Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

43results about How to "No increase in cost" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

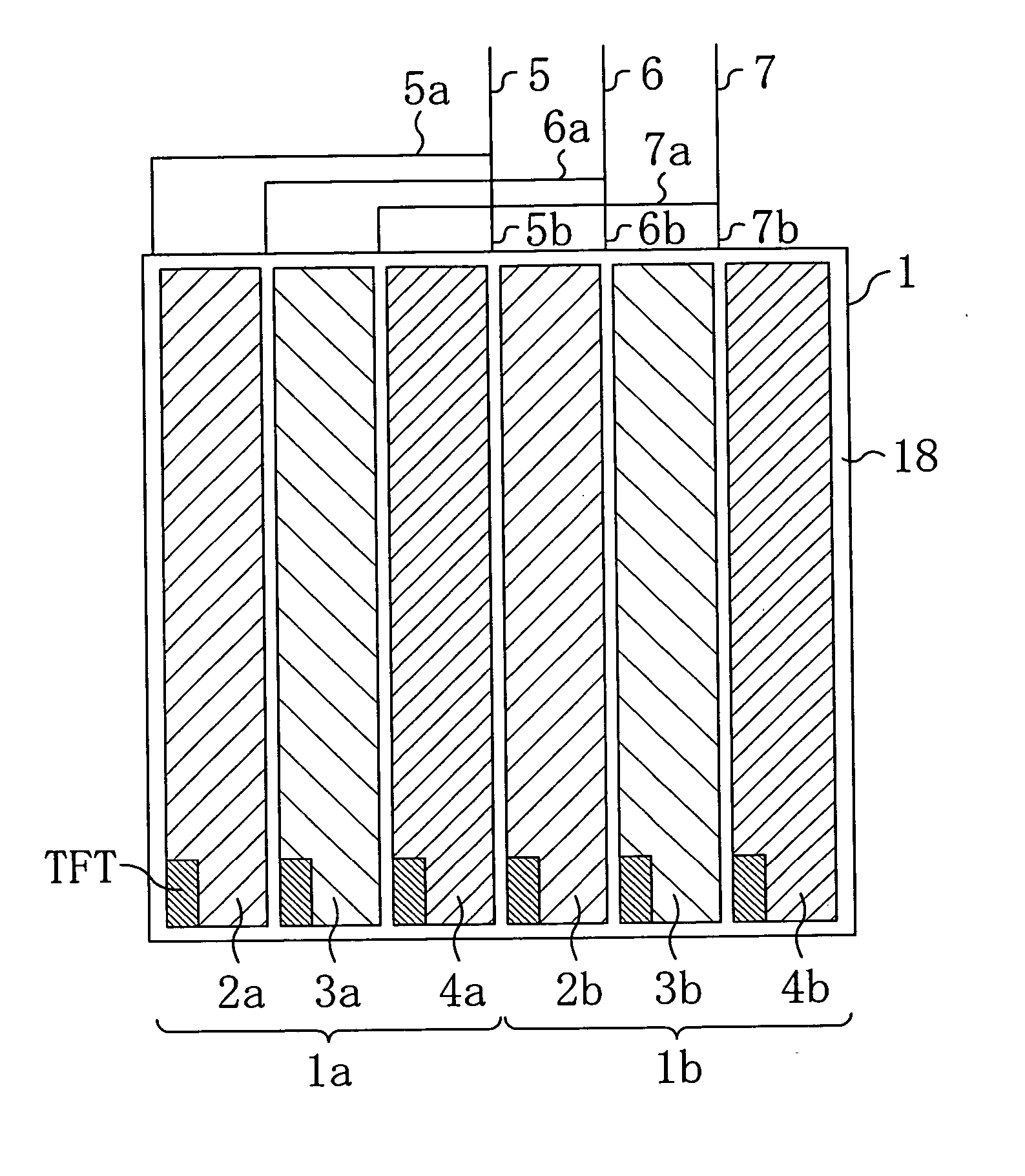

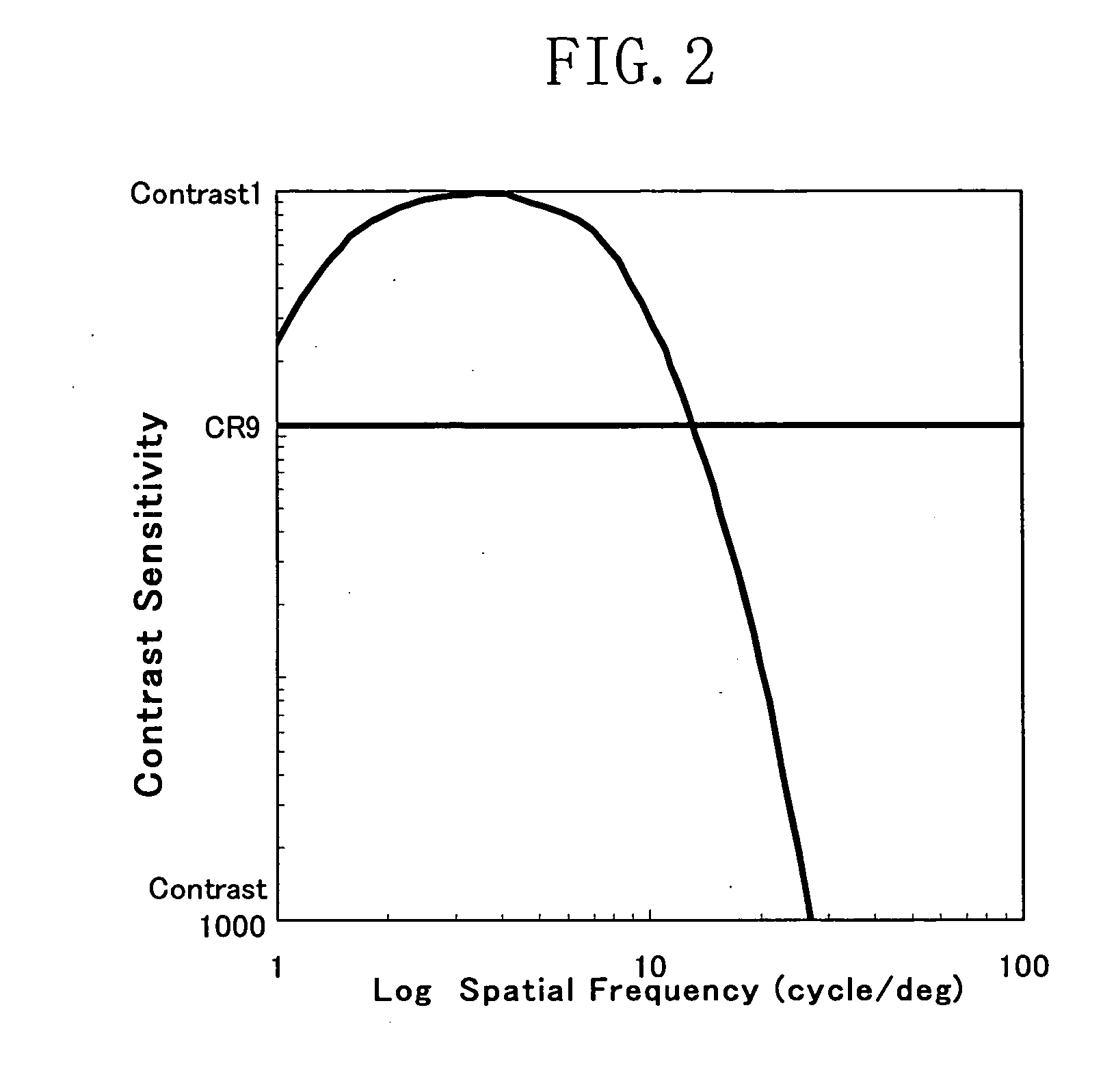

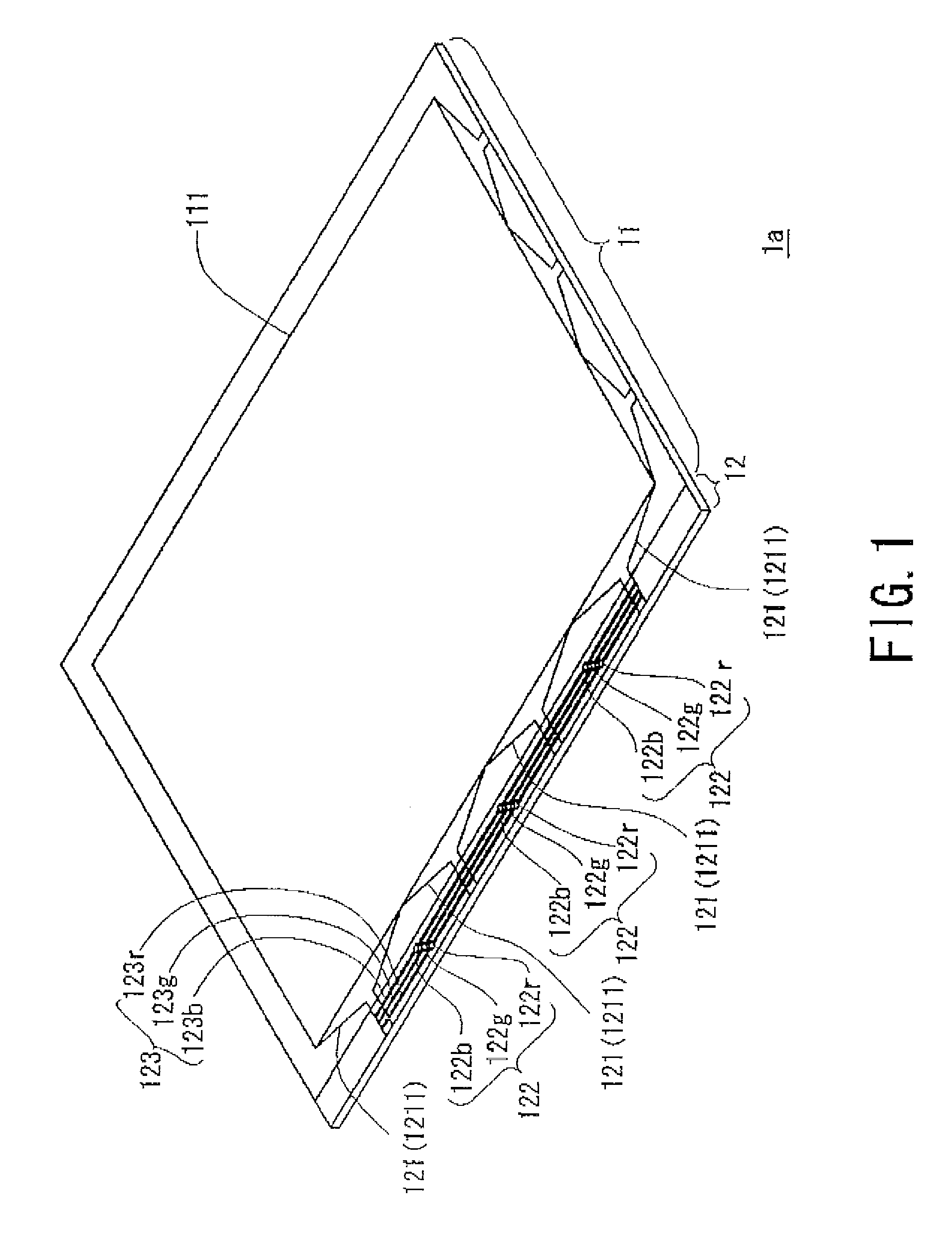

Display device

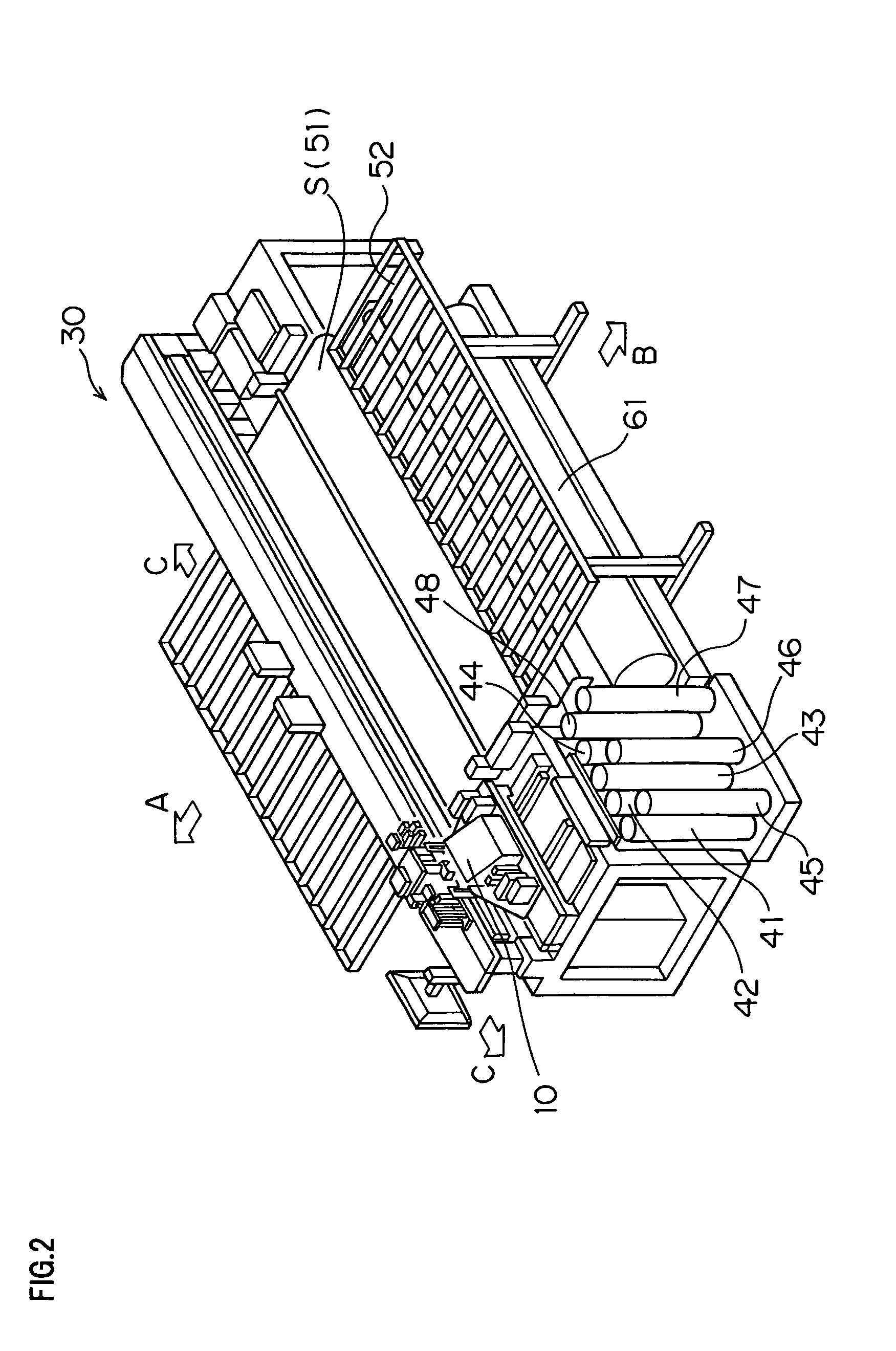

InactiveUS20050168423A1Deterioration of display qualityNo increase in costCathode-ray tube indicatorsNon-linear opticsDisplay devicePattern recognition

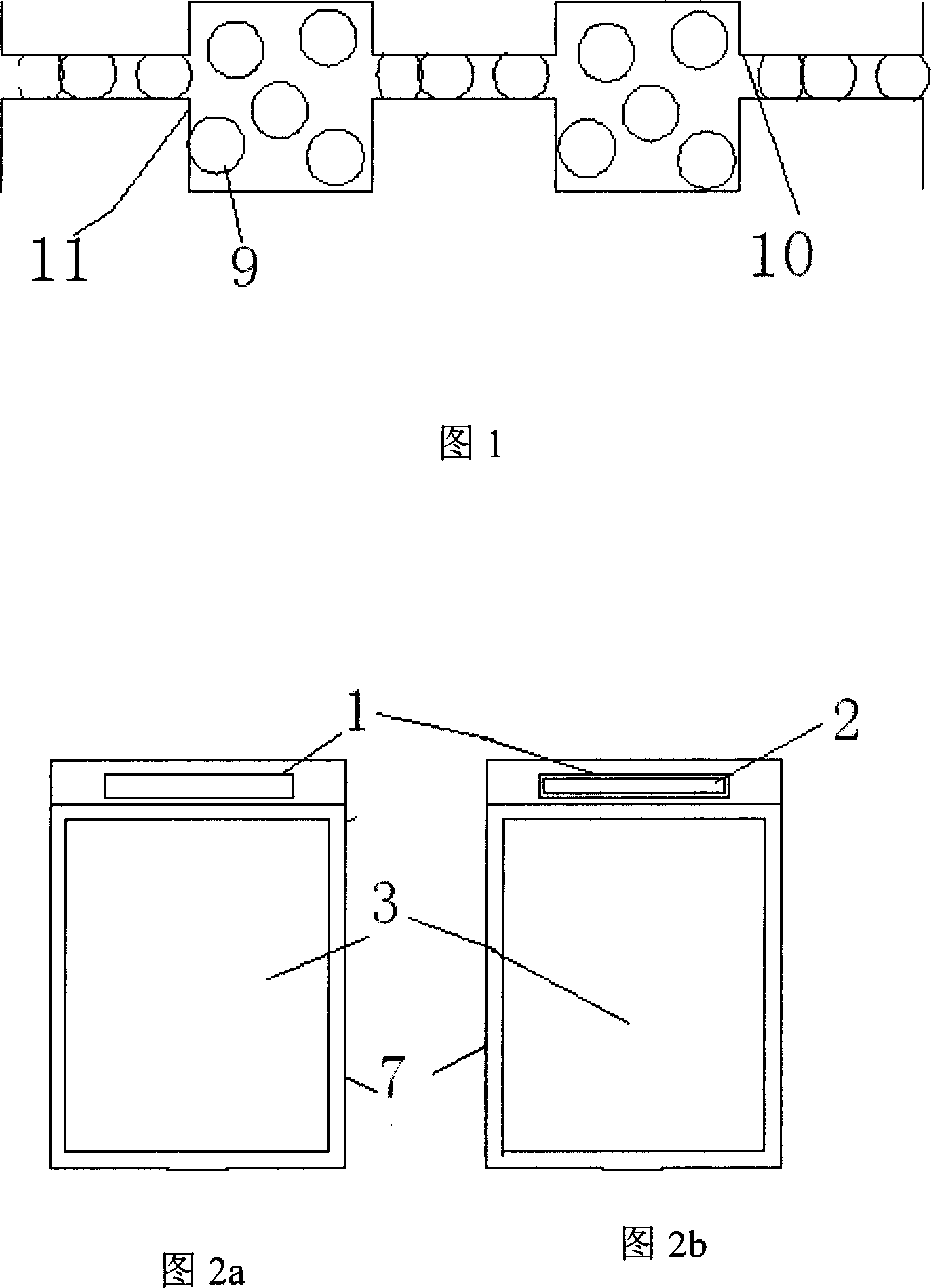

A display device includes a plurality of pixels arranged in a matrix. At least one of the pixels includes two sub-pixel groups. Each of the sub-pixel groups includes sub-pixels of three or more colors. Sub-pixels of the same color in each pixel are driven by the same signal.

