Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

54results about How to "Long-term anti-corrosion effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Epoxy graphene heavy corrosion-resistant coating, and preparation method and application thereof

InactiveCN107739566APlay a physical anti-corrosion effectAct as electrochemical anticorrosionAnti-corrosive paintsEpoxy resin coatingsEpoxyChemical products

The invention relates to the field of corrosion-resistant coating, in particular to epoxy graphene heavy corrosion-resistant coating and a preparation method thereof. The epoxy graphene heavy corrosion-resistant coating mainly comprises the following components in percentage by weight: 0.1 to 5 percent of a graphene material, 30 to 60 percent of epoxy resin, 30 to 50 percent of a pigment filler, 0.1 to 10 percent of a dispersing agent, 0.1 to 5 percent of a coating aid and 8 to 30 percent of a solvent. The components of the coating provided by the invention have synergistic effect, grinding, ultrasonic dispersion and grinding are conducted step by step, the graphene powder is added step by step, the graphene is dispersed uniformly, excellent barrier property and excellent electric conductivity of a nano-sheet layer structure of the graphene on the chemical products are exerted completely, and the corrosion resistance of the epoxy resin heavy corrosion-resistant coating is improved andenhanced, so that the super long-lasting corrosion-resistant effect is achieved and the coating of the prepared coating is thin. The preparation method provided by the invention is simple and practical, and the prepared coating has excellent performance.

Owner:SHANDONG SHENGQUAN NEW MATERIALS CO LTD

Modified silicate waterborne zinc-rich anticorrosive coating employing organic montmorillonite as anti-settling dispersant

The invention relates to an anticorrosive coating, and particularly relates to a modified silicate waterborne zinc-rich anticorrosive coating employing organic montmorillonite as an anti-settling dispersant. The modified silicate waterborne zinc-rich anticorrosive coating is prepared from components A and B, wherein the component A is prepared from 10-60% of flake zinc powder; the component B is prepared from 25-85% of silicone acrylic emulsion-modified potassium silicate solution, 0.1-5% of ricinate, 0.1-5% of organic montmorillonite, 0.1-5% of defoamer, and 0.01-2% of thickener, and the percent is weight percent. The modified silicate waterborne zinc-rich anticorrosive coating has the advantages that the dosage of zinc powder can be greatly reduced, and the cost of the coating is reduced. The water resistance of the coating is improved by the organic emulsion-modified potassium silicate solution; excellent painting hardness of the coating is achieved, the barrier property of the coating is improved, and meanwhile, the anticorrosive coating is almost zero in volatile organic compound (VOC) release property, and free of environmental pollution.

Owner:SHENYANG POLYTECHNIC UNIV

Environmental-friendly anticorrosive paint for power transmission line

ActiveCN103756458AImprove performance indicatorsImprove anti-corrosion performanceAnti-corrosive paintsEngineeringTitanium carbide

The invention belongs to the technical field of power transmission line protection and discloses an environmental-friendly anticorrosive paint for a power transmission line. The paint is prepared from the raw materials in parts by weight: 60 parts of vinyl chloride-vinyl acetate copolymer, 40 parts of polyvinyl pyrrolidone, 30 parts of decabromodiphenyl ethane, 24 parts of emulsified silicone oil, 20 parts of phthalate, 20 parts of polysiloxane, 12 parts of 2-bromo-2-nitro-1,3-propanediol, 9 parts of sodium carboxymethyl cellulose, 8 parts of aluminum tripolyphosphate, 6 parts of water glass, 5 parts of tungsten carbide, 5 parts of titanium carbide, 3 parts of lithium-based bentonite, 2 parts of sodium citrate and 40 parts of water. The anticorrosive paint disclosed by the invention has the advantages that the power transmission line is resistant to corrosion of acid, alkali, salt and steam, the service life of the power transmission line is prolonged greatly, and meanwhile, potential safety hazards are reduced.

Owner:苏州盛泽科技创业园发展有限公司

Novel waterborne zinc-rich anti-corrosive paint

InactiveCN101418150AImprove anti-saggingImprove anti-settling performanceAnti-corrosive paintsWater basedMetasilicate

The invention discloses a novel water-based zinc-rich anti-corrosive paint, which consists of a component a and a component b; according to the total weight percentage of the paint, the component a comprises 50 to 56 percent of zinc powder and 10 to 15 percent of thixotropic agent, and the component b comprises 8 to 10 percent of potassium metasilicate, 17 to 20 percent of water, 1 to 2 percent of thickening agent and 4 to 7 percent of addition agent. When in use, the water-based zinc-rich anti-corrosive paint can be prepared by mixing the component a and component b. The paint system is a water-based system, does not contain organic solvent, has simple preparation method, saves materials, reduces the cost by 5 to 10 percent compared with like products, and has no environment pollution and no influence on constructors. The cured coating has the advantages of excellent ageing-resistant, radiation resistant and solvent resistant performance, good comprehensive performance and long-term corrosion resistance.

Owner:LANGFANG ZKYD ANTI RUST TECH

Novel solvent-free high-performance epoxy anticorrosive paint for steel surface

InactiveCN102206459ALow water absorptionGood construction performanceAnti-corrosive paintsEpoxy resin coatingsZinc phosphateEpoxy

The invention relates to a high-performance solvent-free epoxy anticorrosive paint for a steel surface and a preparation method thereof. The high-performance solvent-free epoxy anticorrosive paint comprises a component A and a component B, wherein the component A comprises 40 weight percent of epoxy resin 830, 30 weight percent of epoxy resin 618 and 30 weight percent of toughening agent (self-made polyurethane epoxy resin); and the component B comprises 50 weight percent of amine hardener, 10 weight percent of zinc phosphate, 10 weight percent of aluminium trippolyhosphate, 10 weight percent of micaceous iron oxide, 5 weight percent of talcpowder (800 meshes), 2 weight percent of precipitated barium sulfate (800 meshes) and 13 weight percent of aluminum powder. The high-performance solvent-free epoxy anticorrosive paint has the characteristics of no solvent, low viscosity, high anticorrosion performance and the like.

