Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

53results about How to "Minimize dissolution" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

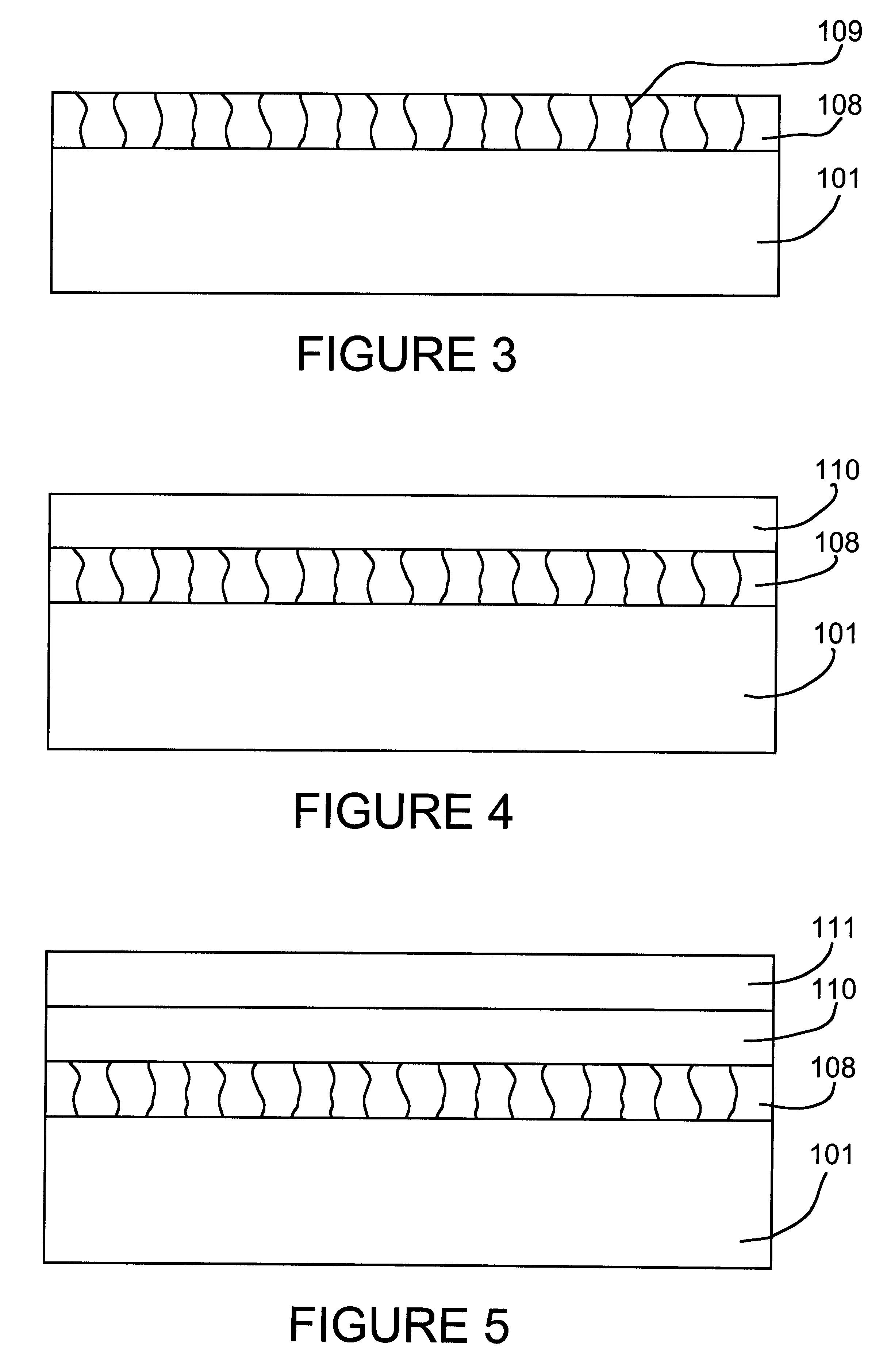

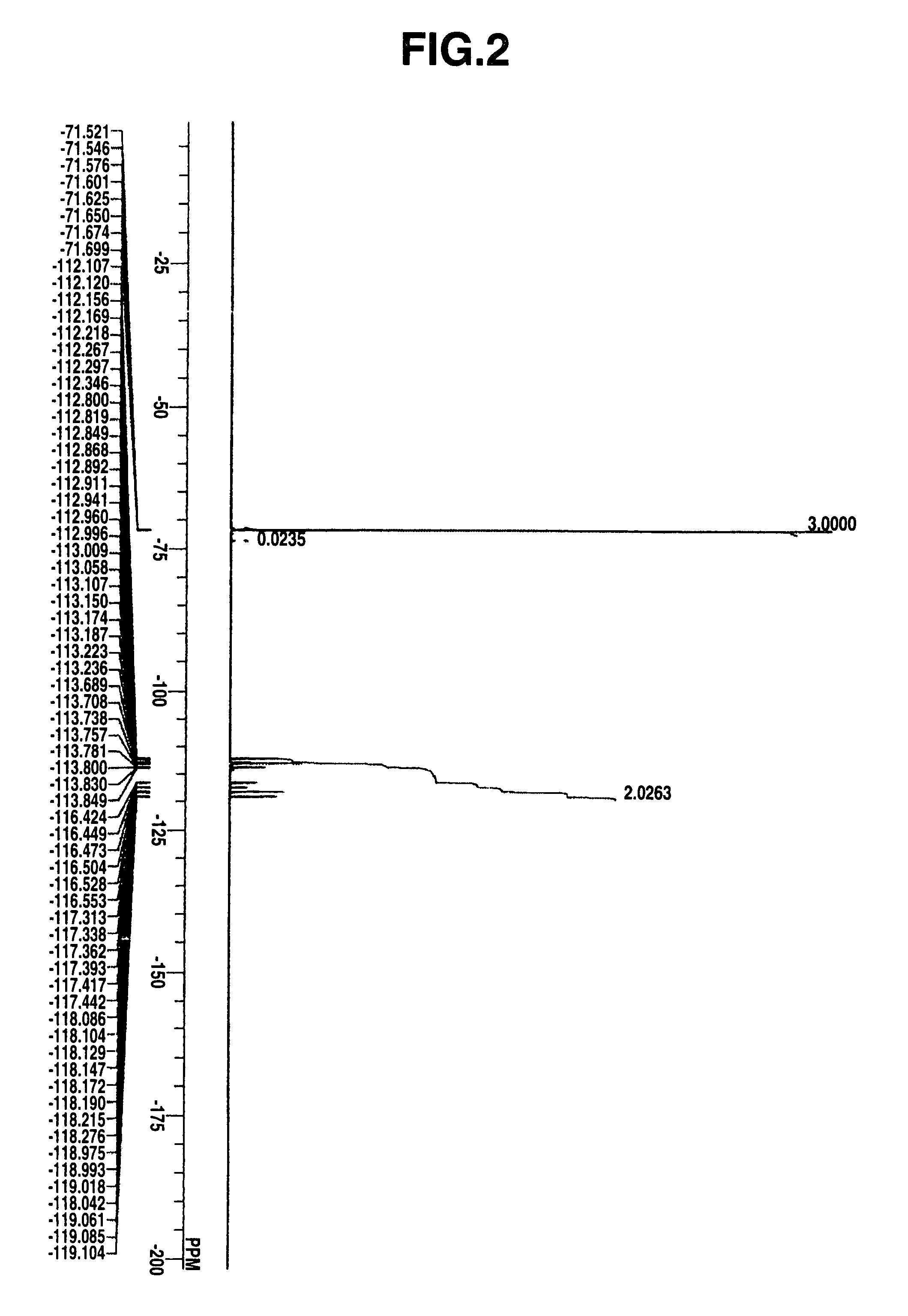

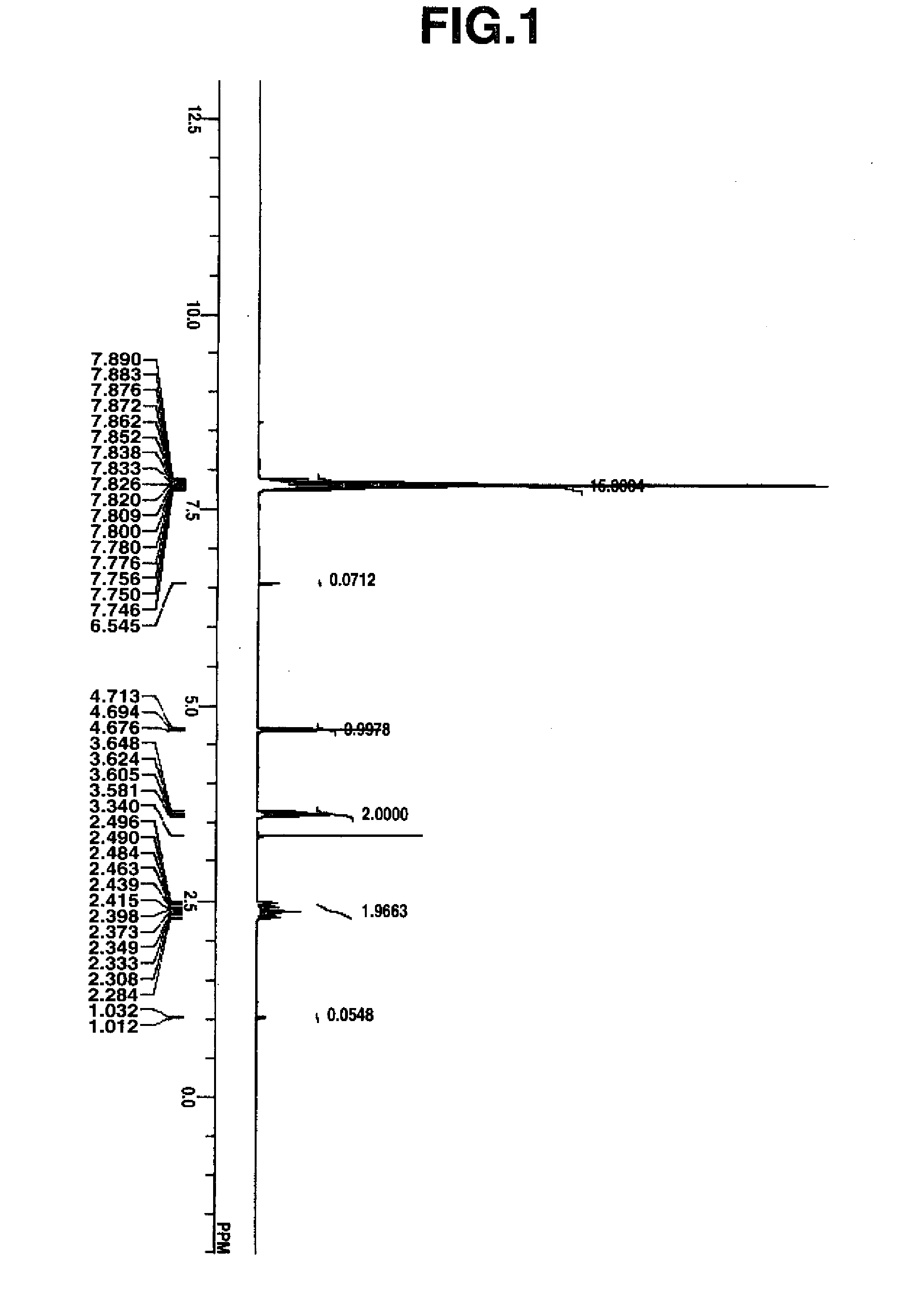

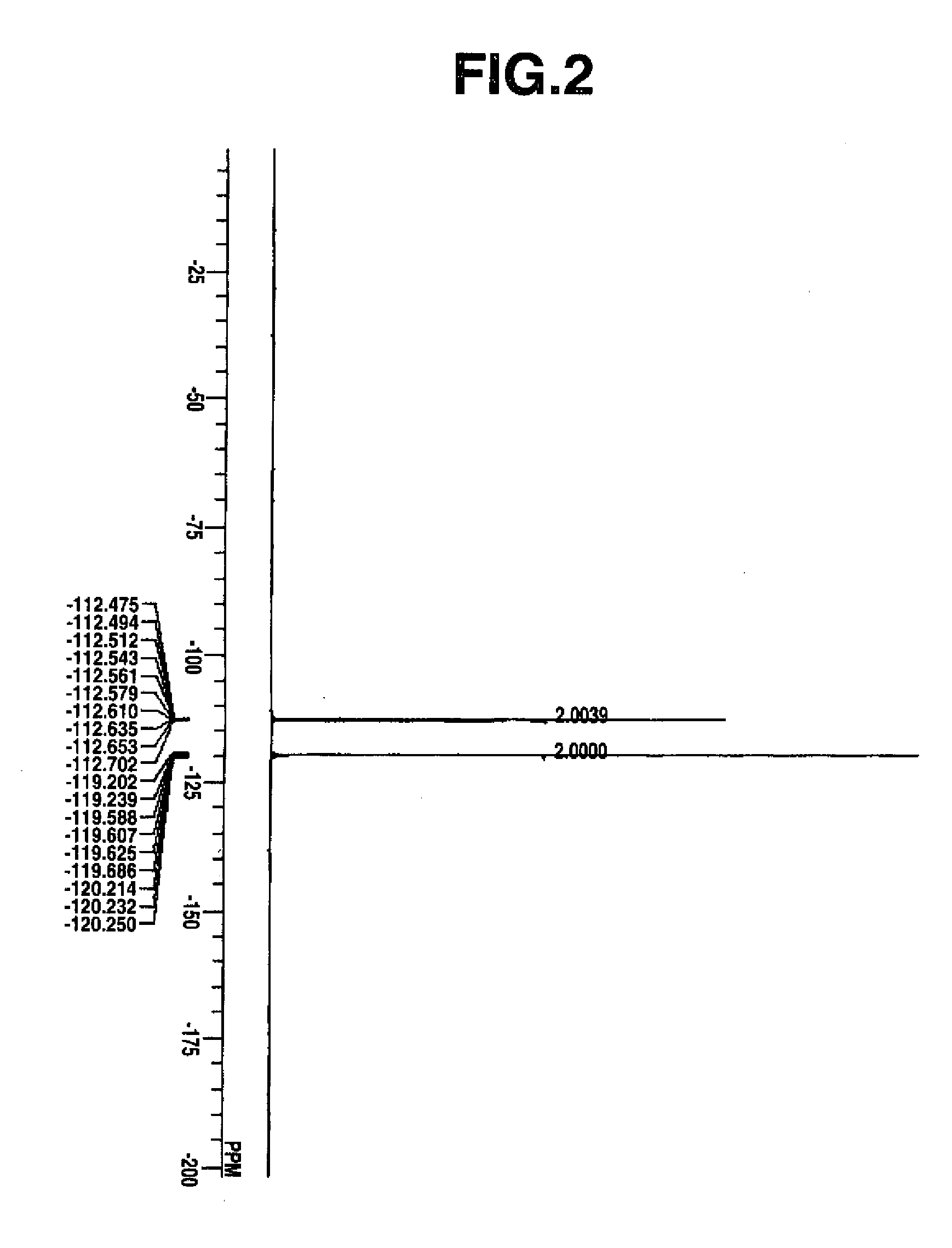

Novel photoacid generators, resist compositions, and patterning process

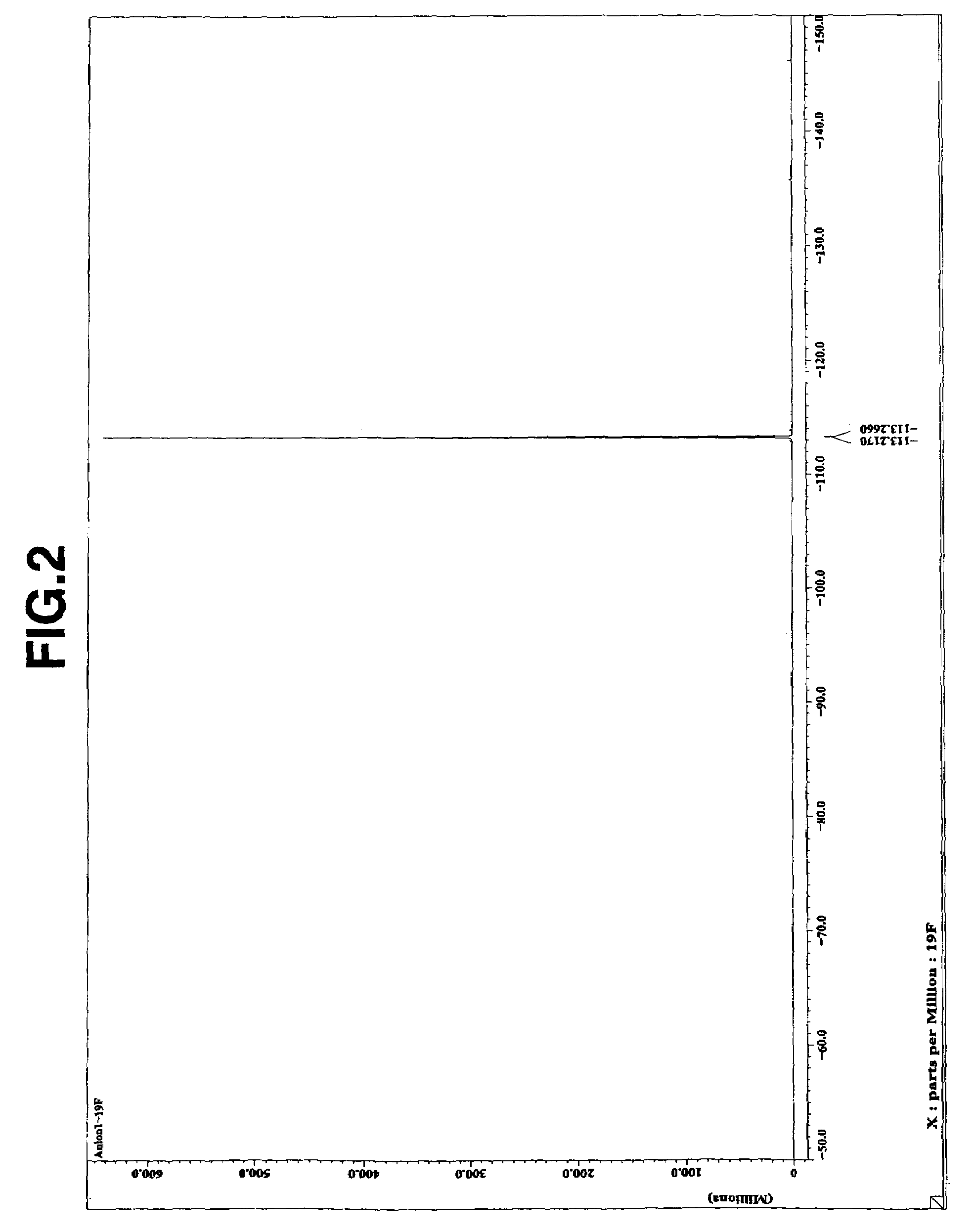

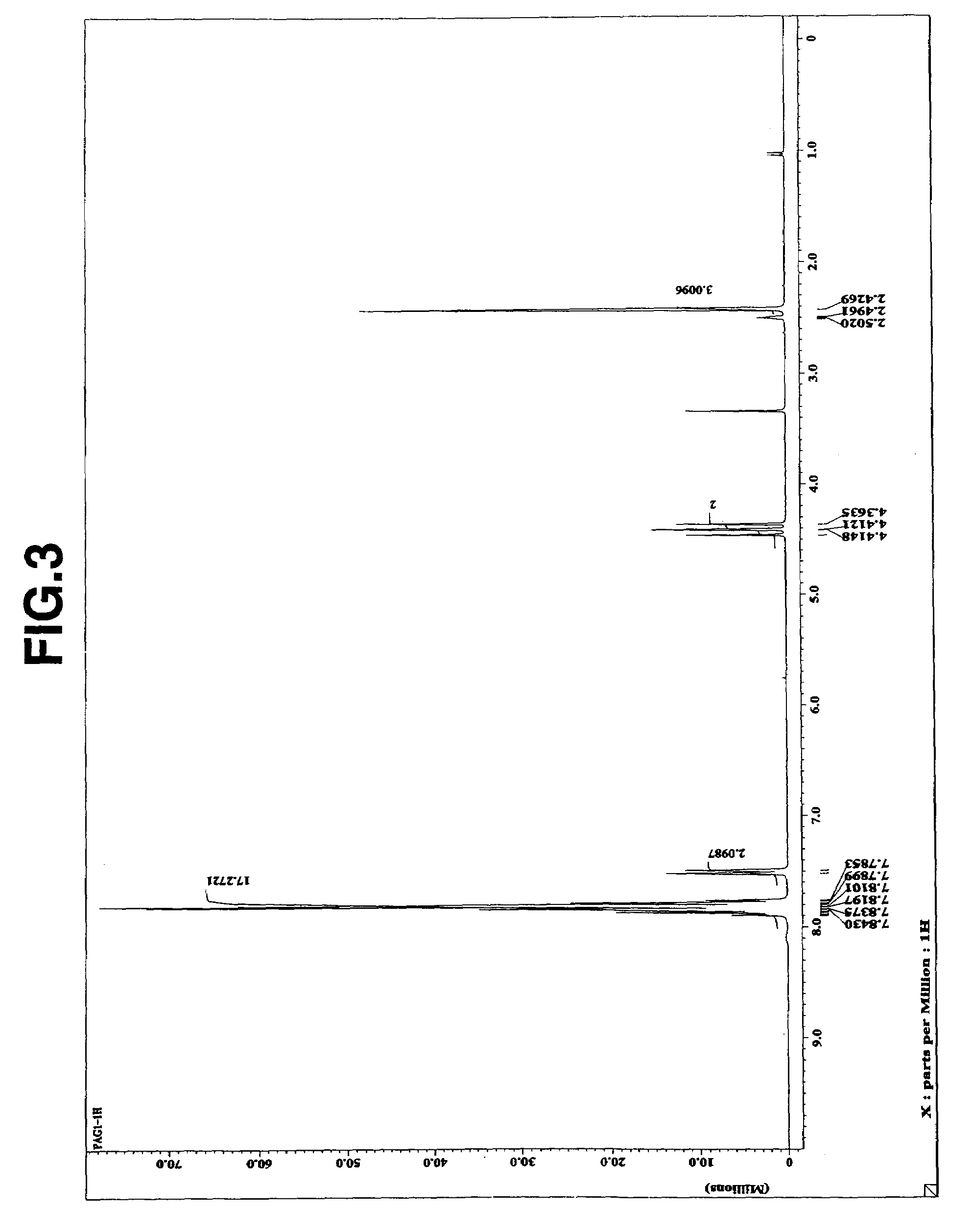

ActiveUS20080085469A1Minimize dissolutionResist formationOrganic chemistryPhotosensitive materialsResistAryl

