Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

152 results about "Chip on glass" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

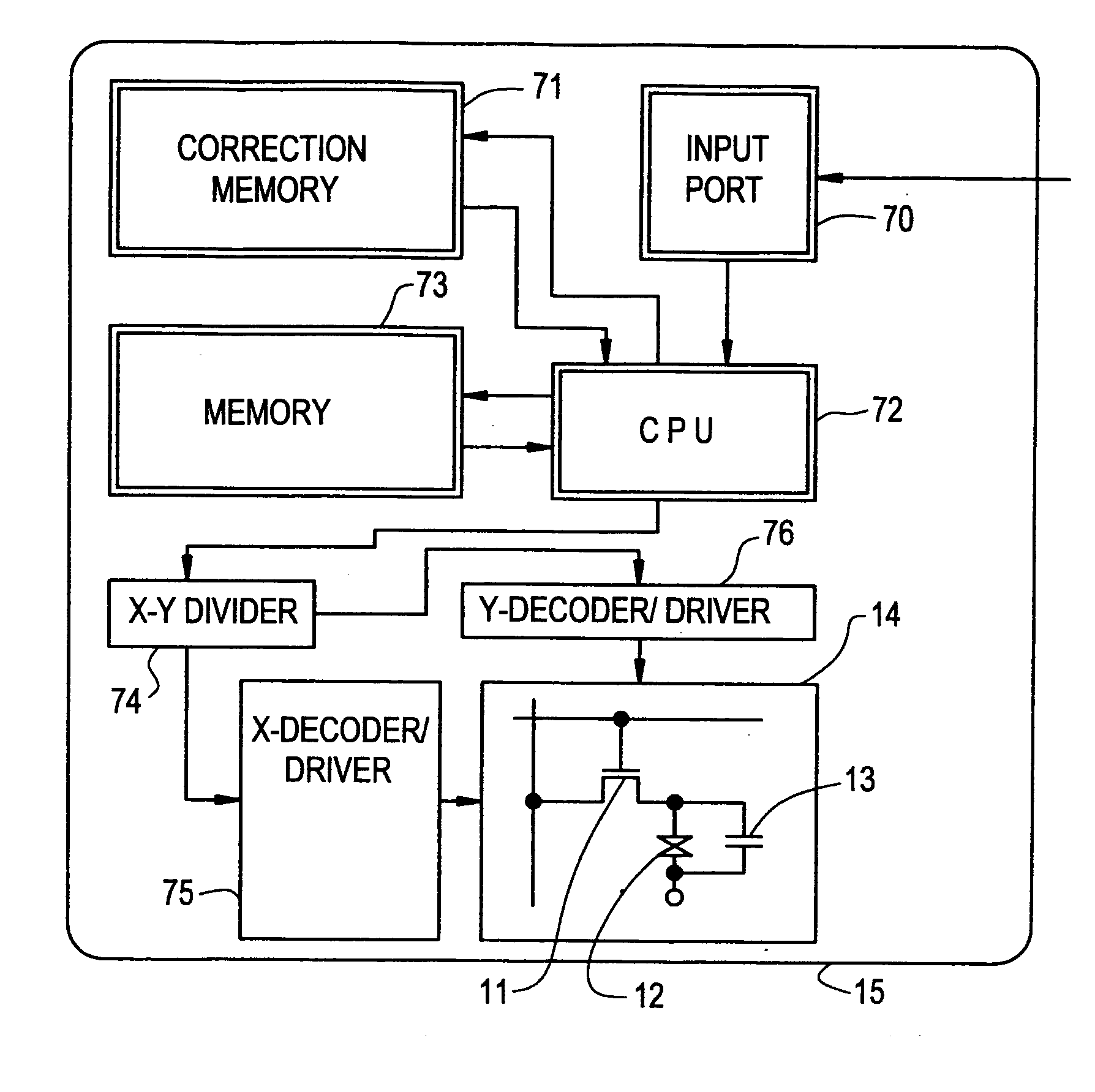

Electrostatic discharge protection device for liquid crystal display using a COG package

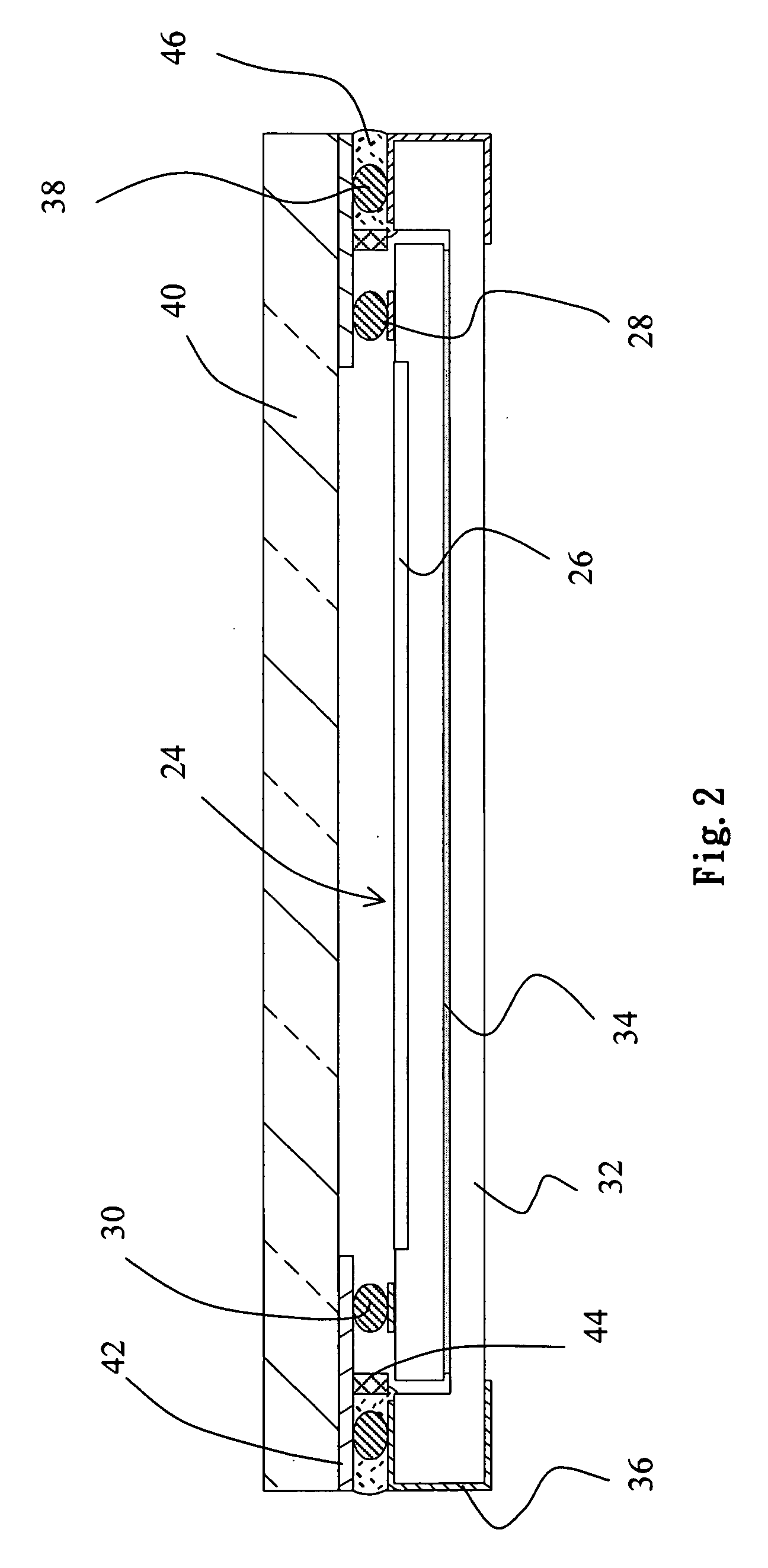

InactiveUS6043971AEmergency protective arrangements for limiting excess voltage/currentNon-linear opticsEngineeringElectrostatic discharge protection

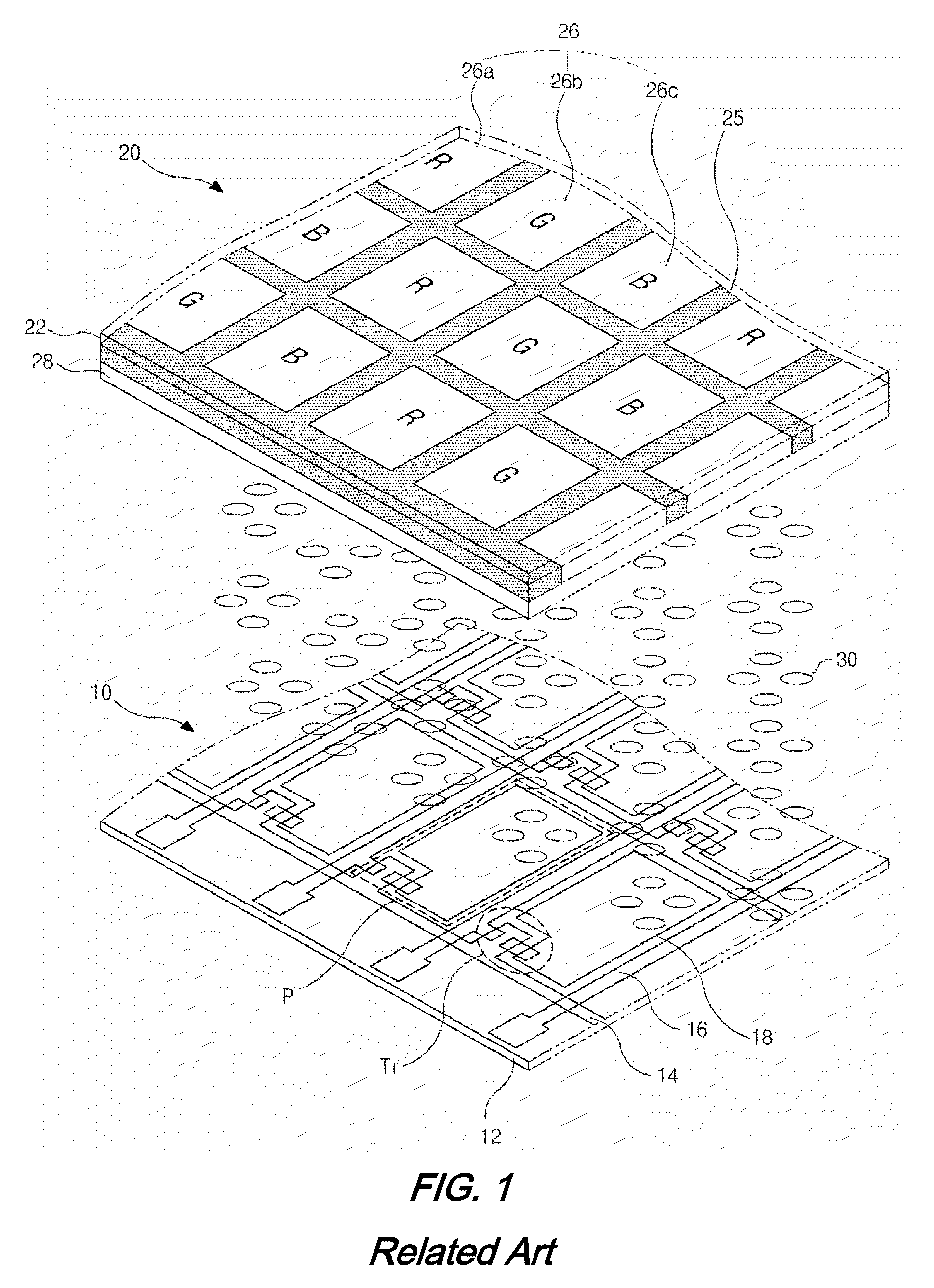

The electrostatic discharge (ESD) protection device for a liquid crystal display using a chip on glass (COG) package is provided. The ESD protection device includes a plurality of gate lines and data lines each of which has an output pad at its end. A plurality of gate line input pads and data line input pads are formed opposite to the output pads of the gate lines and data lines, respectively. A common electrode is formed between the plurality of gate line input pads and output pads and between the data line input pads and output pads. A plurality of electrostatic discharge protection circuits are connected between the input pads and the common electrodes to protect the input pads from electrostatic discharge.

Owner:LG DISPLAY CO LTD

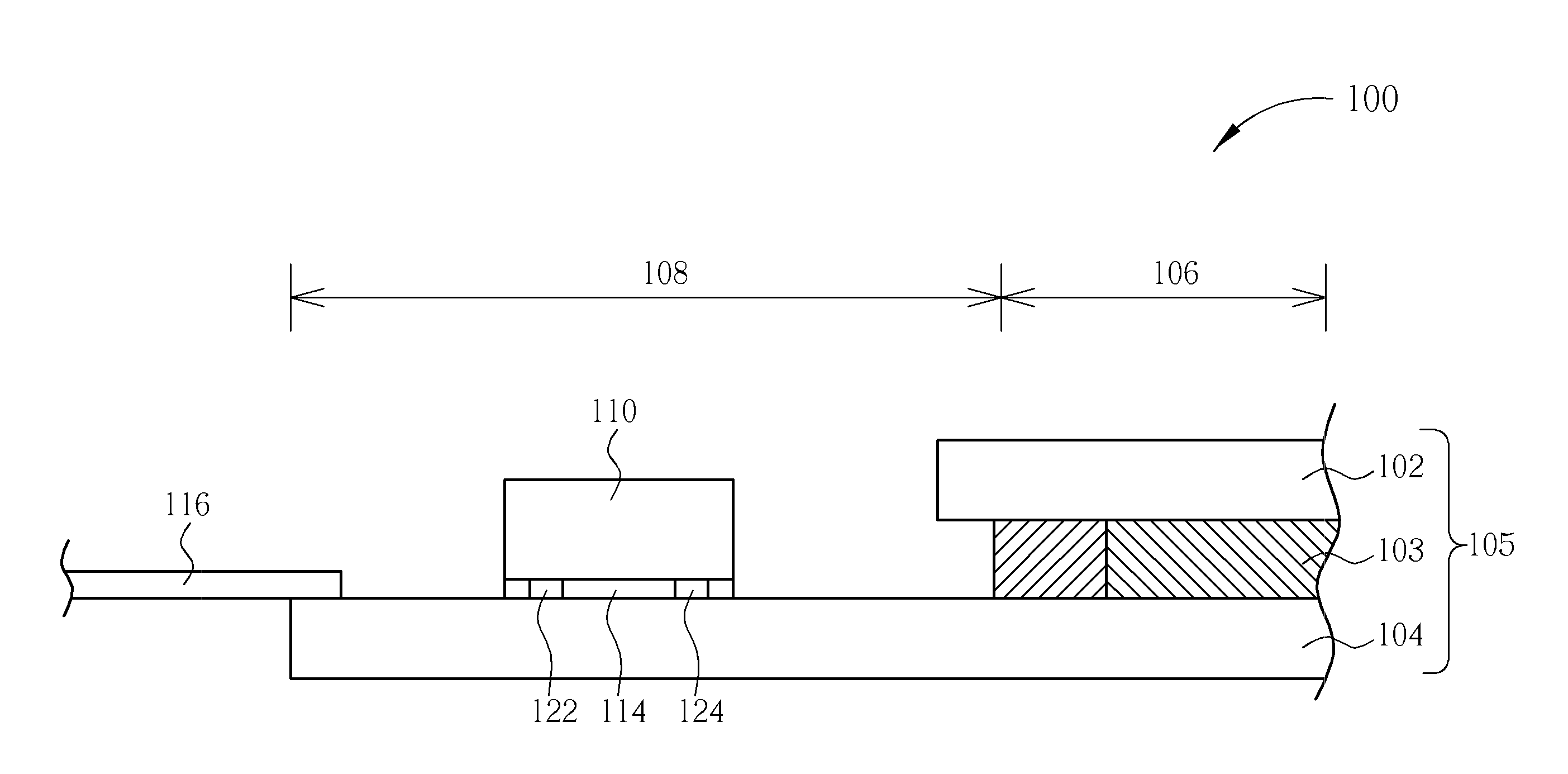

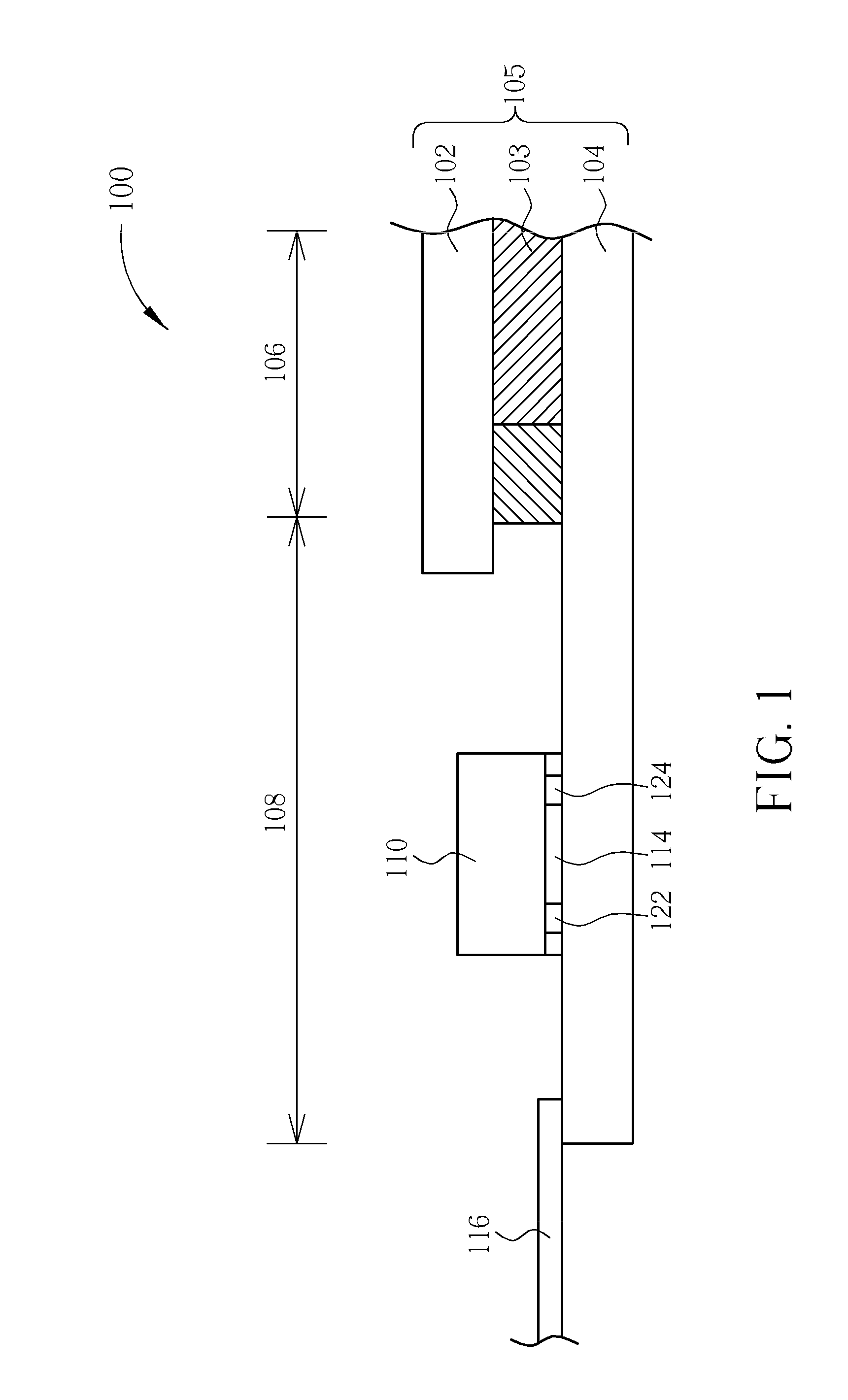

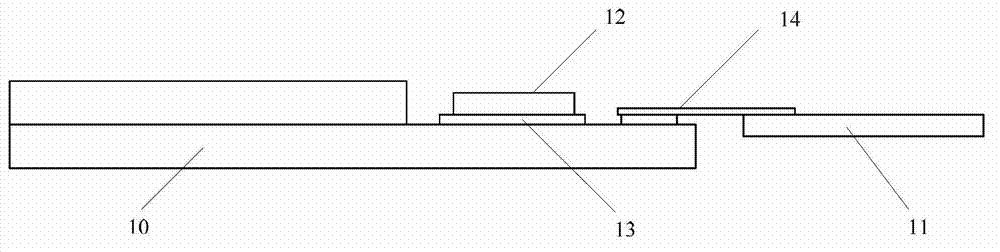

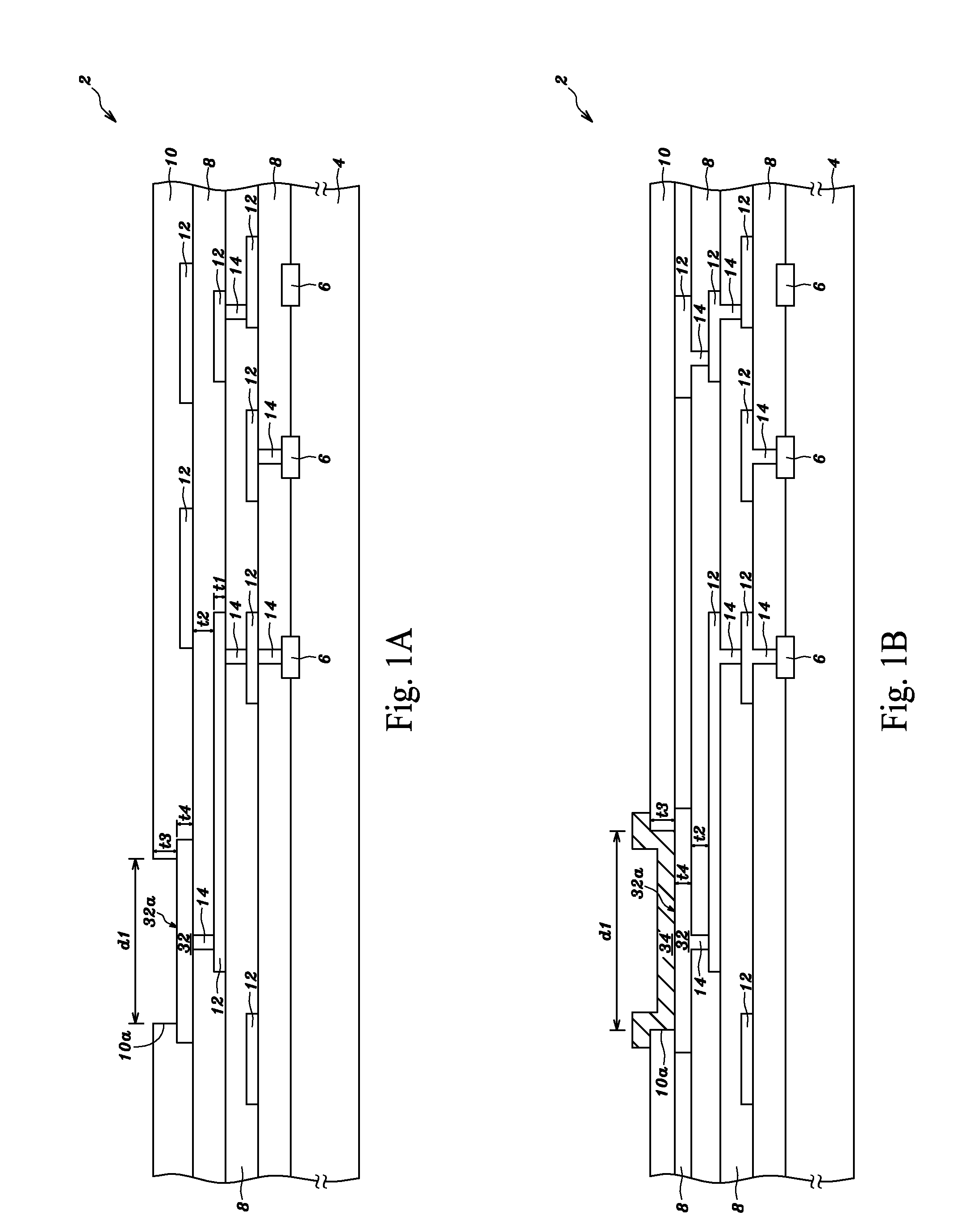

Chip having a driving integrated circuit and liquid crystal display having the same

ActiveUS20090268147A1Semiconductor/solid-state device detailsSolid-state devicesDisplay deviceIntegrated circuit

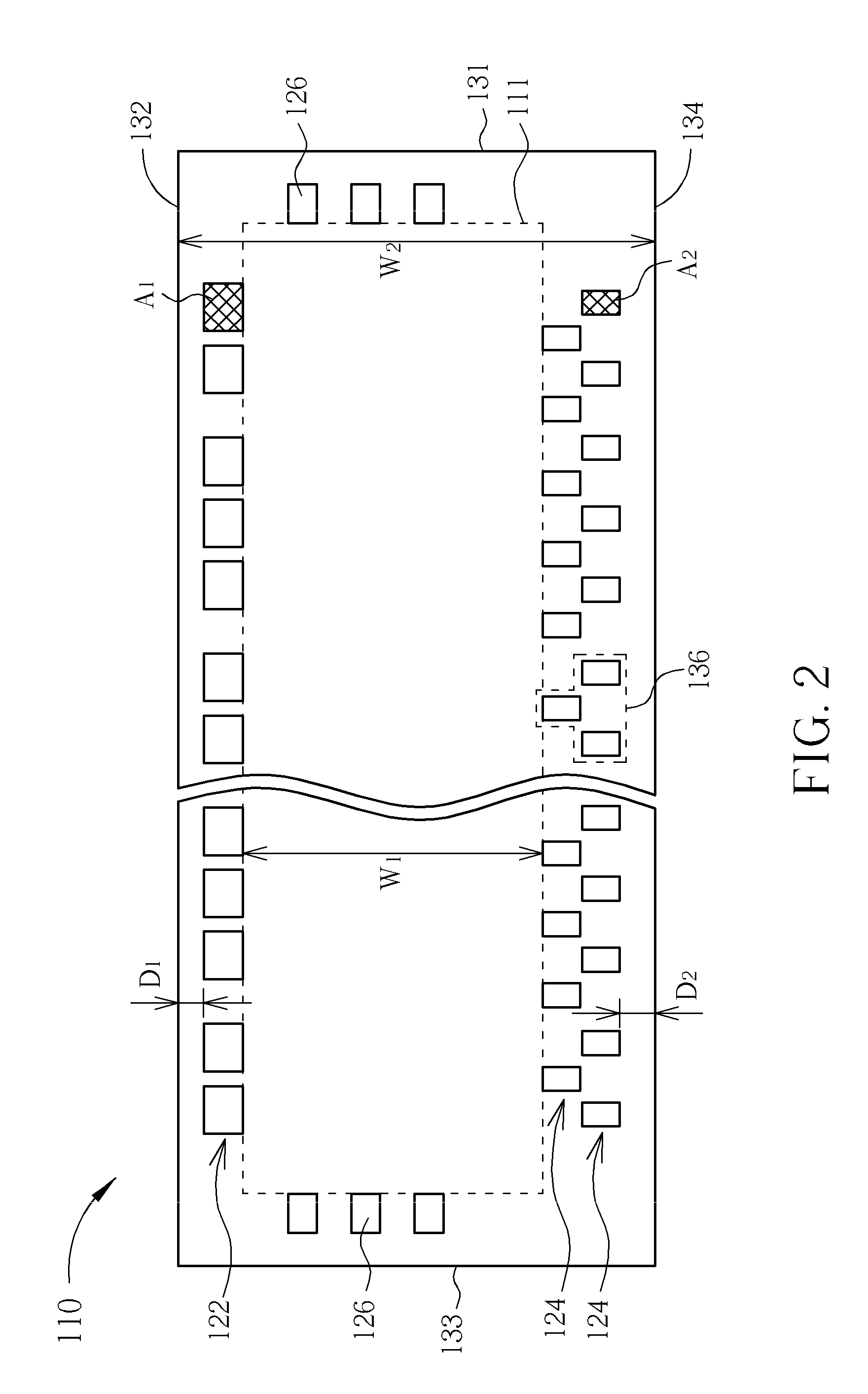

A chip having a bump layout suitable for the chip on glass technology and a driving IC includes a plurality of first bumps and a plurality of second bumps for electrically connecting to a glass substrate of a displayer. The first and second bumps are disposed on a surface of the chip and near two opposite long sides of the chip respectively. The ratio of the total contacting area of the first bumps to that of the second bumps is between 0.8 and 1.2. Thus, a pressure applied on the chip and the glass substrate of the displayer for connection can be uniformly exerted all over the chip, and the stability of the connection is therefore improved.

