Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

55results about How to "Inhibition of volume expansion effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Lithium-ion battery silicon-carbon anode material and preparation method thereof

ActiveCN103199252AInhibition of volume expansion effectLow costCell electrodesCarbon compositesOxygen

The present invention discloses a lithium-ion battery silicon-carbon anode material and a preparation method thereof, and is to improve specific capacity and cycling performance. The material disclosed by the present invention is composed of an oxygen-containing silicon-carbon composite material and a graphite powder, wherein the oxygen-containing silicon-carbon composite material is formed by dispersing an oxygen-containing silicon-based material in a graphite powder and organic cracking carbon. Comparing the present invention with the prior art, the oxygen-containing silicon-based material is constituted by uniformly dispersing silicon particles in SiOx and a first buffer layer is formed, the oxygen-containing silicon-based material is uniformly dispersed in the organic cracking carbon and the graphite powder to form a second expansion buffer layer, thus the volume expansion effect of the silicon during charging and discharging can be effectively inhibited and cycle stability is improved. The lithium-ion battery silicon-carbon anode material is simple in preparation process, low in raw material costs, and easy for mass production.

Owner:BTR NEW MATERIAL GRP CO LTD

Anode material of lithium-ion battery and method for preparing anode material

InactiveCN102544461AHigh specific capacityInhibition internal resistanceCell electrodesAdhesiveCrystalline silicon

The invention discloses an anode material of a lithium-ion battery and a method for preparing the anode material, belongs to the technical field of the lithium-ion batteries, and aims to solve the problems of poor volume effect caused in the electrochemical lithium de-insertion process of a high-capacity silicon anode material of the lithium-ion battery and low electric conductivity of the material. The anode material of the lithium-ion battery is high in coulombic efficiency and high in cycle performance. The anode material of the lithium-ion battery is formed by adding a carbon element and an adhesive into N-type or P-type doped crystalline silicon active powder which serves as a main material and then laminating a mixture. By adoption of the anode material of the lithium-ion battery, high capacity can be realized, and the electric contact performance of a microcrystal active lithium insertion center can be improved, so that the volume of a silicon micro crystal is slightly changed, the cycle stability is improved.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