Owner:中化化工科学技术研究总院有限公司

Preparation method of polyaniline-epoxy graft modified acrylic ester compound

Relating to the technical field of paint production, the invention provides a preparation method of a polyaniline-epoxy graft modified acrylic ester compound. The method includes: in the presence of a solvent, firstly mixing epoxy resin, a functional monomer, acrylic ester and an initiator to prepare carboxyl-containing epoxy graft acrylic ester resin through a solution polymerization technique; then adding aniline, and carrying out in situ oxidation polymerization of aniline on the carboxyl-containing epoxy graft acrylic ester resin, thus obtaining the polyaniline-epoxy graft modified acrylic ester compound. The formed epoxy graft modified acrylic ester resin concentrates the room temperature curable performance, excellent corrosion resistance, strong adhesion to a substrate and other characteristics of epoxy resin, and the water resistance, weatherability, gloss and color retention, adjustable mechanical performance and other characteristics of acrylic ester resin. The compound is compounded in a molecular level state in an organic solvent, and is stable for long-term storage.

Owner:YANGZHOU UNIV

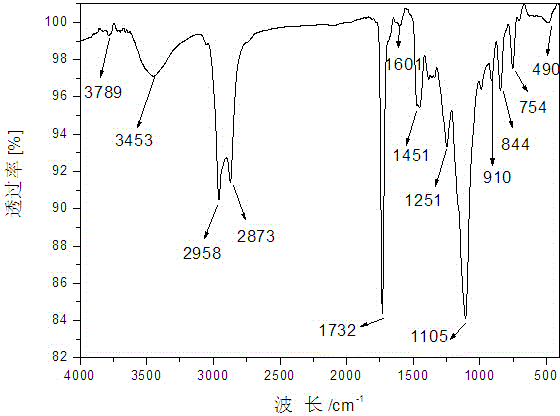

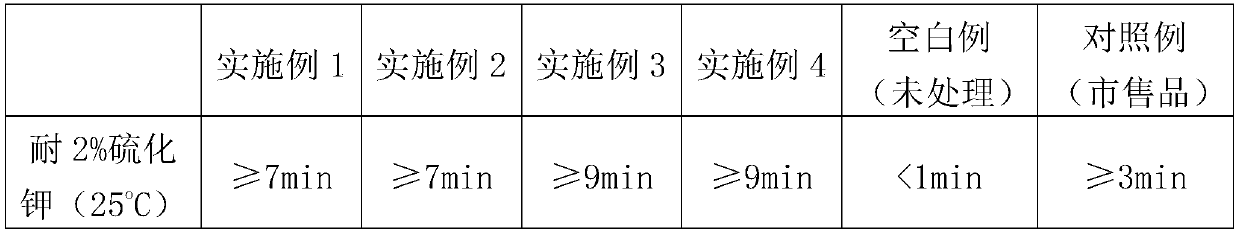

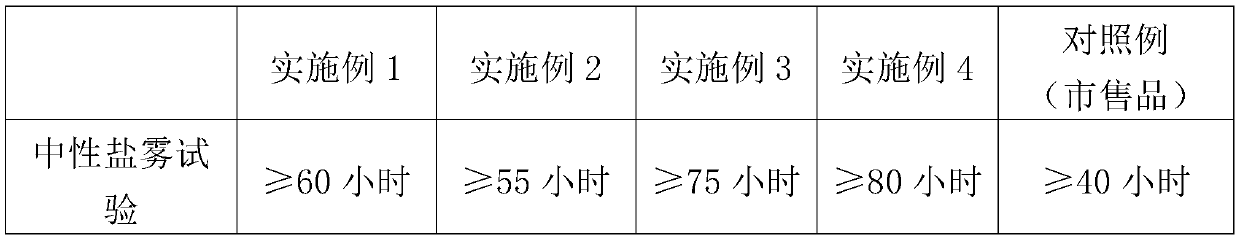

Gold and silver surface anti-oxidation and anti-color-change protecting agent and preparation method and application thereof

InactiveCN110230061AIntegrity guaranteedLong-term anti-corrosion effectMetallic material coating processesEtherBenzethonium chloride

The invention discloses a gold and silver surface anti-oxidation and anti-color-change protecting agent and a preparation method and application thereof, and belongs to the technical field of gold andsilver plating layer protecting agents. The protecting agent comprises the following components in parts by weight: 15-30 parts of color change preventing agents, 10-15 parts of film forming agents,3-8 parts of alcohol ether solvents, 30-50 parts of emulsifying agents, 2-5 parts of benzethonium chloride, 5-10 parts of carboxylic acid type deoxidants, 1-3 parts of corrosion inhibitors, 0.5-1 partof antioxidants, 1-3 parts of brightening agents, and 5-20 parts of water. The prepared protecting agent can form double layers of protecting films to effectively prevent oxidation of gold and silverplating layers by air and corrosion by acid and alkali; meanwhile, the surface corrosion and color change resistance of the plating layers is improved; the brightness of the plating layers is improved; the performances of higher brightness and efficiency are given to the plating layers; the protecting agent also can be applied to surface protection of copper substrates, and the effect can rival chromium salt protecting films; the copper surface colors can be not changed for a long time; the effect of low poison is achieved; and the treatment process is simple.