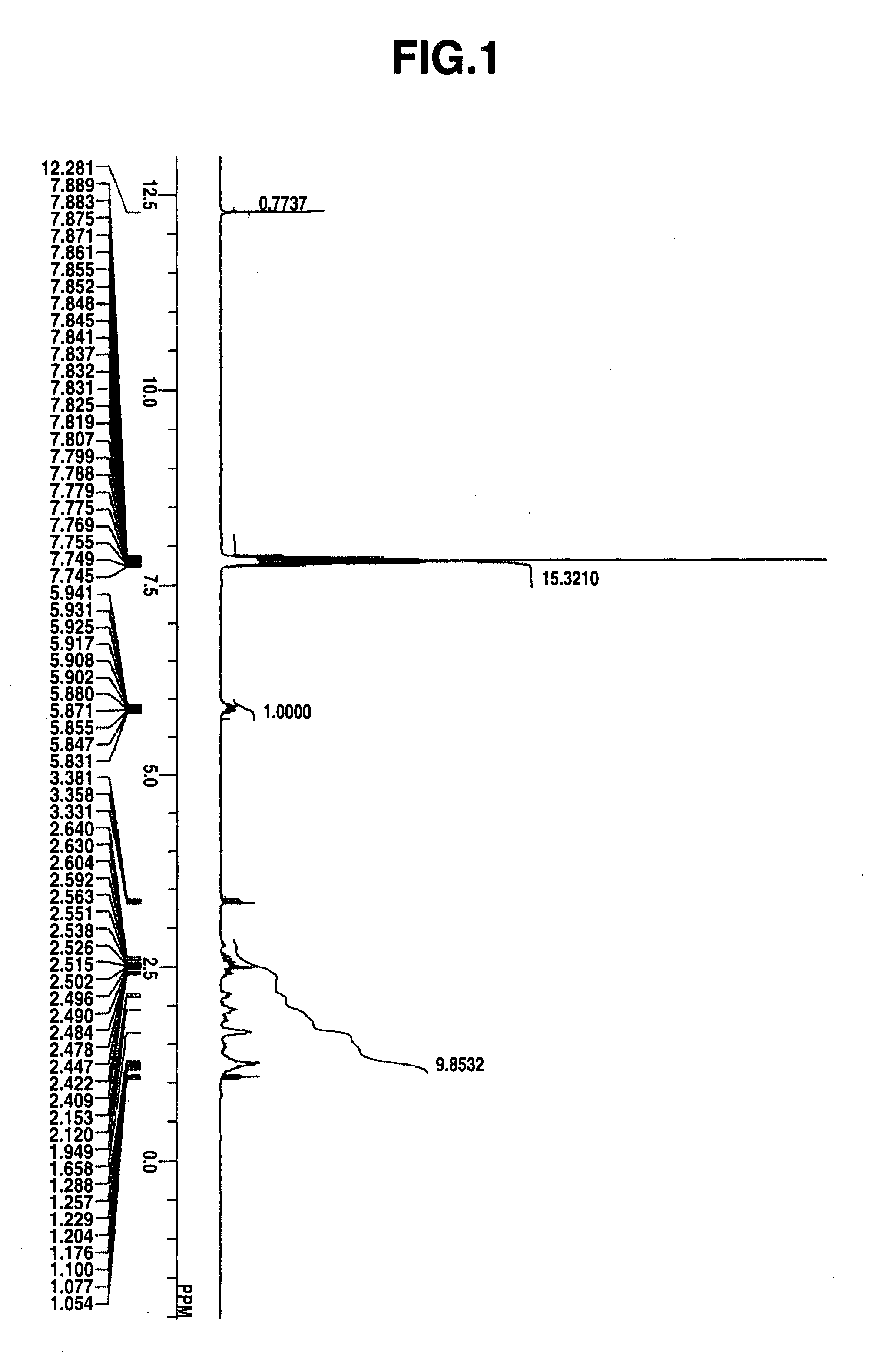

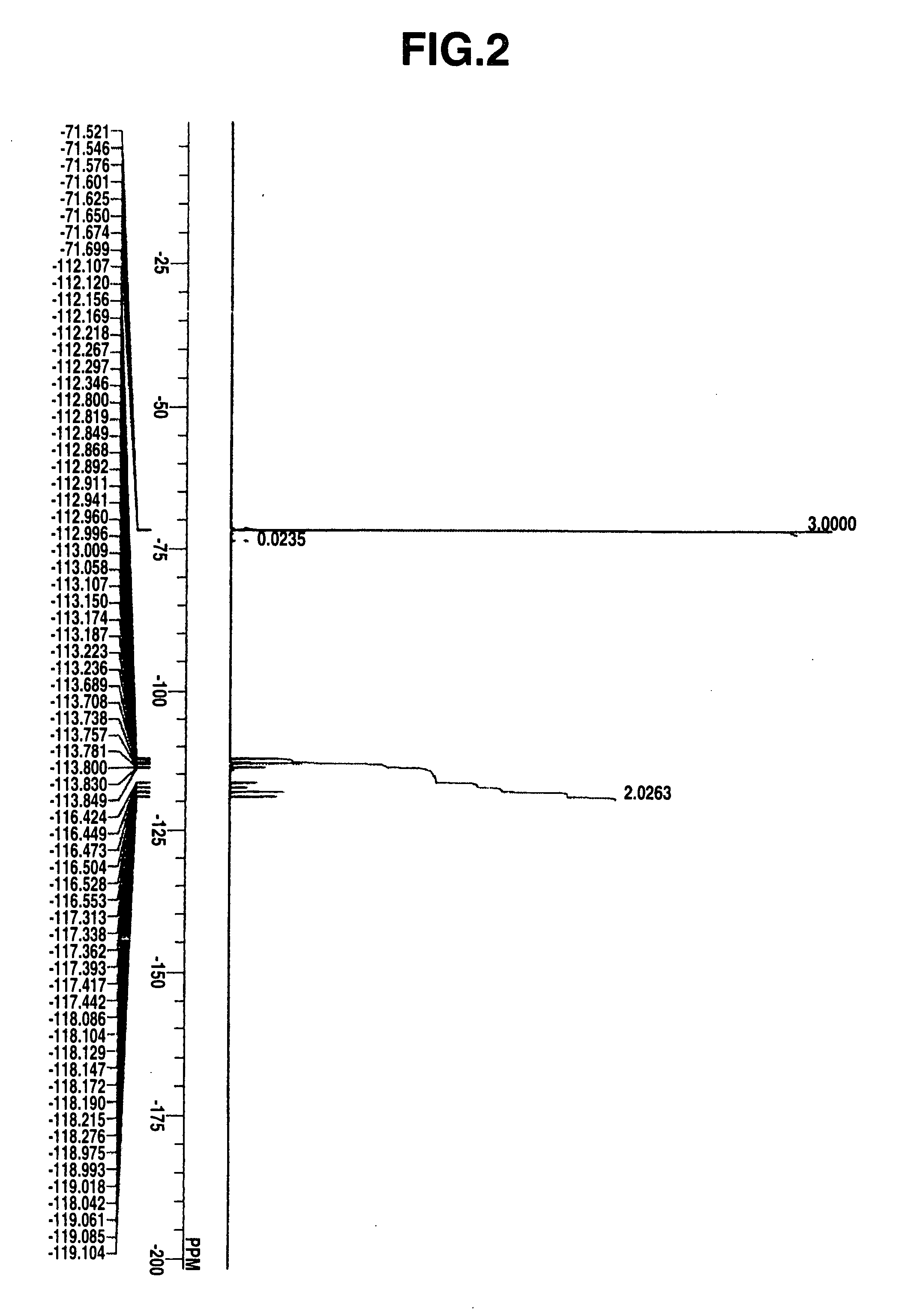

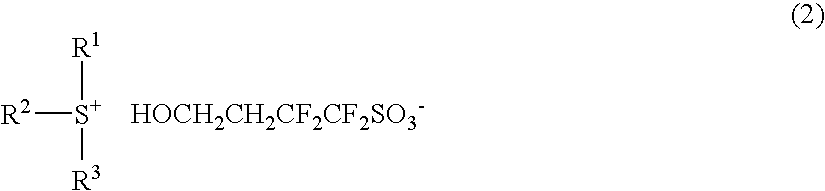

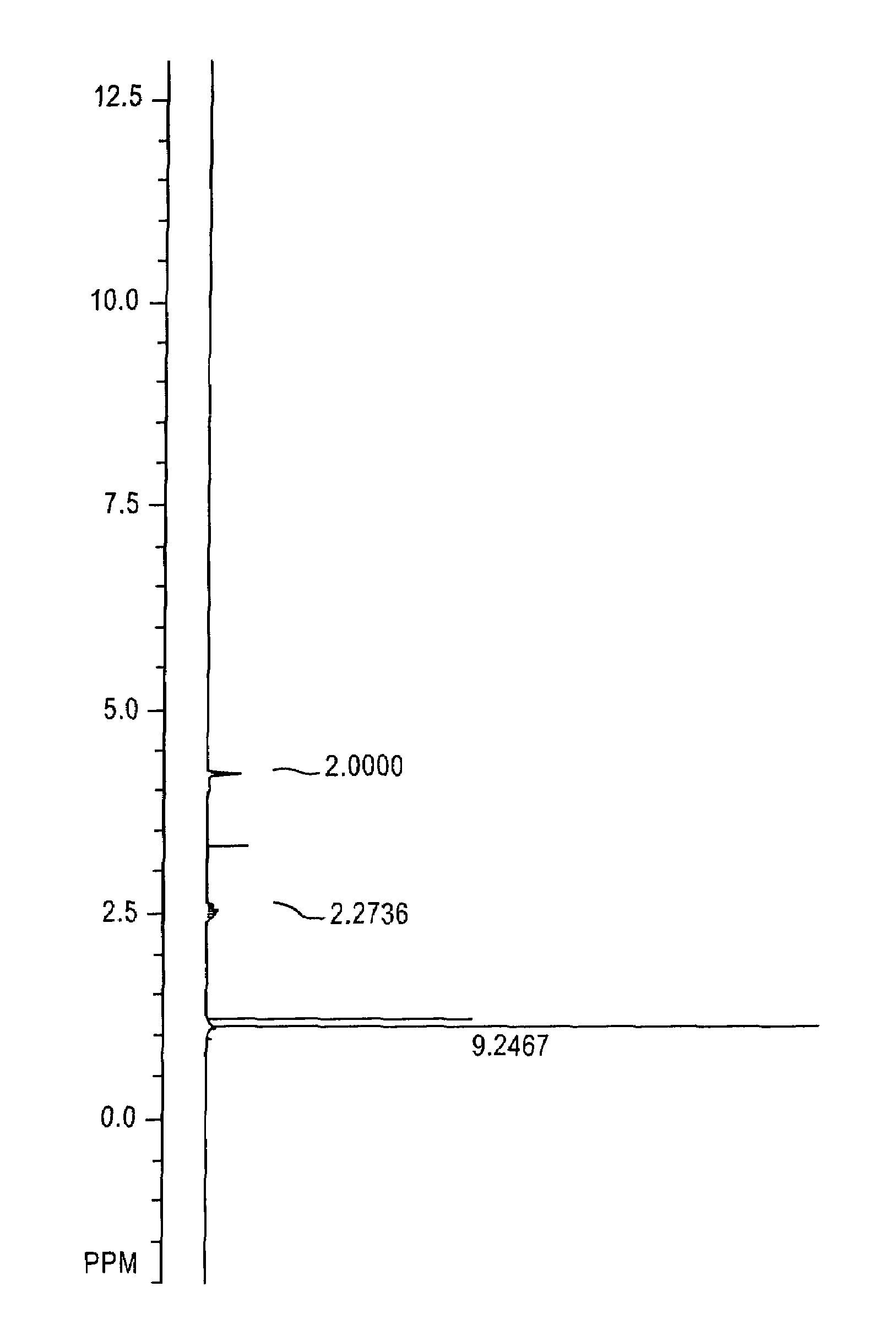

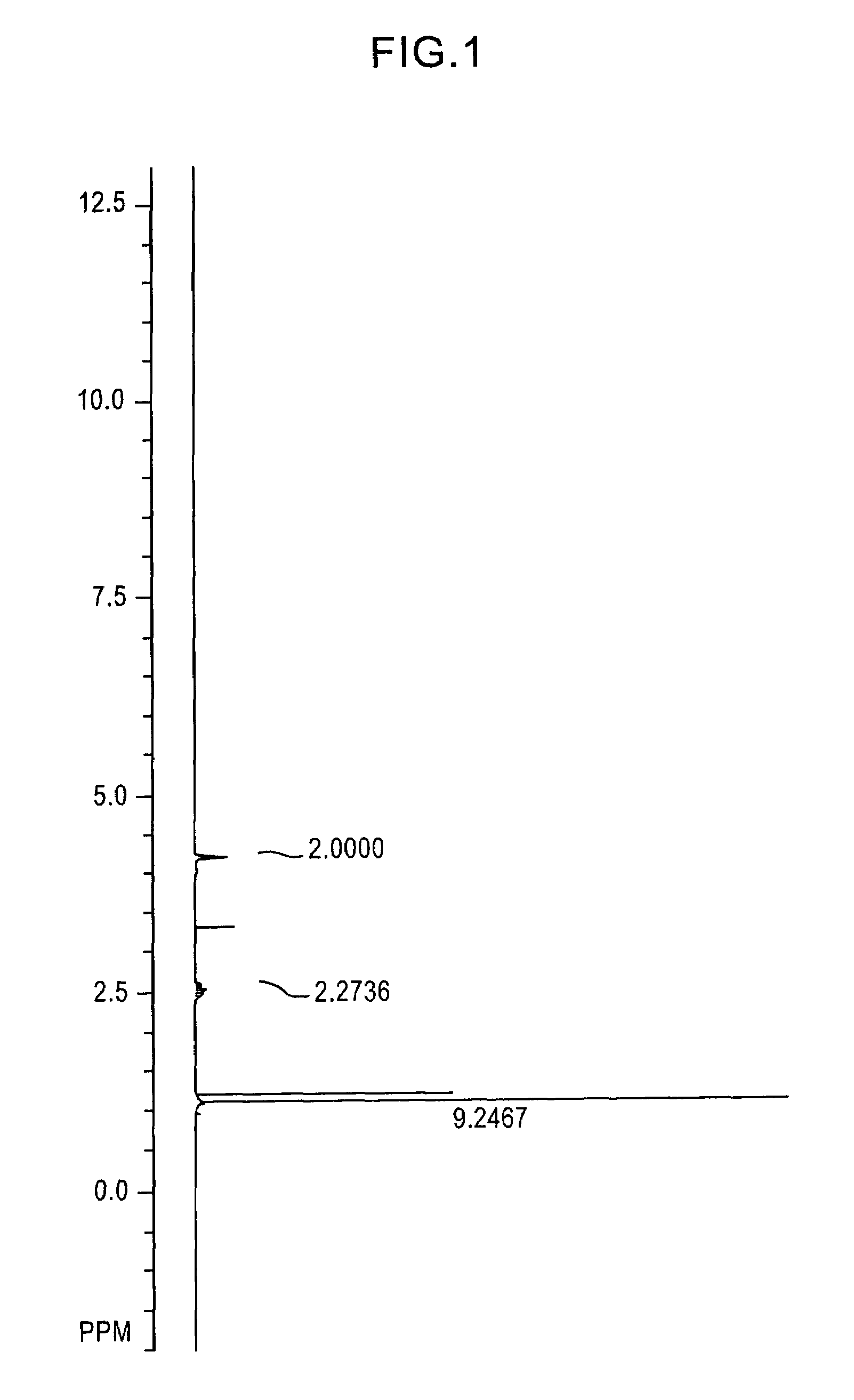

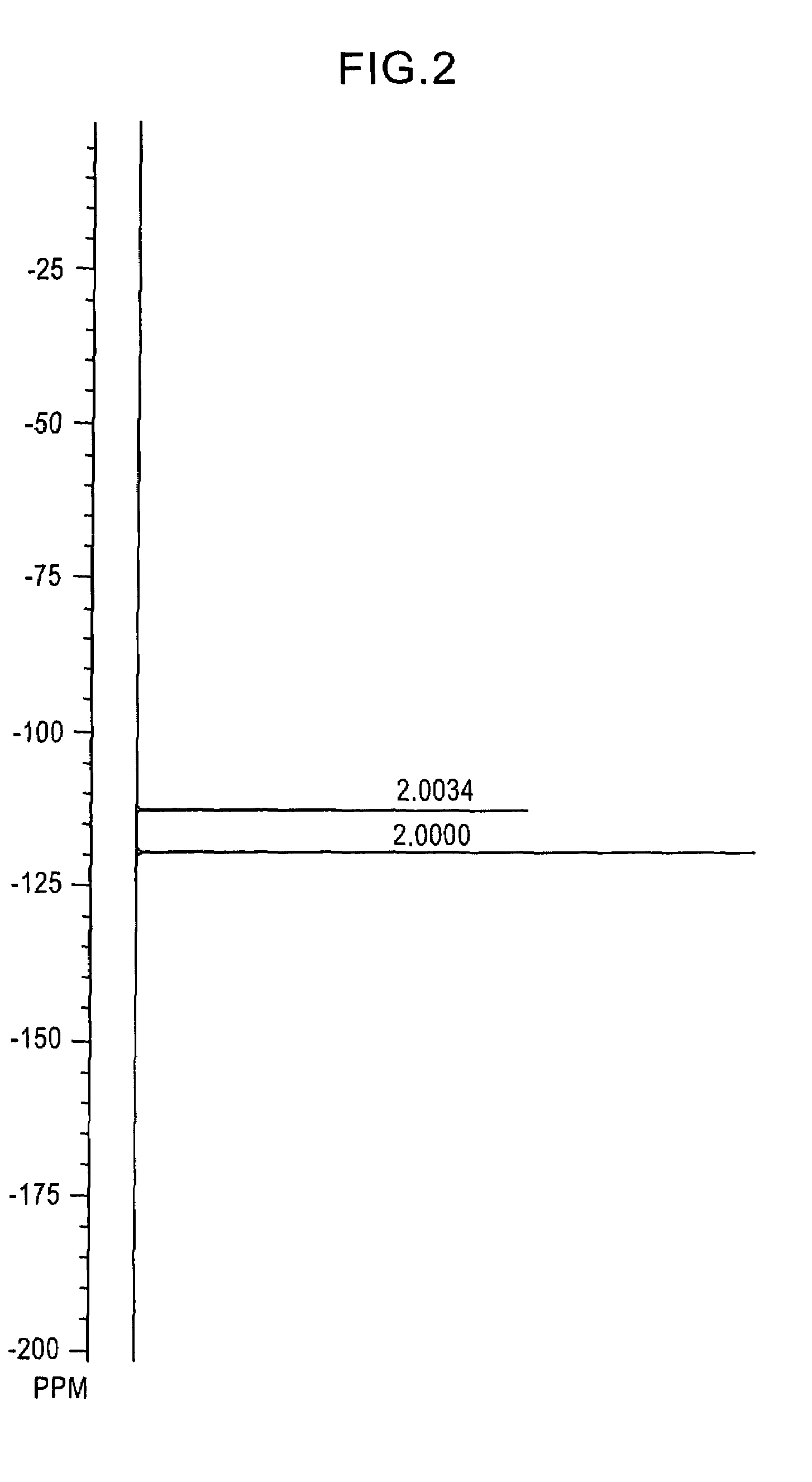

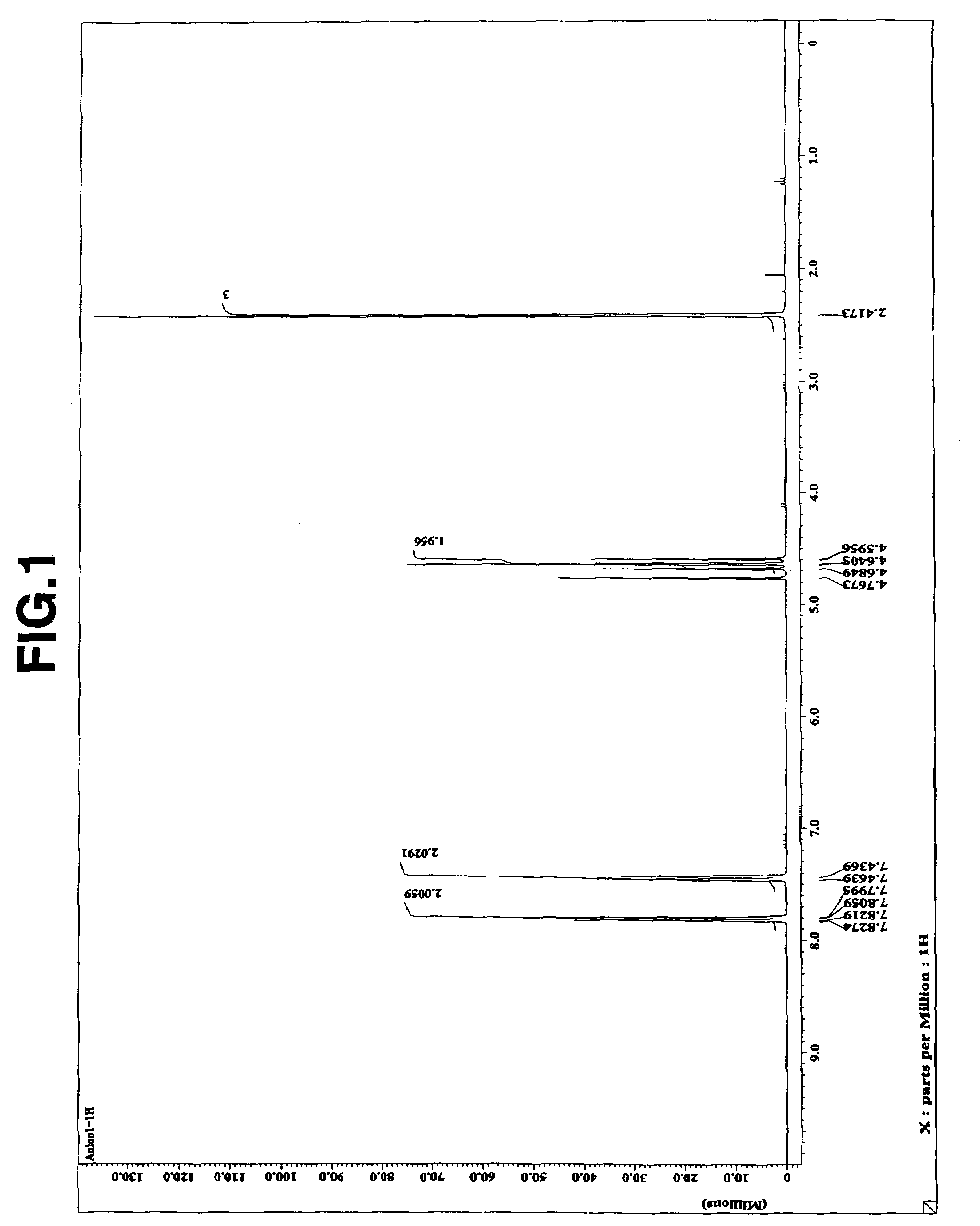

Photoacid generators generate sulfonic acids of formula (1a) upon exposure to high-energy radiation. RC(═O)R1—COOCH(CF3)CF2SO3−H+ (1a) R is hydroxyl, alkyl, aryl, hetero-aryl, alkoxy, aryloxy or hetero-aryloxy, R1 is a divalent organic group which may have a heteroatom (O, N or S) containing substituent, or R1 may form a cyclic structure with R. The photoacid generators are compatible with resins and can control acid diffusion and are thus suited for use in chemically amplified resist compositions.

Owner:SHIN ETSU CHEM IND CO LTD

Controlled plating on reactive metals

InactiveUS6503343B1Avoid consumptionInhibited porositySolid-state devicesSemiconductor/solid-state device manufacturingElectroless nickelSolubility

