalysts, and a blank of a secondary surface layer is composed of, by weight, 70-75% of coarse structural aggregates, 10-15% of plastic high-temperature binders, 0-5% of pore adding agent coarse aggregates and 10-15% of water. A blank of the surface layer and the blank of the secondary surface layer are prepared firstly, the blank of the surface layer contains the orderly distributed structural pug and the pore forming pug, and then single-shaft extrusion forming, drying and sintering are conducted to obtain the water permeable brick. The water permeable brick has high water permeable rate, high strength, high abrasion resistance and durability and is a paving material with excellent ecological and environmental functions.

Owner:四川绿岛环境工程有限公司

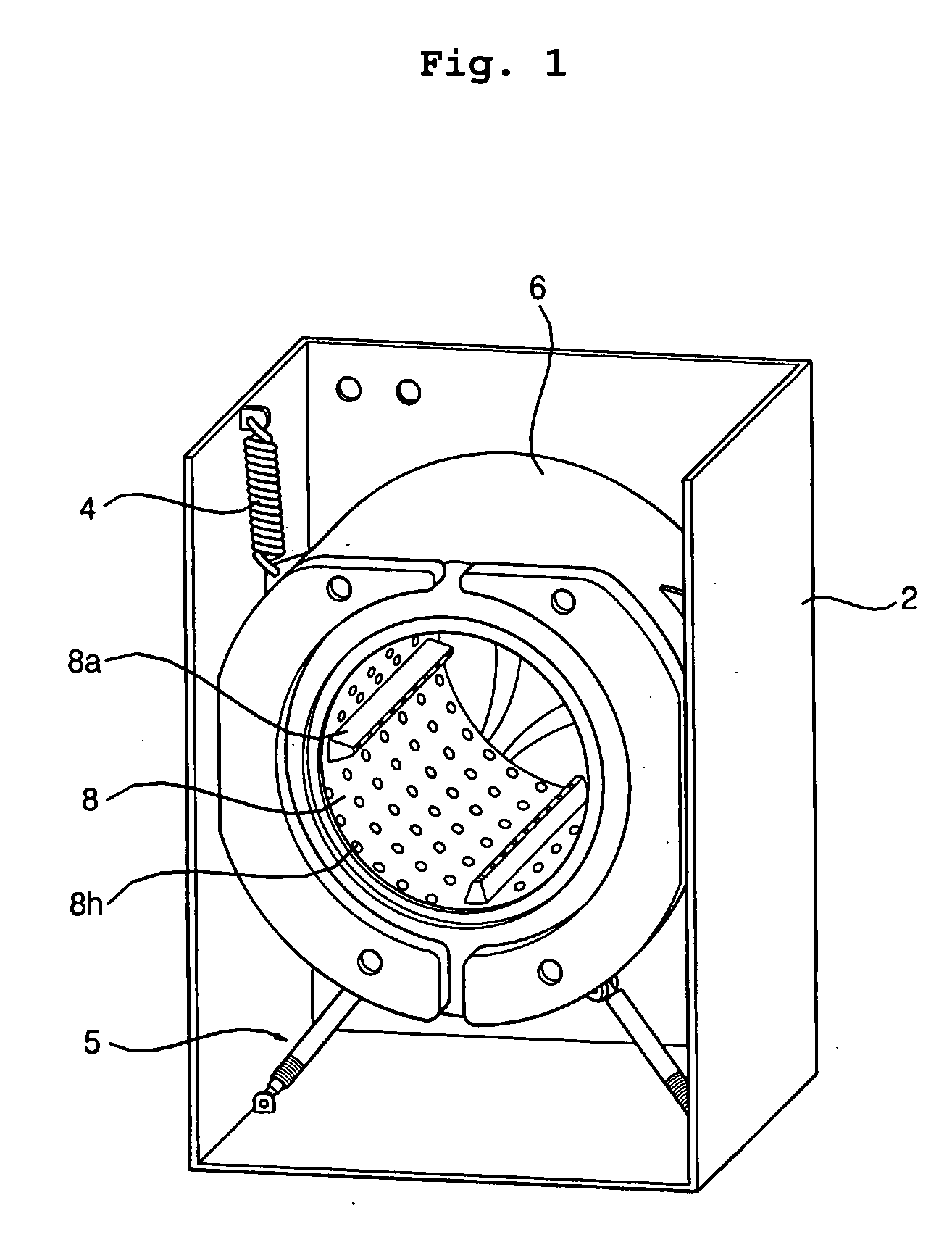

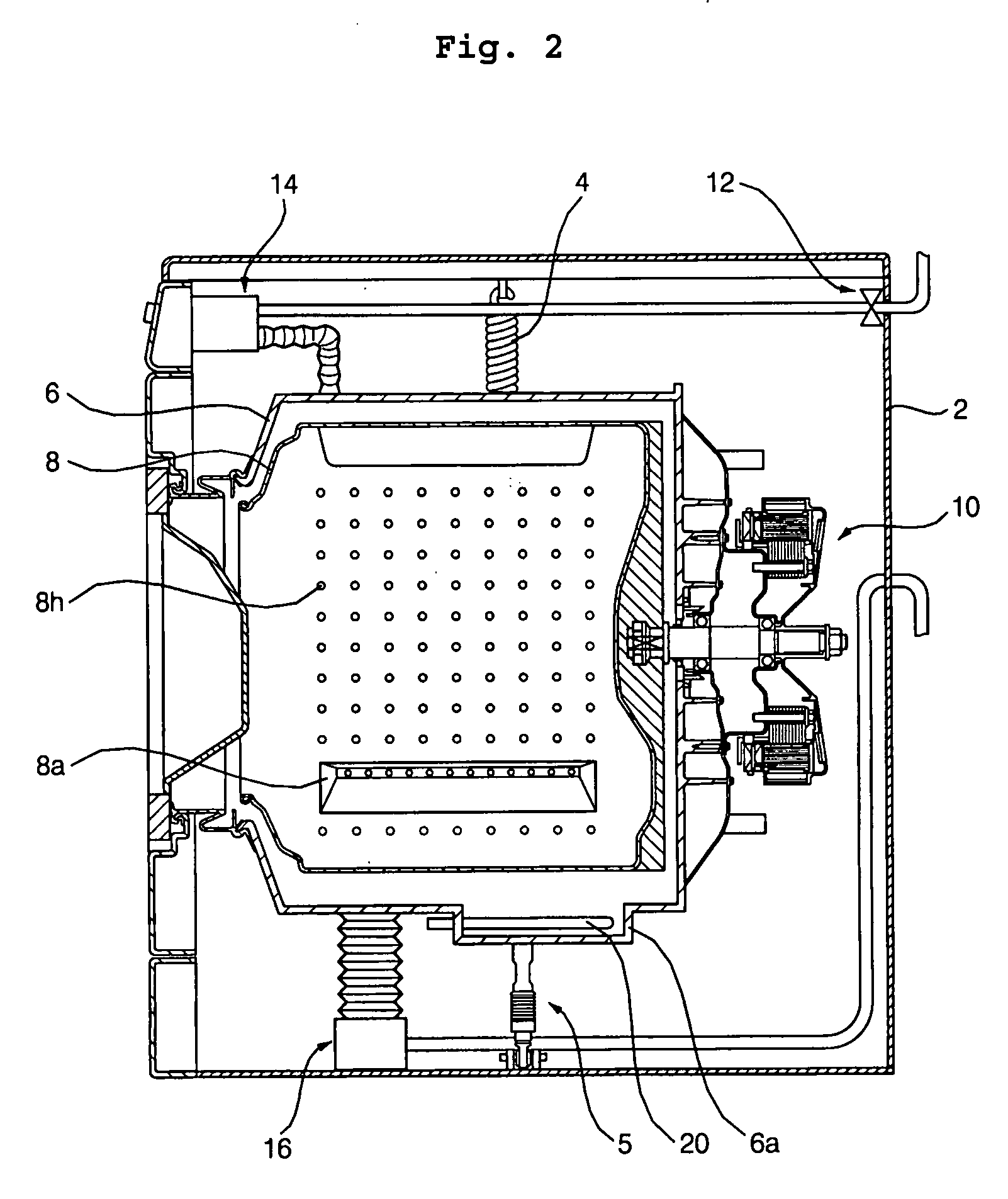

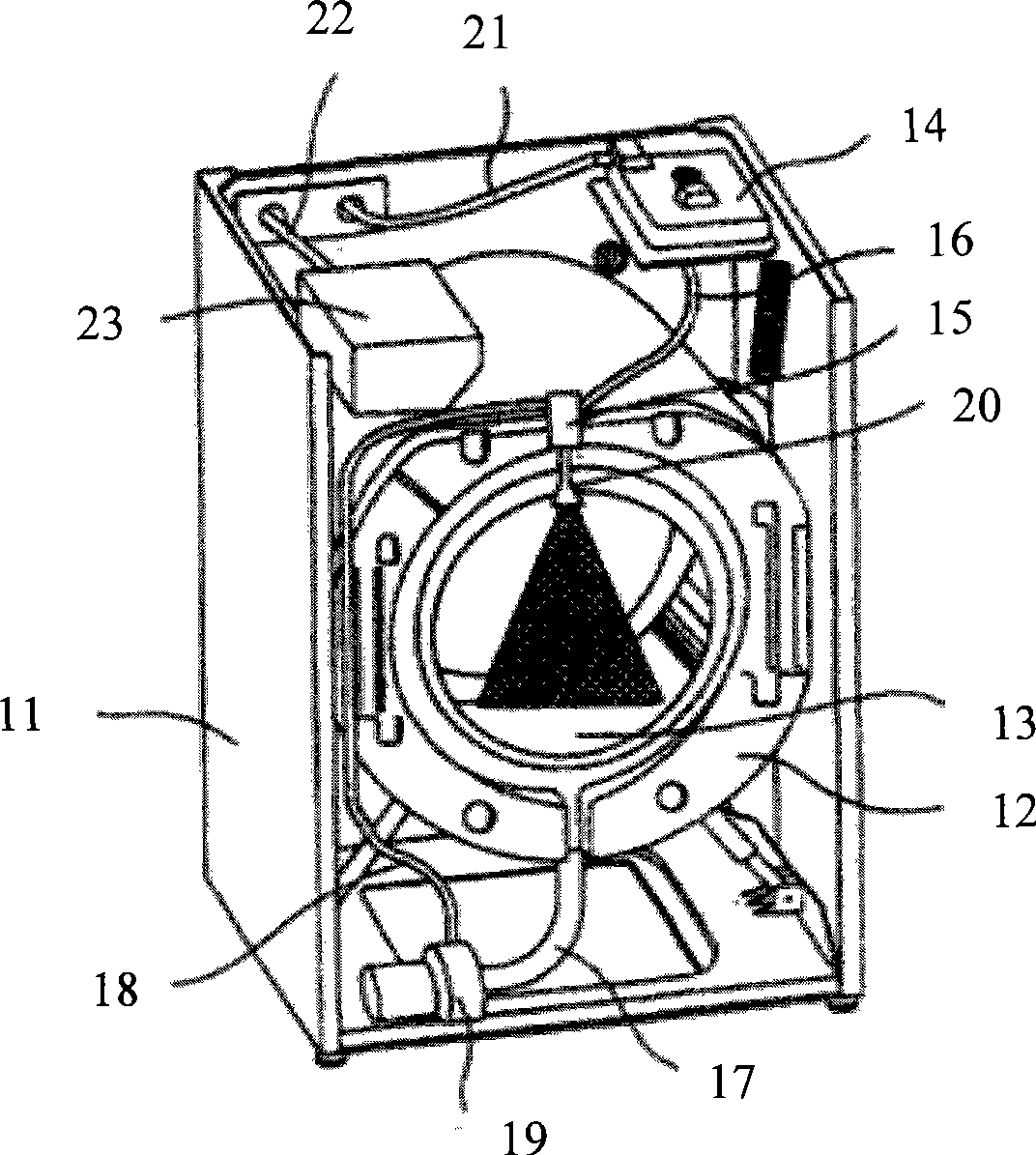

Steam jet drum washing machine

ActiveUS7490493B2Soak fastReduce wasteOther washing machinesControl devices for washing apparatusWash waterProcess engineering