Owner:SHARP KK

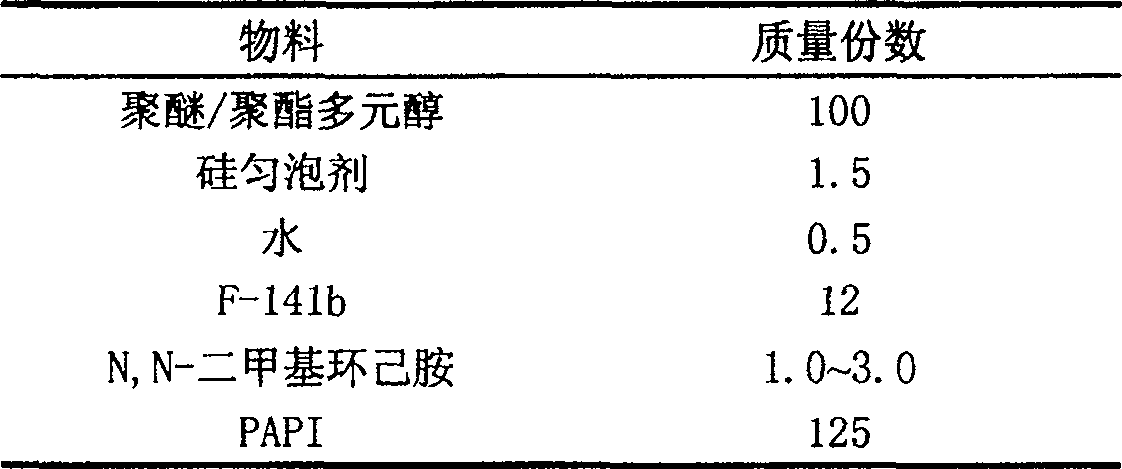

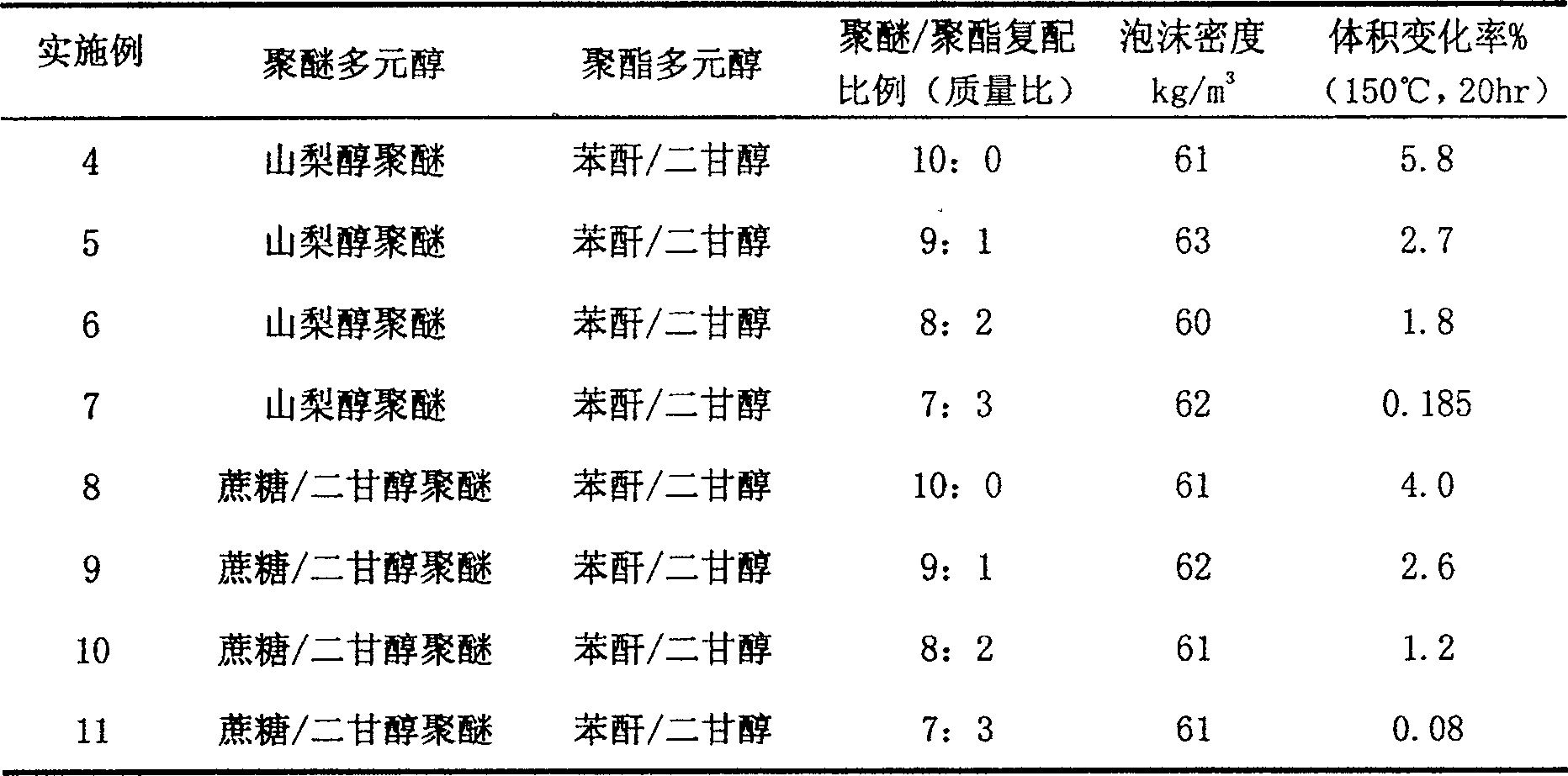

Method for preparing temperature-resistant hard polyurethane foam

The invention discloses a making method of heatproof hard polyurethane foam, which is characterized by the following: adopting composite technique of multiple polyethers / polyester polyol with high functional degree (fn:5-6) or heterocyclic structure in the molecular chain segment; making the aromatic ring structure material of polyester polyol as reacting monomer; allocating polyether polyol and polyester polyol according to certain proportion; reacting under catalyst, foamer, uniform foaming agent and PAPI with the index of isocyanate at 1. 05-1. 10; synthesizing PUF foam.

Owner:CHINA PETROLEUM & CHEM CORP

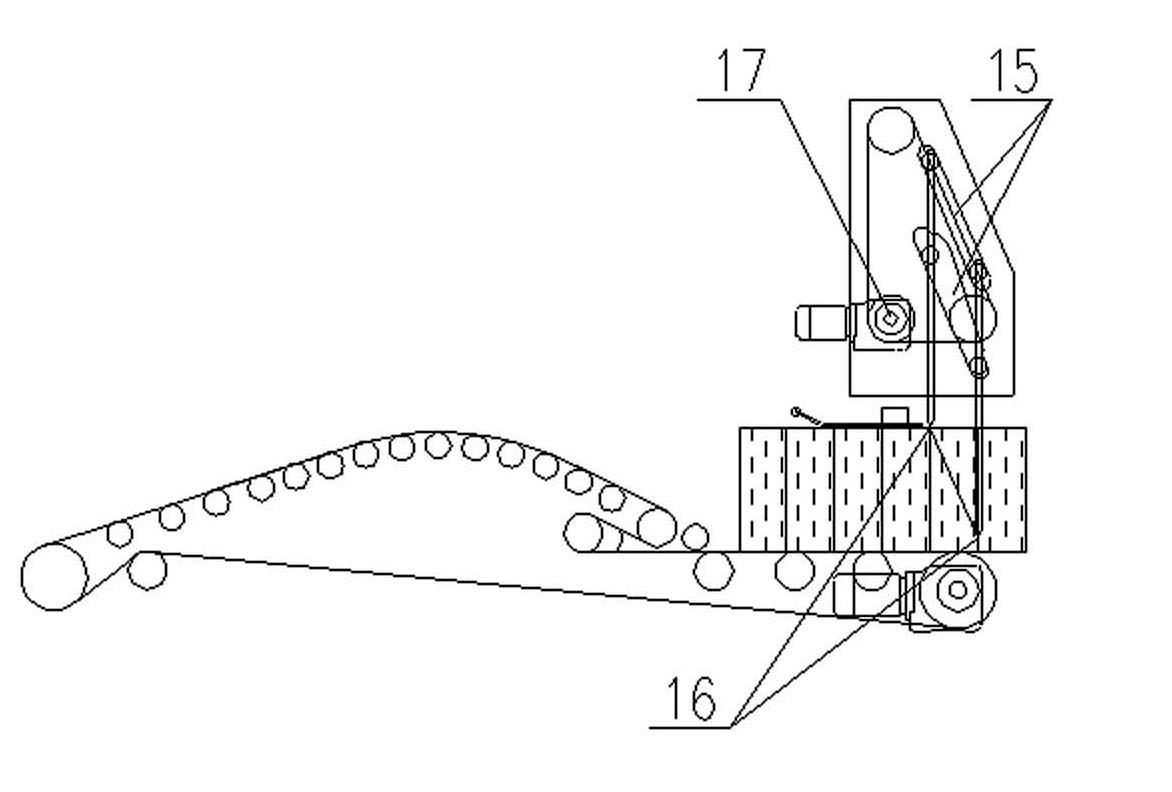

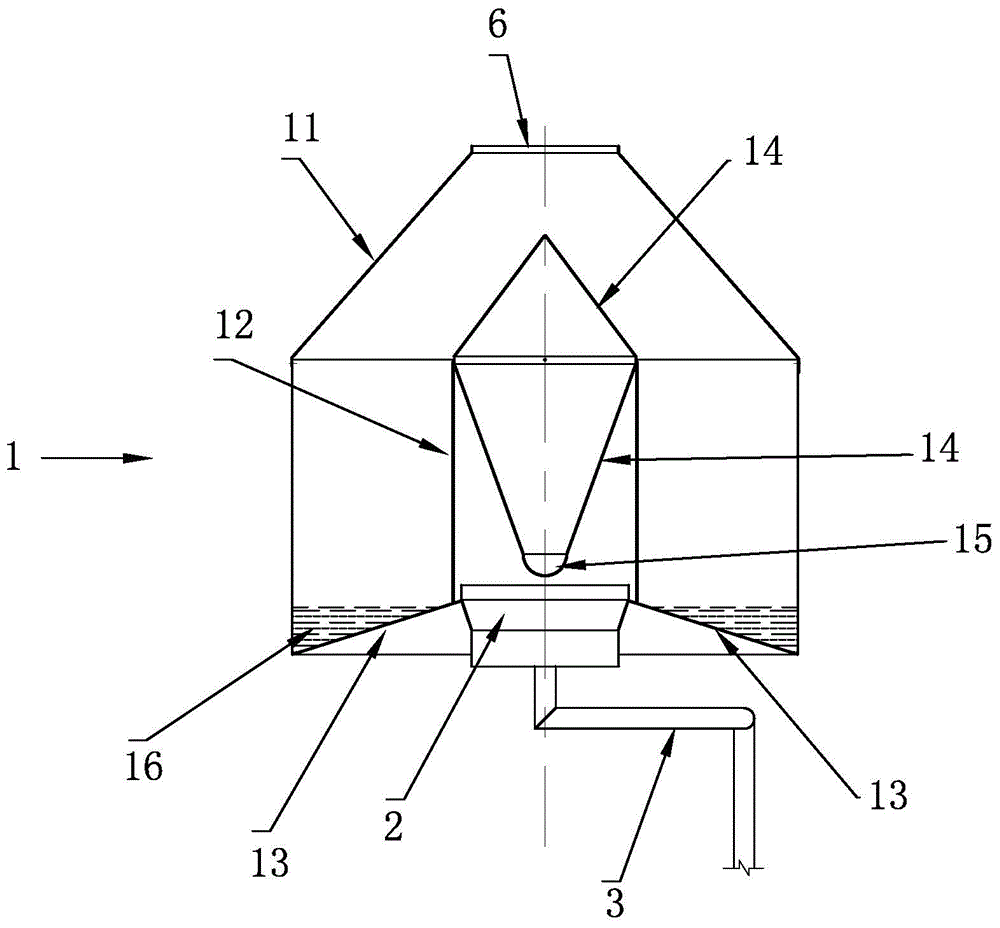

Novel low-density tobacco packet remoistening device

The invention discloses a low-density tobacco packet remoistening device, which comprises a vertical cutting machine, wherein the output end of the vertical cutting machine is connected with a leather belt conveyor capable of weighing and a loosening and remoistening machine in turn; and a pre-loosening device is connected and arranged between the leather belt conveyor and the loosening and remoistening machine. By taking the advantage of the natural lamination characteristics of tobacco blocks, the cut tobacco blocks are made to undergo flexible deformation in geometric form and heating and wetting treatment by the pre-loosening device so as to be softened and remoistened initially. Thus, broken tobacco in subsequent processing in a cylinder of the loosening and remoistening machine is reduced, processing temperature is lowered, the consumption of vapor is reduced, the heating and wetting uniformity is improved, and low-strength loosening and remoistening are realized.