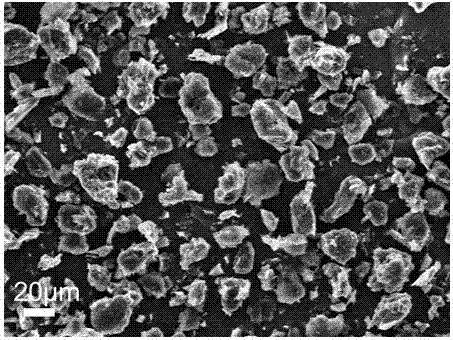

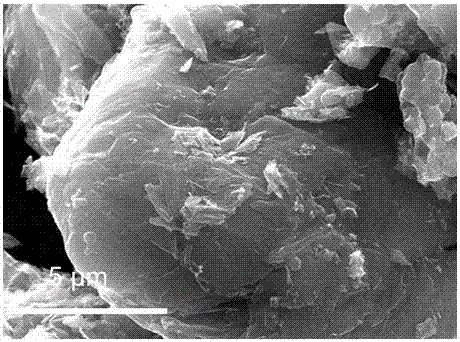

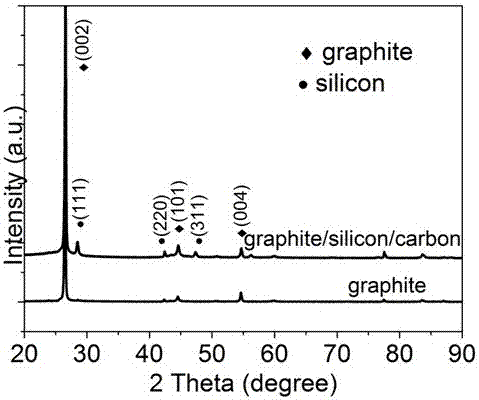

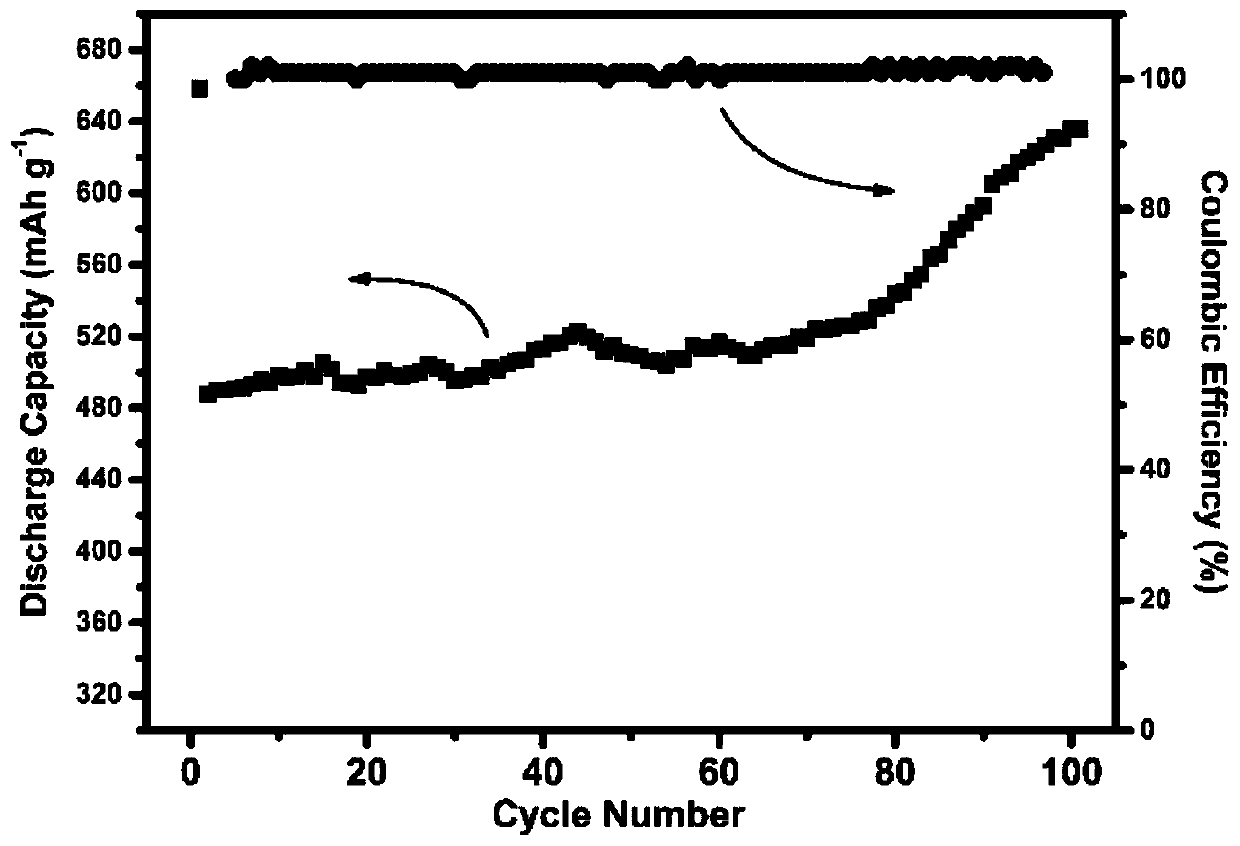

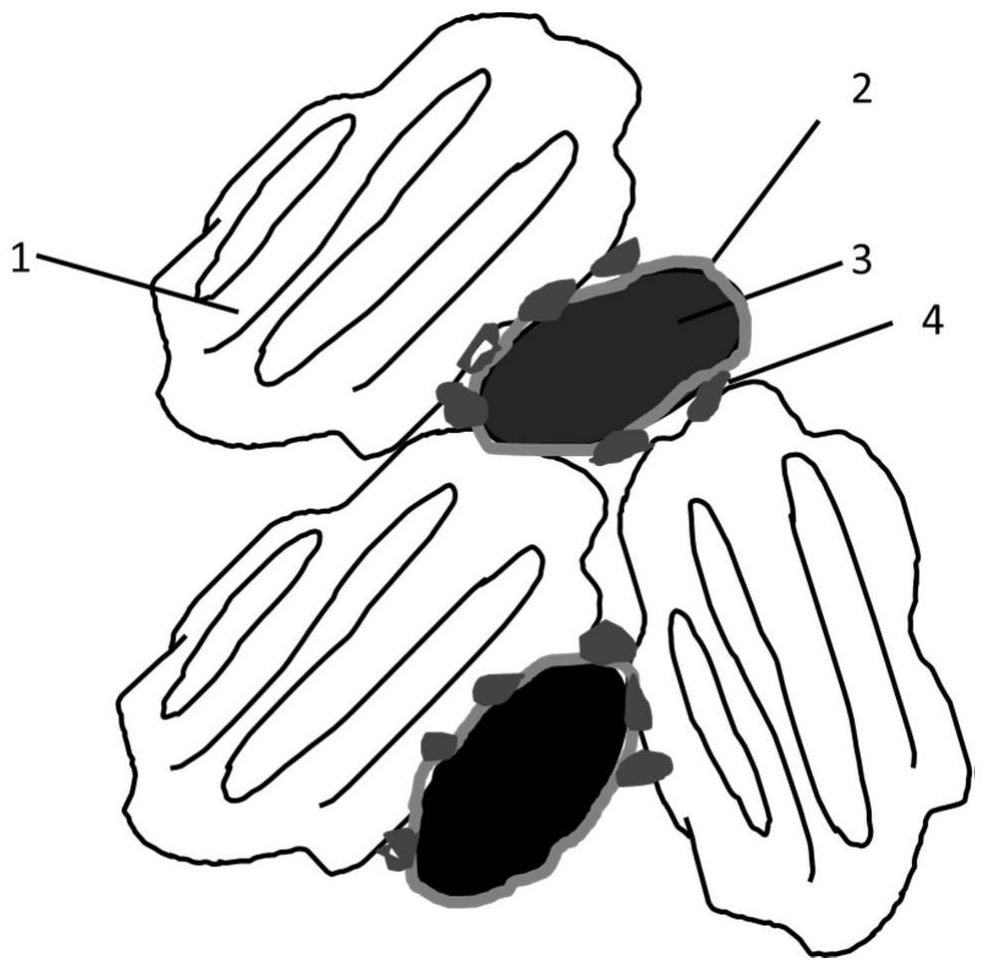

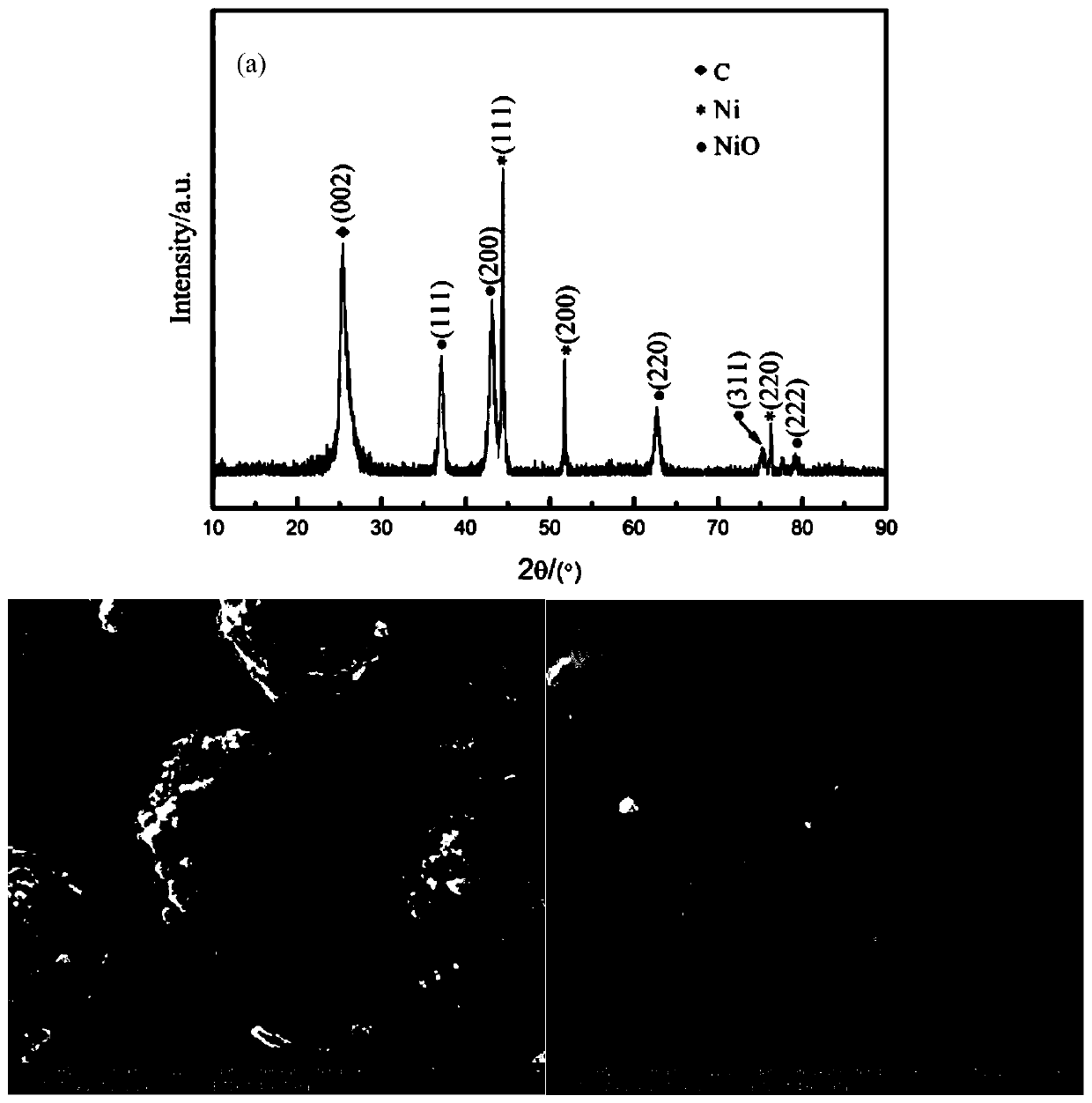

Graphite/silicon@carbon core-shell structure composite spherical cathode material and preparation method thereof

InactiveCN107093721ASimple preparation processReduce the first irreversible capacityCell electrodesSecondary cellsCarbon compositesComposite cathode

The invention discloses a graphite / silicon@carbon core-shell structure composite spherical cathode material and a preparation method thereof. By means of the material, the volume expansion effect of silicon in the lithium de-intercalation process can be inhibited, and a high-capacity lithium iron battery silicon / carbon composite cathode material is obtained. By means of the technical scheme, a spherical graphite / silicon framework precursor serves as the core of the composite cathode material, and an amorphous pyrolytic carbon or graphite-like carbon material wrapping layer serves as the shell; nanometer or micrometer silicon is embedded in flake graphite cracks to form a graphite framework, the volume expansion effect of silicon in the lithium de-intercalation process is inhibited through the mechanical characteristics of the graphite framework, then a spherical framework is formed by mixing and granulating 3-20 wt% of nanometer or micrometer silicon, 50-80 wt% of flake graphite and 10-40 wt% of amorphous pyrolytic carbon or graphite-like carbon, and an amorphous pyrolytic carbon or graphite-like carbon spherical composite conductive carbon net structure wrapping a graphite / silicon surface is formed.

