Fluorine modified epoxy polysiloxane coating and preparation method and application thereof

An epoxy polysiloxane and polysiloxane technology, applied in anti-corrosion coatings, coatings, etc., can solve the problems of loss of anti-corrosion function, short anti-corrosion life, chemical bond breakage, etc., to shorten the surface drying time and prolong the service life. and maintenance time, the effect of low VOC

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] In this embodiment, the fluorine-modified epoxy polysiloxane coating includes component A and component B, and the mass parts of each component are as follows,

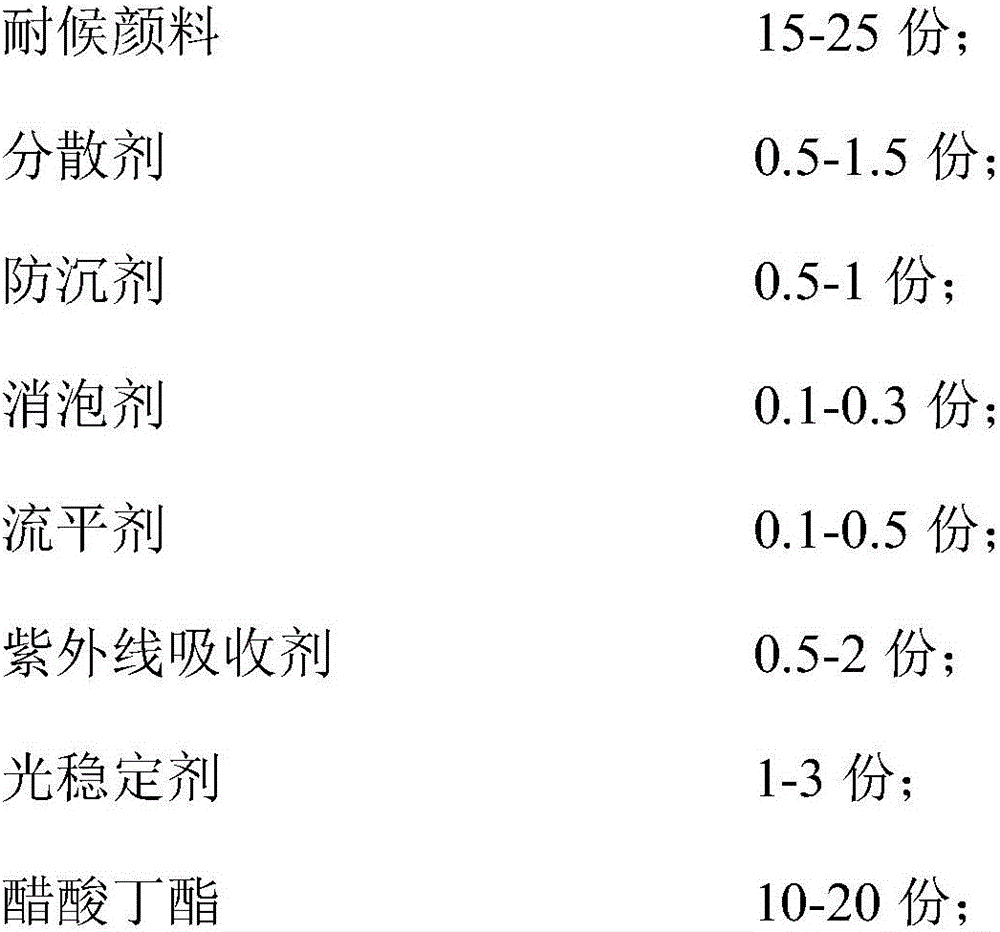

[0028] Component A:

[0029]

[0030] Component B:

[0031] 15 parts of fluorine-modified aminosilane;

[0032] BASF BAXXODUR TM EC 252 1 part.

[0033] Wherein, the preparation process of the fluorine-modified aminosilane is as follows: In a dry 1000mL three-necked flask equipped with a condenser and mechanically stirred, 82.4g of N-(β-aminoethyl)-γ-aminopropylmethyl dimethoxy Silane, 178.4g perfluoroiodohexane, 30gK 2 CO 3 , 50mL isopropanol solvent, react at a temperature of 50-55°C under nitrogen protection for 12 hours, cool down to 20°C, filter off K 2 CO 3 The isopropanol solvent was removed under reduced pressure to obtain liquid transparent fluorine-modified aminosilane. The reaction process is as follows:

[0034]

[0035] The preparation process of fluorine-modified epoxy polysiloxane ...

Embodiment 2

[0045] In this embodiment, the fluorine-modified epoxy polysiloxane coating includes component A and component B, and the mass parts of each component are as follows,

[0046] Component A:

[0047]

[0048] Component B:

[0049] 17 parts of fluorine-modified aminosilane;

[0050] BASF BAXXODUR TM EC 252 2 copies.

[0051] Wherein, the preparation process of the fluorine-modified aminosilane is as follows: In a dry 1000mL three-necked flask equipped with a condenser and mechanically stirred, 82.4g of N-(β-aminoethyl)-γ-aminopropylmethyl dimethoxy Silane, 178.4g perfluoroiodohexane, 30gK 2 CO 3 , 50mL isopropanol solvent, react at a temperature of 50-55°C under nitrogen protection for 12 hours, cool down to 20°C, filter off K 2 CO 3 The isopropanol solvent was removed under reduced pressure to obtain liquid transparent fluorine-modified aminosilane. The reaction process is as follows:

[0052]

[0053] The preparation process of fluorine-modified epoxy polysiloxan...

Embodiment 3

[0062] In this embodiment, the fluorine-modified epoxy polysiloxane coating includes component A and component B, and the mass parts of each component are as follows,

[0063] Component A:

[0064]

[0065]

[0066] Component B:

[0067] 20 parts of fluorine-modified aminosilane;

[0068] BASF BAXXODUR TM EC 252 3 copies.

[0069] Wherein, the preparation process of the fluorine-modified aminosilane is as follows: In a dry 1000mL three-necked flask equipped with a condenser and mechanically stirred, 82.4g of N-(β-aminoethyl)-γ-aminopropylmethyl dimethoxy Silane, 178.4g perfluoroiodohexane, 30gK 2 CO 3 , 50mL isopropanol solvent, react at a temperature of 50-55°C under nitrogen protection for 12 hours, cool down to 20°C, filter off K 2 CO 3 The isopropanol solvent was removed under reduced pressure to obtain liquid transparent fluorine-modified aminosilane. The reaction process is as follows:

[0070]

[0071] The preparation process of fluorine-modified epoxy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com