Owner:QINHUANGDAO TOBACCO MACHINERY

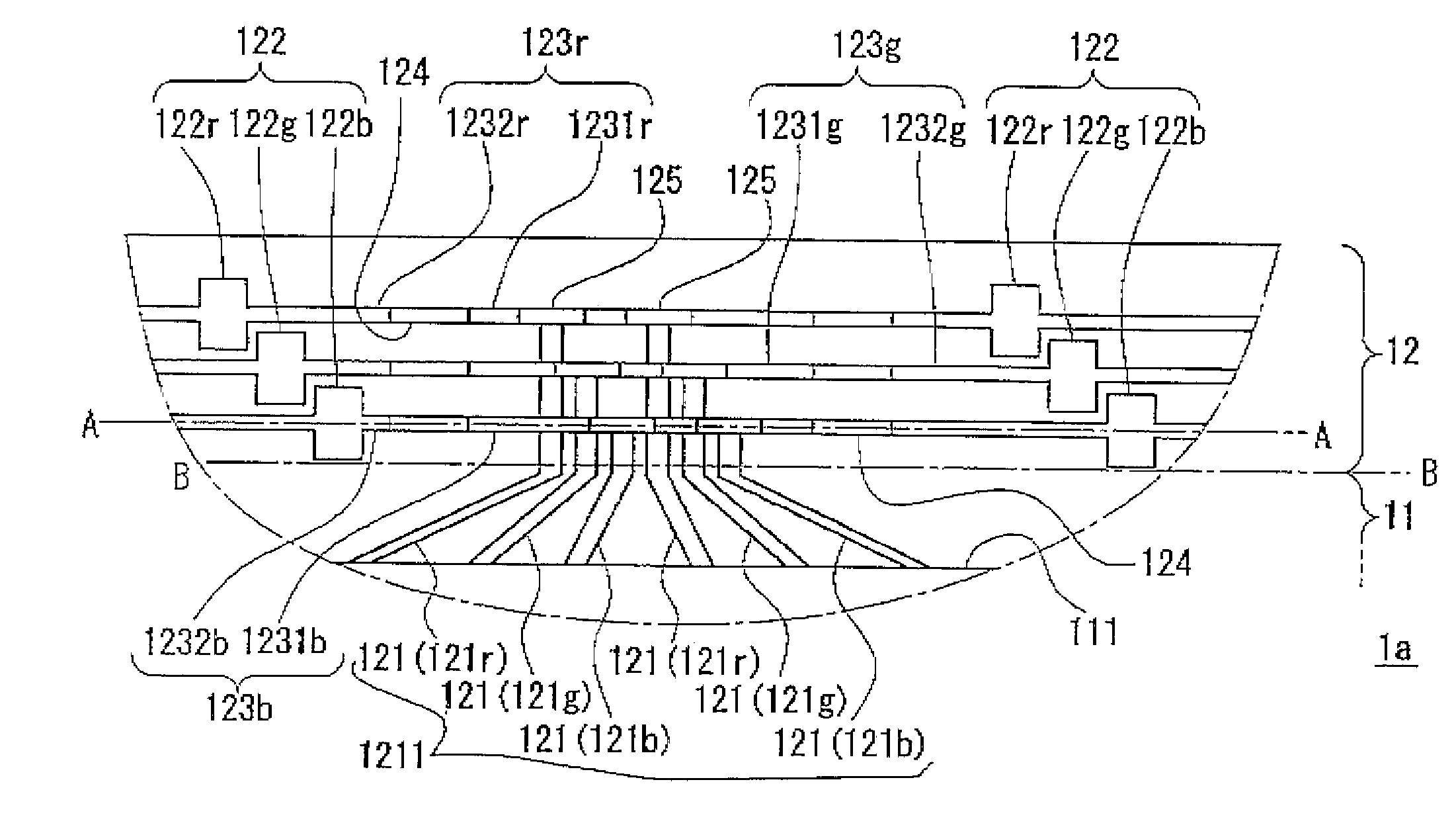

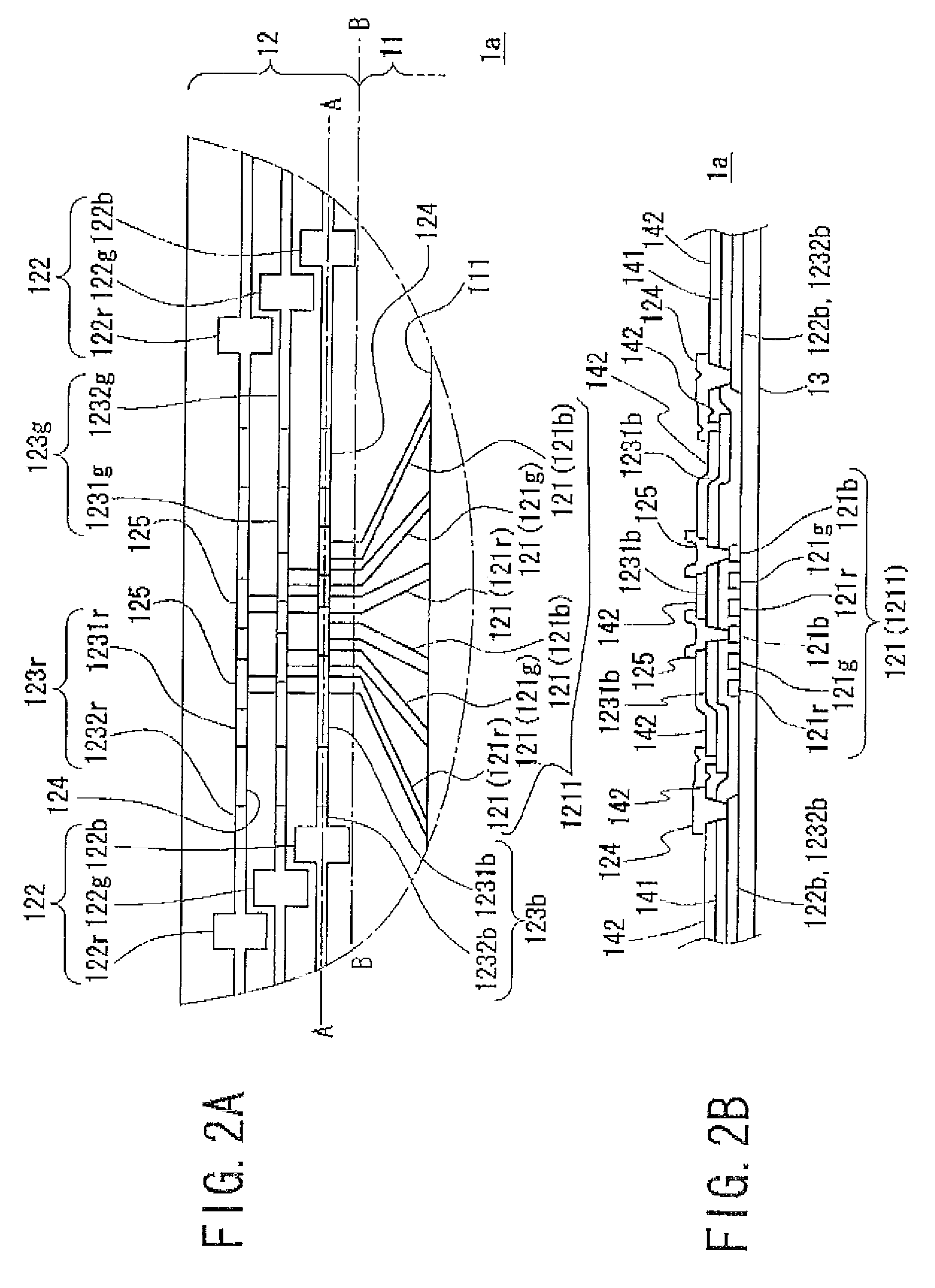

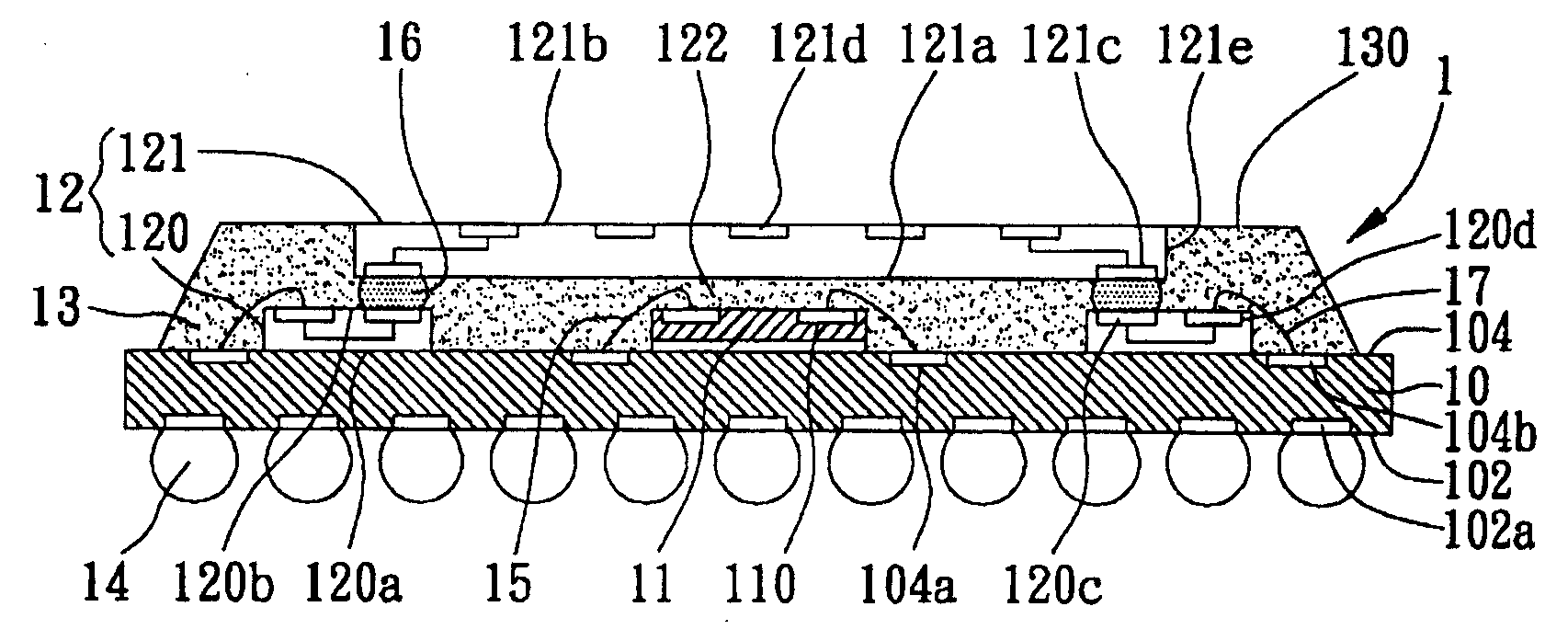

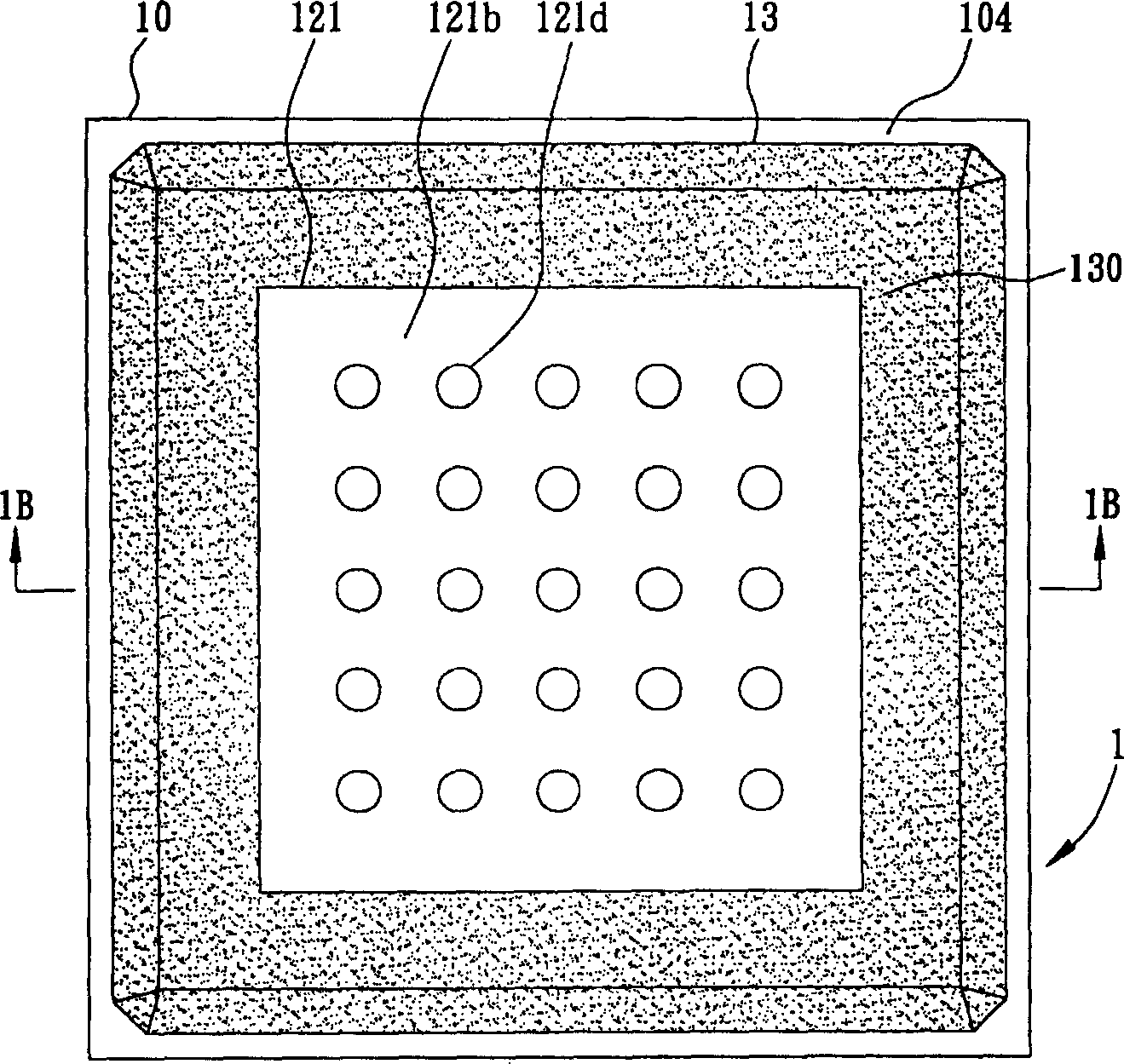

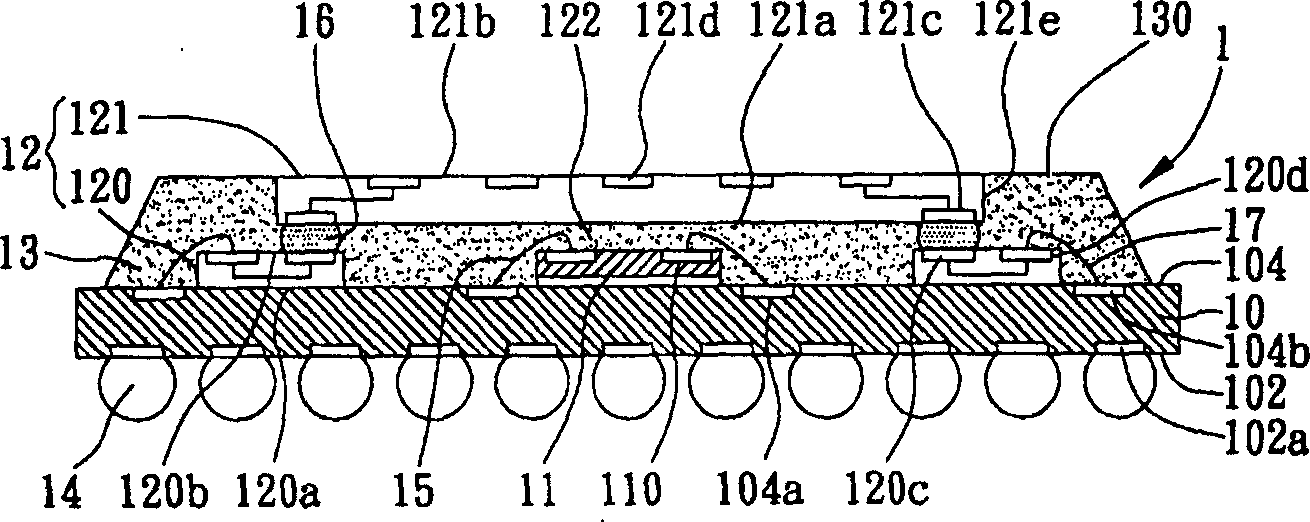

Substrate for a display panel, a display panel having the substrate, a production process of the substrate, and a production process of the display panel

ActiveUS20100000765A1Electrical discharge be preventNo increase in costSolid-state devicesConductive pattern formationEngineeringElectrical conductor

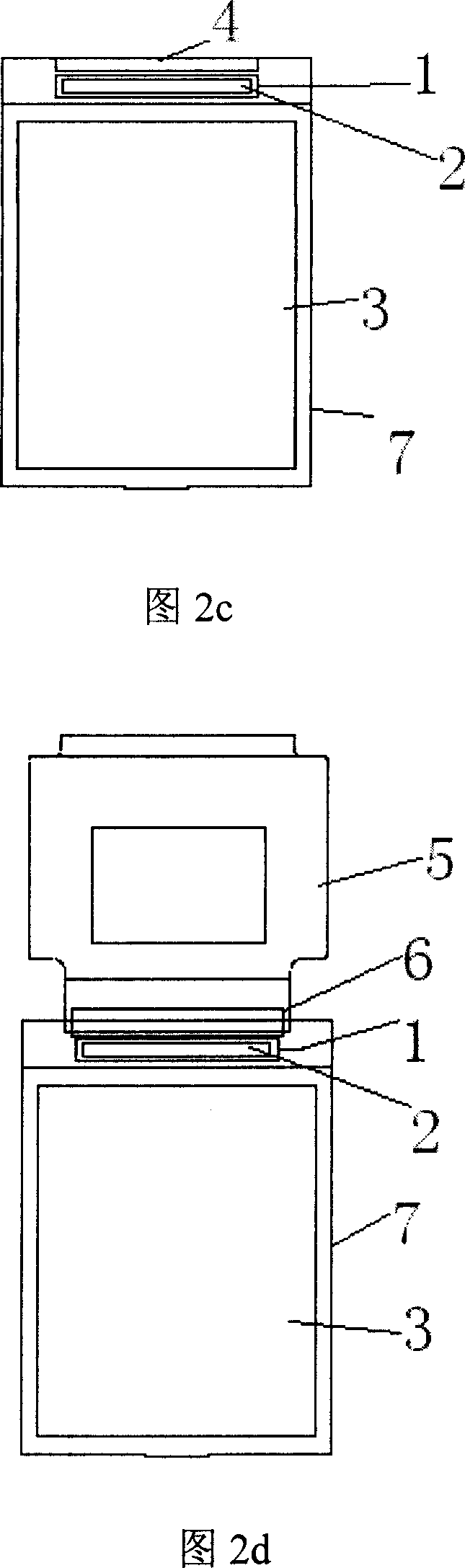

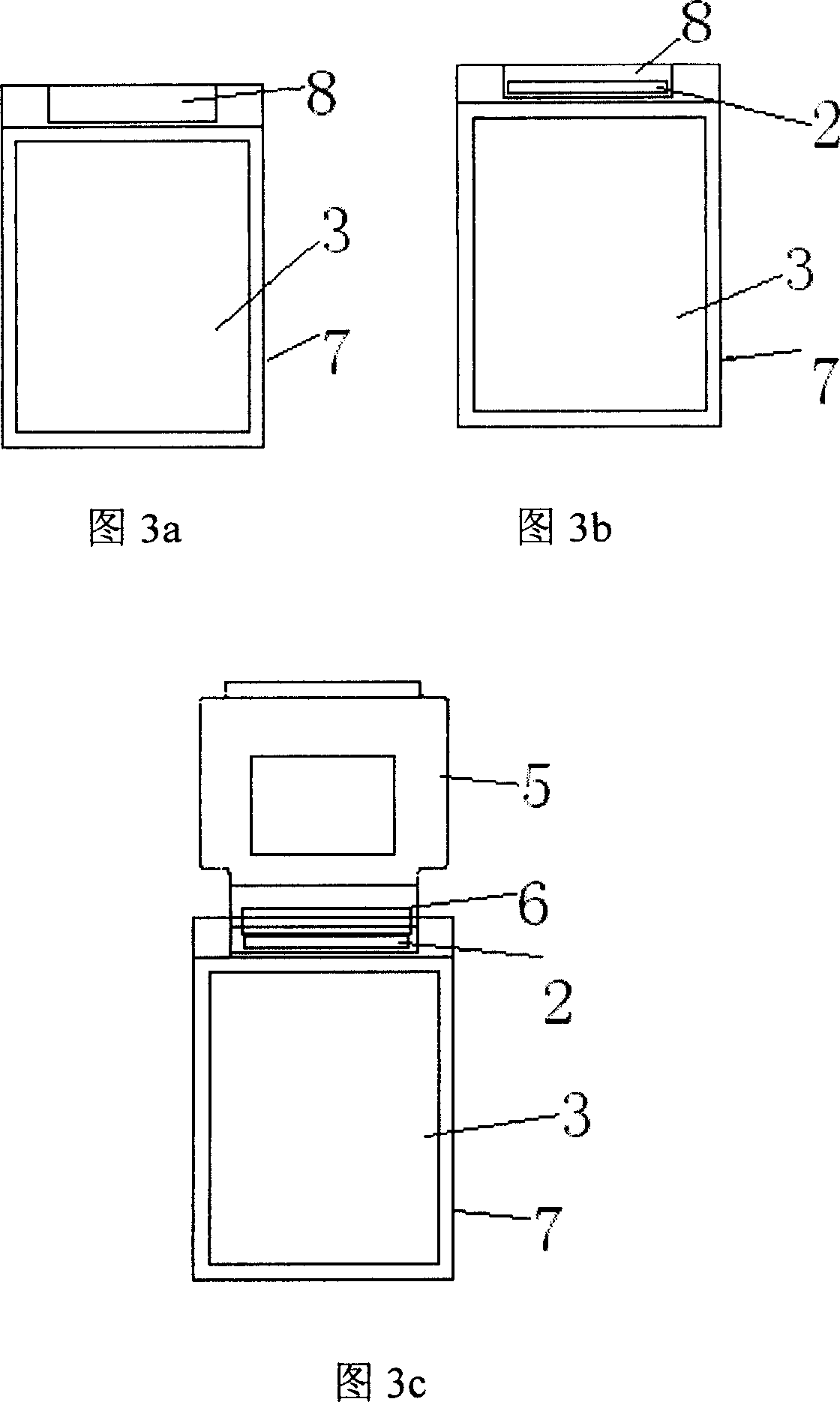

A substrate for a display panel in which insulation breakdown of an insulating film can be prevented, a display panel having the substrate, a production process of the substrate and a production process of the display panel.The substrate includes an inspection line 123 for transferring a signal for inspection which includes a first section 1231 including a portion overlapping with and / or intersecting an input line 121 drawn from a data signal line in a display region 111 between which an insulating film 141 is sandwiched and a second section 1232 which includes a portion other than the portion overlapping with and / or intersecting the input line 121 which are formed to be electrically independent from each other and are arranged to be electrically connected by a conductor 128, wherein a difference between areas of the first section 1231 and the input line 121 is reduced.