Owner:四川聚能仁和新材料有限公司

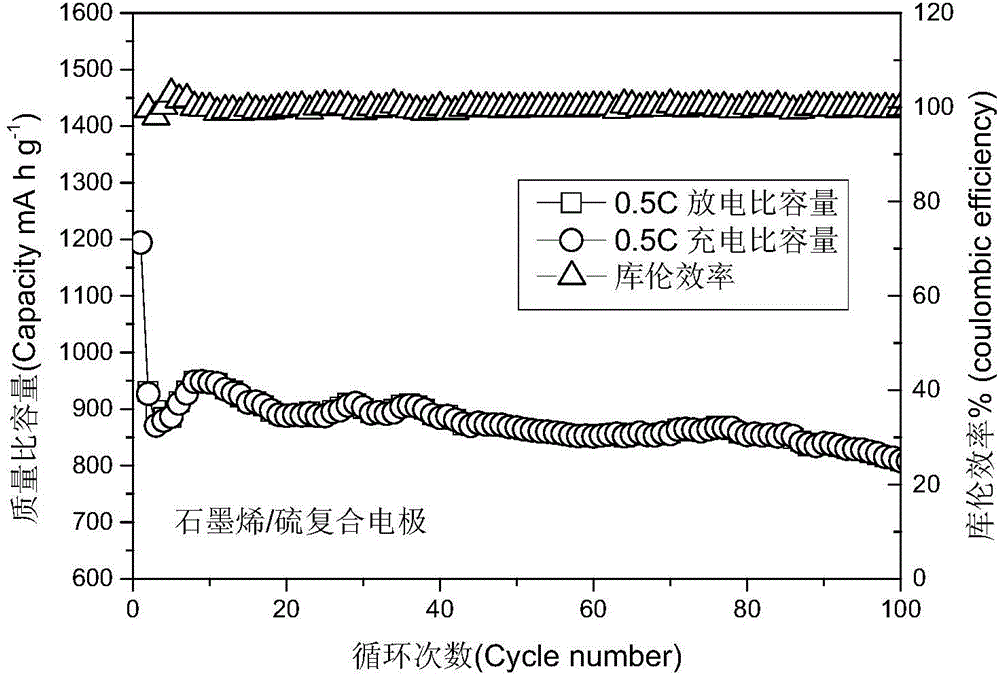

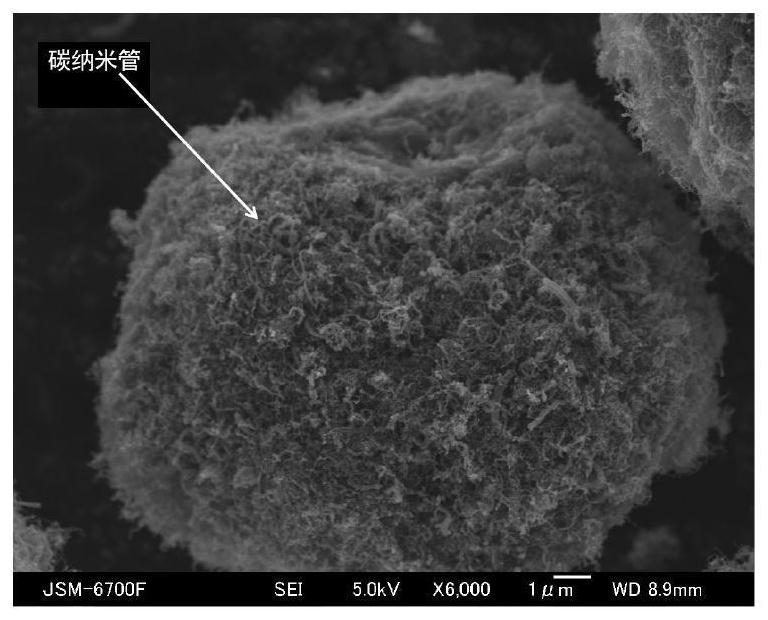

Preparation method of porous graphene/carbon nano tube lithium sulfur anode material

ActiveCN107768637ASuppression cascadingLarge specific surface areaMaterial nanotechnologyCell electrodesPorous grapheneMicrosphere

The invention provides a preparation method of a porous graphene / carbon nano tube lithium sulfur anode material. The method comprises the steps of introducing silicon dioxide microspheres as a template, mixing with a carbon nano tube dispersion liquid, dropwise adding a sodium ascorbate solution, using hydrofluoric acid for soaking for 5 to 7 days, and obtaining a porous graphene / carbon nano tube;grinding with a sulfur elementary substance, using a hydrothermal reaction kettle for heating for 10 to 15h at 140 to 160 DEG C under the argon protection, and obtaining a sulfur / porous graphene / carbon nano tube. The material prepared by the invention adopts the porous graphite / carbon nano tube composite material as a frame so as to form a three-dimensional conductive network structure, so that sulfur can be stored, and a battery performance is improved.

