Rubber and ceramic composite material and preparation method thereof

A composite material and ceramization technology, applied in the field of rubber-ceramic composite material and its preparation, can solve the problems of high hardness reducing the friction coefficient of the belt, high requirements for processing and environment, affecting the service life of the belt, etc. Improves abrasion resistance and prevents tape from slipping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] Two) the preparation technology of rubber ceramic composite material of the present invention is:

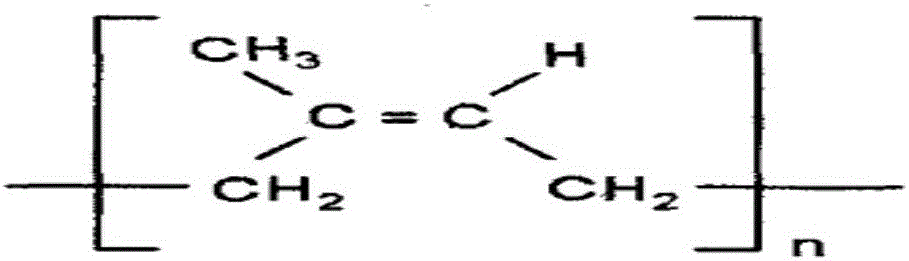

[0024] 1) Using natural rubber as the filling matrix, adding a formula amount of nano-SiO 2 , Nano Al 2 o 3 , Nano-MoO 2 , Nanographene, Si69 for mixing, mixing temperature 50 ℃ -60 ℃, thin pass 2 times, and then pull out 6mm thick material glue.

[0025] 2) Then add the formula amount of sulfur, vulcanization accelerator, nano-ZnO, anti-aging agent, polyester fiber, and other auxiliary materials to the rubber material for mixing. The mixing temperature is 35°C-45°C, thin pass 5 times, and then drawn into 8-10mm thick rubber sheet to obtain vulcanized raw materials for wear-resistant composite materials.

[0026] 3) Steam vulcanize the compacted composite material. Before vulcanization, paste the material on the surface of the component, apply constant pressure, put it into the vulcanization tank, open the boiler steam valve, and put the steam into the pressure tank g...

Embodiment 1

[0037] A rubber ceramic composite material, its components are 55% of natural rubber material, 45% of nanometer powder, all in weight percentage. The nano-powder includes the following components, nano-SiO 2 (Silicon dioxide) 34 parts, nano-Al 2 o 3 (Al2O3) 35 parts, nanometer MoO 2 (molybdenum dioxide) 8 parts, nano-graphene (powder or oil) 18 parts, the particle diameter of described nanoscale particle is 20-30nm, silane coupling agent (Si-69) 5 parts, auxiliary material 5 parts, all The auxiliary materials are 1 part of sulfur, 0.5 part of accelerator, 1 part of ZnO, 0.5 part of anti-aging agent, 1 part of oily anti-wear agent, 0.5 part of polyester fiber, and 0.5 part of pine tar. The consumption of each component in the auxiliary material is the conventional dosage. Both are parts by weight.

Embodiment 2

[0039] A rubber ceramic composite material, the components of which are 56% of natural rubber material and 44% of nanometer powder, all of which are percentages by weight. The nano powder includes the following components, nano SiO 2 (Silicon dioxide) 40 parts, nanometer Al 2 o 3 (Al2O3) 33 parts, nanometer MoO 2 (molybdenum dioxide) 7 parts, nano-graphene (powder or oil) 16 parts, the particle diameter of described nanoscale particle is 20-30nm, silane coupling agent (Si-69) 3 parts, auxiliary material 4 parts, all The auxiliary materials are sulfur, accelerator, ZnO, anti-aging agent, oily anti-wear agent, polyester fiber, pine tar, and the consumption of each component in the auxiliary materials is the conventional amount, all in parts by weight.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com