Owner:SHARP KK

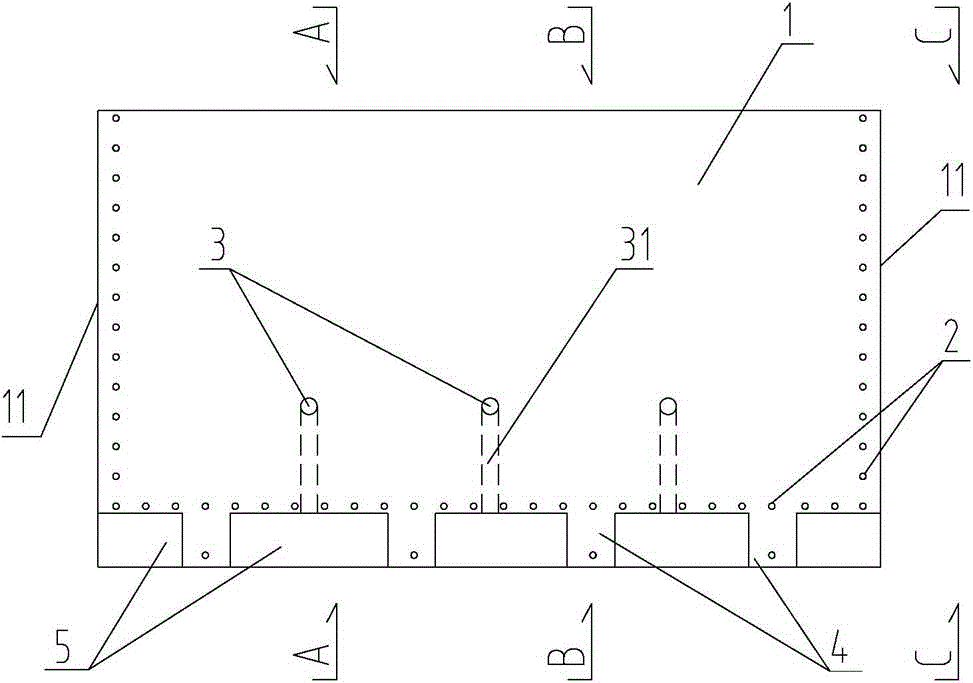

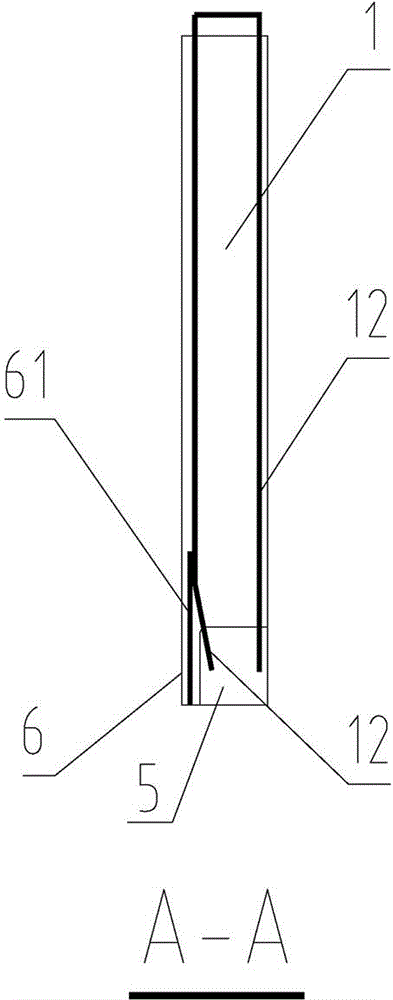

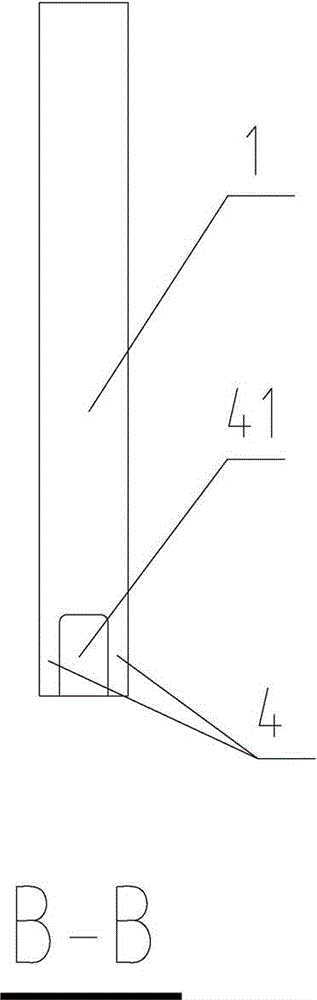

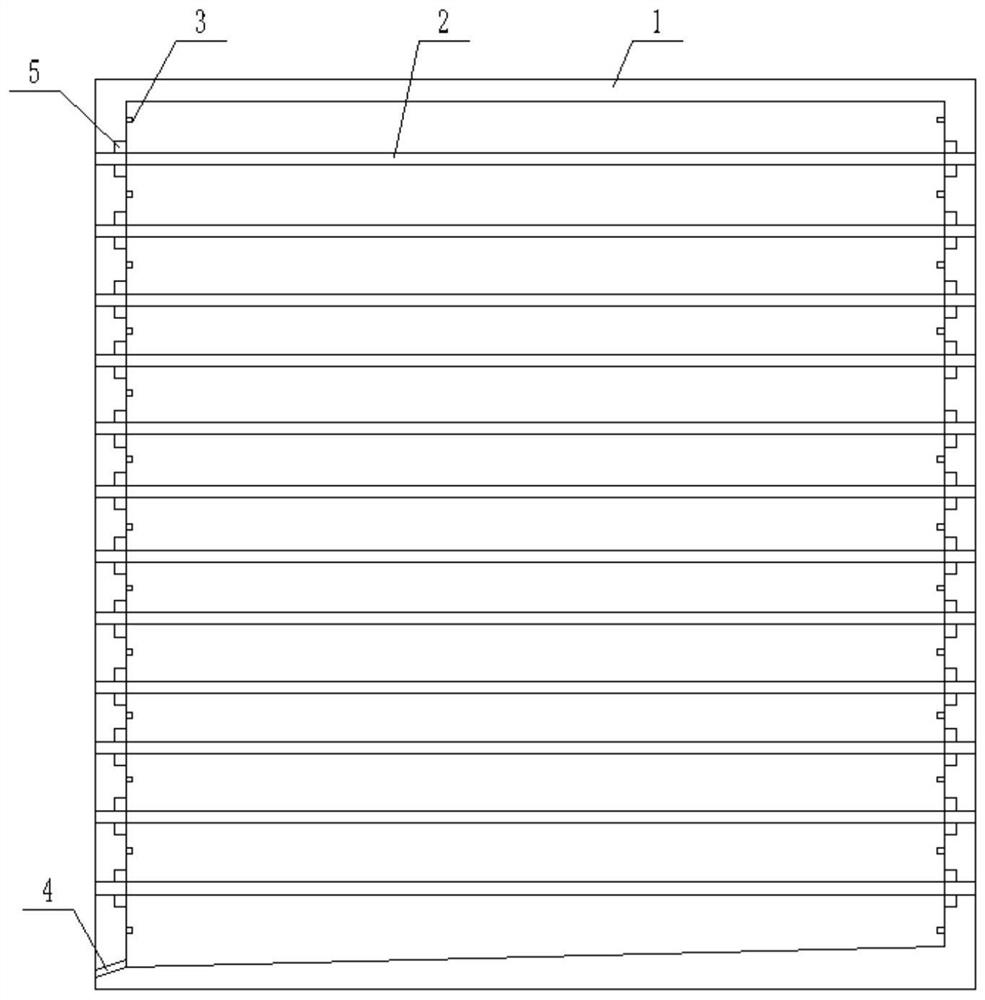

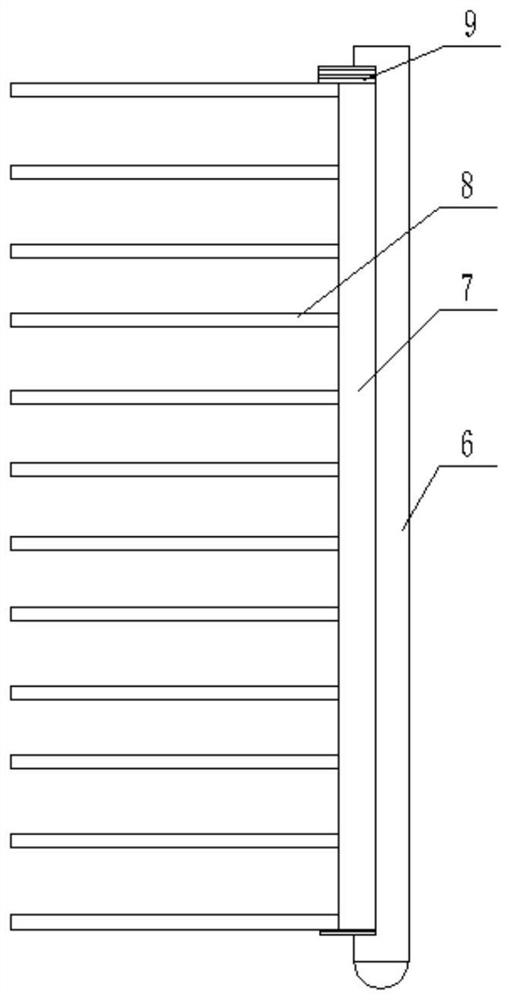

Prefabricated shear wall in cast-in-situ connection mode

ActiveCN105604208AEasy constructionGuaranteed connection qualityConstruction materialWallsRebarThreaded pipe

The invention relates to a prefabricated shear wall in a cast-in-situ connection mode. The prefabricated shear wall comprises a wall, pier heads, bottom upper concave sections and a bottom outer side plate. Side edges are respectively arranged on two sides of the wall, and a groove is formed in the middle of each side edge and is vertically perforated through the wall; wall vertical reinforcing bars are arranged in the wall; the bottom upper concave sections are uniformly distributed at the bottom of the wall; each pier head is arranged between the two corresponding adjacent bottom upper concave sections; air holes are formed in positions above the middles of the bottom upper concave sections; the air holes are communicated with the bottom upper concave sections via pipelines; the thicknesses of the pier heads are identical to the thickness of the wall, and holes are formed in the pier heads; the bottom outer side plate and the wall are integrated with each other, and the bottom outer side plate is positioned on the outer sides of the bottom upper concave sections; internally threaded pipes are embedded in positions close to the side edges of the wall, above the bottom upper concave sections and on the pier heads. The prefabricated shear wall in the cast-in-situ connection mode has the diversified advantages of firm structure, convenience in construction, reliability in connection and the like.

Owner:华汇工程设计集团股份有限公司

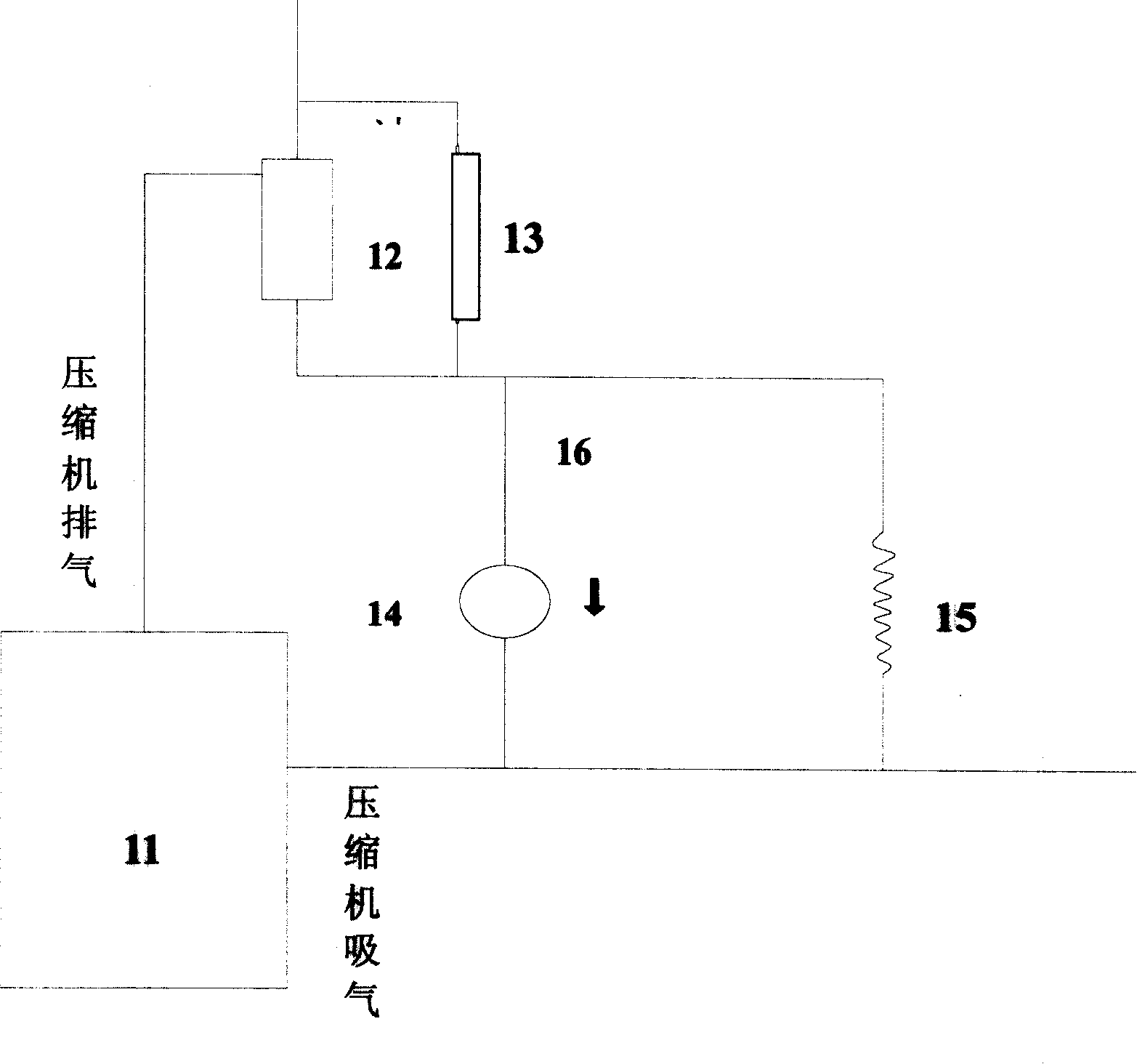

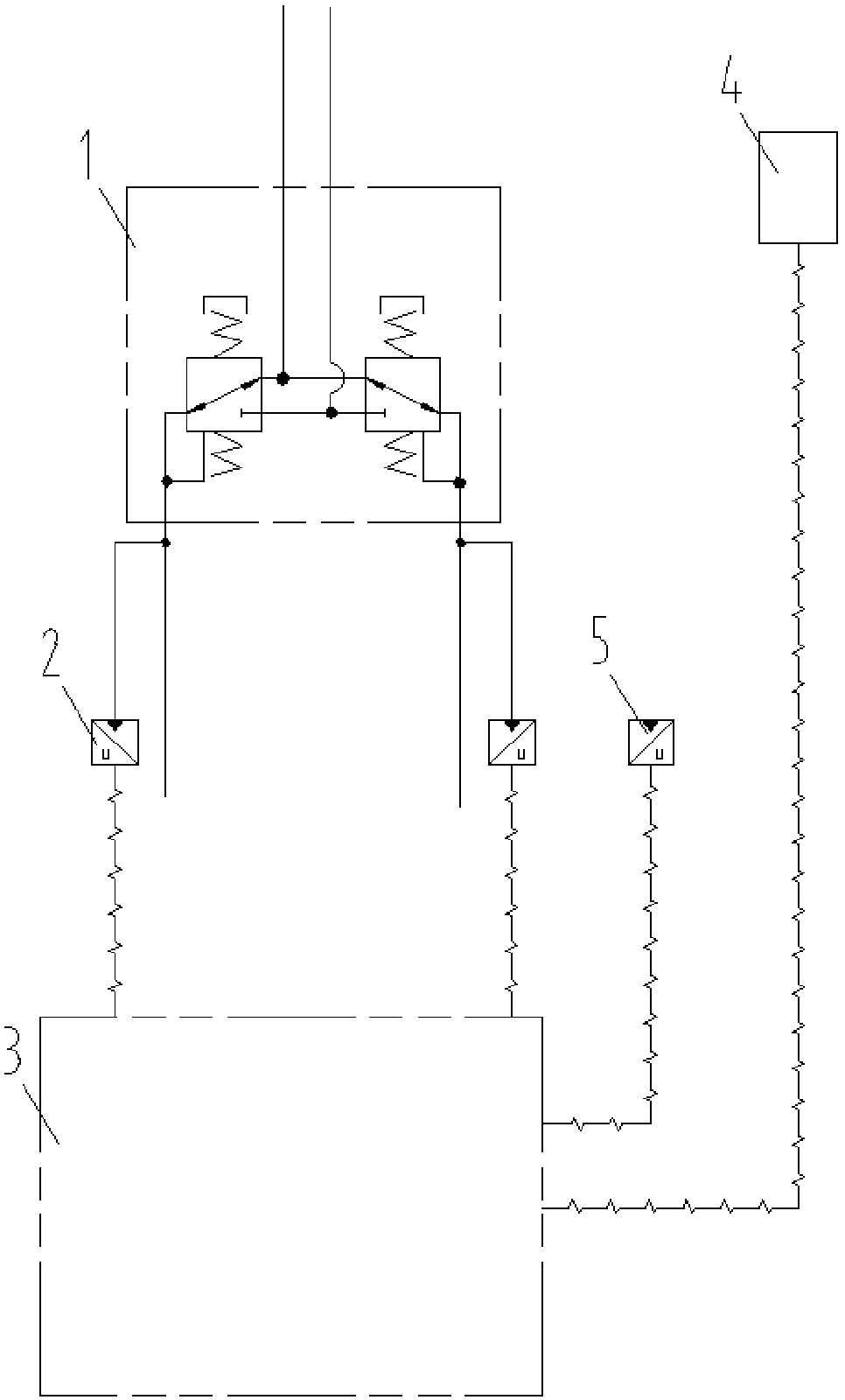

Oil eliminator auxiliary device of air conditioning system and control method thereof

InactiveCN101173656ASufficient oil returnEER/COP improvementPositive displacement pump componentsPositive-displacement liquid enginesFrequency conversionSolenoid valve

The invention relates to an auxiliary device of an oil separator in an air-conditioning system and a control method for the auxiliary device, which comprises a compressor, an oil separator and a return capillary. A pipe branch is in parallel provided with the return capillary between an oil outlet of the oil separator on exhausting side of the compressor and an air suction pipe of the compressor. A solenoid valve is connected in series on the pipe branch. The solenoid valve and an unloading valve of the air-conditioning system are merged into a whole, and oil unloading or return is carried out through controlling the solenoid valve respectively by the program. The control method for the auxiliary device of the oil separator is composed of selecting the return capillary and controlling opening period and duration of the solenoid valve. The invention has the advantages of effectively solving contradiction between normal oil return of the compressor assured by frequency conversion or variable capacity air-conditioning system and realizing high EER / COP and good cooling or heating, the unloading valve and the solenoid valve being merged into a whole, oil return of the compressor being optimized and cost of the system being not increased.