Owner:HANNSTAR DISPLAY CORPORATION

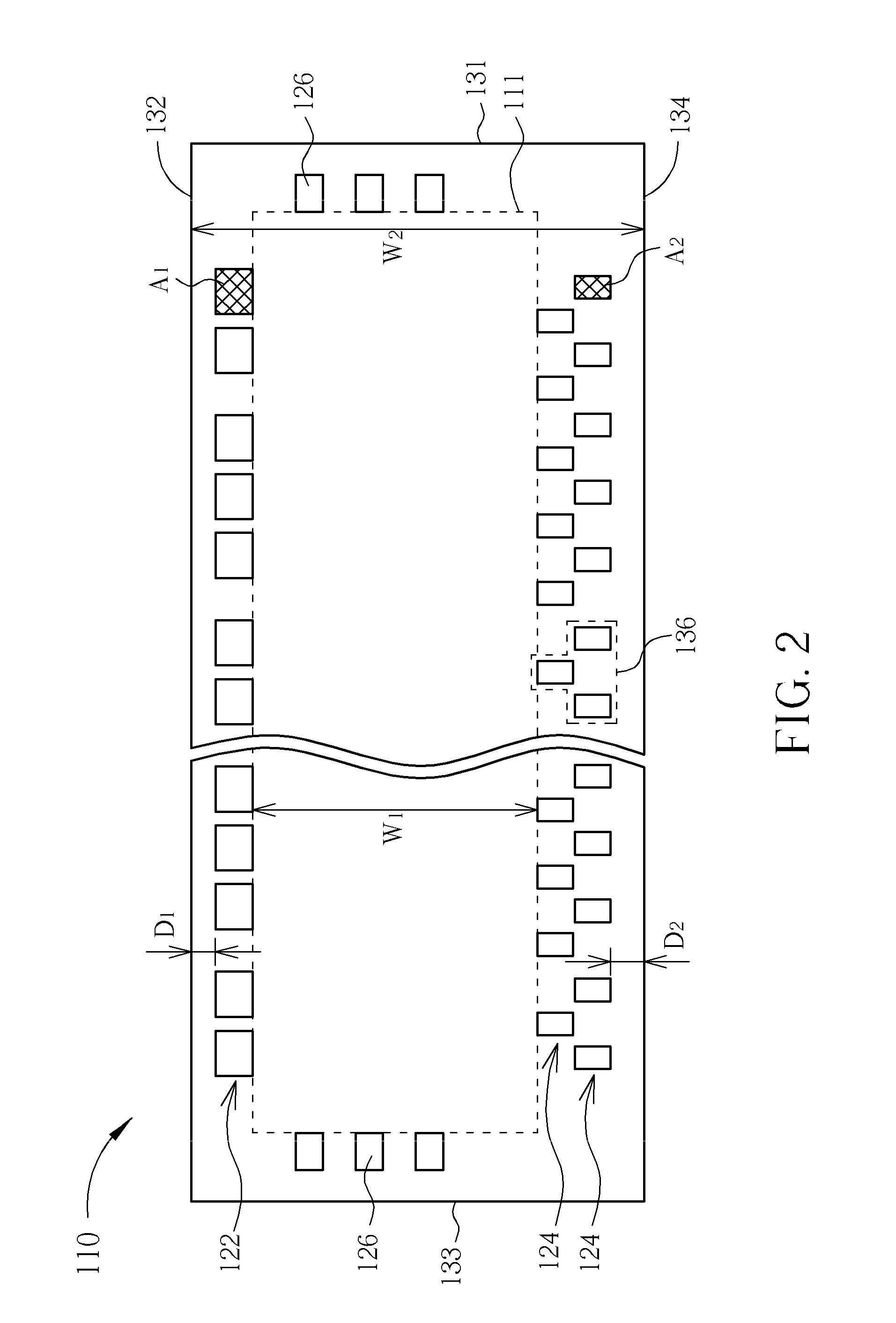

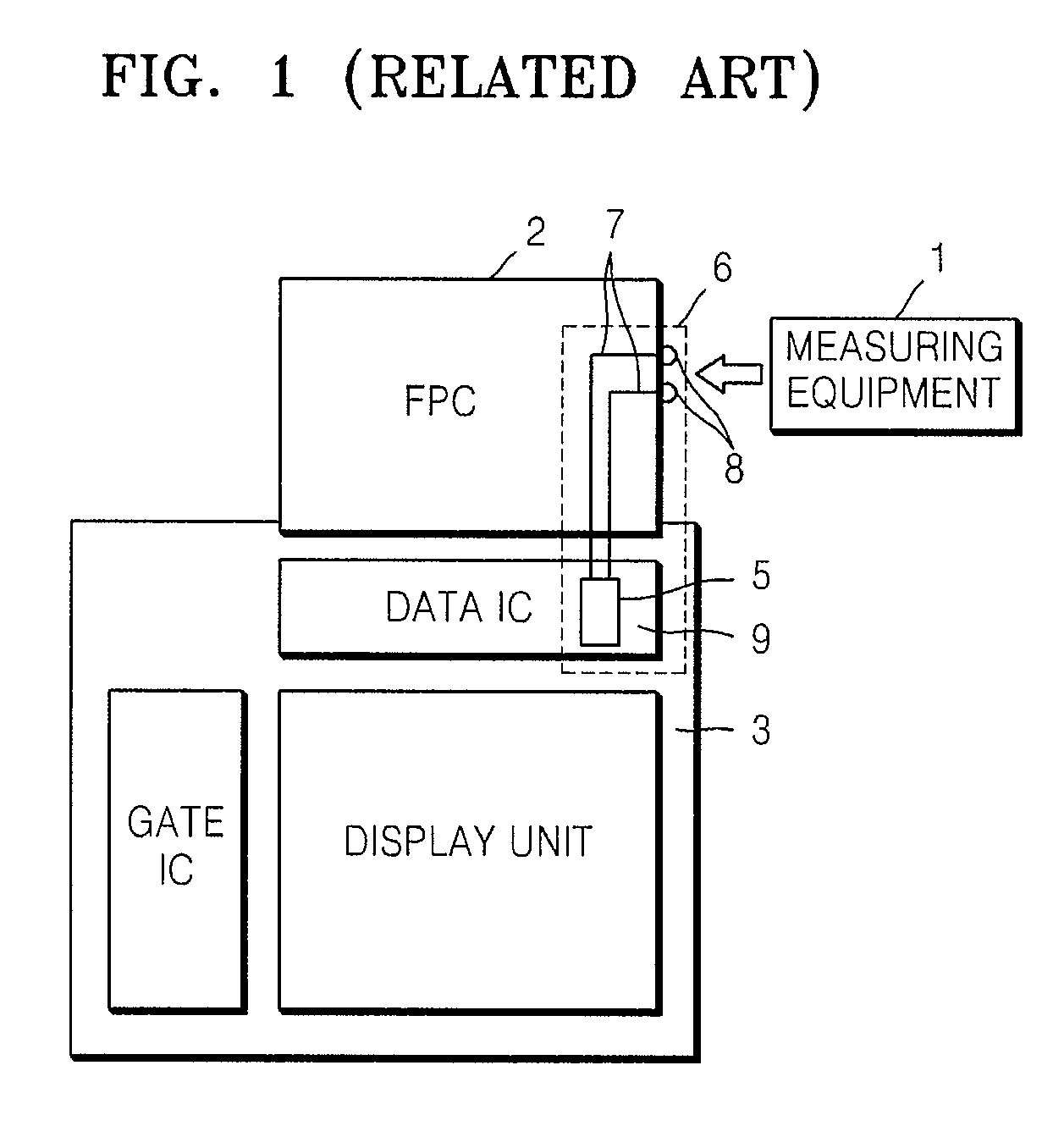

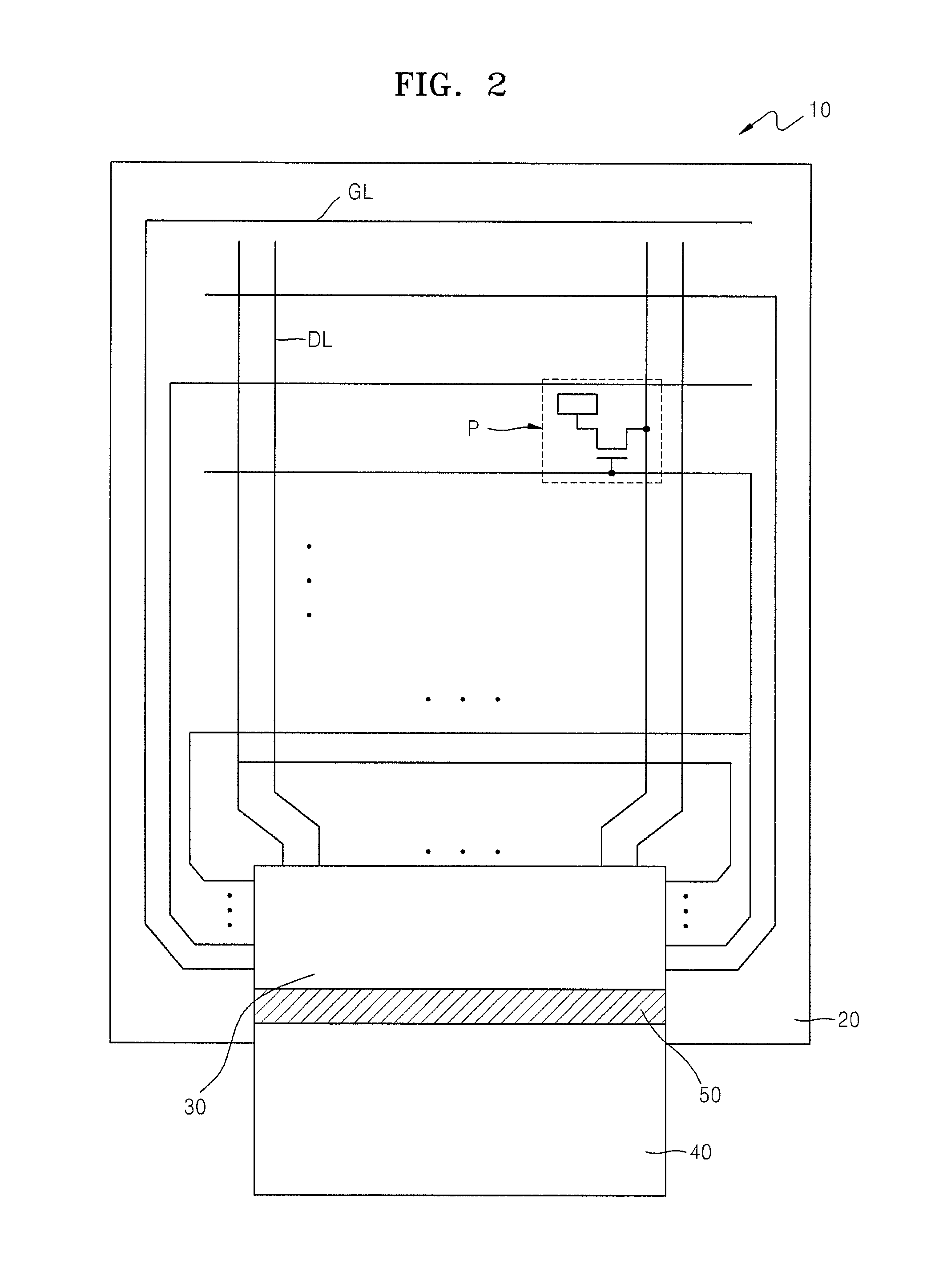

Chip on glass type LCD device and inspecting method of the same

ActiveUS20110018571A1Inhibition effectStatic indicating devicesNon-linear opticsData connectionLiquid crystal

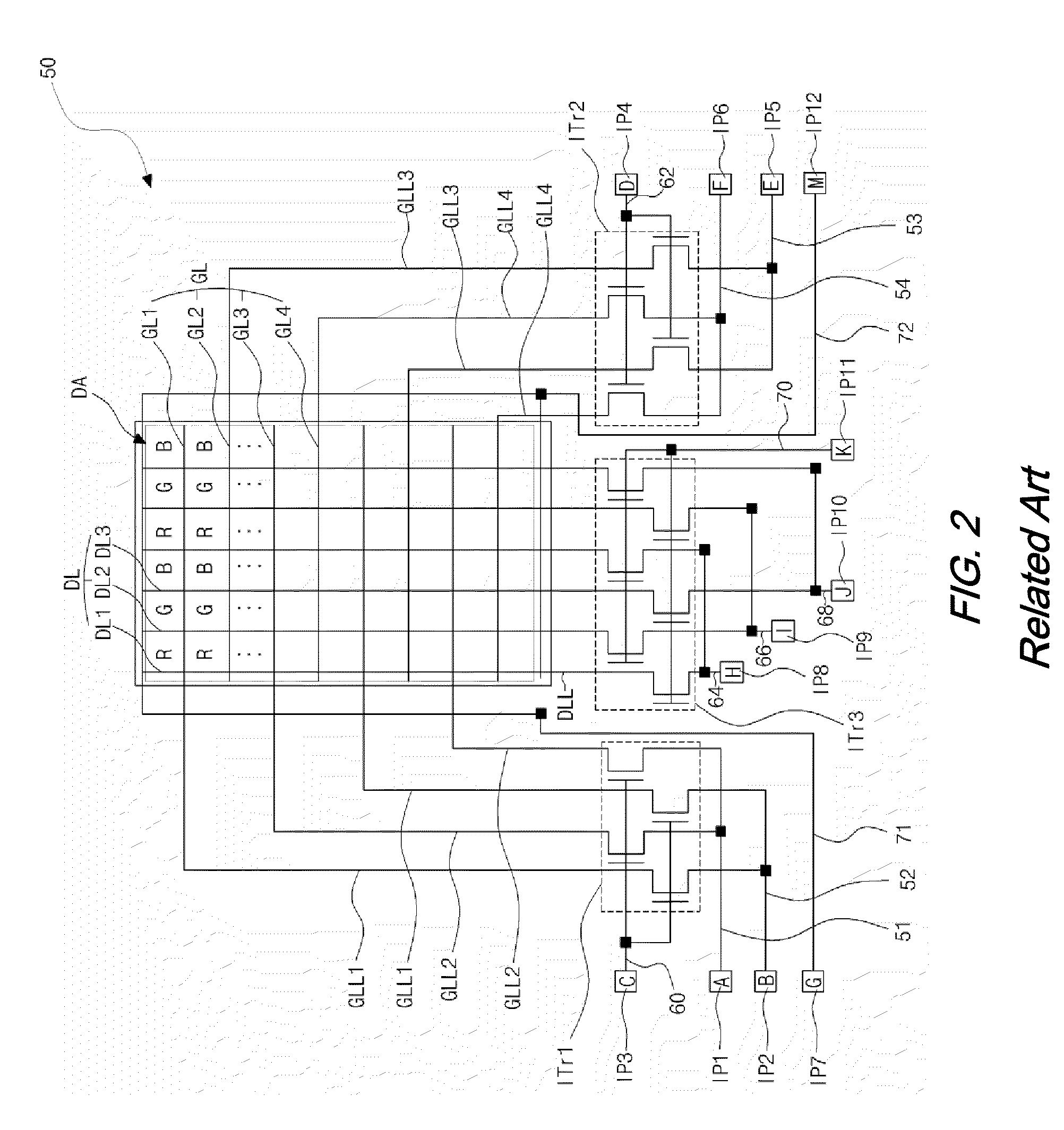

A COG type LCD device includes a first substrate including a display area and first, second, third and fourth non-display areas, gate and data lines in the display area on the first substrate and defining pixel regions, switching thin film transistor at each crossing portion of the gate and data lines and connected to the gate and data lines, a pixel electrode in each pixel region and connected to the thin film transistor, first testing thin film transistors in the second non-display area connected to the data lines and spaced apart from each other with a constant interval therebetween, first, second and third data testing lines connected to one ends of the data lines through the first testing thin film transistors, first, second and third data testing pads connected to the first, second and third data testing lines, respectively, data link lines in the first non-display area and connected to another ends of the data lines, second testing thin film transistors in the first non-display area and connected to the data link lines, gate link lines connected to the gate lines, third testing thin film transistors connected to the gate link lines, gate testing lines connected to the gate lines through the third testing thin film transistors, gate testing pads connected to the gate testing lines, a common testing line and a common pad in the non-display area, a second substrate spaced apart from the first substrate, a color filter layer and a common electrode sequentially formed on the second substrate, wherein the common electrode is connected to the common testing line, and a liquid crystal layer between the first and second substrates, wherein a driving IC is attached in the first non-display area.

Owner:LG DISPLAY CO LTD

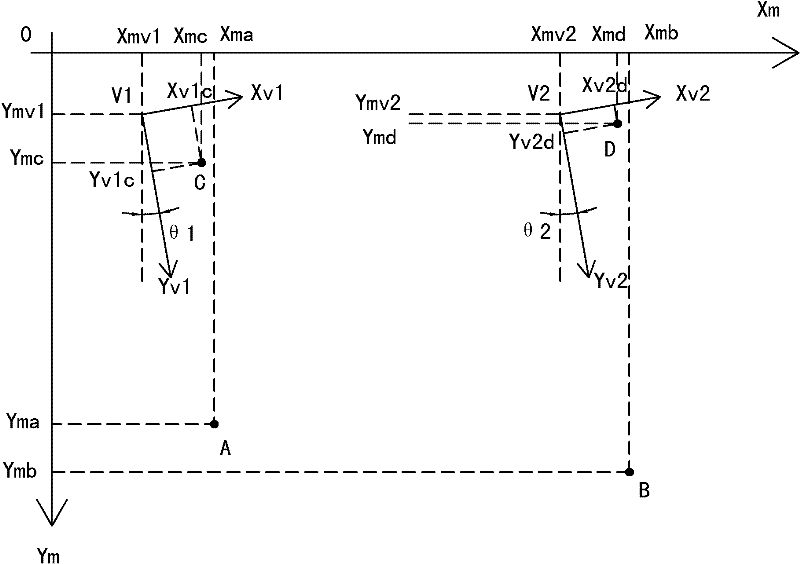

Alignment method for attaching chip or flexible circuit board to circuit substrate

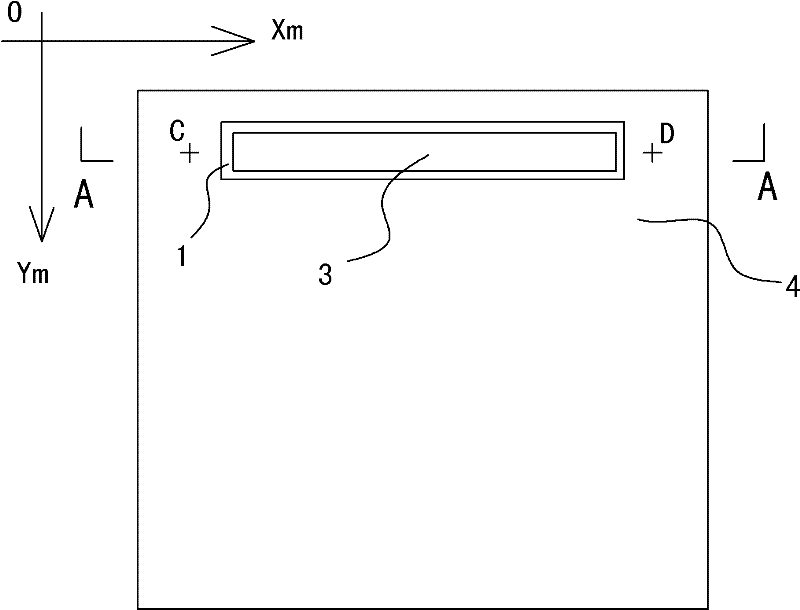

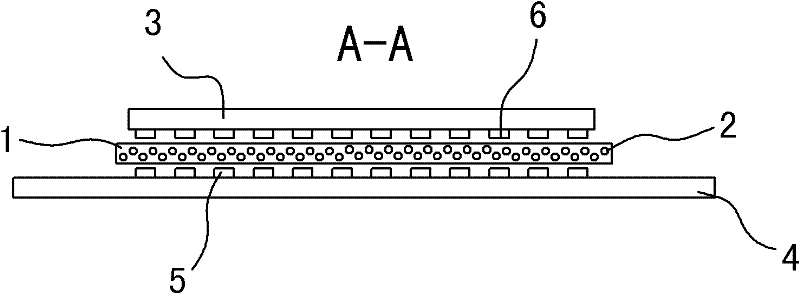

ActiveCN102164460AImprove alignment accuracyGuaranteed alignmentPrinted circuit assemblingSemiconductor/solid-state device testing/measurementChip on filmImaging processing

The invention discloses an alignment method for attaching a chip or a flexible circuit board to a circuit substrate, which is characterized by comprising the following steps of: designing two identification points on the circuit substrate in advance; after the circuit substrate is transferred to a framing table board and positioned, shooting images of the two identification points by using a camera, converting the images of the two identification points into position coordinates of an image coordinate system by using an image processing system; converting image coordinates of the two identification points into mechanical coordinate values of a mechanical coordinate system by using a relationship between the image coordinate system and the mechanical coordinate system; finding out an X-directional offset, a Y-directional offset and a deflection angle around a Z axis between the actual positions of the two identification points and a target position through calculation; and finally adjusting the two identification points to the target position by using an X-directional movement mechanism, a Y-directional movement mechanism and a rotating mechanism around the Z axis, so that the chip or the flexible circuit board is aligned with a conducting terminal of the circuit substrate. By the invention, the alignment precision of a chip on glass (COG), a film on glass (FOG) and a chip on film (COF) is greatly improved.

Owner:苏州凯蒂亚半导体制造设备有限公司

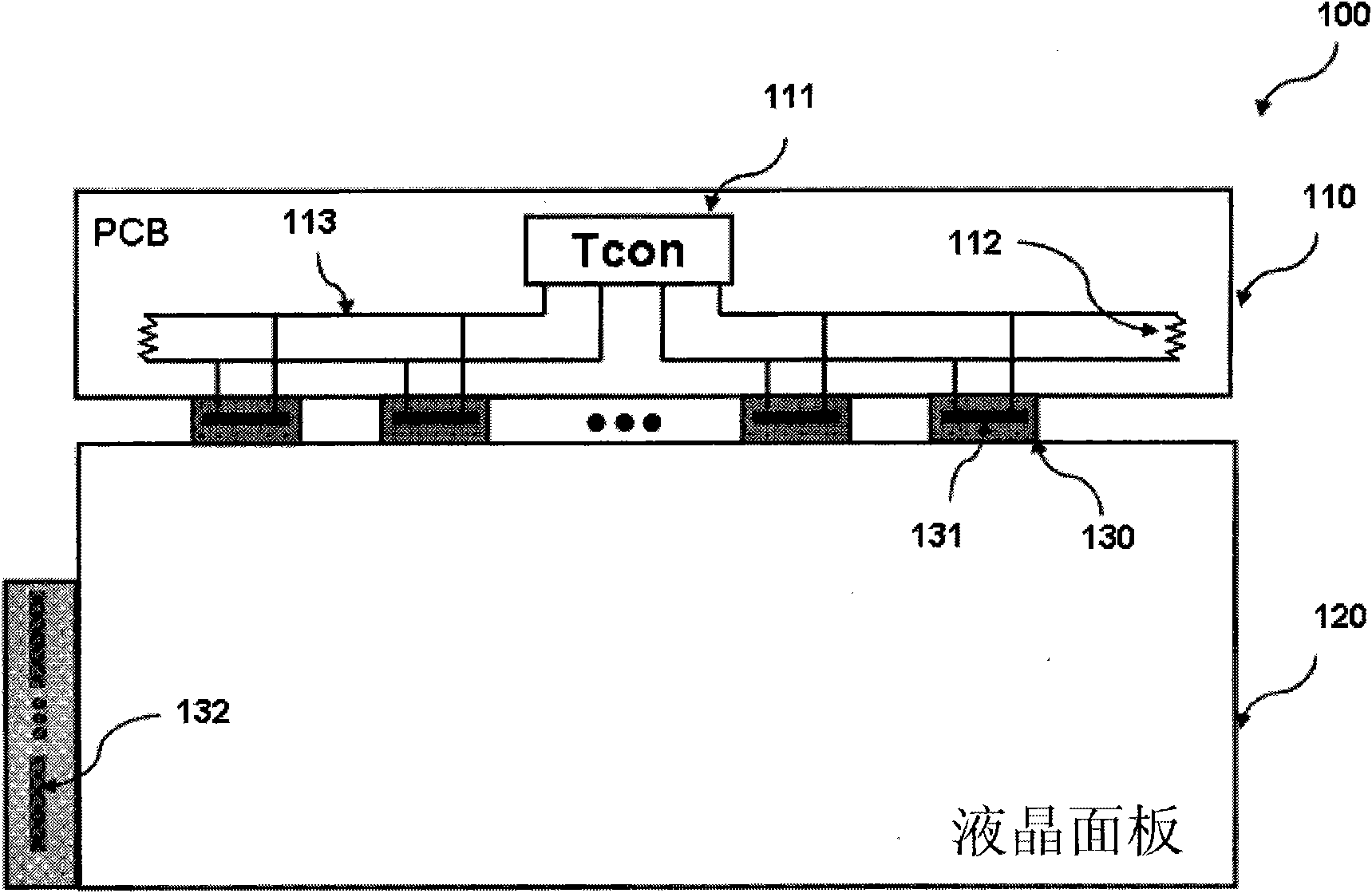

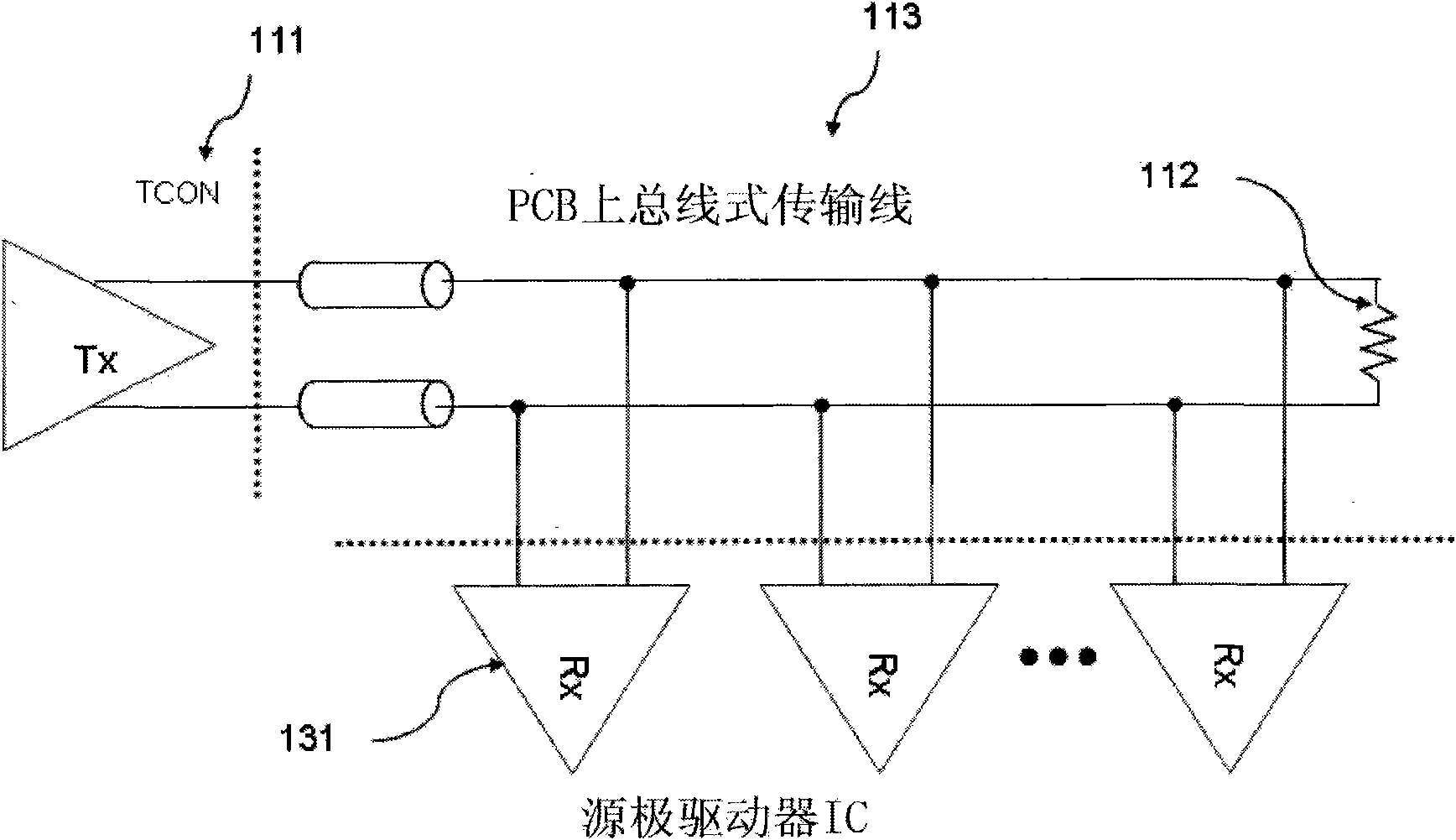

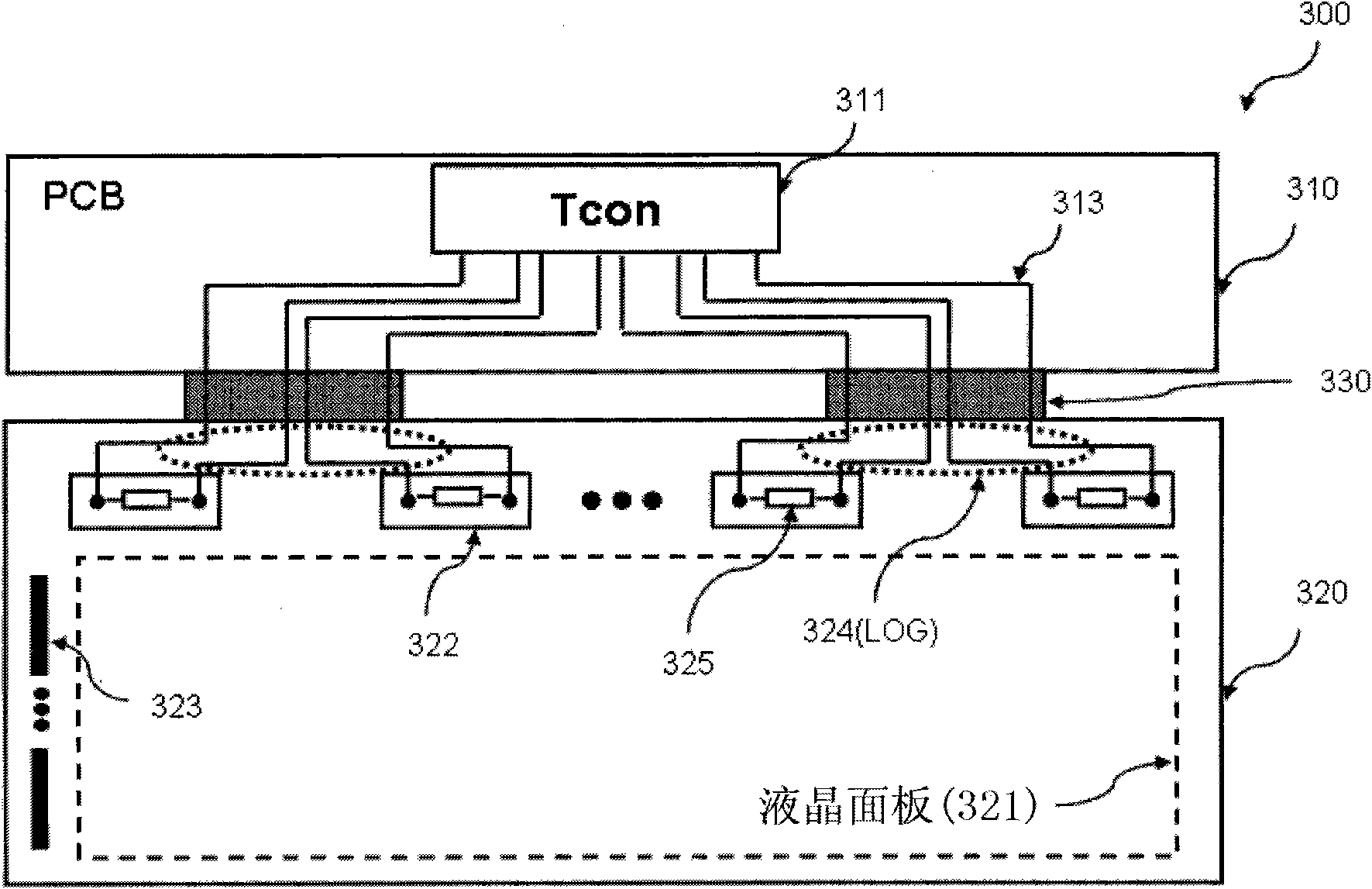

Chip-on-glass (COG) type liquid crystal display device

InactiveCN102254523AReduce reflected wavesAvoid distortionStatic indicating devicesNon-linear opticsImpedance matchingFrequency characteristic

Provided is a chip-on-glass (COG) type liquid crystal display device minimizes a reflected wave from an input terminal of a source driver IC, regardless of the resistance value of a transmission line on a glass substrate, through the use of impedance matching at a front terminal of an LOG and impedance matching at an output terminal of a timing controller, thereby enhancing the frequency characteristic while maintaining a slim and lightweight design, so that it is possible to express a high-resolution high-quality image.

Owner:SILICON WORKS CO LTD

Pad area and method of fabricating the same

ActiveUS20070076393A1Overcome problemsFinal product manufacturePrinted circuit aspectsElectrical connectionInterconnection

A pad area and a method of fabricating the same, wherein the pad area is formed on a substrate to contact a chip on glass (COG) or a chip on flexible printed circuit (COF) with the substrate. Changing a lower structure of the pad area increases contact points between conductive balls and an interconnection layer or reduces a step difference between an interconnection layer and a passivation layer to enhance and ensure electrical connection.