Owner:LG ELECTRONICS INC

Special epoxy impregnating compound for basalt fiber and preparation method of special epoxy impregnating compound

The invention discloses a special epoxy impregnating compound for a basalt fiber and a preparation method of the special epoxy impregnating compound. The special epoxy impregnating compound for the basalt fiber is prepared from the following components in percentage by weight: 5.0%-8.0% of an epoxy latex film-forming agent, 0.1%-1% of a lubricant, 0.5%-1.5% of binder, 0.5%-1.5% of plasticizer, 0.2%-1.0% of an antistatic agent, 0.5%-1.0% of a coupling agent and the balance of soft water. The reinforced textile type impregnating compound is suitable for a basalt-reinforced thermosetting phenolic epoxy resin composite material, is good in textile property, and is capable of promoting the binding force of the basalt fiber and the reinforced thermosetting high-molecular polymer.

Owner:成都中玻复合材料有限公司

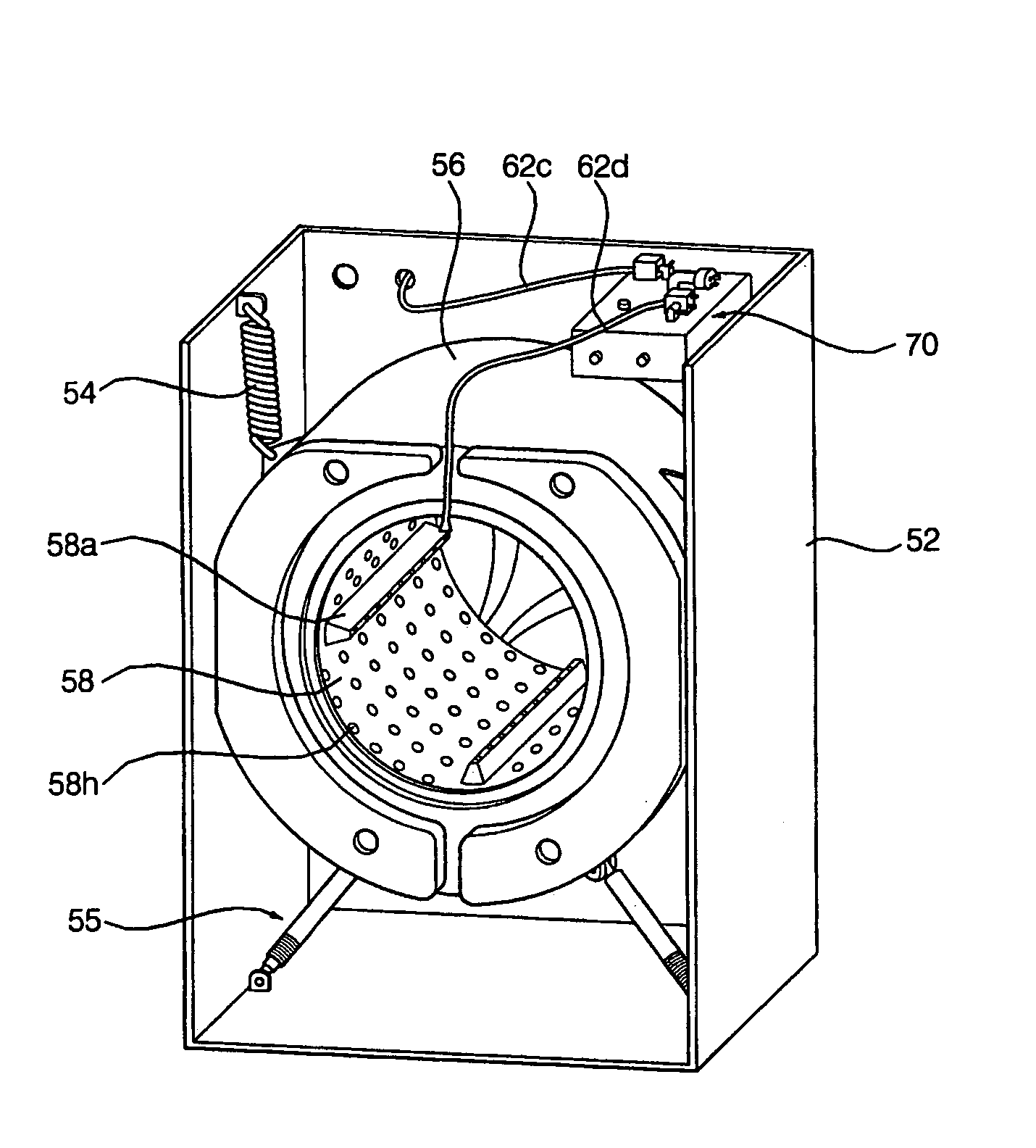

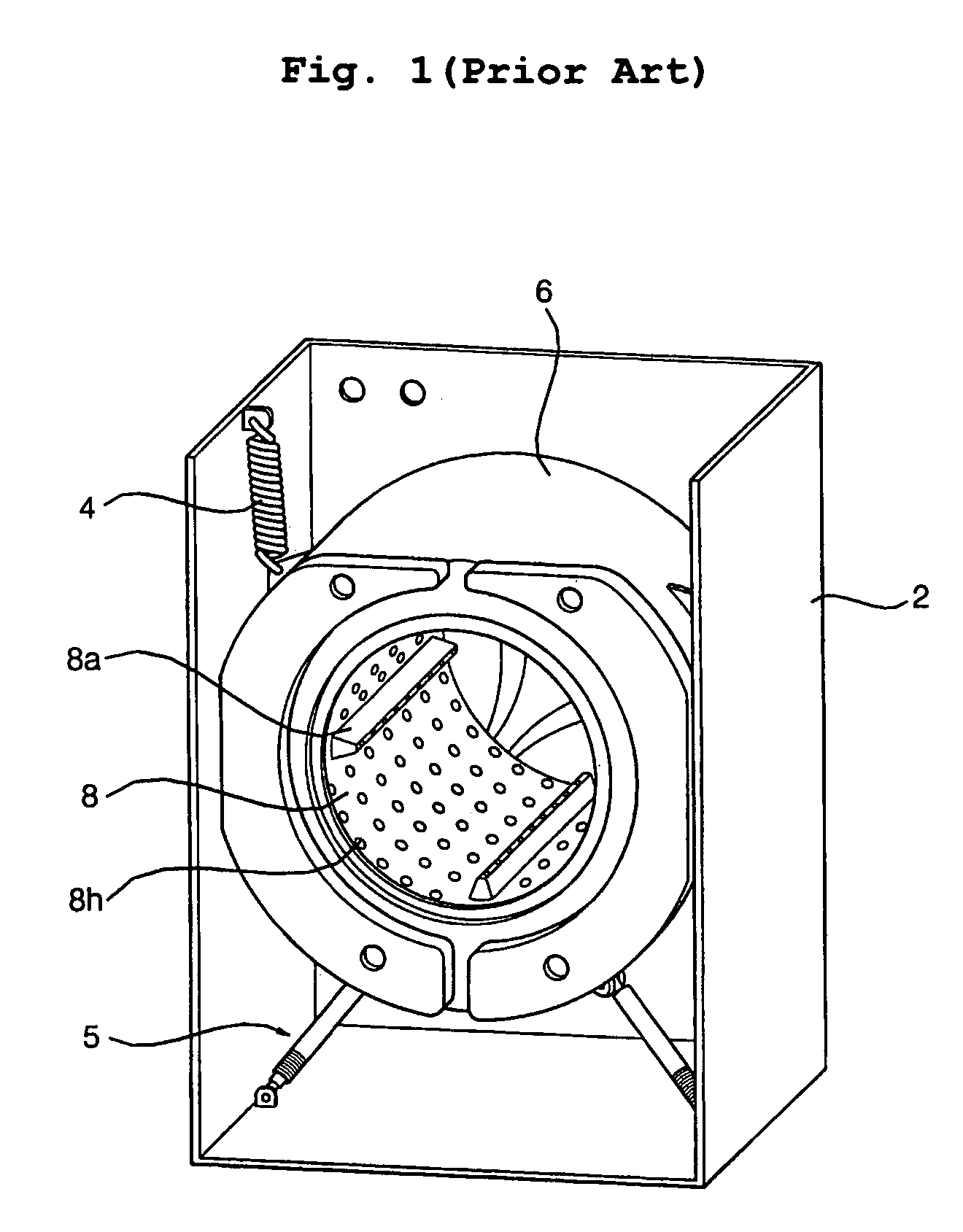

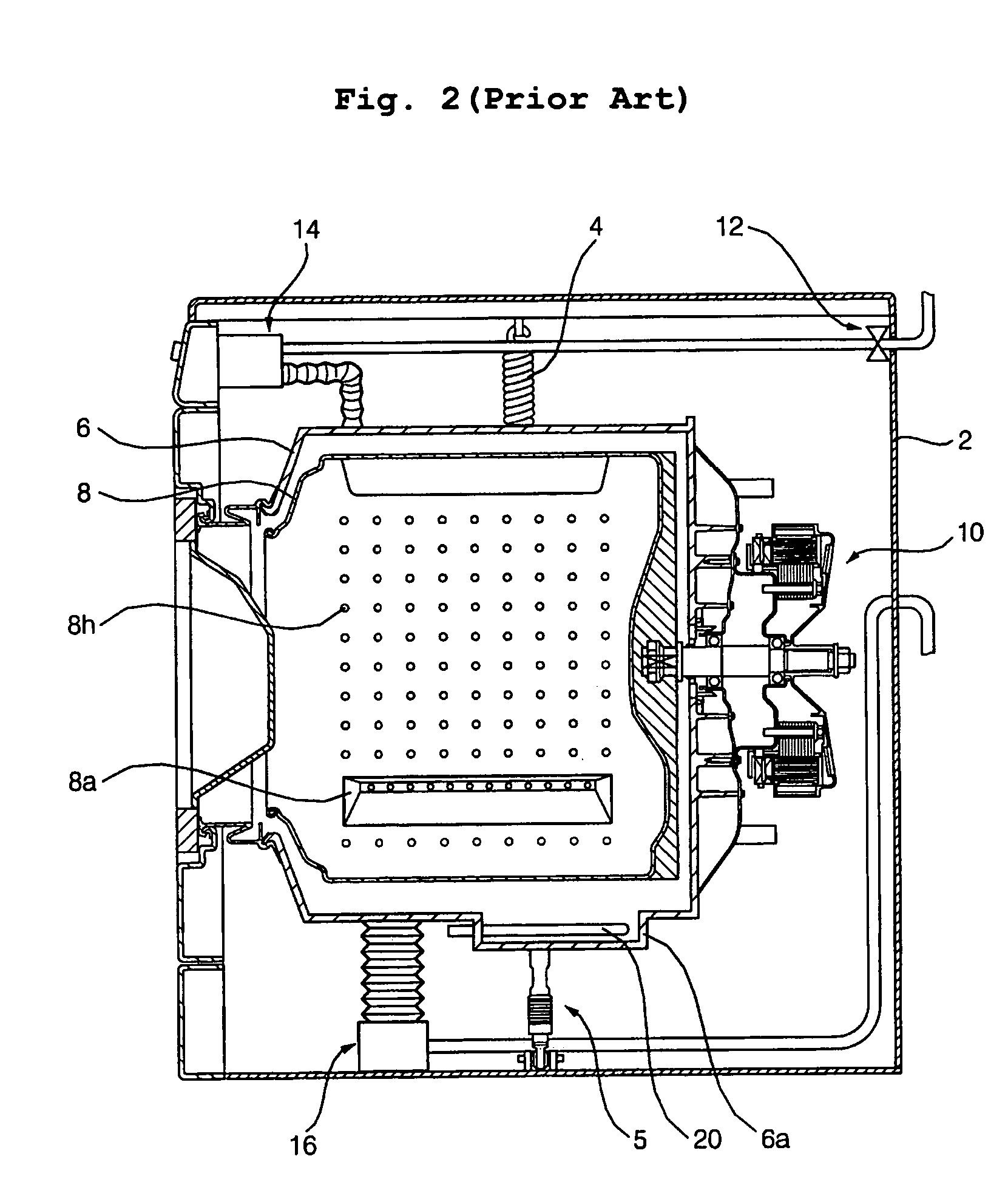

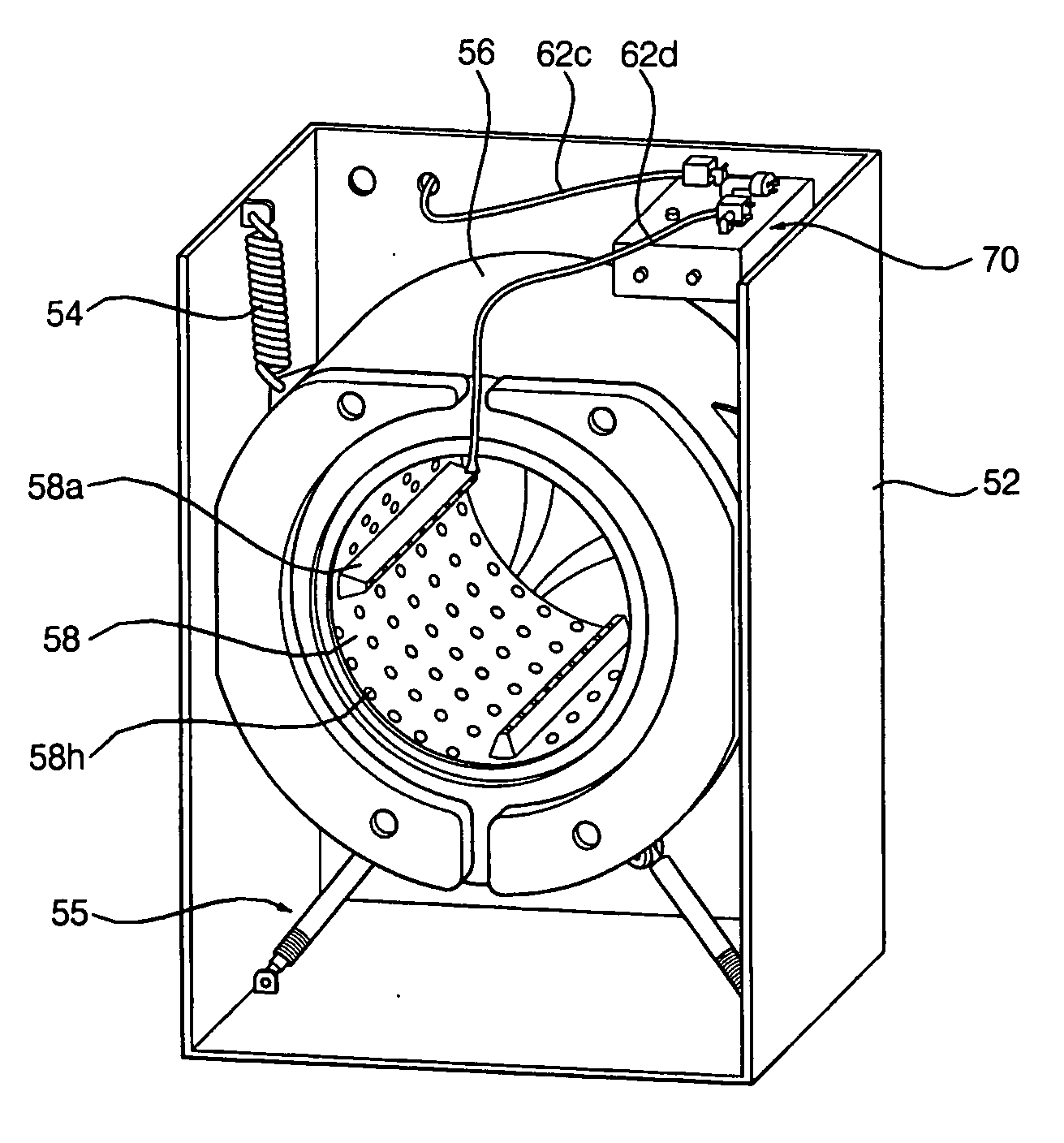

Steam jet drum washing machine

ActiveUS20070137262A1Soak fastReduce wasteOther washing machinesWashing machine with receptaclesWash waterProcess engineering

Disclosed herein is a drum washing machine which is capable of lifting clothes to a predetermined height and then dropping the lifted clothes so that the clothes can be washed by means of friction and impact. The drum washing machine is capable of heating wash water and spraying the heated wash water into a tub and a drum of the washing machine in a phase of high-temperature and high-pressure steam, thereby rapidly soaking clothes in the wash water, improving sterilizing and washing efficiencies of the drum washing machine, and saving wash water and electric energy.