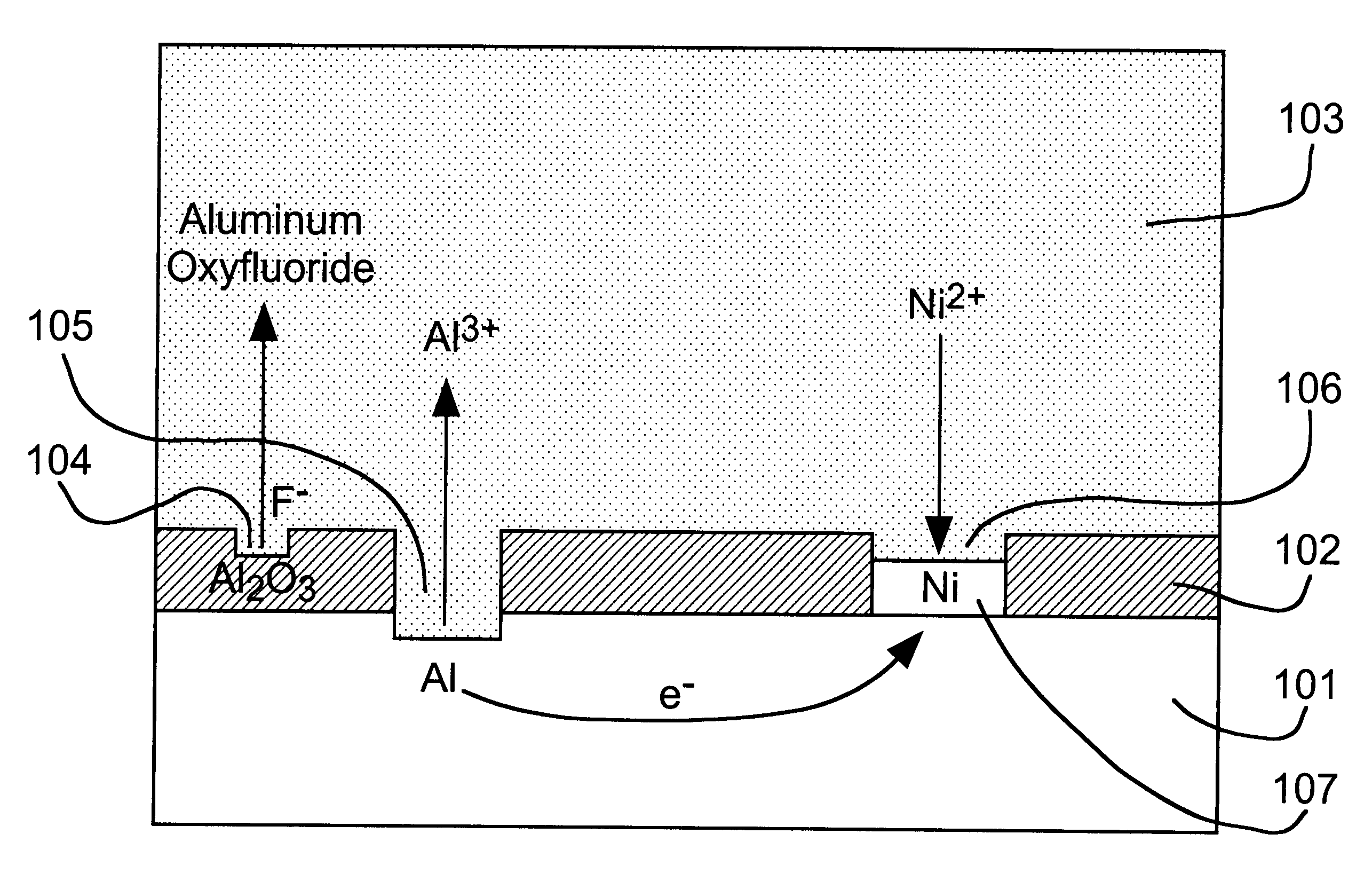

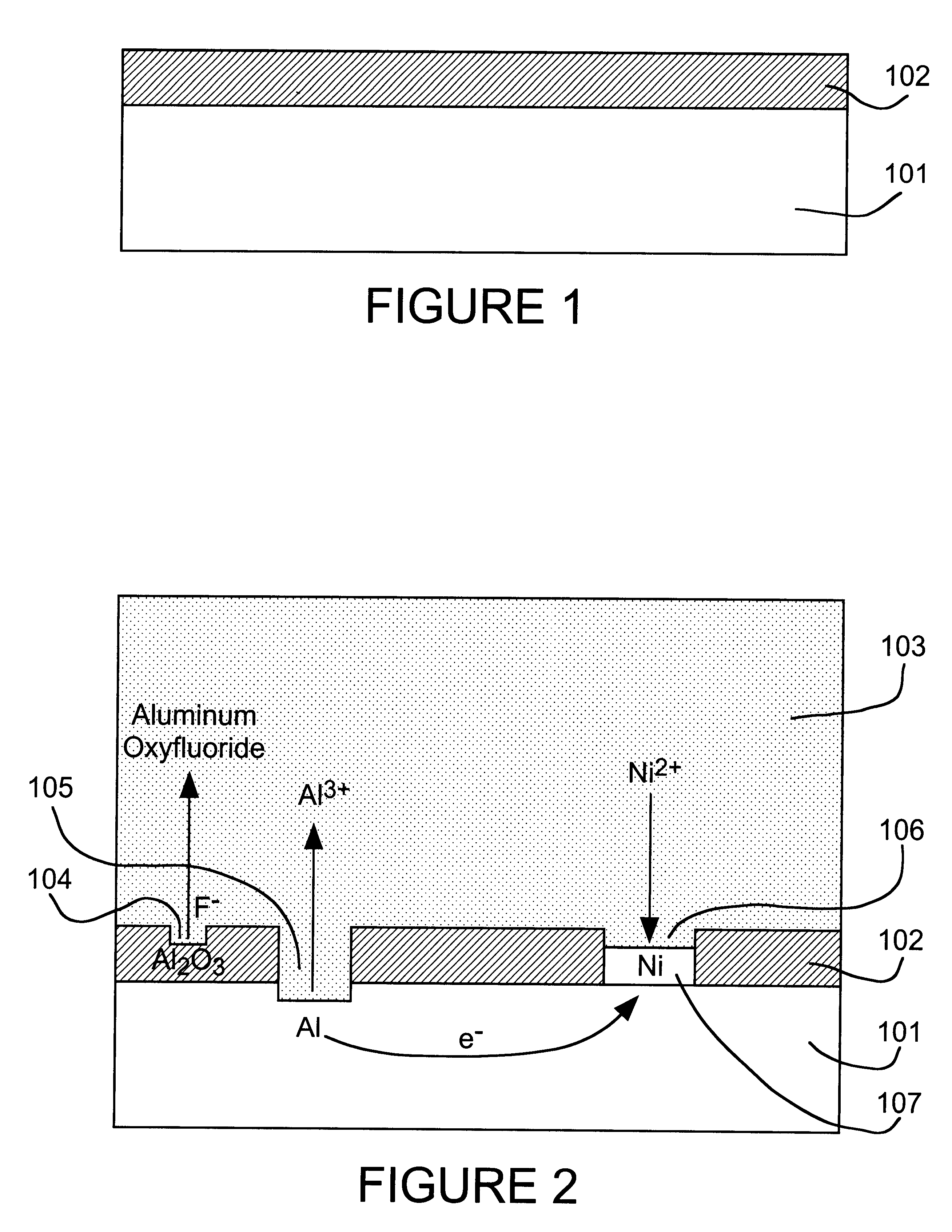

A direct displacement plating process provides a uniform, adherent coating of a relatively stable metal (e.g., nickel) on a highly reactive metal (e.g., aluminum) that is normally covered with a recalcitrant oxide layer. The displacement reaction proceeds, preferably in a nonaqueous solvent, as the oxide layer is dissolved by a fluoride activator. Halide anions are used to provide high solubility, to serve as an anhydrous source of stable metal ions, and to control the rate of the displacement reaction. A low concentration of activator species and little or no solution agitation are used to cause depletion of the activator species within pores in the surface oxide so that attack of the reactive metal substrate is minimized. Used in conjunction with electroless nickel deposition to thicken the displacement coating, this process can be used to render aluminum pads on IC chips solderable without the need for expensive masks and vacuum deposition operations. Such coatings can also be used to preserve or restore wire bondability, or for corrosion protection of aluminum and other reactive structural metals and alloys. A thin layer of immersion gold can be used to protect the thickened coating from oxidation. The solderable aluminum IC chip pads provide the basis for a maskless bumping process for flip chip attachment.

Owner:CALLAHAN CELLULAR L L C

Photoacid generators, resist compositions, and patterning process

ActiveUS7527912B2Minimize dissolutionResist formationOrganic chemistryPhotosensitive materialsResistHigh energy

Photoacid generators generate sulfonic acids of formula (1a) upon exposure to high-energy radiation.RC(═O)R1—COOCH(CF3)CF2SO3−H+ (1a)R is hydroxyl, alkyl, aryl, hetero-aryl, alkoxy, aryloxy or hetero-aryloxy, R1 is a divalent organic group which may have a heteroatom (O, N or S) containing substituent, or R1 may form a cyclic structure with R. The photoacid generators are compatible with resins and can control acid diffusion and are thus suited for use in chemically amplified resist compositions.

Owner:SHIN ETSU CHEM IND CO LTD

Compositions containing benefit agents pre-emulsified using colloidal cationic particles

InactiveUS7871972B2Improve stabilityIncrease depositionInorganic/elemental detergent compounding agentsCosmetic preparationsActive agentColloid

A cleansing or a surface-conditioning composition comprising a mixture of (i) and (ii) in water: i) a surfactant selected from the group consisting of anionic, non-ionic, zwitterionic, cationic, and mixtures thereof; and ii) a hydrophobic benefit agent in a particulate form having a mean particle size in the range of 1-1,000 micron, and a specific gravity of ≧1, not encapsulated within a film or a capsule-like enclosure, the particulate hydrophobic benefit agent comprising: a) a physically-modified form of the hydrophobic benefit agent; and b) a deposition-aid material bonded to the surface of the physically-modified benefit agent, wherein the bonding between the benefit agent and the deposition-aid material is achieved prior to addition to i), wherein said deposition-aid material is not a surfactant having a weight average molecular weight of less than 5,000 Dalton.

Owner:AMCOL INTERNATIONAL CORPORATION

Novel sulfonate salts and derivatives, photoacid generators, resist compositions, and patterning process

ActiveUS20070298352A1Increase acidityAvoid excessive accumulationLithium organic compoundsPhotosensitive materialsResistSulfonate

Owner:SHIN ETSU CHEM IND CO LTD

Detersive compositions containing hydrophobic benefit agents pre-emulsified using sub-micrometer-sized insoluble cationic particles

InactiveUS20060154836A1Improve stabilityIncrease depositionInorganic/elemental detergent compounding agentsCosmetic preparationsEdge surfaceNitrogen

A cationic oil-in-water emulsion for addition to detersive compositions comprising a hydrophilic cationic polymer, an oil-soluble anionic polymer, and a hydrophobic benefit agent in the oil phase made by adding the benefit agent to a hydrophobic liquid; thickening the oil phase with an organophillic smectite clay reacted at clay platelet surfaces to make the clay platelet surfaces hydrophobic while the edge surfaces of the clay remain hydrophilic, such that the benefit agent is adsorbed at an oil / water interface in the emulsion, wherein the anionic polymer is capable of adsorbing the hydrophobic benefit agent at an oil / water interface of the emulsion, and the a hydrophilic, cationic polymer has a cationic nitrogen content of at least 6% by weight, that is incompatible with anionic surfactants, being insoluble in anionic-surfactant solutions containing an amount of 3% or higher of an anionic surfactant, and the hydrophilic cationic polymer has a cationic nitrogen content of at least 0.1% by weight and has a molecular weight of at least 600,000 Dalton.

Owner:AMCOL INTERNATIONAL CORPORATION

Process for producing pentacyl-type crystalline zeolites and a process for producing epsi-caprolactam using the same

InactiveUS6303099B1High activityGood reproducibilityAluminium compoundsLactams preparationPotassiumAmmonium hydroxide

A process for producing a pentacyl-type crystalline zeolite is provided which comprises the steps of (i) preparing a mixture of a silicon compound, water and tetrapropyl ammonium hydroxide, (ii) conducting a hydrothermal reaction of the mixture to obtain a reaction mixture containing zeolite crystals, (iii) separating zeolite crystals from the reaction mixture to collect a remaining solution, (iv) calcinating the resulting zeolite crystals, (v) treating the calcinated zeolite crystals with a solution such as ammonia water and (vi) recycling the solution collected in step (iii) to step (i), wherein in the mixture prepared in step (i) a molar ratio of hydroxide ion to silicon is from about 0.1 to about 0.4 and a molar ratio of potassium to silicon is about 0.1 or less. With this process, a zeolite catalyst having good performance can be produced with good reproducibility.