Owner:广东锴力环保新材料有限公司

Long-acting anti-corrosion solvent-free universal epoxy coating and preparation method thereof

ActiveCN112029382AImprove cure rateLong application periodAnti-corrosive paintsEpoxy resin coatingsEpoxyPolymer science

The invention relates to the technical field of anti-corrosion coatings, and particularly relates to a long-acting anti-corrosion solvent-free universal epoxy coating and a preparation method thereof.The long-acting anti-corrosion solvent-free universal epoxy coating comprises a first component and a second component, wherein the first component comprises epoxy resin, adipic acid modified epoxy resin and graphene dispersion liquid; and the second component comprises an amine mixed curing agent and an amino silane coupling agent. The coating provided by the invention effectively solves the problems of large internal stress, poor coating flexibility and corrosion resistance, easiness in oil surface and gloss loss in a low-temperature environment and a high-humidity environment and the likeof an existing solvent-free epoxy coating system, has excellent corrosion resistance, good recoatability, excellent matching performance with various finishing paints, good weather resistance and thelike, has good film-forming property in low-temperature and high-humidity environments, has no oil surface or gloss loss, and achieves the technical goals of universality of the whole ship and universality in four seasons.

Owner:XIAMEN SUNRUI SHIP COATING

Waterless liquid coolant for engine under extreme conditions and preparation method thereof

InactiveCN106566483AAchieve long-term anti-corrosion effectMake up for the property defect of relatively low charge transfer efficiencyHeat-exchange elementsMetallic material coating processesSodium metasilicateIonic liquid

The invention relates to a waterless liquid coolant for an engine under extreme conditions and a preparation method thereof. The preparation method comprises the following steps: uniformly mixing, by weight, 10 to 20 parts of imidazole ionic liquid, 10 to 30 parts of dipropylene glycol and 40 to 60 parts of propylene glycol under stirring so as to obtain base liquid; adding 0.2 to 2 parts by weight of an organosilicon antifoaming agent into the base liquid and carrying out uniform mixing under stirring; adding 0.7 to 8 parts by weight of a composite corrosion inhibitor into a mixed solution obtained in the previous step, carrying out heating to 70 to 80 DEG C and then carrying out uniform mixing under heating and stirring; and adding 5 to 10 parts by weight of a viscosity-reducing agent into a mixed solution obtained in the previous step and carrying out carrying out uniform mixing under stirring. The invention has the beneficial effects that the waterless liquid coolant has a freezing point of less than -65 DEG C and a boiling point of 255 DEG C, and has long-acting and excellent corrosion resistance; the waterless liquid coolant can rapidly form a metal oxide passive film on the surfaces of a plurality of metals so as to realize anticorrosion and construction of an activated adsorption film-forming corrosion mitigation system; special-effect aluminum corrosion inhibitor, i.e., sodium metasilicate, can protect aluminum structural members in the engine; and tolyltriazole can protect copper structural members in the engine.

Owner:安徽超际环保科技有限公司

Environmental protection highly effective water-based primer

InactiveCN1908091ANo pollution in the processZero emissionAnti-corrosive paintsEmulsion paintsWater basedOrganic solvent

The invention discloses an environmental-protective water-based priming paint, which comprises two formulations: one is 50-60% metasilicate liquid, 20-30% metal dioxide, 15-20% emulsion and 1-10% adjuvant; the other is 70-80% zinc powder and 20-30% white compound Si-Ti rust-proofing powder. The invention adopts water as solvent without polluting and VOC drainage, which can bear washing after drying for 30 min.

Owner:武汉市大汉科技发展有限公司

High-temperature wear-resistant heavy-duty anticorrosion powder coating, and preparation method and coating method thereof

PendingCN113861805ALow costReduce well maintenance and repair costsLiquid surface applicatorsAnti-corrosive paintsFirming agentPowder coating

The invention provides a high-temperature wear-resistant heavy-duty anticorrosion powder coating, and a preparation method and a coating method thereof. The high-temperature wear-resistant heavy-duty powder coating comprises, by mass, 50-65 parts of phenolic modified epoxy resin, 3-9 parts of a curing agent, 3-5 parts of an organic wear-resistant filler, 5-10 parts of an inorganic wear-resistant filler, 3-7 parts of a solid wear-resistant lubricant, 15-30 parts of a pigment filler, 0.2-0.5 part of a curing accelerator and 0.8-1.5 parts of a leveling agent. The components of the high-temperature wear-resistant powder coating are all commercially available materials, are simple and easy to obtain, and are low in cost; and the phenolic aldehyde modified epoxy resin with high strength, heat resistance and acid and alkali resistance is adopted as a main film-forming matter, the long-acting corrosion resistance can still be kept in the harsh H2S / CO2 corrosion environment, and a high-temperature wear-resistant anticorrosion coating layer can be obtained through the high-temperature wear-resistant heavy-duty anticorrosion powder coating.

Owner:北京天乙长科技发展有限公司

Waterborne self-drying anticorrosion priming paint for construction crane and preparation method thereof

ActiveCN104031533AImprove corrosion resistanceGood value for moneyAnti-corrosive paintsPolyester coatingsPolymer scienceSilicon dioxide

The invention discloses a waterborne self-drying anticorrosion priming paint for a construction crane and a preparation method thereof. The priming paint comprises, by weight, 10 to 30% of a resin, 25 to 45% of an auxiliary agent, 2 to 15% of a thickening thixotropic agent, 0.8 to 6% of an antirust pigment, 2 to 4% of silica and 15 to 25% of an auxiliary material. The preparation method for the waterborne self-drying anticorrosion priming paint comprises the following steps: step (1), mixing the resin and the auxiliary material according to a ratio of 4: 6; step (2), putting the resin and the auxiliary material into an agitator for stirring and dispersing, wherein a stirring speed is 400 to 700 r / min; step (3), adding the prepared thickening thixotropic agent, antirust pigment and silica into the agitator for uniform mixing under stirring; and step (4), adding the auxiliary material and carrying out stirring for 40 to 55 min.