Owner:SAMSUNG DISPLAY CO LTD

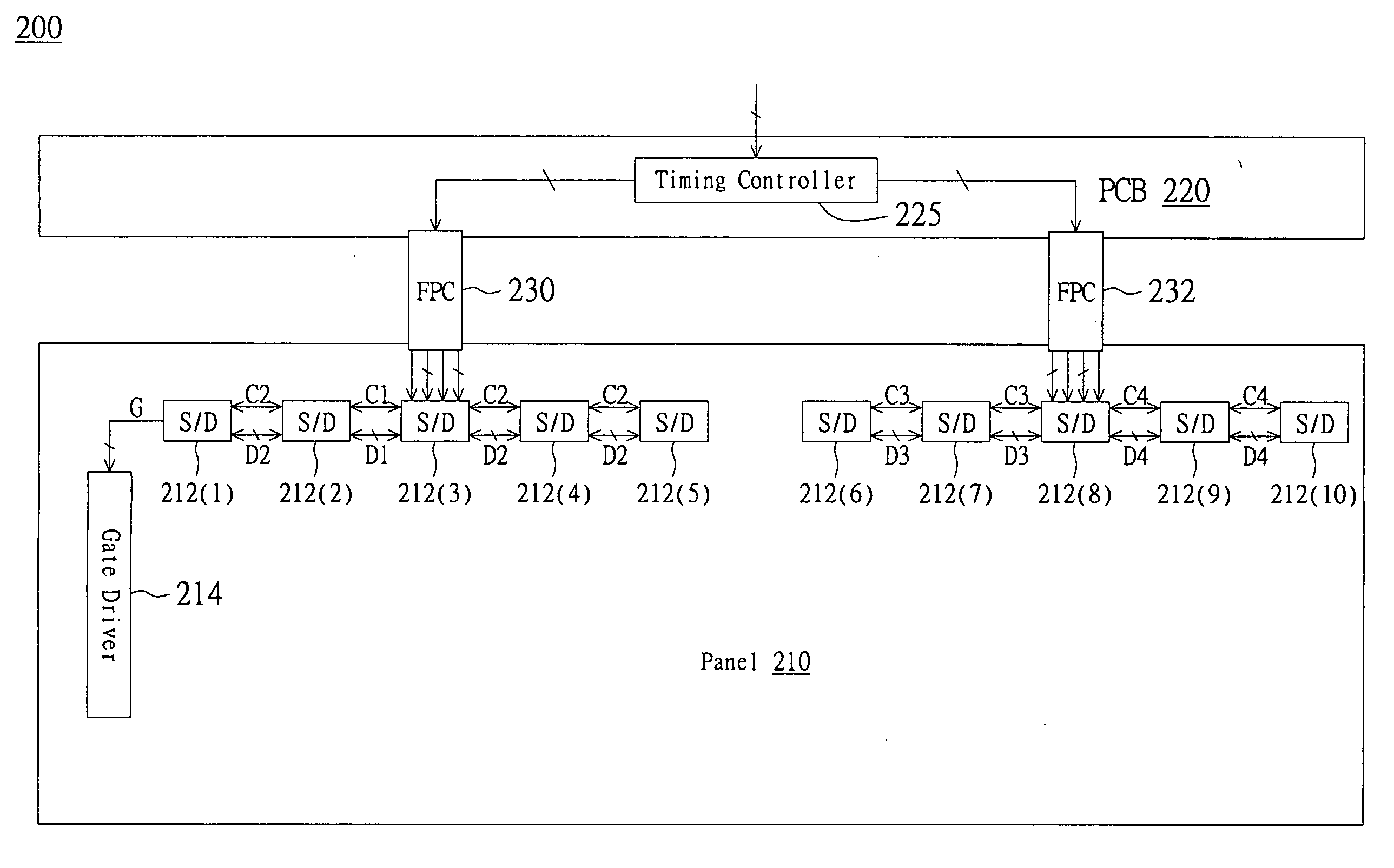

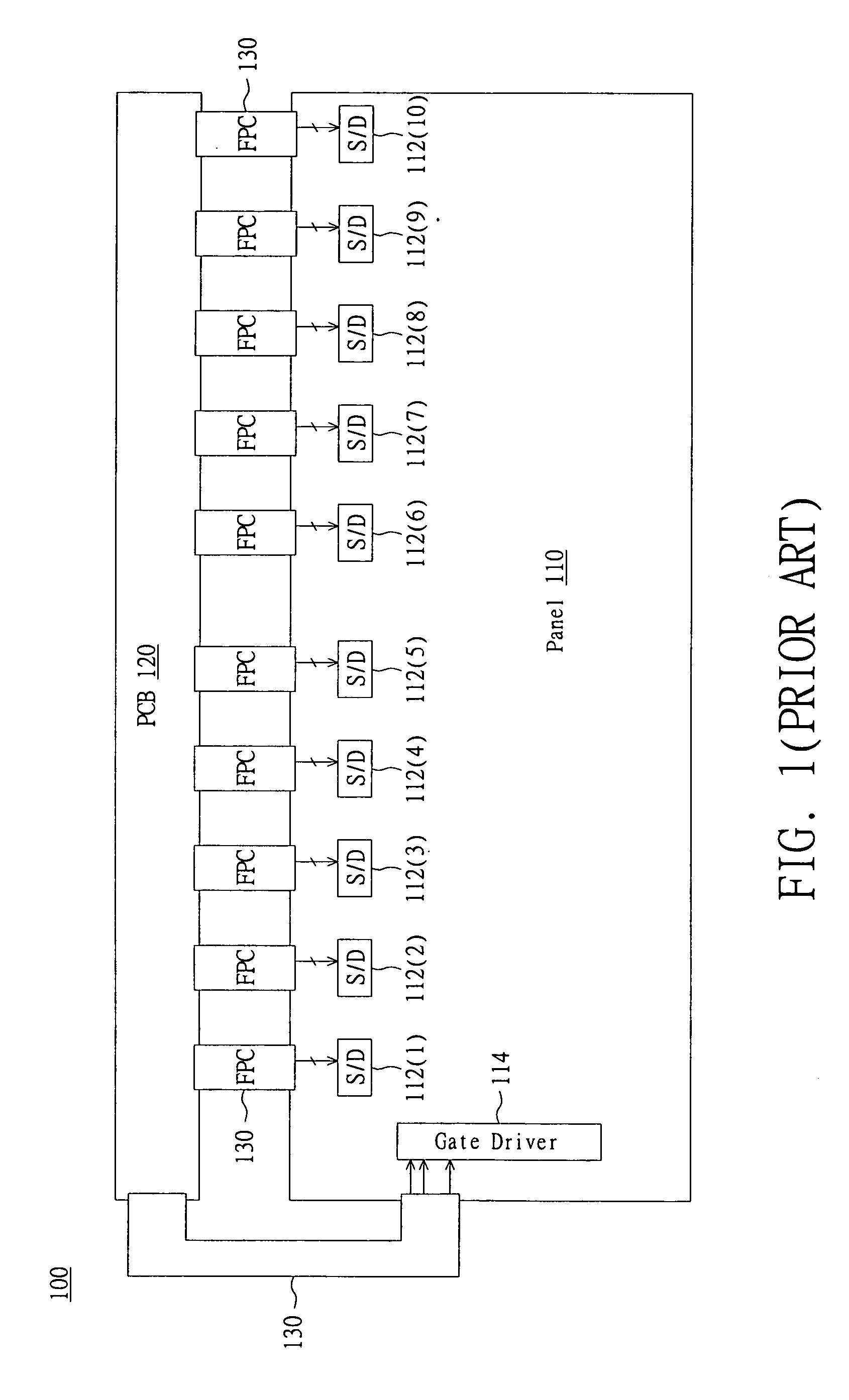

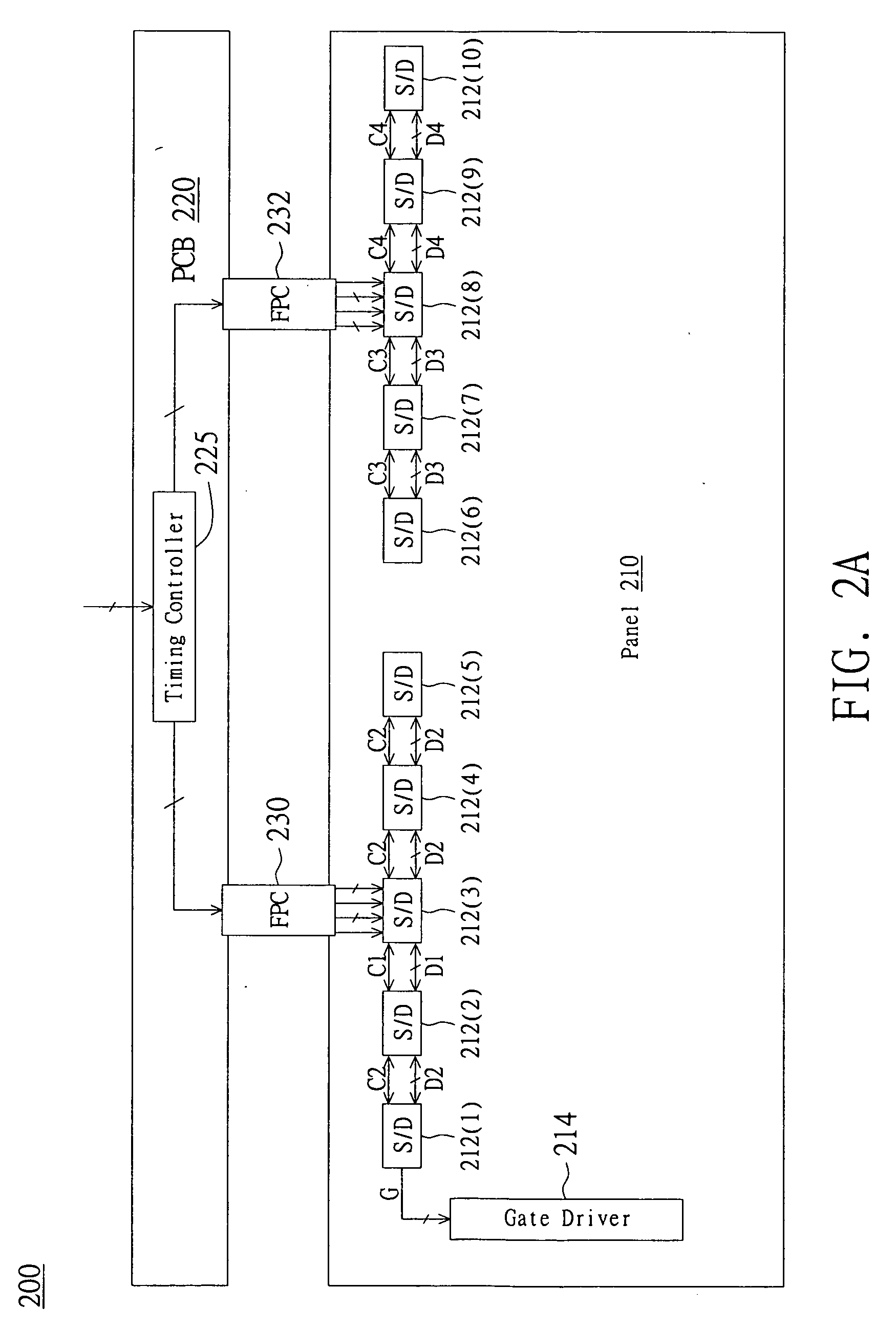

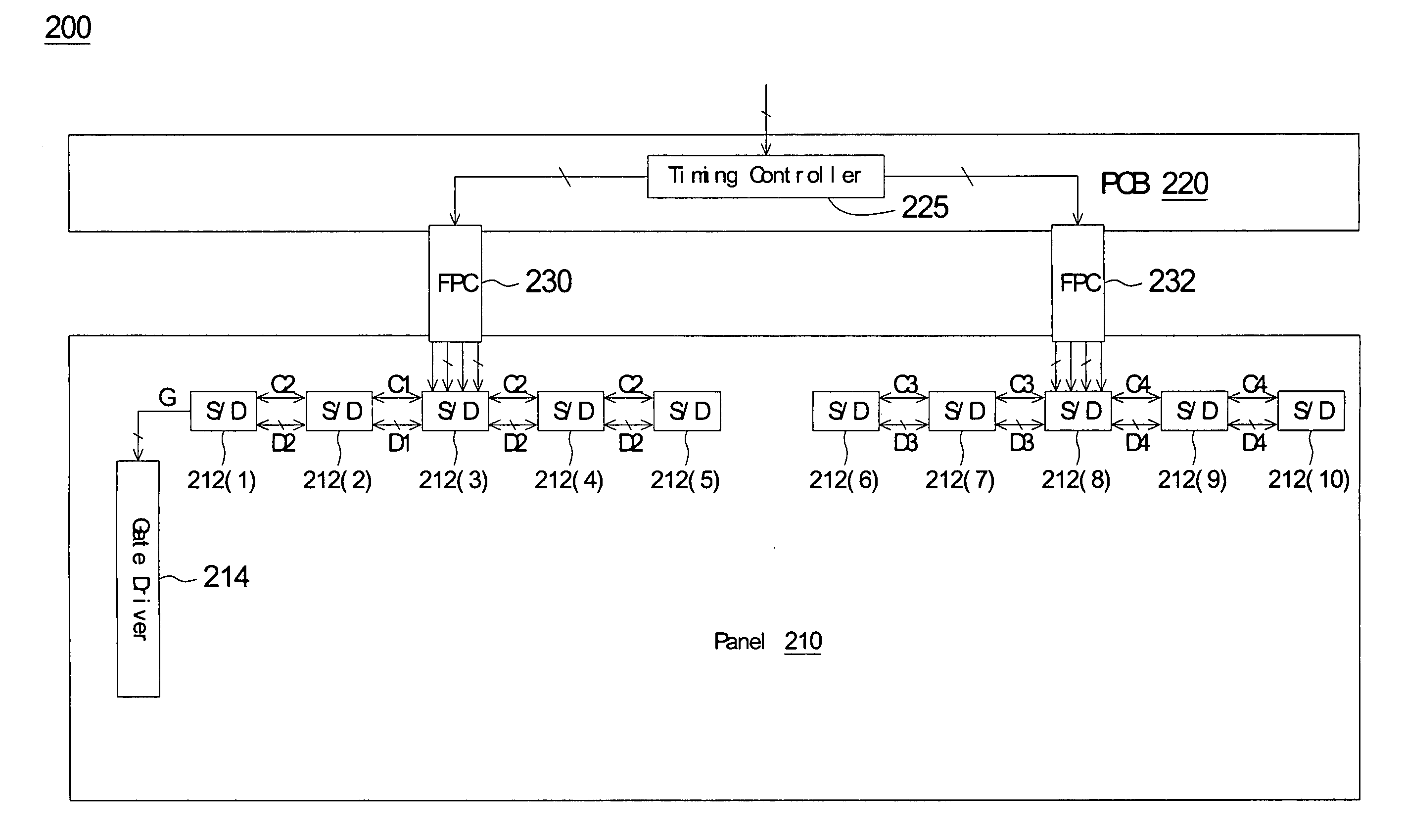

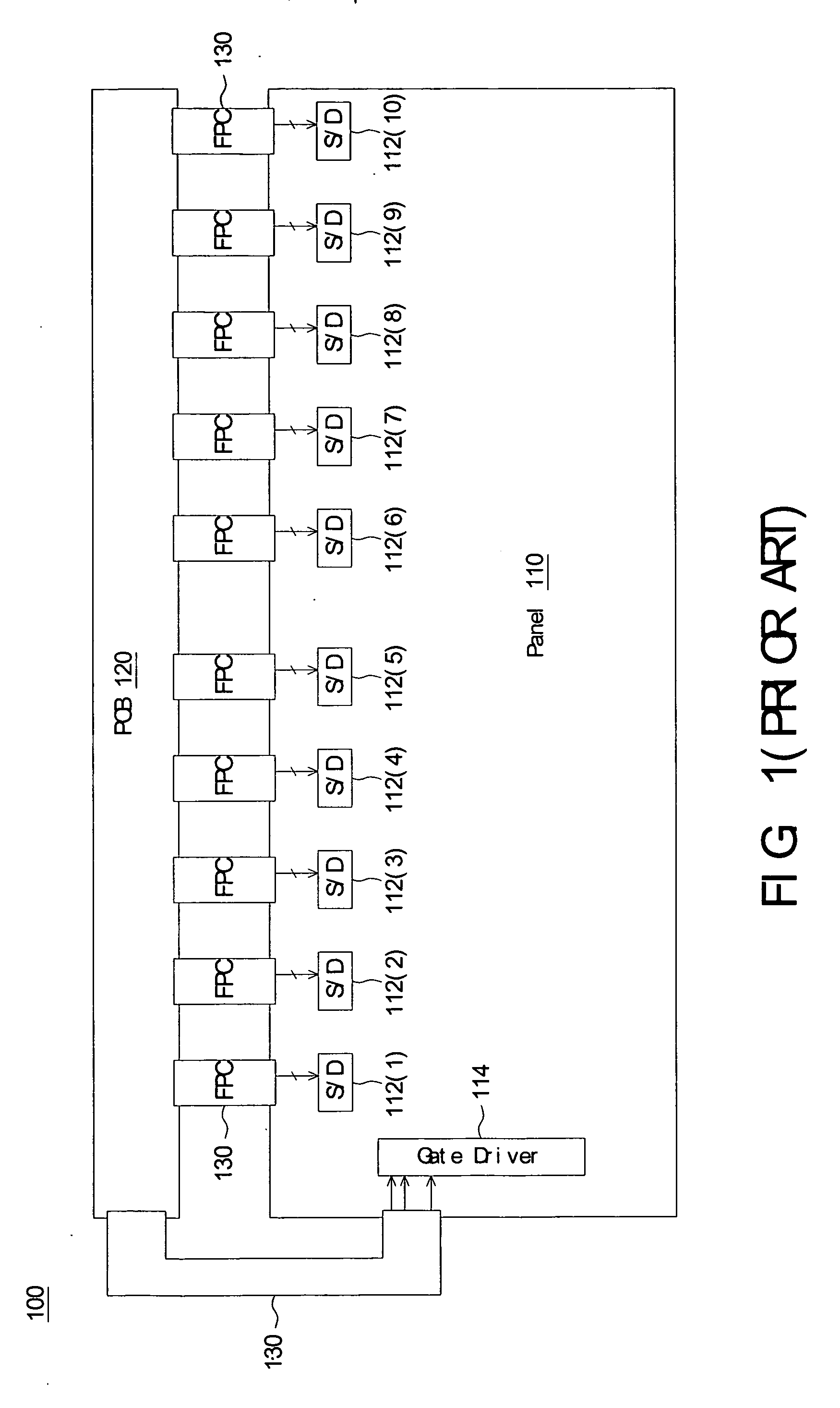

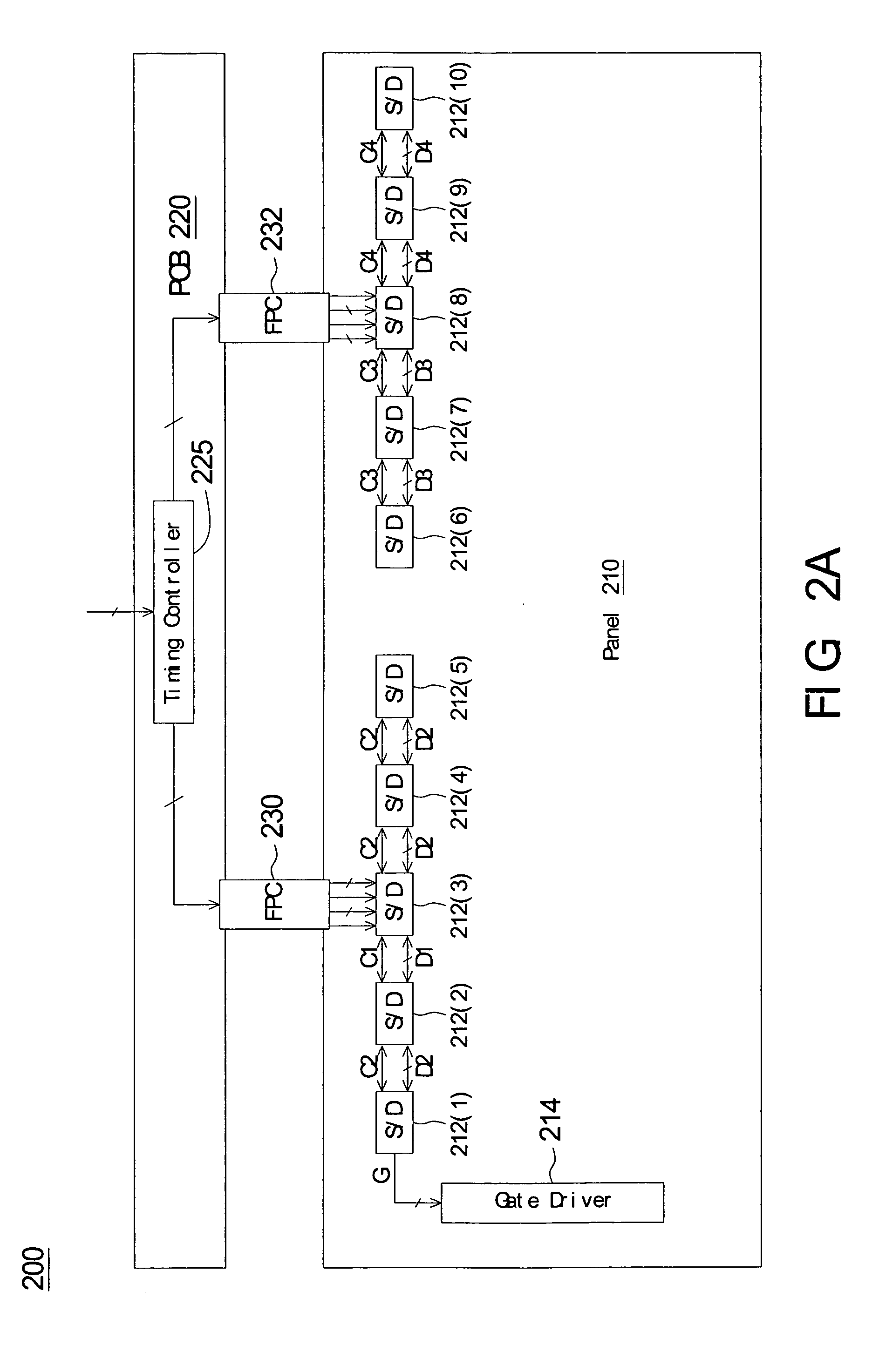

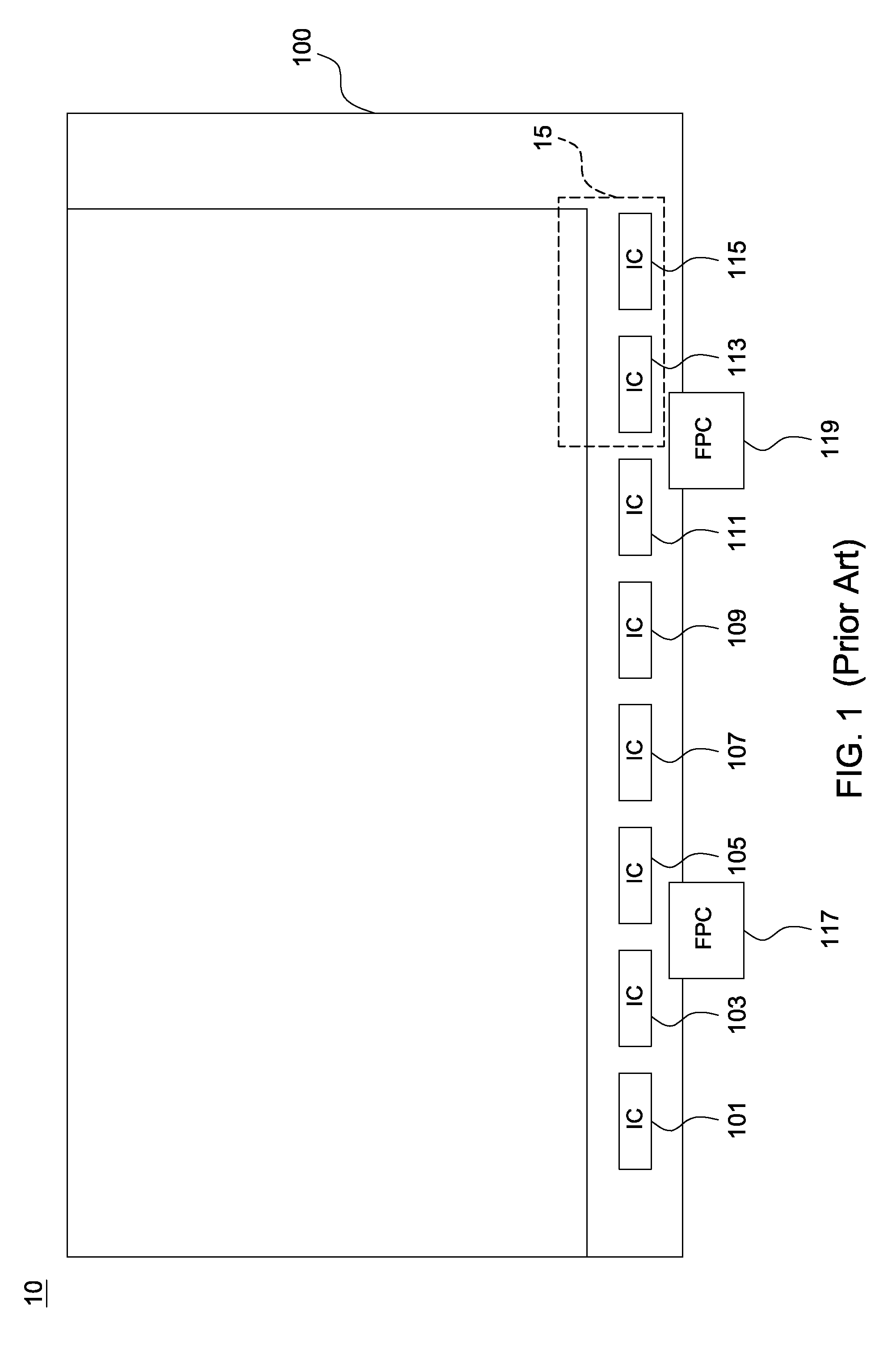

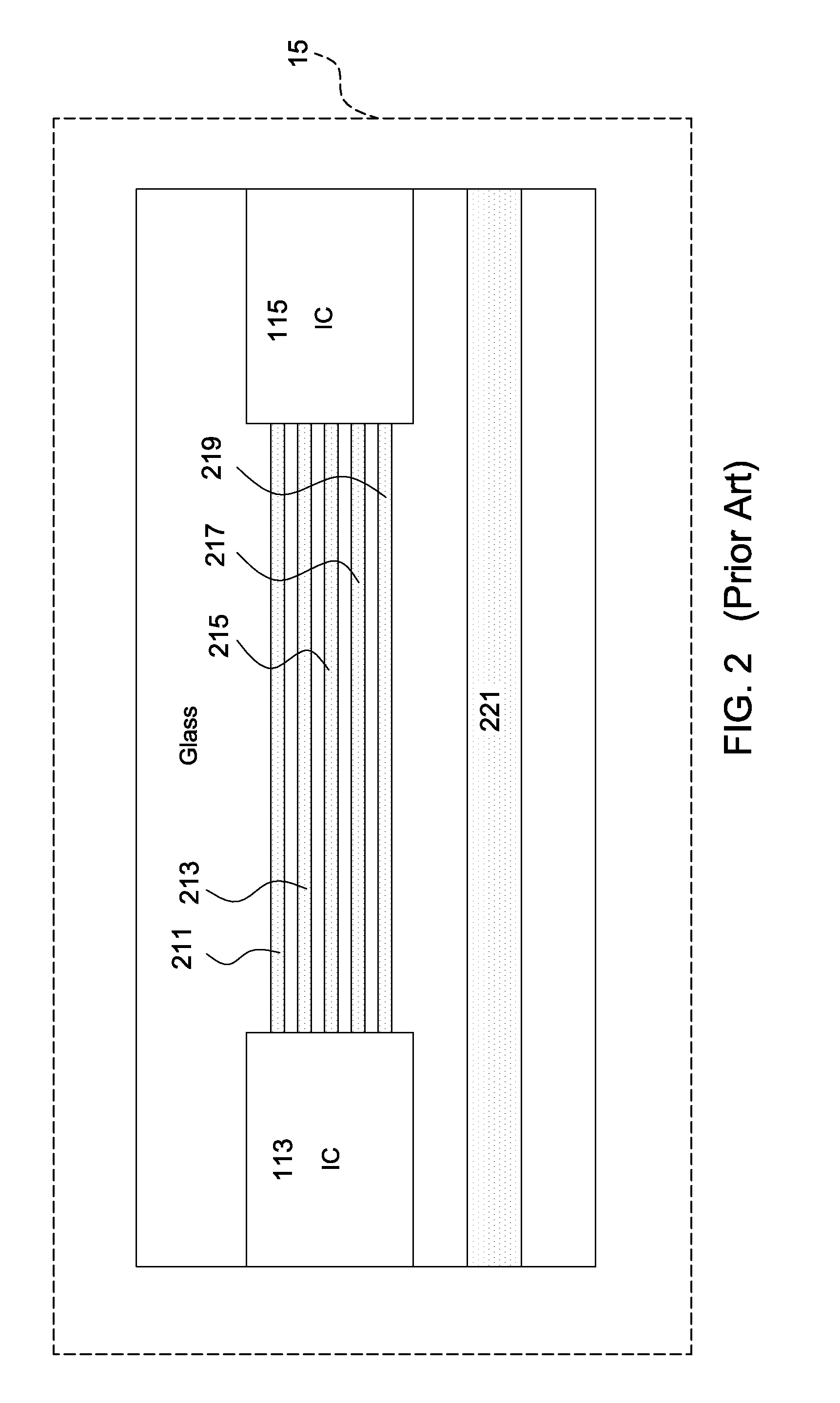

Chip-on-glass liquid crystal display and data transmission method for the same

ActiveUS20060202936A1Batteries circuit arrangementsStatic indicating devicesDisplay deviceFlexible electronics

A display implemented with a unique circuit arrangement. The display includes a glass substrate, a plurality of serial-connected source drivers and at least one gate driver. The source drivers and the at least one gate driver are disposed on the glass substrate using, for example, chip-on-glass technology. The display further includes at least one flexible connector, such as a flexible printed circuit board. Each of the at least one flexible connector corresponds to a selected one of the source drivers. The selected one of the source drivers is configured to receive image data and control information from the corresponded flexible connector, and convey the image data and the control information to at least one neighboring source driver.