Owner:SUMITOMO CHEM CO LTD

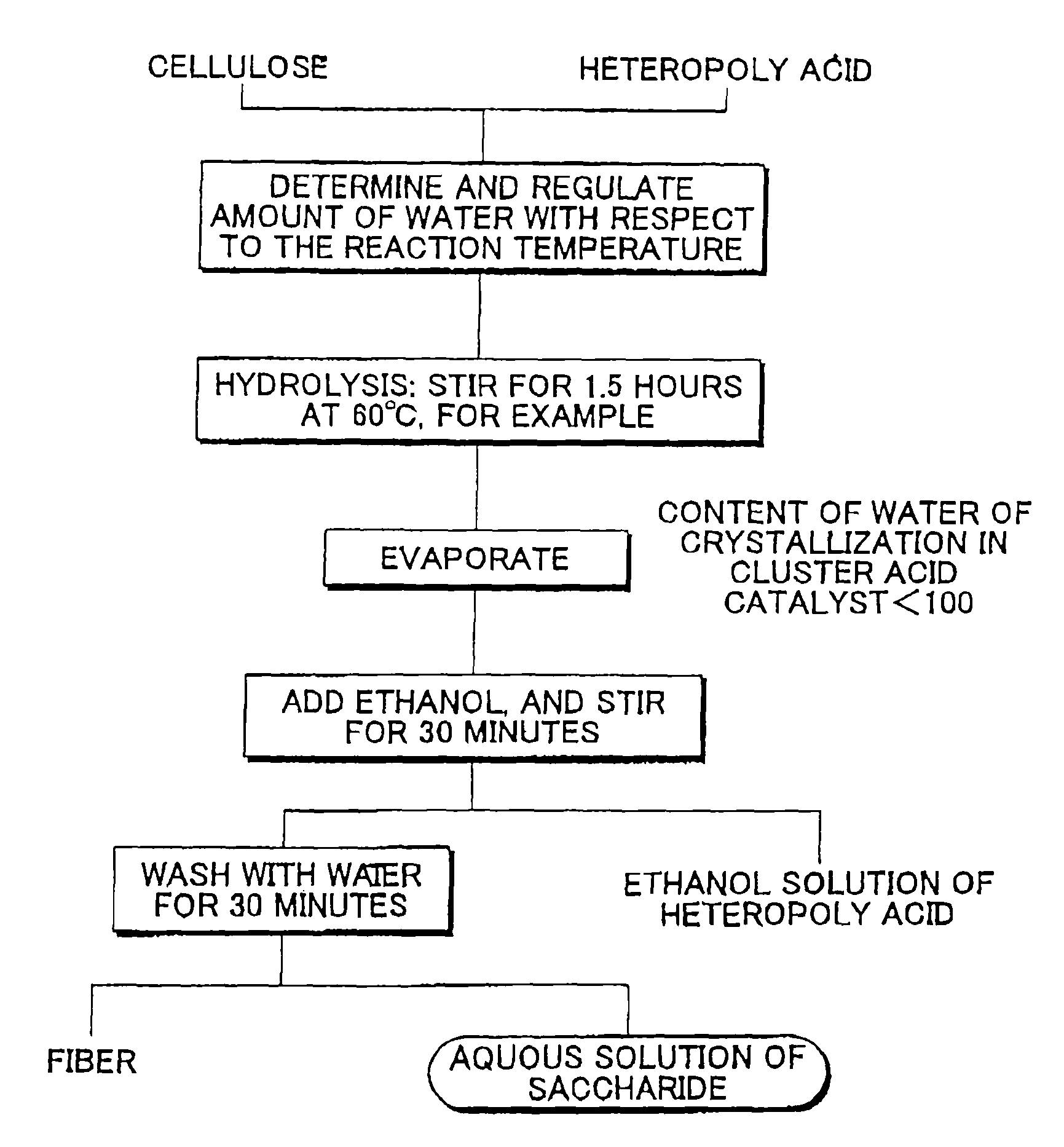

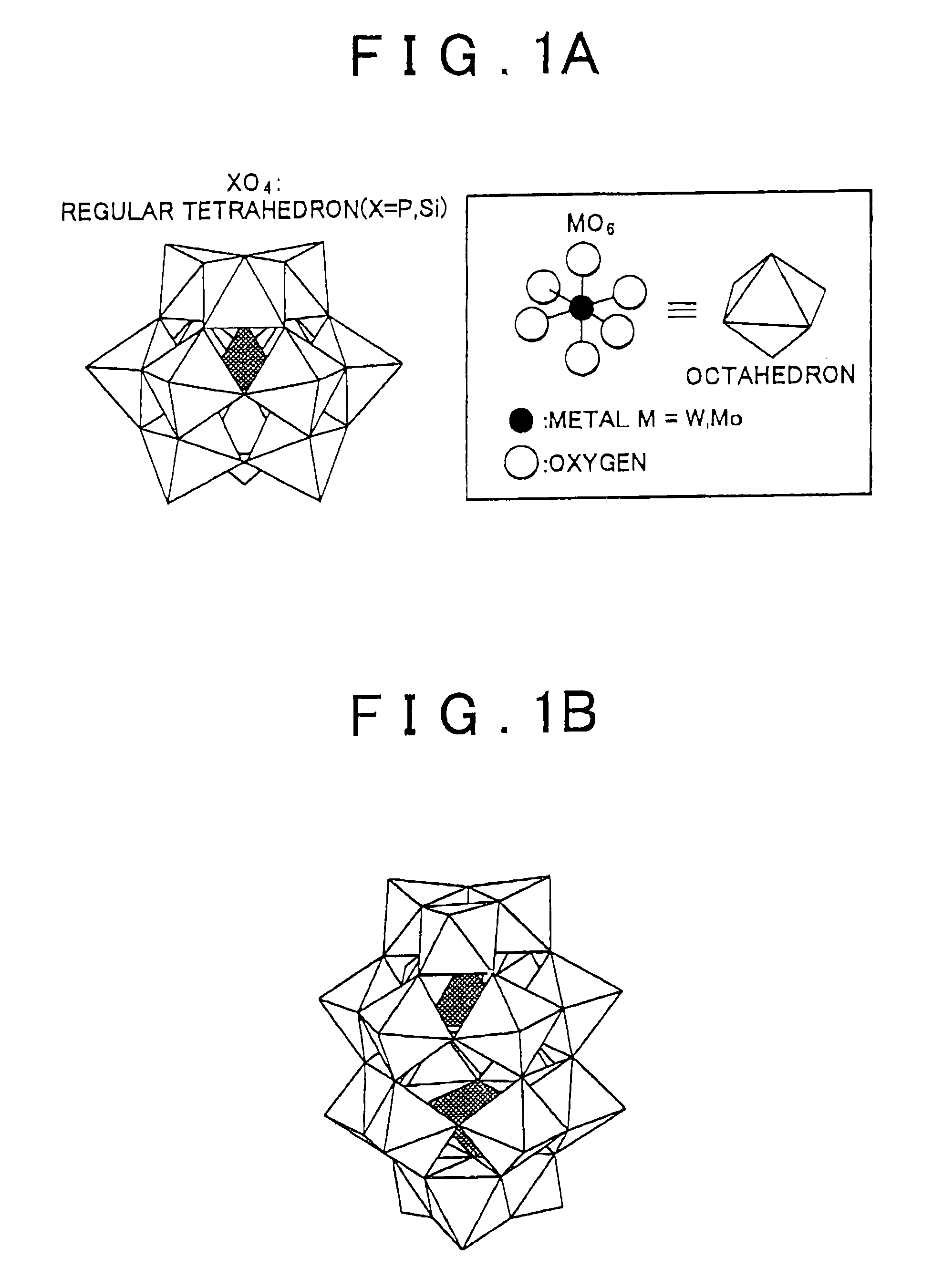

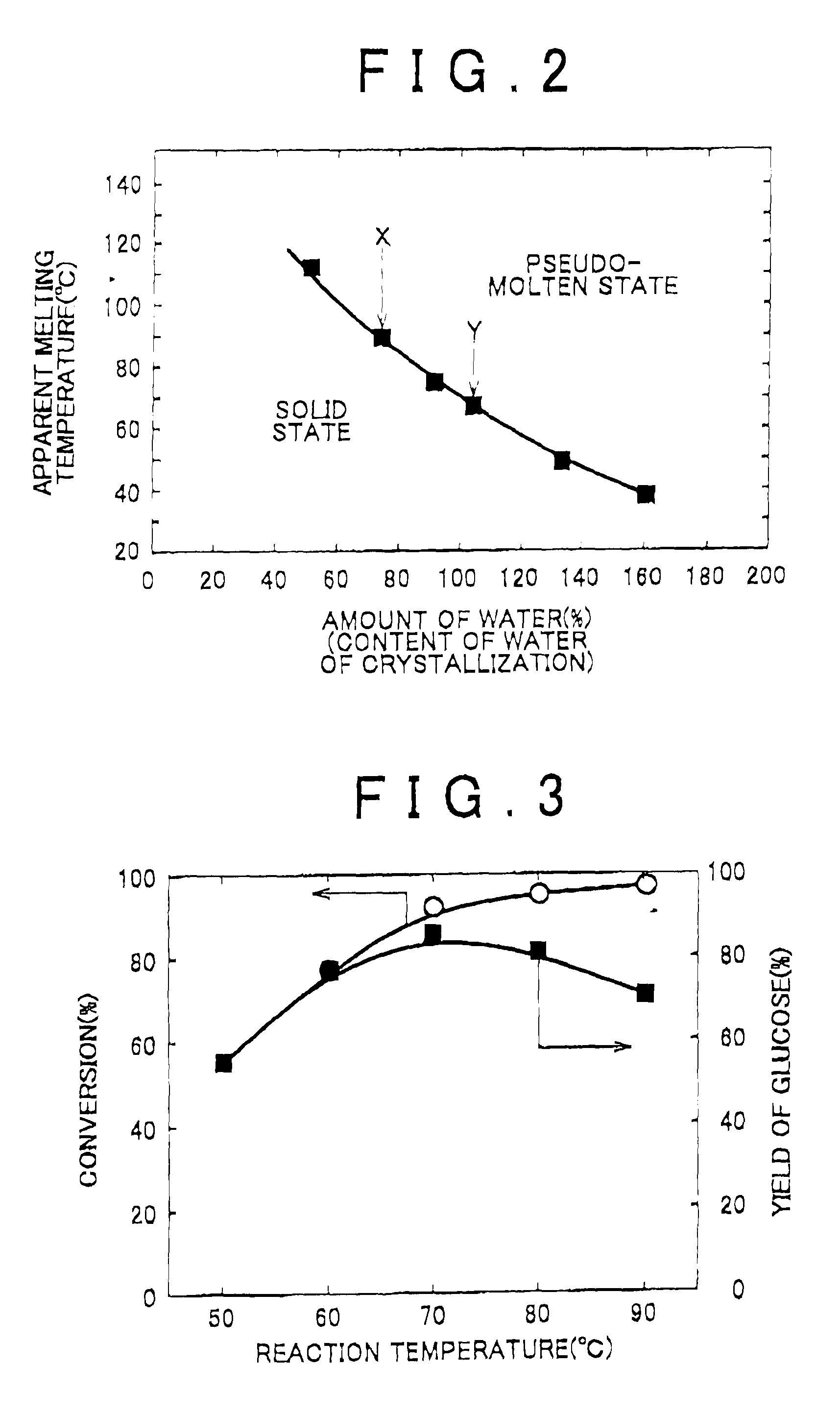

Plant-fiber-material transformation method

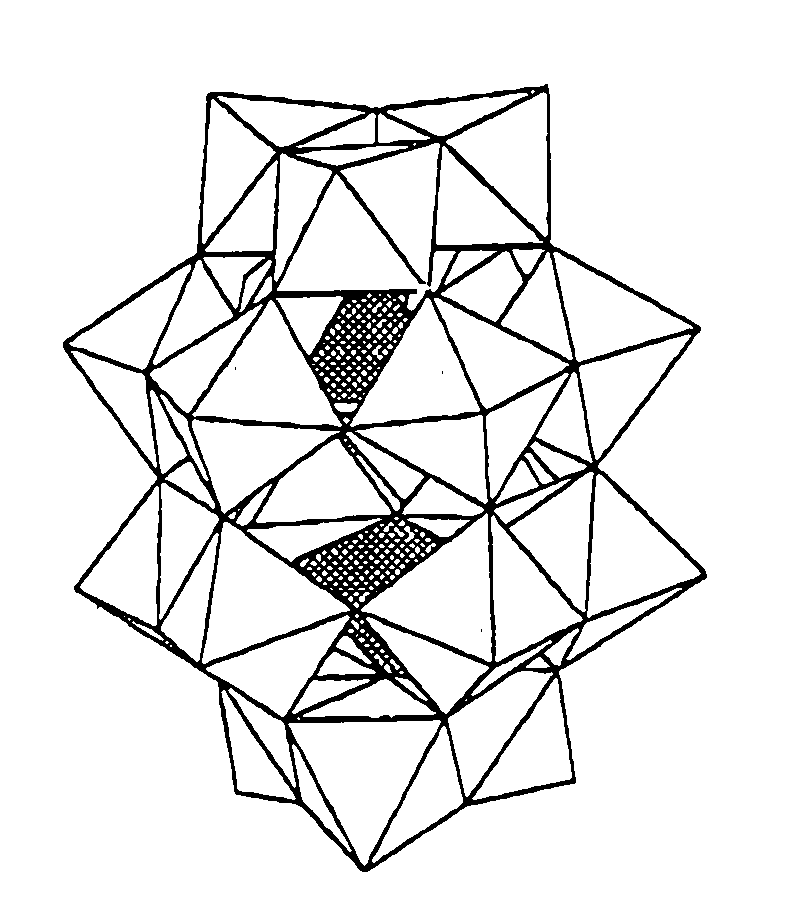

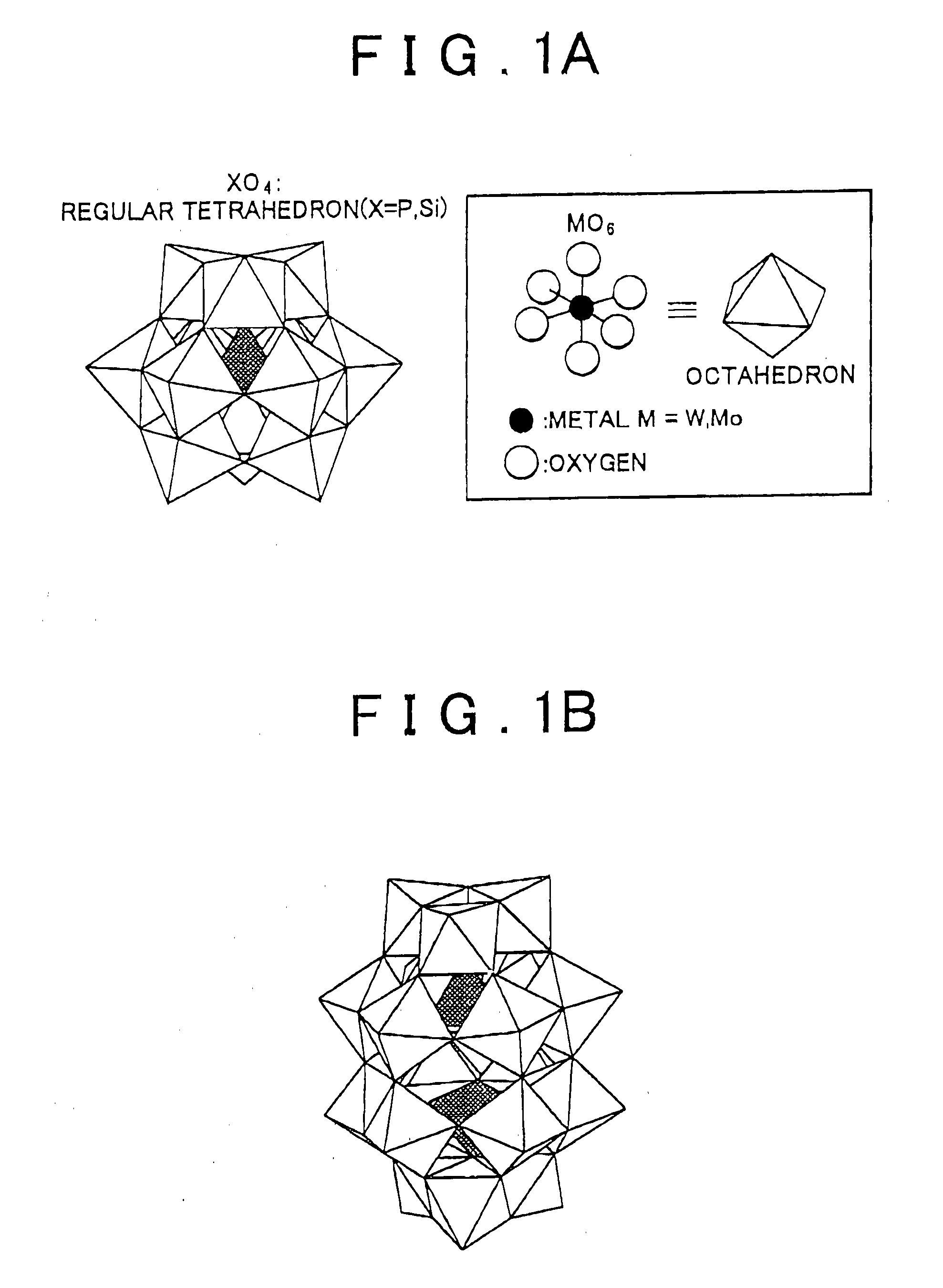

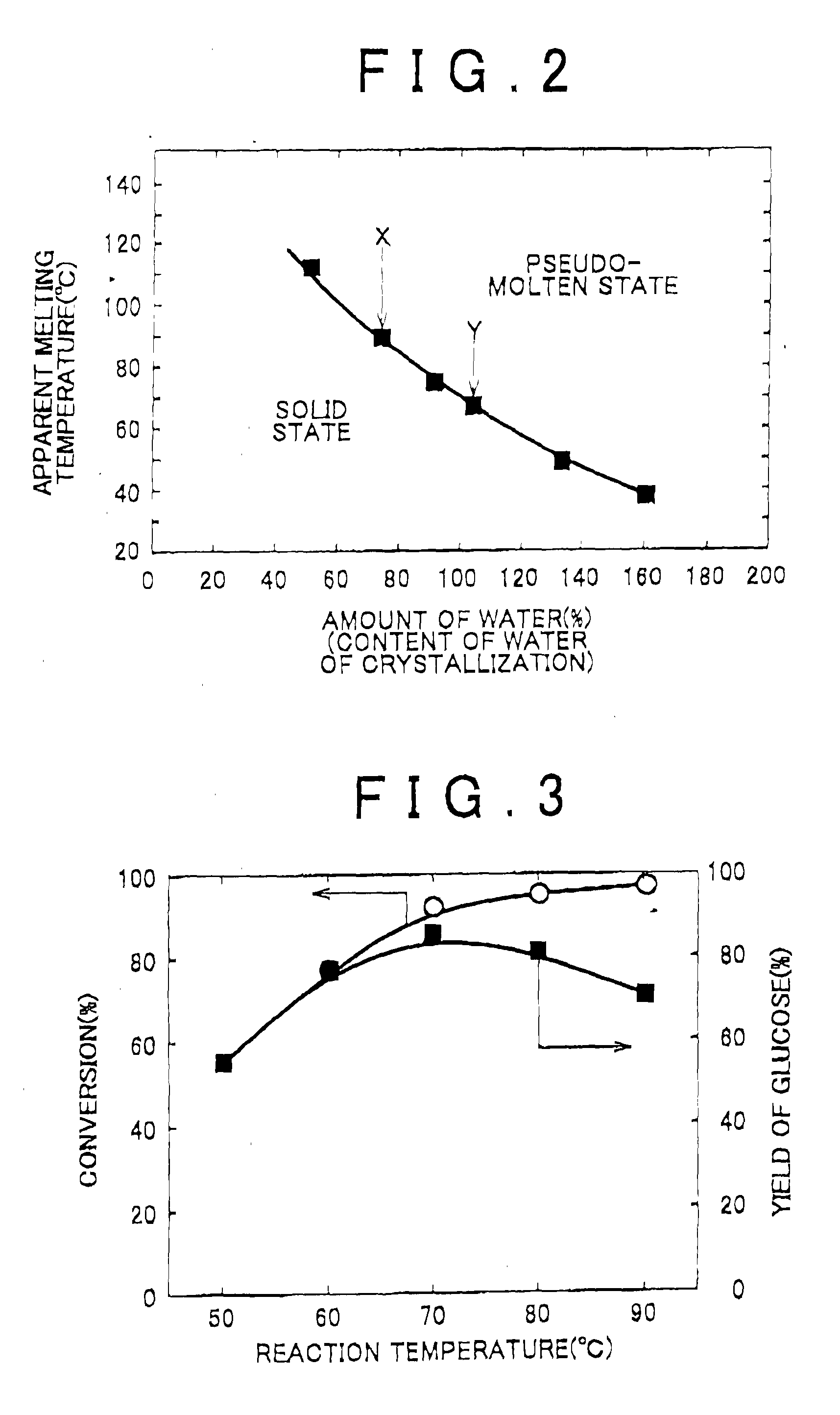

ActiveUS20100126501A1Easy to separateImprove energy efficiencyBiofuelsGlucose productionPlant fibreOrganosolv

Cellulose contained in plant fiber material is hydrolyzed with the use of a pseudo-molten cluster acid as a hydrolysis catalyst to produce saccharide, most of which is glucose. After the glucose is produced, the saccharide is precipitated with the use of an organic solvent, and the saccharide including a solidified saccharide during the hydrolysis and the precipitated saccharide is separated from residues and the cluster acid.

Owner:TOYOTA JIDOSHA KK

Sulfonate salts and derivatives, photoacid generators, resist compositions, and patterning process

ActiveUS7569324B2Minimize dissolutionResist formationLithium organic compoundsOrganic compound preparationResistAryl

Owner:SHIN ETSU CHEM IND CO LTD

Sulfonate salts and derivatives, photoacid generators, resist compositions, and patterning process

ActiveUS7531290B2Minimize dissolutionResist formationLithium organic compoundsOrganic compound preparationResistAryl

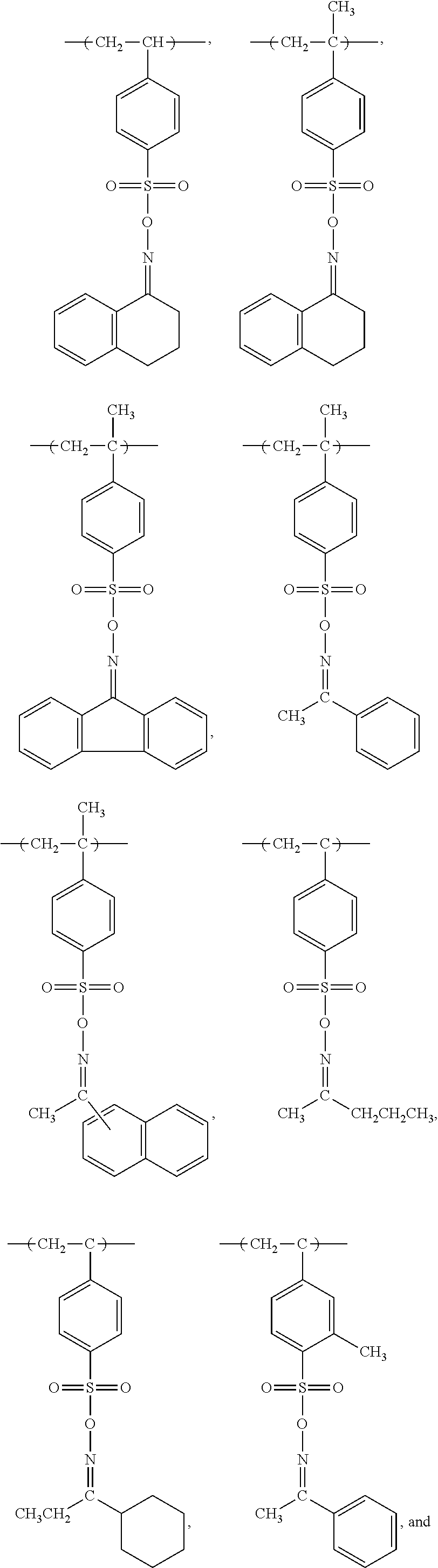

Sulfonate salts have the formula:R1SO3—CH(Rf)—CF2SO3−M+wherein R1 is alkyl or aryl, Rf is H or trifluoromethyl, and M+ is a Li, Na, K, ammonium or tetramethylammonium ion. Onium salts, oximesulfonates and sulfonyloxyimides and other compounds derived from these sulfonate salts are effective photoacid generators in chemically amplified resist compositions.

Owner:SHIN ETSU CHEM IND CO LTD

Compositions containing benefit agent composites pre-emulsified using colloidal cationic particles

InactiveUS7888306B2Improve stabilityIncrease depositionInorganic/elemental detergent compounding agentsPowder deliveryParticulatesSurface conditions

A cleansing or a surface-conditioning composition comprising a mixture of (i) and (ii) in water: i) a surfactant selected from the group consisting of anionic, non-ionic, zwitterionic, cationic, and mixtures thereof; and ii) a hydrophobic benefit agent in a particulate form having a mean particle size in the range of 1-1,000 micron, and a specific gravity of ≧1, not encapsulated within a film or a capsule-like enclosure, the particulate hydrophobic benefit agent comprising: a) a physically-modified form of the hydrophobic benefit agent; and b) a deposition-aid material bonded to the surface of the physically-modified benefit agent material, wherein the bonding between the two said materials is achieved prior to addition to i), wherein said deposition-aid material is not a surfactant having a weight average molecular weight of less than 5,000 Dalton.

Owner:AMCOL ITNERNAT CORP

Compositions containing benefit agents pre-emulsified using colloidal cationic particles

InactiveUS20090148392A1Process stabilityStable coagulationInorganic/elemental detergent compounding agentsCosmetic preparationsParticulatesColloid

A cleansing or a surface-conditioning composition comprising a mixture of (i) and (ii) in water: i) a surfactant selected from the group consisting of anionic, non-ionic, zwitterionic, cationic, and mixtures thereof; and ii) a hydrophobic benefit agent in a particulate form having a mean particle size in the range of 1-1,000 micron, and a specific gravity of ≧1, not encapsulated within a film or a capsule-like enclosure, the particulate hydrophobic benefit agent comprising: a) a physically-modified form of the hydrophobic benefit agent; and b) a deposition-aid material bonded to the surface of the physically-modified benefit agent, wherein the bonding between the benefit agent and the deposition-aid material is achieved prior to addition to i), wherein said deposition-aid material is not a surfactant having a weight average molecular weight of less than 5,000 Dalton.

Owner:AMCOL INTERNATIONAL CORPORATION

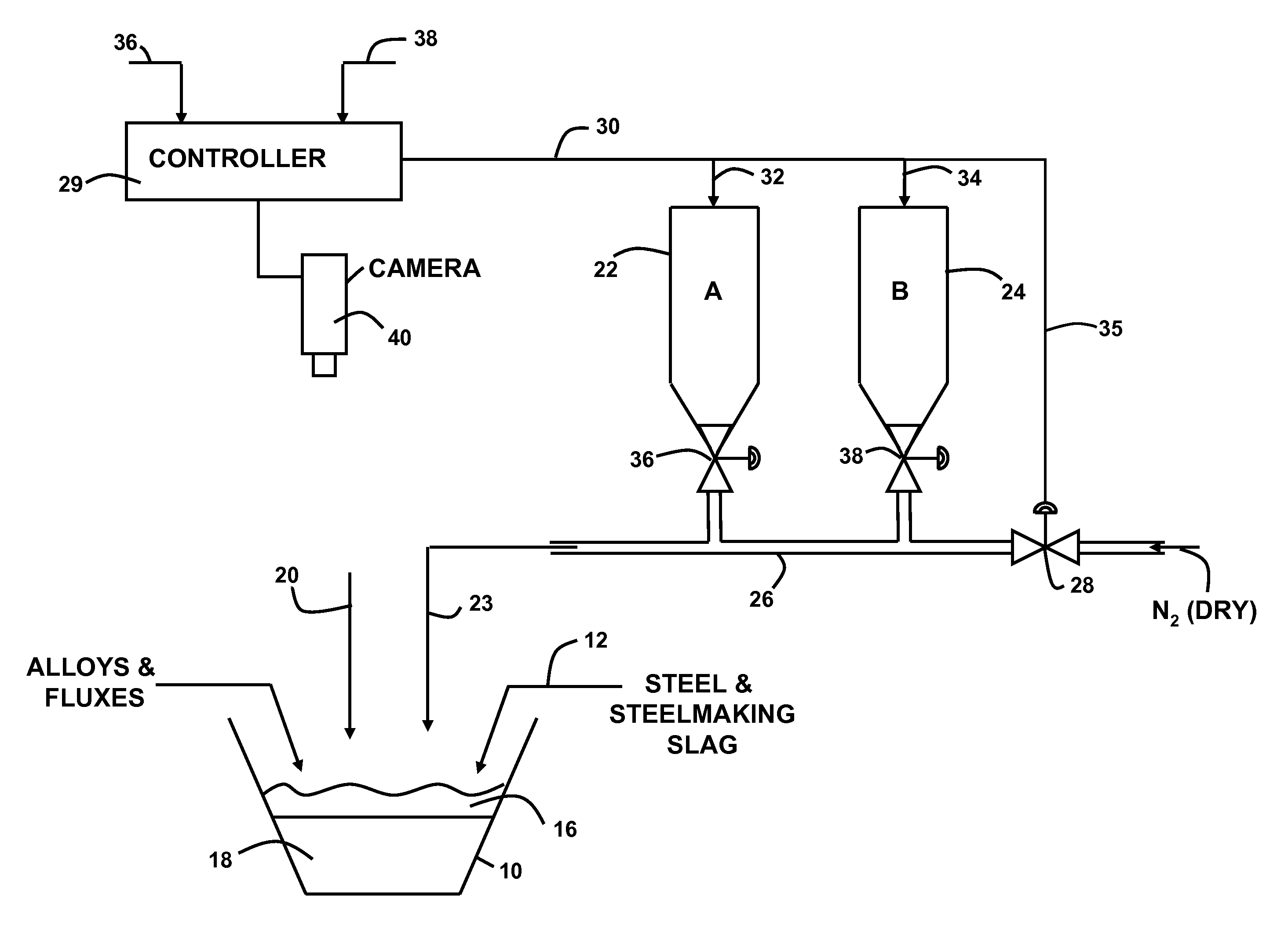

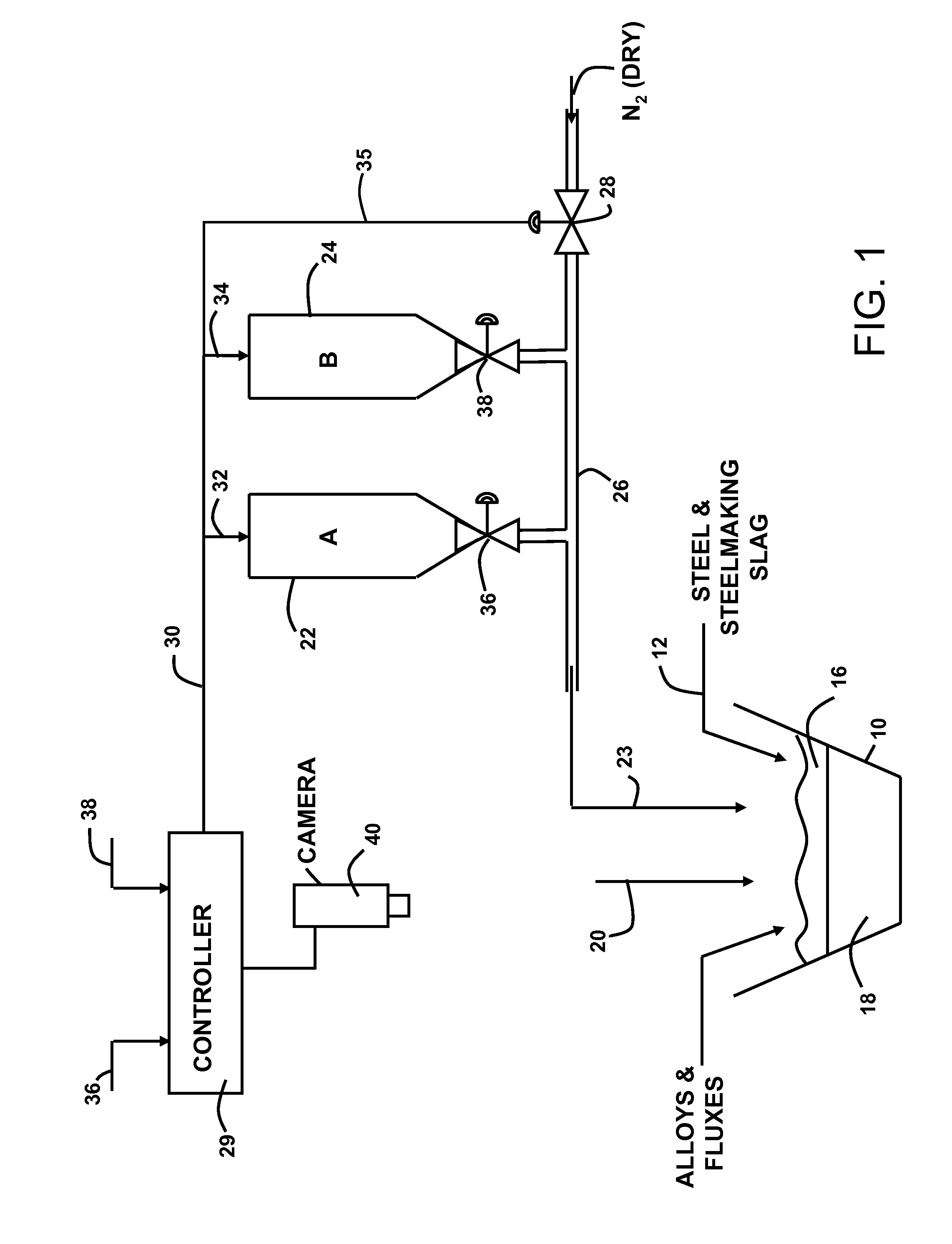

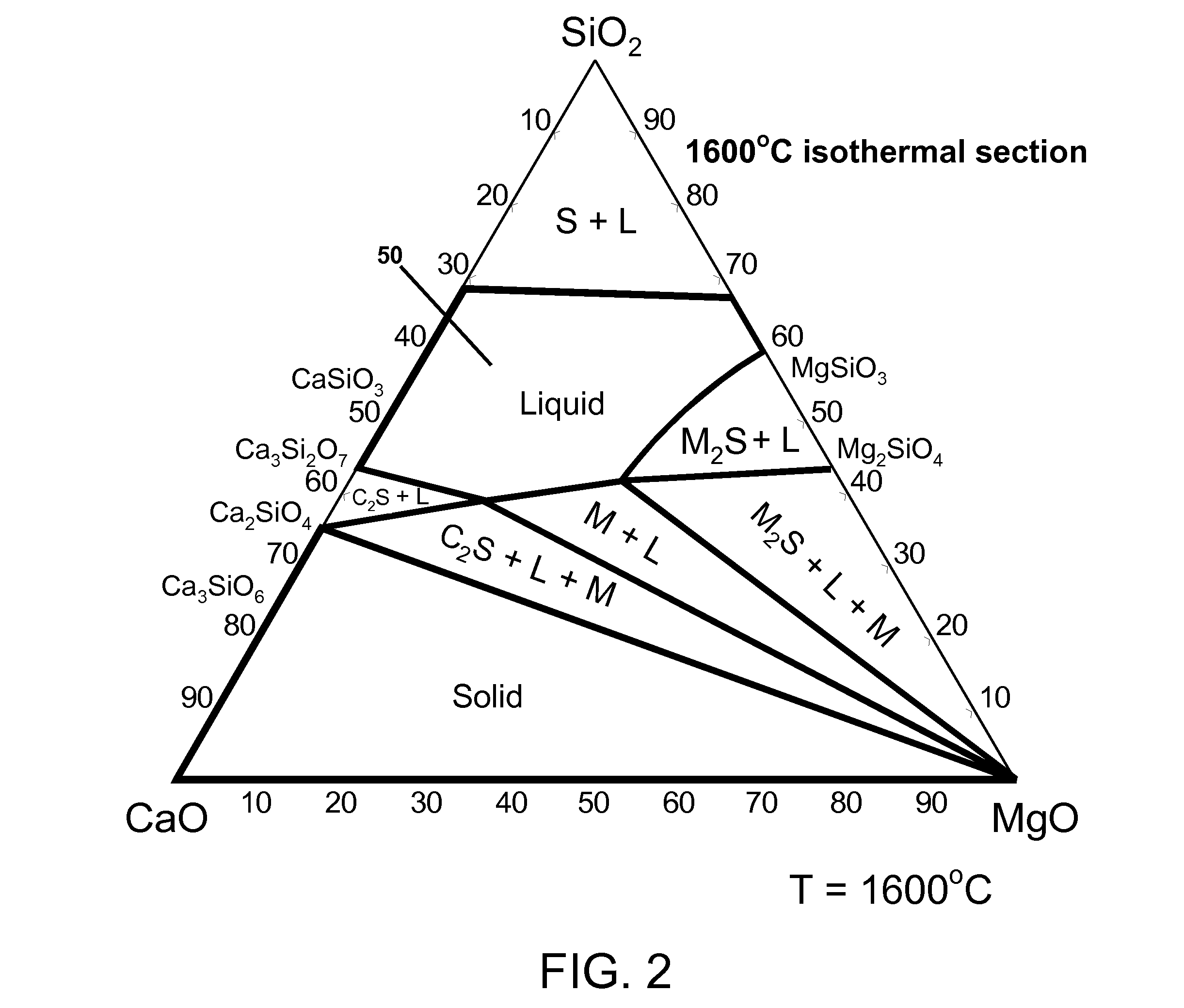

Composition for reducing the oxygen potential of slag

InactiveUS20130019715A1Easy to producePromote productionBlast furnace componentsBlast furnace detailsSteelmakingSilicon oxide

A slag composition containing steelmaking slag and from about 0.3 to about 10 weight percent of reducing agent. The steelmaking slag contains from about 20 to about 55 weight percent of calcium oxide, from about 8 to about 50 weight percent of ferrous oxide, from about 4 to about 20 weight percent of magnesium oxide, from about 8 to about 30 weight percent of silicon oxide, from 0.5 to about 10 weight per cent aluminum oxide, and from about 0.5 to about 10 weight percent of manganese oxide. The reducing agent contains from about 15 to about 70 weight percent of calcium carbide and from about 10 to about 50 weight percent silicon carbide, wherein the ratio of calcium carbide to silicon carbide is between 0.7 and 7.

Owner:NUFLUX

Plant-fiber-material transformation method

ActiveUS8382905B2Easy to separateImprove energy efficiencyBiofuelsGlucose productionCelluloseOrganic solvent

Cellulose contained in plant fiber material is hydrolyzed with the use of a pseudo-molten cluster acid as a hydrolysis catalyst to produce saccharide, most of which is glucose. After the glucose is produced, the saccharide is precipitated with the use of an organic solvent, and the saccharide including a solidified saccharide during the hydrolysis and the precipitated saccharide is separated from residues and the cluster acid.

