Intelligent corrosion inhibitor with pH value sensibility and preparation method of intelligent corrosion inhibitor

A sensitive and corrosion inhibitor technology, which is applied in the field of pH-sensitive core/shell nanostructure corrosion inhibitors and its preparation, can solve the problems of poor controllability of the release of corrosion inhibitor components, narrow pH sensitive range, and failure of corrosion inhibitors and other issues, to achieve the effect of enhanced controllable release ability, wide pH sensitive range, and good release controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Dissolve 5 grams of sodium 2-acrylamide-2-methylpropanesulfonate in 1 liter of pure water, and then adjust the pH value of the solution to 8, and use a stirrer to vigorously stir the solution at a speed of 1500 rpm. The temperature of the solution was raised to 70°C, and then 7.5 grams of corrosion inhibitor sodium silicate and 30 grams of N-isopropylacrylamide were added under the condition of nitrogen gas, and 2 grams of sodium persulfate was added after continuous vigorous stirring for 2 hours, and the reaction was carried out for 20 hours After cooling to 15°C, add 5 ml of a polypropyleneimine aqueous solution with a concentration of 15 g / L, ultrasonically mix for 2 hours, and vacuum dry at 45° for 12 hours to obtain a shell composed of polypropyleneimine and polyacrylamide A pH-sensitive core / shell nanostructure corrosion inhibitor composed of propanesulfonic acid and poly(N-isopropylacrylamide) loaded with sodium silicate as a corrosion inhibitor component, which c...

Embodiment 2

[0028]Dissolve 3 grams of ammonium isethionate in 1 liter of pure water, and then adjust the pH value of the solution to 8, use a stirrer to vigorously stir the solution at a speed of 1500 rpm, and at the same time raise the temperature of the solution to 70 ° C, and then Add 6 grams of corrosion inhibitor cerium nitrate and 20 grams of D-lactic acid under the condition of nitrogen gas, continue to stir vigorously for 2 hours, add 0.5 grams of ammonium persulfate, cool to 15 °C after 20 hours of reaction, and then add 3 milliliters of 20 g / L polyphthalimide aqueous solution, ultrasonic mixing for 2 hours, vacuum drying at 45 ° for 12 hours, to obtain a shell composed of polyphthalimide and polyisethionic acid, The core is composed of poly-D-lactic acid loaded with cerium nitrate, a corrosion inhibitor, which is a pH-sensitive core / shell nanostructure corrosion inhibitor that can inhibit metal corrosion for a long time.

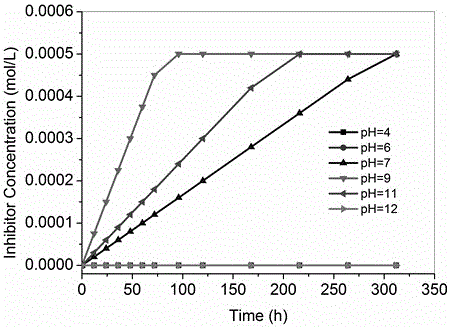

[0029] The characterization and test results of the corr...

Embodiment 3

[0031] Dissolve 4 grams of sodium 2-acrylamide-2-methylpropanesulfonate in 1 liter of pure water, and then adjust the pH value of the solution to 8, and use a stirrer to vigorously stir the solution at a speed of 1500 rpm. The temperature of the solution was raised to 70°C, and then 5 grams of corrosion inhibitor sodium molybdate and 20 grams of N-isopropylacrylamide were added under the condition of nitrogen gas, and 1 gram of sodium persulfate was added after continuous vigorous stirring for 2 hours, and the reaction was carried out for 20 hours After cooling to 15°C, 5 ml of polyphthalimide aqueous solution with a concentration of 10 g / L was added, ultrasonically mixed for 2 hours, and then vacuum-dried at 45° for 12 hours to obtain a shell made of polyphthalimide. Composed of imide and polyacrylamide methylpropane sulfonic acid, the core is composed of poly-N-isopropylacrylamide loaded with corrosion inhibitor sodium molybdate, a pH sensitive and long-lasting inhibitor of m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com