Dielectric ceramic composite and manufacturing method of electronic element thereof

The technology of a dielectric ceramic and its manufacturing method, which is applied in the field of dielectric ceramic composition, can solve the problems of product reliability reduction, etc., and achieve the effect of improving dielectric strength, good reliability, and fine and uniform ceramic crystal grains

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

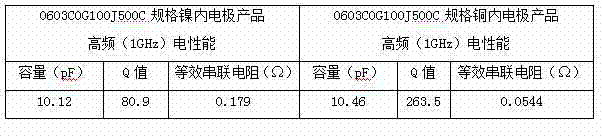

Image

Examples

Embodiment Construction

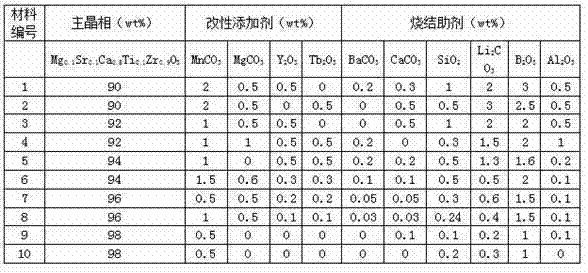

[0022] The present invention will be described in detail below in conjunction with the examples and accompanying tables.

[0023] As shown in Table 1, the present invention discloses a dielectric ceramic composition that can be co-fired with copper. 3 , 0.1molSrCO 3 , 0.8 mol CaCO 3 , 0.1 molTiO 2 , 0.9 mol ZrO 2 ratio for mixing and dispersing. After the dispersion is dried and sieved, it is calcined at 1150°C to obtain the main material Mg 0.1 Sr 0.1 Ca 0.8 Ti 0.1 Zr 0.9 o 3 , and then add the modification additives and sintering aids listed in Table 1 in a predetermined proportion. The modified additive is MnCO 3 , MgCO 3 , Re 2 o 3 One or more of them, where Re 2 o 3 For rare earth oxides, sintering aids include BaCO 3 , CaCO 3 , SiO 2 , Li 2 CO 3 , B 2 o 3 , Al 2 o 3 one or more of them.

[0024]Table 1: Formula table of main materials, modification additives and sintering aids

[0025]

[0026] After the above formulations of porcelain powde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com