Owner:LG ELECTRONICS INC

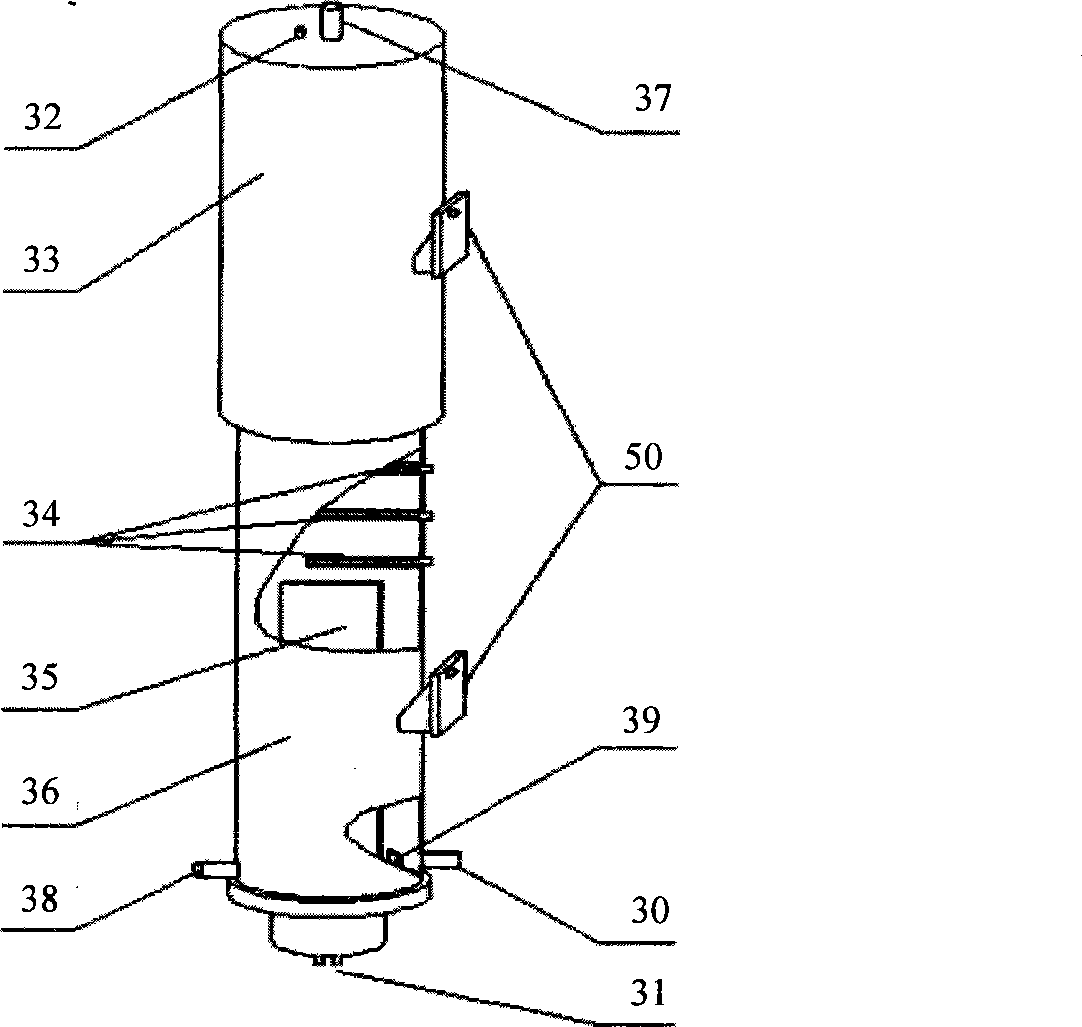

Vertical pultrusion process and device of multilayer fiber composite laminated section bar

InactiveCN101913254AImprove performanceOvercome shortcomings such as oxidationOther domestic articlesYarnFiber bundle

The invention relates to a vertical pultrusion process of a multilayer fiber composite laminated section bar, which comprises the steps of: arranging longitudinal and circular fibers on a tubular core die to form a fiber bundle laminated fiber composite laminate and tracting to move; introducing one part of glue into the fiber composite laminate and injecting, injecting the other part of glue from the outer part of the fiber composite laminate to ensure that the glue dips the fiber composite laminate; and finally, heating for forming and cooling. A pultrusion device comprises a tracting machine used for tracting the fiber composite laminate and a heating forming die, wherein the heating forming die is provided with an internal and external injection device, a tubular core die is arranged on the internal and external injection device, an internal injection hole of the internal and external injection device is connected with one pipe mouth of the tubular core die, the other pipe mouth of the tubular core die and an external injection hole of the internal and external injection device are connected to an injection pump, at least one group of yarn distributors are sleeved on the tubular core die and comprise a longitudinal yarn coil and a circular yarn winder, and the longitudinal yarn coil is positioned in front of the circular yarn winder along the traction direction.