Owner:TOYOTA JIDOSHA KK

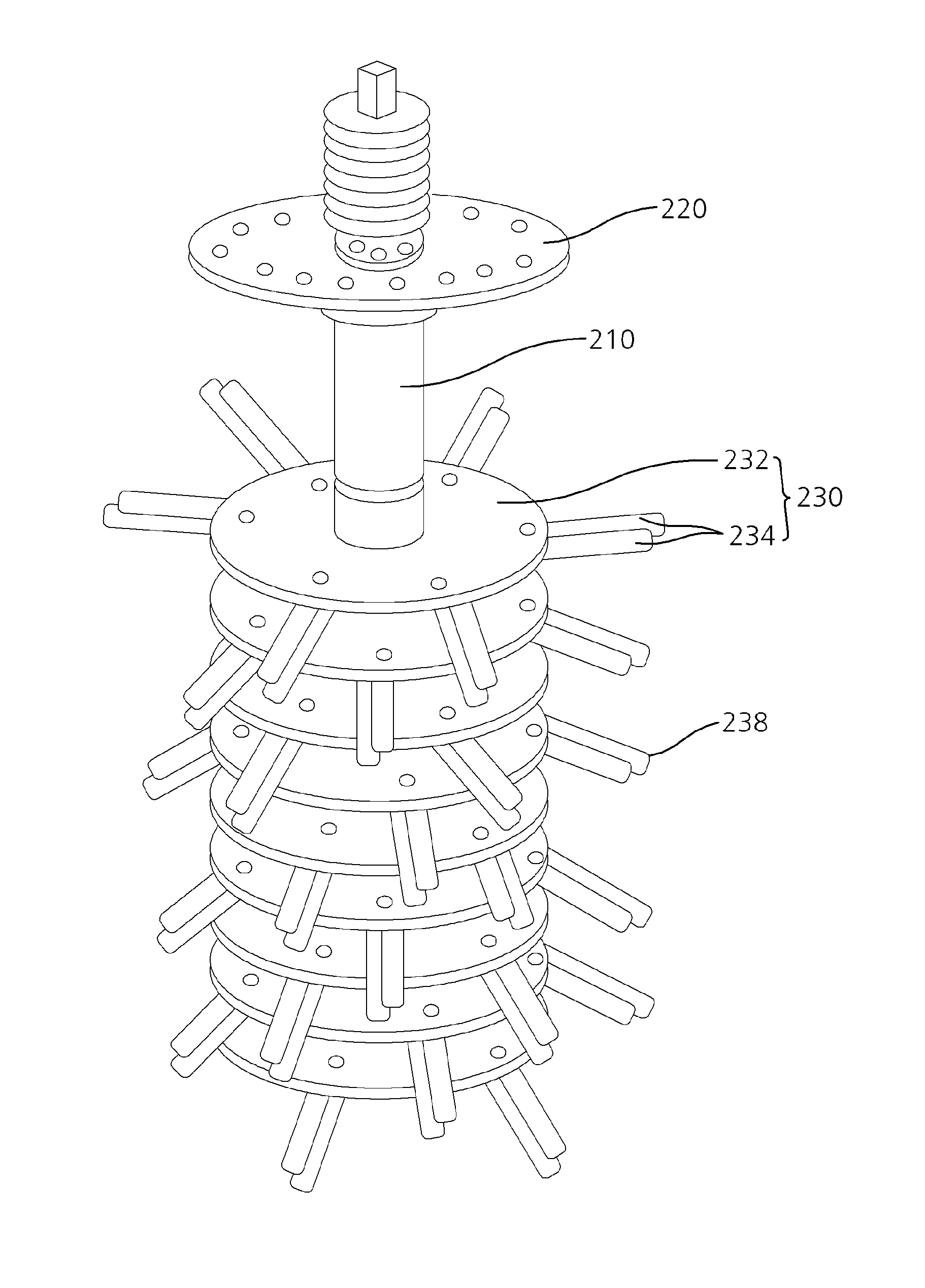

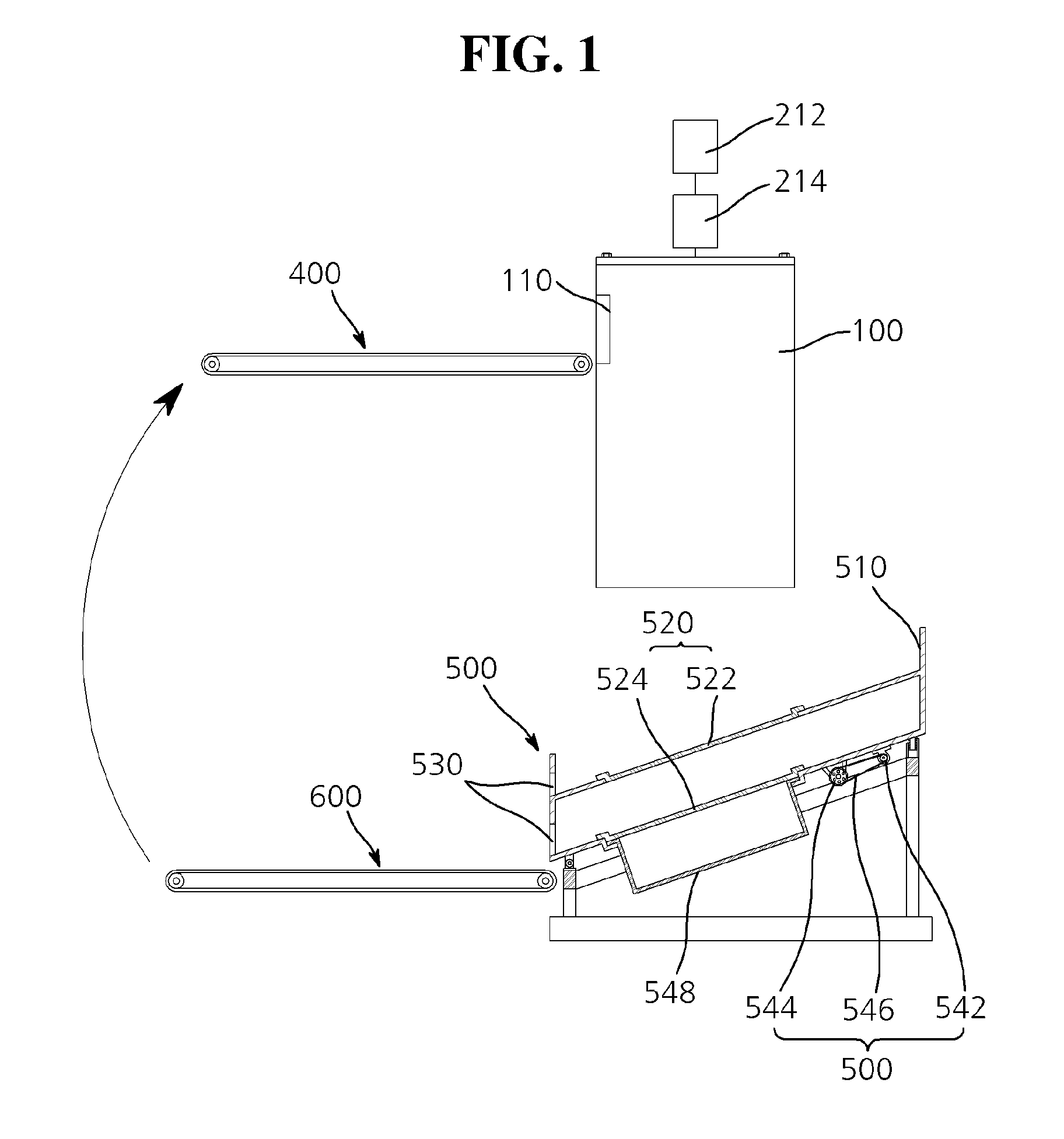

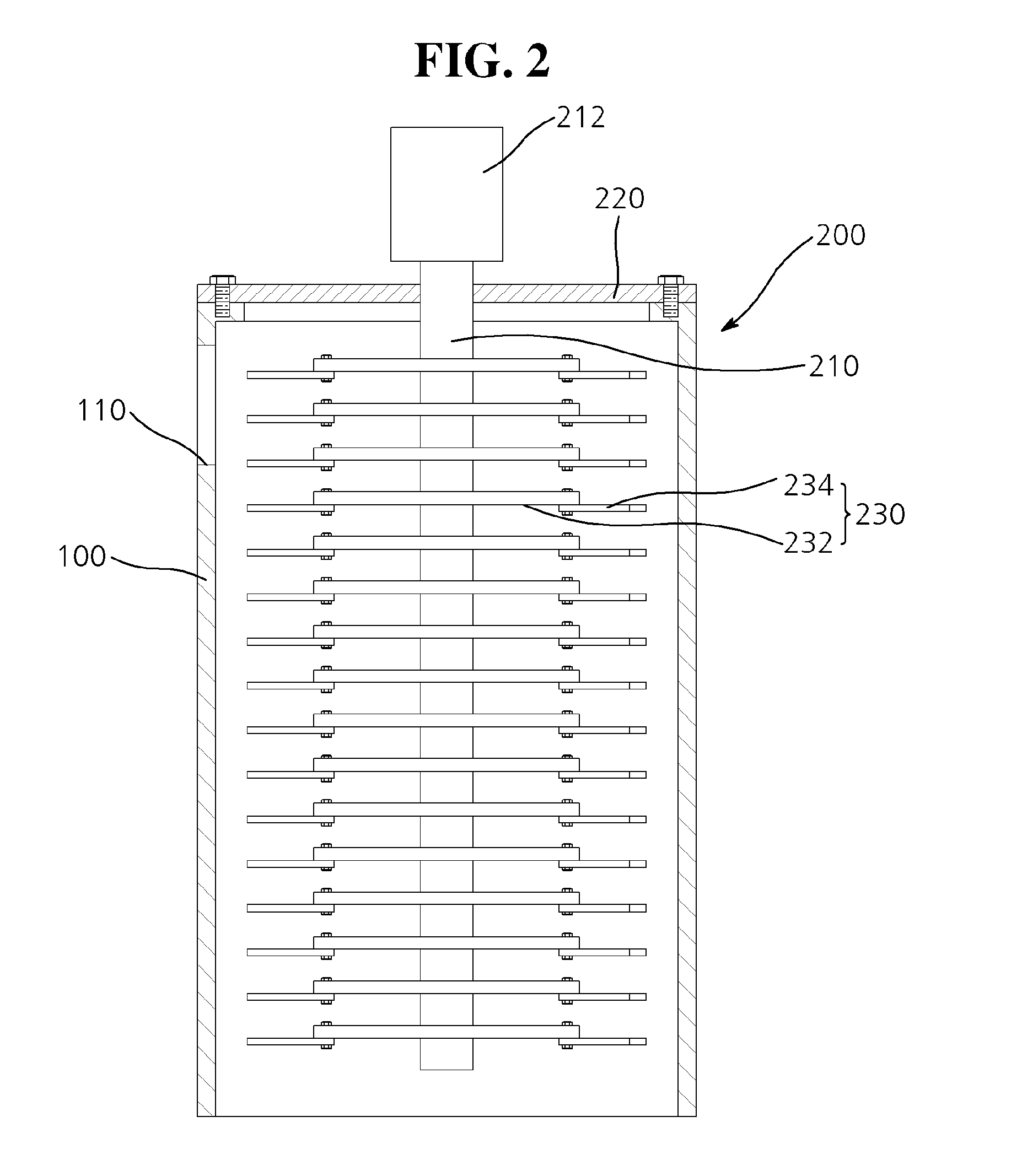

Pretreatment apparatus for removing pith from cornstalk, pulp manufacturing method using cornstalk, and paper manufacturing method using cornstalk pulp

InactiveUS20130276998A1Deteriorates qualityDeteriorates yieldCellulosic pulp after-treatmentNon-fibrous pulp additionPaper manufacturingMechanical engineering

A pretreatment apparatus for removing pith from cornstalks and separating husks therefrom includes a casing that receives cornstalks in a free-fall manner through an upper side thereof and allows the corn stalks to be discharged through a lower side thereof, and a rotor inserted into the casing and rotating inside the casing to hit cornstalk chips. The rotor includes a shaft inserted into the casing to be rotated by external force, a cover member holding the shaft so as to allow rotation of the shaft therein and connected to the entirety or part of an open upper side of the casing, and a hitting unit formed on a circumference of the shaft and hitting the corn stalks input into the casing.