Owner:JIANGSU XIN AN NEW MATERIALS TECH

Novel mechanical equipment cleaning agent

The present invention discloses a novel mechanical equipment cleaning agent, which is prepared from the following raw materials by weight: 4.2-6.5 parts of triethanolamine, 3.5-5.5 parts of a surfactant, 5.6-7.8 parts of peroxide phosphate, 2.3-5.5 parts of ethanol, 2.5-4.4 parts of sodium gluconate, 3.2-5.4 parts of water, and 3.3-6.5 parts of sodium tripolyphosphate. The novel mechanical equipment cleaning agent has the following characteristics that: the novel mechanical equipment cleaning agent has powerful penetration ability, does not have characteristics of easy combustion and easy explosion during use, has high safety factor, can not cause great adverse effects to the work environment, and does not contain nitrite, phenol, formaldehyde and other substances harmful to the environment; oil stains can be rapidly separated from the surface of work-pieces with heating, scrubbing and other manners during cleaning when the powerful metal equipment cleaning liquid is used so as to be dispersed into the cleaning liquid; and the novel mechanical equipment cleaning agent has characteristics of no toxicity and harm on operators, good safety, good environmental protection, easy waste liquid treatment, low cleaning cost, and high economic benefits.

Owner:QINGDAO SHUAIWANG OIL CHEM

One-component epoxy aluminum-rich coating for steel structure, and preparation method thereof

InactiveCN105315834AWith cathodic protectionImprove adhesionAnti-corrosive paintsEpoxy resin coatingsEpoxyBound property

The invention discloses a one-component epoxy aluminum-rich coating for steel structure, and a preparation method thereof. The coating comprises, by mass, 30-40% of one-component epoxy resin, 40-50% of aluminum powder, 5-10% of a solvent and 1-5% of an assistant. The coating has the advantages of excellent binding property, chemical corrosion resistance, wear resistance, quick drying property, water penetration resistance, flame resistance, realization of a long-term anticorrosion effect, and can be specially used to protect the steel structure.

Owner:JIANGSU XIN AN NEW MATERIALS TECH

Coating and anti-corrosion method for steel products

The invention relates to a coating anti-corrosion method for steel materials arranged in oceans, lakes, rivers and the like. First, paste mineral grease anti-corrosion material is applied on the surface of the steel, and a strip-shaped mineral oil anti-corrosion tape is wound on it, and then the protective cover and the foam plastic material or plastic material arranged on the inner surface of the protective cover are used Covered with cushioning material made of rubber. The anti-corrosion method of the invention can protect steel structures in water bodies such as oceans, rivers and lakes from corrosion in a long-term, efficient and stable manner.

Owner:株式会社那卡波技工 +1

Fluorine modified epoxy polysiloxane coating and preparation method and application thereof

The invention provides a fluorine modified epoxy polysiloxane coating and a preparation method and application thereof. The defects that polysiloxane is low in intensity and poor in binding power are relieved through siloxy groups, epoxy groups and hydroxyl groups, the prepared fluorine modified epoxy polysiloxane coating has the long-acting antiseptic property, therefore, the service life and maintenance duration of steel are prolonged, and remarkable social benefits and economic benefits are achieved. Through fluorine modification, the ultraviolet light resistance is improved, and the water resistance of a paint film is improved. By means of introduction of modified alicyclic amine to participate in a curing reaction, the flexibility of the paint film is improved, and the surface drying time of the paint film is shortened. Through good matching of the coating with zinc-rich primer and an intermediate coating, the current requirements for corrosion protection and ultra-long weather fastness can be met; the fluorine modified epoxy polysiloxane coating is free of isocyanate, low in toxicity, environmentally friendliness, high in solid content and low in VOC, and the environment protection requirement of modern antiseptic coating can be met.

Owner:湖北山虎涂料有限公司

Sea spray splash zone corrosion protection corrosion prevention solution and protection method thereof

The invention relates to a corrosion protection method, in particular to a sea spray splash zone corrosion protection corrosion prevention solution and a protection method thereof. The sea spray splash zone corrosion protection corrosion prevention solution comprises epoxy glue, a compound type corrosion inhibitor and zinc powder, the mass ratio of the epoxy glue to the zinc powder is equal to (1-4.6) : (2-9), the concentration of the compound type corrosion inhibitor in the corrosion prevention solution reaches 0.1-1.8g / L; the compound type corrosion inhibitor comprises a corrosion inhibitorand zinc dihydrogen phosphate with a mass ratio of 3: (0.1-1); and the corrosion inhibitor comprises triethanolamine, phosphoric acid and an additive with a mass ratio of (23-46) : (22-32) : (0.1-1).The invention is suitable for corrosion prevention protection on a steel material used in a sea spray splash region, thus service life of the steel material is prolonged.

Owner:INST OF OCEANOLOGY - CHINESE ACAD OF SCI

Environmental protection high efficiency water finishing paint

InactiveCN1718650AMeet the needs of long-term heavy-duty anti-corrosion engineeringImprove performanceEmulsion paintsHigh resistanceUltraviolet

An environment protection type efficient water surface paint is proportionally prepared from silicate solution, metallic oxide, acrylate emulsion and assistant for the formula A, or from zinc powder, active magnetic iron powder, refractory iron oxide black, refractory iron oxide yellow and refractory iron oxide gree for the formula B. Its advantages are no poison and pollution and high resistance to water flushing, corrosion, organic solvent, etc.