Owner:高宝安

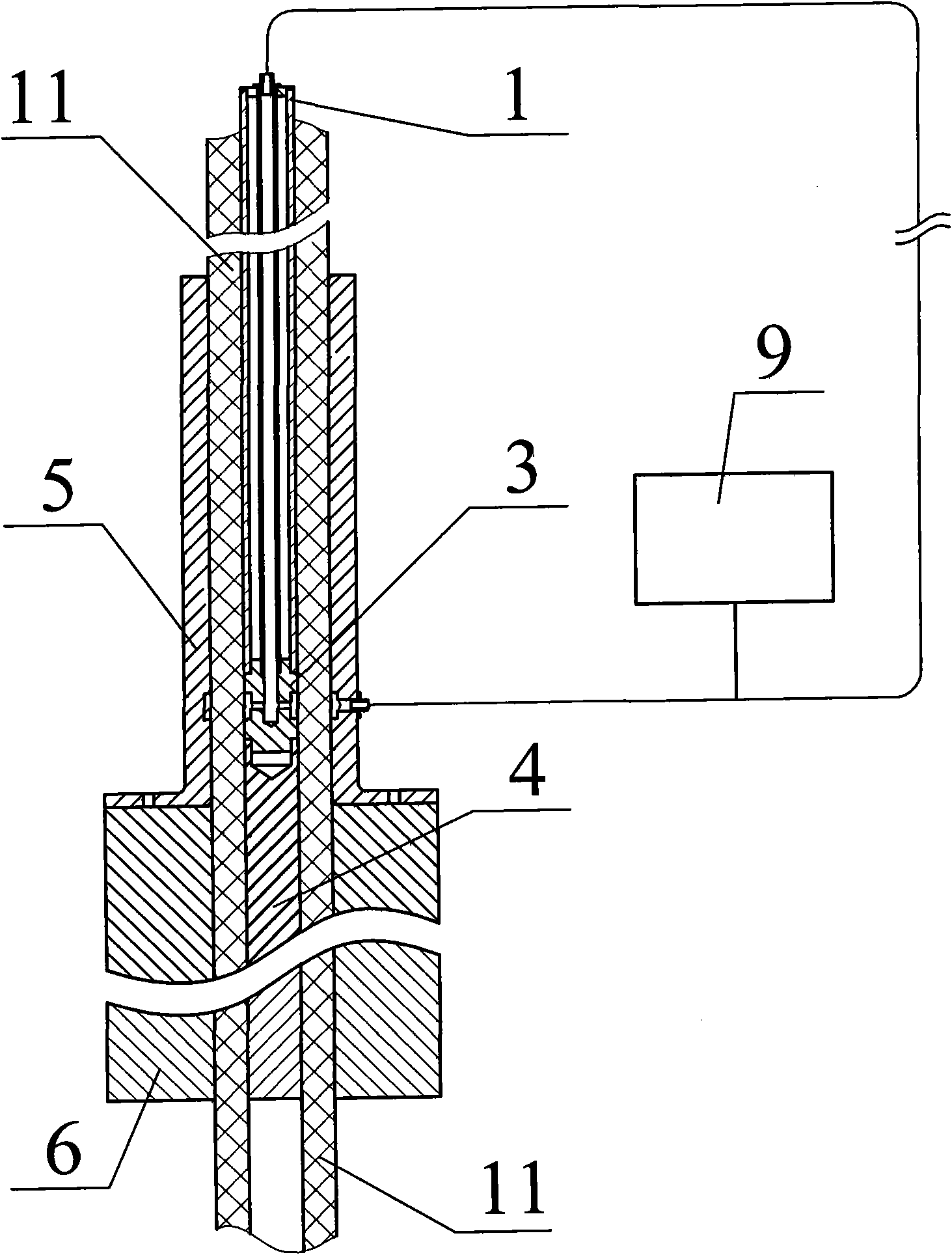

Steam generator of washing machine and wave wheel washing machine equipped with the same

ActiveCN101498092ALow costReduce thicknessOther washing machinesSteam generation plantsThermodynamicsLaundry washing machine

The invention discloses a steam generator of a washing machine and a rotary drum washing machine with the steam generator. The steam generator is of a long column drum structure, a water space capable of storing water is arranged at the lower part of the long column drum structure, and a steam space capable of storing steam is arranged at the upper part of the long column drum structure and is communicated with the water space. The steam generator of the long column drum structure is mounted between the side wall of a casing and the side wall of an outer drum of the rotary drum washing machine. The steam generator structure effectively utilizes the space of the rotary drum washing machine, can mount the steam generator under the condition that an original structure of the rotary drum washing machine is not changed so as to add the steam generation function for the rotary drum washing, and has simple structure and low cost.

Owner:HAIER GRP CORP +1

Preparation method of pulling-extruded polyurethane fiber reinforced composite material

InactiveCN108943773AReal-time control of gelation timeAvoid cloggingPolymer scienceTraction - action

The invention discloses a preparation method of a pulling-extruded polyurethane fiber reinforced composite material. The preparation method comprises the following steps: passing heads of continuous fibers, the mass fractions of which are 50-85%, through a mold, wherein the mold is at least provided with a glue-injecting permeating area, a pre-forming area and a curing area; injecting immediatelysynthesized polyurethane fibers into the glue-injecting permeating area of the mold at a high pressure through a polyurethane fiber injecting system, wherein the continuous fibers in the glue-injecting permeating area are fully permeated by the high pressure polyurethane fibers; moving the heads of the continuous fibers under the traction action of a traction device, wherein the polyurethane fiberpermeated continuous fibers move to the pre-forming area to be heated and gelled under the traction action to obtain a pre-formed continuous fiber reinforced composite material; and then pulling thepre-formed continuous fiber reinforced composite material which is cured and formed in the curing area out of the mold under the continuous traction acting force generated by the traction device. According to the preparation method disclosed by the invention, the mold can be prevented from being blocked after the content of the continuous fibers is improved.

Owner:SUZHOU HENG CHUAN PHOTOVOLTAIC TECH CO LTD

Impregnating compound for basalt fibers

The invention discloses a special impregnating compound for basalt fibers and a preparation method of the impregnating compound. The impregnating compound comprises raw materials in percentage by weight as follows: 2%-10% of water-soluble epoxy resin, 1%-8% of polyvinyl alcohol, 0.5%-1.0% of a coupling agent, 0.2%-0.8% of an antistatic agent, 0.08%-0.25% of a pH regulating agent and the balance of deionized water. The impregnating compound for surface modification of the basalt fibers is prepared in the rated weight proportion and directly coats surfaces of the basalt fibers during basalt production drawing, surface modification is completed after drying, and the impregnating compound is more convenient to use and has the good adhesion and film-forming property.

Owner:晏玲莉

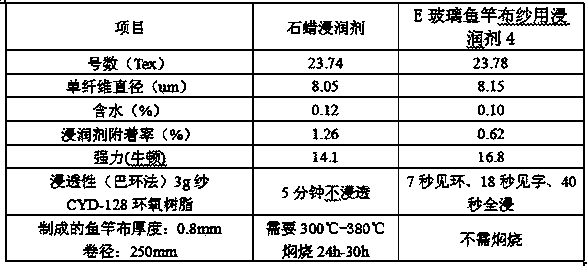

Reinforcing yarn size for glass fibers and preparation method thereof

The invention relates to a reinforcing yarn size for glass fibers and a preparation method thereof, and belongs to the technical field of sizes for glass fibers. The size comprises 4.0-5.5% of a filmogen emulsion, 1.7-4% of a lubricating agent, 0.5-1.5% of a water soluble epoxy resin binder, 0.2-1.0% of an inorganic antistatic agent, 0.5-1.5% of an aminosilane coupling agent and the balance softened water. The filmogen emulsion comprises polyethylene glycol-4000 (PEG-4000), boron trifluoride diethyl etherate, epoxy resin E-44, epoxy resin E-20 and water with a ratio of (1-2): (0.005-0.01): (1-1.5): (0.8-1.2): (8-10). Glass fibers drawn through the size can bear repeatedly bending deformation and have a good textile performance, and woven glass fiber cloth can be applied to production of composite materials without heat treatment and is quick in soakage and high in binding force when compounded with matrix resin.

Owner:SICHUAN FIBERGLASS GRP

Production technology of mini-jacquard weft elastic yarn-dyed fabric made of aloe fiber

ActiveCN104947285AColors are bright without being flashyRaise the gradeSingeingSeaming textilesFiberYarn

The invention discloses a production technology of mini-jacquard weft elastic yarn-dyed fabric made of aloe fiber. The production technology comprises steps as follows: winding, warping, sizing, weaving and finishing, wherein the finishing comprises steps as follows: fabric inspection, fabric turning, sewing, singeing, desizing, setting, preshrinking and plaiting. The specification, the style and the dyed yarn arrangement of the mini-jacquard weft elastic yarn-dyed fabric made of the aloe fiber are designed, winding, warping, sizing, weaving and finishing processes are optimized, the production efficiency is up to 92%, and the rate of first-grade goods put in storage is up to 98%.

Owner:IANGSU COLLEGE OF ENG & TECH

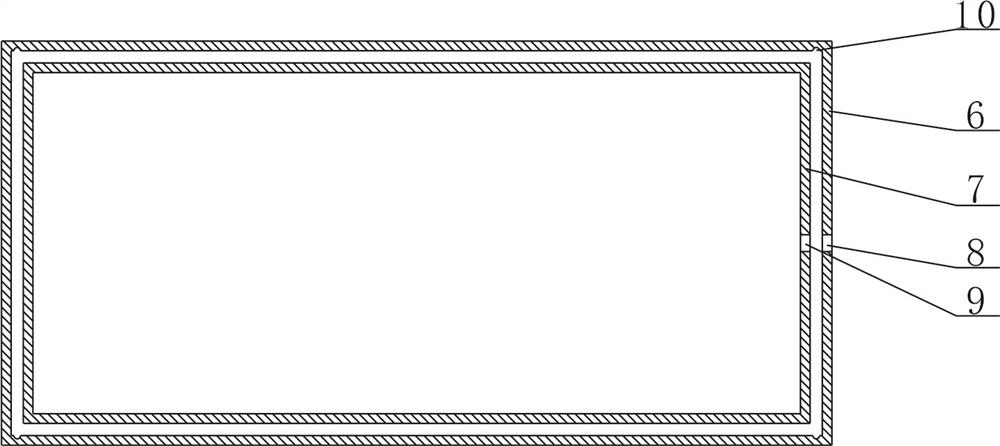

Absorbency substance and manufacturing method thereof

ActiveCN1981723AGuaranteed cushioning effectMaintain quality styleAbsorbent padsBaby linensBi layerSkin contact

The invention provides an absorbable article and a method for manufacturing the same, which has strong felling of stereo perception, high shock-absorbing capacity, capable of minimizing area contacting with skin, and can maintain concavo convex embossing shape all the time. A surface sheet (3) is a multilayer sheet having two layer which comprises at least a non-woven favrics layer (3A) constituting skin contacting layer and a plastic film layer (3B) stacking on a non-skin contacting layer side of the non-woven favrics layer (3A), and the plastic film layer (3B) is formed by materials having the melting point lower than the non-woven favrics layer. Concavo convex shape embossing and a plurality of tapping treatments are implemented on a compounding sheet comprising the surface sheet (3) and a second non-woven favrics sheet (6) formed by materials having the melting point lower than the non-woven favrics layer (3A) which is bonding to the inner side fo the surface sheet (3), in a heating condition not less than the melting point of the plastic film layer (3B) and the non-woven favrics sheet (6), and less than the melting point of the non-woven favrics layer (3A).

