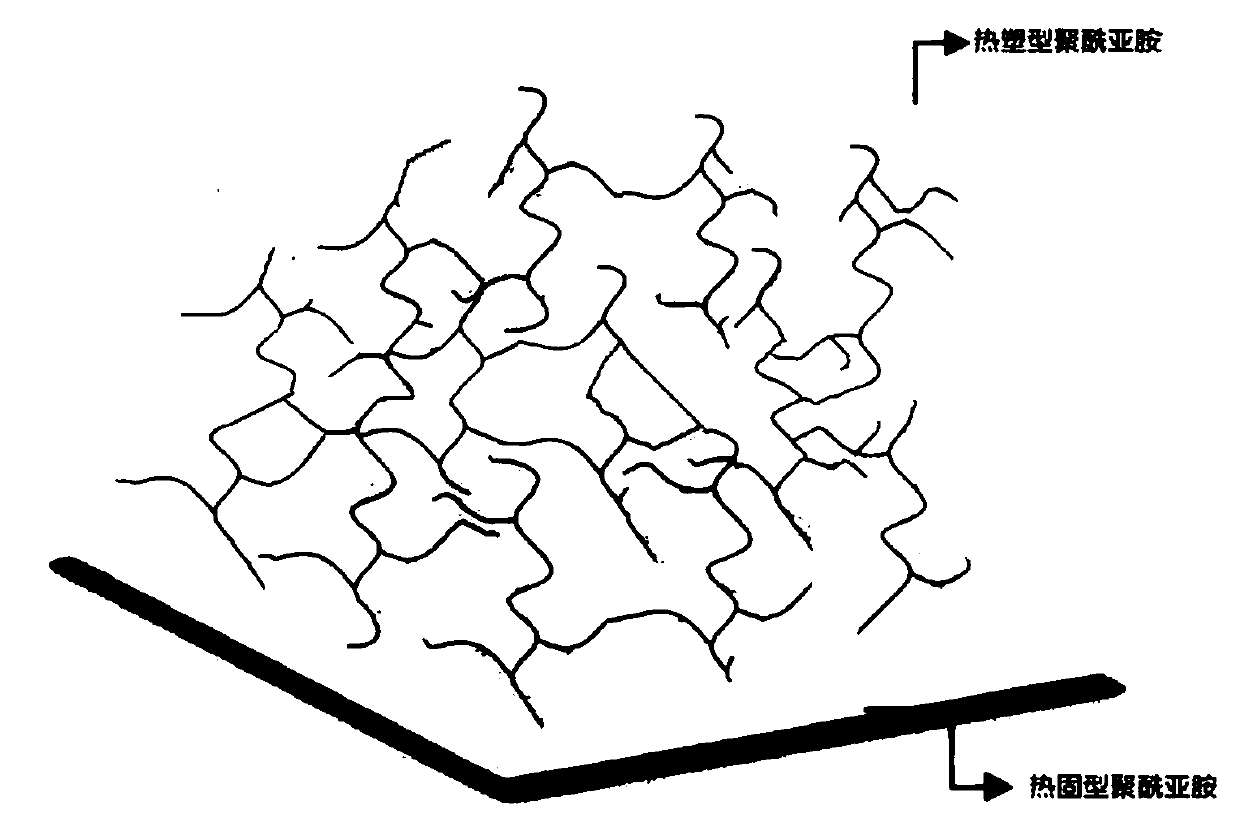

Preparation method of non-interface thermoplastic thermosetting polyimide composite film

A technology of polyimide and composite film, which is applied in the direction of coating, etc., and can solve the problems of low dimensional stability of the thermoplastic layer when heated, delamination and blistering, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