Owner:WUHAN FUMAISHI NEW MATERIAL CHEM

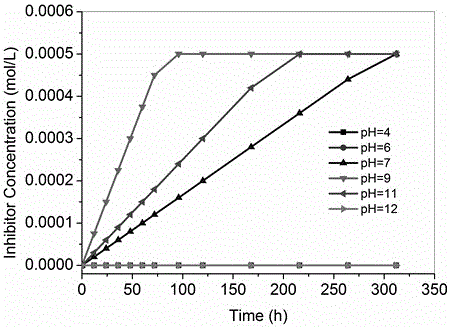

Intelligent corrosion inhibitor with pH value sensibility and preparation method of intelligent corrosion inhibitor

The invention provides an intelligent corrosion inhibitor with pH value sensibility and a preparation method of the intelligent corrosion inhibitor. The intelligent corrosion inhibitor with pH value sensibility is of a spherical nucleus / shell nanometer structure, the particle diameter is about within the range from 60 nanometers to 150 nanometers, the shell thickness is about within the range from 5 nanometers to 20 nanometers, the pH sensibility interval ranges from 7 to 11, and the intelligent corrosion inhibitor is composed of a hydrophilic shell which is made of a macromolecule material with pH sensibility and a hydrophobic nucleus made of a polymer substrate loaded with corrosion inhibition components. The corrosion inhibitor has the beneficial effects that the pH sensibility interval is wide, varieties of corrosion inhibition components can be released, the structure is fine, and the release controllability of the corrosion inhibition components is good; and losing and failures of the corrosion inhibition components can be avoided effectively so that the corrosion inhibition components can intelligently play a role in inhibiting metal corrosion for a long time. Meanwhile, the invention provides a preparation method of the intelligent corrosion inhibitor which has the pH value sensibility, is of the nucleus / shell nanometer structure and can intelligently inhibit the metal corrosion for a long time.

Owner:濮阳市东浦科技发展有限公司

Double-component aqueous inorganic zinc-enriched priming paint

InactiveCN110054957ASimple compositionEasy constructionAnti-corrosive paintsChemical/physical/physico-chemical stationary reactorsTO-18Emulsion

The invention provides a double-component aqueous inorganic zinc-enriched priming paint. The double-component aqueous inorganic zinc-enriched priming paint comprises a component A and a component B ata weight ratio of 7:3; the component A comprises, by weight, 35 to 45 parts of an aqueous amino resin, 12 to 25 parts of acrylic emulsion, 5 to 15 parts of silica sol, and 11 to 18 parts of zinc powder; the component B comprises, by weight, 5 to 15 parts of kaolin, 4 to 11 parts of modified nano silica, and 30 to 45 parts of deionized water. A new formula is adopted, the double-component aqueousinorganic zinc-enriched priming paint is simple in composition, and convenient in construction. The paint film of the double-component aqueous inorganic zinc-enriched priming paint possesses excellentelectrochemical protection performance and strong adhesion capacity, is capable of tolerating high temperature of 400 to 500 DEG C continuously, is low in electrical resistivity, is excellent in anti-static performance, anti-radiation performance, and salt spray resistance, and possesses long-lasting anti-corrosion effect.

Owner:镇江禹亨新材料有限公司

Special coating for modified cold primer oil pipeline, and preparation method thereof

InactiveCN103992741AImprove adhesionGood chemical resistanceRubber derivative coatingsWax coatingsPhysical chemistryChemical corrosion

The invention relates to a special coating for a modified cold primer oil pipeline. The special coating comprises 20-30wt% of modified resin, 50-60wt% of an asphalt liquid, 10-12wt% of 52# paraffin, 8-10wt% of talcum powder and 1-5wt% of an assistant. The special coating can be directly sprayed to reduce bubbles brought by brush coating and roll coating; and chlorinated rubber is used as a binder, so the mass fraction of Cl in the coating is 62-65%, and the coating has a good heat resistance. The chlorinated rubber has the advantages of excellent adhesion, chemical corrosion resistance, wear resistance, easy drying, water permeation resistance, flame retardation and the like; and a long term anticorrosion effect is realized, the selection of 52# paraffin makes the coating have toughness, and the chlorinated rubber is used as the binder, and also has a drying prompting effect due to the easy drying property in order to obviously improve the dryness of the asphalt liquid.

Owner:JIANGSU XIN AN NEW MATERIALS TECH

Anti-corrosive agent as well as anti-corrosive system and anti-corrosive method

ActiveCN105038420AMeet environmental protection requirementsSimple preparation processWax coatingsFibre typesManufacturing technologyMicrocrystalline wax

The invention relates to an anti-corrosive agent. The anti-corrosive agent comprises the following substances in parts by weight: 5-15 parts of mineral oil, 60-80 parts of PE wax, and 10-20 parts of microcrystalline wax. The anti-corrosive agent provided by the invention can also be made into a corresponding anti-corrosive tape and an anti-corrosive system. The anti-corrosive agent does not contain toxic volatile substances or heavy metals, and meets the requirements for environmental friendliness; the manufacturing technology of the anti-corrosive tape is simple, the batch production can be easily realized, and the production efficiency is high; the anti-corrosive system established by the anti-corrosive material and the anti-corrosive tape can achieve the long-acting corrosion prevention effect, the service life of base materials is prolonged, and the use safety of the base materials is improved.

Owner:SUZHOU JINQIANG NEW MATERIALS

Environment-friendly long-acting self-secretion anti-corrosion paint and preparation method thereof

PendingCN106978056ASimple preparation processAvoid contamination damageAnti-corrosive paintsPolyurea/polyurethane coatingsSolventHydrolysis

The invention relates to environment-friendly long-acting self-secretion anti-corrosion paint and a preparation method thereof. The environment-friendly long-acting self-secretion anti-corrosion paint is prepared from aromatic environment-friendly preservatives, degradable polypolyol, diisocyanate, acrylic acid based self-polishing resin, chain expanding agents, catalysts and a first solvent. The anti-corrosion paint optionally contains urethane acrylate. The anti-corrosion paint has the advantages that an environment-friendly effect is achieved; during ship navigation and ship stop, preservatives can be peeled off by self through hydrolysis and can be slowly and uniformly released; the dependence on ship navigation speed is reduced; the long-acting anti-corrosion effect can be achieved on ships, submarines, offshore production platform facilities and the like. A process for preparing the environment-friendly long-acting self-secretion anti-corrosion paint is simple, and is applicable to industrial production.