Owner:DAIO PAPER CORP

Manufacturing method and manufacturing apparatus for electrical device with film covering

ActiveCN103137997ASoak fastDoes not cause flyingHybrid capacitor electrolytesElectrolytic capacitorsBiomedical engineeringElectrolyte

The invention provides a manufacturing method and a manufacturing apparatus for an electrical device with film covering. The manufacturing method for the electrical device with film covering according to the invention can be employed to realize the effect that electrolyte is hard to be uneven in permeation in a battery set so that the electrolyte can be filled within a short time period. The manufacturing method for the electrical device with film covering comprises a pressure reducing procedure for reducing the pressure inside an electrolyte filling cavity equipped with a bag-shaped laminated film package body to lower than the atmospheric pressure, wherein the bag-shaped laminated film package body is provided with an opening part and accommodates the battery set, and the battery set is provided with an anode and a cathode which are laminated up and separated by an insulating film; an electrolyte filling procedure for filling the electrolyte of a specified amount from the opening part into the package body, after the pressuring reducing procedure; and a pressuring increasing and reducing procedure for increasing the pressure inside the electrolyte filling cavity to higher than the pressure in the electrolyte filling procedure and then reducing the pressure, after the electrolyte filling procedure and before sealing the opening part.

Owner:ENVISION AESC JAPAN LTD

Polyester emulsion film former for medium-alkali direct twistless roving impregnating compound

The invention relates to a polyester emulsion film former for a medium-alkali direct twistless roving impregnating compound. A preparation method of the polyester emulsion film former for the medium-alkali direct twistless roving impregnating compound comprises the following steps: carrying out a condensation polymerization reaction of hydrophilic diacid or dialcohol to synthesize hydrophilic unsaturated or saturated polyester, feeding and mixing the unsaturated or saturated polyester, a solvent and deionized water according to a feeding ratio of 10:1:14, and adopting a phase reversal method to prepare the polyester emulsion film former for the medium-alkali direct twistless roving impregnating compound. The polyester emulsion film former has the advantages of good stability, good wire drawing operationality, good binding bunching to glass fibers after the film formation, fast permeation and less hairiness, and is suitable for the medium-alkali direct twistless roving impregnating compound.

Owner:NANTONG TIANHE RESIN

Preparation method of wetting agent for E glass fishing rod gauze

The invention relates to a preparation method of an organic-material-containing E glass fiber surface treating agent. The preparation method comprises the following steps: adding citric acid into deionized water to regulate the pH value to 3-4, slowly adding a silane coupling agent, and stirring at 60-80 rpm for 30-60 minutes; mixing a plasticizer and an emulsifier, melting by heating, and uniformly adding 5-20 times by weight of 70-90 DEG C deionized water within 30-60 minutes while stirring; cooling to 30 DEG C below; adding 80-90 DEG C deionized water into an imidazoline cation lubricant, and stirring uniformly to obtain a transparent solution; adding 30-50 DEG C deionized water into an antistatic agent, and stirring uniformly to obtain a transparent solution; respectively adding 1-5 times by mass of deionized water into an epoxy emulsion film former and an unsaturated polyester film former; and mixing all the substances prepared in all the steps above, adding deionized water, and stirring at 50-60 rpm for 30-40 minutes. The product can enable the E glass fiber fishing rod gauze to have high permeation speed and favorable binding property with epoxy resin, unsaturated polyester resin and phenol aldehyde resin.

Owner:陕西汇友友基新材料有限公司

Enhanced glass fiber sizing agent

The invention discloses an enhanced glass fiber sizing agent and a preparation method thereof. During the preparation, coupling agents, glacial acetic acid, lubricating agents, main film forming agents and wetting agents are sequentially added into deionized water; after sufficient stirring and reaction, a finished product of the sizing agent is obtained. The finished product is prepared from 0.05to 0.2 percent of glacial acetic acid, 0.2 to 0.6 percent of coupling agents A, 0.4 to 0.9 percent of coupling agents B, 0.4 to 0.8 percent of lubricating agents, 15 to 25 percent of main film forming agents and the balance of deionized water. By using the sizing agent provided by the invention, the technical problems of poor stability, poor sizing effect and low sizing efficiency of a conventional sizing agent can be effectively solved.

Owner:SHANDONG FIBERGLASS GRP

Novel glass fiber impregnating compound and preparing method thereof

The invention discloses a novel glass fiber impregnating compound. The novel glass fiber impregnating compound is prepared from, by weight, 20-30 parts of vinyl water-borne epoxy resin, 20-30 parts of 3,4-epoxy group-6-methyl cydohexane formic acid-3,4-epoxy group-6-methyl cyclohexane methyl ester epoxy resin, 10-20 parts of hydroxypropylation modified pea starch, 3-5 parts of coupling agent, 0.5-2 parts of lubricating agent, 0.5-1 part of collecting agent, 0.5-1 part of surfactant, 0.5-2 parts of polyvinylpyrrolidone, 0-0.5 part of antistatic agent, 0.5-1 part of defoamer and 300-500 parts of water. By adding polyvinylpyrrolidone to the formula, adhesive force of the impregnating compound can be improved, viscosity of the impregnating compound can be improved, fiber breakage can be prevented, plasticity and stiffness can be improved, and broken filament generation can be reduced. Three film-forming agents are adopted; yarn impregnation speed is high, heat resistance is high, binding power is high, film-forming property is high, and protective property is high; protection and collection of glass fiber during high-speed jetting and rolling can be achieved easily, production efficiency is improved, and mechanical property of glass fiber is improved.

Owner:TONGCHENG GLASS FIBER OF ANHUI DANFENG GROUP

Reinforced soakage agent for basalt fibers

The invention discloses a soakage agent for basalt fibers and a preparation method of the soakage agent. The soakage agent is prepared from 2%-8% of water-soluble epoxy resin, 1%-5% of a polyester emulsion, 2%-4% of a vinyl resin emulsion, 0.5%-1.0% of a coupling agent, 0.2%-0.8% of an antistatic agent, 0.6%-1.2% of a plasticizer, 0.08%-0.25% of a pH regulator and the balance of deionized water. The soakage agent which is prepared in the rated weight ratio and used for surface modification of the basalt fibers can be directly applied to the surfaces of the basalt fibers in the production and drawing process of the basalt fibers, surface modification can be completed after drying, the soakage agent is more convenient to use, and an aqueous solution of the soakage agent has good adhesion and film-forming properties.

Owner:晏玲莉

Quick clearing device for wall coating

InactiveCN111042561AReduce vibrationReduce noiseBuilding repairsHouse buildingMechanical engineering

The invention discloses a quick clearing device for a wall coating, and relates to the technical field of house constructional engineering. The quick clearing device comprises a frame body, wherein aspiral scraper and a roller are arranged on opposite inner side surfaces of the frame body; a motor box and a water tank are arranged on the outer side surface of the frame body; a saw-tooth-shaped groove is formed in the peripheral side surface of the spiral scraper; and water injecting pins are arranged at the peripheral side of the roller. The saw-tooth-shaped spiral scraper can be utilized toperform deep and wall-along planar scraping on wall paint, so that the problems that existing manual scraping is great in labor intensity, is low in efficiency, is noisy by adopting the rotary scraper, and generates great dust are solved; and a roller is arranged, and water injecting pins are arranged at the peripheral side of the roller in the form of an array, so that the problems that the coating cannot be soaked as an existing wall is sprayed with water for a short time, and quick clear for paint is unfavorable are solved.

Owner:ANHUI SANDI ELECTRONICS TECH CO LTD

Emulsion based hair cosmetic

Provided is an emulsion based hair cosmetic containing (A) a cationic surfactant, (B) a higher alcohol, (C) L-histidine, (D) L-arginine, and (E) 0.1-0.5 mass% of a water-soluble polymer compound, wherein the total compounded amount and the mass ratio of the components (C) and (D) are: (C) 0.01-0.5 mass%, (D) 0.01-0.5 mass%, and (C) + (D) = 0.05-0.6 mass%; and (C) / (D) = 0.2-5.

Owner:LION CORP

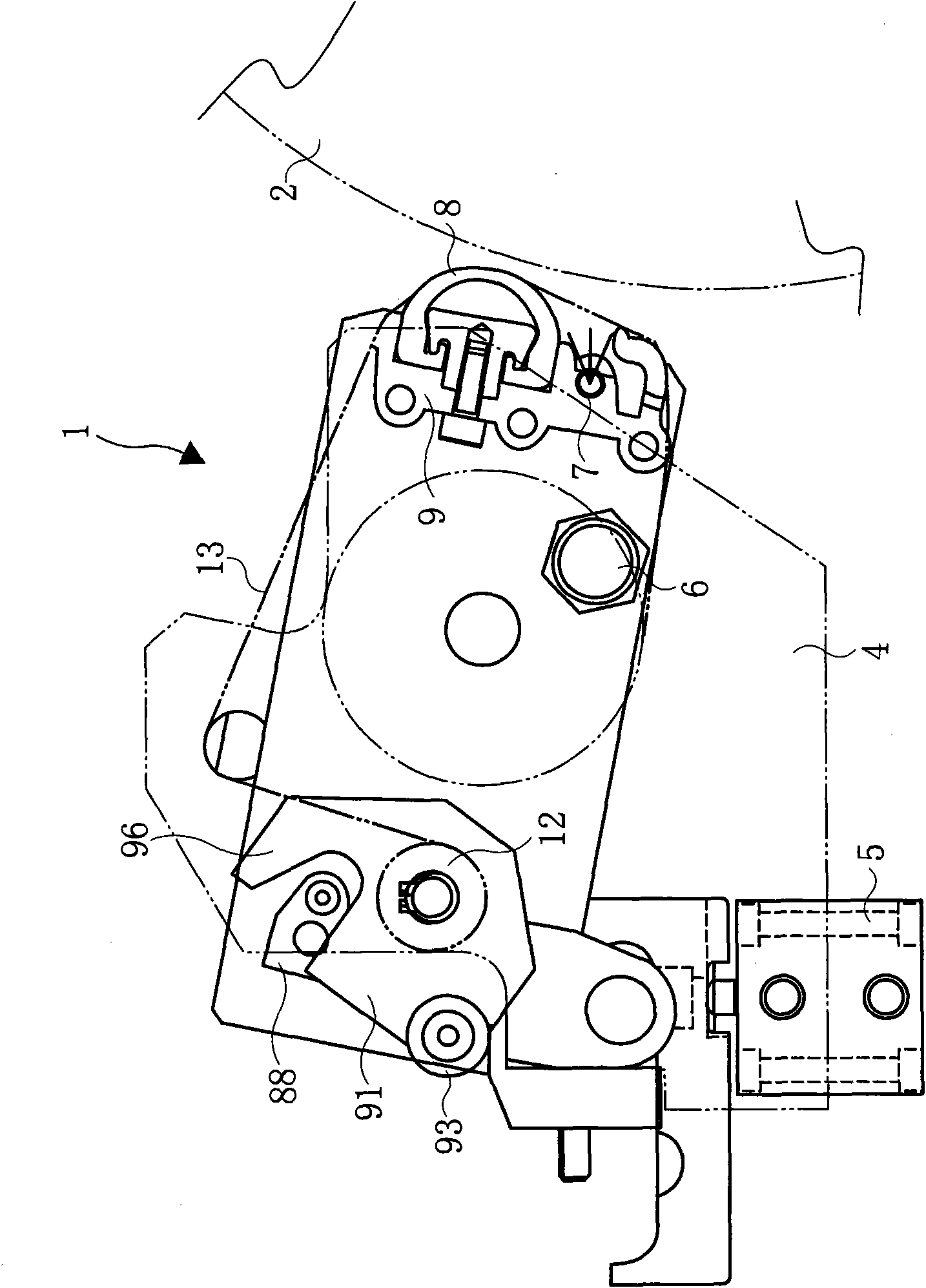

Cylinder rinsing device

InactiveCN101801670AImprove cleaning efficiencyAvoid wrinklingMixing methodsCleaning using toolsEngineeringConductor Coil