Owner:HIMAX TECH LTD

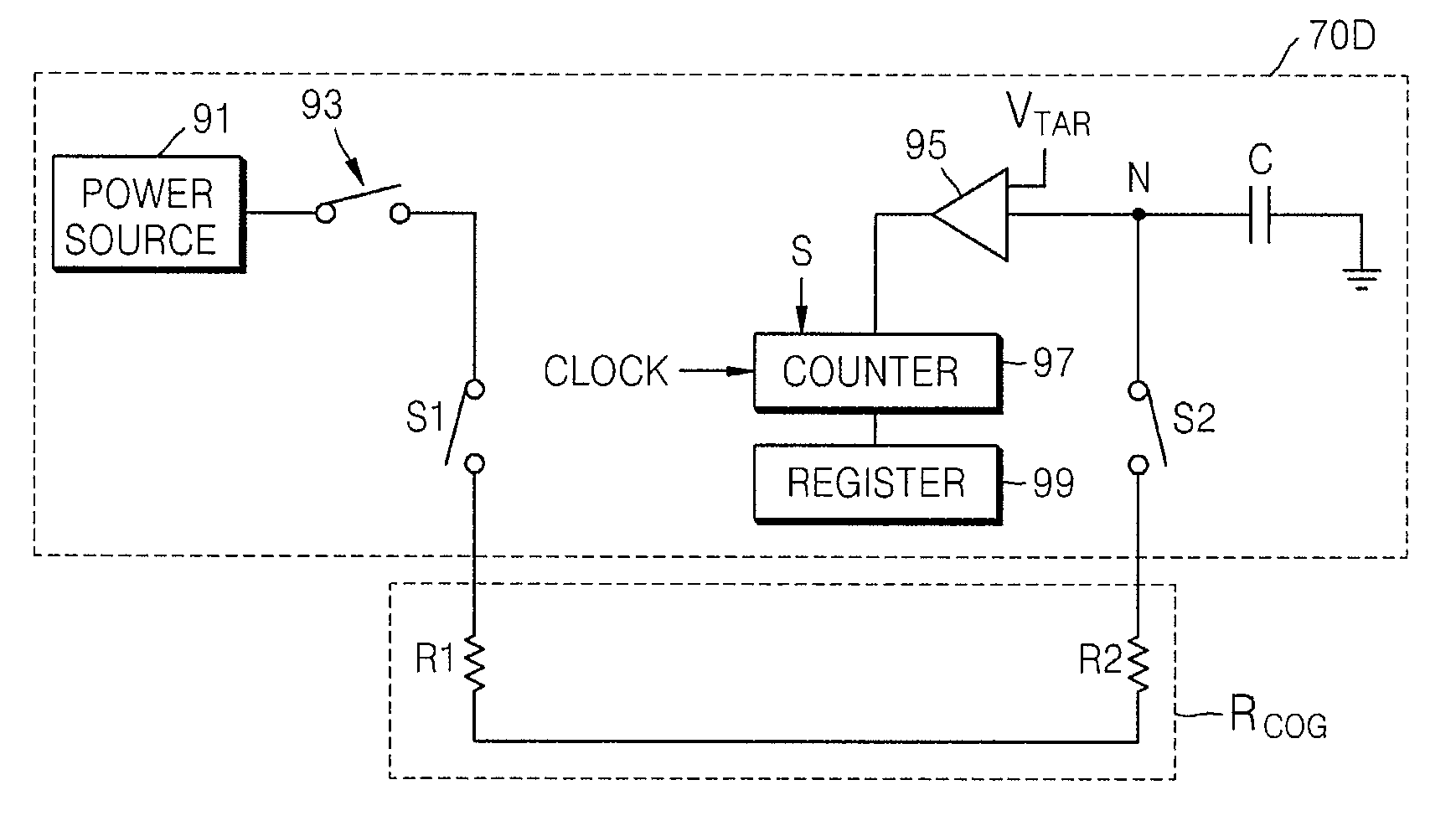

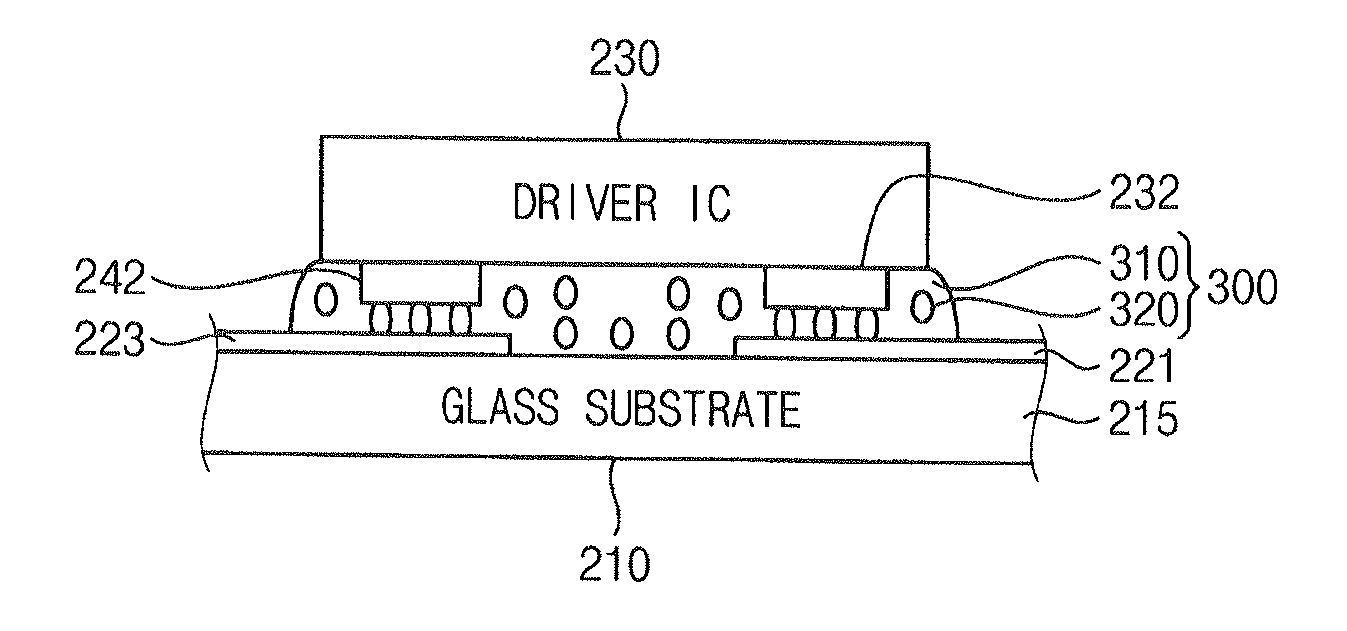

Driving Integrated Circuit and Display Apparatus Including the Same

A driving integrated circuit (driving IC) connected to a display panel by a chip on glass (COG) method includes a pair of bumps electrically coupled to a test pad of the display panel; a power source electrically coupled to a first bump of the pair of bumps; a circuit device electrically coupled between a ground terminal and a second bump of the pair of bumps; and a node measuring unit for measuring a voltage at a node between the second bump and the circuit device.

Owner:SAMSUNG DISPLAY CO LTD

Ultraviolet (UV)/moisture dual-cured laminated adhesive and preparation method thereof

InactiveCN102559121AFast curingImprove efficiencyPolyureas/polyurethane adhesivesModified epoxy resin adhesivesDual cureAdhesive

The invention discloses an ultraviolet (UV) / moisture dual-cured laminated adhesive and a preparation method thereof. The UV / moisture dual-cured laminated adhesive is prepared by mixing ultraviolet-curable (methyl) acrylate resin, moisture-curable modified (methyl) acrylate resin, a (methyl) acrylic reactive diluent, a moisture-curable (methyl) acrylic reactive diluent, a photoinitiator and a catalyst in an appropriate formula ratio. Compared with a moisture-cured laminated adhesive, the invention has the advantages that: the UV / moisture dual-cured laminated adhesive is quickly cured, the efficiency is high, and the production cost is reduced. Compared with a UV-cured laminated adhesive, the UV / moisture dual-cured laminated adhesive has the advantages that: the disadvantage that a shaded part cannot be cured is overcome; and the protection effect of glue is improved. According to the results, the adhesive fully meets the production process requirements of laminated adhesives which are applied to the protection of printed circuit boards (PCB) and laminated adhesives for the protection of chip on glass (COG).

Owner:TONSAN ADHESIVES INC

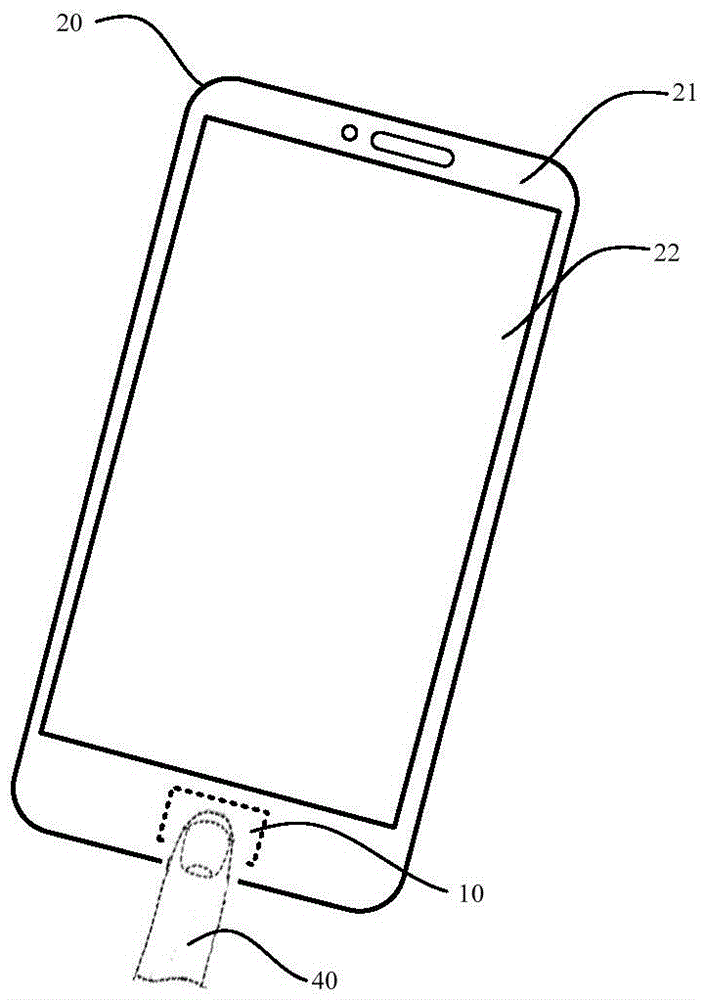

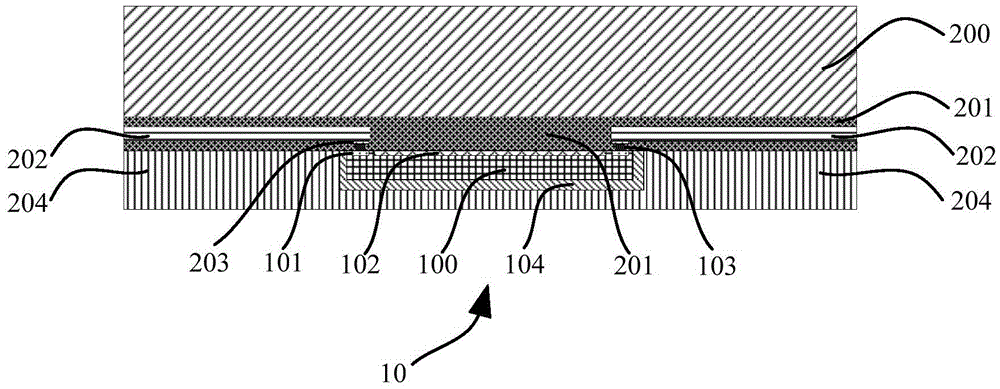

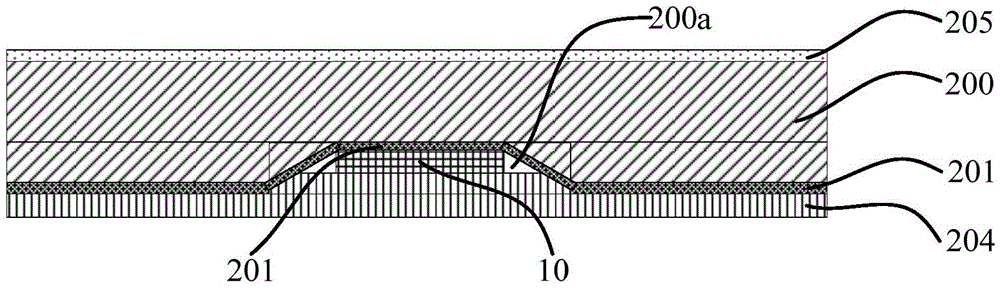

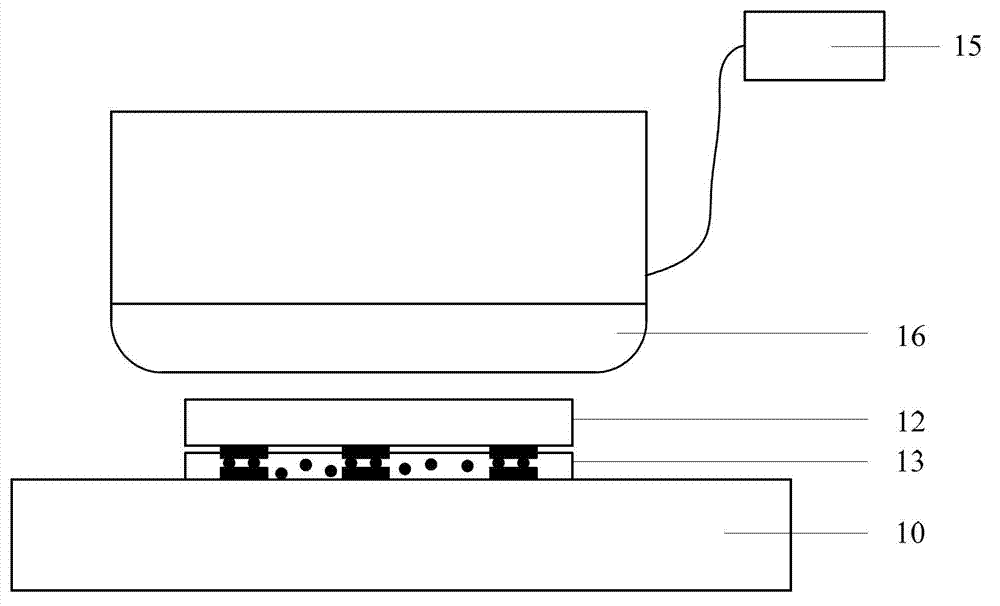

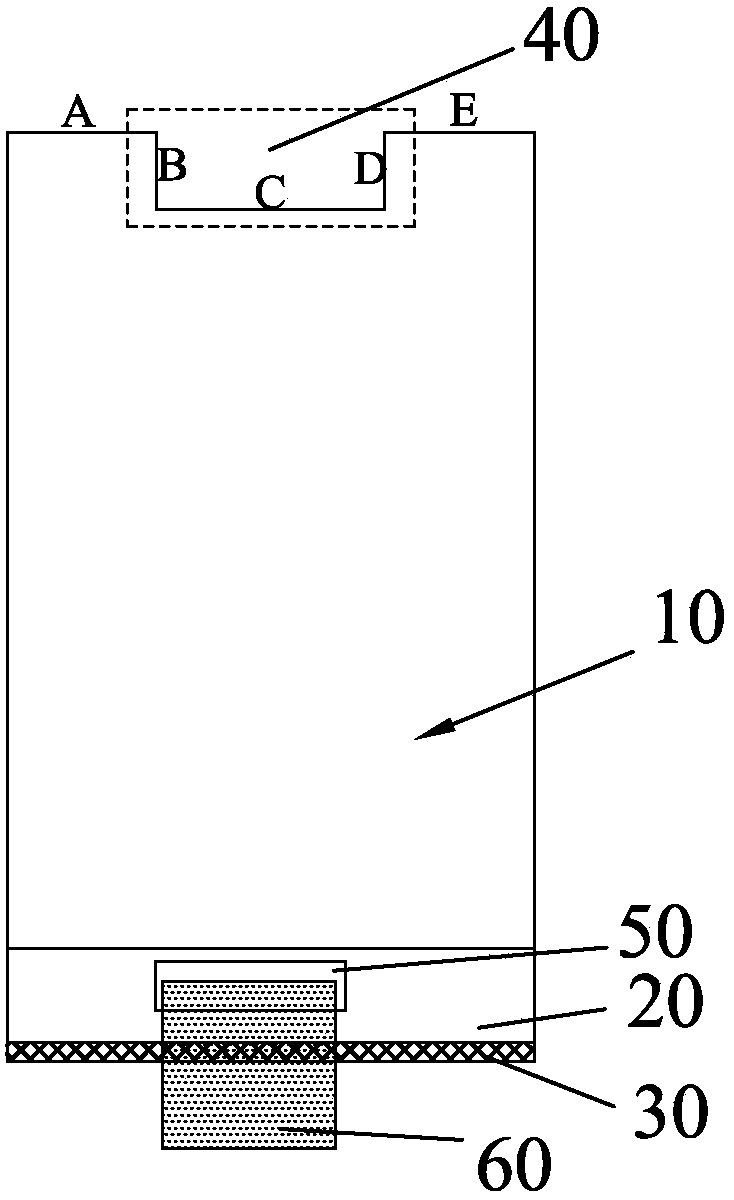

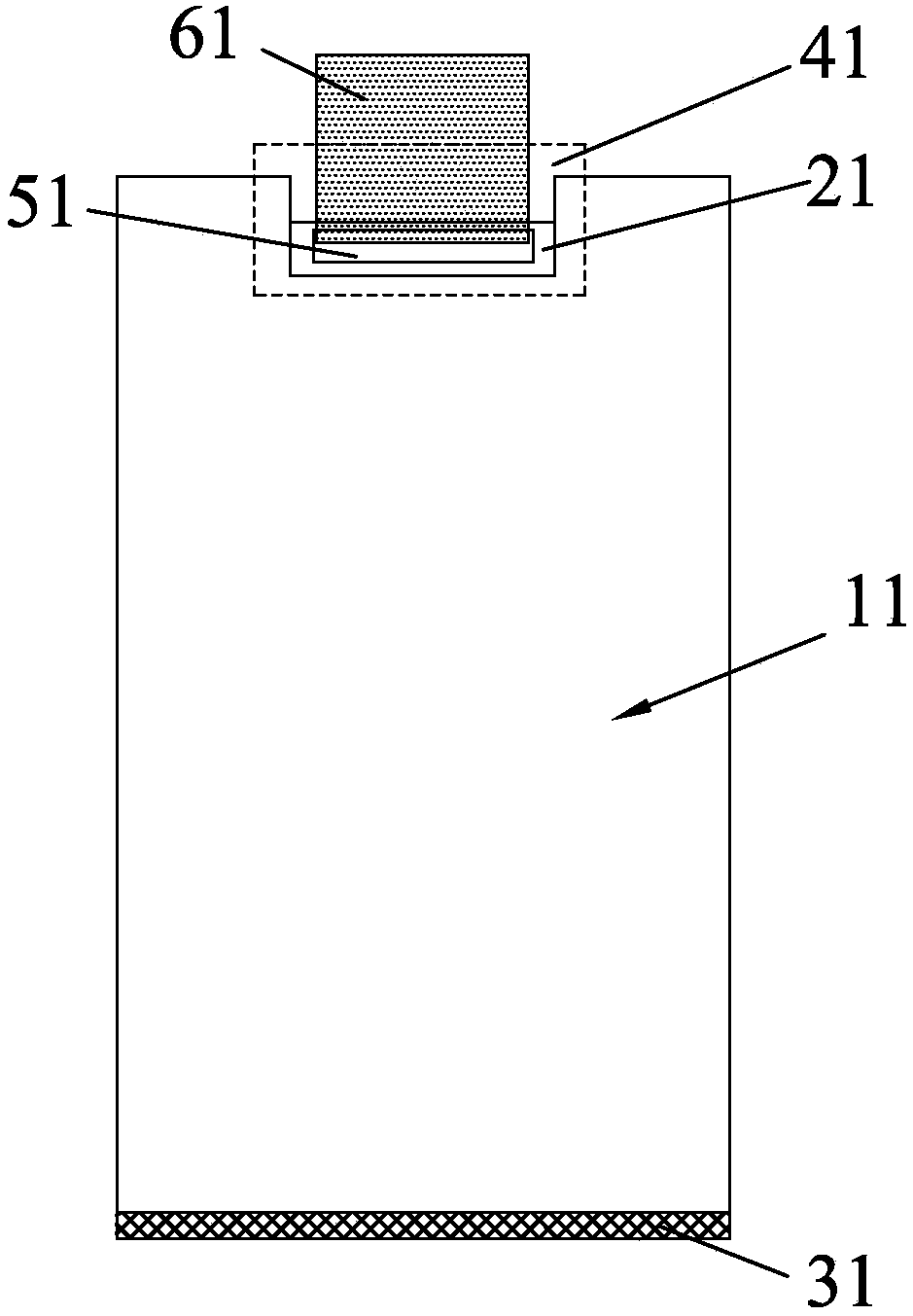

Mobile terminal with fingerprint sensor packaging structure

ActiveCN105631421AAvoid residueImprove inspection sensitivityPrint image acquisitionInput/output processes for data processingAnisotropic conductive filmManufacturing technology

The invention discloses a mobile terminal with a fingerprint sensor packaging structure. A capacitive semiconductor fingerprint sensor COG (Chip On Glass) packaging technology is adopted. The mobile terminal comprises a case, a display screen, a touch screen cover plate and a semiconductor capacitive fingerprint sensor. A touch screen module comprises the touch cover plate and a touch inductive sensor film. The touch screen cover plate covers the semiconductor capacitive fingerprint sensor through an anisotropic conductive film. Therefore, the semiconductor capacitive fingerprint sensor is arranged below the non-display area of the touch screen so as to achieve the objective of hiding the fingerprint sensor. The fingerprint sensor has extremely high detection sensitivity and can acquire a fingerprint image through the touch screen cover plate of a few hundred microns. Besides, the manufacturing technology of the standard COG packaging technology is adopted with no requirement for more modification of the touch screen production technology so that processing difficulty is reduced and efficiency is enhanced, and satisfaction of users in using the fingerprint identification sensor is enhanced.

Owner:SHANGHAI FINGER TECH CO LTD

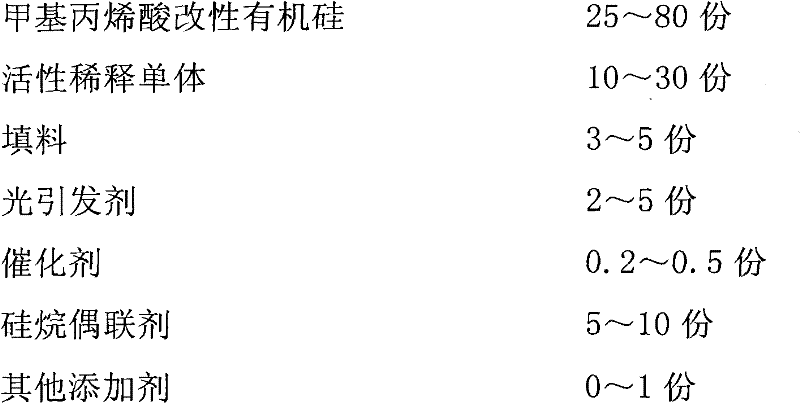

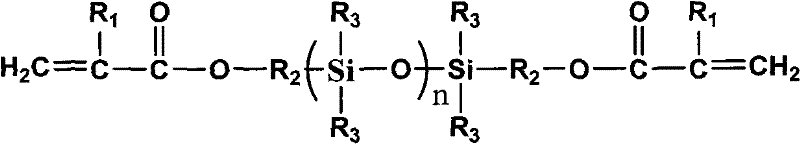

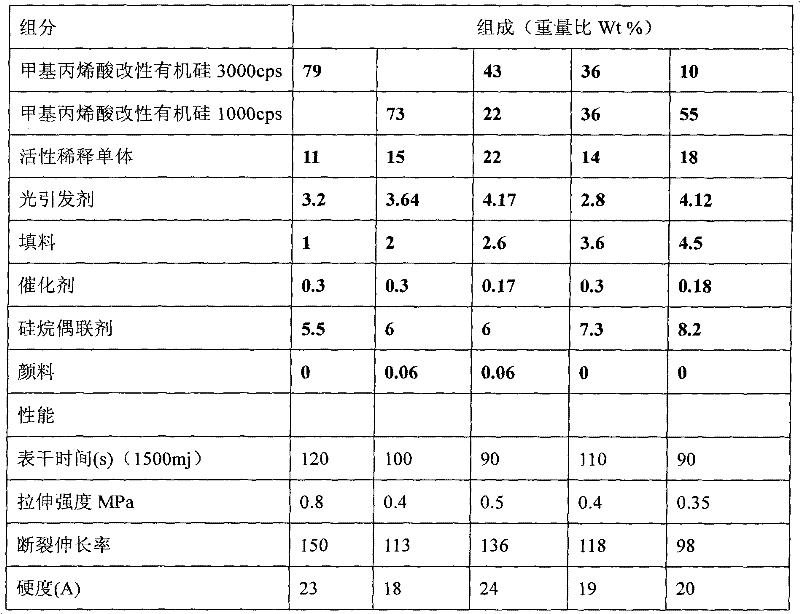

UV (Ultraviolet)/moisture double cured silicon rubber and preparation method thereof

The invention discloses UV (Ultraviolet) / moisture double cured silicon rubber, which consists of the following components in parts by weight: 25-80 parts of methacrylic acid modified organic silicon, 10-30 parts of an active diluted monomer, 3-5 parts of a filler, 2-5 parts of a photo-initiator, 0.2-0.5 part of a catalyst, 5-10 parts of a silane coupling agent and 0-1 parts of other additives. The UV / moisture double cured silicon rubber has the advantages of quick curing, high efficiency and reduction in production cost. An adhesive fully meets the process requirements of protection production of a laminated adhesive for protecting a PCB (Printed Circuit Board) and a COG (Chip on Glass) chip.

Owner:TONSAN ADHESIVES INC

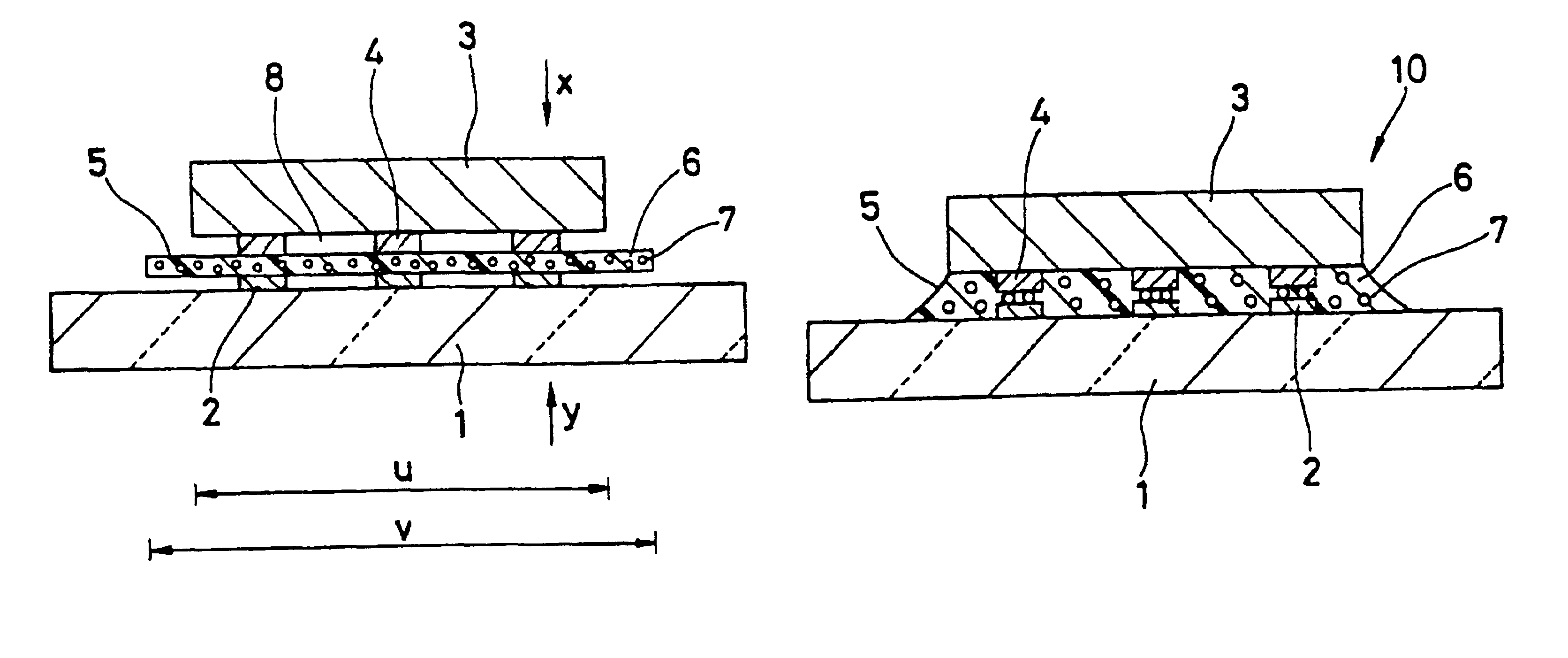

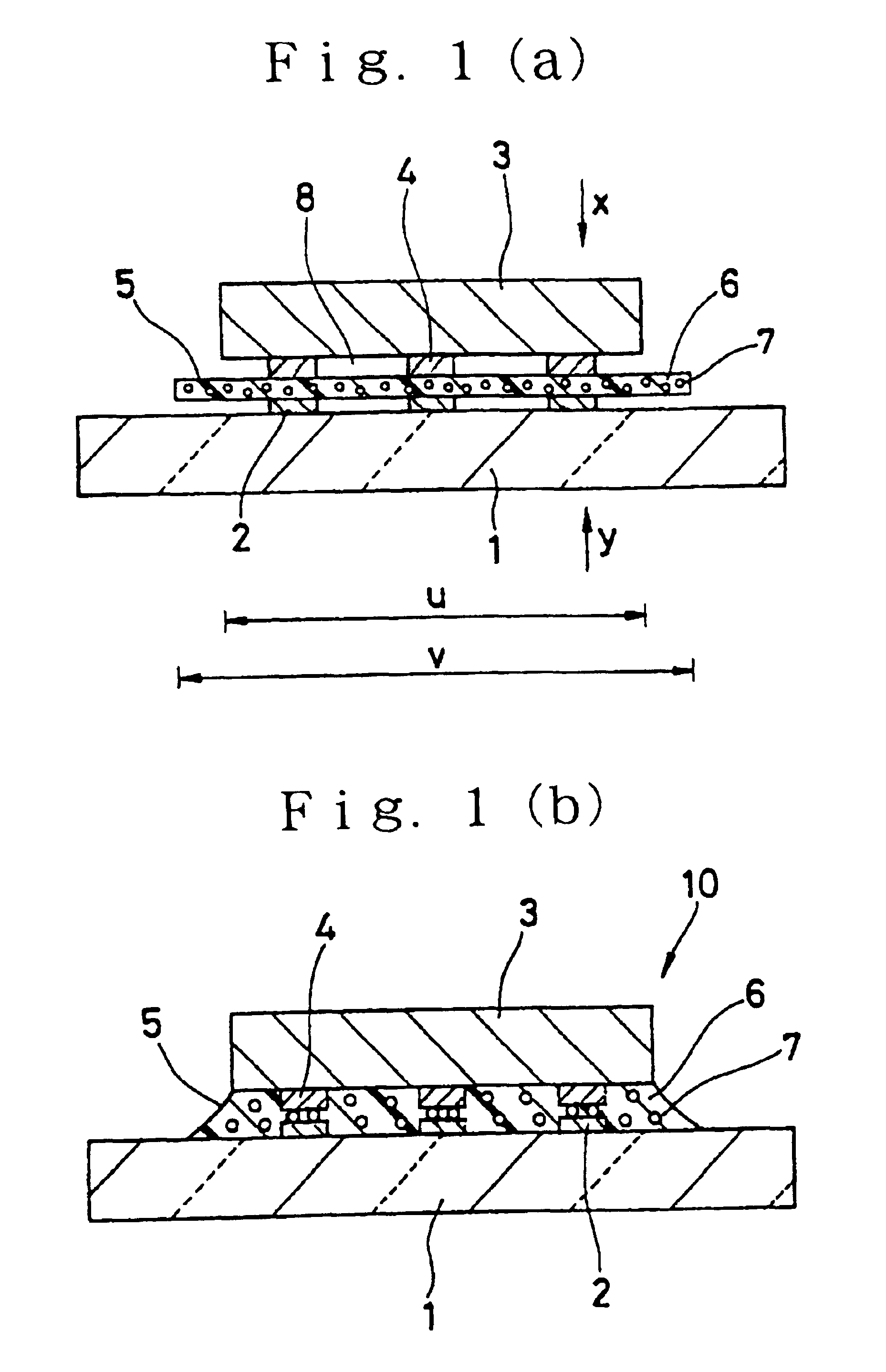

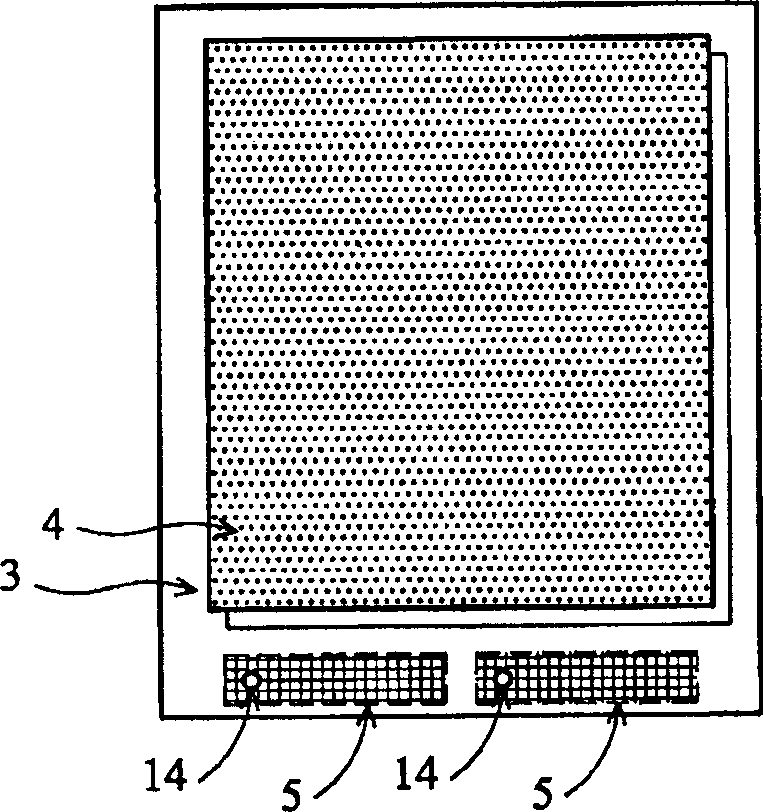

COG-assembly and connecting material to be used therein

InactiveUS6903463B1Reduce generationEasy to storeLiquid crystal compositionsLayered productsStress concentrationSemiconductor chip

A chip-on-glass (COG) assembly, in which the electrodes of the semiconductor chips (3) are held in direct connection with the corresponding electrodes on the substrate glass circuit board (1), utilizes a layer (5) of a connecting material for bonding and connecting the semiconductor chip (3) with the substrate board (1). The connecting material can provide a reduced stress concentration at the boundaries between the binder layer (5) and the chip (3) and between the binder layer (5) and the glass board (1), even at higher adhesive strengths, bringing about less deformation, such as warping, of the resulting bonded assembly, even when using a thinner substrate glass board, and provides a superior bonding strength and excellent electroconductive performance. The connecting material is made up of, on the one hand, an adhesive component (6) containing a thermosetting resin and, on the other hand, electroconductive particles (7) and has a characteristic feature that a tensile elongation percentage at 25° C., after having been cured, is at least 5%.