Owner:XINGTAI UNIV

Powerful metal equipment cleaning liquid

The present invention discloses a powerful metal equipment cleaning liquid, which is prepared from the following raw materials by weight: 4.3-5.6 parts of sodium phosphate, 2.8-4.5 parts of butane, 5.6-7.8 parts of trisodium phosphate, 3.5-5.4 parts of butanol, 5.5-7.5 parts of triethanolamine oleate, 2.4-5.5 parts of a stabilizer, and 3.3-6.5 parts of ethylenediamine tetramethylenephosphonic acid. The powerful metal equipment cleaning liquid has the following characteristics that: the powerful metal equipment cleaning liquid has powerful penetration ability, does not have characteristics of easy combustion and easy explosion during use, has high safety factor, can not cause great adverse effects to the work environment, and does not contain nitrite, phenol, formaldehyde and other substances harmful to the environment; oil stains can be rapidly separated from the surface of work-pieces with heating, scrubbing and other manners during cleaning when the powerful metal equipment cleaning liquid is used; the powerful metal equipment cleaning liquid has characteristics of no toxicity and harm on operators, safety, environmental protection, easy waste liquid treatment, low cleaning cost, high economic benefits, effectively improved processing environment and plant health status, and easily-improved work efficiency; and the cleaning agent provides a long term antirust effect for the cleaned mechanical equipment.