Owner:CPNPHLDG

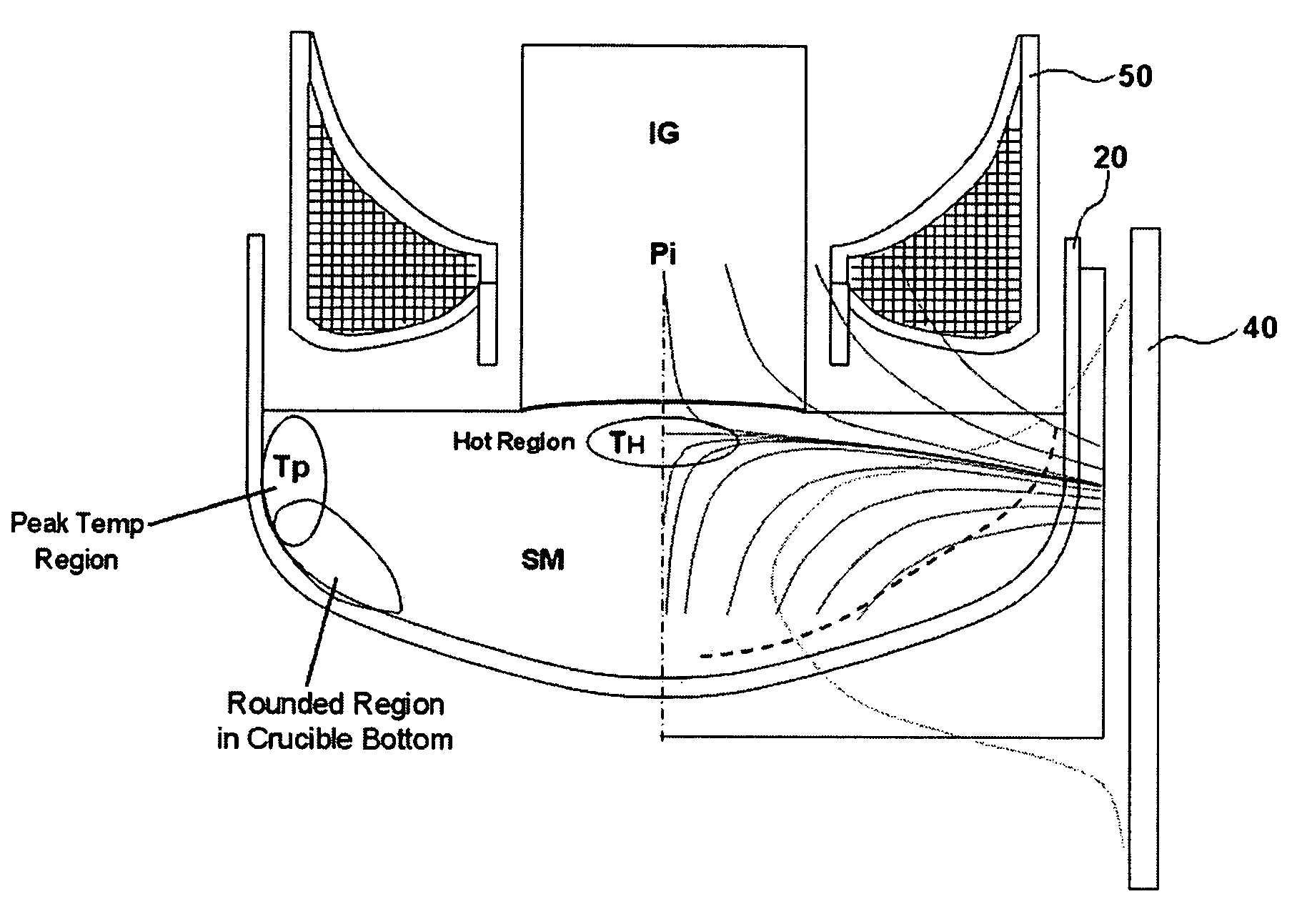

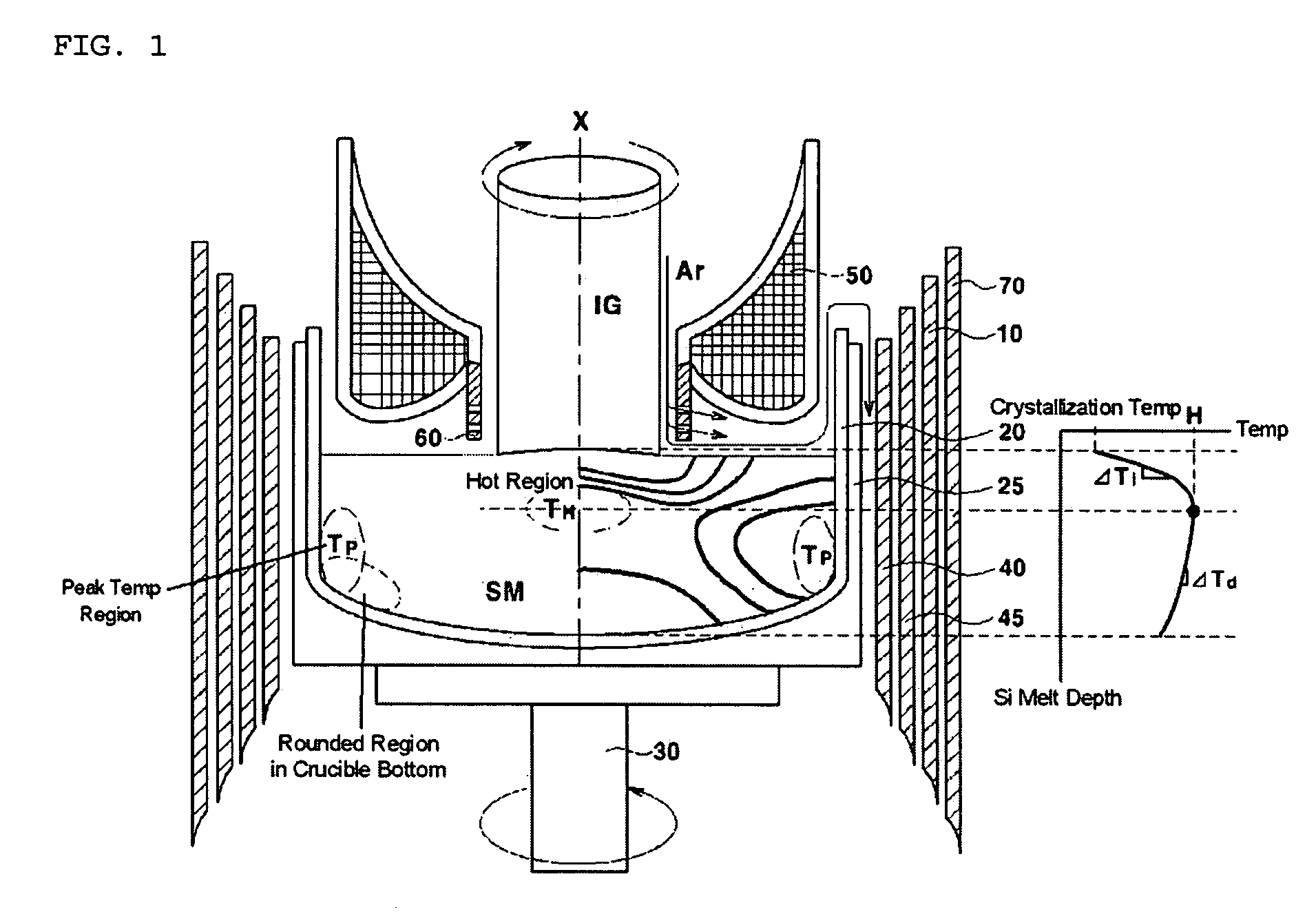

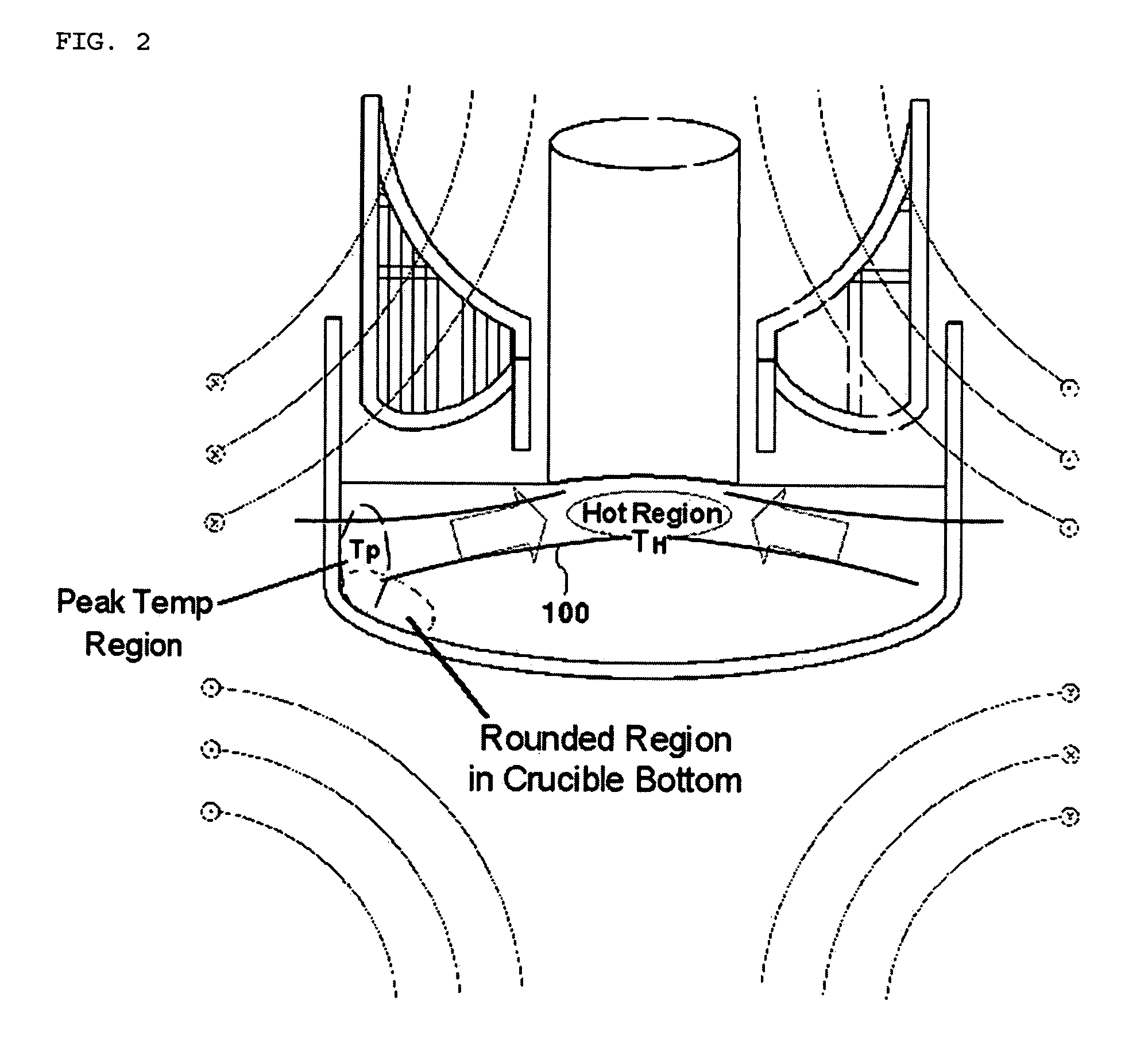

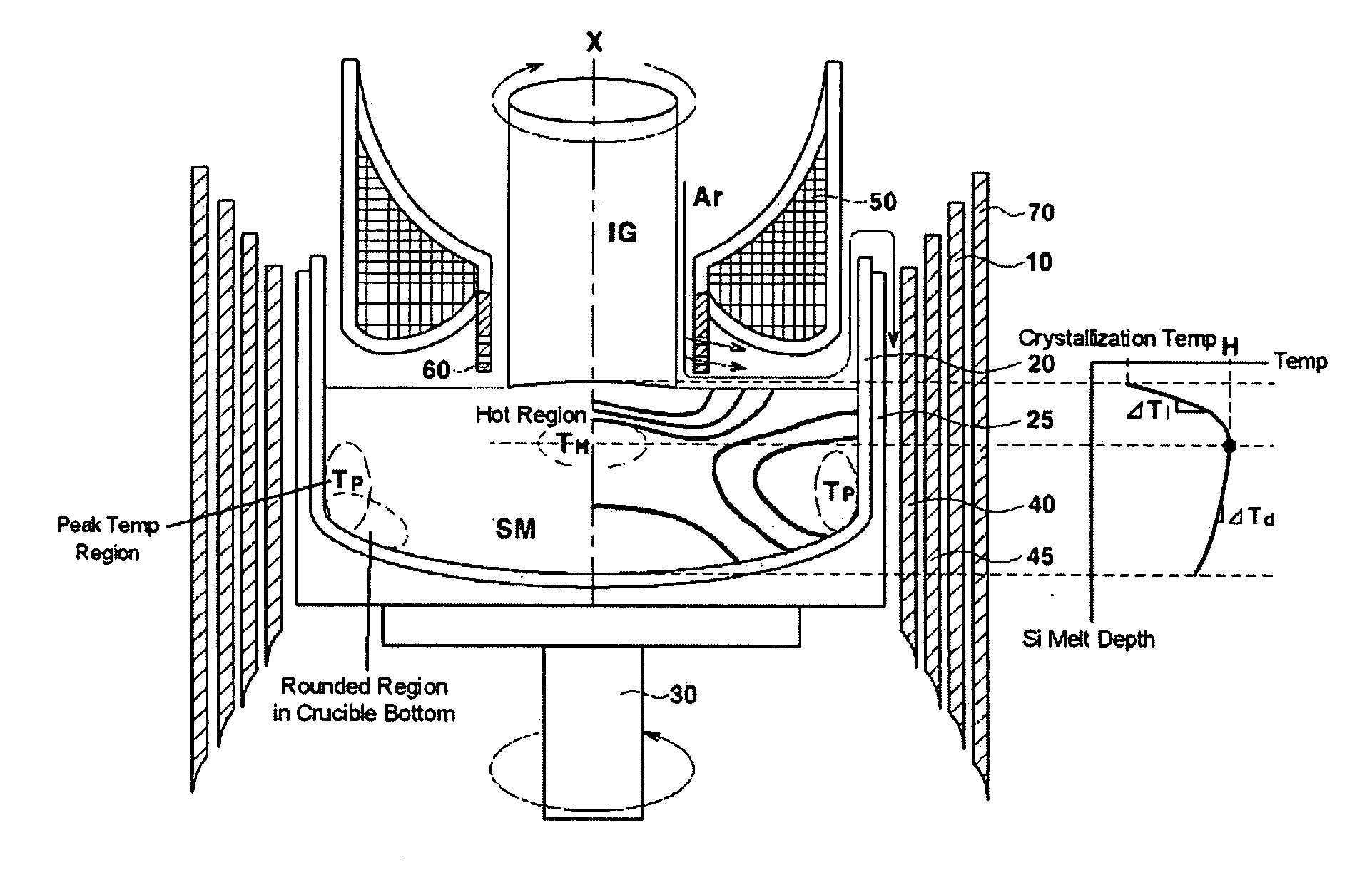

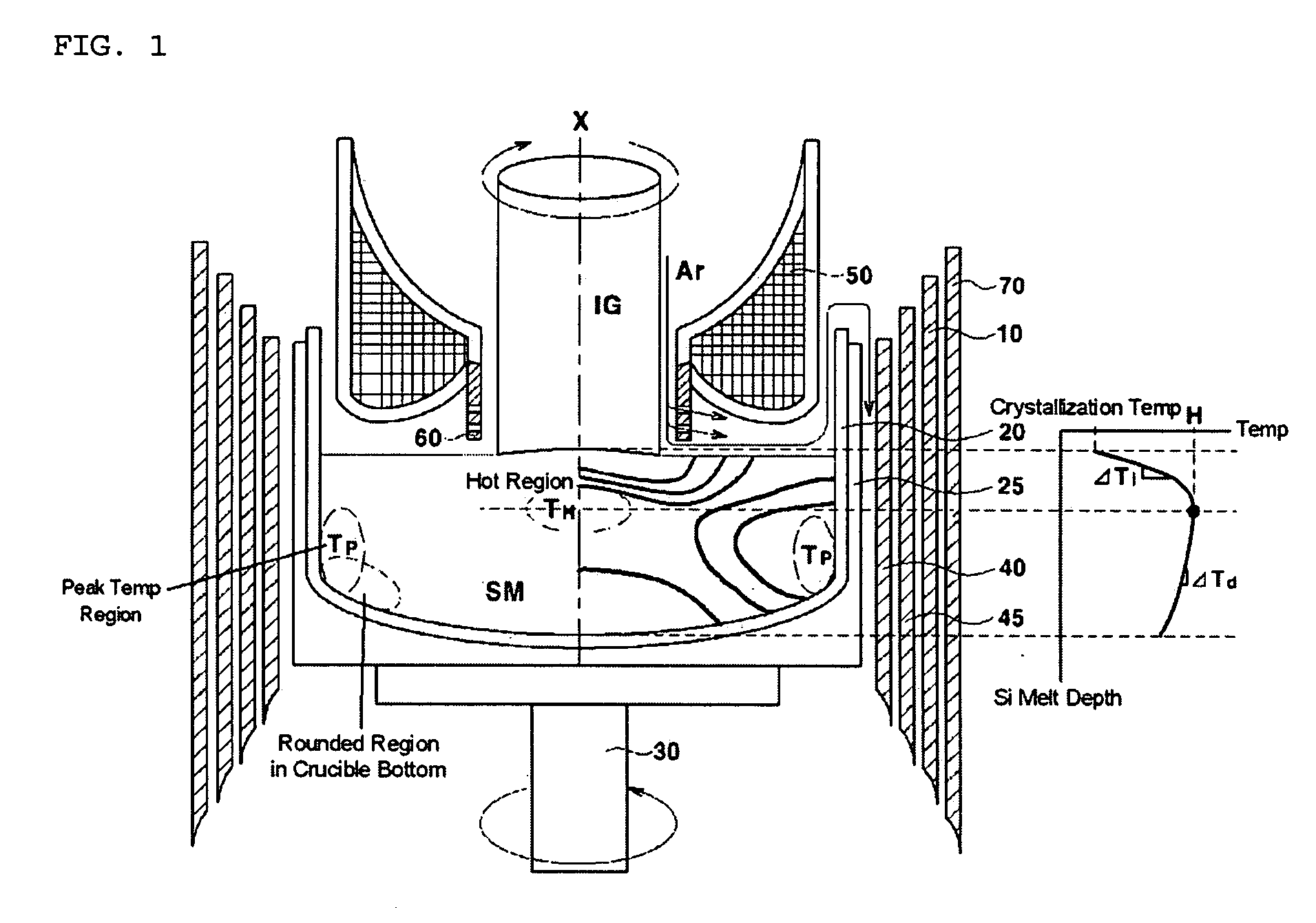

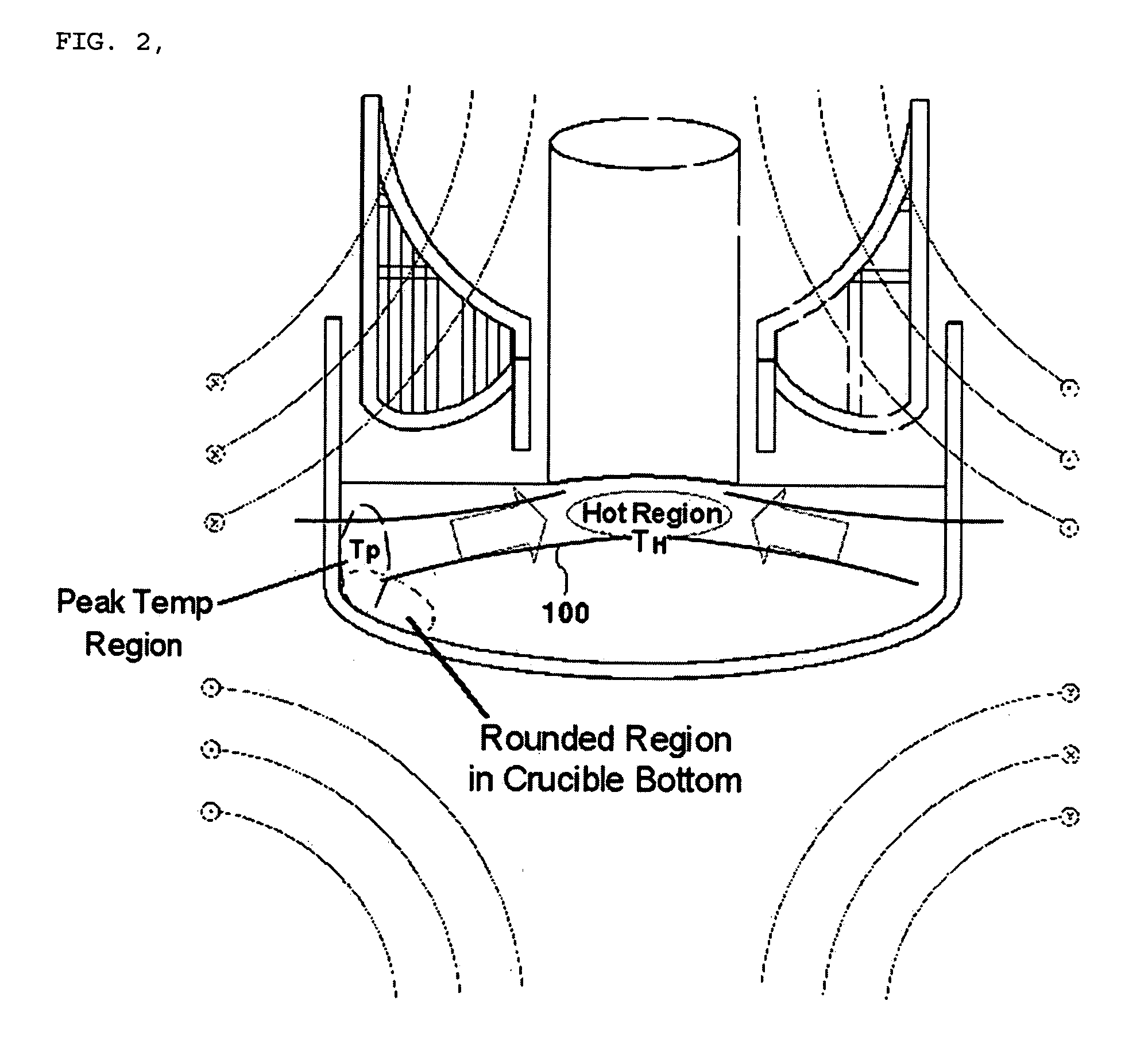

Method and apparatus for growing high quality silicon single crystal, silicon single crystal ingot grown thereby and wafer produced from the same single crystal ingot

ActiveUS7559988B2Improve productivityQuality improvementPolycrystalline material growthBy zone-melting liquidsProduction rateCzochralski method

The invention relates to a technique for producing a high quality Si single crystal ingot with a high productivity by the Czochralski method. The technique of the invention can control the magnetic field strength of an oxygen dissolution region different from that of a solid-liquid interface region in order to control the oxygen concentration at a desired value.