Intended is to provide a cylinder rinsing device having a novel constitution thereby to prevent the flapping phenomenon of a pressure pad and to mount the pressure pad easily. The cylinder rinsing device comprises a rinsing cloth winding roll having a pressure pad made of an elastic member for pushing a piece of rinsing cloth to a cylinder surface. A pressure pad (8) is fixed between a pad mounting plate (9) and a pad holding bar (20) and formed of an elastic material into a semicircular shape. The pressure pad (8) is made thin at the pushing portion of its central portion (16) and thick at the base portions (15) of its two end portions, and the base portions (15) have retained portions (17) to be pushed by the pad holding bar (20). The pressure pad (8) has an inward inclined face made thicker in the widthwise direction by inclining the inner faces (152) of the base portions (15) inward to the bottom face. The pad mounting plate (9) extends in the trunk length direction of the cylinder, and has such a recess (25) formed on the side to confront the cylinder as to receive the pressure pad. The pad holding bar (20) has such an inward inclined face (203) on the side wall to contact the inner face of the pressure pad (8) as is inclined inward in a converging state toward the bottom portion. The inward inclined face (203) of the pad holding bar (20) is pushed to abut on the inward inclined face of the pressure pad (8), and the inward inclined faces of the base portions (15) of the pressure pad (8) are pushed onto the wall face of the pad mounting plate (9) on the side of the recess (25).

Owner:JPE

Preparation method of composite rose flower tea

The invention belongs to the technical field of food processing and particularly discloses a preparation method of composite rose flower tea. The preparation method includes the steps of: 1) weighingraw materials including: 18-30 parts of rose flowers, 5-10 parts of lily, 3-6 parts of radices lithospermi, 3-6 parts of chrysanthemum indicum and 1-5 parts of red dates; 2) processing of rose flowers: successively performing microwave, fumigation and drying treatment to the rose flowers; 3) treatment of other raw materials: mixing and extracting other raw materials to prepare an extract powder; 4) spray coating treatment: spray-coating the rose flowers with the extract powder. The composite rose flower tea has abundant nutrients and is high in sensing quality, and has strong functions of beautifying and nourishing face, quieting heart to nourish spirit and tonifying and activating blood.

Owner:柳州市汉象教育咨询有限责任公司

Washing-resistant cow clothing leather processing technology

InactiveCN108998589AImprove efficacySoak fastTanning treatmentPre-tanning chemical treatmentHair removalEngineering

The invention discloses a washing-resistant cow clothing leather processing technology, and relates to the technical field of cow leather clothes. The washing-resistant cow clothing leather processingtechnology specifically comprises the following steps of 1, carrying out batch soaking, namely classifying the raw leather with the similar thickness, and placing raw leather in a drum to be processed, and adding clear water into the drum for soaking the raw leather, soaking the dried leather for 2-3 days, soaking wet salted hides for 1-2 days, adding an immersion aid in the soaking process, andaccelerating the soaking of water; 2, performing hair removal and degreasing, removing the grease on the surfaces of the cells in the cow leather and the hair on the surface of the original leather byusing a depilating machine after being soaked in the step 1 to expose the natural and fine grain surfaces; and 3, soaking the leaching acid, soaking Ca(OH)2 with the mass fraction being 10% for 1-2 hours, and expanding the cow leather to a certain thickness. According to the washing-resistant cow leather processing technology, the processing technology is simple and comprehensive, the water washing resistance of the cow leather is greatly improved by the adoption of the chrome tanning agent, so that the problem that the cow leather becomes dry and hard after being cleaned for multiple times is avoided.

Owner:宁波元元尚品服饰科技有限公司

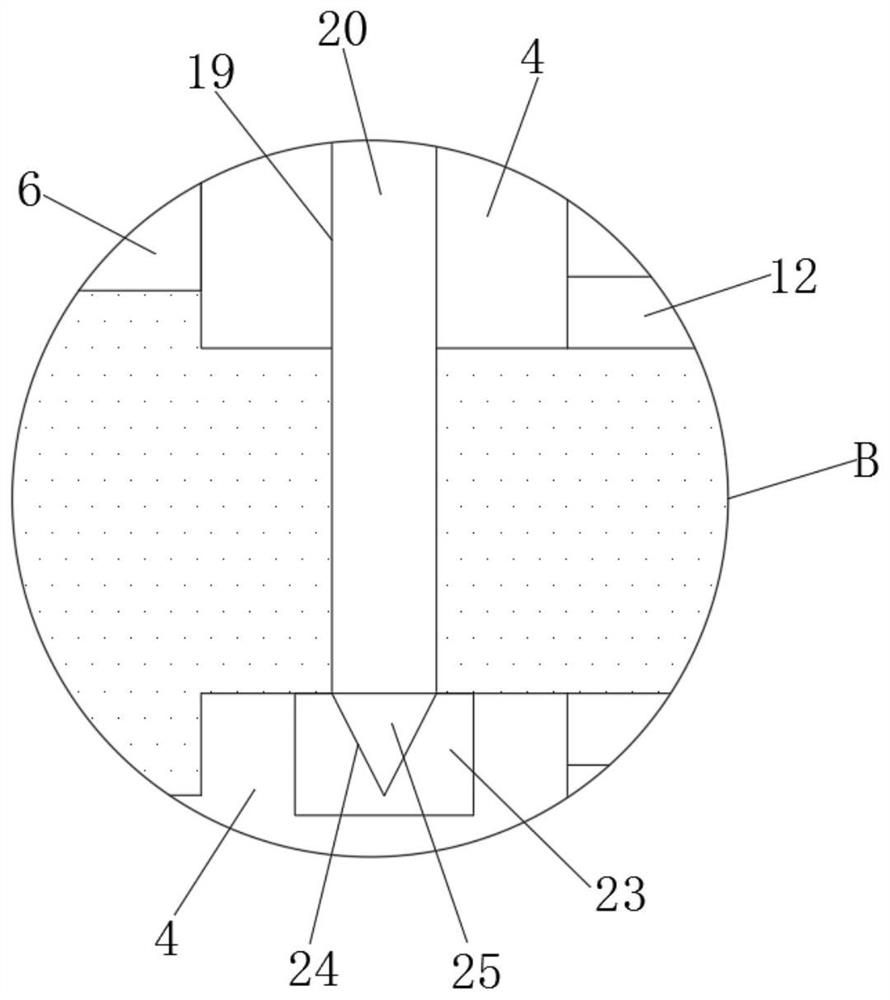

Medical air purification and degerming sterilizer

InactiveCN112432289AFast injectionSoak fastMechanical apparatusLighting and heating apparatusMedicineAir cleaning

The invention discloses a medical air purification degerming sterilizer which structurally comprises a sterilizer body, an air inlet plate and a display screen. The display screen is fixedly embeddedin the front end of the sterilizer body, the sterilizer body and the air inlet plate are of an integrated structure, and a downward extending plate can extend downwards along a plate body through pushing force generated by disinfectant between an inner frame and an outer frame to the downward extending plate, so that the downward extending plate can extend into a built-in block. The disinfectant between the inner frame and the outer frame can be rapidly injected into the built-in block from multiple directions through a liquid permeating cavity, and the interior of the built-in block can be rapidly soaked by the disinfectant. Through reverse thrust generated by the disinfectant to the space between two outward expanding plates, the outward expanding plates can extend outwards along a middle fixing block under the cooperation of a transition rod, so that a contact plate can push the downward extending plate to extend upwards into the built-in block, and the situation that the downward extending plate at the bottom of the inner frame difficultly extrudes into the built-in block due to the fact that little disinfectant is discharged into a filter layer is effectively avoided.

Owner:武汉星光宝盒房地产经纪有限公司

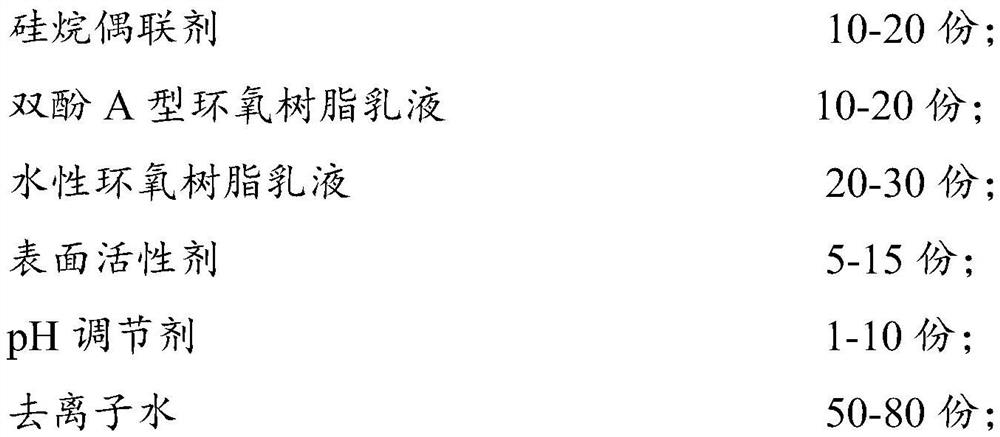

Glass fiber reinforced PMMA composite material and preparation method thereof

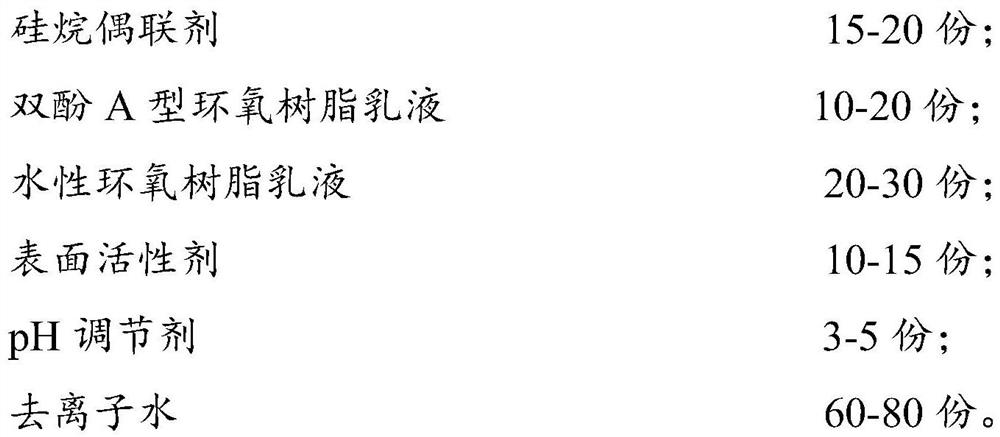

The invention discloses a glass fiber reinforced PMMA composite material and a preparation method thereof, and belongs to the technical field of high polymer materials. The composite material comprises PMMA resin, modified glass fibers and a compatilizer; the surface of the modified glass fiber is coated with an impregnating compound, and the impregnating compound is composed of a silane coupling agent, a bisphenol A epoxy resin emulsion, an unsaturated polyester resin emulsion, a surfactant, a pH regulator and deionized water; the silane coupling agent is a mixture of methacrylic acid chromium tetrachloride, gamma-methacrylic acid propyl trimethoxy silane and divinyl triamine propyl triethoxy silane in a mass ratio of 1: (0.3-0.7): 0.2; and the surfactant is a mixture of fatty alcohol-polyoxyethylene ether and dodecyl dimethyl amine oxide in a mass ratio of (1-1.5): 0.5. According to the invention, the modified glass fiber is added into PMMA, so that the prepared composite material has higher mechanical properties.