Owner:QINGDAO SHUAIWANG OIL CHEM

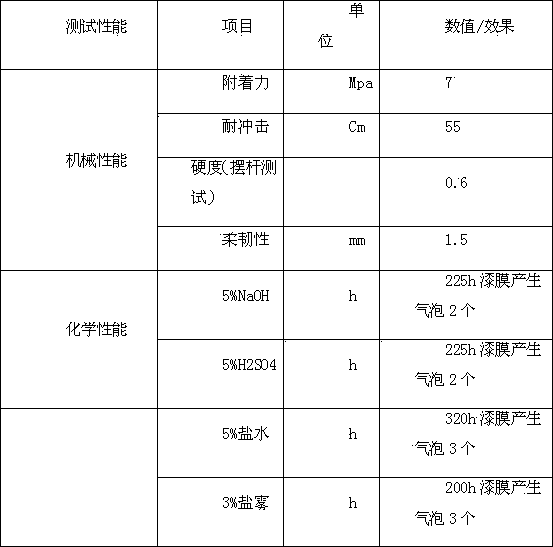

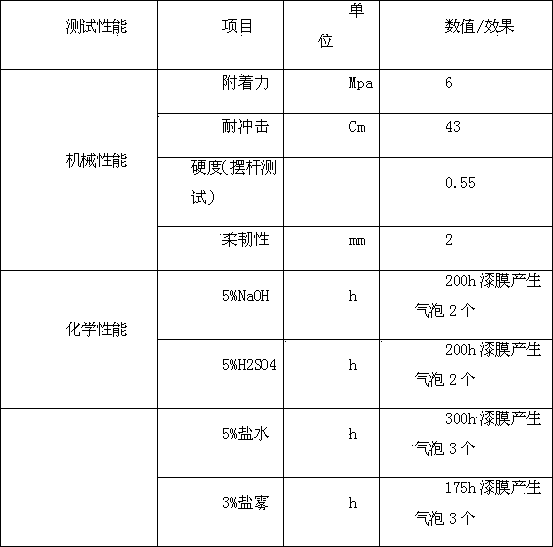

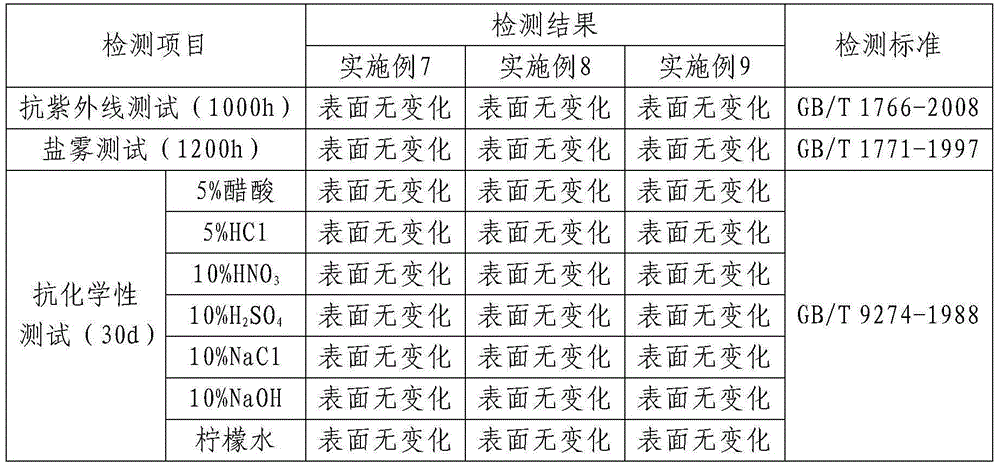

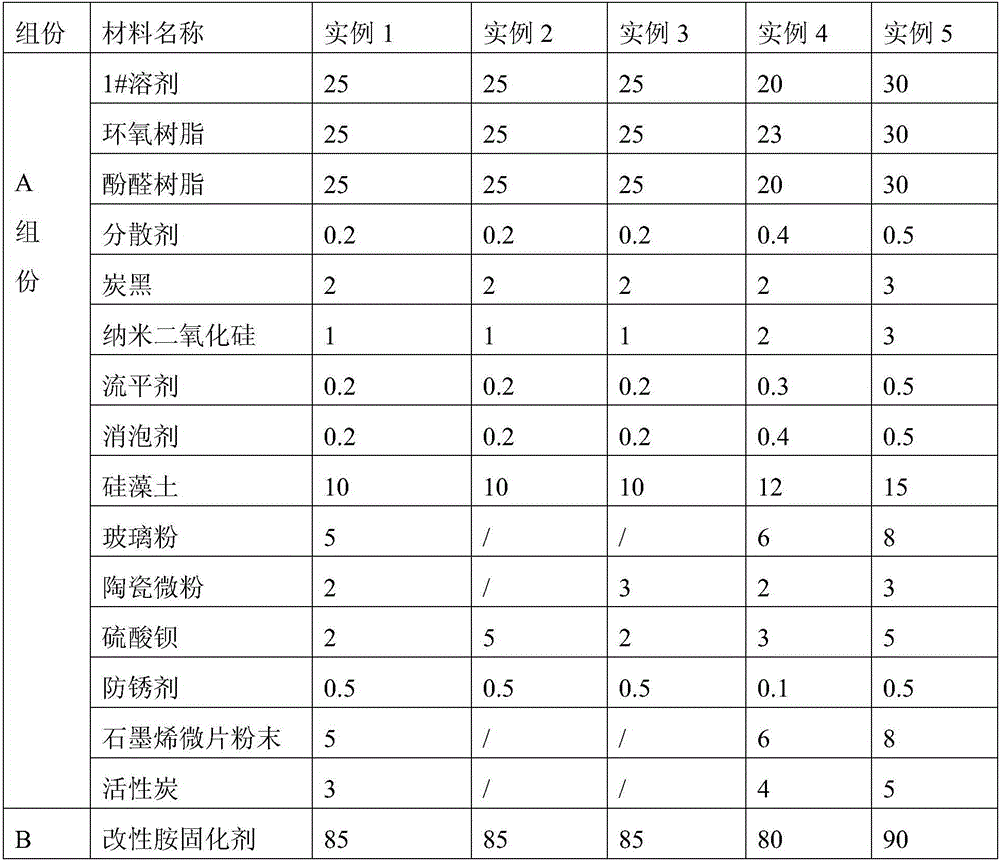

A kind of anticorrosion coating for the inner wall of desulfurization and denitrification device and preparation method thereof

ActiveCN105086772BIncrease crosslink densityImprove corrosion resistanceAnti-corrosive paintsEpoxy resin coatingsEpoxyShock resistance

An anticorrosive coating used on the inner wall of a desulfurization and denitrification device comprises a main paint component A and a curing agent component B. The main paint component A comprises, by weight, epoxy resin, phenolic resin, nano-silicon dioxide, diatomite, ceramic micro-powder, glass powder, carbon black, a dispersing agent, a flatting agent, a defoaming agent, barium sulfate, an antirust agent, a 1# solvent, graphene nano-platelet powder and activated carbon. The curing agent component B comprises, by weight, a modified amine hardener and a 2# solvent. The weight ratio of the component A to the component B is 3.5-4.5:1. The anticorrosive coating is used for corrosion prevention of the inner wall of a dust remover of the desulfurization and denitrification device, is convenient to apply, corrosion of highly corrosive flue gas (such as SO<2>, NO<x>, HF and HCl) to the steel inner wall is effectively prevented, corrosion of highly corrosive liquid (such as H<2>SO<4>, HCl and HF) is effectively prevented, and meanwhile a paint film formed by the anticorrosive coating has very high abrasion resistance, temperature endurance and cold and hot shock resistance.

Owner:江苏云湖新材料科技有限公司

Novel low-cost environment-friendly detergent

The invention discloses a novel low-cost environment-friendly detergent which is prepared from the following raw materials in parts by weight: 4.2-6.5 parts of cocoalkanoylamido propyl betaine, 3.5-5.5 parts of a surfactant, 5.6-7.8 parts of myristyl-dimethyl pyridine ammonium bromide, 2.3-5.5 parts of diethylenetriaminepenta methylene-phosphonic acid, 2.5-4.4 parts of fatty alcohol polyoxyethylene (3) ether, 3.2-5.4 parts of water and 3.3-6.5 parts of a preservative. The low-cost environment-friendly detergent disclosed by the invention has powerful infiltration capacity, does not have the characteristics of flammability and combustibility during use, is high in safety coefficient, does not cause great adverse effect to the working environment, and is free from environmentally hazardous substances such as nitrite, phenol and formaldehyde. When the detergent is used, greasy dirt is separated from the surface of a workpiece as soon as possible by way of heating, scrubbing and the like in cleaning, so that the detergent dispersed to a cleaning liquid is nonhazardous to operators and has better safe environmental protection property.

Owner:QINGDAO HUIERTONG TRADING

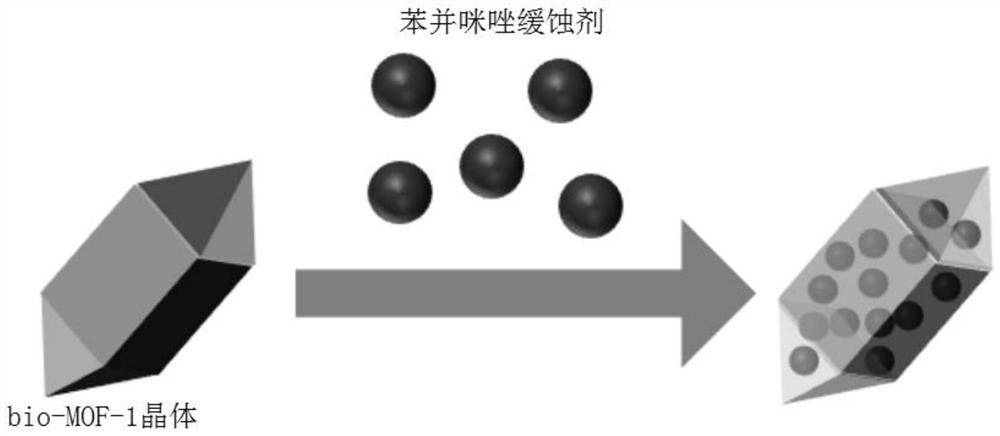

Compound of biological metal organic framework packaging corrosion inhibitor as well as preparation method and application of compound