Owner:LG SILTRON

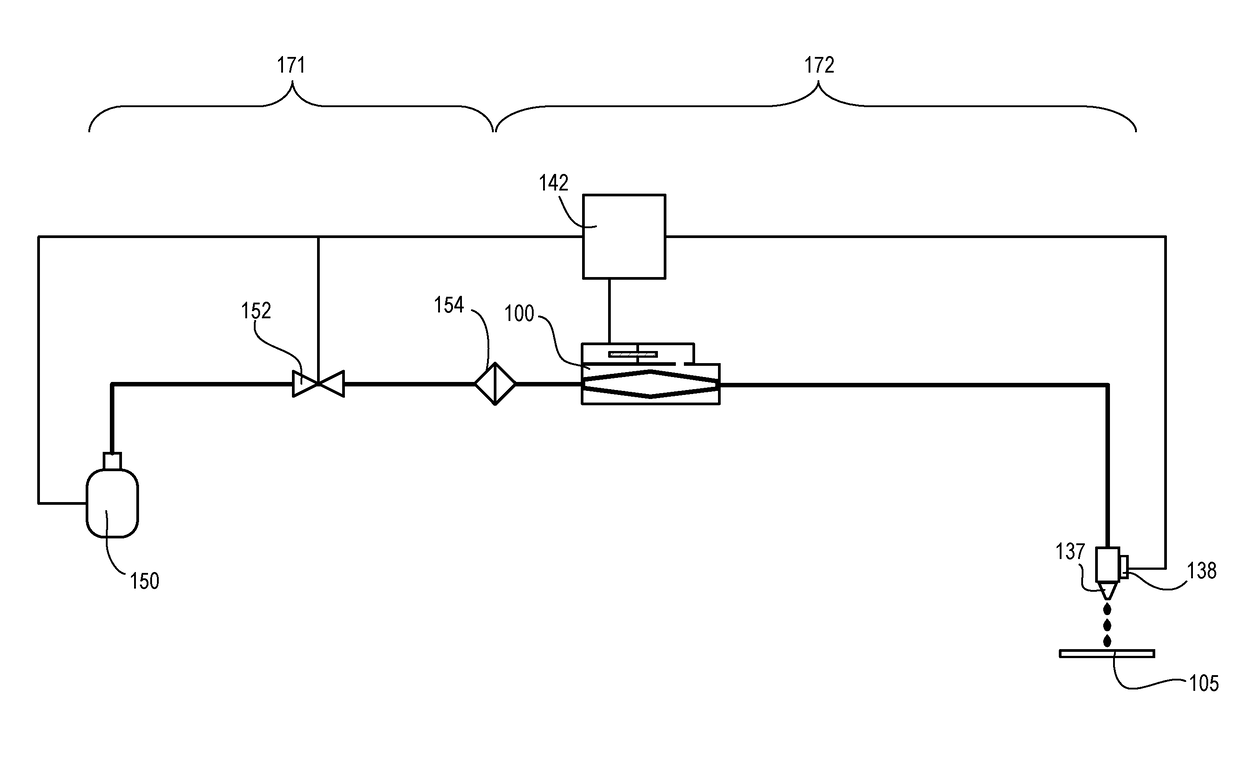

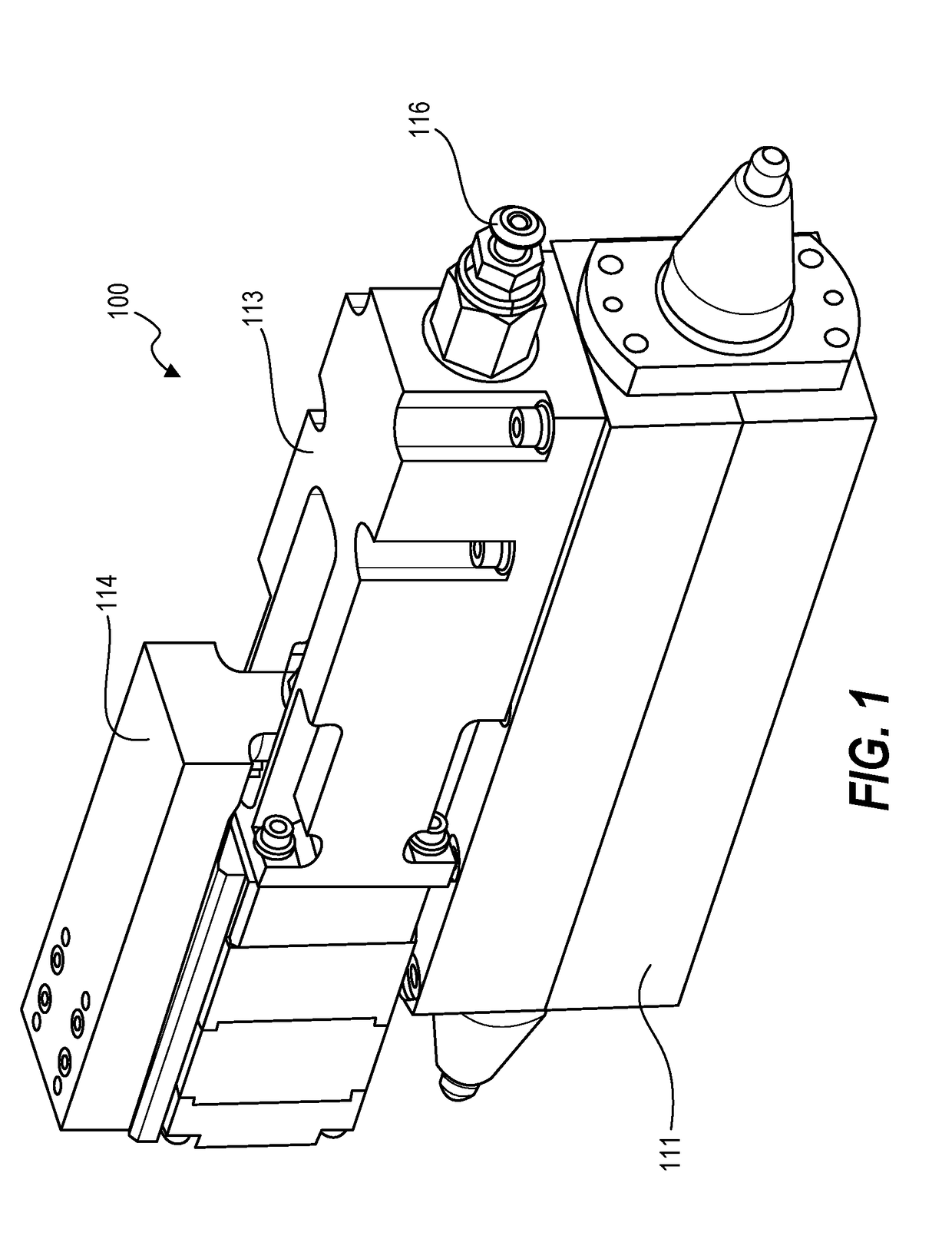

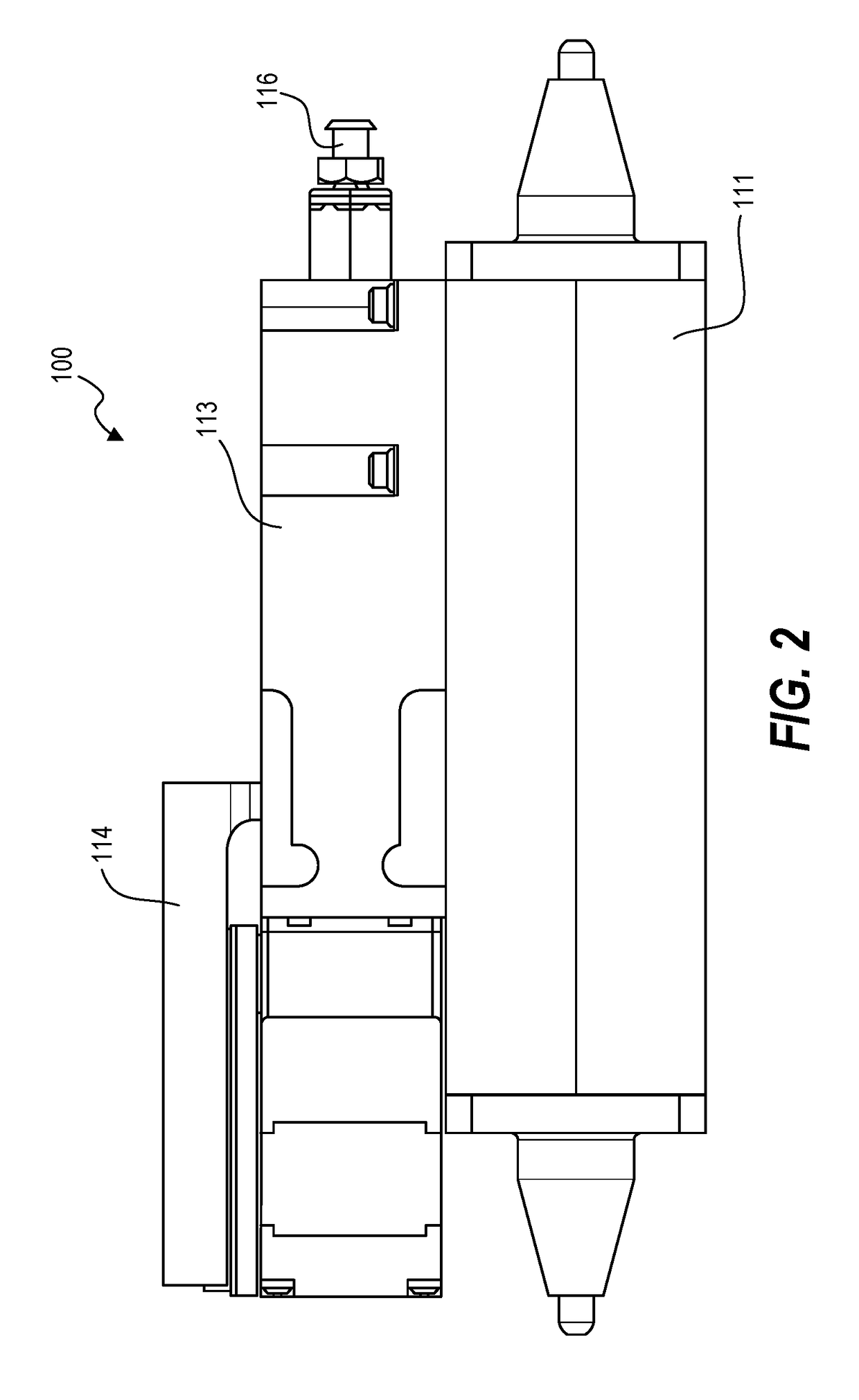

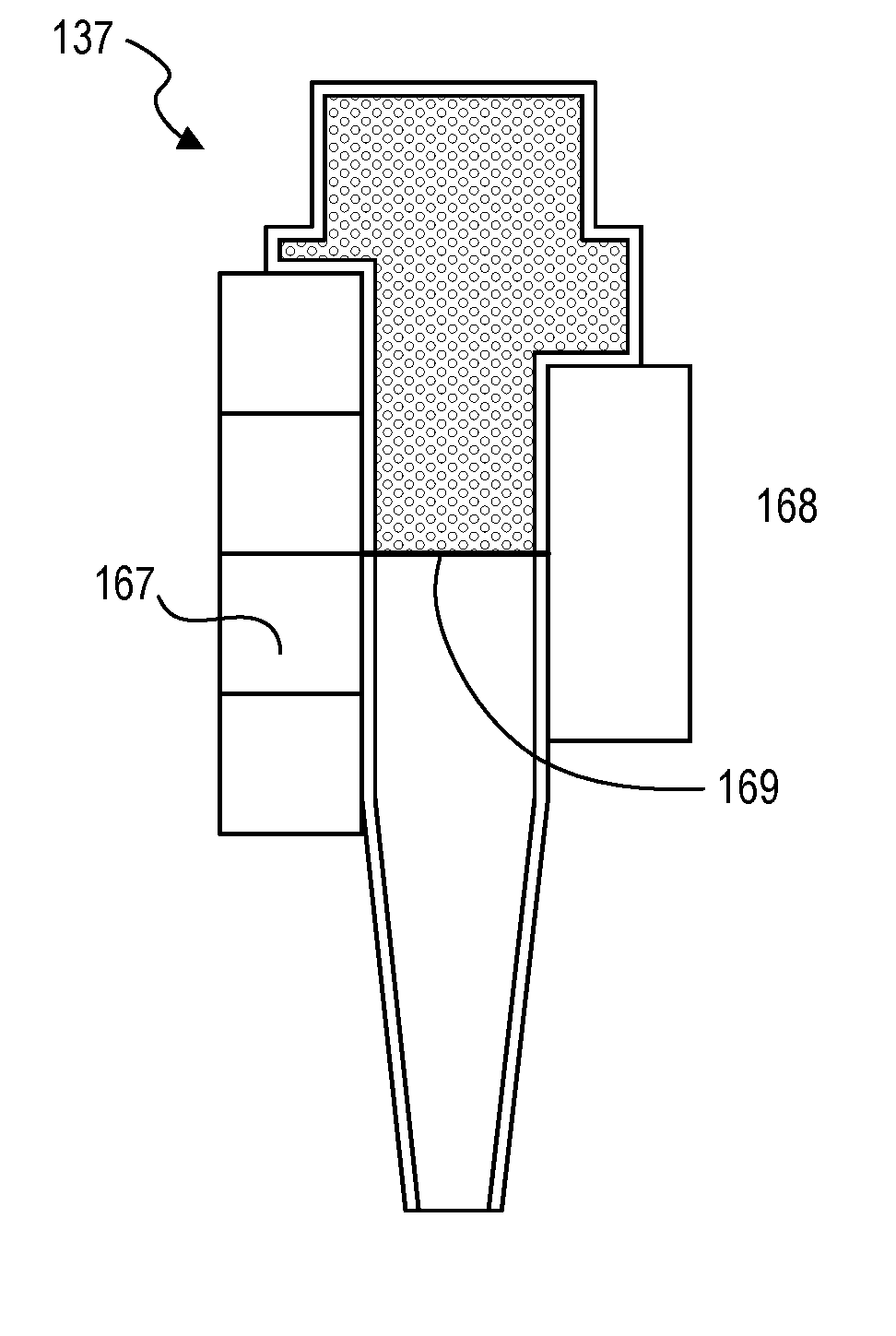

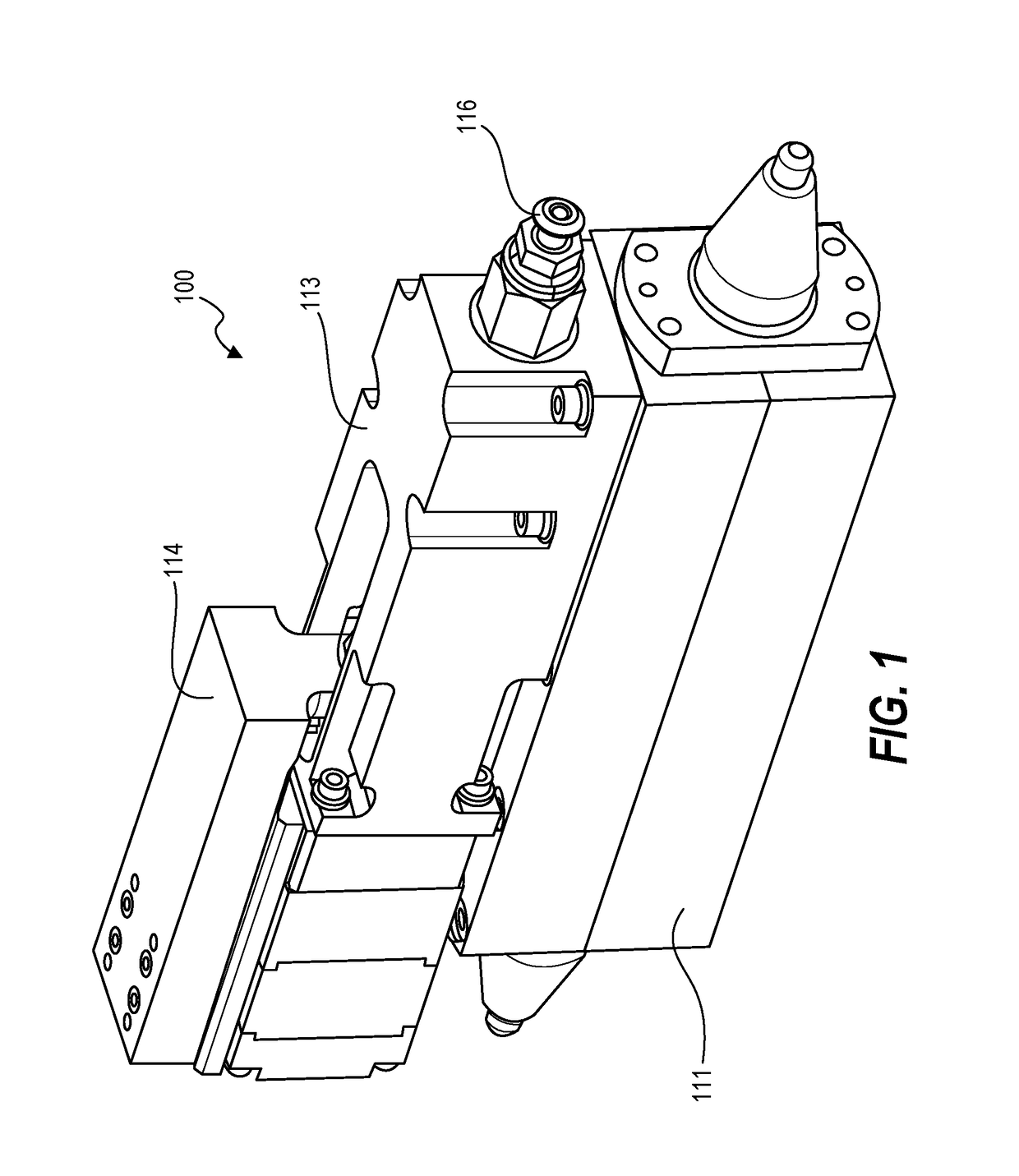

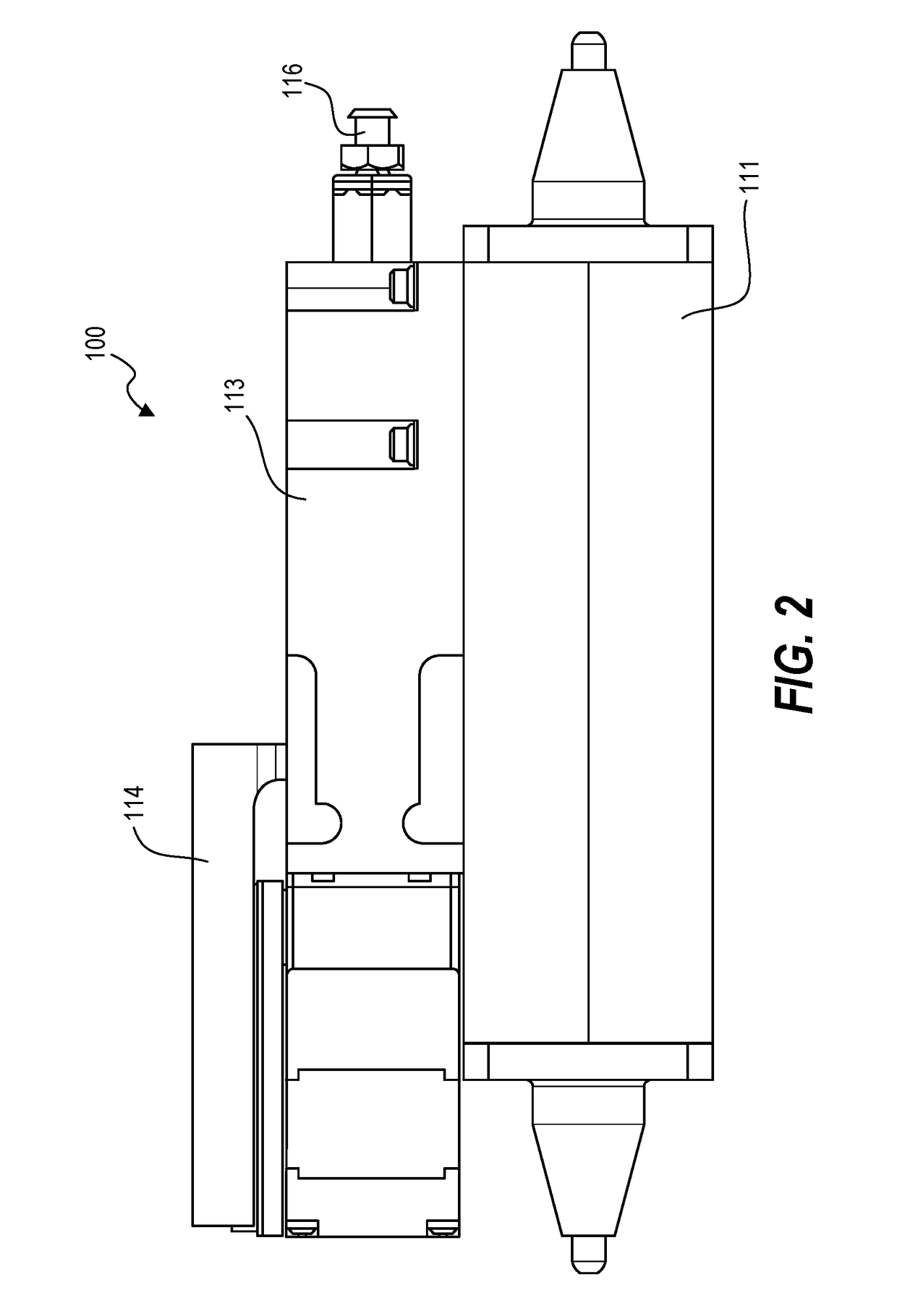

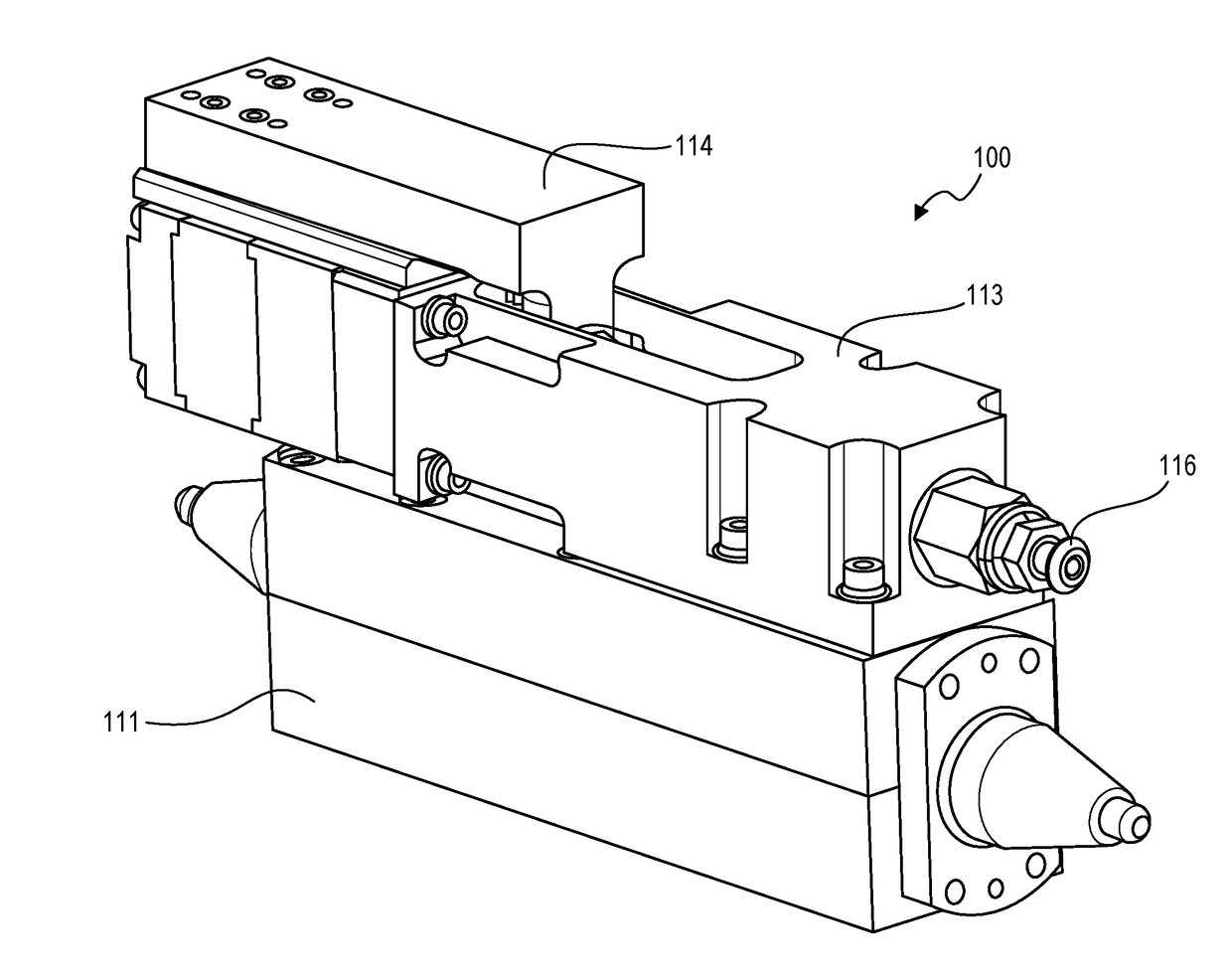

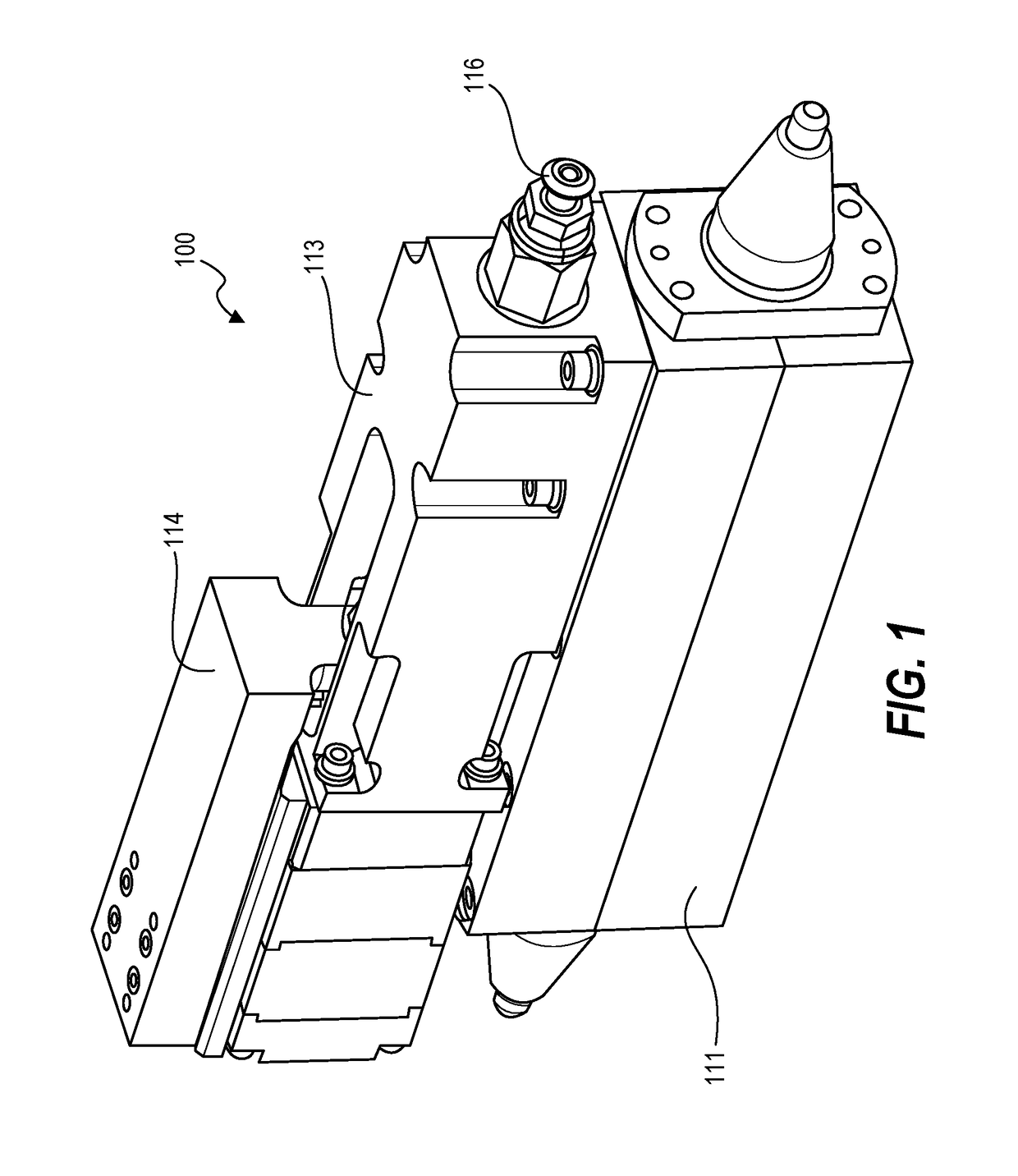

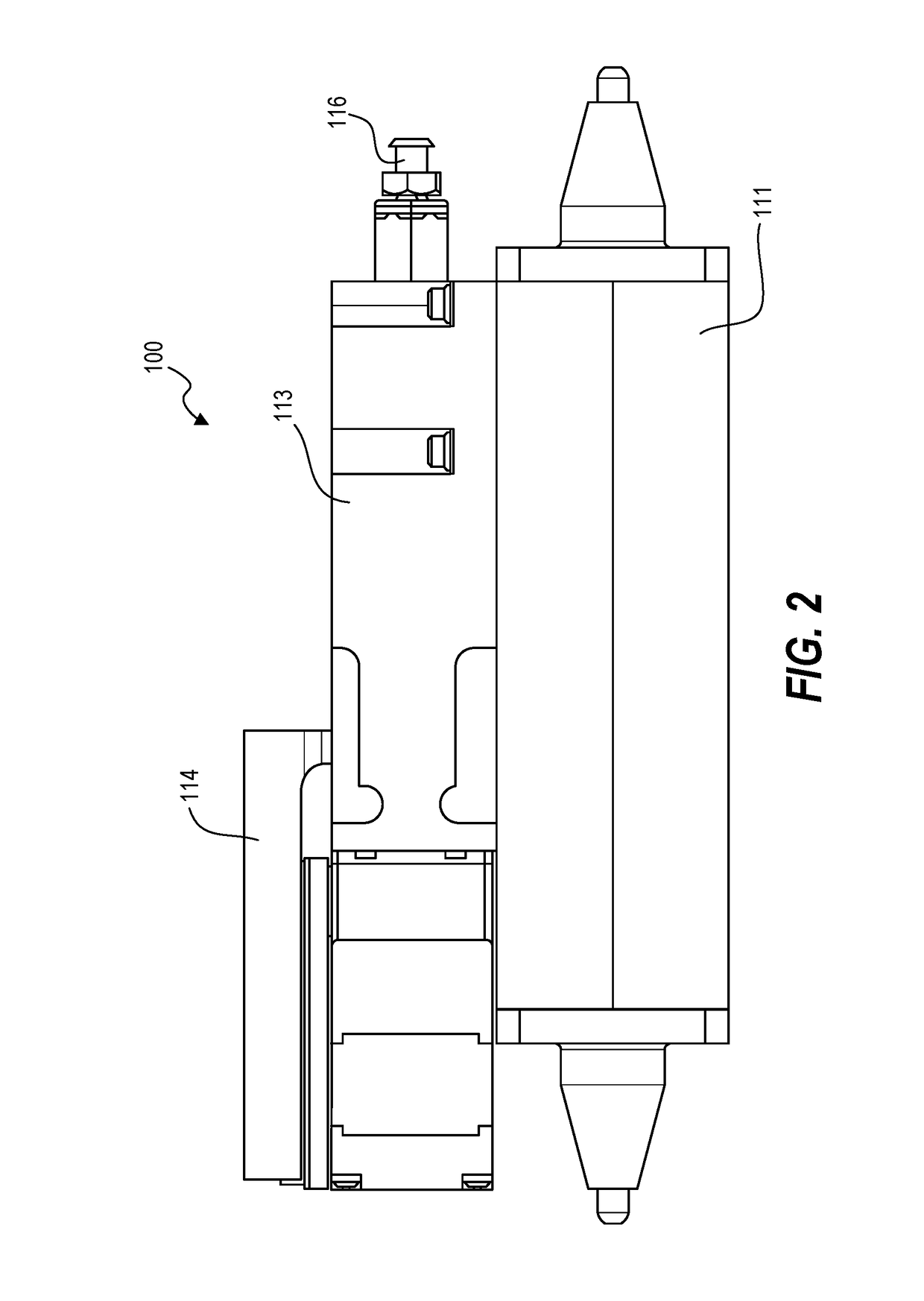

High-Purity Dispense System

ActiveUS20180047562A1Reduce defectsDefect minimizationLiquid surface applicatorsSemiconductor/solid-state device manufacturingMicrofabricationBladder base

Techniques herein include a bladder-based dispense system using an elongate bladder configured to selectively expand and contract to assist with dispense actions. This dispense system compensates for filter-lag, which often accompanies fluid filtering for microfabrication. This dispense system also provides a high-purity and high precision dispense unit. A process fluid filter is located downstream from a process fluid source as well as a system valve. Downstream from the process fluid filter there are no valves. Dispense actions can be initiated and stop while the system valve is open by using the elongate bladder. The elongate bladder can be expanded to stop or pause a dispense action, and then be contracted to assist with a dispense action.

Owner:TOKYO ELECTRON LTD

Compositions containing benefit agent composites pre-emulsified using colloidal cationic particles

ActiveUS20080242582A1Increase depositionImprove stabilityInorganic/elemental detergent compounding agentsCosmetic preparationsParticulatesSurface conditions

A cleansing or a surface-conditioning composition comprising a mixture of (i) and (ii) in water: i) a surfactant selected from the group consisting of anionic, non-ionic, zwitterionic, cationic, and mixtures thereof, and ii) a hydrophobic benefit agent in a particulate form having a mean particle size in the range of 1-1,000 micron, and a specific gravity of ≧1, not encapsulated within a film or a capsule-like enclosure, the particulate hydrophobic benefit agent comprising: a) a physically-modified form of the hydrophobic benefit agent; and b) a deposition-aid material bonded to the surface of the physically-modified benefit agent material, wherein the bonding between the two said materials is achieved prior to addition to i), wherein said deposition-aid material is not a surfactant having a weight average molecular weight of less than 5,000 Dalton.