Owner:SYNERGY INNOVATION INST OF GDUT HEYUAN

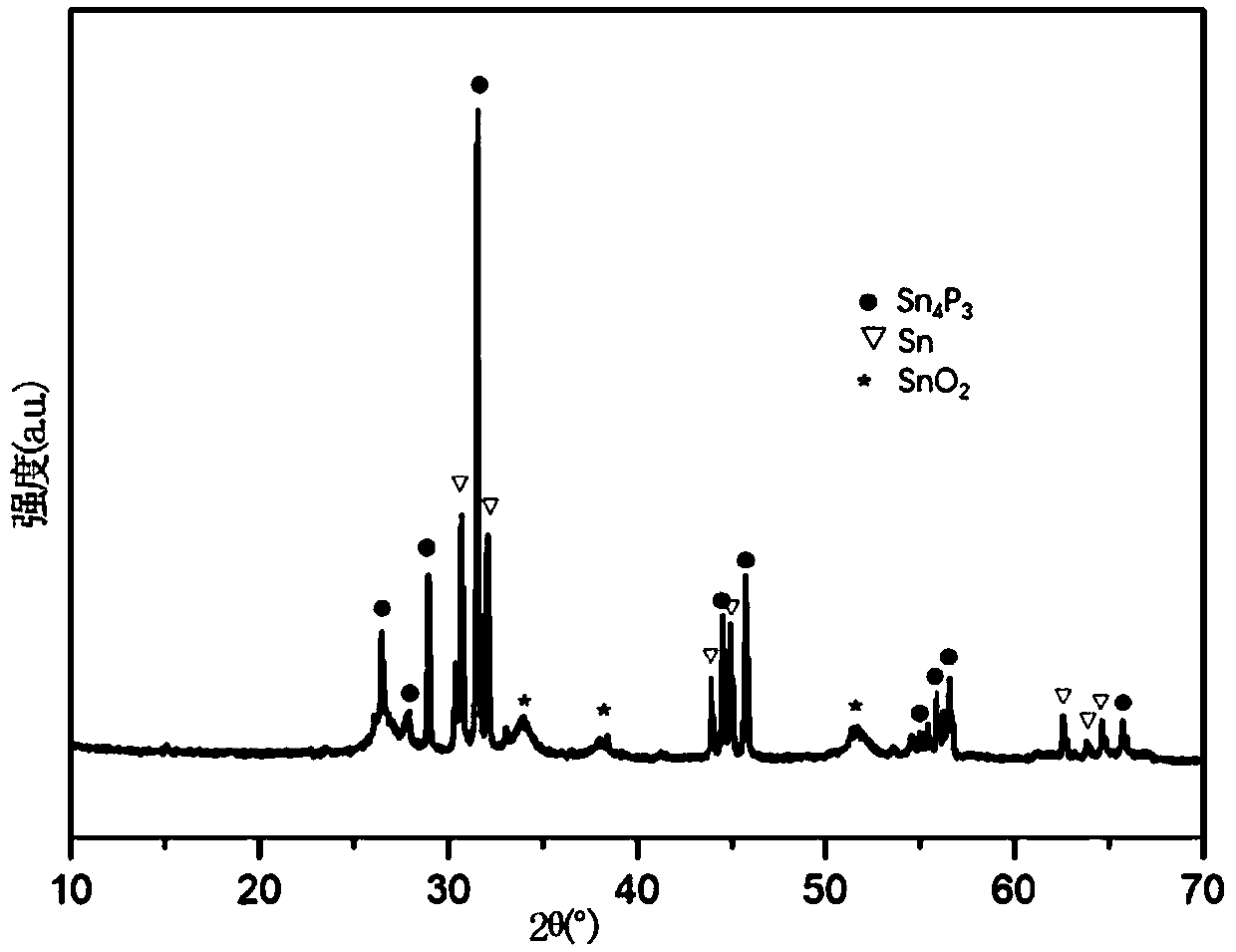

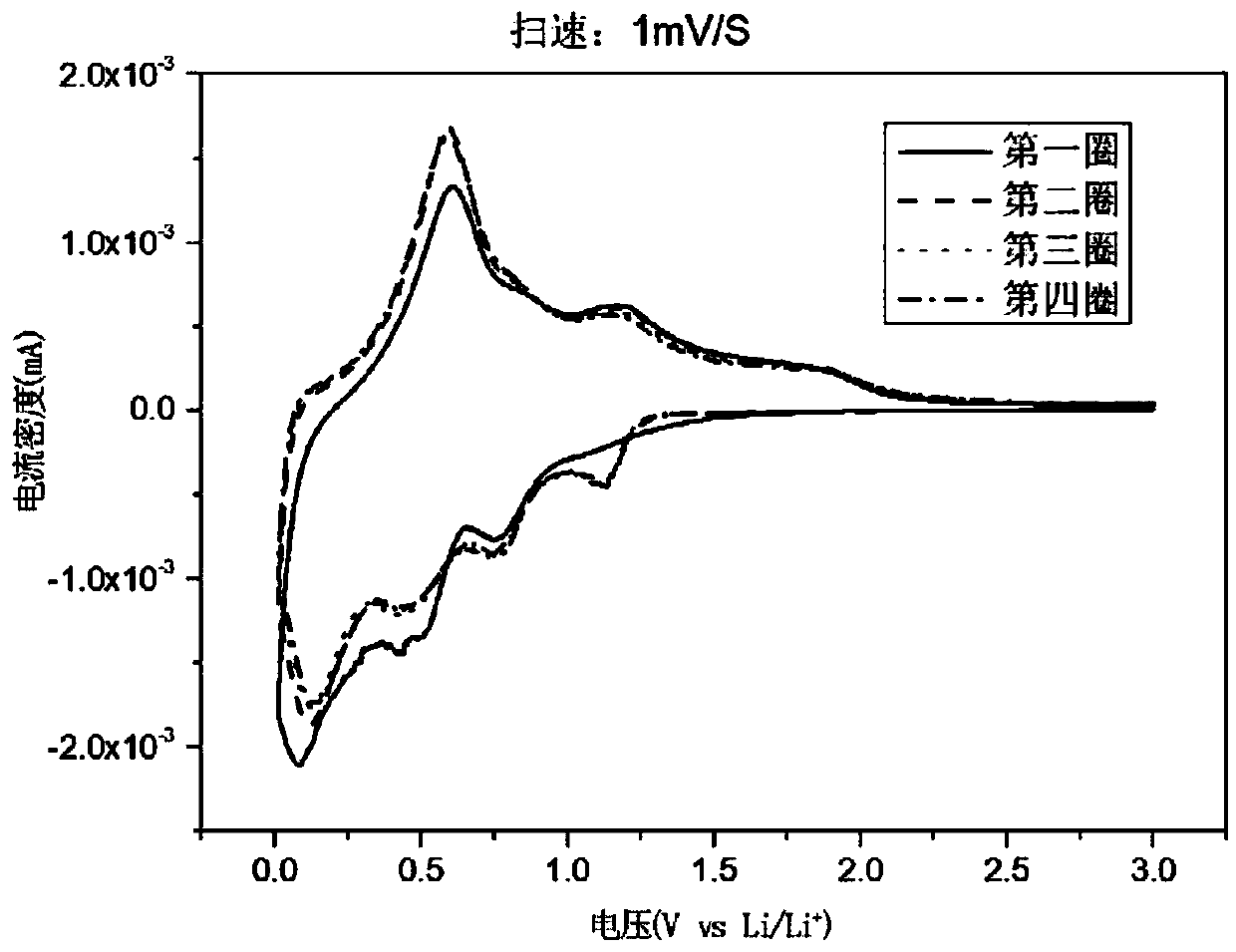

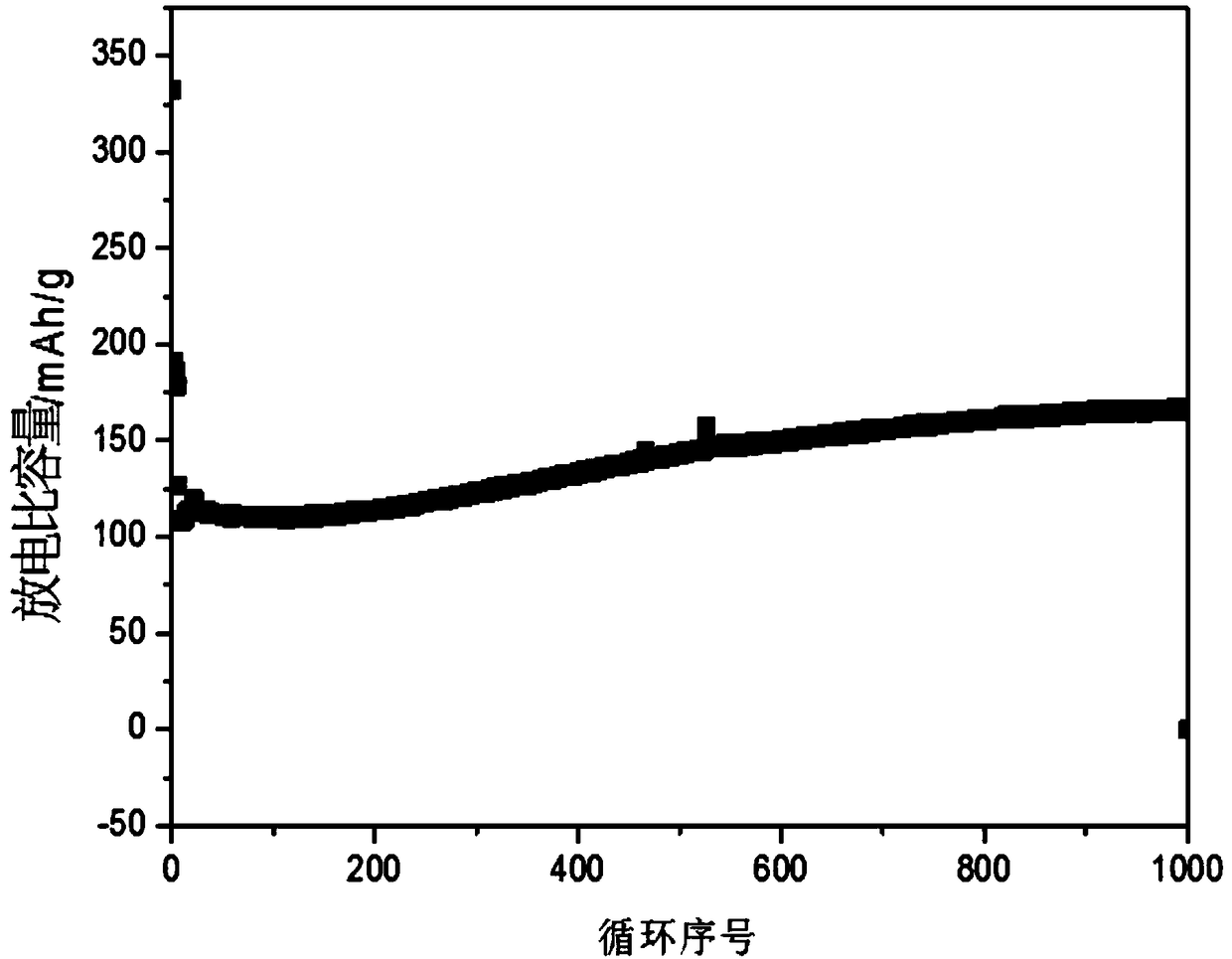

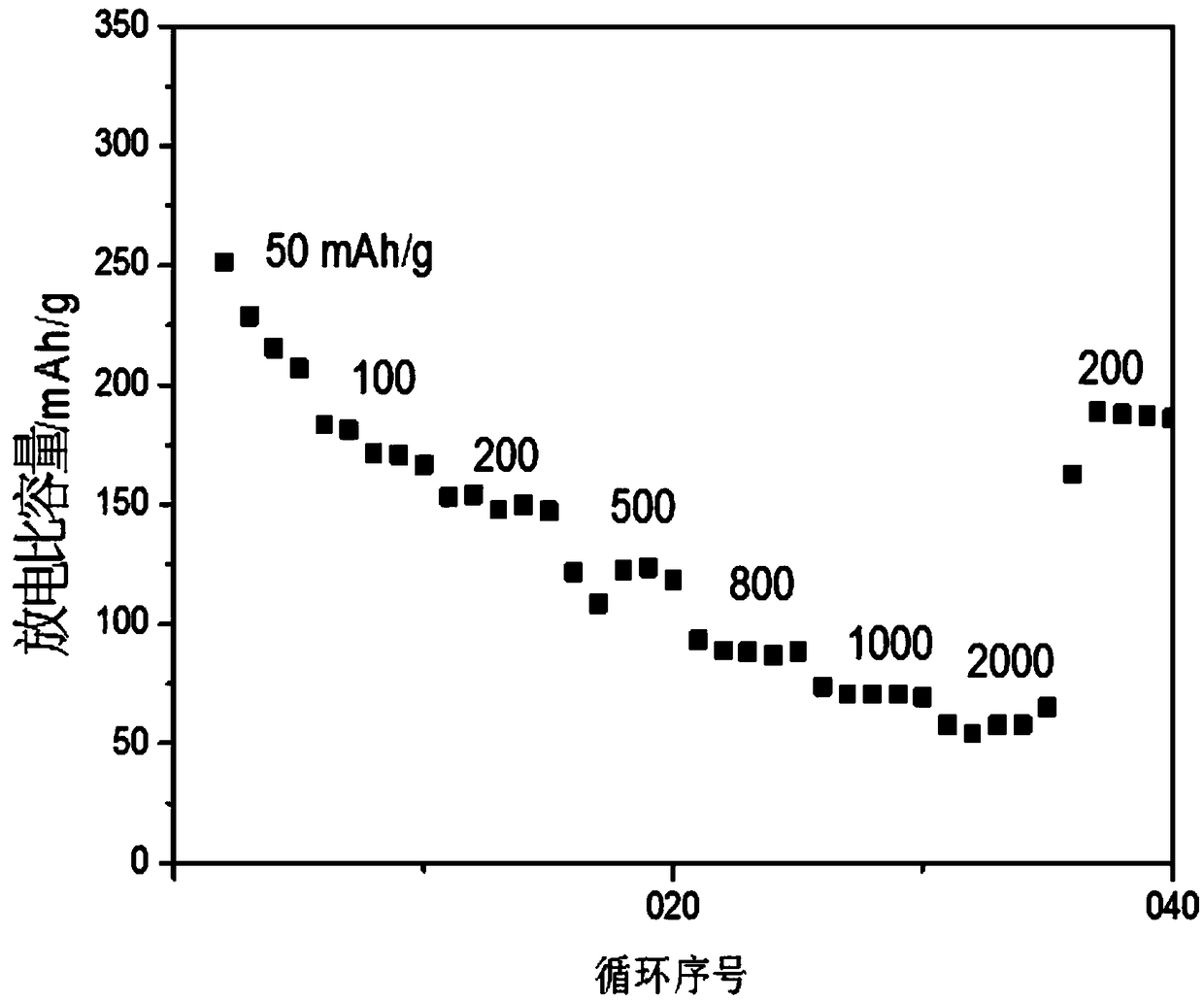

Tin-phosphide composite material and preparation method and application thereof

ActiveCN110034283AInhibition of volume expansionImprove conductivityCell electrodesSecondary cellsTin dioxideCarbon layer

The invention provides a tin-phosphide composite material and a preparation method and application thereof. The preparation method comprises the following steps: performing the hydrothermal reaction of a tin source material and a carbon source material under an alkaline condition to obtain a hollow tin dioxide ball with carbon sources attached to the surface; carrying out carbonization treatment of the tin dioxide in an inert atmosphere to obtain a hollow tin dioxide sphere coated with a carbon layer on the surface; and heating the hollow tin dioxide sphere coated with the carbon layer on thesurface and a phosphorus source material in an inert atmosphere to react, so as to obtain the composite material containing tin phosphide, hollow tin dioxide, carbon and carbon as a coating layer. Thematerial obtained by the preparation method of the tin-phosphide composite material contains tin phosphide, hollow tin dioxide and carbon, and the carbon is a coating layer, so that the tin phosphidecomposite material has good electrical conductivity, can effectively inhibit the volume expansion effect and improve the electrochemical performance of the battery when being used as a negative electrode active material of the battery, and the preparation method is simple in condition, low in requirement on equipment and suitable for large-scale production.