Owner:SHANDONG FIBERGLASS GRP

Soaking device for preparing traditional Chinese medicine liquid

InactiveCN112206155ASpeed up soakingSlow ascentPharmaceutical product form changePressesMedicinal herbsHydraulic cylinder

The invention discloses a soaking device for preparing a traditional Chinese medicine liquid. The soaking device comprises a soaking box; a front fixing plate and a rear fixing plate are fixedly connected to the top end of the soaking box separately; a first hydraulic cylinder is fixedly connected to the inner side wall of the soaking box; a first cavity is formed in the first hydraulic cylinder;a first piston is slidably connected into the first cavity; and a first ejector rod which penetrates rough the first hydraulic cylinder is fixedly connected to one side wall of the first piston. Liquid medicine infiltrated in the liquid medicine is squeezed out, then the squeezed medicinal materials are put back into clear water, the internal structures of the medicinal materials are damaged, themedicinal materials can be rapidly soaked with the clear water, the medicinal material soaking speed is increased, and the efficiency of preparing the liquid medicine by soaking the medicinal materials is remarkably improved; and effective medicine components in the medicinal materials can be fully soaked and taken out, waste is reduced, and in addition, the whole process is easy to operate and convenient to use.

Owner:林兴寿

Glass fiber reinforced polypropylene composite material and preparation method thereof

The invention discloses a glass fiber reinforced polypropylene composite material and a preparation method thereof, and belongs to the technical field of high polymer materials. The composite material comprises polypropylene resin, modified glass fibers, an antioxidant and a compatilizer, the surface of the modified glass fiber is coated with an impregnating compound; the impregnating compound is prepared from a silane coupling agents, a bisphenol A type epoxy resin emulsion, a water-borne epoxy resin emulsion, a surfactant, a pH regulator and deionized water, wherein silane coupling agent is a mixture of vinyltriethoxysilane, gamma-glycidyl ether propyl trimethoxysilane and vinyl tri(beta-methoxyethoxy) silane in mass ratio of (1-1.2): 1: 0.4; and the surfactant is a mixture of fatty alcohol polyoxyethylene ether sodium sulfate and nonylphenol polyoxyethylene ether in a mass ratio of 1: (1.1-1.5). According to the invention, the modified glass fiber is added into polypropylene, so that the prepared composite material has higher mechanical properties.

Owner:SHANDONG FIBERGLASS GRP

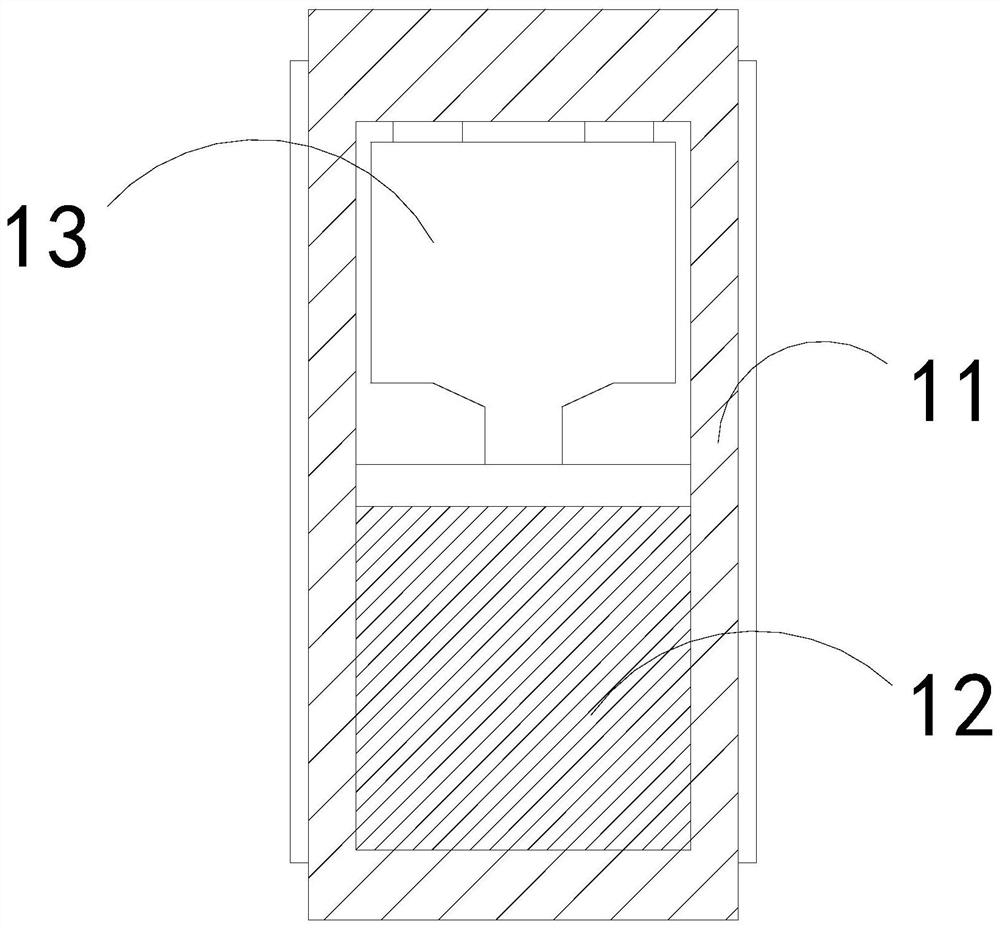

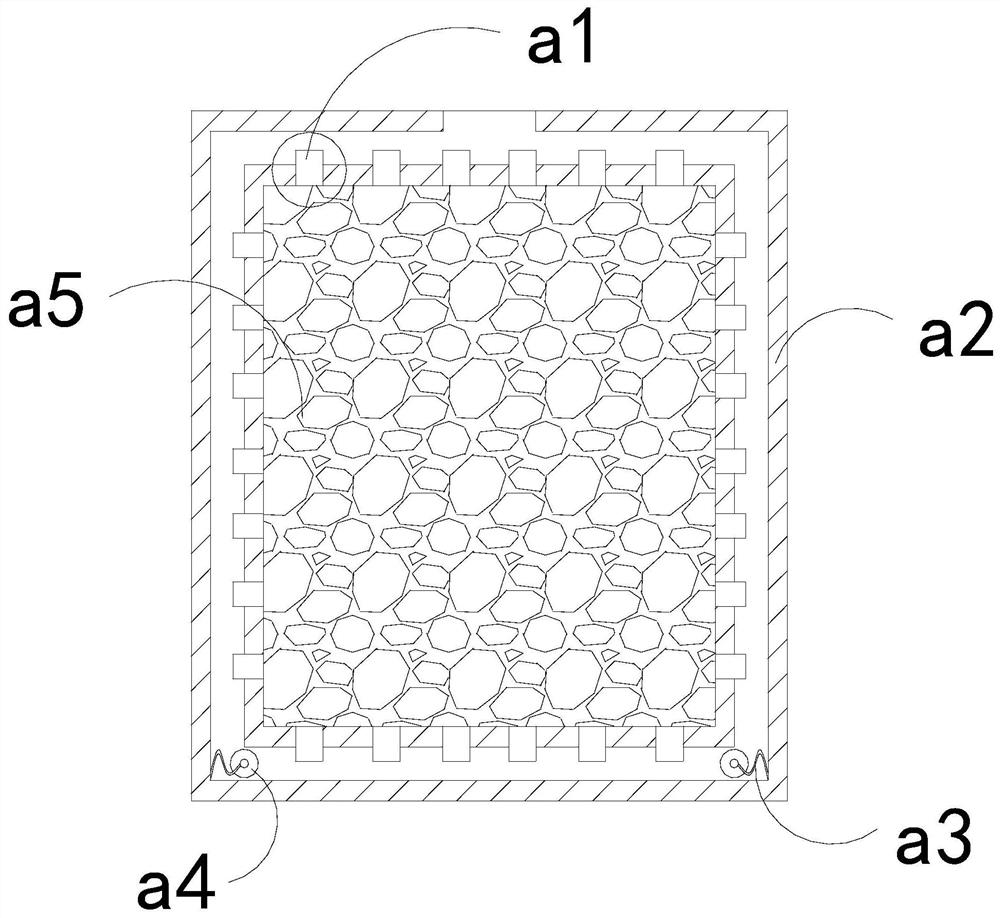

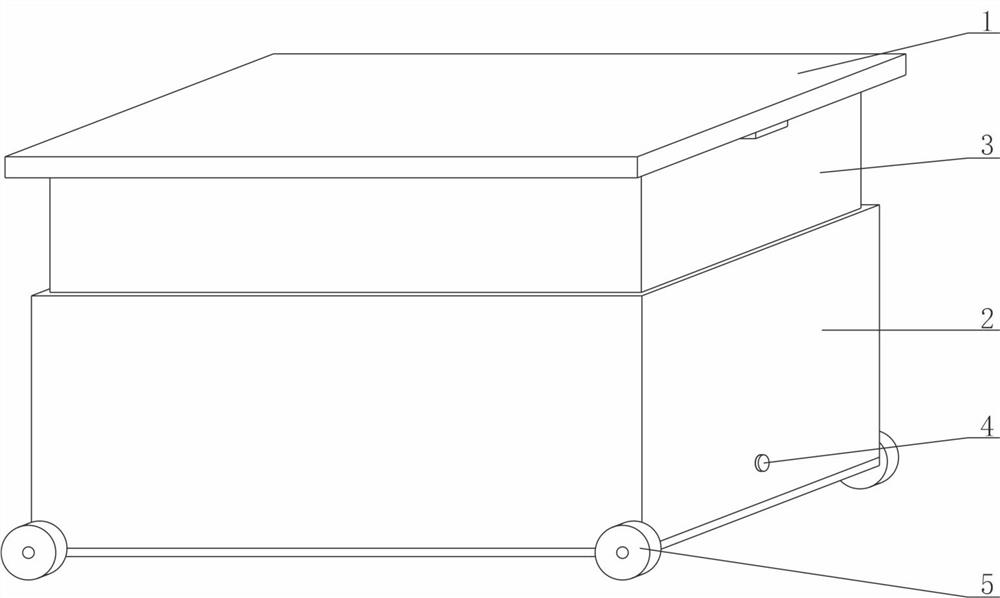

Ceramic tile soaking device capable of avoiding hollowing

InactiveCN112982898AAvoid hollowingSoak fastBuilding constructionsStructural engineeringMechanical engineering

The invention provides a ceramic tile soaking device capable of avoiding hollowing, and relates to the field of engineering construction equipment. The device comprises a box body, an extension device, a cover plate, a fixed plate, a support rod, a first buffer part and a second buffer part, the extension device, the fixed plate and the first buffer part are arranged on the box body, the support rod is arranged on the fixed plate, the cover plate is arranged on the extension device, and the second buffer part is arranged on the cover plate. The box body is composed of a bottom plate, a connecting plate, a vibrator, a first shell, a second shell, a supporting block, wheels and a sealing plug, the extension device is composed of a fixing frame, a limiting block and a spring buckle, the first buffer part is composed of a first buffer pad and a clamping block, and the second buffer part is composed of a second buffer pad and a clamping block. The device is simple in structure and convenient to operate, the ceramic tile soaking time can be shortened, water can effectively and rapidly enter ceramic tiles, the four corners and glaze surfaces of the ceramic tiles are prevented from being impacted and damaged, and losses of users are reduced.