Owner:AMCOL INTERNATIONAL CORPORATION

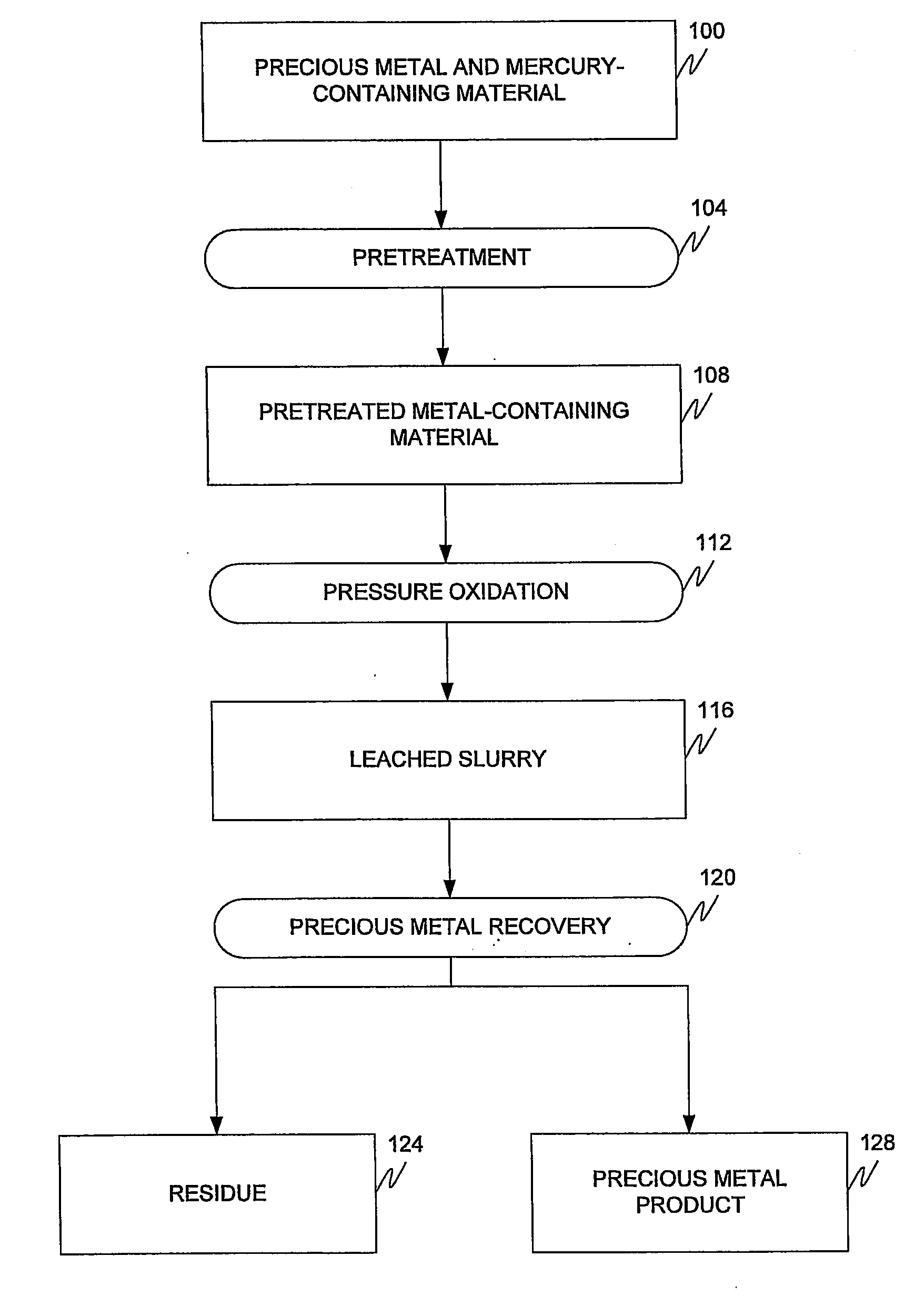

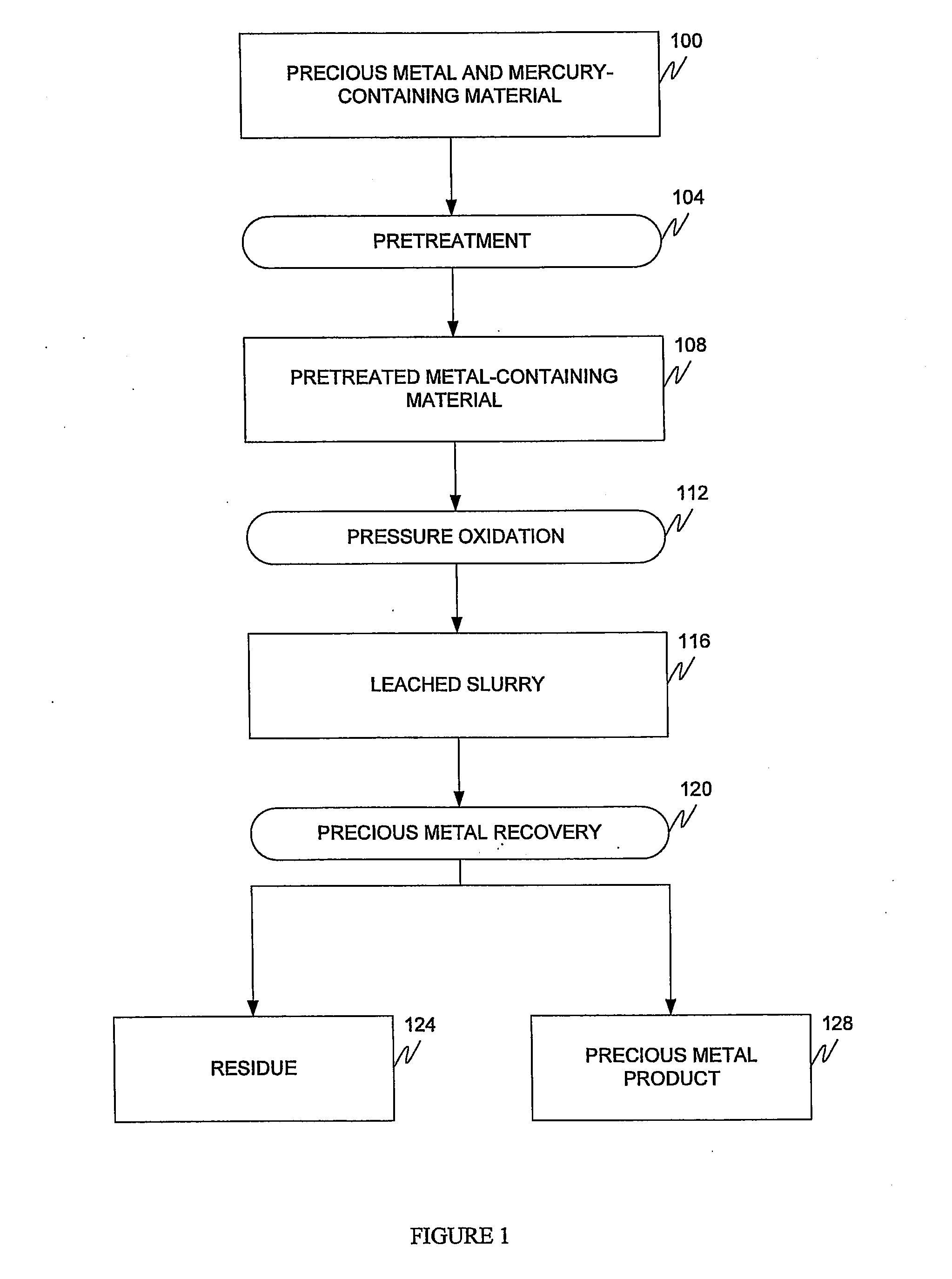

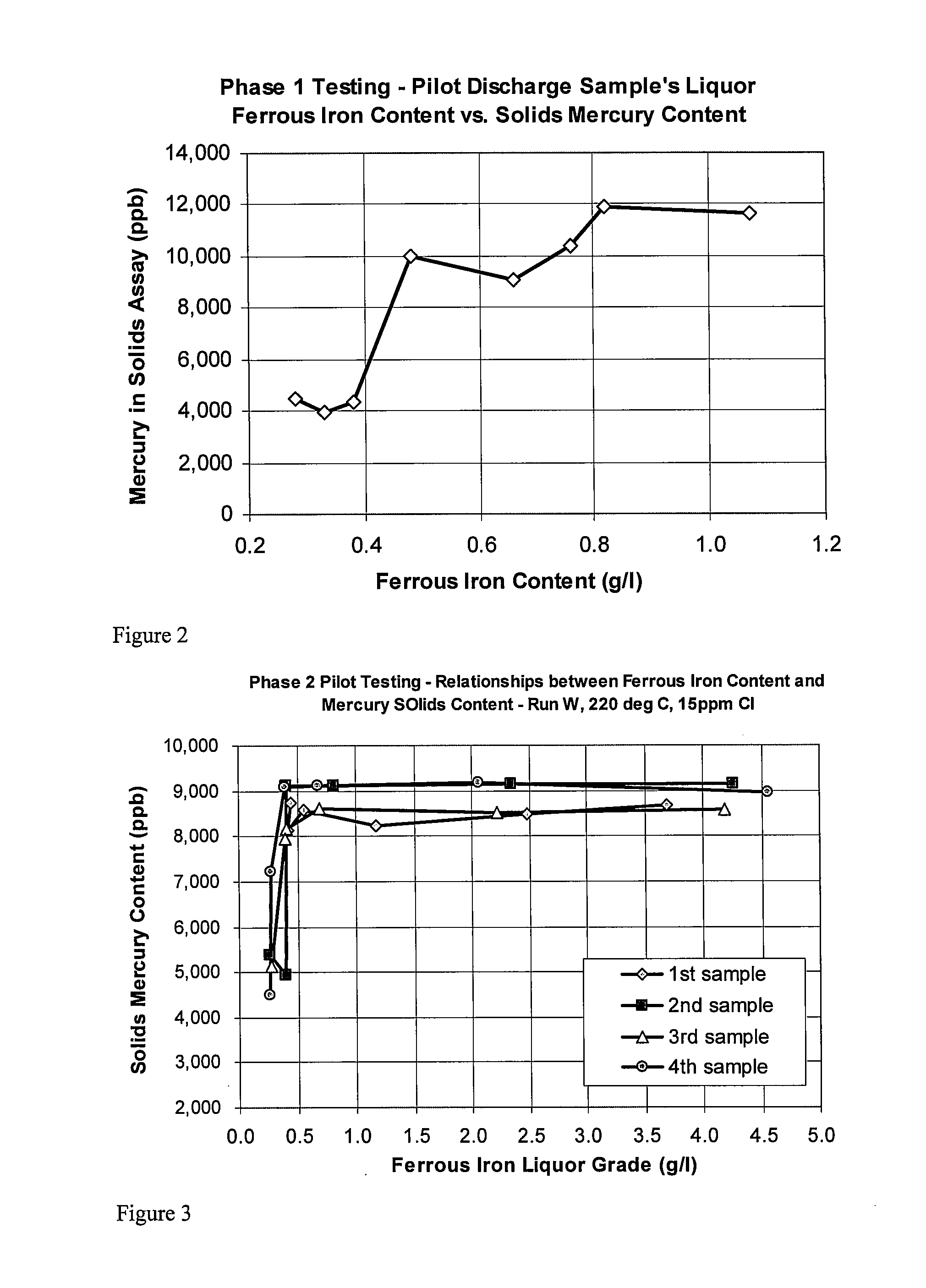

Process for mercury control during pressure oxidation

ActiveUS20090074608A1Reduce contentSimplify effluent treatmentSolvent extractionGold compoundsHalogenPressure oxidation

A method for suppressing mercury dissolution during pressure oxidation of precious metal-containing materials in the presence of halogens and halides is provided. Pressure oxidation is performed under controlled oxidative conditions to maintain the mercury predominantly in the solid residue.

Owner:BARRICK GOLD

Method of manufacturing ceramic sheet and method of manufacturing gas sensing element

InactiveUS20080099126A1Slow changeShrinking and dimensional changeLamination ancillary operationsLaminationPorosityMetallurgy

Methods of manufacturing a ceramic sheet and a gas sensing element are disclosed. At least ceramic powder, a binder and a plasticizer are blended and mixed in slurry. The slurry is formed into unfired green sheets, on which paste is printed. Each of the unfired green sheets has porosity greater than 5%. In the manufacturing methods, the unfired green sheets are pressurized with a pressure of 10 MPa at a temperature above 60° C., after which the paste is printed on surfaces of the unfired green sheets. In the method of manufacturing the gas sensing element, a shielding layer, a porous diffusion resistance layer and the unfired green sheets for a sensing layer, a reference gas airspace forming layer and a heating layer are stacked to form a stacked ceramic body, whish is fired to obtain the gas sensing element.

Owner:NIPPON SOKEN +1

Detersive compositions containing hydrophobic benefit agents pre-emulsified using sub-micrometer-sized insoluble cationic particles

InactiveUS7569533B2Improve stabilityIncrease depositionInorganic/elemental detergent compounding agentsCosmetic preparationsPolymer scienceOil emulsion

A cationic oil-in-water emulsion, for addition to detersive compositions, comprising hydrophilic cationic polymers, a surface-active, anionic polymer that is capable of adsorbing at an air-water interface or an oil-water interface and / or is oil-soluble, and a hydrophobic benefit agent in the oil phase made by adding the benefit agent to a hydrophobic liquid; thickening the oil phase with an organophillic smectite clay reacted at clay platelet surfaces to make the clay platelet surfaces hydrophobic while the edge surfaces of the clay remain hydrophilic, such that the organophillic smectite clay is adsorbed at an oil / water interface in the emulsion, and one of the hydrophilic, cationic polymers has a cationic nitrogen content of at least 6% by weight, that is incompatible with anionic surfactants, being insoluble in anionic-surfactant solutions containing an amount of 3% or higher of an anionic surfactant, and another hydrophilic cationic polymer has a cationic nitrogen content of at least 0.1% by weight and has a molecular weight of at least 600,000 Dalton.

Owner:AMCOL INTERNATIONAL CORPORATION

Compositions containing benefit agent composites pre-emulsified using colloidal cationic particles

ActiveUS7915214B2Improve stabilityIncrease depositionInorganic/elemental detergent compounding agentsCosmetic preparationsParticulatesColloid

A cleansing or a surface-conditioning composition comprising a mixture of (i) and (ii) in water: i) a surfactant selected from the group consisting of anionic, non-ionic, zwitterionic, cationic, and mixtures thereof, and ii) a hydrophobic benefit agent in a particulate form having a mean particle size in the range of 1-1,000 micron, and a specific gravity of ≧1, not encapsulated within a film or a capsule-like enclosure, the particulate hydrophobic benefit agent comprising: a) a physically-modified form of the hydrophobic benefit agent; and b) a deposition-aid material bonded to the surface of the physically-modified benefit agent material, wherein the bonding between the two said materials is achieved prior to addition to i), wherein said deposition-aid material is not a surfactant having a weight average molecular weight of less than 5,000 Dalton.

Owner:AMCOL INTERNATIONAL CORPORATION

Method and apparatus for growing high quality silicon single crystal, silicon single crystal ingot grown thereby and wafer produced from the same single crystal ingot

ActiveUS20070022942A1Improve productivityQuality improvementPolycrystalline material growthBy zone-melting liquidsProduction rateLiquid interface

The invention relates to a technique for producing a high quality Si single crystal ingot with a high productivity by the Czochralski method. The technique of the invention can control the magnetic field strength of an oxygen dissolution region different from that of a solid-liquid interface region in order to control the oxygen concentration at a desired value.

Owner:LG SILTRON

Process for producing a solder preform having high-melting metal particles dispersed therein

ActiveUS20090014092A1Short timeMinimize dissolutionWelding/cutting media/materialsThin material handlingSemiconductor chipDissolution

[Problems] A conventional process for producing a solder preform in which a predetermined amount of high-melting metal particles are directly put into molten solder and stirred, requires a long time for dispersing the high-melting metal particles by stirring. Therefore, in the conventional method for producing a solder preform, dissolution of the high-melting metal particles into the molten solder occurred during stirring, and their particle diameters became small. If a semiconductor chip and a substrate are soldered with a solder preform containing metal particles having such decreased diameters, the space between portions being soldered becomes narrow, and a sufficient bonding strength is not obtained.[Means for Solving the Problems] In the present invention, a premixed master alloy having a higher proportion of the high-melting metal particles in solder is first prepared, then the premixed master alloy is put into molten solder to disperse the high-melting metal particles. Aa a result, the high-melting metal particles can be uniformly dispersed in solder in a short length of time. Accordingly, a solder preform which is obtained by the process for producing a solder preform according to the present invention can maintain a predetermined clearance between portions being soldered, and a sufficient bonding strength is obtained.

Owner:SENJU METAL IND CO LTD

High-Precision Dispense System With Meniscus Control

ActiveUS20180047563A1Reduce defectsDefect minimizationLiquid surface applicatorsSemiconductor/solid-state device testing/measurementMicrofabricationEngineering

Techniques herein include a bladder-based dispense system using an elongate bladder configured to selectively expand and contract to assist with dispense actions. This dispense system compensates for filter-lag, which often accompanies fluid filtering for microfabrication. This dispense system also provides a high-purity and high precision dispense unit. A meniscus sensor monitors a position of a meniscus of process fluid at a nozzle. The elongate bladder unit is used to maintain a position of the meniscus at a particular location by selectively expanding or contracting the bladder, thereby moving or holding a meniscus position. Expansion of the elongate bladder is also used for a suck-back action after completing a dispense action.

Owner:TOKYO ELECTRON LTD

Compositions containing benefit agent composites pre-emulsified using colloidal cationic particles

InactiveUS20080286367A1Increase depositionImprove stabilityInorganic/elemental detergent compounding agentsPowder deliverySpecific gravityColloidal particle

A cleansing or a surface-conditioning composition comprising a mixture of (i) and (ii) in water: i) a surfactant selected from the group consisting of anionic, non-ionic, zwitterionic, cationic, and mixtures thereof; and ii) a hydrophobic benefit agent in a particulate form having a mean particle size in the range of 1-1,000 micron, and a specific gravity of ≧1, not encapsulated within a film or a capsule-like enclosure, the particulate hydrophobic benefit agent comprising: a) a physically-modified form of the hydrophobic benefit agent; and b) a deposition-aid material bonded to the surface of the physically-modified benefit agent material, wherein the bonding between the two said materials is achieved prior to addition to i), wherein said deposition-aid material is not a surfactant having a weight average molecular weight of less than 5,000 Dalton.

Owner:AMCOL ITNERNAT CORP

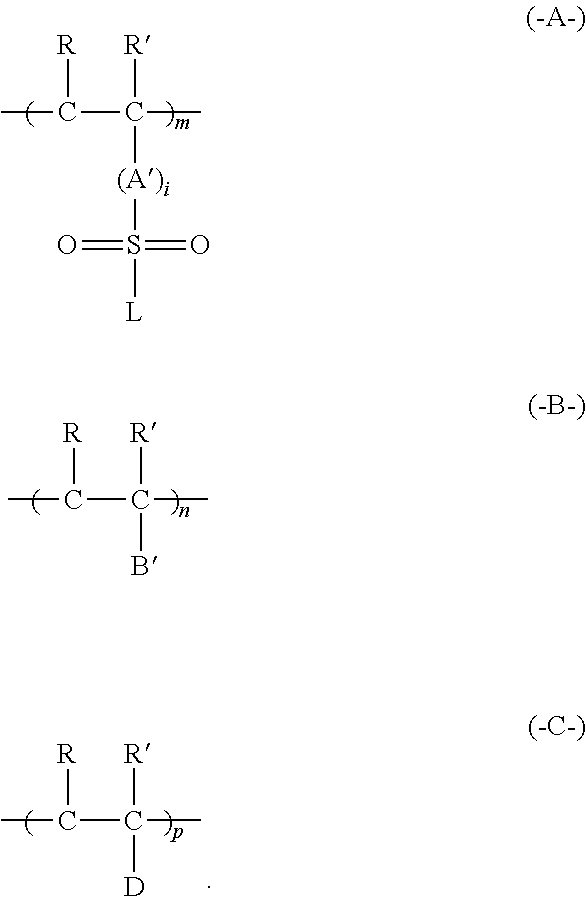

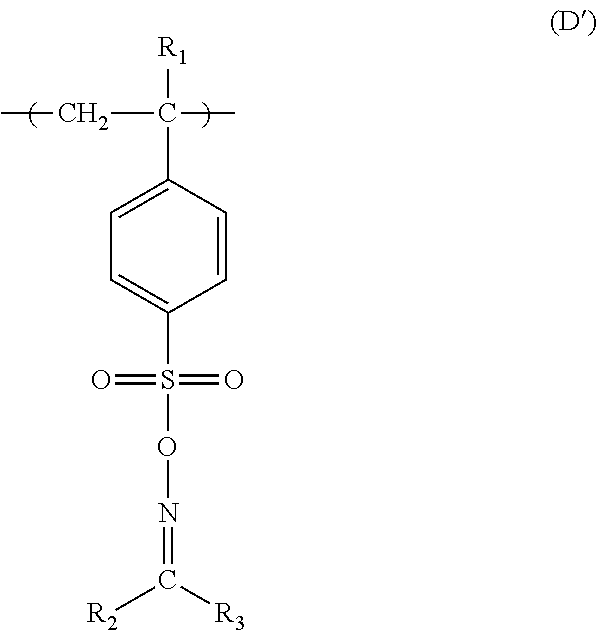

Forming conductive metal pattern using reactive polymers

ActiveUS20150140285A1Promote polymer crosslinkingImprove hydrophilicityPhotosensitive materialsDecorative surface effectsPolymer scienceSide chain

A conductive metal pattern is formed in a polymeric layer that has a reactive polymer that comprises (1) pendant groups that are capable of providing pendant sulfonic acid groups upon exposure to radiation, and (2) pendant groups that are capable of reacting in the presence of the sulfonic acid groups to provide crosslinking. The polymeric layer is patternwise exposed to provide a polymeric layer comprising non-exposed regions and exposed regions comprising a polymer comprising pendant sulfonic acid groups. The exposed regions are contacted with electroless seed metal ions to form a pattern of electroless seed metal ions. The electroless seed metal ions are reduced to provide a pattern of electroless seed metal nuclei that are then electrolessly plated with a conductive metal.

Owner:EASTMAN KODAK CO

High-Purity Dispense Unit

ActiveUS20180046082A1Reduce defectsDefect minimizationLiquid surface applicatorsSemiconductor/solid-state device testing/measurementBladder baseMicrofabrication

Techniques herein include a bladder-based dispense system using an elongate bladder configured to selectively expand and contract to assist with dispense actions. This dispense system compensates for filter-lag, which often accompanies fluid filtering for microfabrication. This dispense system also provides a high-purity and high precision dispense unit. A modular hydraulic unit houses the elongate bladder and hydraulic fluid in contact with an exterior surface of the bladder. When pressurized process fluid is in the elongate bladder, hydraulic controls can selectively reduce pressure on the bladder to cause expansion, and then selectively increase hydraulic pressure to assist with a dispense action.

Owner:TOKYO ELECTRON LTD

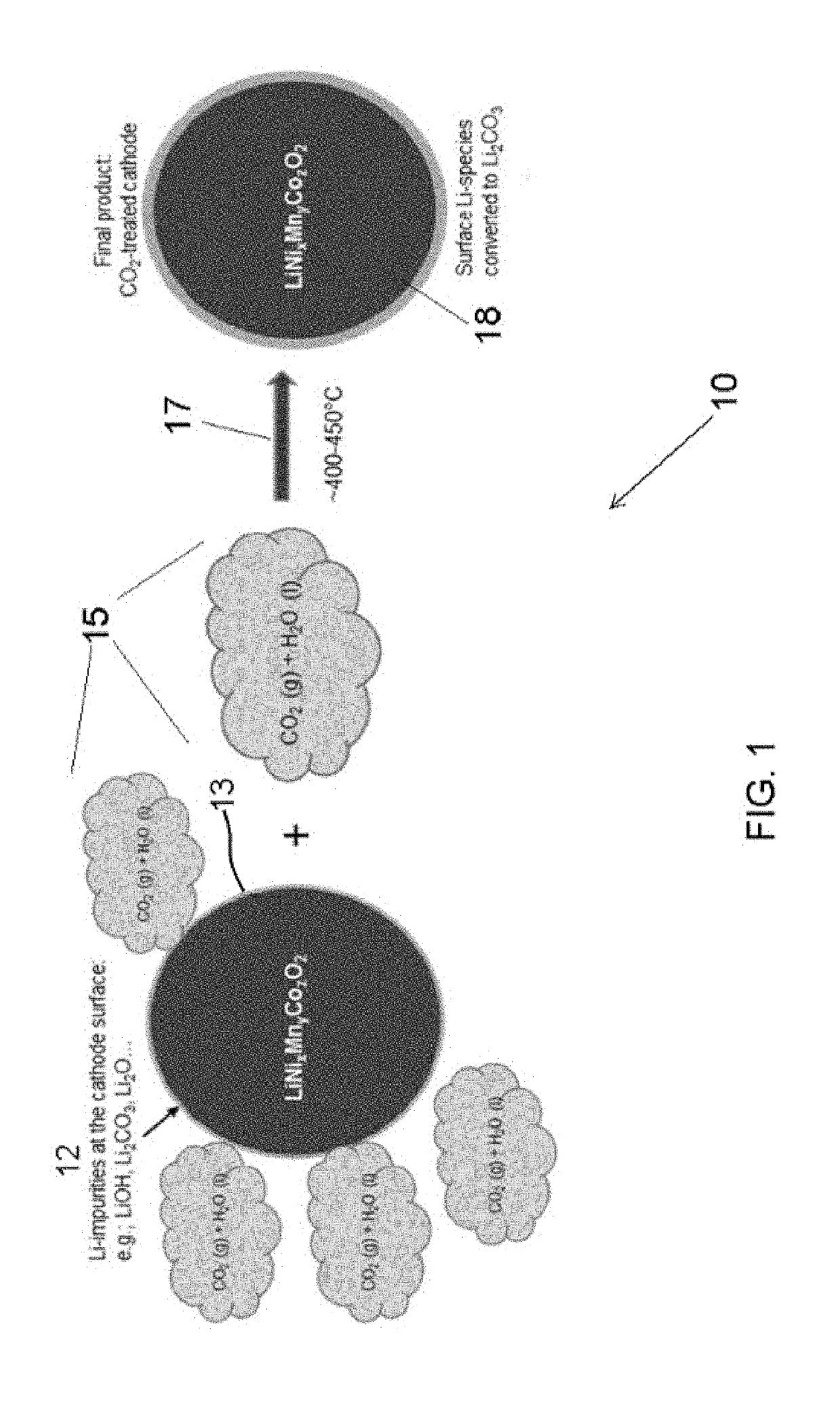

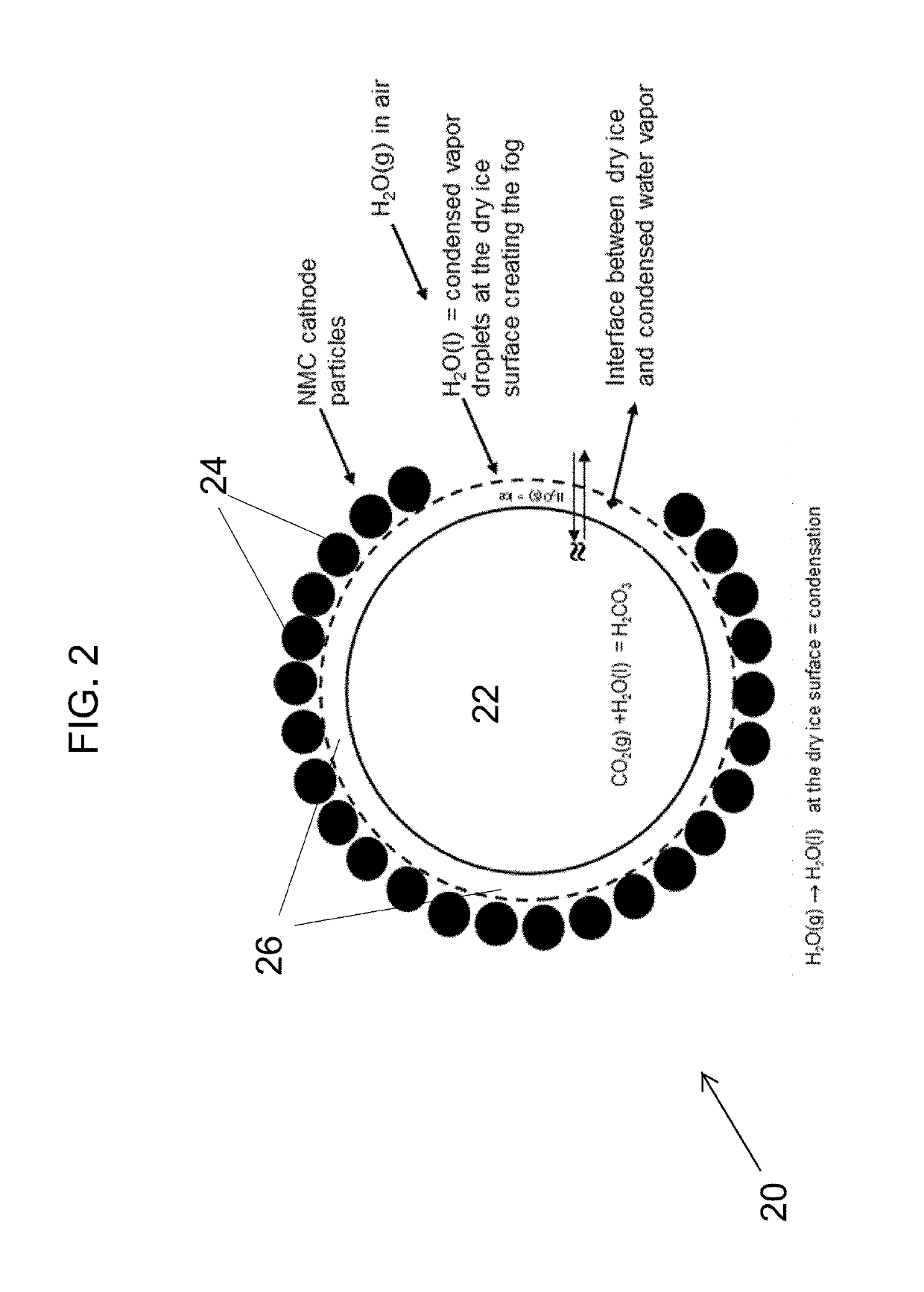

Carbon dioxide treatment of cathodes

ActiveUS20190326591A1Reduced responseEnhances electrophoretic kinetics of reactionElectrode thermal treatmentSecondary cellsAtmospheric airLithium carbonate

A method for producing water resistant cathodes is discussed. The method uses mixing cathode powder with solid carbon dioxide to create a mixture and heating the mixture to a temperature. The heating occurs for a time sufficient to cause lithium carbonate coatings to form on the powder. A method for coating lithium-containing cathode surfaces is also discussed. This method uses simultaneously sublimating solid CO2 and condensing atmospheric water vapor onto surfaces. Afterwards allowing the lithium to react with the sublimated CO2 for a time sufficient to create a lithium carbonate film on the surface.

Owner:UCHICAGO ARGONNE LLC

Forming conductive metal patterns using reactive polymers

InactiveUS20150125674A1Improve hydrophilicityImprove adhesionPhotosensitive materialsPrinted circuit aspectsPolymer scienceCarboxylic acid

A conductive pattern is prepared in a polymeric layer that has (a) a reactive polymer comprising pendant tertiary alkyl ester groups, (b) a compound that provides an acid upon exposure to radiation having a λmax of at least 150 nm and up to and including 450 nm, and (c) a crosslinking agent. The polymeric layer is patternwise exposed to provide a polymeric layer comprising non-exposed regions and exposed regions comprising a polymer comprising carboxylic acid groups. The exposed regions are contacted with electroless seed metal ions to form a pattern of electroless seed metal ions. The pattern of electroless seed metal ions is then reduced to provide a pattern of corresponding electroless seed metal nuclei. The corresponding electroless seed metal nuclei are then electrolessly plated with a conductive metal.

Owner:EASTMAN KODAK CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com