Owner:DEXERIALS CORP

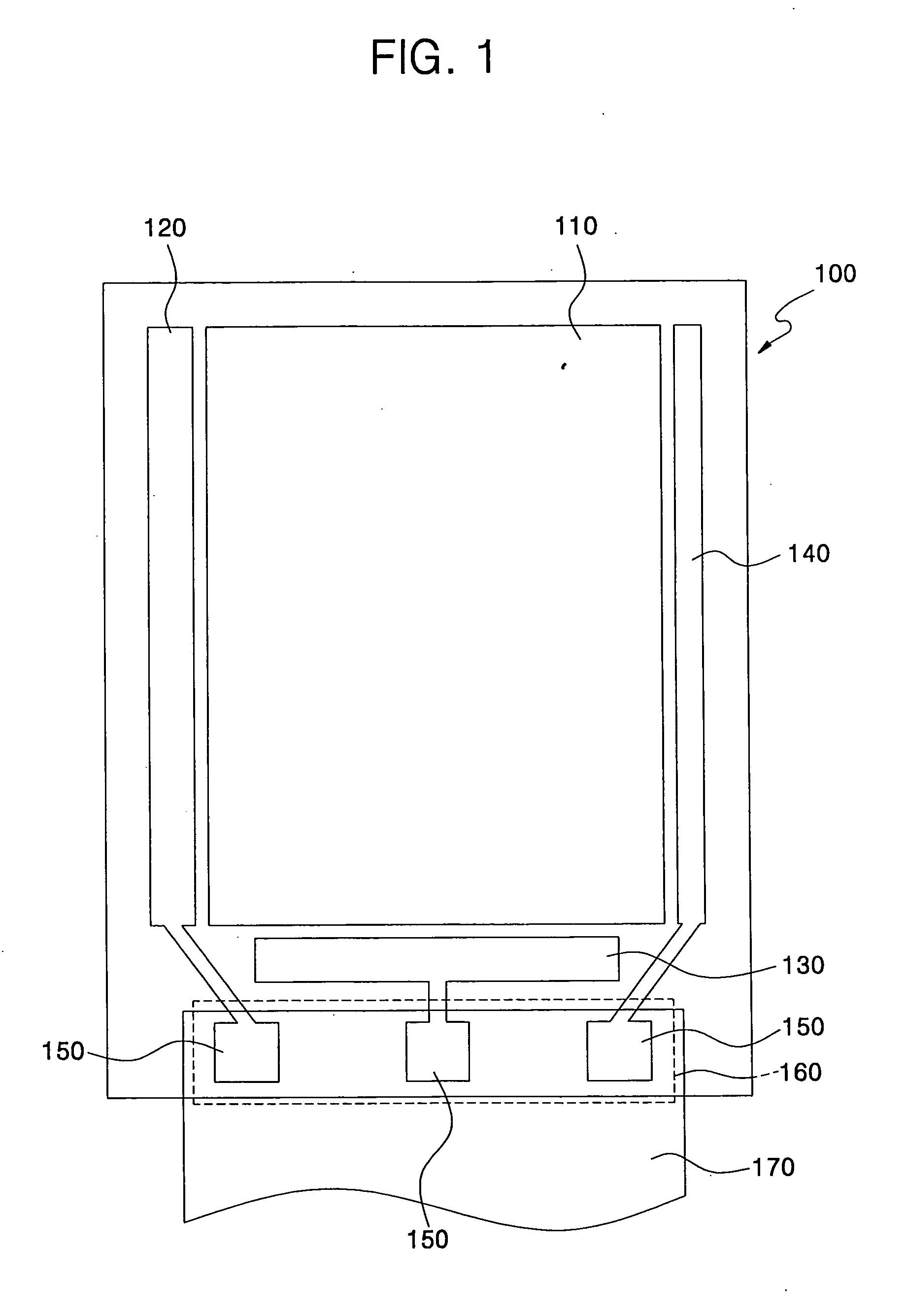

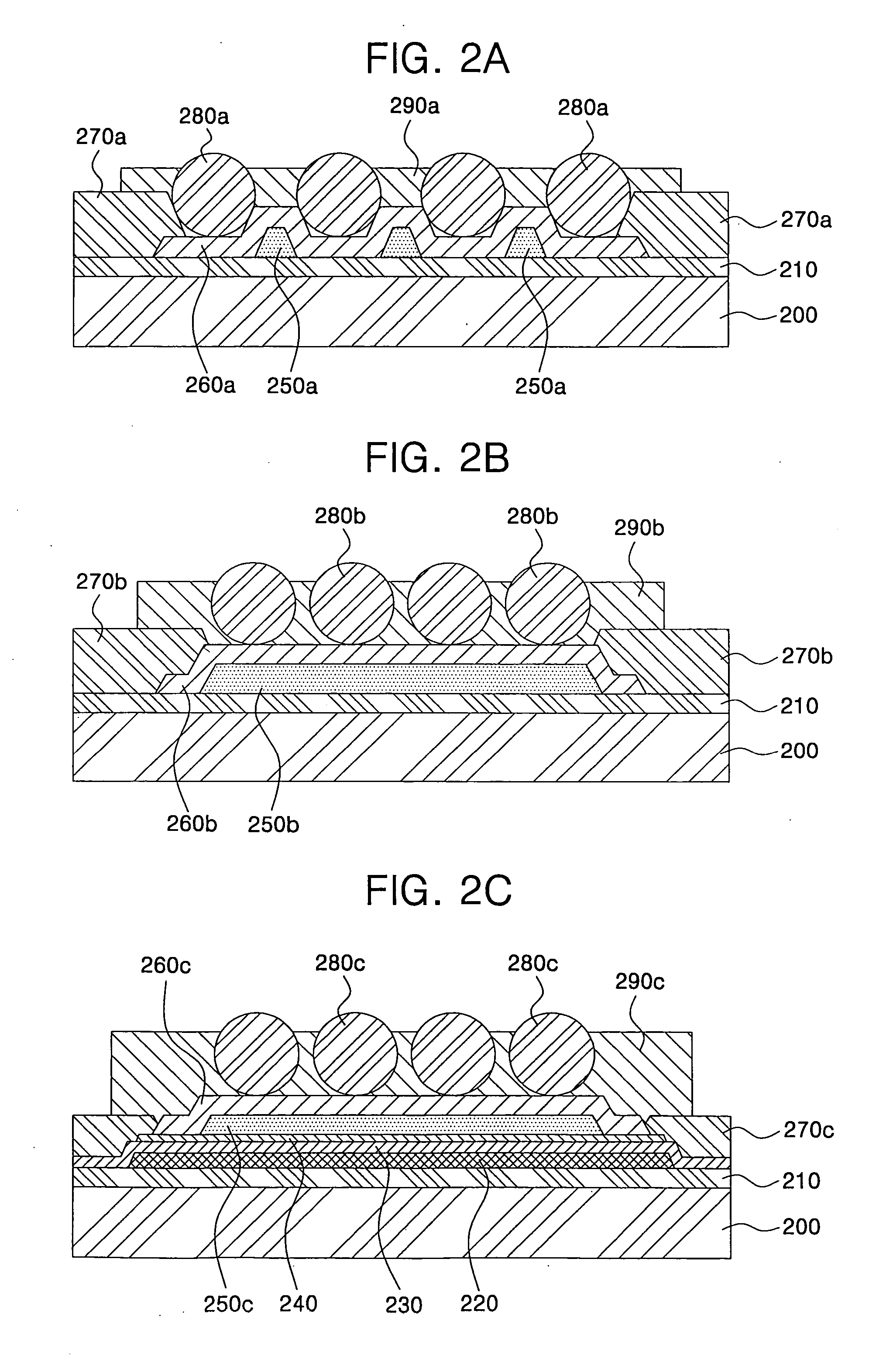

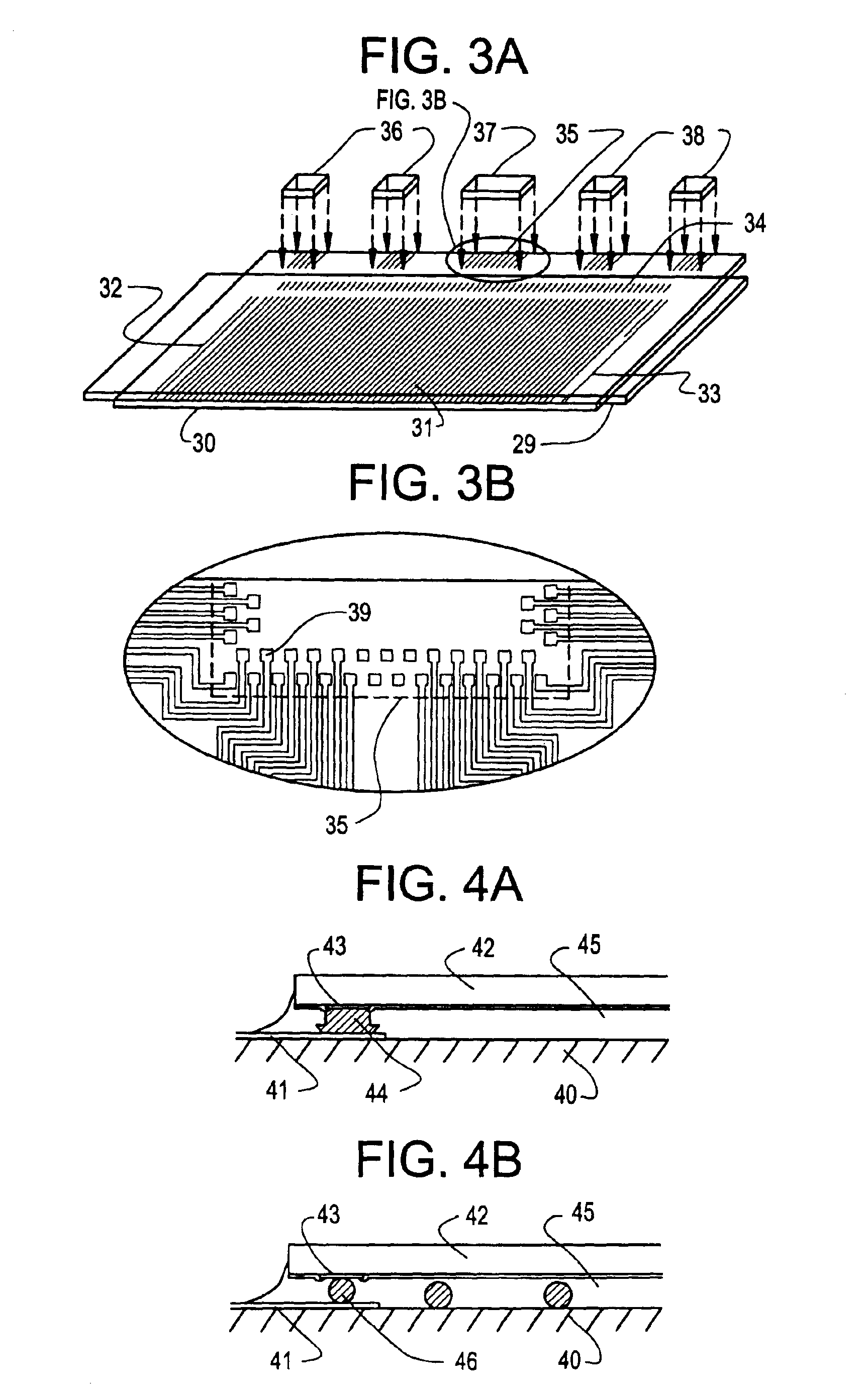

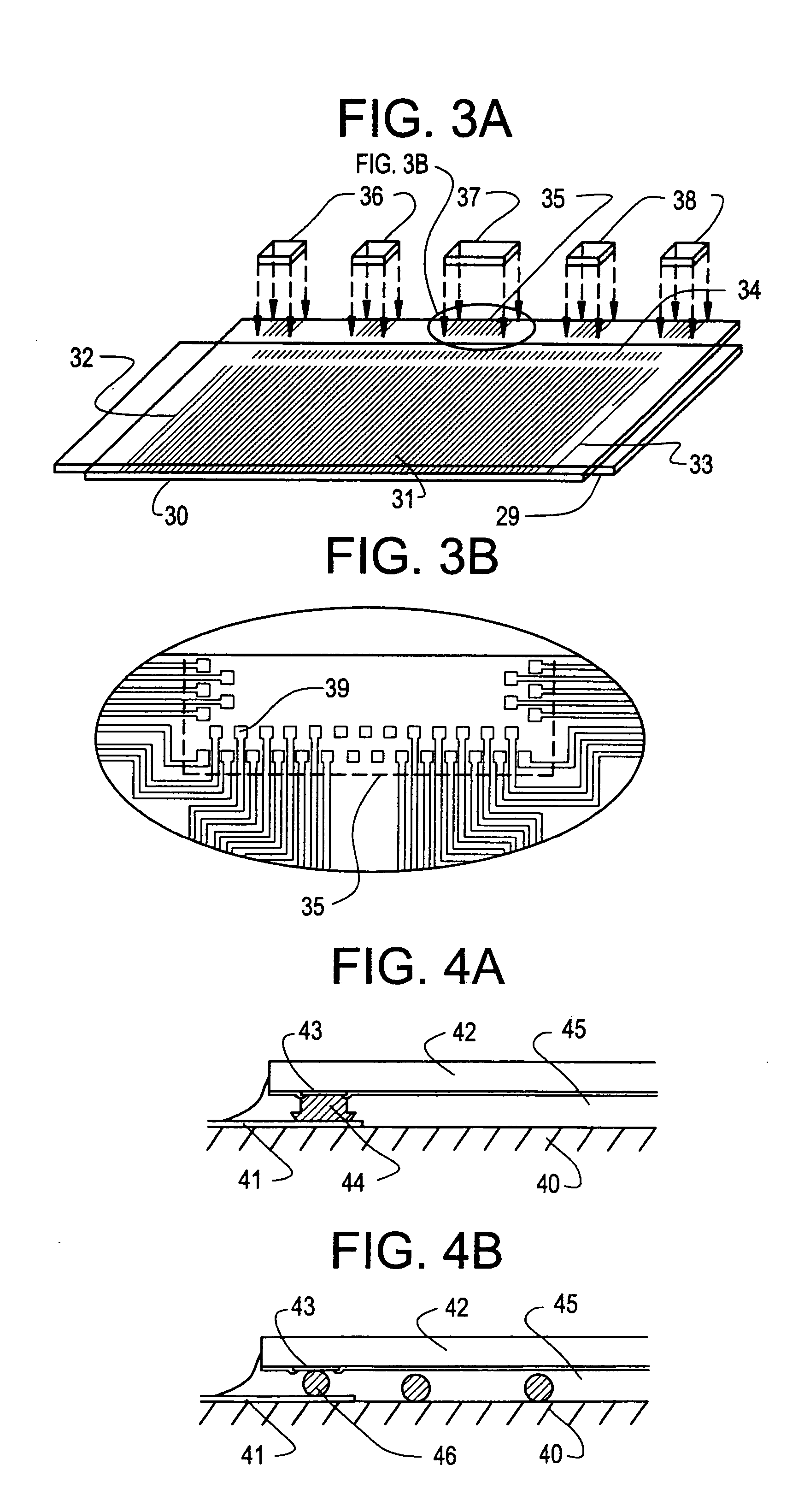

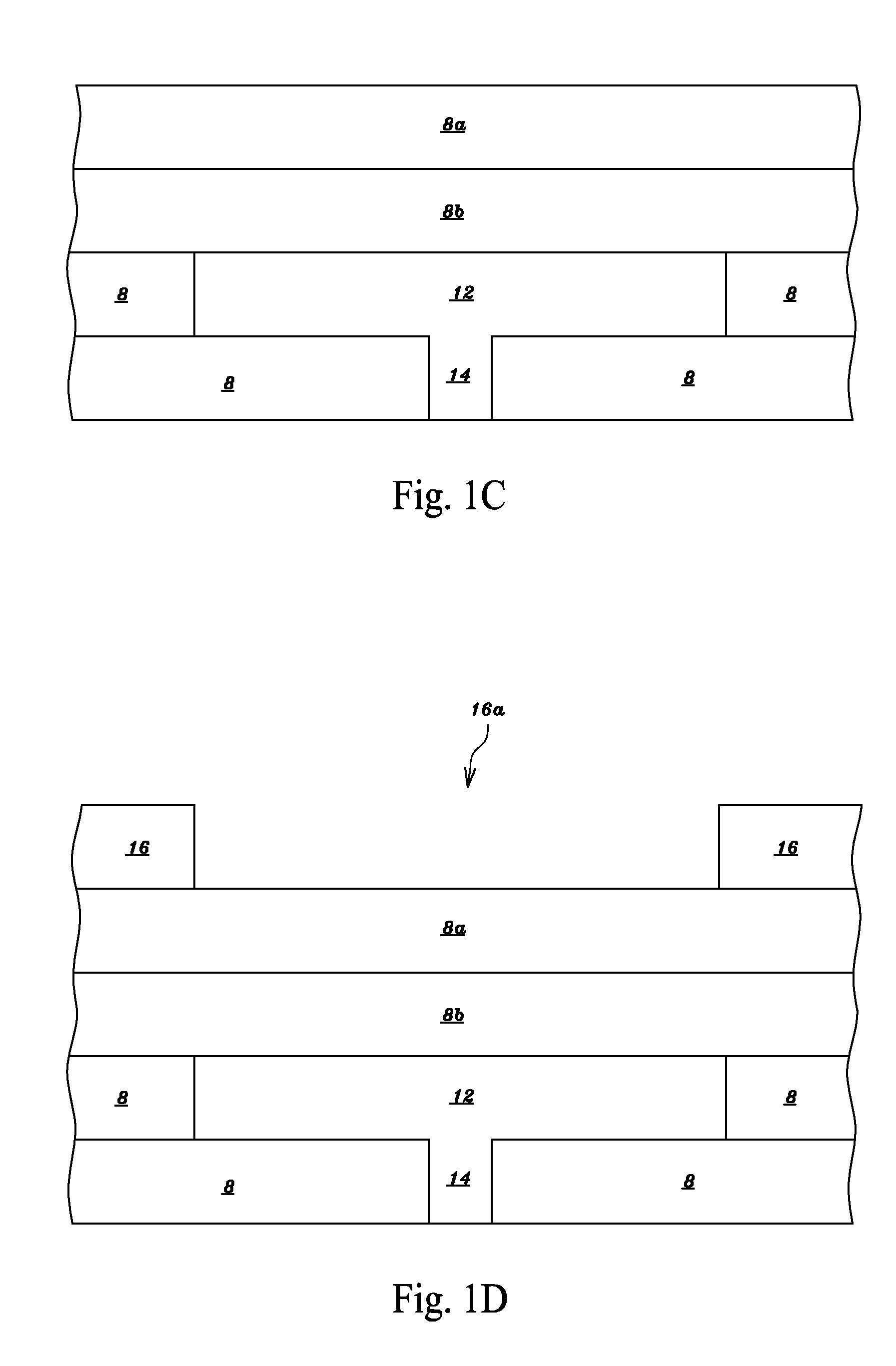

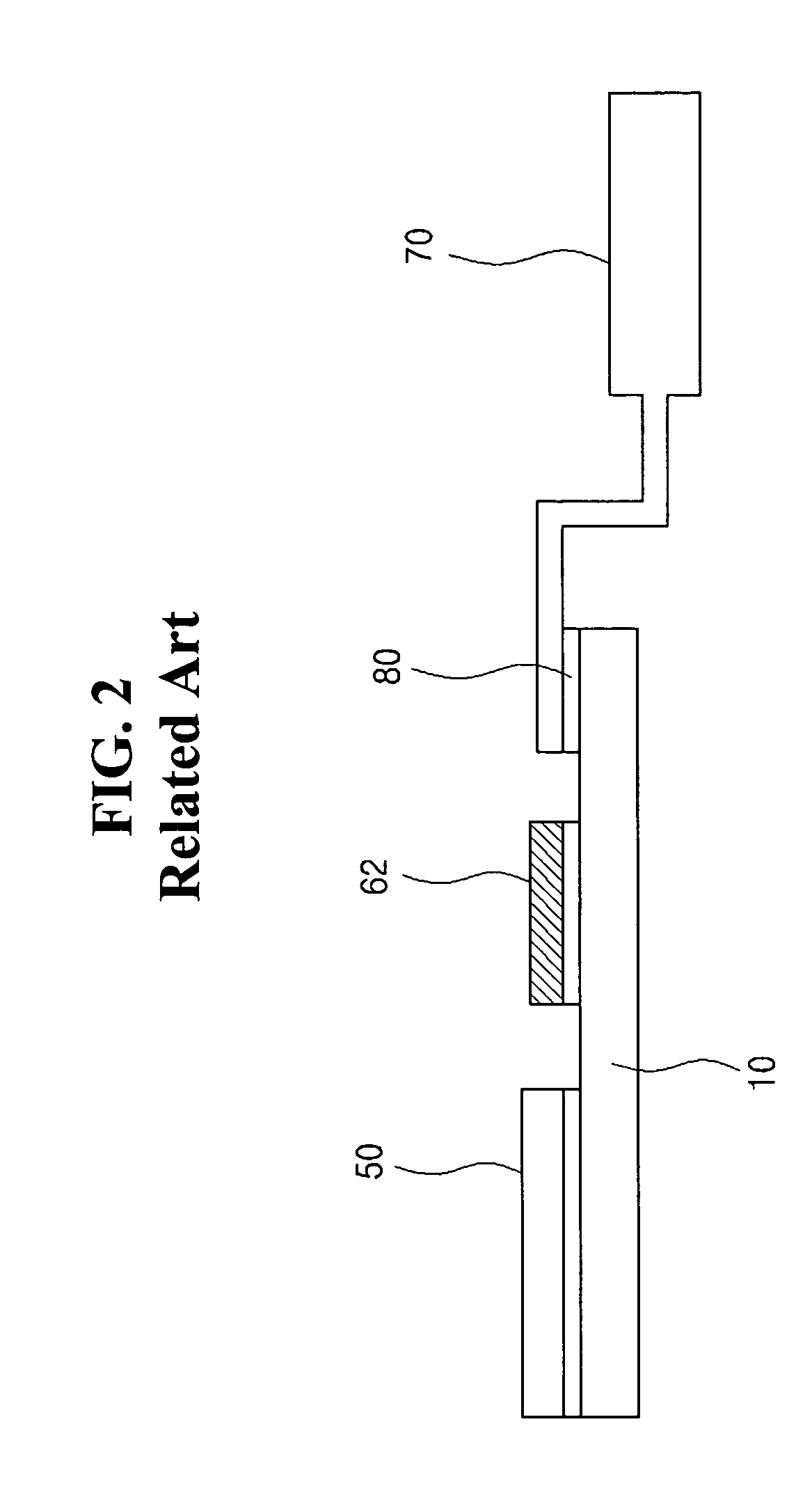

Chip on glass type liquid crystal display device and method for fabricating the same

ActiveUS20050243234A1Prevent abnormal contactSolid-state devicesPretreatment controlAdhesiveEngineering

A chip on glass type liquid crystal display device and a method for fabricating the same are provided in which a surface of a pad electrode for attaching a flexible printed circuit film is embossed to increase an adhesive force between a pad electrode and a flexible printed circuit film, thereby ensuring contact between the pad electrode and the flexible printed circuit film. Unit pixels in an active region contain thin film transistors formed at intersections of gate lines and data lines. A pad electrode is formed in an inactive region. An embossing pattern is formed on the pad electrode. An adhesive is provided on the pad electrode including the embossing pattern and an external drive circuit part is connected to the pad electrode by the adhesive.

Owner:LG DISPLAY CO LTD

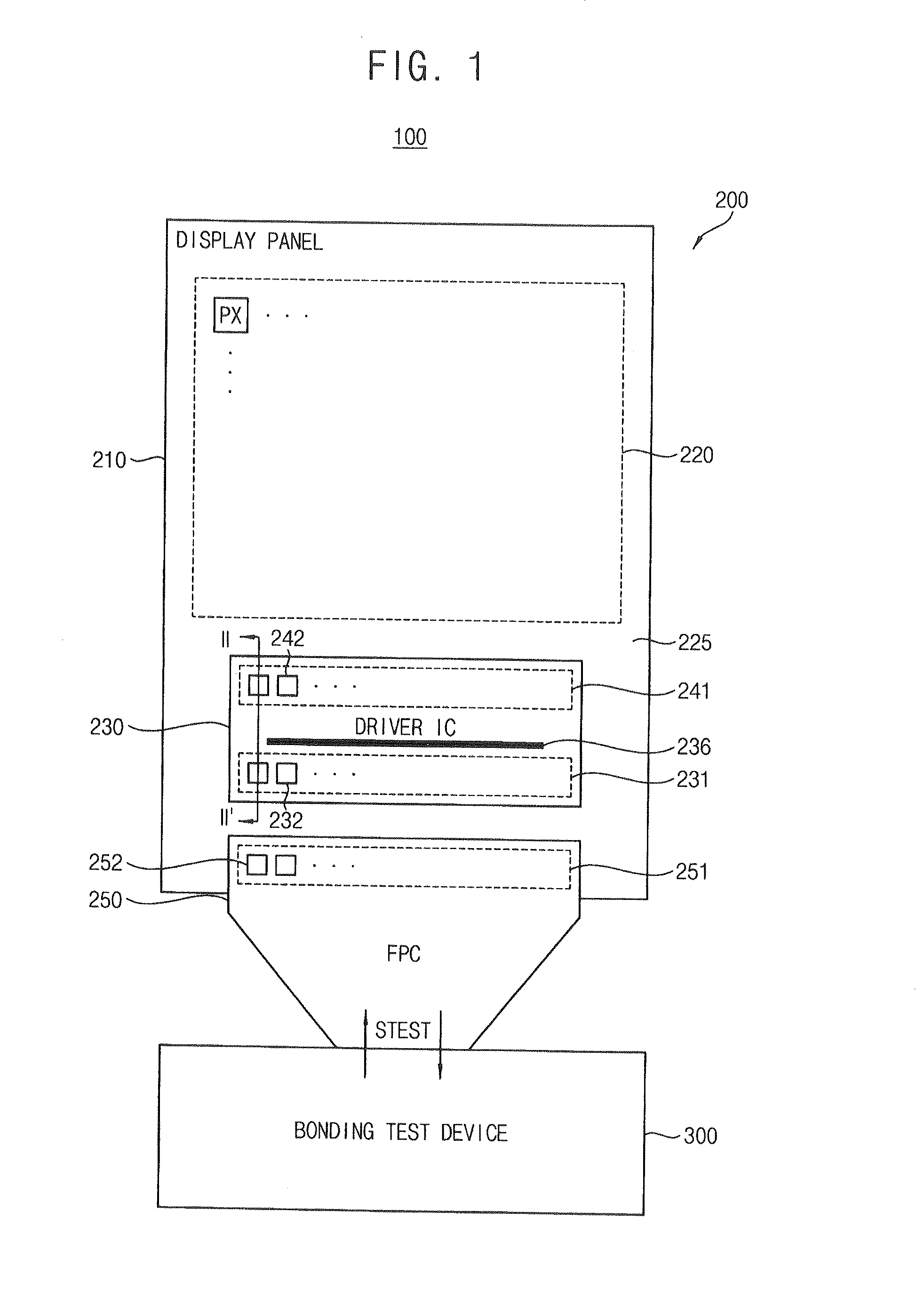

Display device and bonding test system

ActiveUS20140117998A1Reduce in quantityElectronic circuit testingStatic indicating devicesDisplay deviceEngineering

A display device includes a display panel having a glass substrate, a first input pad formed on the glass substrate and a second input pad formed on the glass substrate, and a driver integrated circuit mounted on the glass substrate of the display panel using a chip-on-glass (COG) method. The driver integrated circuit includes first and second input bumps respectively coupled to the first and second input pads, and an internal ground line coupled to the first and second input bumps. The first input bump of the driver IC receives a test signal through the first input pad when a COG bonding test is performed, and receives a ground voltage when the display device operates.