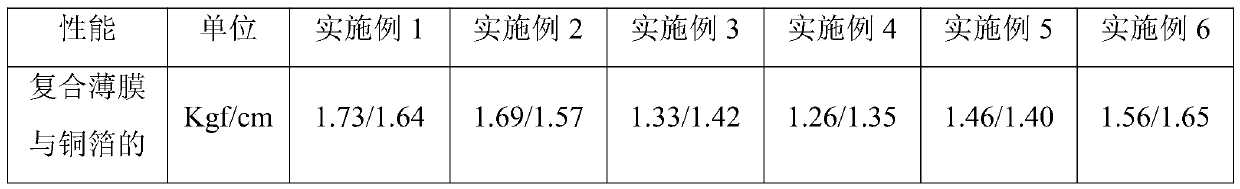

Embodiment 1

[0075] The preparation method of thermoplastic thermosetting polyimide composite film comprises the following steps:

[0076] (1) Under the condition of normal pressure filled with nitrogen in the stirred tank at 35°C, first dissolve 4,4'-diaminodiphenyl ether and p-phenylenediamine in dimethylacetamide solvent, and then add pyromellitic tetra Formic dianhydride, 3,3', 4,4'-biphenyl dianhydride for polymerization reaction, reaction time 4 hours, 3,3', 4,4'-biphenyl dianhydride: pyromellitic dianhydride: 4 , The molar ratio of 4'-diaminodiphenyl ether:p-phenylenediamine is 0.15:0.85:0.50:0.502, and the polyamic acid glue A with a solid content of 19.3wt% is obtained;

[0077] (2) Under the condition of normal pressure filled with nitrogen in the stirred tank at 45°C, first dissolve 3,4'-diaminodiphenyl ether in dimethylacetamide solvent, and then add 3,3',4,4 '-Diphenyl ether dianhydride is polymerized, the reaction time is 5.5 hours, the molar ratio of 3,3',4,4'-diphenyl ethe...

Embodiment 2

[0082] The preparation method of thermoplastic thermosetting polyimide composite film comprises the following steps:

[0083] (1) Under the condition of normal pressure filled with nitrogen in the stirred tank at 35°C, first dissolve 4,4'-diaminodiphenyl ether and p-phenylenediamine in dimethylacetamide solvent, and then add pyromellitic tetra Formic dianhydride, 3,3', 4,4'-biphenyl dianhydride for polymerization reaction, reaction time 4 hours, 3,3', 4,4'-biphenyl dianhydride: pyromellitic dianhydride: 4 , The molar ratio of 4'-diaminodiphenyl ether:p-phenylenediamine is 0.15:0.85:0.52:0.483, and the polyamic acid glue A with a solid content of 19.3wt% is obtained;

[0084] (2) Under the condition of normal pressure filled with nitrogen in the stirred tank at 45°C, first dissolve 4,4'-diaminodiphenyl ether in dimethylacetamide solvent, and then add 3,3',4,4 '-Diphenyl ether dianhydride is polymerized, the reaction time is 4.5 hours, the molar ratio of 3,3',4,4'-diphenyl ethe...

Embodiment 3

[0089] The preparation method of thermoplastic thermosetting polyimide composite film comprises the following steps:

[0090] (1) Under the condition of normal pressure filled with nitrogen in the stirred tank at 35°C, first dissolve 4,4'-diaminodiphenyl ether and p-phenylenediamine in dimethylacetamide solvent, and then add pyromellitic tetra Formic dianhydride, 3,3', 4,4'-biphenyl dianhydride for polymerization reaction, reaction time 4 hours, 3,3', 4,4'-biphenyl dianhydride: pyromellitic dianhydride: 4 , The molar ratio of 4'-diaminodiphenyl ether:p-phenylenediamine is 0.15:0.85:0.55:0.453, and the polyamic acid glue A with a solid content of 19.3wt% is obtained;

[0091] (2) Under the condition of normal pressure filled with nitrogen in the stirred tank at 45°C, first dissolve 4,4'-diaminodiphenyl ether in dimethylacetamide solvent, and then add 2,2'-phenylene sulfide -4,4',5,5'-biphenyl dianhydride for polymerization reaction, reaction time 4 hours, 2,2'-phenylene sulfid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com