Owner:HAIER GRP CORP +1

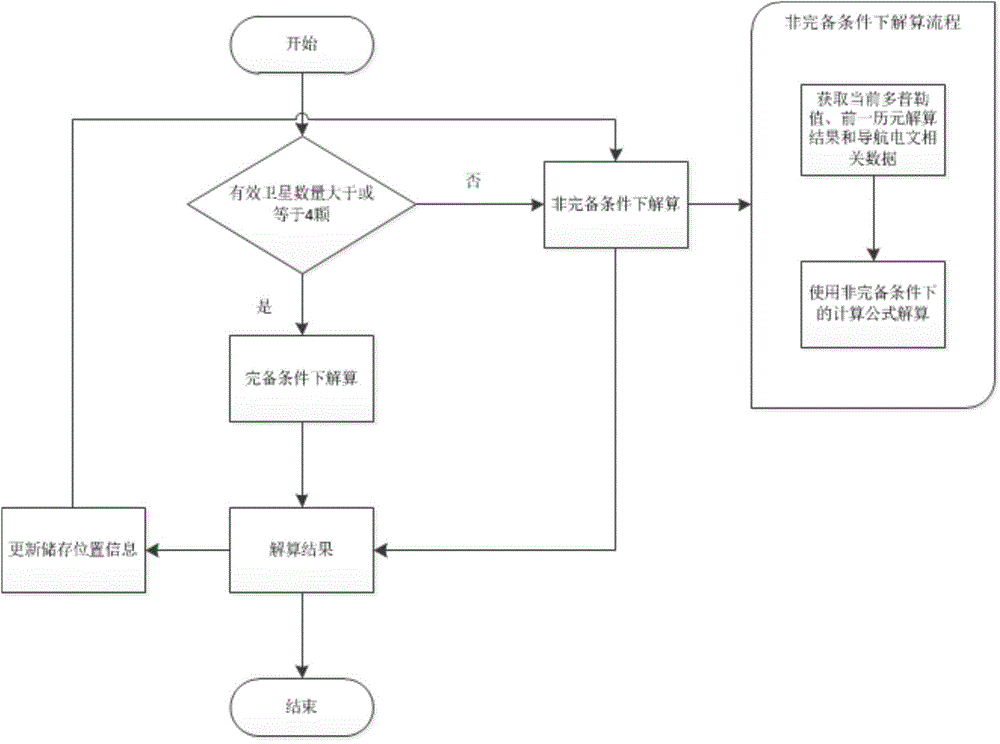

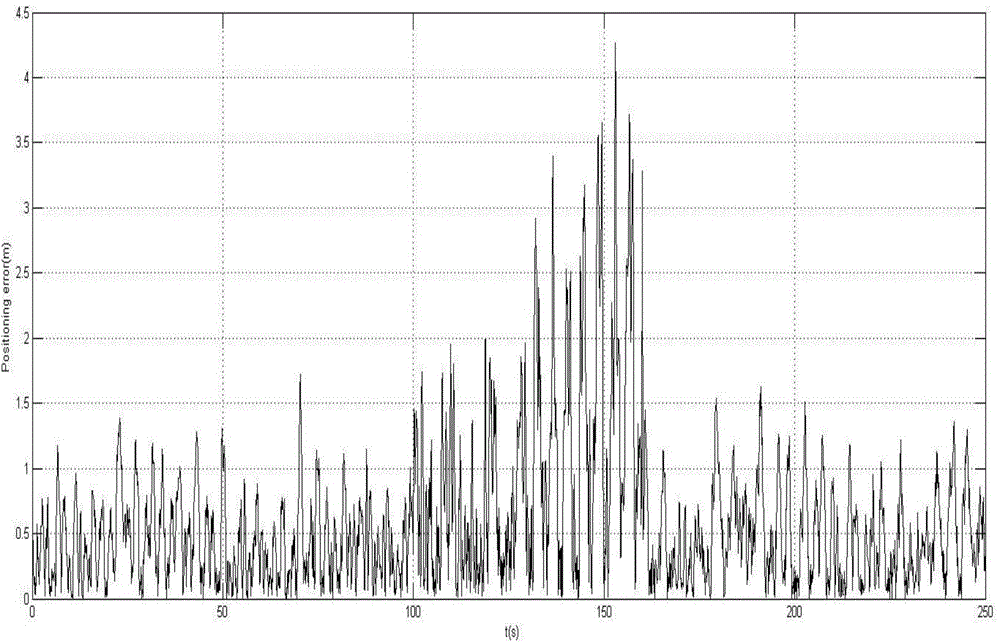

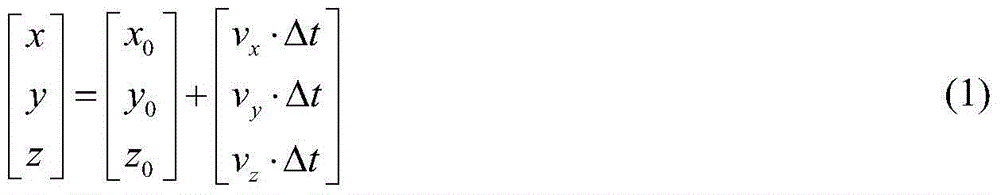

Satellite navigation positioning method based on doppler velocity measurement under transient and incomplete condition

ActiveCN104793225ARealize the positioning functionSolve the problem of temporarily unable to locateSatellite radio beaconingVIT signalsElectronic map

The invention discloses a satellite navigation positioning method based on doppler velocity measurement under a transient and incomplete condition. The satellite navigation positioning method comprises the steps that normal positioning is conducted under the condition that satellite signals are complete, and related positioning information is stored; when the satellite signals are shielded, and the number of visible satellites is three, the satellite navigation positioning method under the incomplete condition is executed, an auxiliary equation is established according to the relation among doppler frequency offset, the receiver velocity and the satellite velocity, cutoff of first-order terms and linearization of a nonlinear system of equations are conducted through taylor expansion, and then the nonlinear system of equations is calculated through a least square method, so that the position and the velocity of a receiver are obtained; when the number of the visible satellites is recovered to be four or more, a positioning method under the complete condition is executed. The actual test result shows that the satellite navigation positioning method achieves the positioning result required by navigation in the transient and incomplete period of dozens of seconds, and therefore the effectiveness of the GNSS receiver is improved. The satellite navigation positioning method does not rely on additional sensors, does not require additional instruments and meters, does not require electronic map supporting, and is small in calculated amount and free of increase of the system cost.

Owner:BEIHANG UNIV

Method for solving problem of solder resist photosensitive white oil pencil marks

InactiveCN109819599ANo need to increase wattageNo need to extend exposure timeNon-metallic protective coating applicationCooking & bakingScreen printing

The invention discloses a method for solving the problem of solder resist photosensitive white oil pencil marks. The method comprises the steps that a metal substrate is pretreated through sand blasting or volcanic ash; crude oil and printing ink are standardized by manufacturers: the viscosity is controlled to be 140-170 dga.s; the metal substrate is printed through a screen printing machine, andthe thickness of ink on the circuit surface is controlled to be 20-30 [mu]m; the metal substrate stands for 30 min at the corresponding position after being printed each time; the metal substrate ispre-baked for the first time at the temperature of 75 DEG C for 32 minutes; after the metal substrate is pre-baked for the first time, after the printing ink is cooled, pre-baking for the second timeis performed at the temperature of 80 DEG C for 13 minutes; and the exposure grade of a 21-grade exposure ruler is controlled to be 9-13. According to the invention, through the pre-baking mode afterprinting is optimized, the method solves the problem of high-reflectivity solder resist white oil pencil marks, and meanwhile, the ink hardness is improved, traces left on the surfaces of the processing inks are avoided, pencil marks cannot be generated in the subsequent processing process, the appearance requirements of users are met, the reflectivity of the ink is reserved, and the ink can be popularized and used in the industry.

Owner:KINWONG ELECTRONICS TECH LONGCHUAN

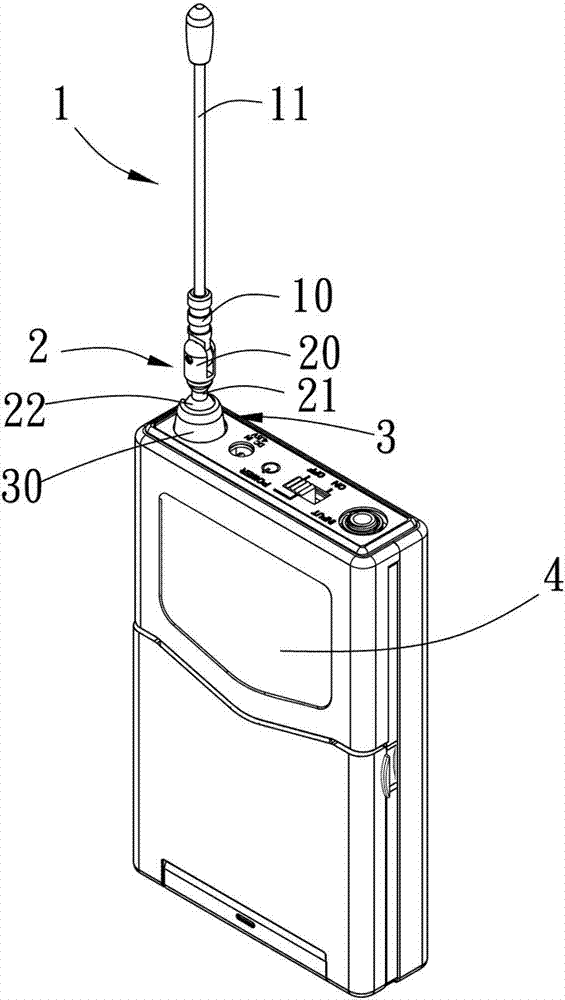

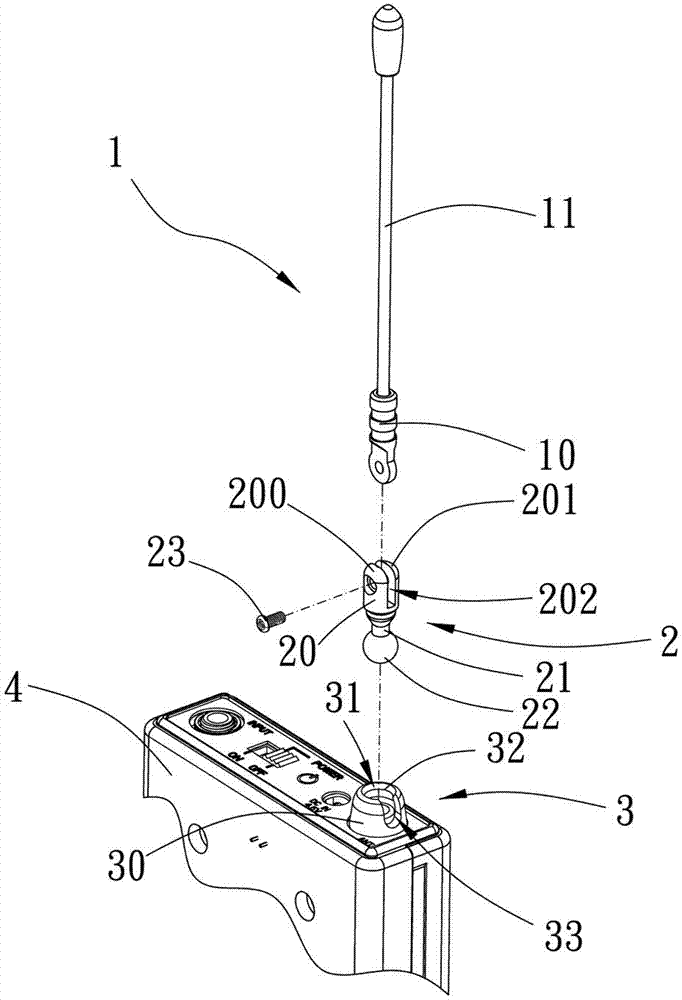

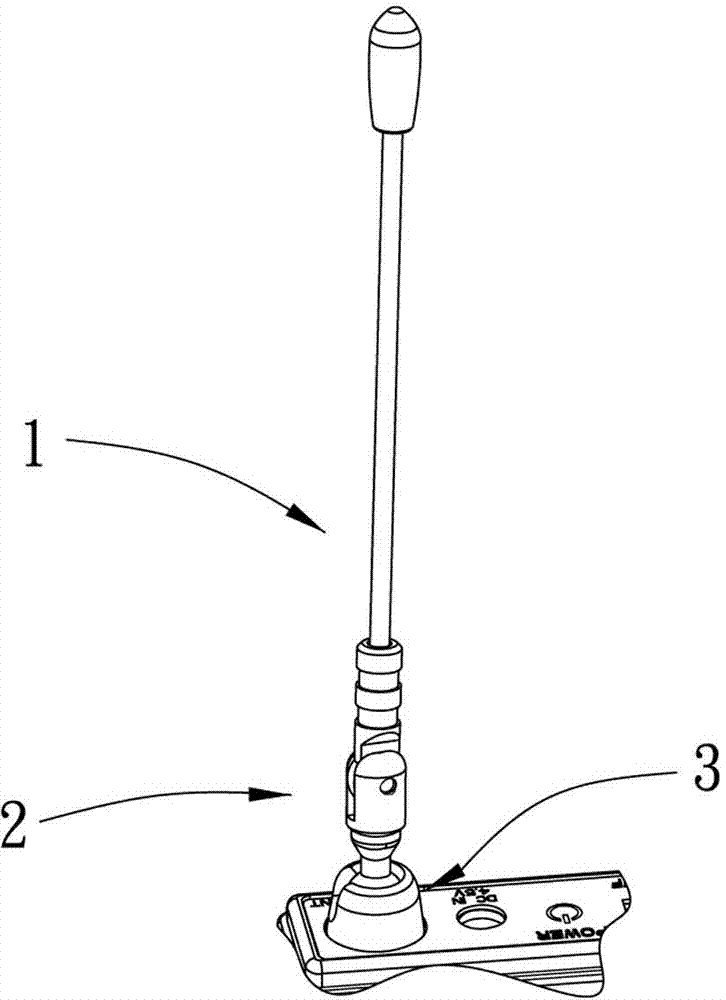

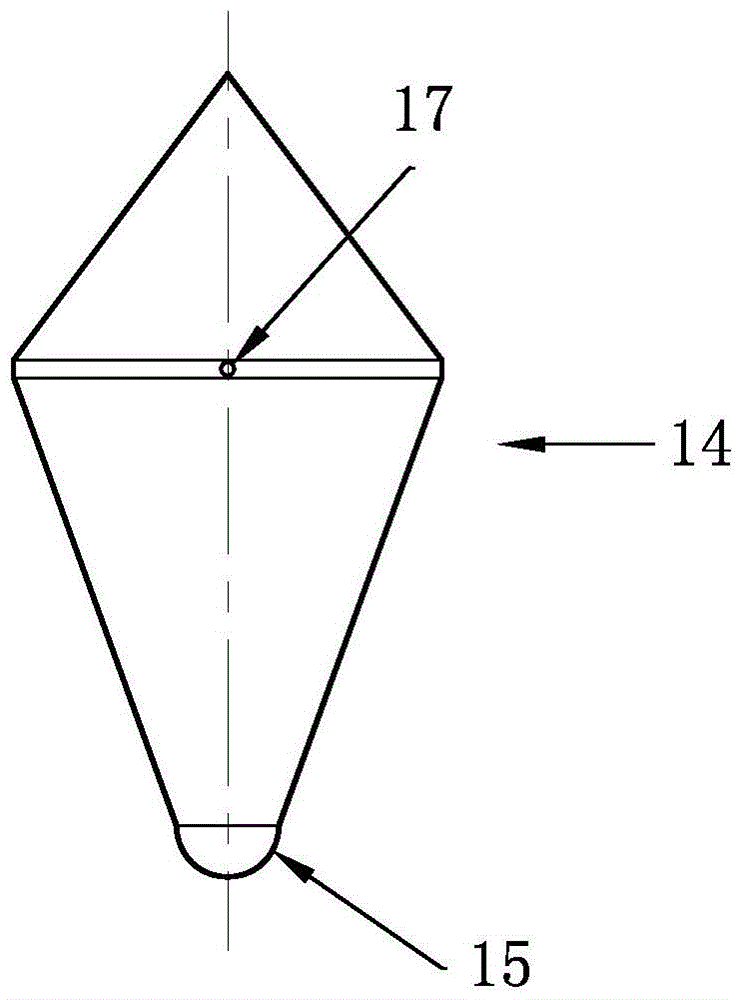

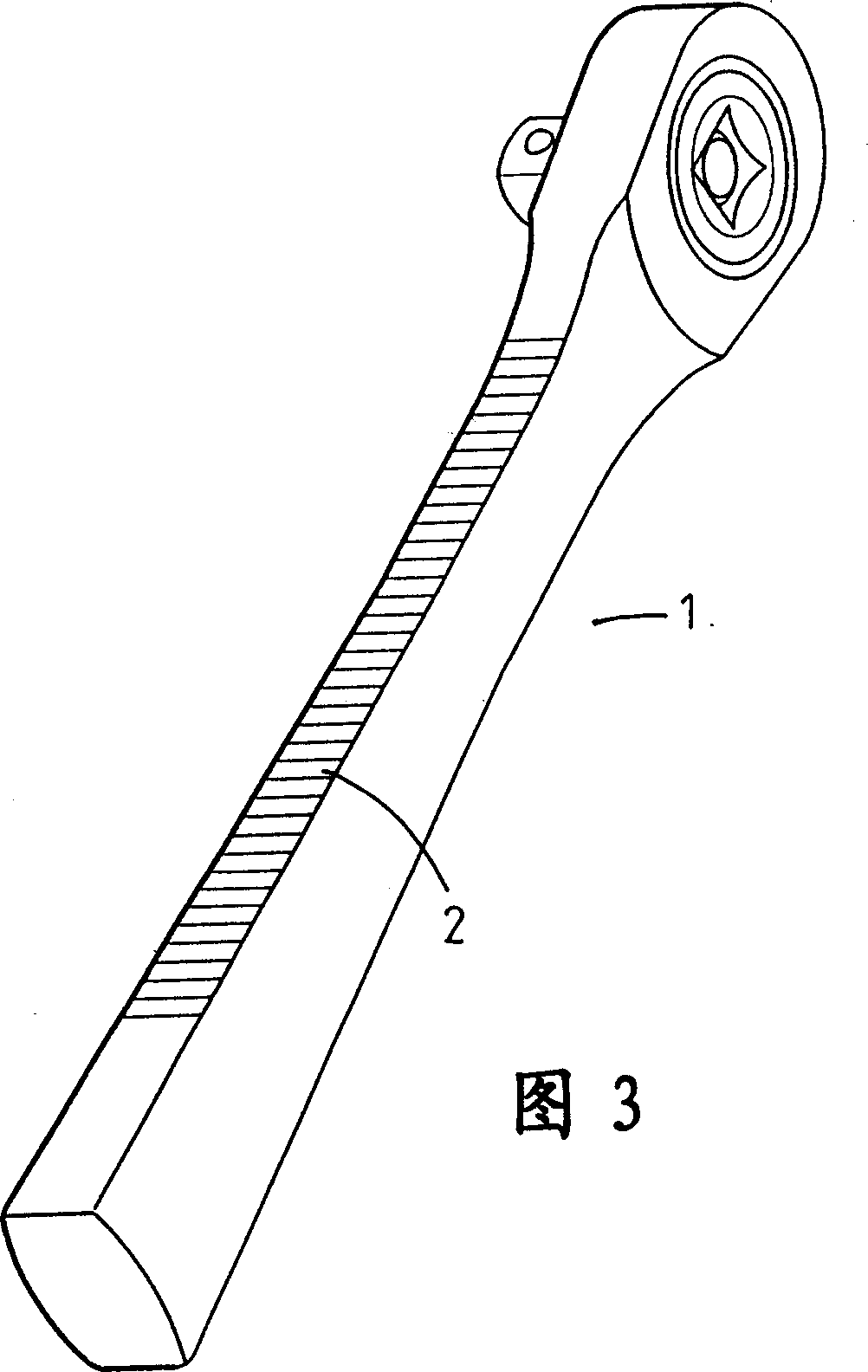

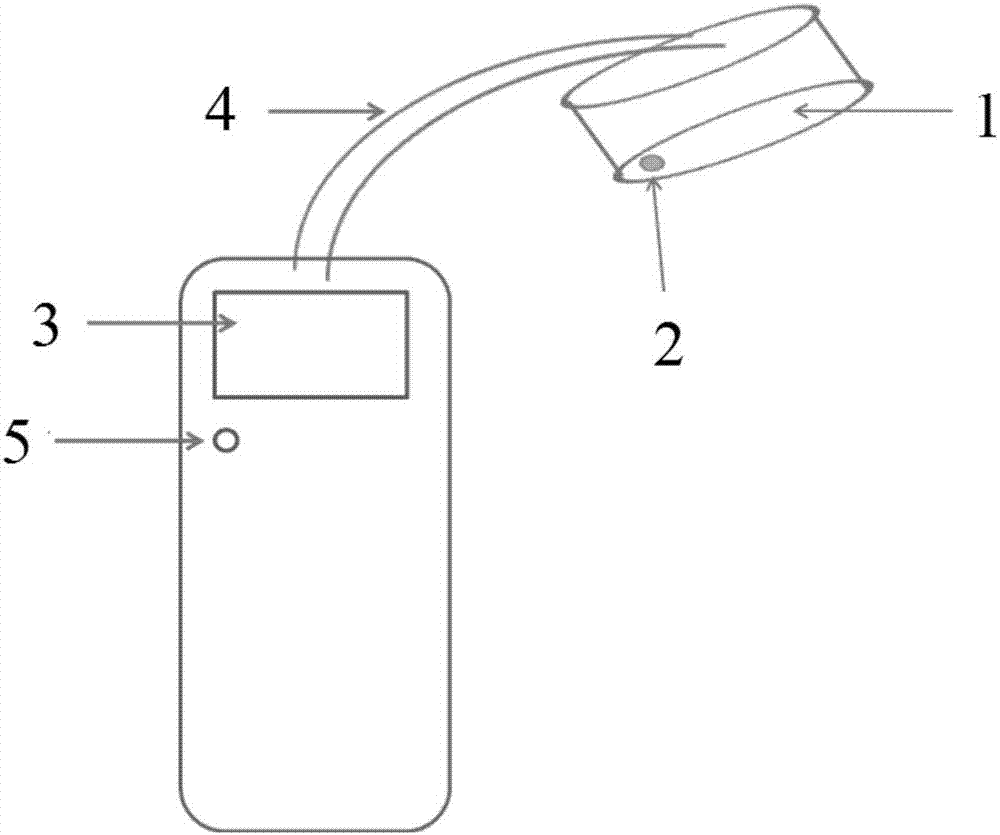

Antenna for receiver and emitter of wireless microphone, and receiver and emitter arranged with antenna

InactiveCN102820520AGood structure like newSimple structureAntenna supports/mountingsMouthpiece/microphone attachmentsWireless microphoneMaximum diameter

The present invention provides an antenna for the receiver and emitter of a wireless microphone, including an antenna body which contains an antenna rod body and a connecting seat in connection with the antenna rod body; a connecting body, including a pivot connection portion, a neck portion, and a sphere, wherein the neck is connected between the pivoting portion and the sphere, and the pivot portion and the connecting seat are pivotally connected to each other; a base having an annular retaining wall, the retaining wall encloses an accommodating space having at least one opening, the maximum diameter of the opening is smaller than the maximum diameter of the sphere, and the sphere is located in the accommodating space so that the connecting body is rotatably connected to the base. The antenna body of the present invention, in addition to pivoting movement relative to the connecting body, can be rotated relative to the base, while the connecting body may optionally be swung to rotate on a different axis so that the antenna body can yaw in all directions and adjust in rotation. The antenna can still maintain good as new connecting structure even being repeatedly pulled to adjust.

