High-temperature wear-resistant heavy-duty anticorrosion powder coating, and preparation method and coating method thereof

A high-temperature wear-resistant powder coating technology, which is applied in powder coatings, anti-corrosion coatings, epoxy resin coatings, etc., can solve the problems of non-environmental protection and intolerance of wear-resistant coatings, achieve low cost, reduce friction coefficient, and reduce oil wells Effect of maintenance and repair costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

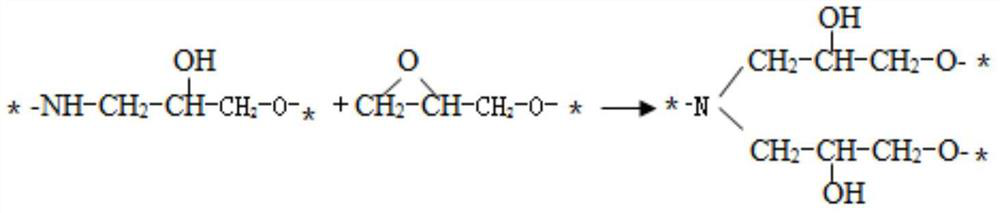

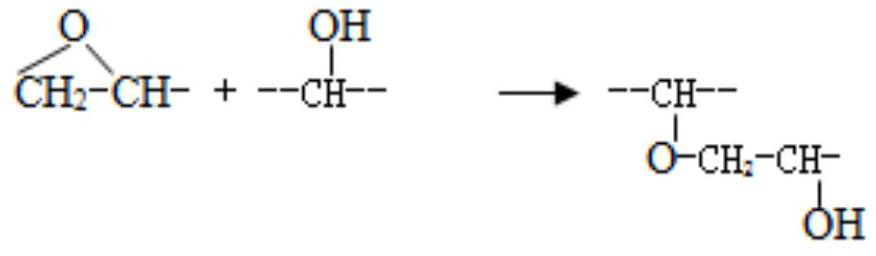

Method used

Image

Examples

preparation example Construction

[0044] In another typical embodiment of the present application, a method for preparing high temperature wear resistant anti-corrosion powder coatings is provided. The preparation method includes weighing each component in accordance with the composition of the high temperature wear resistant to prevent the powder coating; prefix the components to obtain a premix; mix the premix, extrud out, table, to obtain a molded product The molded article was pulverized to obtain a high temperature wear resistant anti-corrosion powder coating.

[0045] During the preparation of high temperature wear resistant anti-corrosion powder coatings, there is no need to use water or organic solvent, which is fully compliant; in addition, the steps in the above process are the steps that can be achieved in the prior art conventional operation, so it is easy to Uploaded, the obtained high temperature wear resistant anti-corrosion powder coating is solid coating, not only high wear resistance, but also ma...

Embodiment 1

[0050] Example 1 The high temperature wear resistant anti-corrosion powder coating comprises: a mass content of phenol carhyde epoxy resin (epoxy equivalent 270) is 50 parts, 3.9 parts of dicyandiamide (equivalent ratio of dicyandide and phenol carhyde epoxy resin) 1.0), polytetrafluoroethylene fine powder (particle size is less than 5 μm, droplet point is greater than 300 ° C), nano zirconium oxide (particle diameter is less than 200 nm), 6 parts of molymide (particle size at 325 to 1250) Room), 0.3 parts of dimethylimidazole, 1.5 parts of polyacrylate, 27.3 parts of titanium powder, quartz powder and carbon black (between 600 to 1250).

[0051] According to the above-mentioned ratio, the material weighing is applied to the high speed premixer, and the mixture is mixed at room temperature at room temperature at room temperature at room temperature, and the extruder is fed into the extruder by the feed pipe. Out, the extruder temperature control: the mixed zone temperature is 75 °...

Embodiment 2

[0053] In this example, the present invention is substantially the same, and the components of high temperature wear-resistant anti-corrosion powder coating include: phenol carhyde epoxy resin (epoxy equivalents of 240), 4.2 parts of dicyandiamide (double The equivalent ratio of the cyanide and phenol carhyde epoxy resin is 0.8), and the polytetrafluoroethylene fine powder (less than 5 μm having a particle size is greater than 150 ° C), and the nano-zirconia (particle diameter is less than 200 nm) 6 parts, diulfide molybdenum (6 parts of the particle size between 325 to 1250), 0.3 parts of dimethylimidazole, 1 polyacrylate, titanium white powder and quartz powder (between 600 to 1250 mesh).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Drop melting point | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com