Owner:SAMSUNG DISPLAY CO LTD

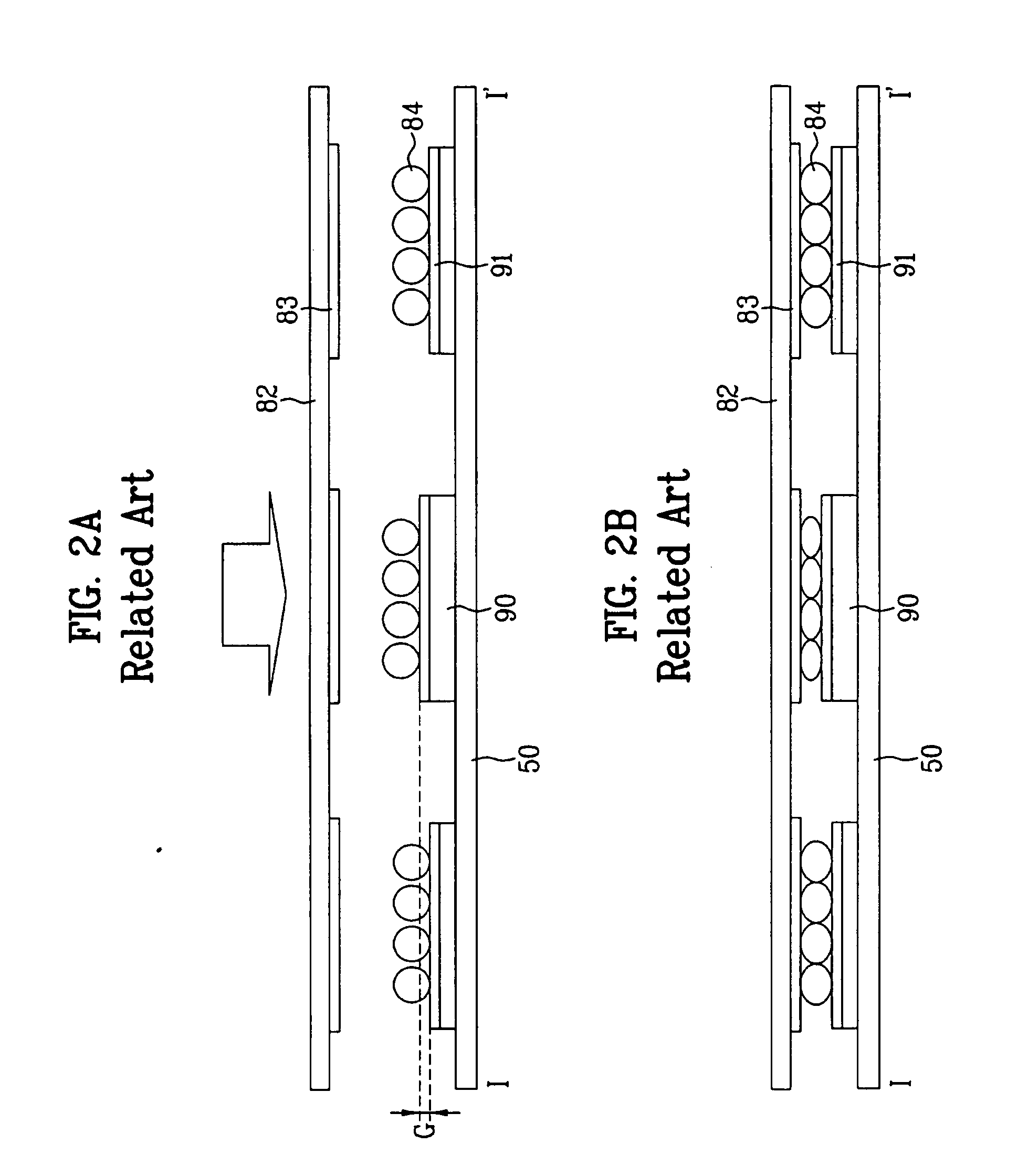

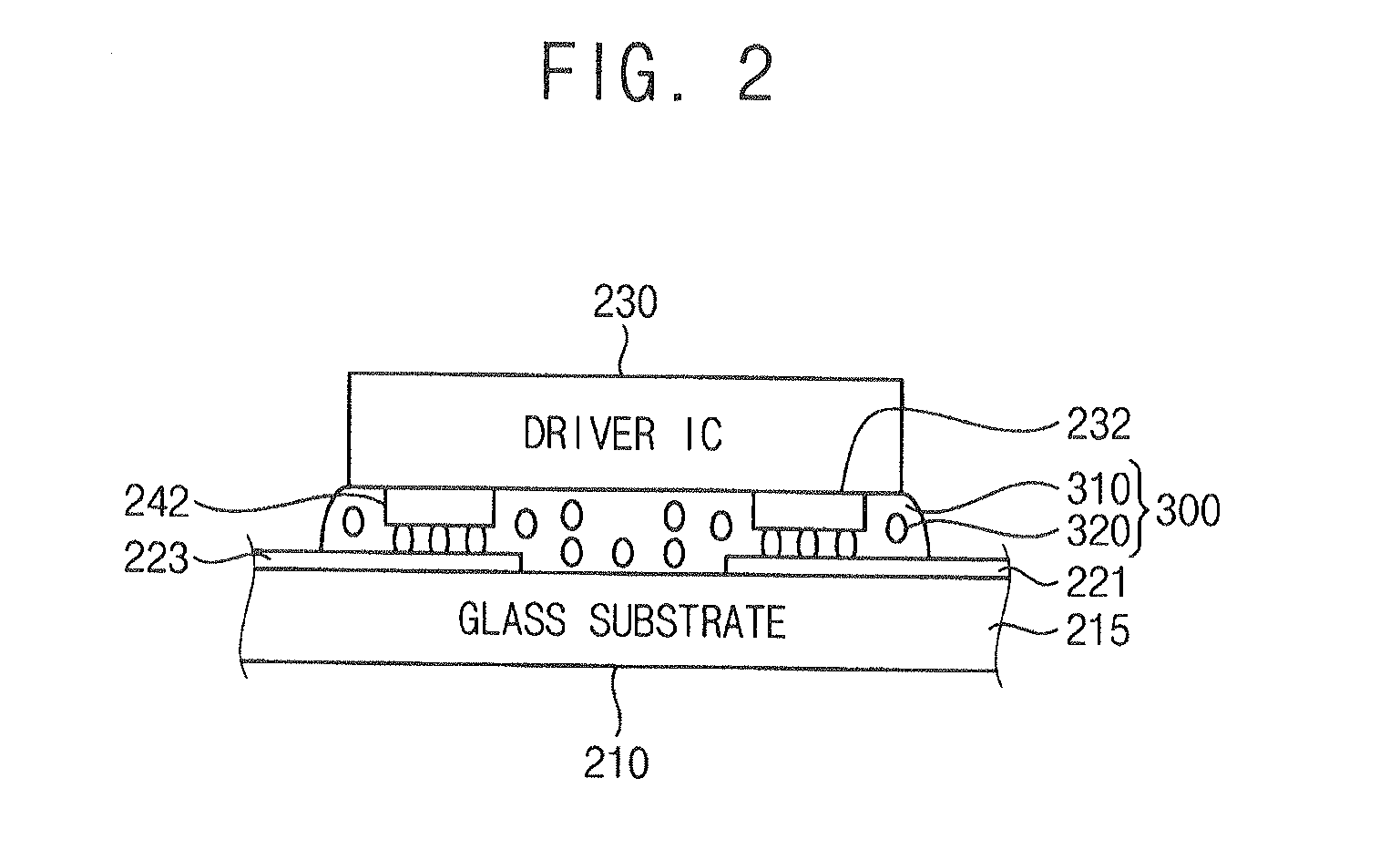

Liquid crystal display driver integrated circuit package

InactiveUS7002809B2Reduce the differenceQuality improvementSemiconductor/solid-state device detailsSolid-state devicesDevice failurePressure controlled ventilation

Disclosed is an LCD driver integrated circuit package and a chip on glass type LCD device using the package. The LCD driver integrated circuit package includes a mold that has signal output bumps and signal input bumps formed thereon, wherein the signal output bumps and the signal input bumps have different surface areas that contact the mold and an adjacent conductive film. Due to the different contact surface areas, different amounts of pressure are applied to different parts on the conductive film when a force is applied to the mold. One or more bump pressure control patterns are formed on the mold compensate for the difference in pressure caused by this difference between the total contact areas. Accordingly, the LCD driver integrated circuit package can be mounted on a chip on glass type LCD panel without causing device failure.

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS TECH CO LTD

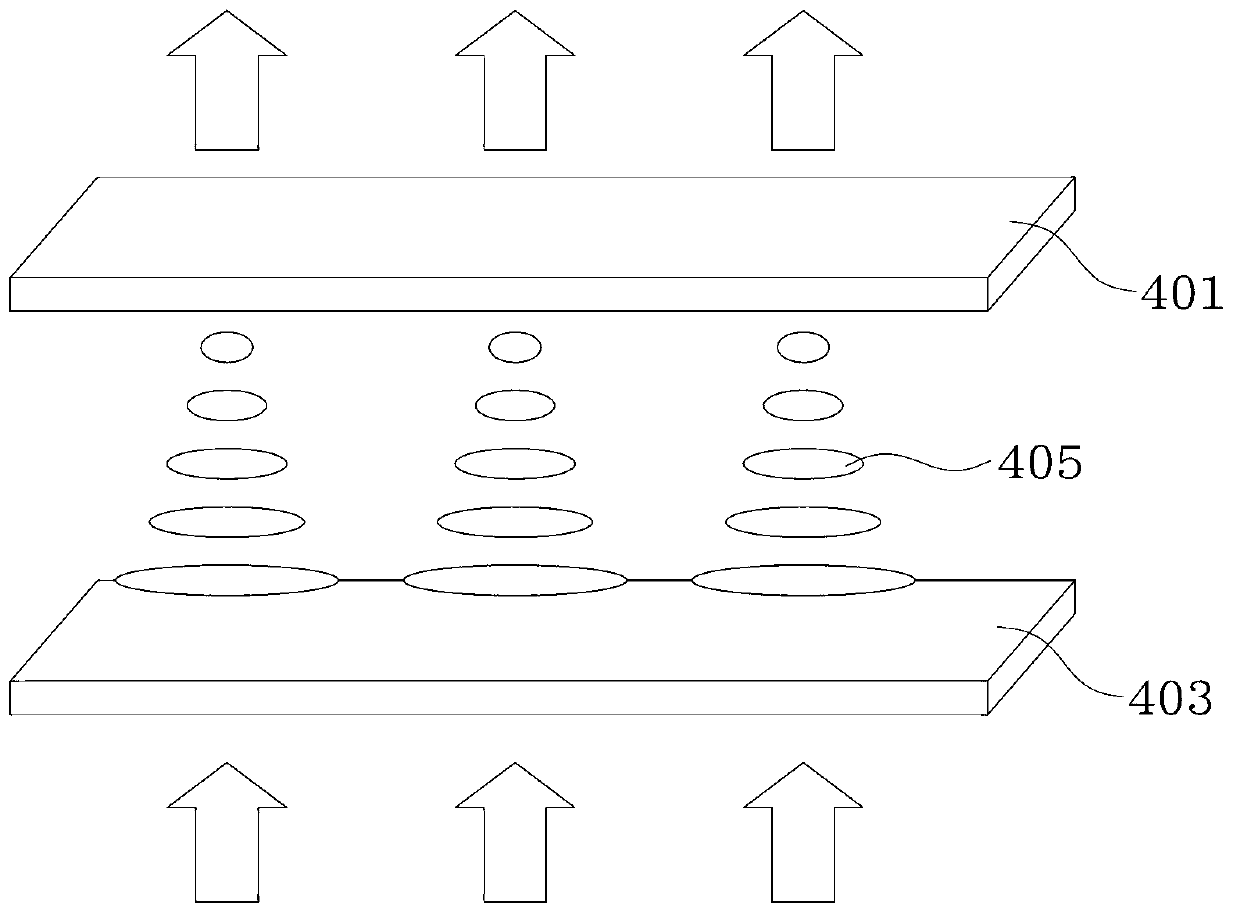

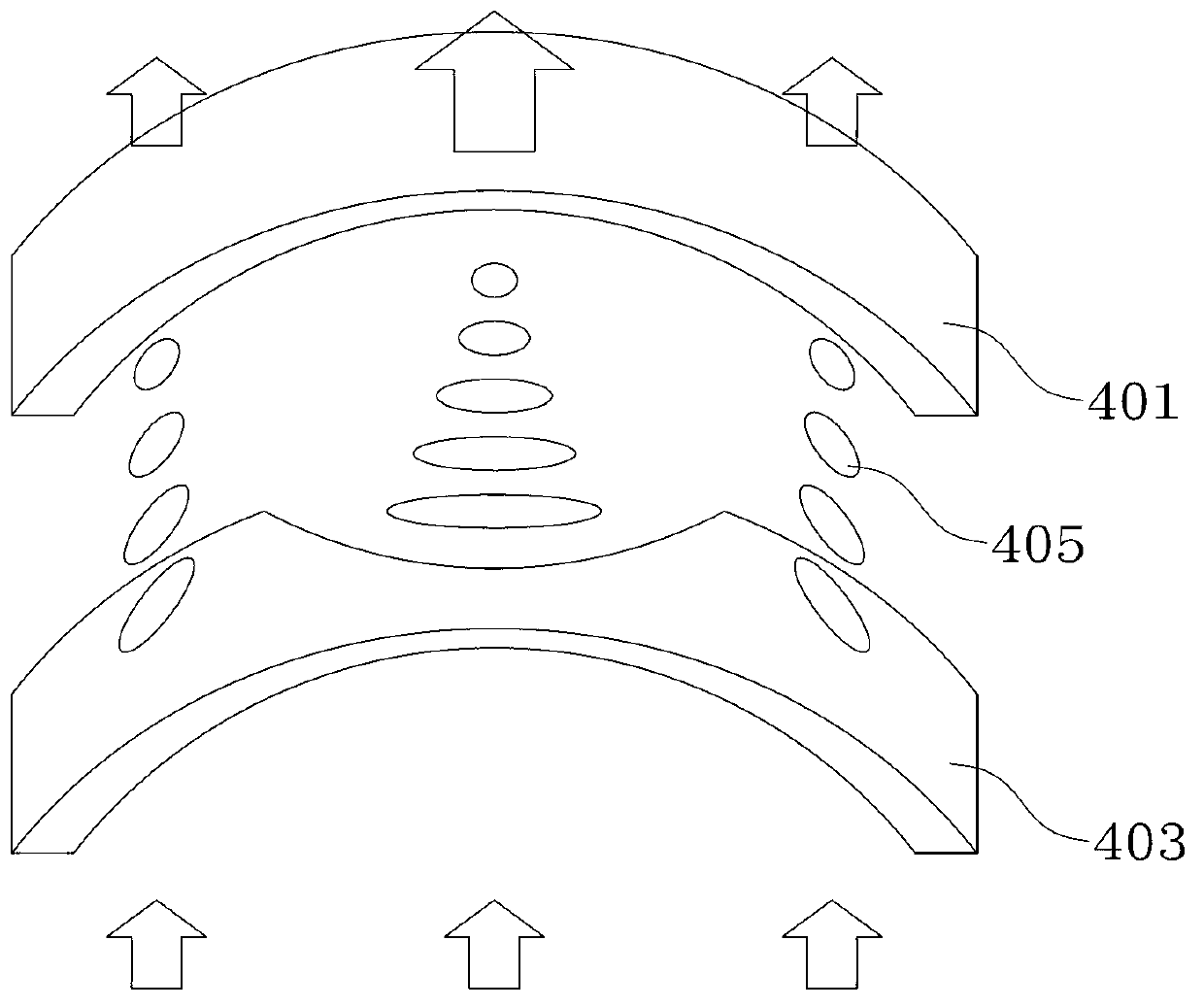

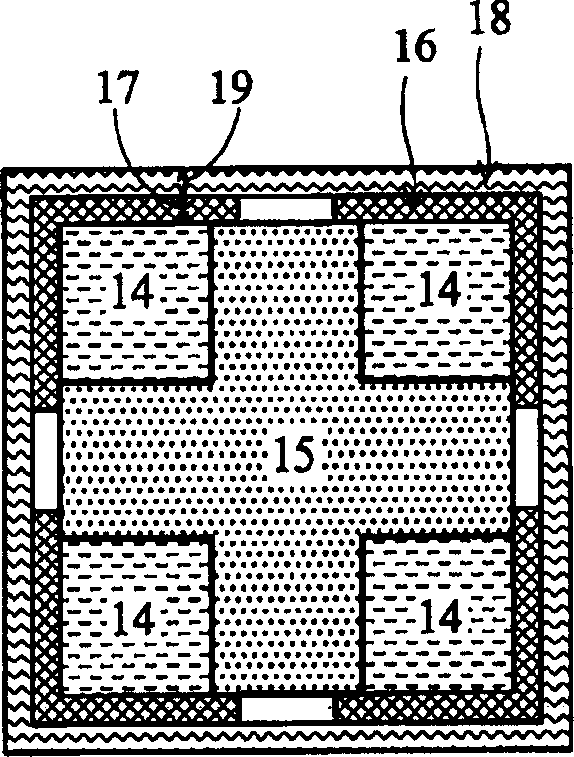

Liquid crystal display panel

InactiveCN103018938AImprove COG mura phenomenonResistance to internal tensile stressNon-linear opticsEngineeringThermal expansion

The invention provides a liquid crystal display panel, which comprises a printed circuit board component, a glass substrate and an adhesive tape, wherein a jointing area is arranged on one side of the glass substrate; the printed circuit board component and the glass substrate are adhered by means of the adhesive tape; the glass substrate comprises a first surface and a second surface opposite to each other; the jointing area is positioned on the first surface; and the adhesive tape is positioned on the second surface. The adhesive tape is composed of a plurality of discontinuous adhesive strips so that the deformation quantity of the glass substrate is uniformed. Through the application of the liquid crystal display panel, the printed circuit board component and the glass substrate are firmly adhered by means of the adhesive tape, and the adhesive tape is configured to be in a discontinuous manner (such as sectional type or roulette manner), so that the internal pulling stress caused when the glass substrate is in press fit can be inhibited, and COG (Chip On Glass) mura of the panel is improved. Moreover, the deformation space caused by expansion with heat and contraction with cold of the glass substrate can be reserved through the adhesive tape in the discontinuous manner so that the deformation influence due to difference of chip thermal expansion coefficients of the glass substrate and the jointing area is eliminated.

Owner:AU OPTRONICS (SUZHOU) CORP LTD +1

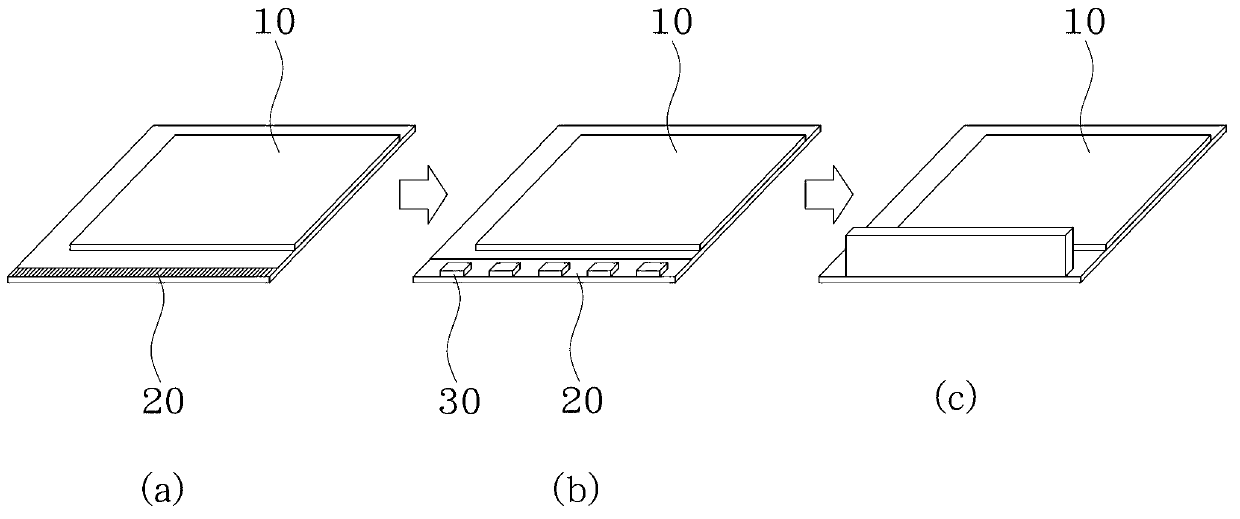

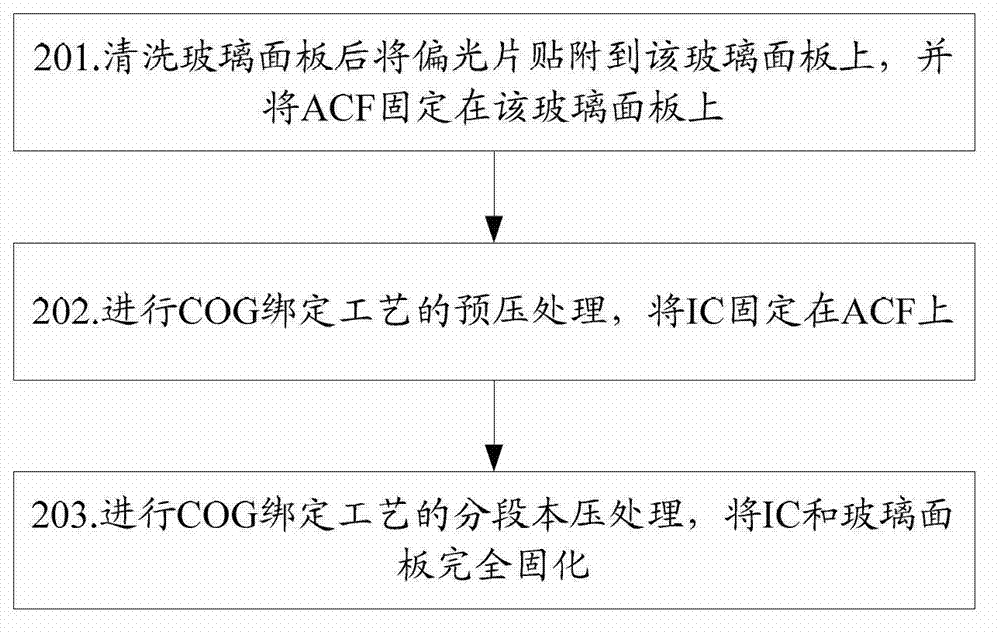

COG (Chip On Glass) bonding method and temperature control device

InactiveCN103592785AInternal stress reliefReduce crackingTemperature control using electric meansNon-linear opticsTemperature controlAnisotropic conductive adhesive

The invention discloses a COG (Chip On Glass) bonding method. The COG bonding method comprises attaching a Polaroid to a glass panel after the glass panel is cleaned and fixing an ACF (Anisotropic Conductive adhesive Film) on the glass panel; performing the pre-bonding treatment of the COG bonding process and fixing an IC (Integrated Circuit) on the ACF; performing the segment main bonding treatment of the COG bonding process and performing the complete curing on the IC and the glass panel. The invention also provides a temperature control device. According to the technical scheme of the COG bonding method and the temperature control device, the process of the COG bonding process is achieved through the segment main bonding process and accordingly the IC and the glass panel can have the same swelling amount and accordingly the badness can be avoided.

Owner:BEIJING BOE OPTOELECTRONCIS TECH CO LTD

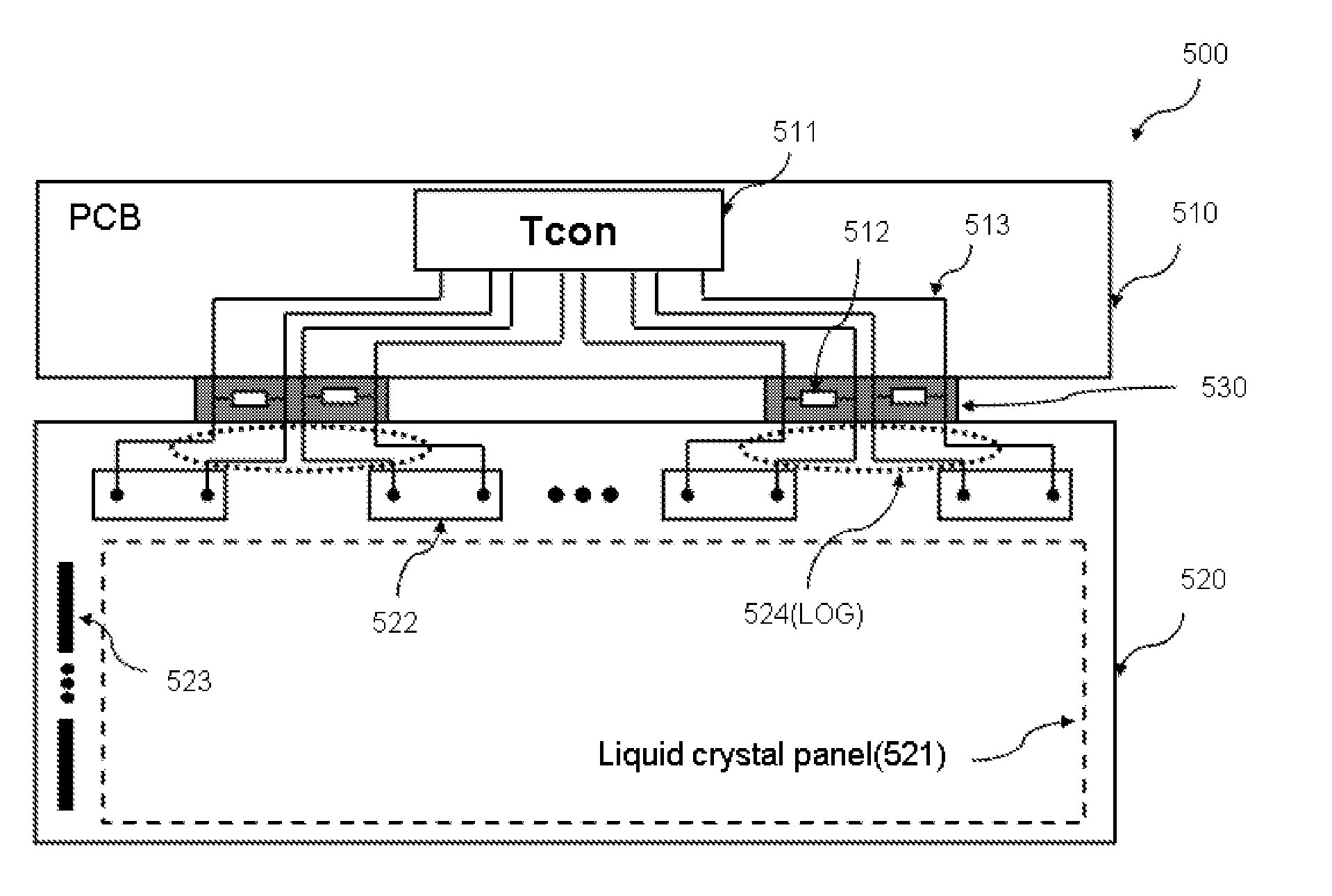

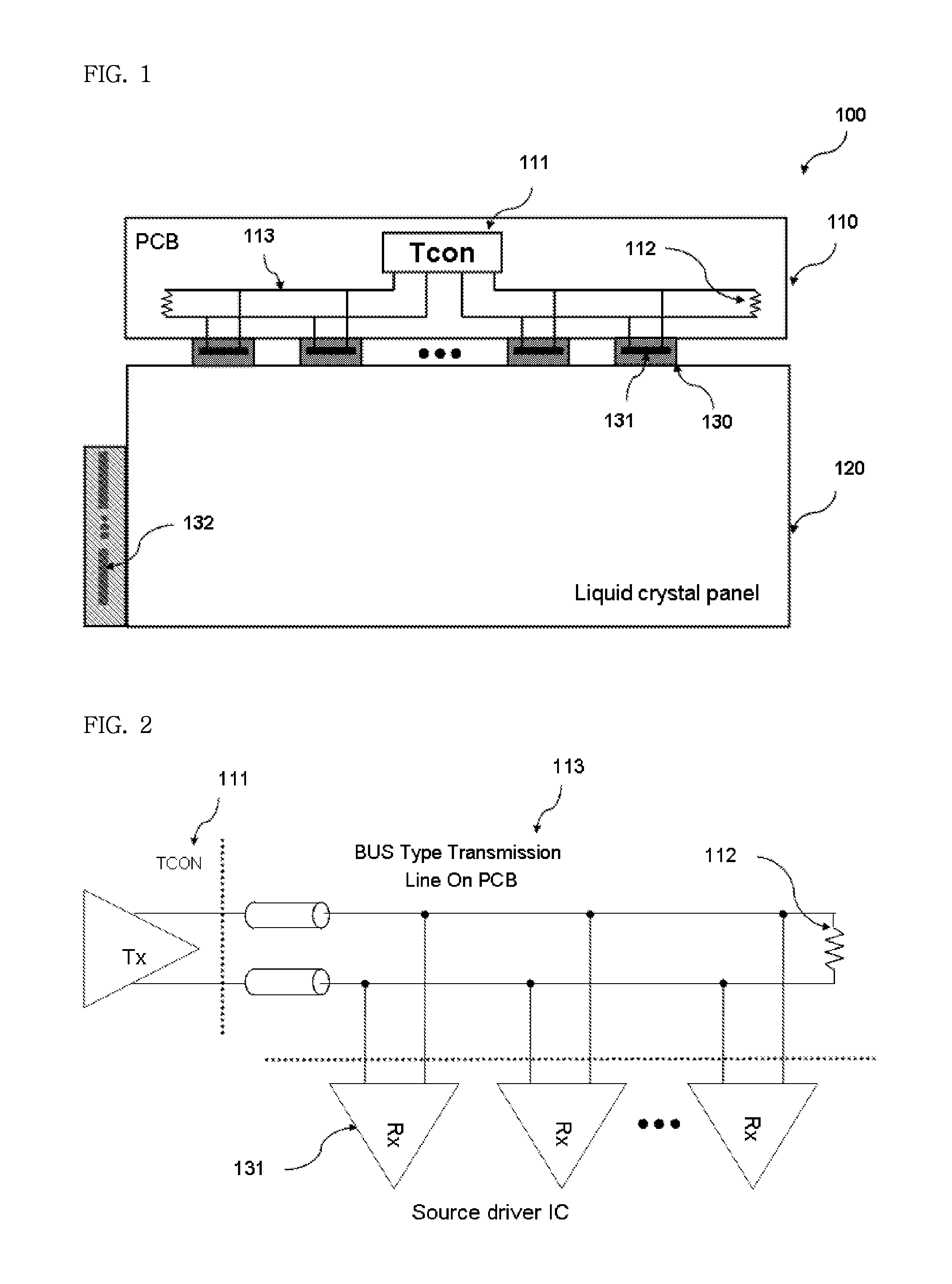

Chip-on-glass type liquid crystal display device

InactiveUS20110285679A1Avoid signal distortionHigh-resolution imageCathode-ray tube indicatorsNon-linear opticsElectrical resistance and conductanceImpedance matching

A chip-on-glass (COG) type liquid crystal display device minimizes a reflected wave from an input terminal of a source driver IC, regardless of the resistance value of a transmission line on a glass substrate, through the use of impedance matching at a front terminal of an LOG and impedance matching at an output terminal of a timing controller, thereby enhancing the frequency characteristic while maintaining a slim and lightweight design, so that it is possible to express a high-resolution high-quality image.

