Connection method of display screen and drive partial common one layer aeolotropism conductive film

A driving part, anisotropic technology, applied in nonlinear optics, instruments, optics, etc., can solve the problem of high production cost, and achieve the effect of reasonable and economical process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

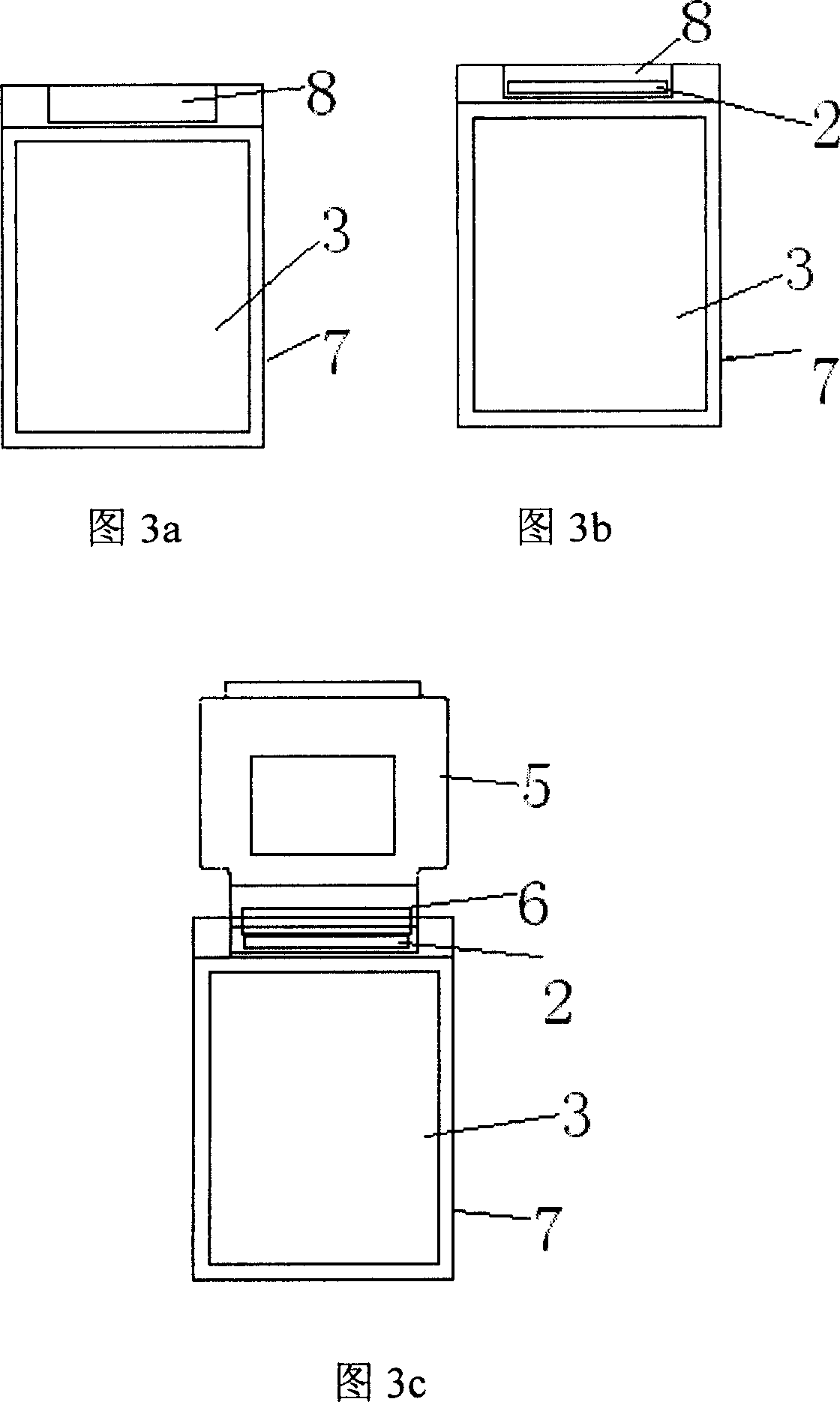

[0020] An embodiment of the present invention is given below in conjunction with accompanying drawing 3 to describe the technical solution of the present invention in detail.