Owner:CHANFUL VOICE TECHNIC

Preparation method of dyeing prevention agent

The invention discloses a preparation method of a dyeing prevention agent. The preparation method comprises the following steps: adding 57 to 59 parts of water into a reaction kettle; heating to 70 to90 DEG C; meanwhile, rotating stirring blades in the reaction kettle; slowly adding 14 to 16 parts of polyester type dyeing prevention powder under the state that the stirring blades rotate and at the rotary speed of 20 to 40r; after the powder is completely dissolved, closing a heating device; slowly adding 14 to 16 parts of fatty alcohol type surfactant and 11 to 13 parts of polyamine type color fixing agent until the components are uniformly stirred; standing and cooling; discharging into a packaging bucket and conveying into a factory for direct utilization. The preparation method of thedyeing prevention agent has the advantages of ingenious technology and simple technological steps and is suitable for being popularized.

Owner:广州市德鹏新材料科技有限公司

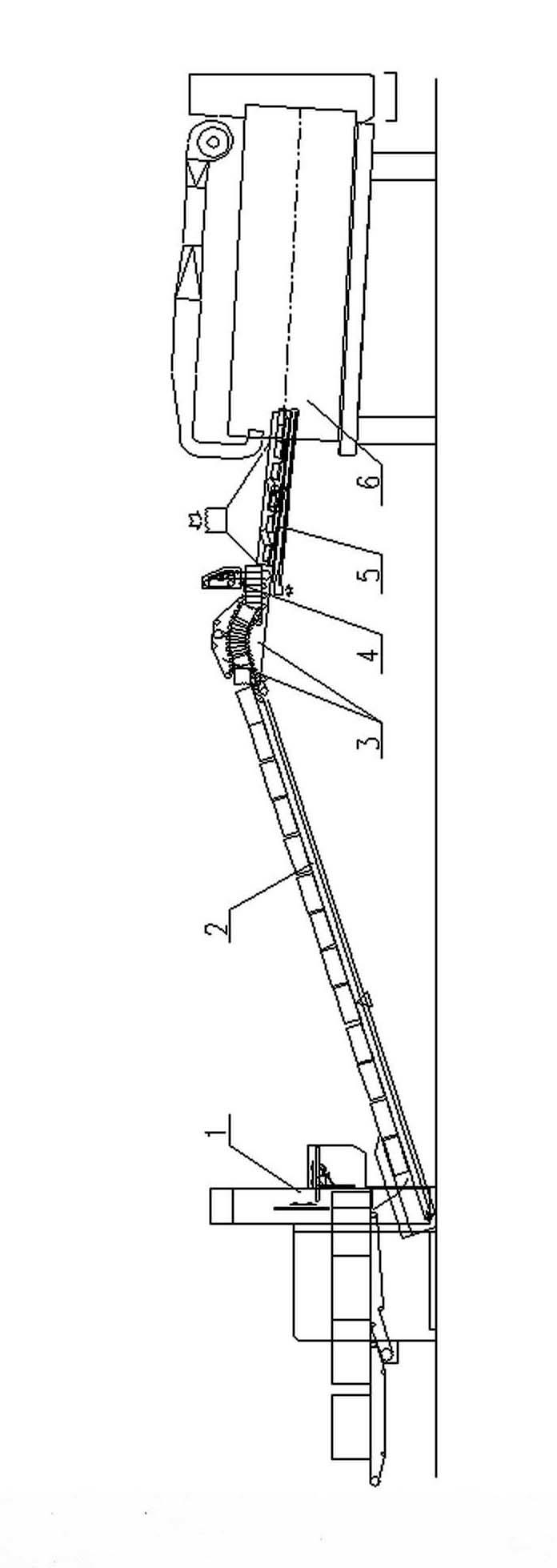

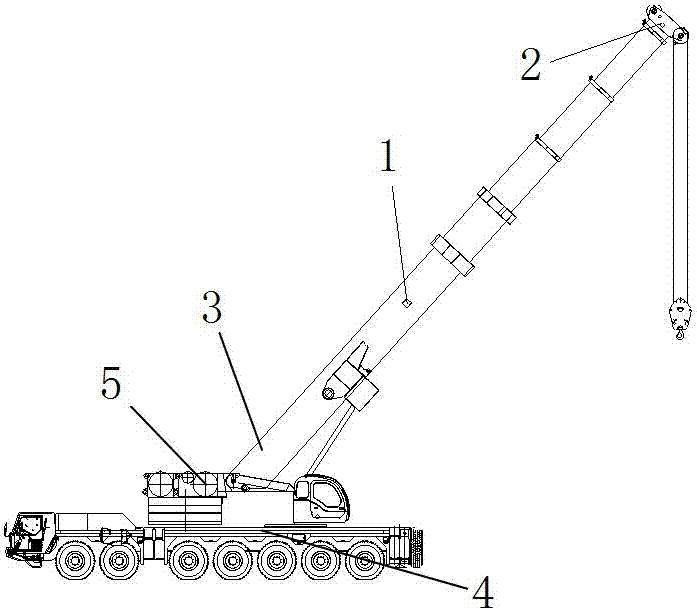

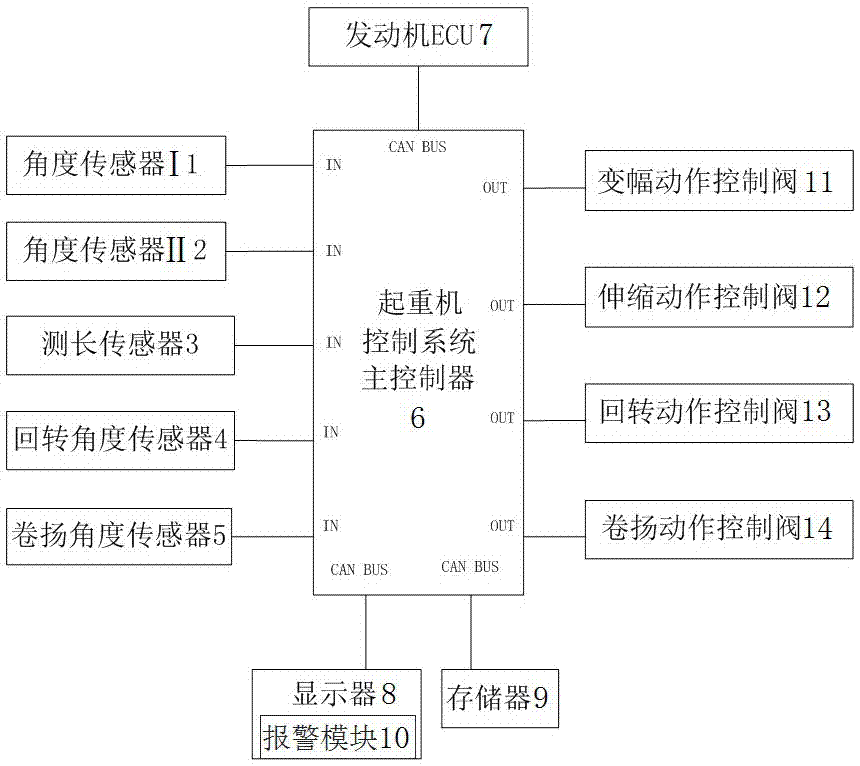

Crane full-working-condition oil consumption monitoring system and method

ActiveCN107973230AHigh precisionNo increase in costRelative volume flow measurementsCranesControl systemMonitoring system

The invention discloses a crane full-working-condition oil consumption monitoring system and a method. The control method comprises the steps that signals are fed back to a main controller through a first angle sensor or a second angle sensor, a length measuring sensor, a rotation angle sensor and a winding rotation speed sensor so that the current working condition of a crane can be obtained, andthe oil consumption amount is calculated through the data transmitted by an engine ECU, then is displayed on a display device and stored in a storage for checking conveniently in the future. According to the system, the structure is simple, the effect is obvious, the signals collected by the engine ECU are directly used so that the instantaneous oil consumption can be collected in real time, andthe using characteristics of the crane and the sensor network and the control logic of the control system of the crane are combined, so that the working condition is judged, the working condition oilconsumption, the average oil consumption and the total oil consumption are calculated, the increased cost does not exist, and the implementation difficulty is low; and the engine ECU directly sends the oil injection quantity data to the main controller of the control system, and the calculation result is high in precision.

Owner:XUZHOU HEAVY MASCH CO LTD

Carbon-based slow-release fertilizer coated with bio-oil film

InactiveCN110105141AGood sustained release effectReduce lossesAlkali orthophosphate fertiliserAmmonium orthophosphate fertilisersPotassium nitrateChloride

The invention discloses a carbon-based slow-release fertilizer coated with bio-oil film and compositions, combination mode and preparation process of a carbon-based slow-release fertilizer body coatedwith the bio-oil film. The slow-release capacity of the carbon-based slow-release fertilizer coated with the bio-oil film is further improved relative to common carbon-based fertilizers, the nutrientloss rate is reduced to a greater degree, and the yield of crops is increased. In the preparation process of the carbon-based slow-release fertilizer coated with the bio-oil film, wheat straw resources are fully and reasonably utilized, and the carbon-based slow-release fertilizer coated with the bio-oil film meets the green and sustainable development concept. The novel carbon-based slow-releasefertilizer is prepared from, by mass, 80-120 parts of biochar, 15-22 parts of potassium nitrate, 4-9 parts of monopotassium phosphate, 1-3 parts of potassium chloride and 60-90 parts of bio-oil. Thestructure of the novel carbon-based slow-release fertilizer is in a cylindrical particle shape.

Owner:谭中欣 +1

Connection method of display screen and drive partial common one layer aeolotropism conductive film

InactiveCN101118330AReasonable and economical process flowShort production processNon-linear opticsQuality assuranceMethods of production

The present invention relates to a connection method for a display and driving parts sharing an anisotropic conductive film, which includes the steps as follows: S1. A widened ACF is affixed to a chip pressing region which covers the glass substrate of the display and the Regional pressing region of a heat pressure region; S2. A chip is pressed and connected at the chip pressing region on the ACF; S3. The glass substrates of the display and the heat pressure region of FPC flexible circuit board are pressed by heat. Compared with the traditional production method, the method decreases the production process, reduces the investments of production equipments and production materials, and reduces the production cost; in addition, the function and quality assurance of products made by the invention are the same to products made by the prior art.

Owner:SHANGHAI CHENXING ELECTRONICS SCI & TECH CO LTD

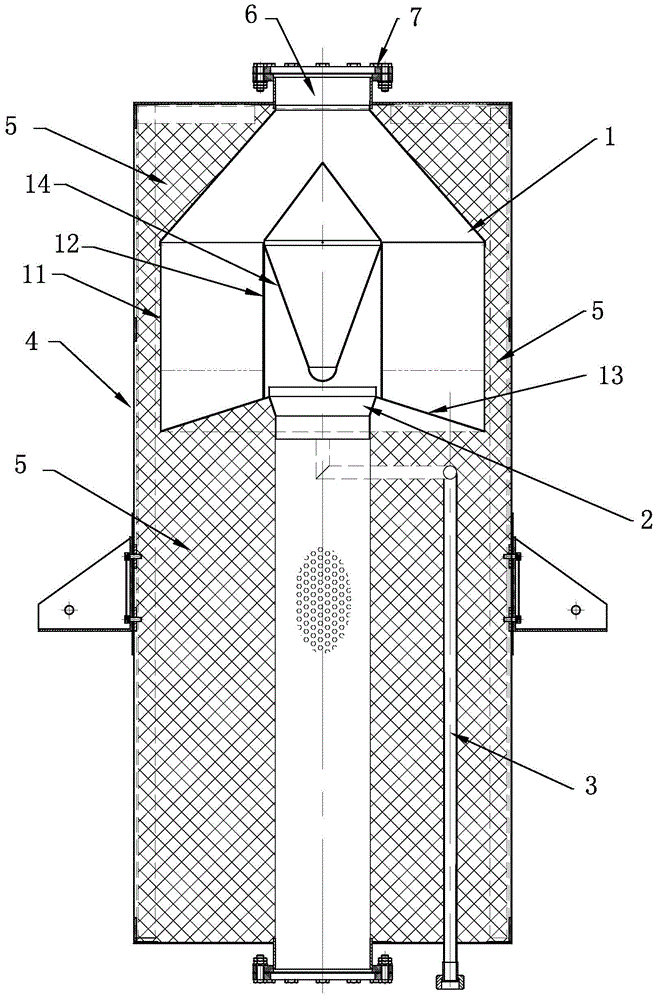

Rainproof structure used in silencer and silencer adopting structure

ActiveCN104234803BFunctions that do not affect noiseReduce manufacturing costExhaust apparatusSilencing apparatusWater dischargeEngineering

Owner:深圳中雅机电实业有限公司

Production method of anti-formaldehyde paint

The invention provides a production method of an anti-formaldehyde paint. The method is characterized by mainly including the step of dispersing water, assistants and powder. The method is characterized by the step of adding the anti-formaldehyde assistant and an anti-formaldehyde emulsion into dispersed powder. The content of the anti-formaldehyde assistant is 03-0.6%, the content of the anti-formaldehyde emulsion is 15-25%, the main component of the anti-formaldehyde assistant and the anti-formaldehyde emulsion is diazo group with a content of 1-3%, the assistants are a dispersant and a defoaming agent, after the adding step, a step of adding a thickener and a leveling agent is replenished, the content of the thickener and the leveling agent is 3-8%, the dispersion step is 25-35min, the time of the adding step and the replenishing step is 10-25min, and the equipment used in the dispersion step is a dispersion machine and a sand mill. The method provided by the invention has the advantages that: 1. the method can rapidly absorb and decompose formaldehyde in indoor air; 2. the method is simple and is convenient for production; and 3. the cost is not increased.

Owner:张彬

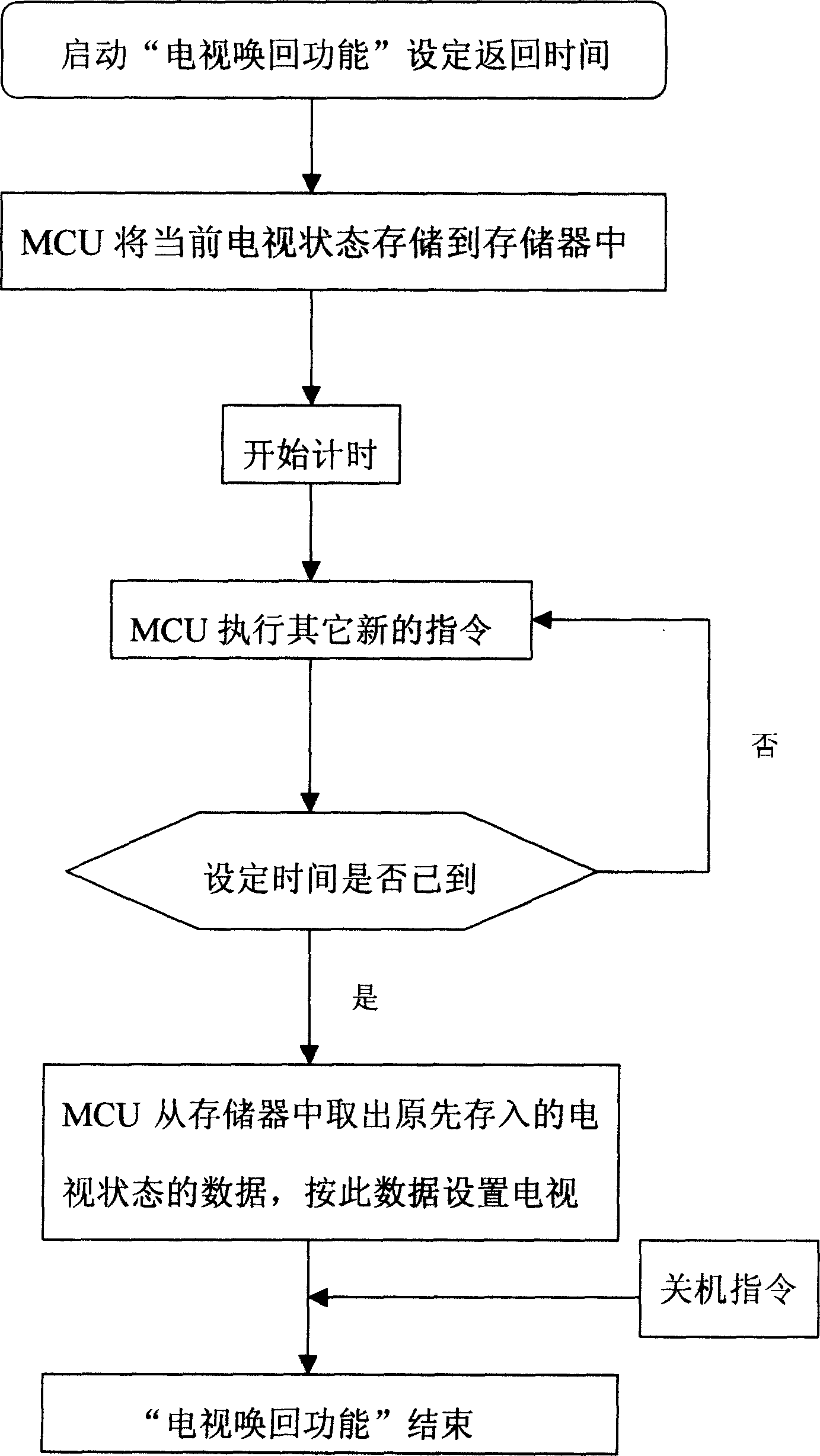

TV. channel returning method

InactiveCN1561104ALow costNo increase in costProgram control using stored programsTwo-way working systemsUser inputData storing

This invention relates to a method for recalling TV channels including the following steps: 1)a user inputs an order of starting 'TV recall' to a central processor and sets the return time 2) the central processor stores the present TV state in a memory and begins counting time 3) when the time reaches to the set return time, the central processor pauses operation of other instructions and picks up the data stored in the memory to redesign TV set according to these data and the TV recovers the state before starting the order of recalling TV.

