Method for preventing leaking of molten metal in injection molding of metal material

一种熔融金属、注塑成型的技术,应用在熔融金属从铸包中浇注的控制、金属加工设备、制造工具等方向,能够解决难以取下冷插塞、大注塑阻力等问题,达到防止泄漏的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

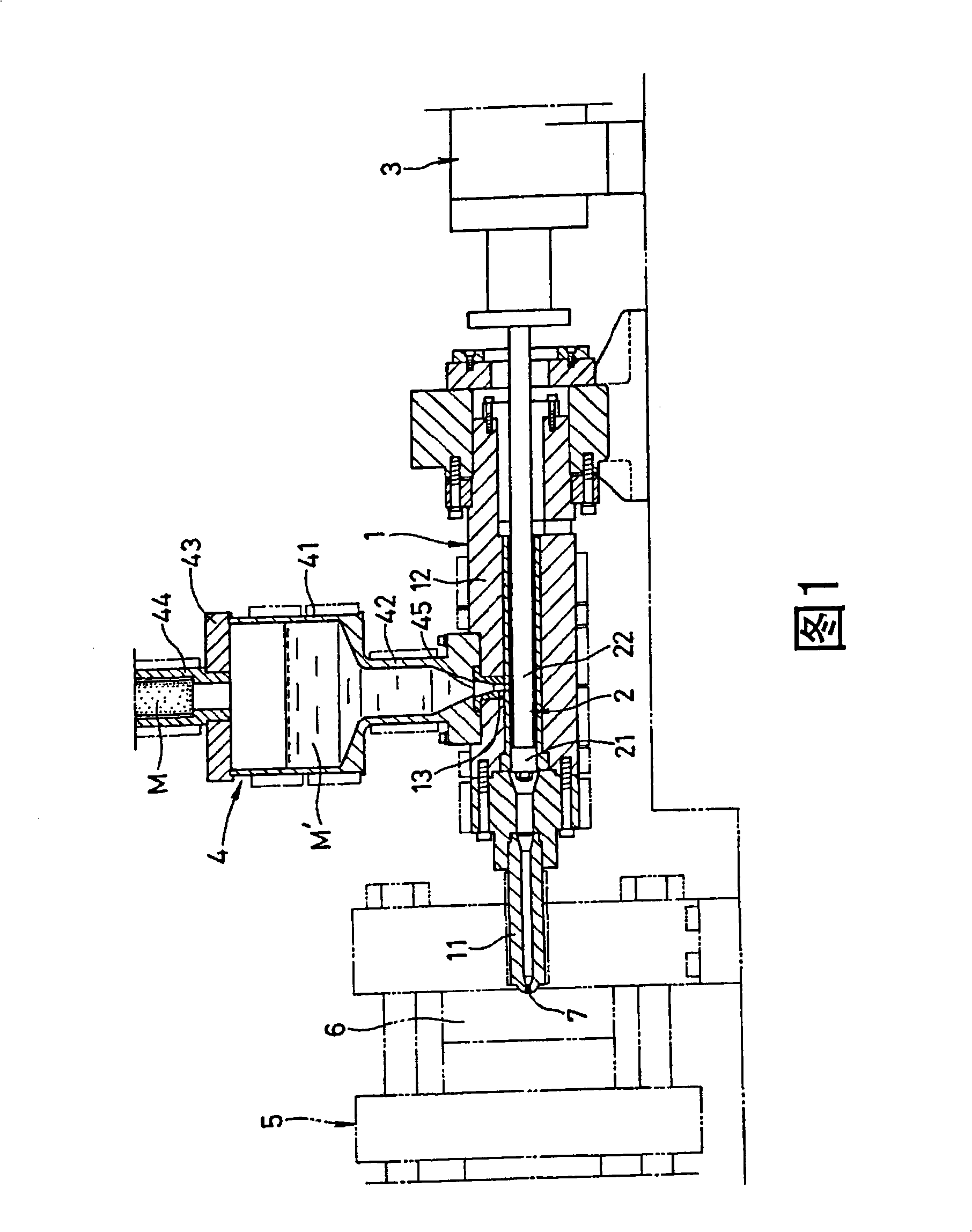

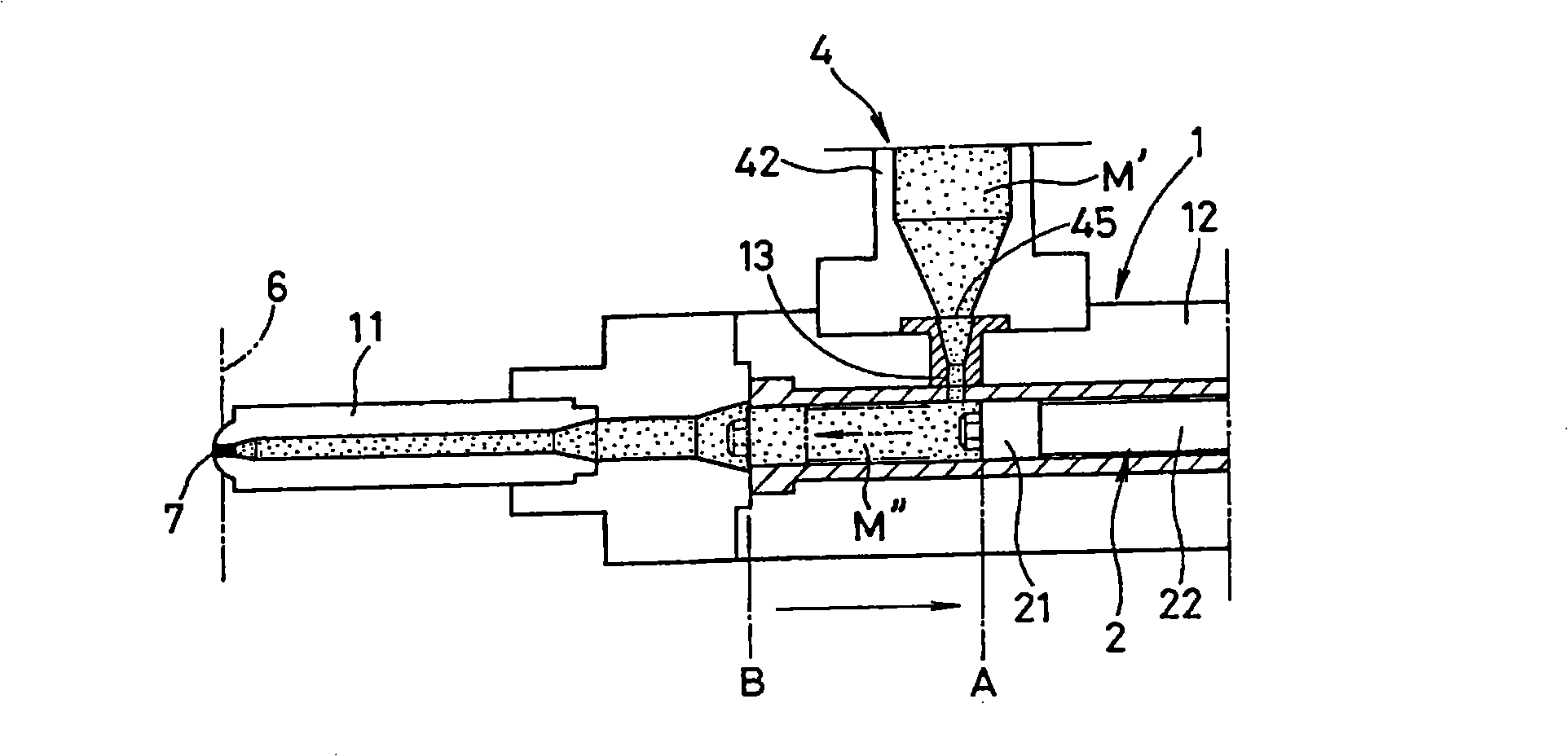

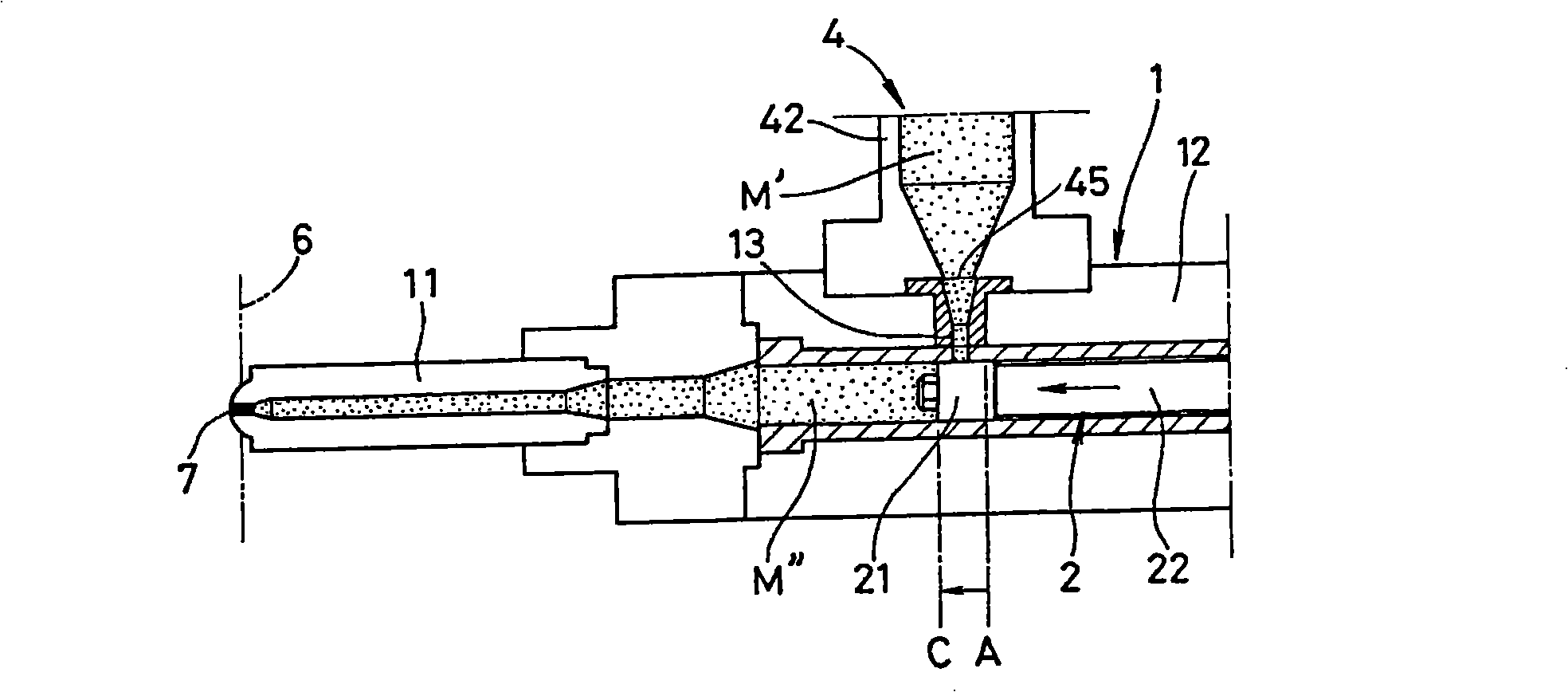

[0028] In the drawings, reference numeral 1 denotes an injection cylinder. The injection cylinder 1 includes a cylinder body 12 having a nozzle 11 at a tip end thereof, and includes a plunger 2 arranged inside the cylinder body 12 so as to be able to travel forward and backward. The plunger 2 includes a plunger head 21 and a plunger rod 22, which are connected to the injection molding drive unit 3 located behind the injection molding cylinder. The plunger head 21 is adapted to travel from a rearward position A behind a supply opening 13 formed at an upper forward position of the cylinder 12 (see figure 2 ). Heating means using band heaters are installed on the outer peripheries of the nozzle 11 and the cylinder 12 so that the temperature of each heater is individually controlled.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com