Owner:侯艳艳

Process for producing dried food eaten after hot-water cooking or hot-water reconstitution, and dried noodle

InactiveCN1897826AIncrease surface areaGreat tasteFood preservationFood preparationThermal waterDried food

Dried food is produced by processing a processing subject obtained by forming a preparation of starchy raw material into given shape through a process (1) to (3) comprising at least (1) the first step (P1) in which boiling treatment is conducted, (2) the second step (P2) of after the first step (P1), bringing the boiled processing subject into contact with an aqueous solution and (3) the third step (P3) of air drying the processing subject after the second step (P2) in such conditions that the temperature is in the range of 45 to 100 DEG C and the humidity in the range of 5 to below 55%. Therefore, the invention provided, for example, a process for producing dried food that enables short-time hot-water cooking or hot-water reconstitution, ensuring pleasant palate feeling and that excels in loosenability.

Owner:YAMADAI

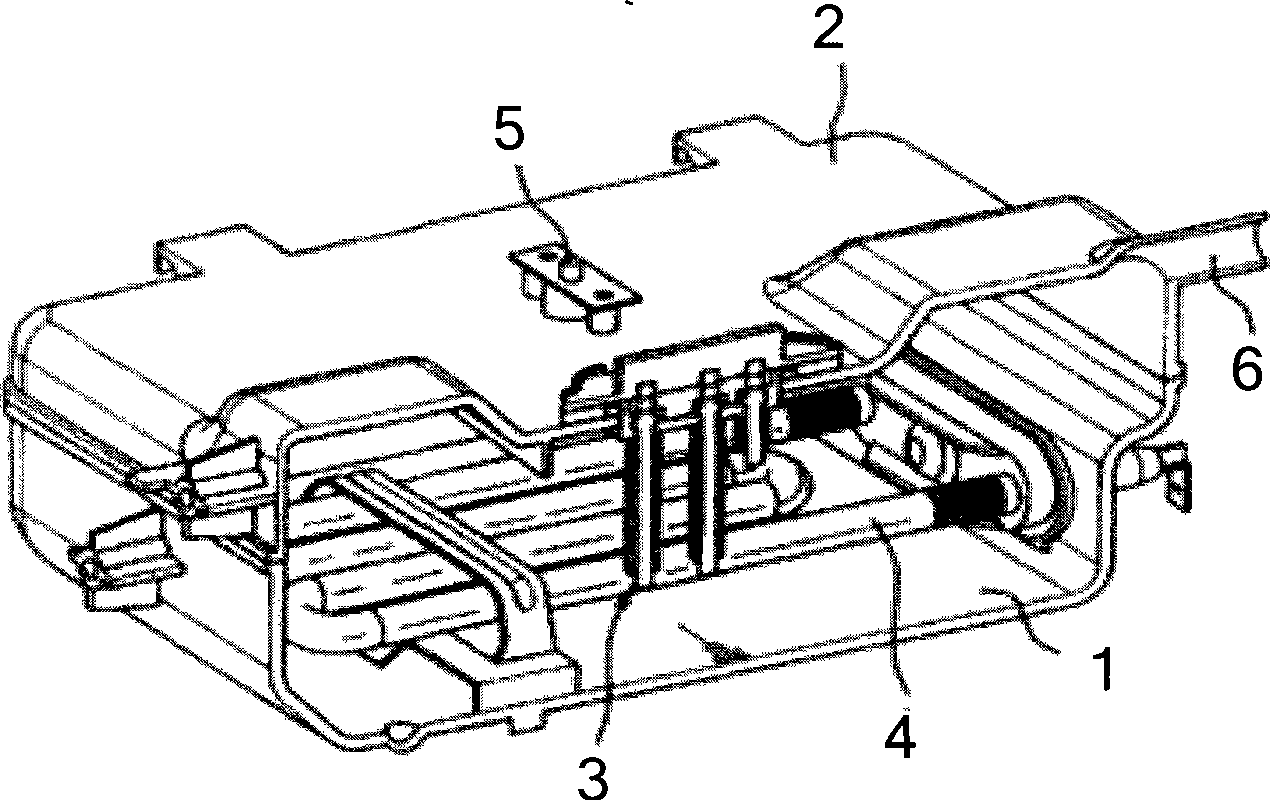

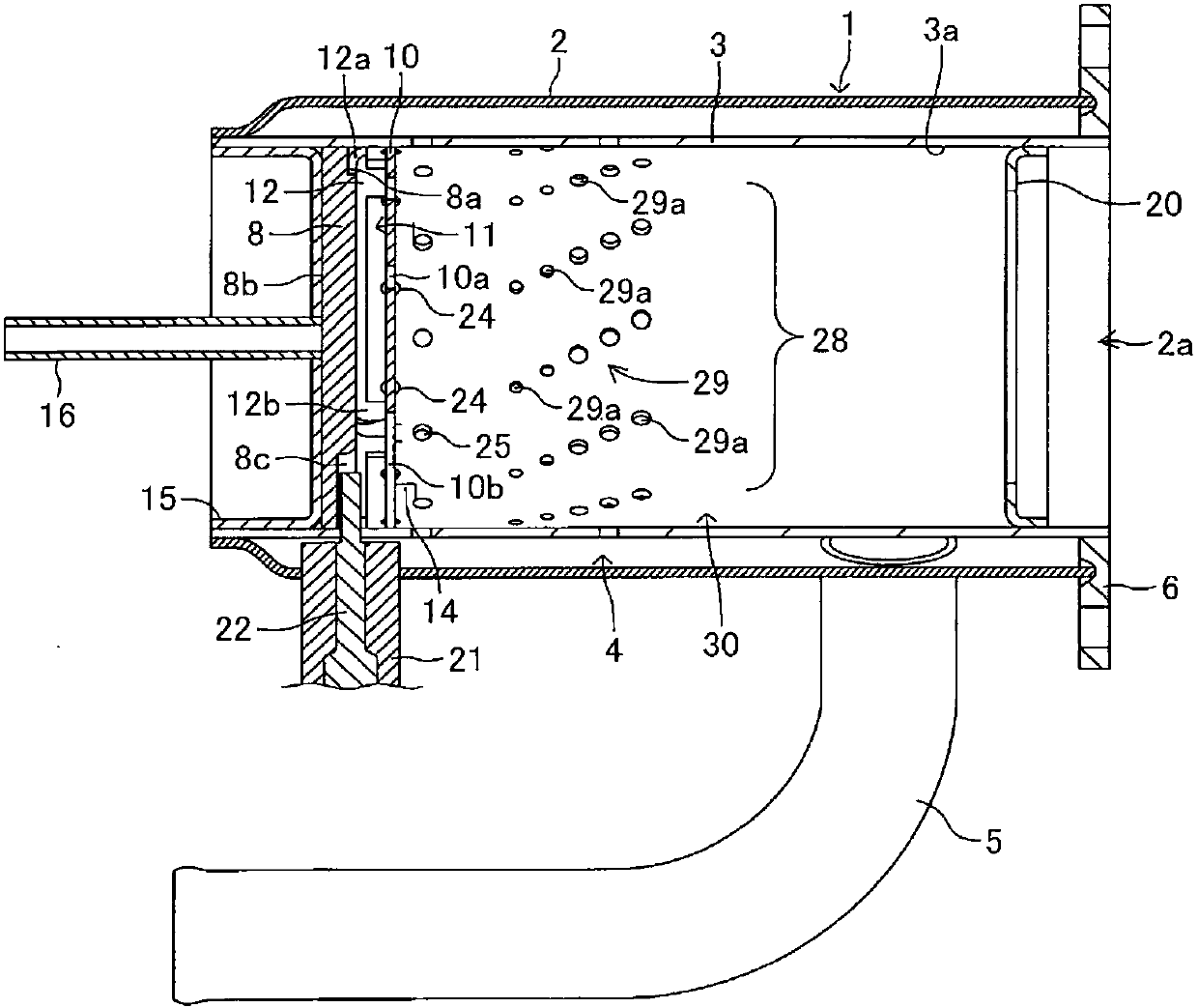

Evaporative-type burner

ActiveCN107614975AImprove fire resistanceExtend your lifeIncandescent ignitionCapillary burnersCombustorCombustion chamber

Disclosed is an evaporative-type burner. An acceleration member (10) is disposed across a prescribed gap on an impregnation member (8) that is installed on the upstream end of a combustion chamber (30), an ignition device (22) and a first air supply port (24) are provided in an ignition space upstream from the acceleration member (10), and a second air supply port (28) is provided in a combustionspace downstream from the acceleration member (10). Fuel is supplied to the smooth surface of the impregnation member (8), and at least part of the ignition device (22) is accommodated in a recess (8c) or notch (32) formed in the impregnation member (8). A configuration is adopted such that the flow of air supplied to the combustion space from the second air supply port (28) increases further downstream. This improves ignition performance in the evaporative-type burner (1), and minimizes incomplete combustion of fuel on the downstream side of the combustion chamber (30).

Owner:SANGO CO LTD

Glass fiber reinforced polyvinyl chloride composite material production system and method

The invention discloses a glass fiber reinforced polyvinyl chloride composite material production system and method, and belongs to the technical field of inorganic non-metallic materials. The glass fiber reinforced polyvinyl chloride composite material production system comprises a material mixing device, a heating device, a tank furnace wire drawing device, an infiltration wire collecting device and a composite material mixing and extruding device. Glass fiber raw materials are uniformly mixed through the material mixing device and are pneumatically conveyed to the tank furnace wire drawing device, the tank furnace wire drawing device is heated through the heating device, so that the raw materials are molten, then wire drawing forming is carried out to obtain glass fiber precursors, the surfaces of the glass fiber precursors are coated with an impregnating compound to obtain precursor cake, and the raw materials of the composite material are mixed and extruded by using a composite material mixing and extruding device to obtain the glass fiber reinforced composite material. The glass fiber production equipment is simple, the compatibility of the prepared glass fiber and resin is good, and the prepared glass fiber reinforced resin composite material has wider application under the general background of automobile lightweight.

Owner:SHANDONG FIBERGLASS GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com