Owner:SILICON WORKS CO LTD

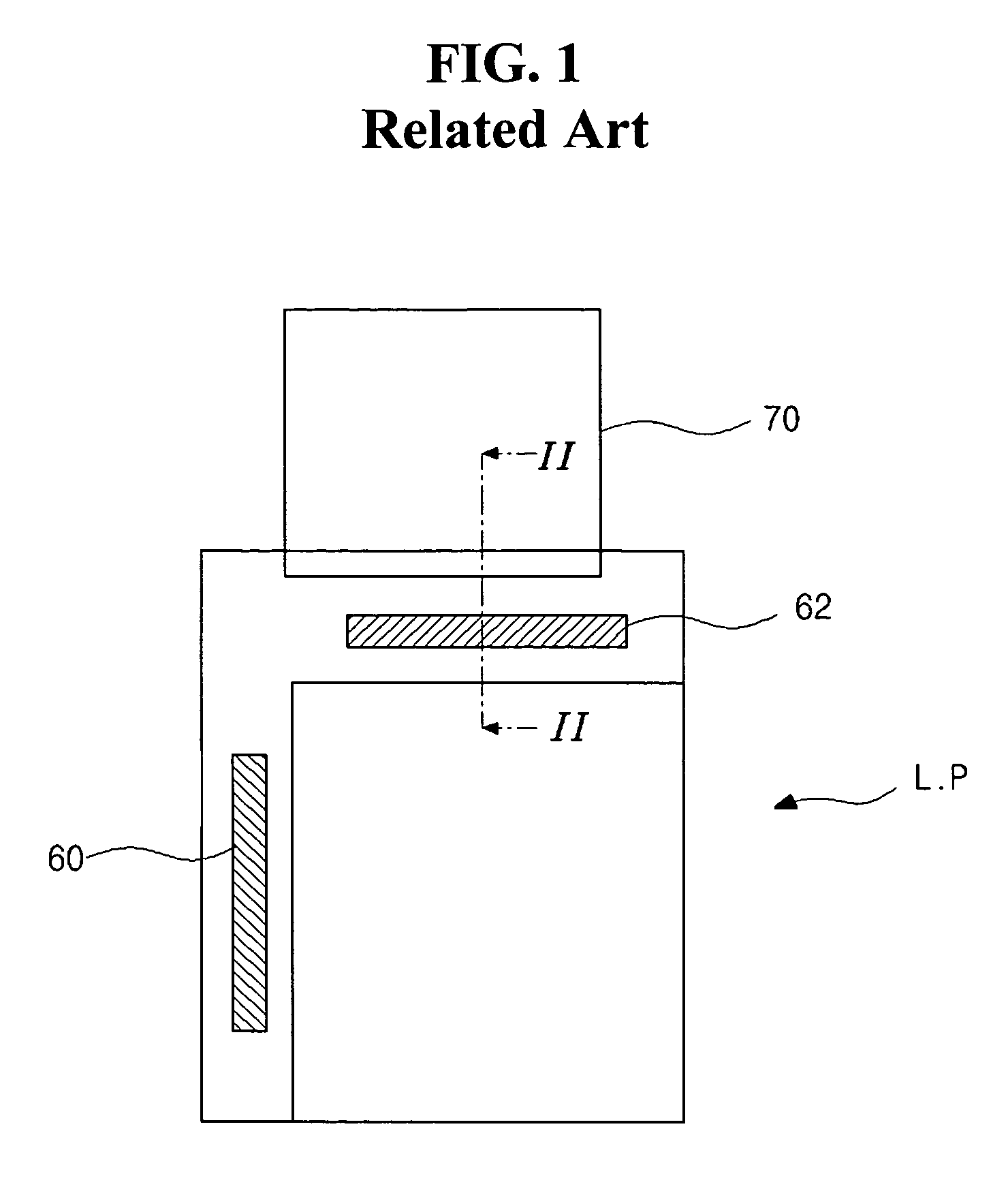

Electro-optical device and method for manufacturing the same

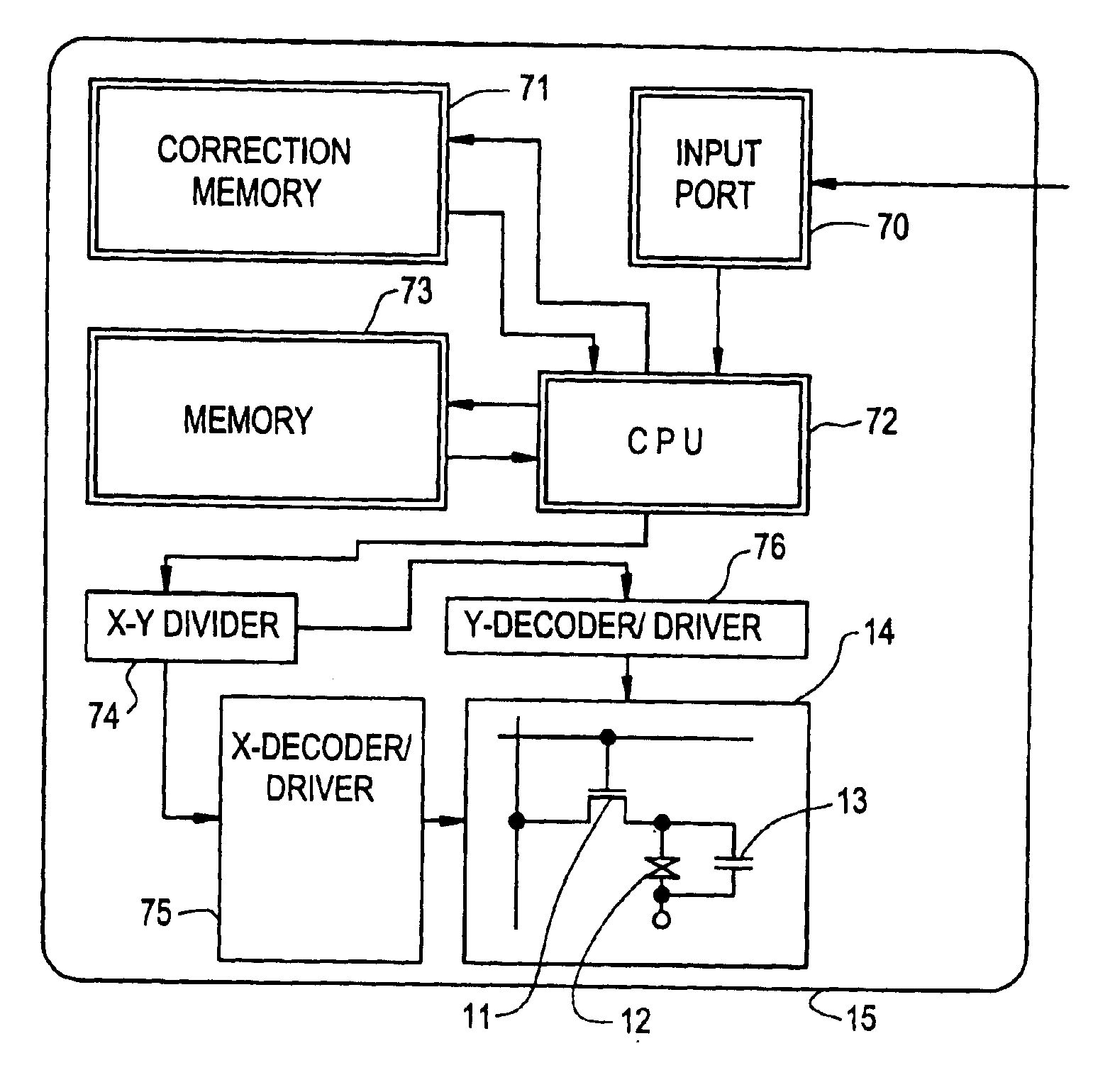

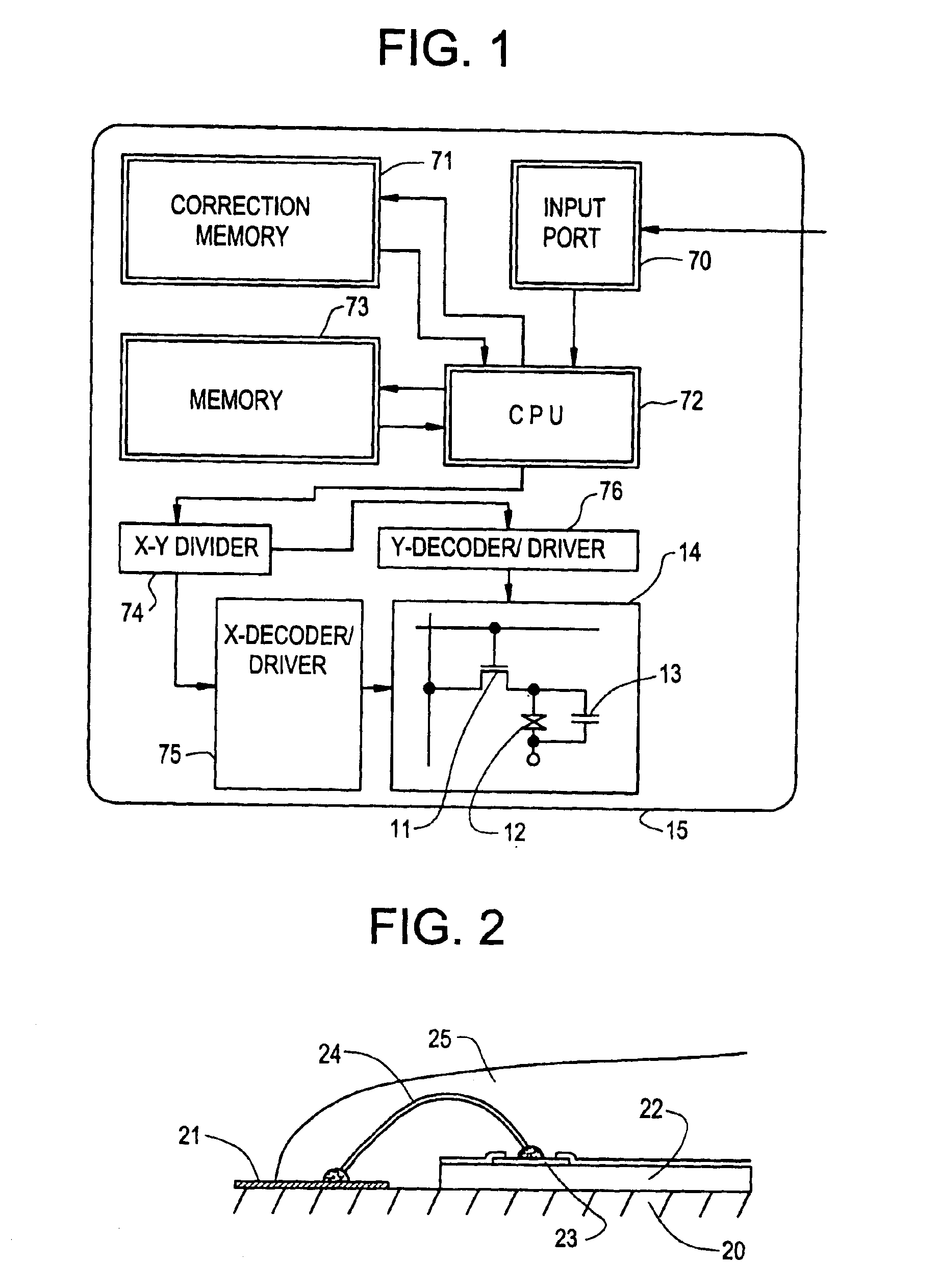

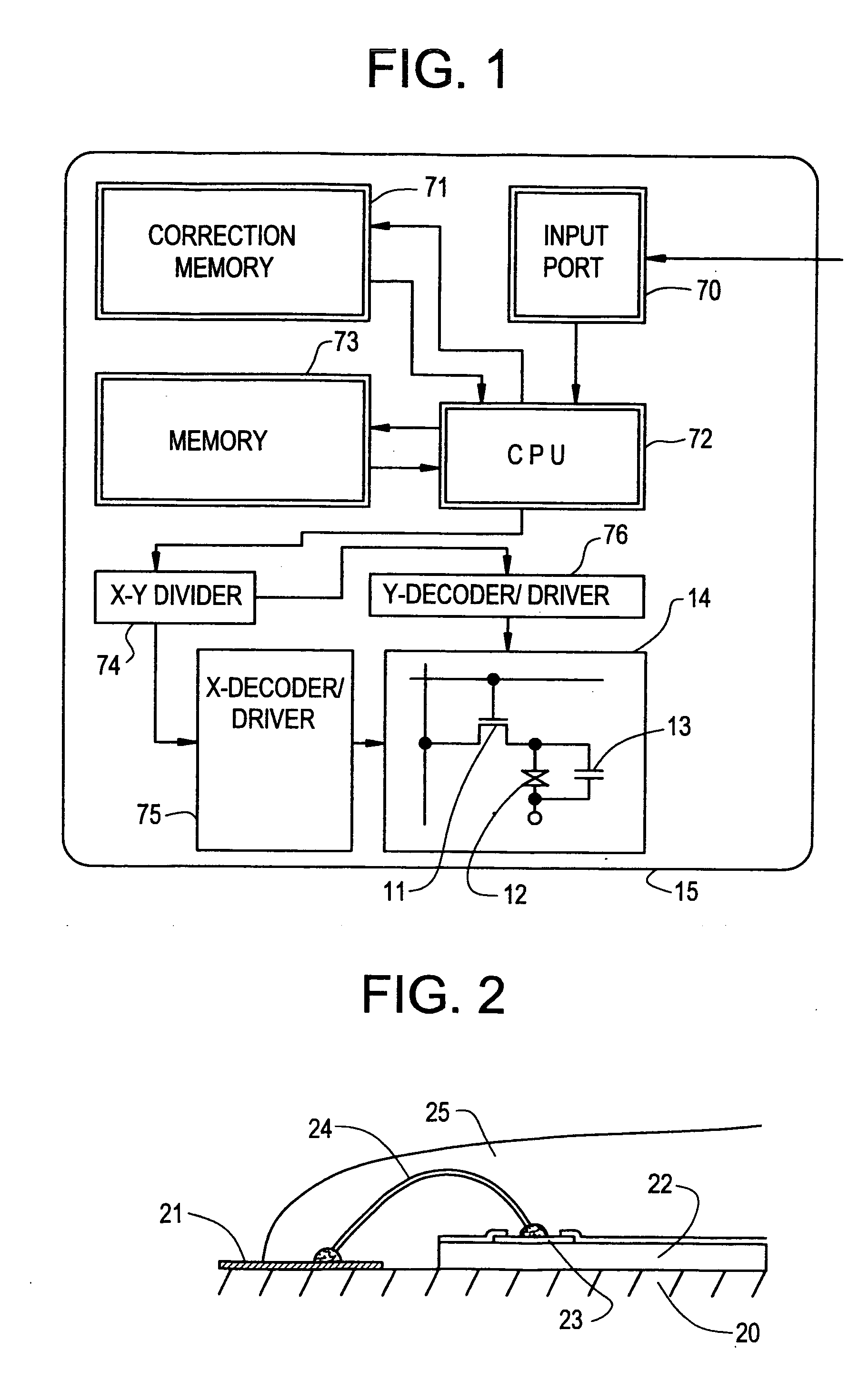

InactiveUS7081938B1Solid-state devicesSemiconductor/solid-state device manufacturingDriver circuitActive matrix

Using thin film transistors (TFTs), an active matrix circuit, a driver circuit for driving the active matrix circuit or the like are formed on one substrate. Circuits such as a central processing unit (CPU) and a memory, necessary to drive an electric device, are formed using single crystalline semiconductor integrated circuit chips. After the semiconductor integrated circuit chips are adhered to the substrate, the chips are connected with wirings formed on the substrate by a chip on glass (COG) method, a wire bonding method or the like, to manufacture the electric device having a liquid crystal display (LCD) on one substrate.

Owner:SEMICON ENERGY LAB CO LTD

Method for transmitting control signal of chip-on-glass liquid crystal display

InactiveUS20060202938A1Reduce in quantitySave power consumptionStatic indicating devicesControl signalData field

A method for transmitting control signals of a liquid crystal display is provided. The LCD includes a timing controller. The method packs the control signals of the timing controller into a control packet which comprises a header field and a control item having a control field and a data field. The header field indicates the start of the control packet, the control field records a type of an event, and the data field records a parameter of the event. The control packet is transmitted on one or a limited number of transmission lines.

Owner:HIMAX TECH LTD

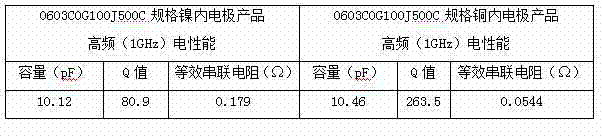

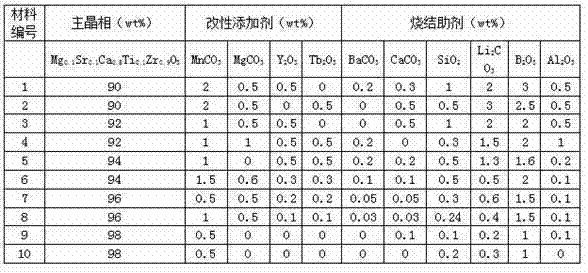

Dielectric ceramic composite and manufacturing method of electronic element thereof

The invention discloses a dielectric ceramic composite and a manufacturing method of an electronic element thereof. The dielectric ceramic composite comprises a principal crystalline phase, a modified additive and a sintering aid. The structural formula of the principal crystalline phase is (Mg[gamma]Sr[alpha]Ca(1-alpha-gamma))m(Ti[beta]Zr[1-beta])O3, wherein 0 <= alpha <=1, 0 <= beta <=1, 0 <= gamma <= 1 and 0.9 <= m <= 1.1,. The modified additive is one or more of MnCo3, MgCO3 and Re2O3, wherein Re2O3 is a rare earth oxide, and the sintering aid comprises one or more of BaCO3, CaCO3, SiO2, Li2CO3, B2O3 and Al2O3. The dielectric ceramic composite provided by the invention meets the media characteristics of COG (Chip On Glass), the dielectric constant is between 20-30 and an ROHS (Restriction of Hazardous Substances) demand is satisfied. An MLCC (Multiplayer Ceramic Chip Capacitor) prepared by the dielectric ceramic material is lower in dielectric loss, and excellent in dielectric constant temperature coefficient and dielectric frequency characteristic.

Owner:CHAOZHOU THREE CIRCLE GRP

Profiled screen panel

InactiveCN108761627AReduce widthIncrease the proportionMechanical apparatusLight guides for lighting systemsChip on filmFlexible circuits

The invention relates to a profiled screen panel. The upper end of the profiled screen panel has a longitudinal groove formed by opening / notch design. The bonding pad area of the panel is disposed inthe groove and is provided with a connection terminal. The connection terminal is electrically connected to a driving chip and a flexible circuit board. The flexible circuit board is bent to the backof the panel. The driving chip is pressed against the flexible circuit board by a chip-on-film sealing method, or the driving chip is pressed against a circuit binding region around the connecting terminal by a chip-on-glass packaging method. The width of the lower frame of the profiled screen panel can be effectively reduced; and the ratio of the screen of a terminal is increased.

Owner:WUHAN CHINA STAR OPTOELECTRONICS TECH CO LTD

Electro-optical device and method for manufacturing the same

InactiveUS20060256273A1Solid-state devicesSemiconductor/solid-state device manufacturingDriver circuitActive matrix

Using thin film transistors (TFTs), an active matrix circuit, a driver circuit for driving the active matrix circuit or the like are formed on one substrate. Circuits such as a central processing unit (CPU) and a memory, necessary to drive an electric device, are formed using single crystalline semiconductor integrated circuit chips. After the semiconductor integrated circuit chips are adhered to the substrate, the chips are connected with wirings formed on the substrate by a chip on glass (COG) method, a wire bonding method or the like, to manufacture the electric device having a liquid crystal display (LCD) on one substrate.

Owner:SEMICON ENERGY LAB CO LTD

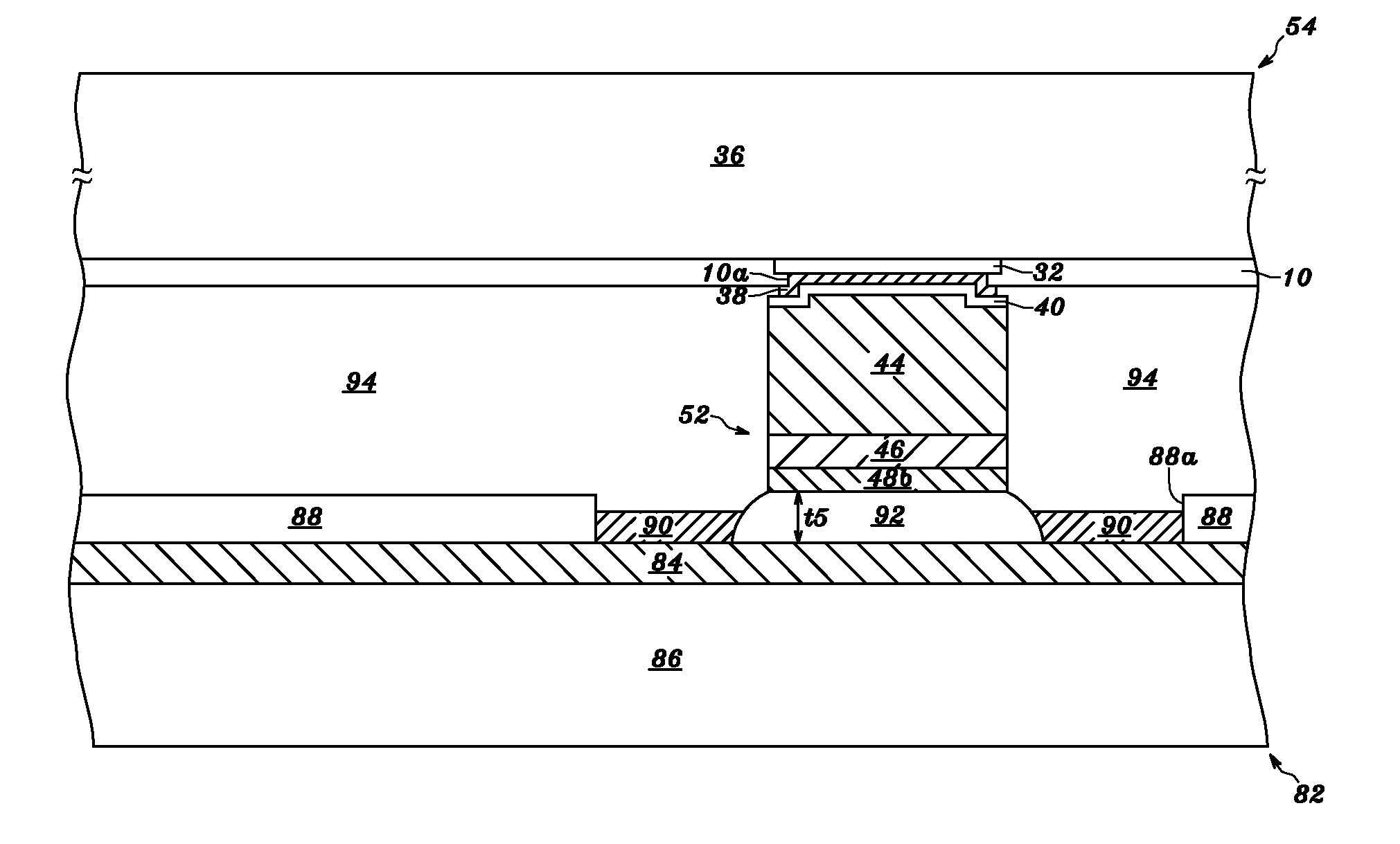

Chip assembly with interconnection by metal bump

ActiveUS8193636B2Improve electrical performanceReduce manufacturing costSemiconductor/solid-state device detailsSolid-state devicesChip on filmSemiconductor chip

A chip assembly includes a semiconductor chip, a bump and an external circuit. The semiconductor chip includes a semiconductor substrate, a transistor in and on the semiconductor substrate, multiple dielectric layers over the semiconductor substrate, a metallization structure over the semiconductor substrate, wherein the metallization structure is connected to the transistor, and a passivation layer over the metallization structure, over the dielectric layers and over the transistor. The bump is connected to the metallization structure through an opening in the passivation layer, wherein the bump includes an adhesion / barrier layer and a gold layer over the adhesion / barrier layer. The external circuit can be connected to the bump using a tape carrier package (TCP), a chip-on-film (COF) package or a chip-on-glass (COG) assembly.

Owner:QUALCOMM INC

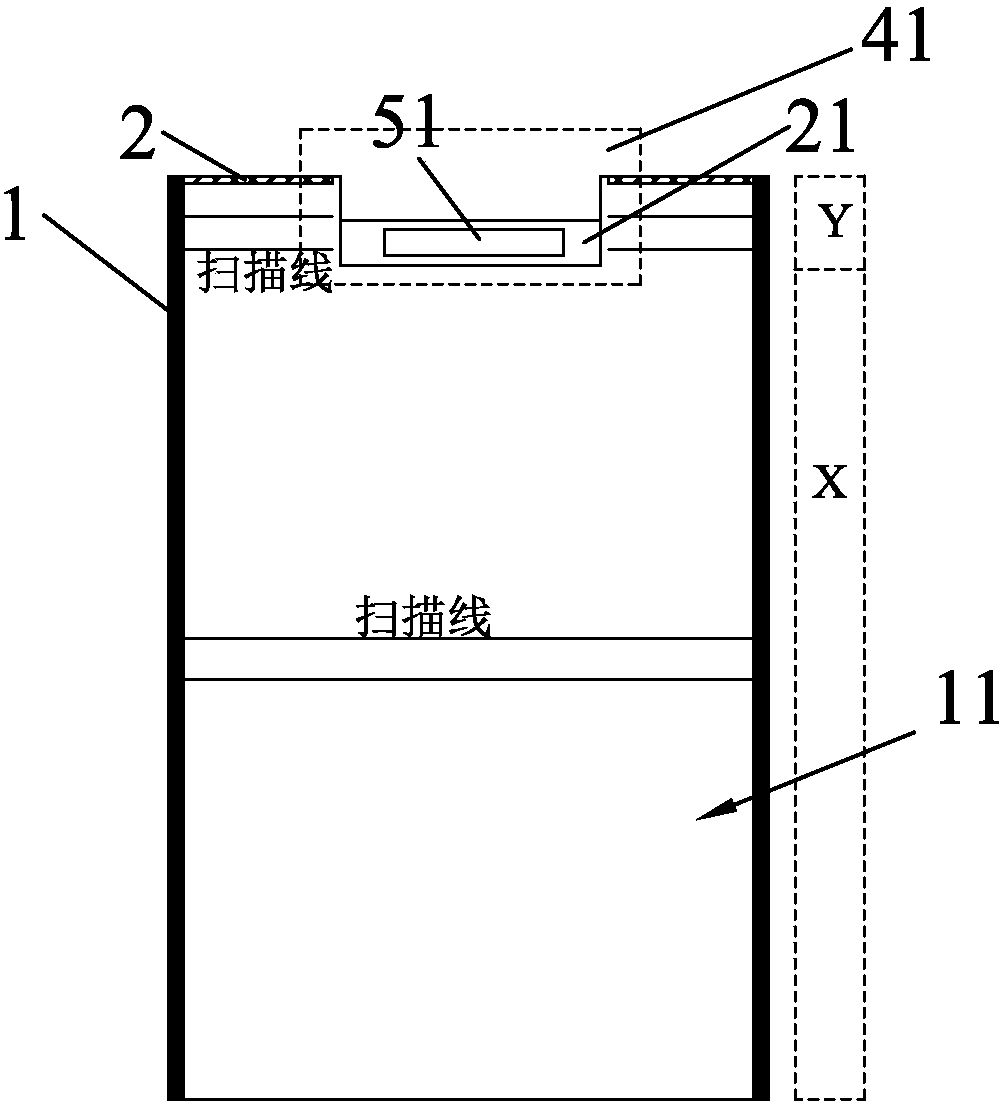

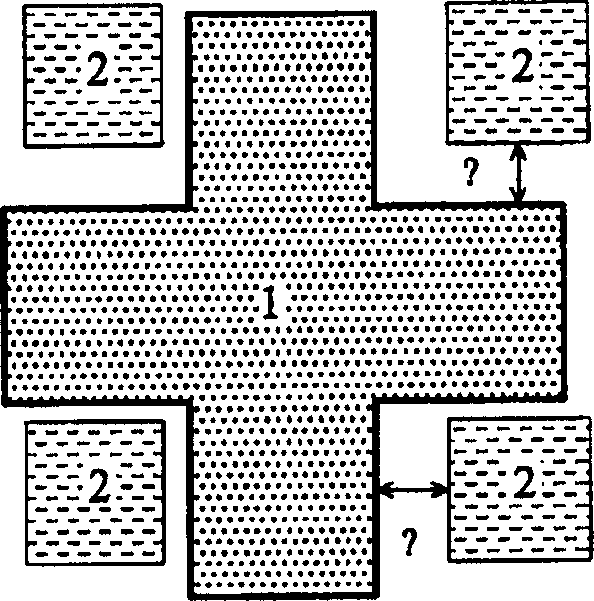

Alignment detection structure and alignment offset detection method

InactiveCN1844845AImprove tuning efficiencyReduce scrap rateStatic indicating devicesElectrical testingComputer scienceChip on glass

The invention relates to an aim detecting structure, which comprises an aim picture on the basic plate, and a frame with known width on the periphery of said picture. The invention can be used in COG (Chip-On-Glass) technique, that with the aim mark of chip, after COG pressing, judging the deflection amount via the relative position of aim mark and the frame; therefore, the invention can directly calculate the deflection after compressing chip to adjust the machine after COG process.

Owner:AU OPTRONICS CORP

Image sensor package structure

InactiveUS20070090478A1Improve package yieldAvoid pollutionSolid-state devicesSemiconductor devicesCMOSSolder ball

An image sensor package structure is proposed, in which an image sensor is fixed on a substrate having metallization traces and an adhesion layer. Electric paths of the package structure are changed from the COG (chip on glass) process to the CIS (CMOS image sensor) process to improve electric characteristics. Moreover, spacers are formed at appropriate positions to prevent glue overflow from contaminating the sensing regions and solder balls. The proposed package structure can also shrink the package area to greatly enhance the yield and quality.

Owner:SIGURD MICROELECTRONICS CORP

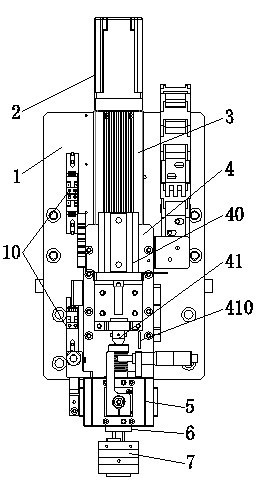

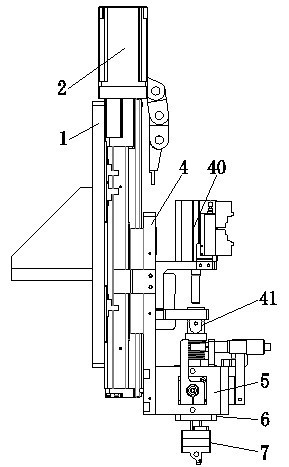

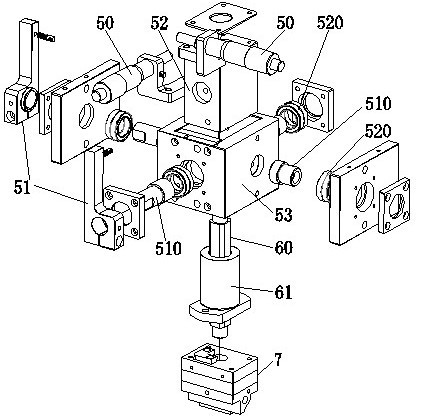

Fully automatic COG (Chip On Glass) bonder pre-pressing pressing head unit

The invention discloses a fully automatic COG (Chip On Glass) bonder pre-pressing pressing head unit, which comprises a stand, a servo motor, a rolling guide rail intelligent combined unit and an adapter plate, wherein the adapter plate is provided with a cylinder, a cylinder connecting rod and a pressing head adjusting component; the servo motor is used for driving the rolling guide rail intelligent combined unit to move the adapter plate up and down; the pressing head adjusting component is fixed on the lower part of the adapter plate; an adjusting end part of the pressing head adjusting component is provided with a high-rigidity rolling needle guide component and a pressing head component; and the pressing head adjusting component is used for performing forward and backward adjustment and leftward and rightward adjustment on the pressing head component through the high-rigidity rolling needle guide component. According to the mode, the fully automatic COG bonder pre-pressing pressing head unit can be positioned above and below Z axis with high accuracy, and the pressing head can be used for continuously and stably adsorbing an IC (Integrated Circuit) chip and then attaching the IC chip to an LCD (Liquid Crystal Display) screen.