Owner:彭惠敏 +1

Novel high-capacity hydrogen storage electrode material

InactiveCN101740771AGood hydrogen release platformIncrease pressureCell electrodesElectricityDesorption

The invention relates to a novel high-capacity hydrogen storage material which is suitable for negative electrode material of Ni-MH secondary battery; the novel high-capacity hydrogen storage alloy is characterized in that: the material is La-Mg-Ni alloy, wherein the content of La is 30-38 percent (mass percent), the content of Mg is 0.6-2.6 percent (mass percent), and the remaining content is Ni, and the atomic ratio of the atomic ratio sum of the La and Mg and the Ni is controlled to be 1:3.5; in the novel high-capacity hydrogen storage alloy, by adding alloying elements Mg in the La2Ni7 type alloy, La atom is replaced by the Mg atom, so as to form stable substitutional type solid solution (La, Mg)2Ni7 alloy, and avoid decrystallizatoin tendency of the La2Ni7 type alloy in the hydrogen adsorption and desorption process. The material is used for manufacturing the negative electrode of Ni-MH secondary battery and greatly improve the discharging chemistry capacity and the electric circulating life of the hydrogen storage battery, thereby having commercial use purpose.

Owner:章应

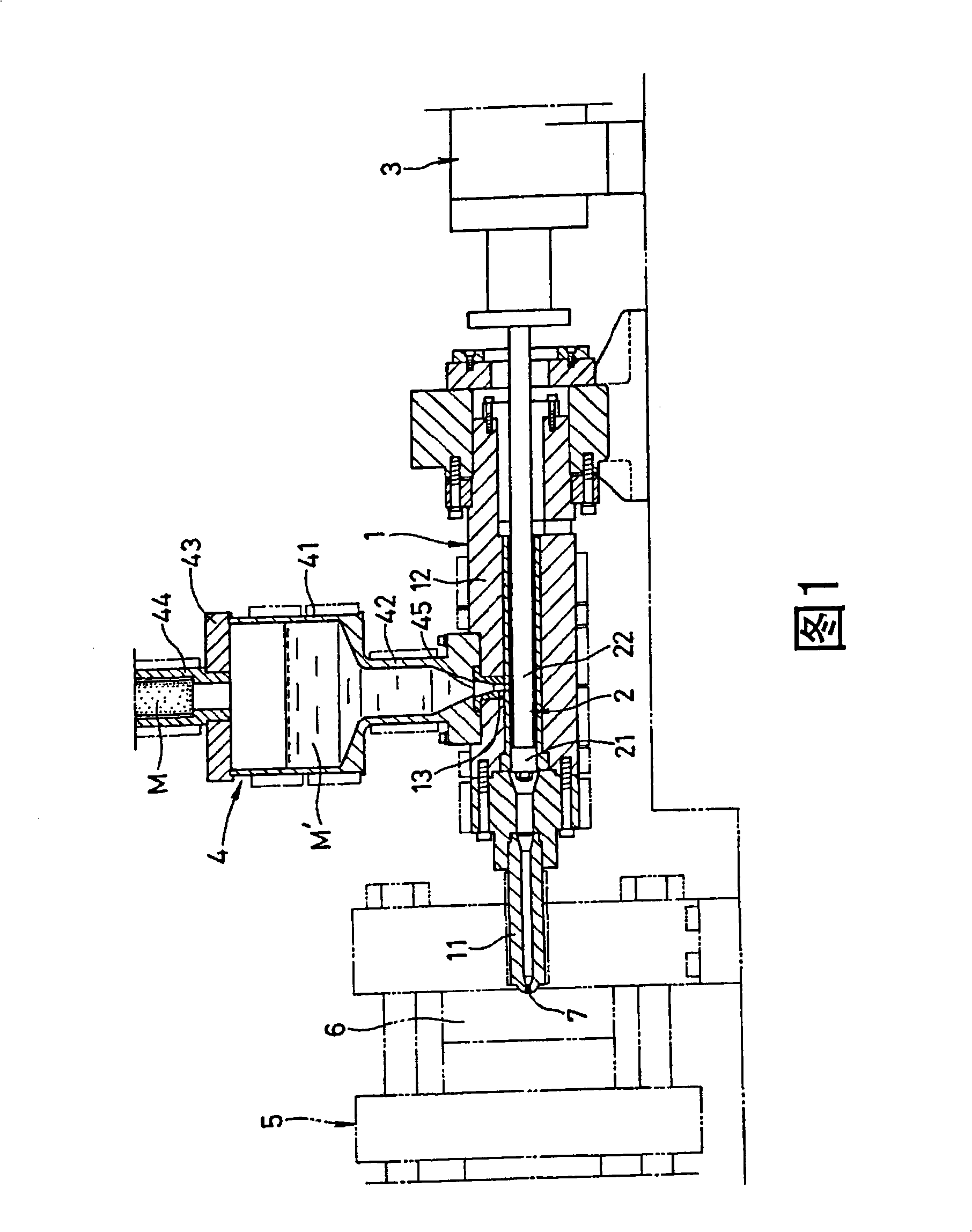

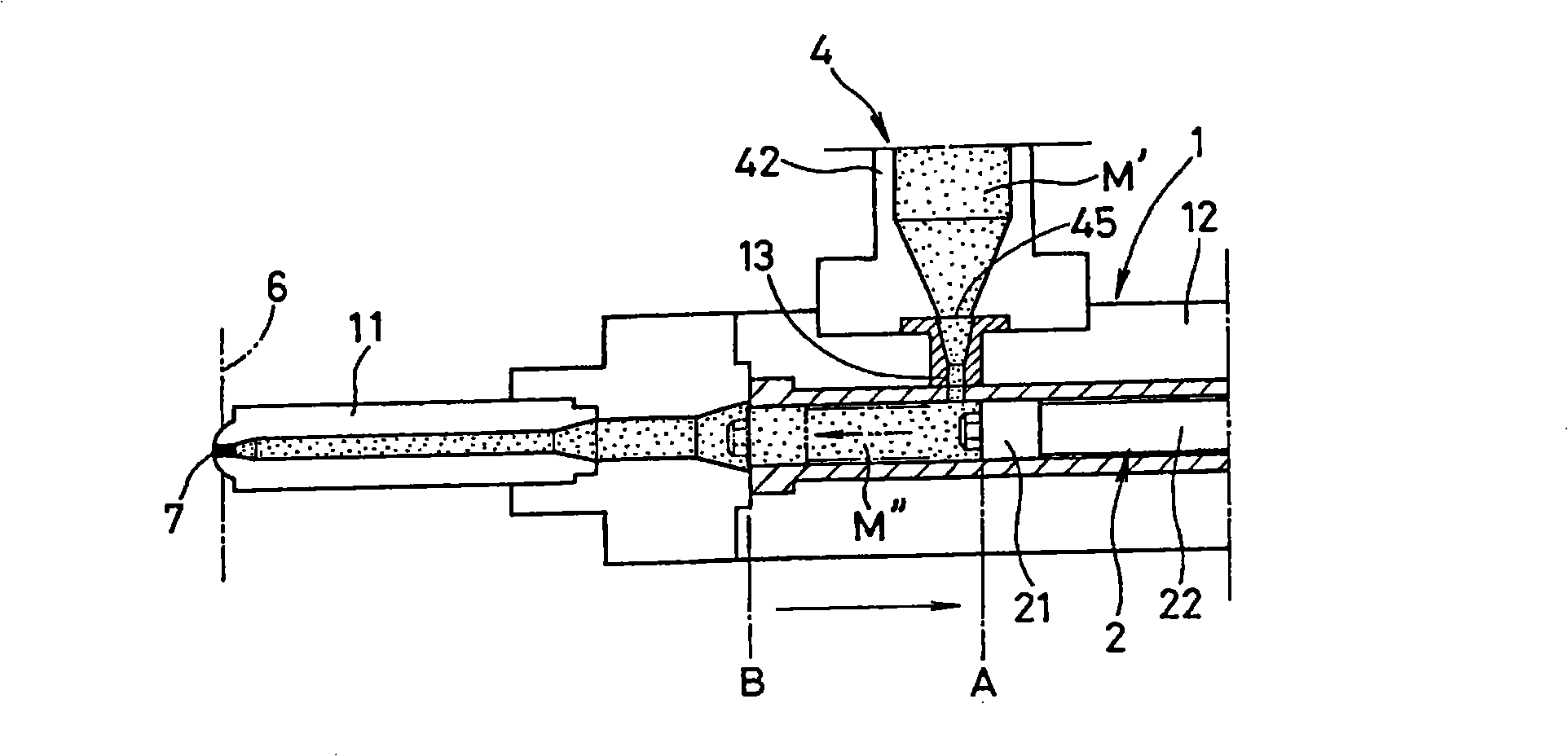

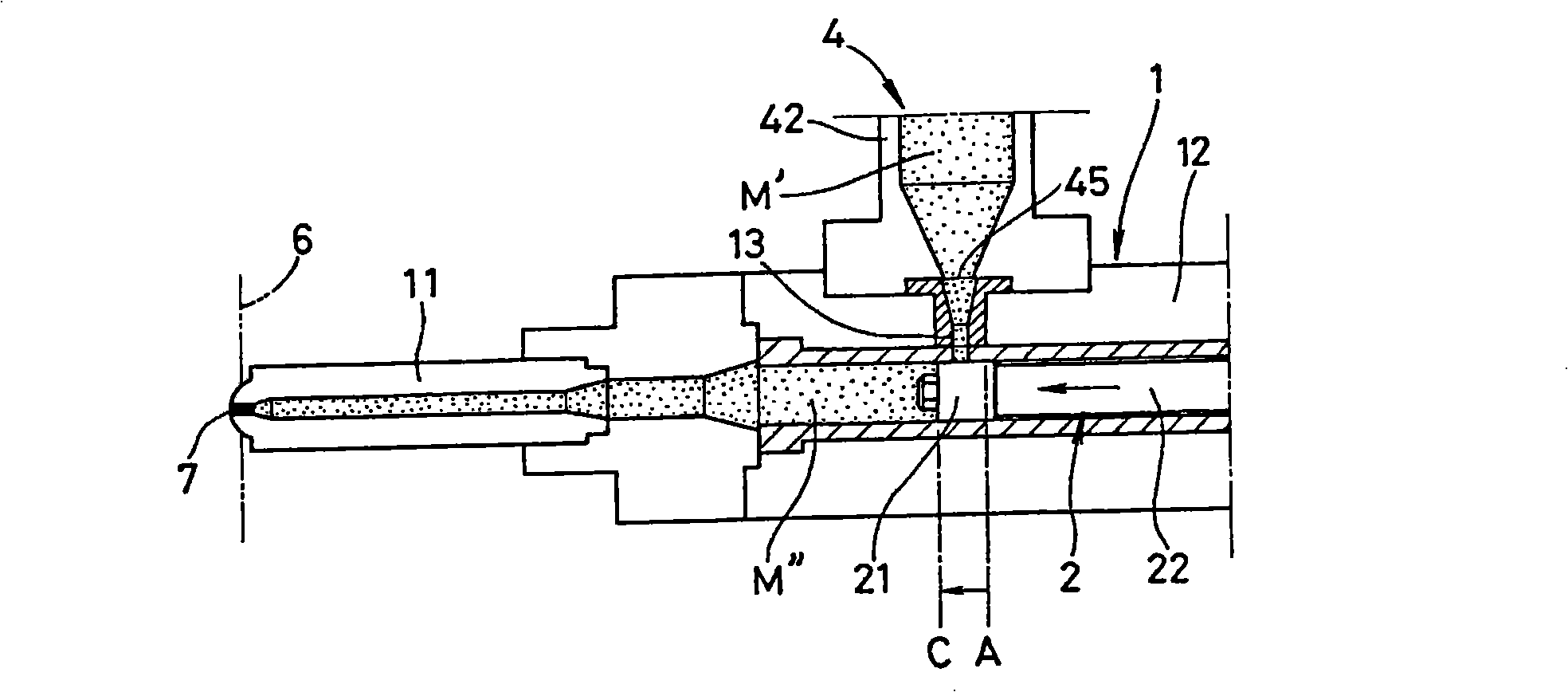

Method for preventing leaking of molten metal in injection molding of metal material

InactiveCN101402135APrevent leakageNo increase in costMolten metal pouring equipmentsLow speedInjection moulding

This is provided a method for preventing leaking of molten metal from a nozzle in an injection apparatus provided with a plunger within a cylinder body, a supply opening formed in an upper portion of the cylinder body, and a furnace for melting and holding the metal material provided on a top portion of the injection cylinder and having an outlet at the bottom end of the furnace communicated with the supply opening. The method comprises the following steps: metering the molten metal by travel of the plunger head backward from the most forward position to the backward position at the rear of the supply opening while maintaining nozzle touching after completion of an injection step and supplying the molten metal from the furnace into the cylinder body through the supply opening, after completion of the metering, closing the supply opening by travel of the plunger head forward at low speed from the backward position to a stand-by position ahead of the supply opening for cutting off the communication between the molten metal in the cylinder body and the molten metal in the furnace.

Owner:NISSEI PLASTIC IND CO LTD

Target radiofrequency ablation system

PendingCN107198566AImprove securityLittle side effectsSurgical instruments for heatingLight therapyAblation radiofrequencyControl system

The invention provides a target radiofrequency ablation system which comprises an irradiation head, an infrared thermometer, a lymph node tracer agent and a center control system. The center control system comprises a laser wavelength control unit, a temperature monitoring unit and a warning unit. Based on a photothermal effect and photothermal treatment of tumors, by combination with the characteristics of high photothermal conversion efficiency of dyes, the target radiofrequency ablation system is used for treatment of superficial organ tumor lymphatic system transfer to achieve the goal of reducing local recurrence, and an effect of radiotherapy on lymphatic metastasis is supplementing and even replaced to a certain extent. The target radiofrequency ablation system is high in safety, including safety of an injection material and laser. The target radiofrequency ablation system is simple and convenient in process and low in cost. After an operation, short-time laser irradiation is performed every day, a patient's wound healing is not affected, the patient's pain is not increased, and only a little cost is increased.