The invention belongs to the technical field of marine steel corrosion protection, and particularly relates to a biological type metal organic framework packaging corrosion inhibitor compound and a preparation method and application thereof.From the active adsorption molecule design level, firstly, a biological type metal organic framework (bio-MOF-1) with corrosion inhibition components is synthesized through a hydrothermal synthesis method; and then the compound is used as a carrier to package a corrosion inhibitor object, so that the synergistic corrosion inhibition effect of the active components of the compound is fully exerted, and the compound is used for inhibiting corrosion of carbon steel and other metal material products serving in a seawater circulation system. In a corrosion induction stage of a metal corrosion area, an object imidazole molecule is firstly diffused to inhibit corrosion, and when corrosion is further intensified, an aromatic heterocyclic organic ligand is dissociated to generate a synergistic corrosion inhibition effect with imidazole, so that an excellent anti-corrosion effect is achieved. The preparation method is simple in synthesis and high in yield, and the obtained corrosion inhibitor compound has the characteristics of targeted protection, dual corrosion inhibition, efficient effect and the like.

Owner:SUN YAT SEN UNIV

Improved environment-friendly cleaning agent

InactiveCN104674233AImprove securityGood safety and environmental protectionActive agentSurface-active agents

The invention discloses an improved environment-friendly cleaning agent. The improved environment-friendly cleaning agent is prepared from the following raw materials in parts by weight: 4.2-6.5 parts of capric glycerides, 3.5-5.5 parts of a surfactant, 5.6-7.8 parts of diethylene glycol monoethyl ether, 2.3-5.5 parts of tert-butyl hydroxyanisole, 2.5-4.4 parts of methyl cyclohexane, 3.2-5.4 parts of a phosphorus-free water softener and 3.3-6.5 parts of an abrasive agent. The low-cost environment-friendly cleaning agent disclosed by the invention has powerful permeability, does not have combustible and explosive characteristics during use, is high in coefficient of safety, cannot cause relatively large adverse effects on working environment and does not contain environment harming substances, such as nitrite, phenol and formaldehyde; during use, oily dirt is enabled to be separated from the surfaces of workpieces as soon as possible by means of heating, scrubbing and the like during cleaning, so as to be dispersed into cleaning liquid, so that the cleaning agent is non-toxic to operating personnel and has relatively good safety and environment-friendliness.

Owner:QINGDAO KERUN PLASTIC MACHINERY

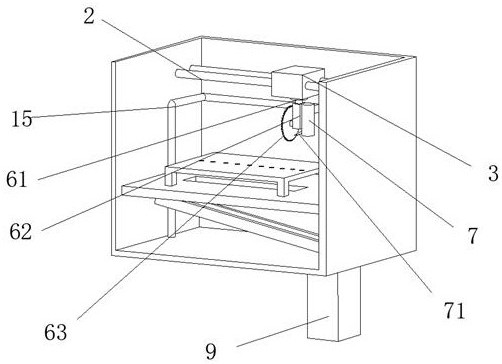

Long-acting corrosion inhibition cooling liquid supply device for cutting machine tool

PendingCN113927366ASpeed through the filter fasterClean up in timeHeat-exchange elementsMaintainance and safety accessoriesEngineeringCirculating pump

The invention discloses a long-acting corrosion inhibition cooling liquid supply device for a cutting machine tool, and relates to the technical field of workpiece machining. The long-acting corrosion inhibition cooling liquid supply device comprises a cutting box body provided with a cutting mechanism capable of sliding in a reciprocating mode, a circulating box body is installed below the cutting box body, the circulating box body comprises a filtrate box, and a filter screen is arranged in the filtrate box. A vacuum pump is fixedly connected to the inner wall of the circulating box body and communicates with the filtrate box through a vacuum pipe, the bottom of the filtrate box is connected with the water inlet end of a liquid conveying pump, the water outlet end of the liquid conveying pump communicates with a liquid storage box installed at the bottom of the circulating box body, and a circulating pump is connected to the other side of the liquid storage box. The water outlet end of the circulating pump is connected with a circulating pipe, the tail end of the circulating pipe is connected with a liquid spraying mechanism, and the liquid spraying mechanism is used for spraying corrosion inhibition cooling liquid. The long-acting corrosion inhibition cooling liquid supply device for the cutting machine tool can be used for collecting, filtering, storing and circularly supplying the used corrosion inhibition cooling liquid, and the treated cooling liquid is circularly used, so that the production cost is reduced.

Owner:安徽军明机械制造有限公司

Water-based self-drying anti-corrosion primer for engineering cranes and preparation method thereof

ActiveCN104031533BImprove corrosion resistanceGood value for moneyAnti-corrosive paintsPolyester coatingsAdjuvantSilicon dioxide

The invention discloses a water-based self-drying anti-corrosion primer for engineering cranes and a preparation method thereof. The primer is composed of resin, auxiliary agent, thickening thixotropic agent, antirust pigment, silicon dioxide and auxiliary materials. For: resin: 10-30%, additives: 25-45%, thickening thixotropic agent: 2-15%, anti-rust pigment: 0.8-6%, silicon dioxide: 2-4%, auxiliary materials: 15- 25%; the preparation method of the water-based self-drying anti-corrosion primer is carried out according to the following steps: step (1): mix the resin and the auxiliary agent in a ratio of 4:6; step (2): put the above resin and the auxiliary agent into the stirring Stir and disperse in the kettle at a stirring speed of 400-700r / min; Step (3): Add all the configured thickening thixotropic agent, antirust pigment and silicon dioxide into the stirring kettle and stir evenly; Step (4): Finally, add auxiliary materials and stir for 40-55 minutes.

Owner:JIANGSU XIN AN NEW MATERIALS TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com