Owner:江苏凯立智能制造有限公司

Liquid crystal display

ActiveUS8063497B2Semiconductor/solid-state device detailsSolid-state devicesDisplay deviceEngineering

Owner:HANNSTAR DISPLAY CORPORATION

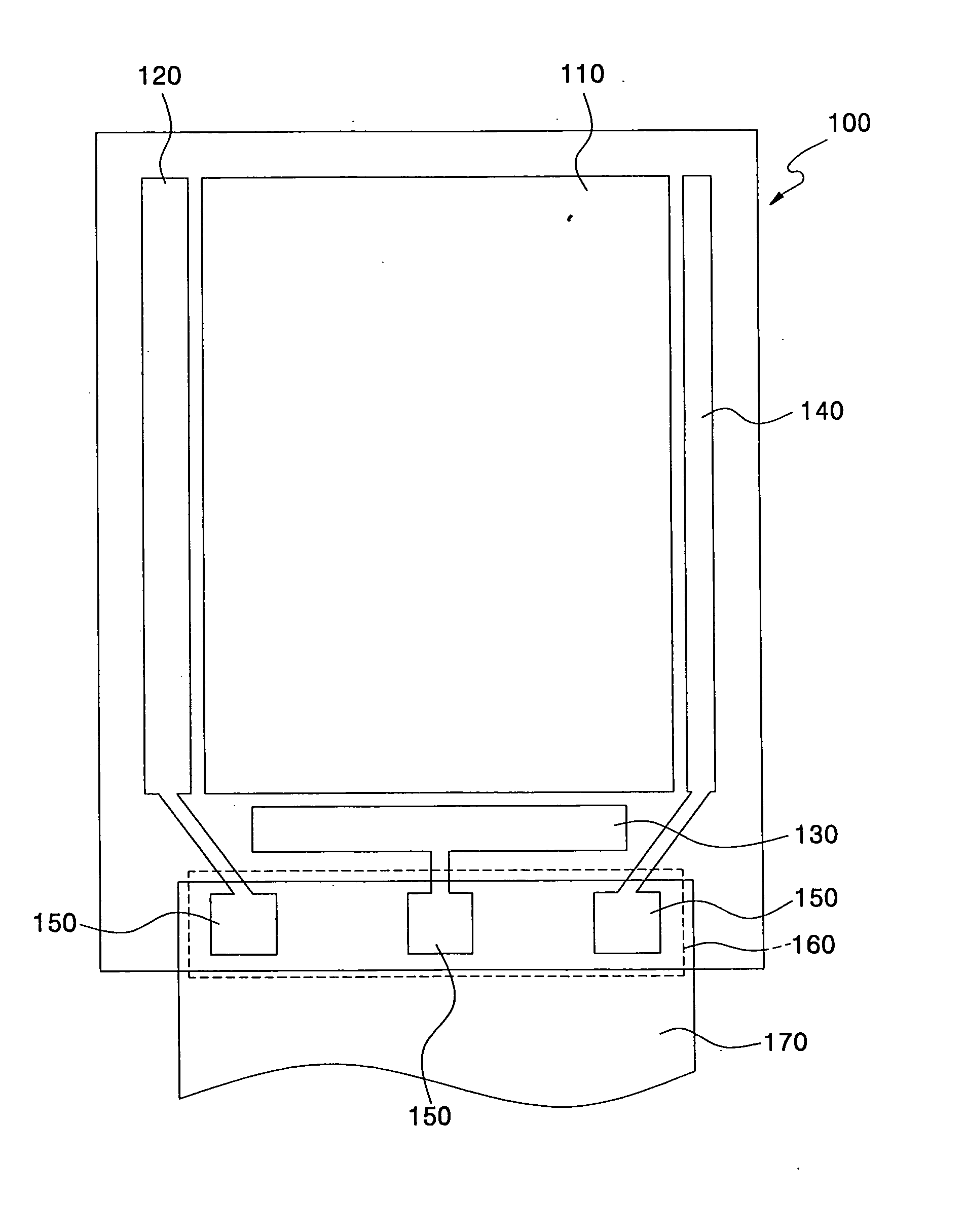

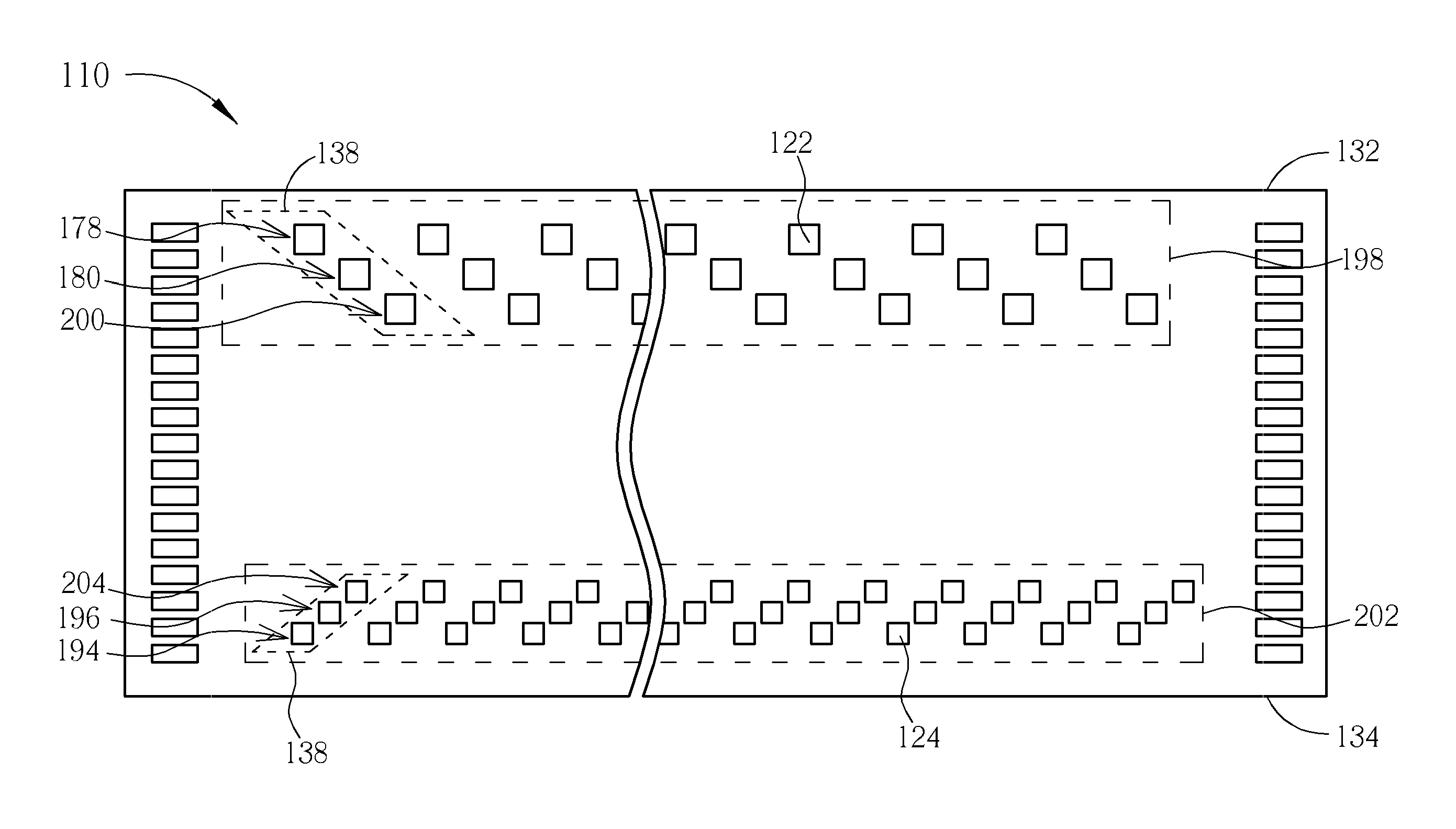

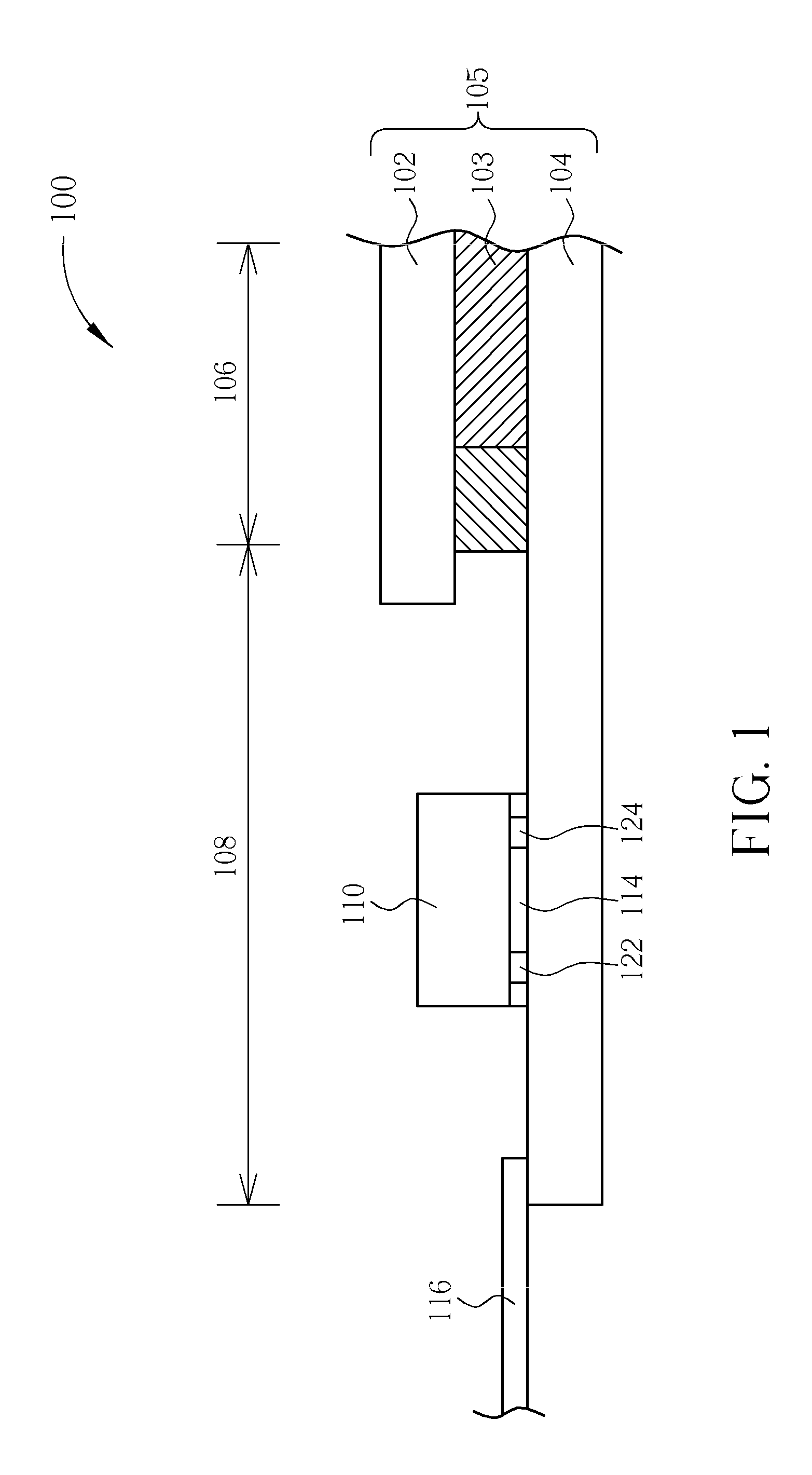

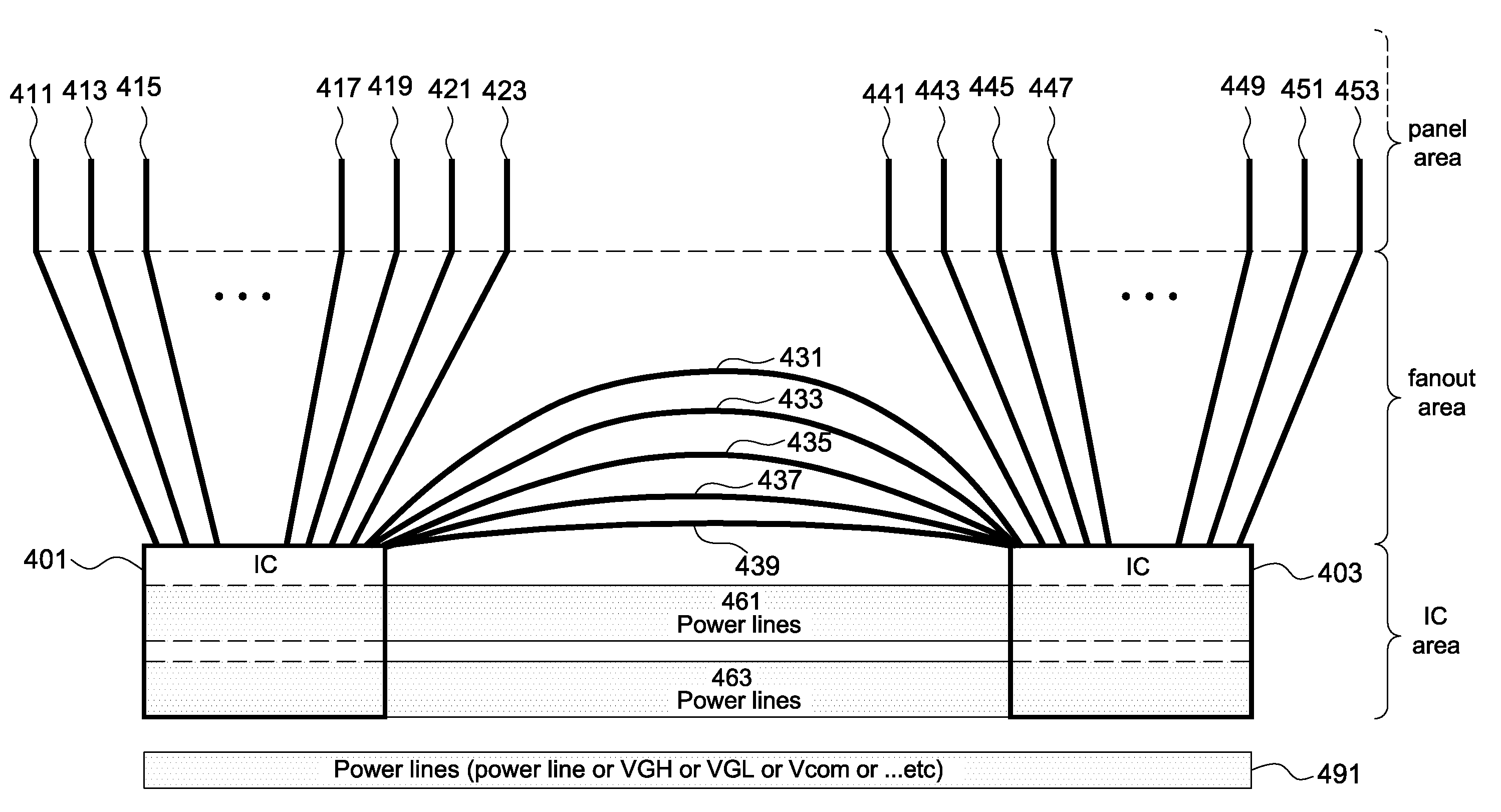

Chip-on-glass panel device

A chip-on-glass panel device includes a glass substrate having a pixel area, an integrated circuit area, and a fan out area, the fan out area located between the pixel area and the IC area, a plurality of integrated circuit devices arranged within the integrated area of the glass substrate, each of the plurality of integrated circuit devices havean active surface, a plurality of output pads, each arranged on the active surface, and a plurality of signal pads / gamma pads, each arranged on the active surface, and a plurality of signal wires / gamma wires, each having a curved shape geometry and disposed within the fan out area, for connecting the plurality of signal pads / gamma pads of adjacent ones of the plurality of integrated circuit devices through the fan out area.

Owner:HIMAX TECH LTD

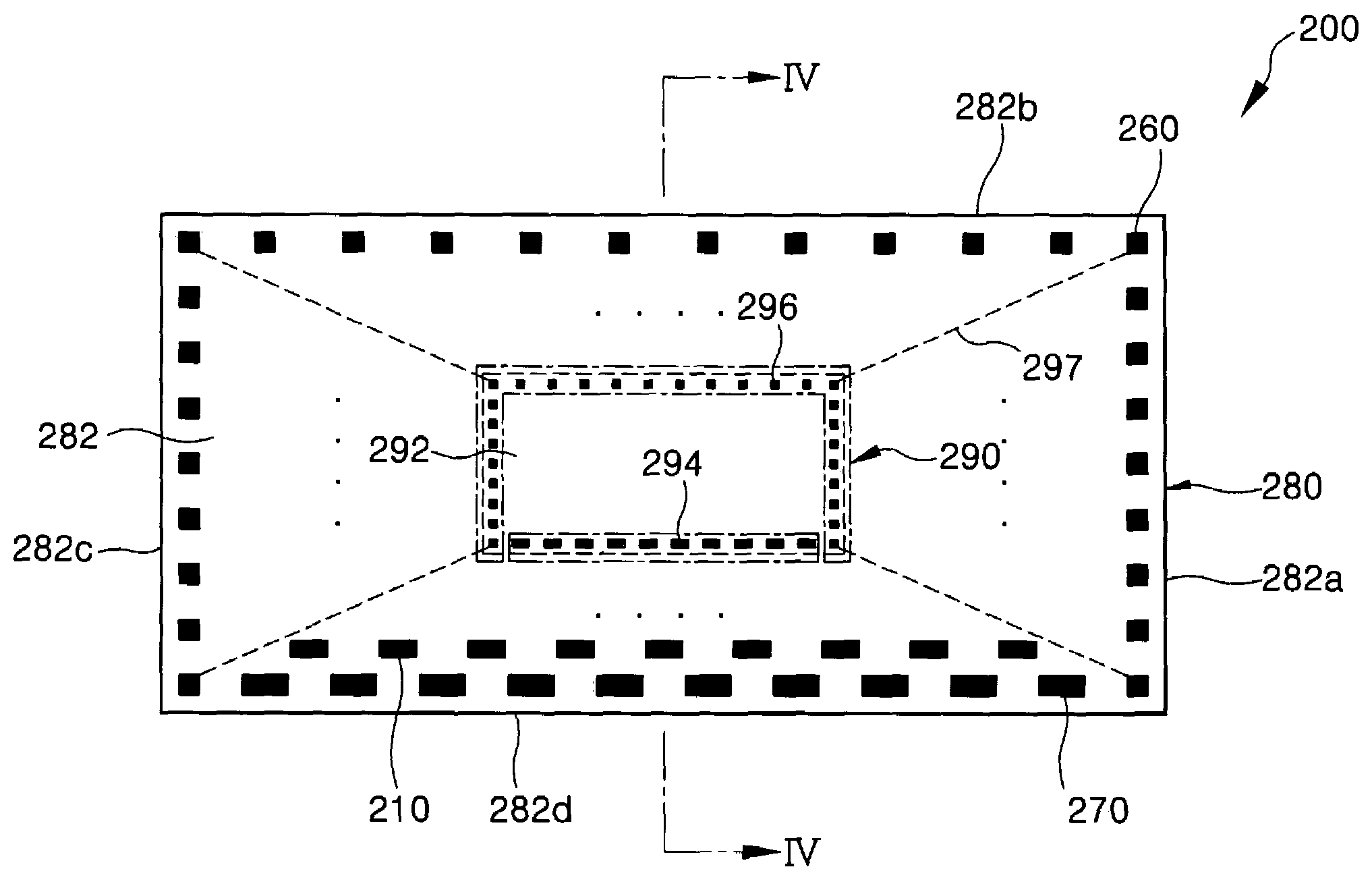

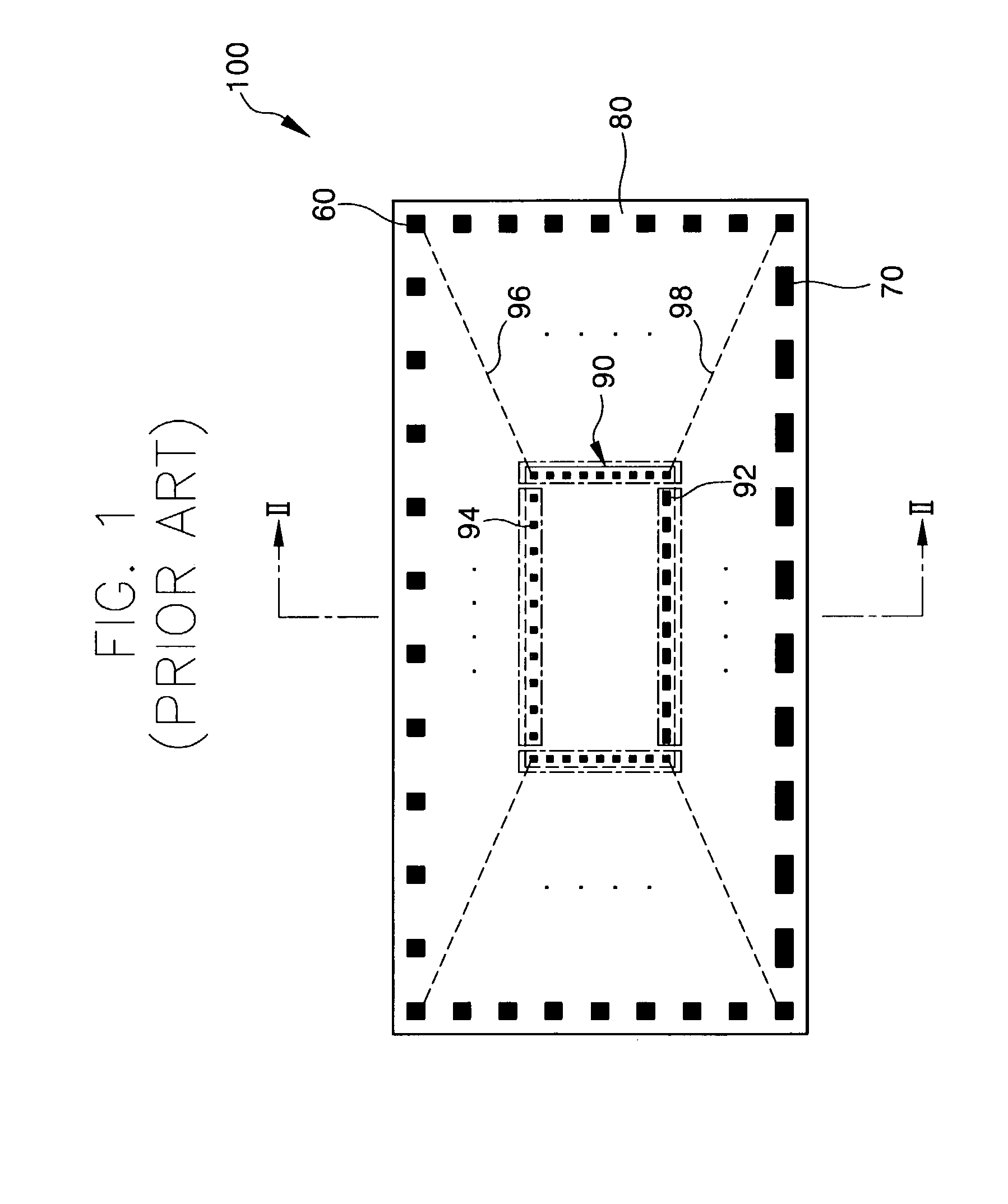

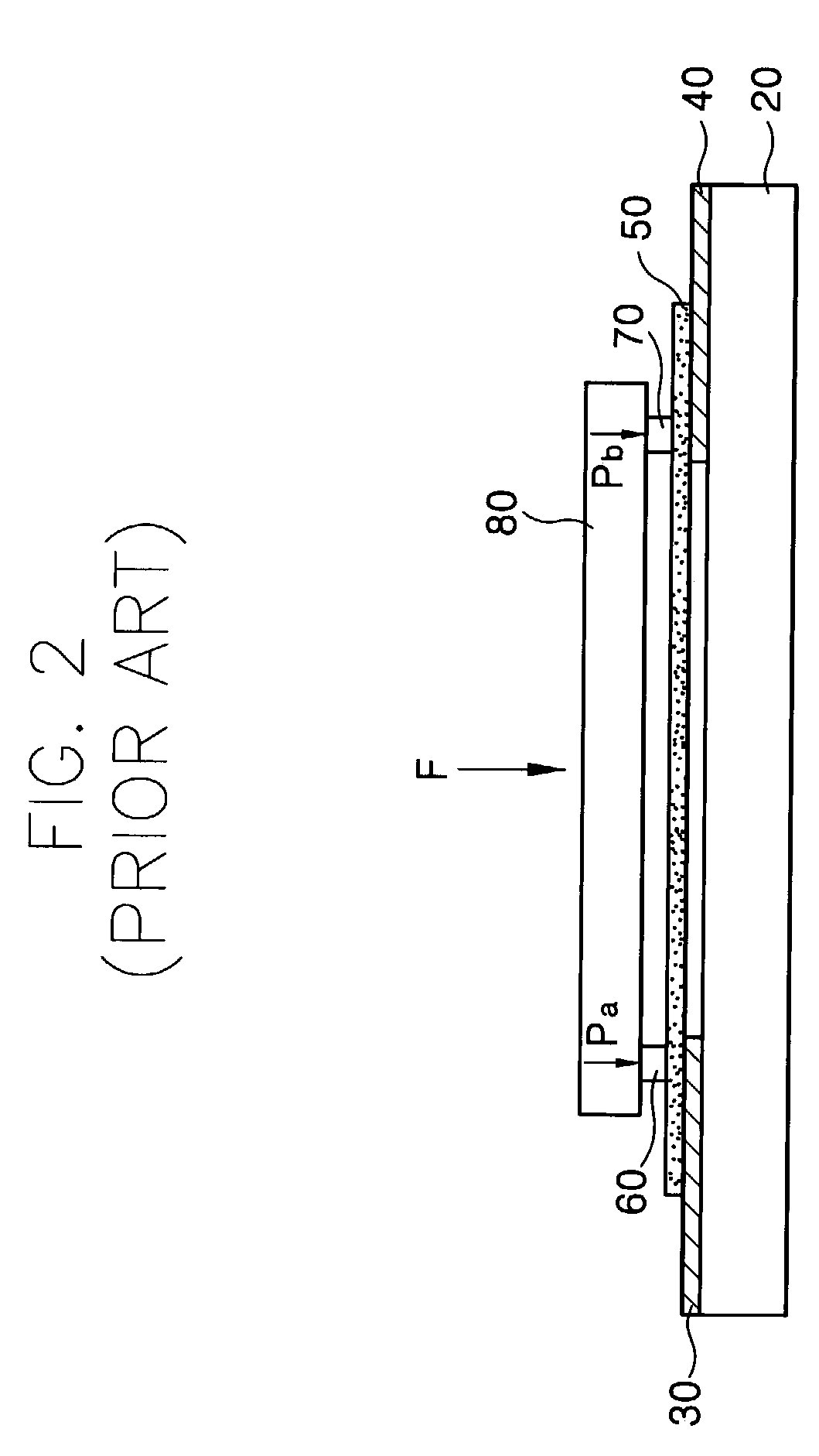

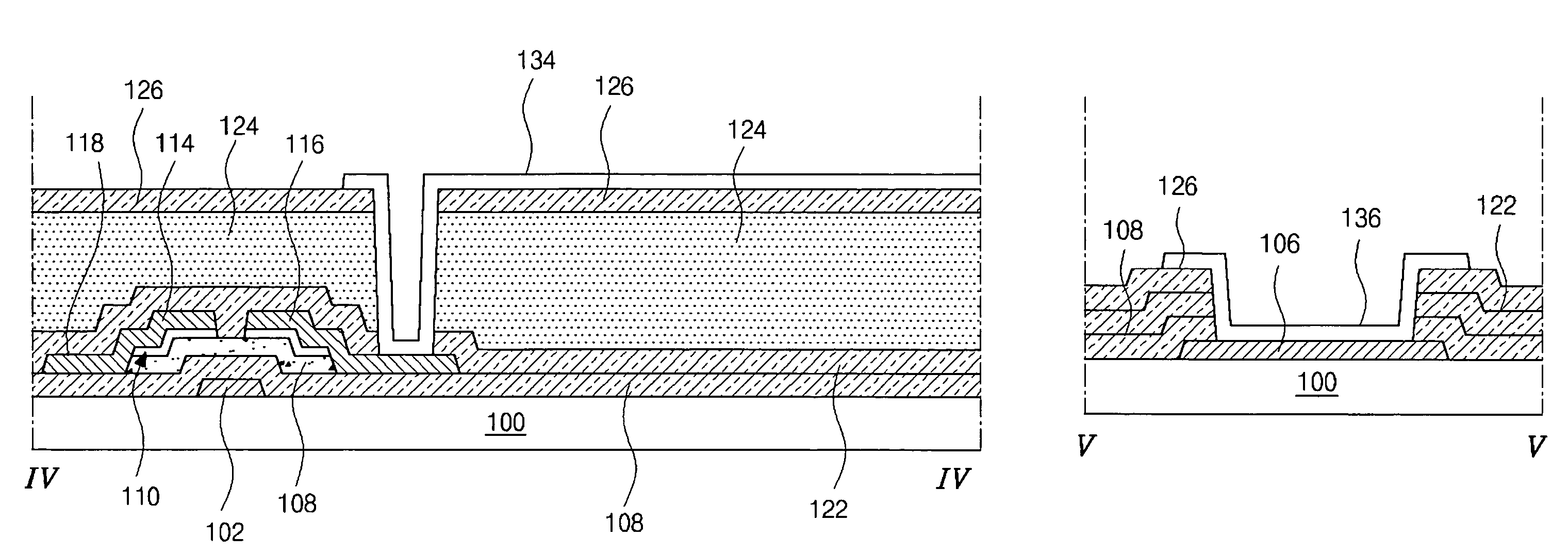

Chip-on-glass array substrate of liquid crystal display device and method of fabricating the same

An array substrate device for a liquid crystal display device includes a gate line, a gate pad connected to a first end of the gate line, a gate insulating layer covering the gate line and the gate pad, a data line over the gate insulating layer and crossing the gate line to define a pixel region, a data pad connected to a first end of the data line, a thin film transistor disposed at a crossing region of the gate and data lines, a first inorganic insulating layer formed on the substrate covering the thin film transistor, the data line, and the data pad, a first organic insulating layer along an entire surface of the first inorganic insulation layer except at portions corresponding to the gate and data pads, a transparent pixel electrode disposed over the first organic insulating layer and connected to the thin film transistor, and a transparent gate pad terminal and a data pad terminal disposed over the first organic insulating layer and connected to the gate and data pads, respectively.

Owner:LG DISPLAY CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com