Owner:CHONGQING MEDICAL UNIVERSITY

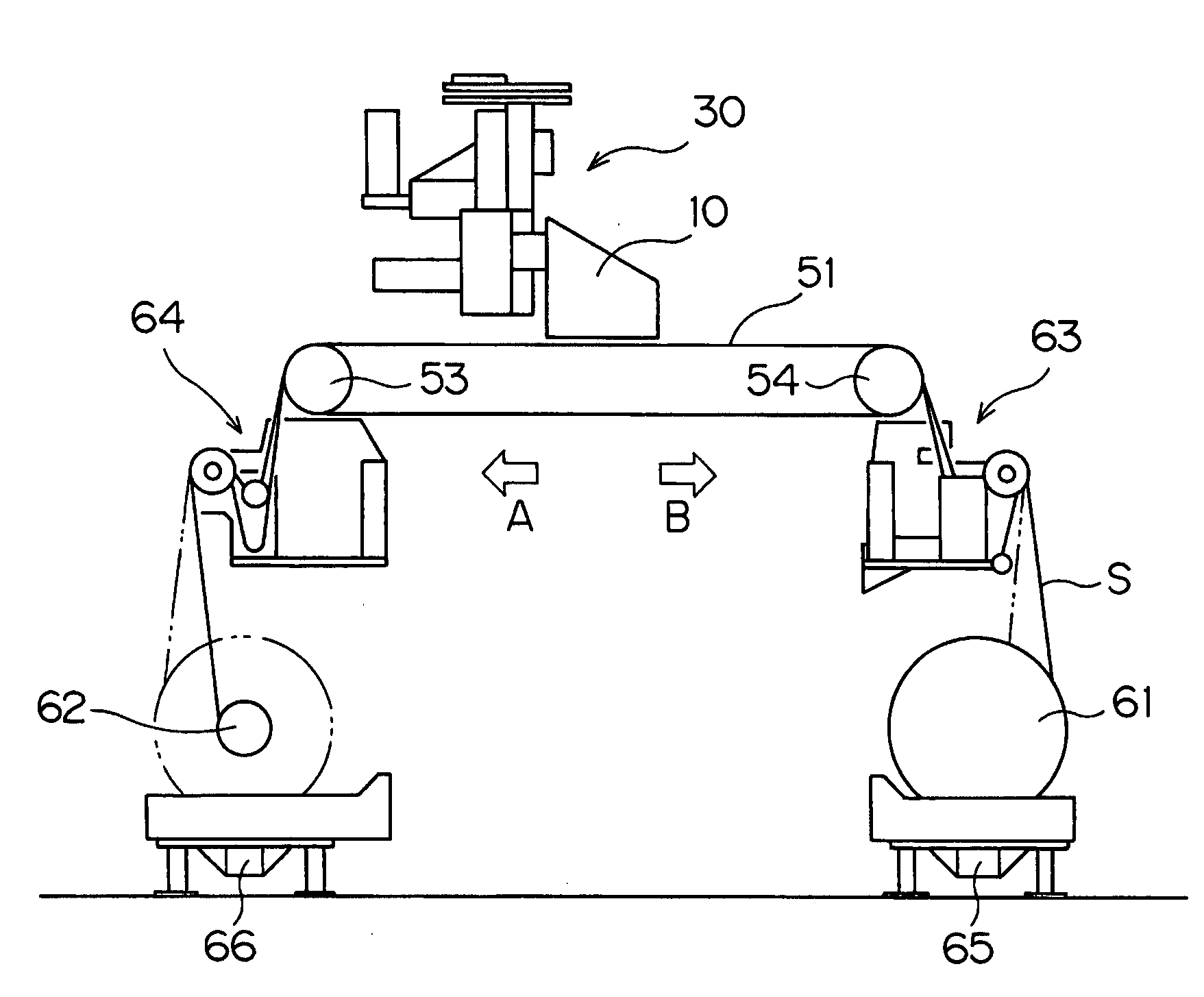

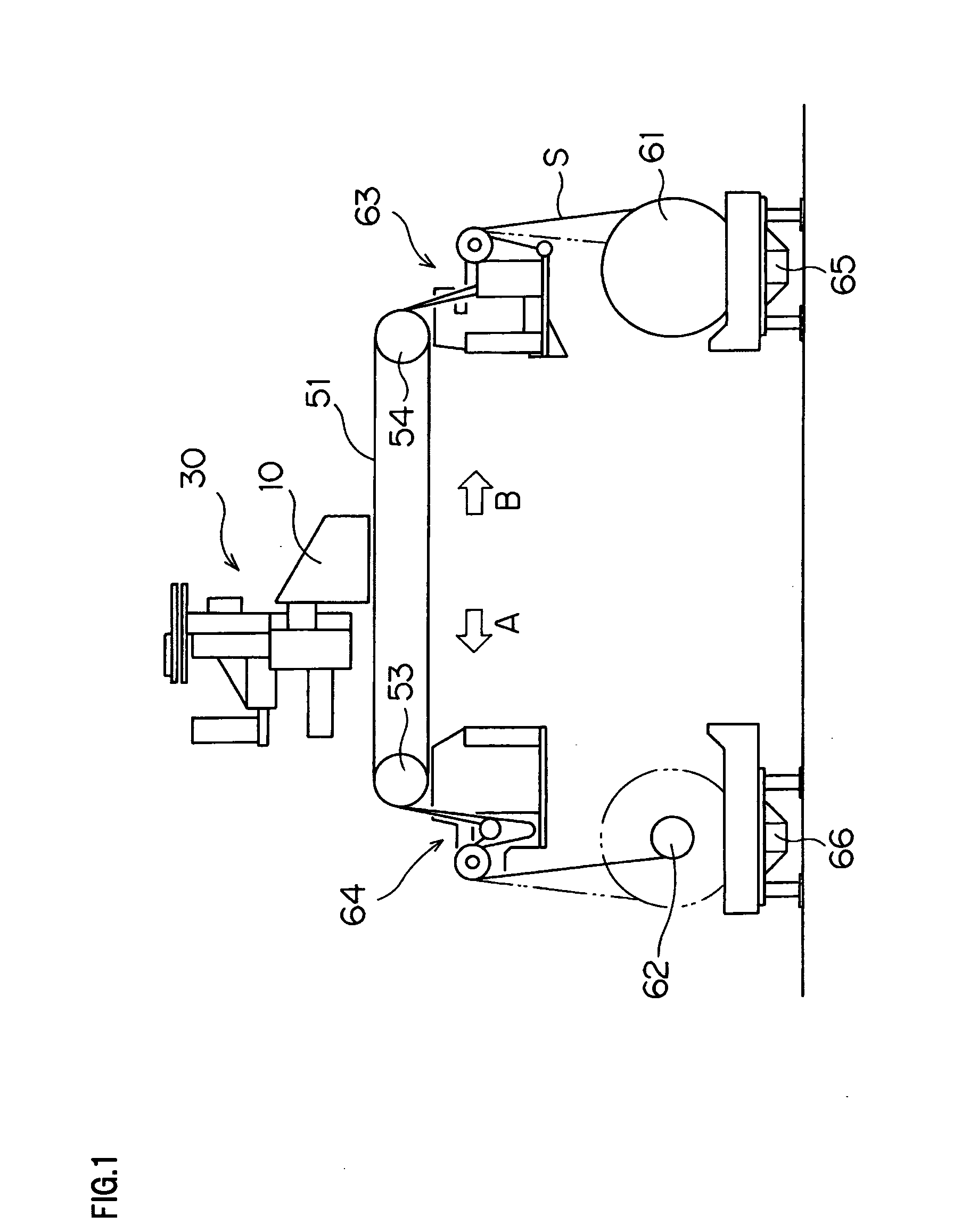

Inkjet recording apparatus

InactiveUS20080297581A1No increase in costSimple constructionOther printing apparatusEngineeringRecording media

Owner:DAINIPPON SCREEN MTG CO LTD

Titanium-molybdenum-nickel alloy composite board and manufacturing method thereof

ActiveCN105128446AIncrease the number ofGood value for moneyMetal layered productsHydrogenNickel alloy

The invention discloses a titanium-molybdenum-nickel alloy composite board which is used for manufacturing a power plant chimney. The titanium-molybdenum-nickel alloy composite board comprises a titanium-molybdenum-nickel alloy board and a substrate steel board; the titanium-molybdenum-nickel alloy board is made of titanium-molybdenum-nickel alloy and prepared from, by weight, 0.2%-0.4% of molybdenum, 0.6%-0.9% of nickel, 0.08% of carbon, 0.15% of silicon, 0-0.015% of hydrogen, 0-0.2% of oxygen, 0.3% of ferrum and the balance titanium. According to the titanium-molybdenum-nickel alloy composite board, the structures of the titanium-molybdenum-nickel alloy board and the substrate steel board are more reasonable, the cost performance of the metal composite board for a power plant is improved, the life of the metal composite board is prolonged, the usage temperature is increased, the unit capacity is increased, the design requirements are completely met, and the economical effeciency is high. The invention further provides a manufacturing method of the composite board.

Owner:BAOJI TAICHENG METAL CO LTD

Titanium-chromium-copper alloy panel and production method thereof

InactiveCN109811191AReduce maintenance costsReasonable structureMetal layered productsSteel platesChromium

The invention discloses a titanium-chromium-copper alloy panel and a production method thereof. The panel is used for the production of power plant chimneys. A titanium-chromium-copper alloy panel anda substrate steel plate are included, the titanium-chromium-copper alloy panel is produced by titanium-chromium-copper alloy, and the titanium-chromium-copper alloy comprises, by weight, 0.2-0.4% ofchromium, 0.6-0.9% of copper, 0.08% of oxygen, 0.15% of magnesium, 0-0.015% of chromium, 0-0.25% of the oxygen, 0.3% of iron and the balanced titanium. The structures of the titanium-chromium-copper alloy panel and the substrate steel plate are more reasonable, the cost performance of metal panels for power plants is improved, the service life of the metal panels is prolonged, single-machine capacity is improved, designing demands are completely met, and the economical performance is high. The invention further provides a production method of the panel.

Owner:王鹏

A double-template molecular imprinting purification method for tetrandrine A and B

ActiveCN111153909BNo increase in costAchieve purificationIon-exchange process apparatusOrganic chemistryTetrandrinePharmaceutical Substances

The present invention relates to a medicine extraction and purification technology, in particular, it provides a technical method for efficiently separating tetrandrine and B at the same time; that is, using methacrylic acid, ethylene glycol dimethacrylate and azobis Isobutylcyanide and other target molecular powders tetrandrine and B are synthesized, and then the target molecule is eluted to obtain a double-template molecularly imprinted polymer. The column and preparative chromatograph further separate the tetrandrine and B, and the purity of the obtained tetrandrine and B reaches more than 99%.

Owner:CSPC JIANGXI GOLDEN LOTUS PHARMA CO LTD

Semiconductor packaging member for semiconductor device stacking and its manufacture method

ActiveCN101165886BImprove reliabilityImprove qualityPrinted circuit assemblingSemiconductor/solid-state device detailsElectrical conductorElectrical connection

The method comprises: setting up and electrically-connecting at least on semiconductor chip; through an electrical connection structure composed of an upper layer circuit board and lower layer circuit board, the semiconductor chip is connected to the baseboard; said semiconductor chip is held by a holding space in the electrical connection structure; forming a sealing gel used for covering the semiconductor chip and the electrically connection structure; after completing the forming of sealing gel, multi weld pads are exposed from the sealing gel in order to make at least one semiconductor component electrically connected to the upper layer circuit board so as to form a stack structure.

Owner:SILICONWARE PRECISION IND CO LTD

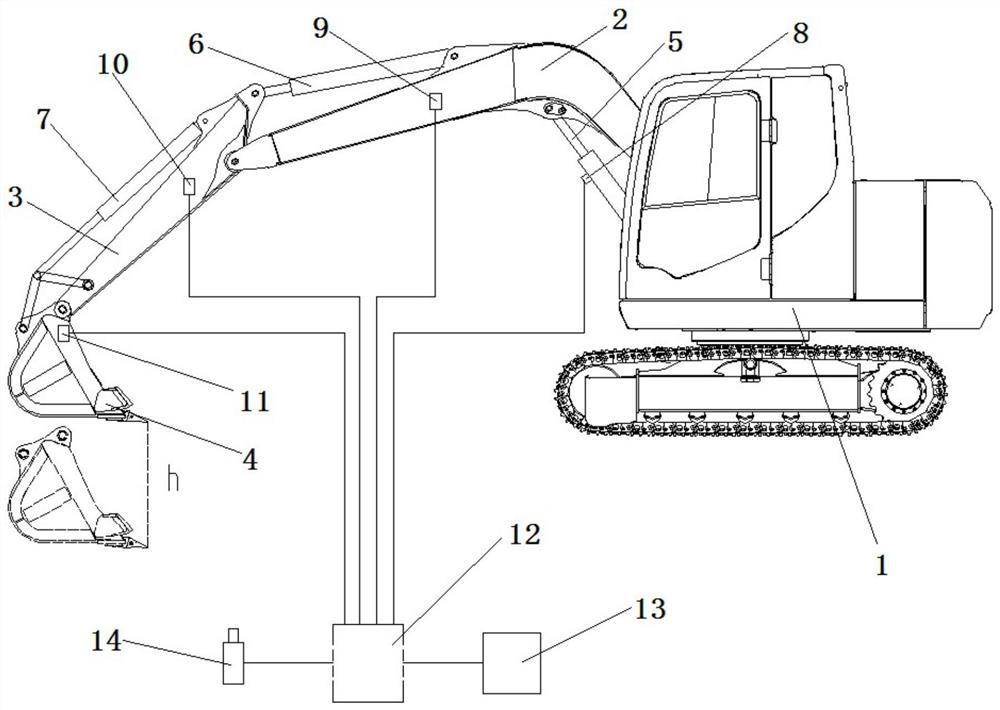

Timing system and identification method for working condition identification of construction machinery breaker

The invention relates to use identification and timing for use of a breaking hammer in an engineering machine, aims at solving the problem of inaccurate timing for use of a breaking hammer in an engineering machine, and provides an identification and timing system, and an identification and timing method for a working condition using a breaking hammer in an engineering machine. The identification and timing system comprises a vibration sensor for measuring vibration, a main pump pressure sensor, an installation boom movement induction device and a control unit, wherein the control unit receives measurement values of the vibration sensor, the pressure sensor and the induction device, and judges a working state of the engineering machine; and a timer carries out accumulative timing when the engineering machine is under an impact working condition using the breaking hammer. The system disclosed by the invention is simple and reliable, and capable of accurately accumulating a working time of the working condition using the breaking hammer. In addition, only the vibration sensor is added relative to the original machine, thus the cost is basically not increased.

Owner:LIUZHOU LIUGONG EXCAVATORS +2

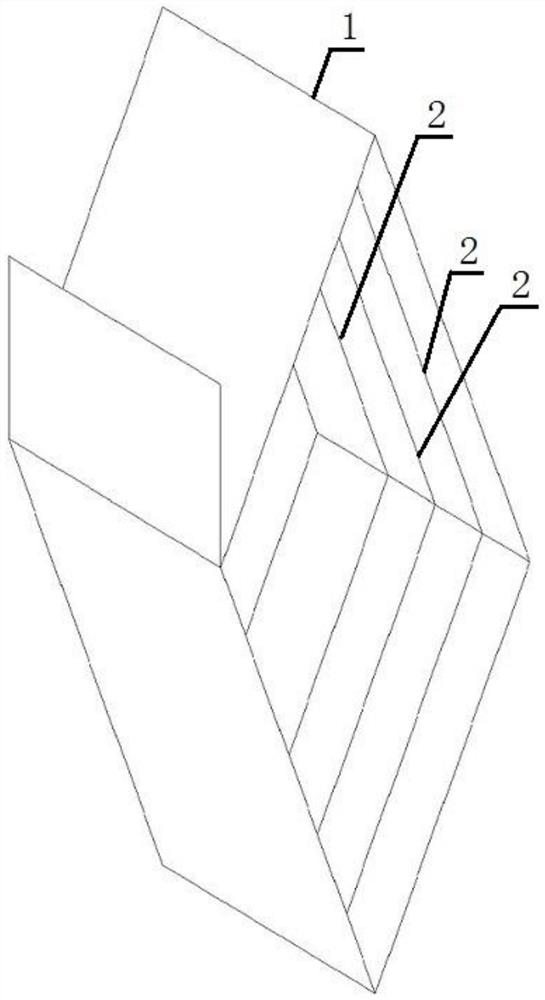

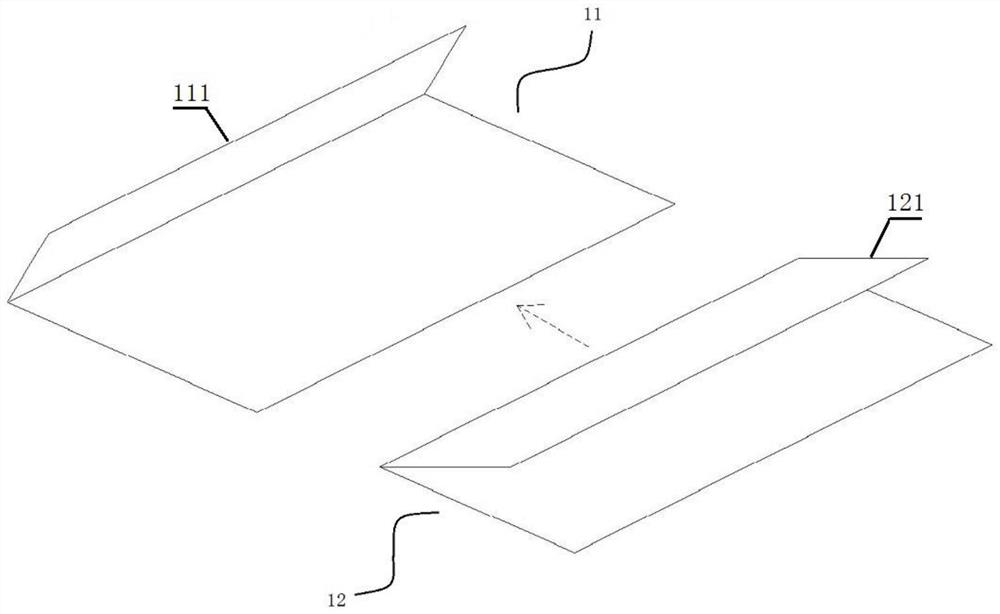

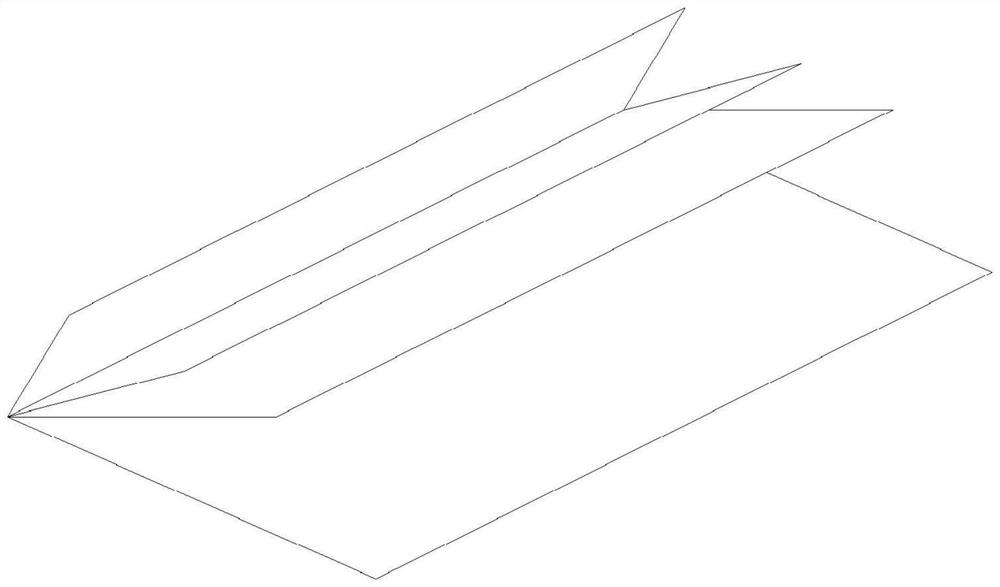

Valve port device with sealing function for valve bag

The invention relates to a valve port device with a sealing function for a valve bag. More than one valve block is arranged in a valve barrel; one end of each valve block, which faces a feeding port of the valve barrel, is fixed on the inner wall of the valve barrel; and one end of each valve block, which faces a discharging port, is movably separated from the valve barrel. The valve port device provided by the invention is used on a paper, plastic or paper-plastic composite valve port bag and used for replacing an existing valve port, and the multiple valve blocks are arranged in the valve barrel, so that material leakage can be stopped multiple times and in multiple dimensions: materials in the bag are extruded in multiple directions from outside to inside to enable the valve barrel to be closed to achieve primary sealing, materials remaining in the valve barrel and materials extruded into the valve barrel can be intercepted by the secondary valve block to achieve secondary sealing,and a gap between the secondary valve block and the discharging port of the valve barrel is filled with the materials which can expand to further reduce a main channel of the valve port device to prevent the materials from leaking so as to achieve tertiary sealing. Due to the multi-layer and multi-dimensional sealing mode, material leakage is greatly relieved.

Owner:广州元坤新材料有限公司

Anti-seepage method for large closed pool in high-altitude desert environment

PendingCN114135135AAvoid the risk of increased repair costsLow costBuilding material handlingForming/stuttering elementsArchitectural engineeringStructural engineering

The invention discloses an anti-seepage method for a large closed pool in a high-altitude desert environment, which comprises an anti-seepage construction method in the pouring construction process of the large closed pool, and specifically comprises the following steps: firstly, controlling the quality of raw materials to control and adjust the shrinkage of concrete so as to reduce the generation of shrinkage cracks; secondly, the mixing proportion of the concrete is reasonably designed to reduce the shrinkage of the concrete and reduce the generation of shrinkage cracks; thirdly, construction cold joints generated in the construction process are controlled and reduced; and finally, controlling the curing conditions of the concrete to reduce temperature cracks and shrinkage cracks of the concrete. The method is good in anti-seepage effect and has the advantages of reducing the cost, reducing the maintenance risk, shortening the construction period and the like.

Owner:THE SIXTH CONSTR CO LTD OF CHINA NAT CHEM ENG

Method for preparing temperature-resistant hard polyurethane foam

The invention discloses a making method of heatproof hard polyurethane foam, which is characterized by the following: adopting composite technique of multiple polyethers / polyester polyol with high functional degree (fn:5-6) or heterocyclic structure in the molecular chain segment; making the aromatic ring structure material of polyester polyol as reacting monomer; allocating polyether polyol and polyester polyol according to certain proportion; reacting under catalyst, foamer, uniform foaming agent and PAPI with the index of isocyanate at 1. 05-1. 10; synthesizing PUF foam.

Owner:CHINA PETROLEUM & CHEM CORP

Excavator silting working condition detection system and detection method

ActiveCN108487366BNo increase in costReduce accidentsSoil-shifting machines/dredgersDriver/operatorControl engineering

The invention relates to an excavator, and provides a bogged-down condition detection system for the excavator to safely detect whether a bogged-down condition risk exists in a construction position of the excavator. When the excavator detects whether the bogged-down condition risk exists in the construction position, a bucket baseplate is flatly placed in the construction position to be detected,a boom cylinder is retracted to sink a bucket into the ground till the boom cylinder cannot be further retracted, a controller calculates an acting force onto the plane of the bucket baseplate from the ground and the sinking depth of the bucket according to a detected parameter value, the maximum ground pressure which can be borne by the construction position and the permitted sinking depth of the whole machine are compared in combination with area calculation of the plane of the bucket baseplate to judge whether the construction position can lead to a bogged-down condition of the whole machine, and a judgement result is displayed on a display. The bogged-down condition detection system can accurately judge whether the bogged-down condition of the whole machine can occur in the construction position or not under the condition of guaranteeing that the whole machine is away from a dangerous position, and a driver is reminded, so that the probability of an accident is effectively reduced.

Owner:LIUZHOU LIUGONG EXCAVATORS +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com