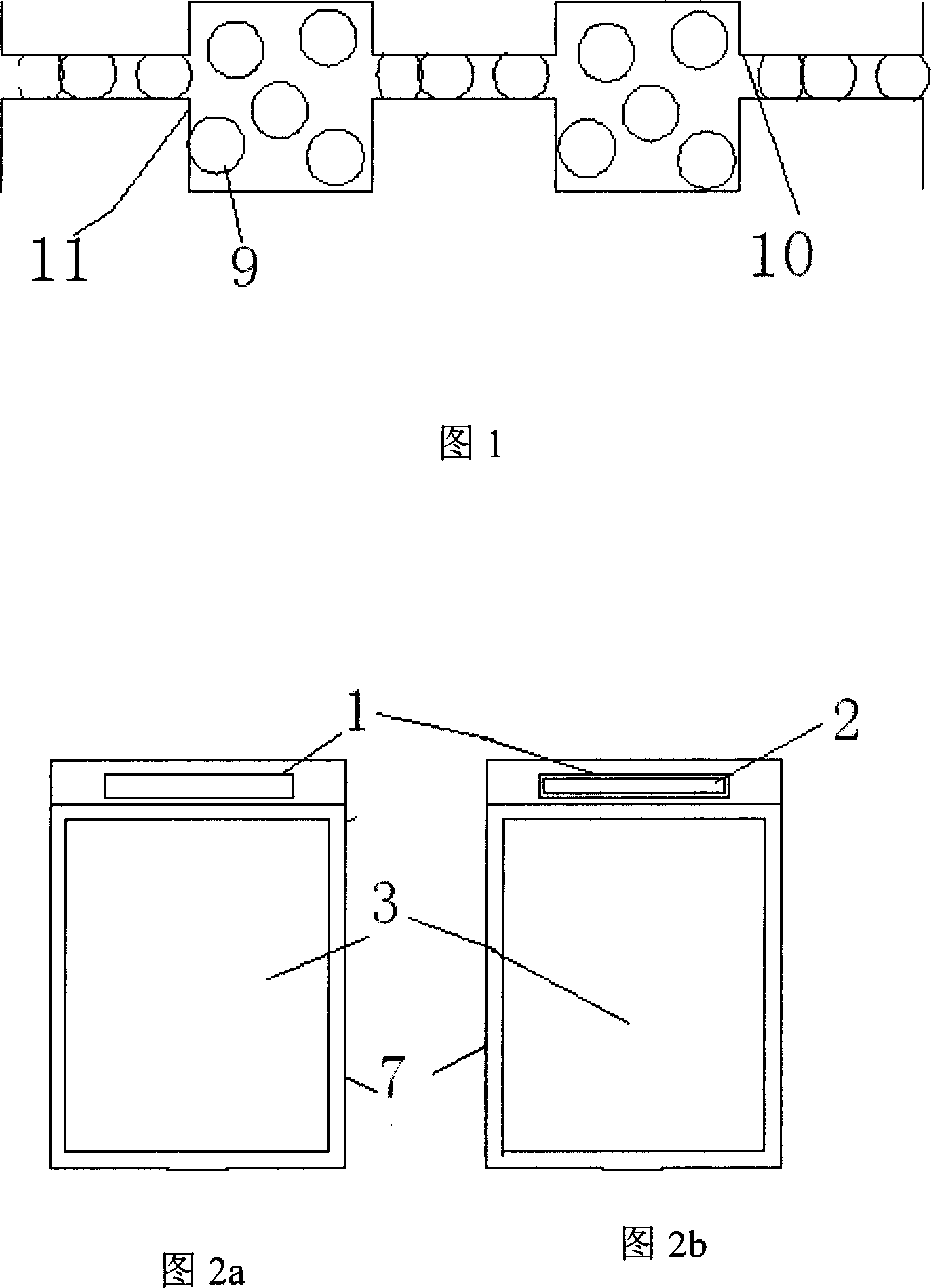

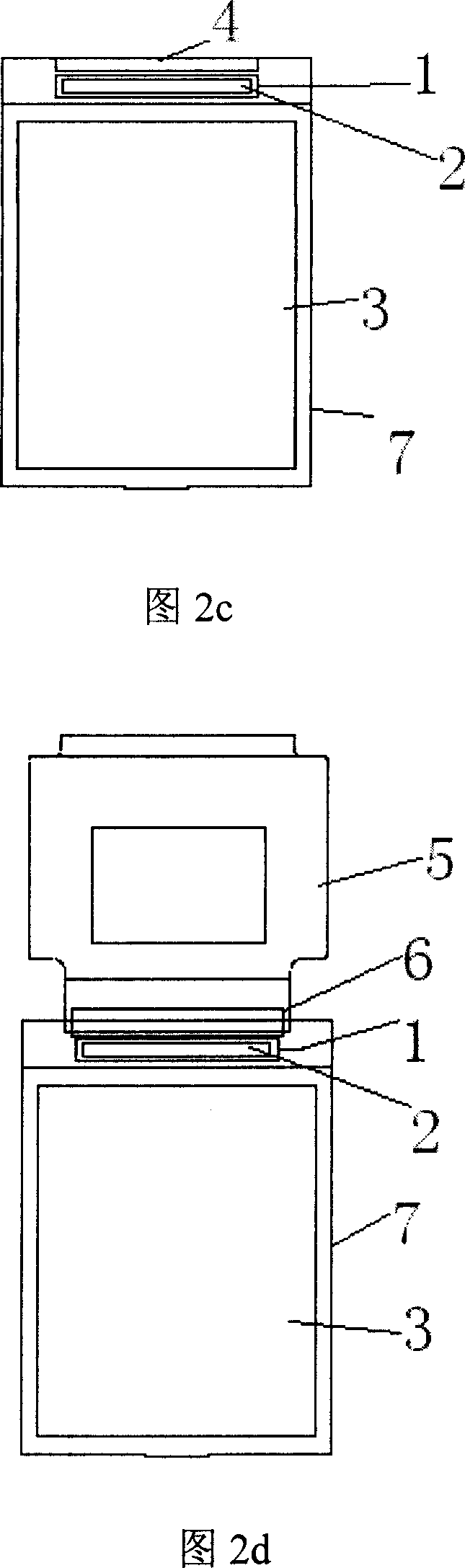

[0021] A method in which the display screen and the driving part share a layer of anisotropic conductive film connection during the liquid crystal production process. Considering that the ACF technical standard of COG is higher than that used for FOG, the ACF technical standard of COG will now be used The increased width of the ACF enables it to cover the crimp area of both the first and second ACF layers. After the chip crimping process is completed, it directly enters the hot pressing FPC process, so that the existing ACF replaces the first layer ACF and the second layer ACF in the prior art. and change the production flow to:

[0022] Attaching the ACF to the crimping area 8 covering the crimping chip area 1 and the thermal pressing area 4 in the prior art on the glass substrate 7 of the display s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com