Owner:SOUTH UNIVERSITY OF SCIENCE AND TECHNOLOGY OF CHINA

Selenium-doped ferrous disulfide carbon-coated composite material and preparation and application methods thereof

ActiveCN109437123AHigh activityImprove electrochemical activityCell electrodesSecondary cellsSodium-ion batteryCarbon coated

The invention discloses a selenium-doped ferrous disulfide carbon-coated composite material. The composition of the selenium-doped ferrous disulfide carbon-coated composite material is FeSe*S2-*@C, wherein x is 0.1-1.9. When applied to sodium ion batteries, the selenium-doped ferrous disulfide carbon-coated composite material can effectively inhibit volume expansion effects and increase actual specific capacity, rate capability and cycling performance. The invention also discloses preparation and application methods of the selenium-doped ferrous disulfide carbon-coated composite material.

Owner:中山高容新能源科技有限公司

A high-performance lithium-sulfur battery cathode material and a preparation method thereof

InactiveCN109273699AHighlight substantiveEasy transferMaterial nanotechnologyCell electrodesPorosityFlower like

The invention belongs to the technical field of lithium-sulfur batteries, in particular to a high-performance lithium-sulfur battery cathode material and a preparation method thereof. The material isporous flower-shaped CoP / C @ S composite. Using cobalt chloride dimethanol as precursor, Porous flower-like CoP / C @ S composites were synthesized by low temperature phosphating process, the porous structure of the composite can effectively coat sulfur, The porosity and nanometer size of CoP / C @ S composites endow them with superionic conductivity and larger electrode / electrolyte interface, which improves the conductivity and promotes the transport of electrons and ions. The results show that CoP / C @ S composites possess the characteristics of high porosity and nanometer size, which can inhibitthe dissolution of polysulfides and improve the utilization of active substances.

Owner:INT ACAD OF OPTOELECTRONICS AT ZHAOQING SOUTH CHINA NORMAL UNIV

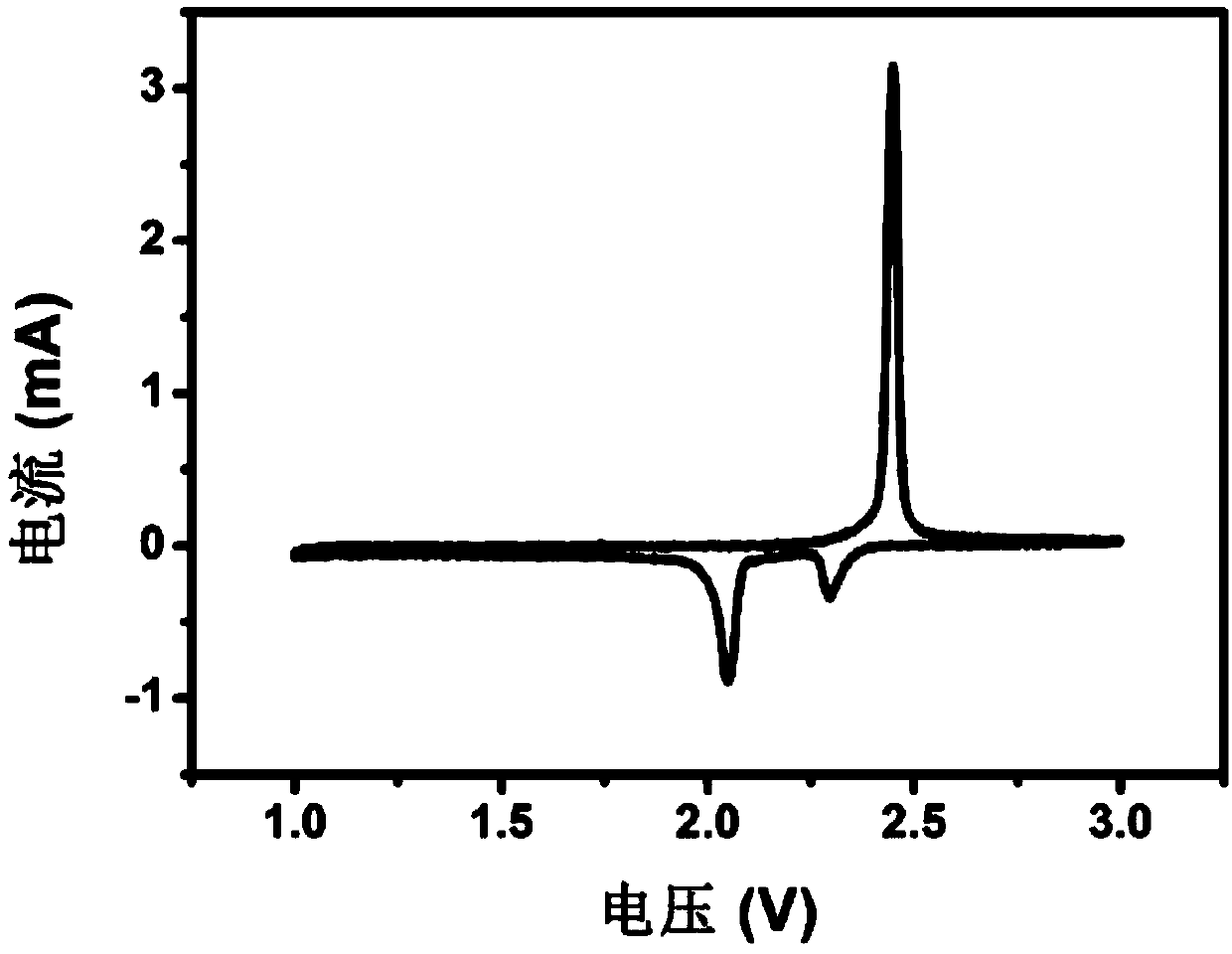

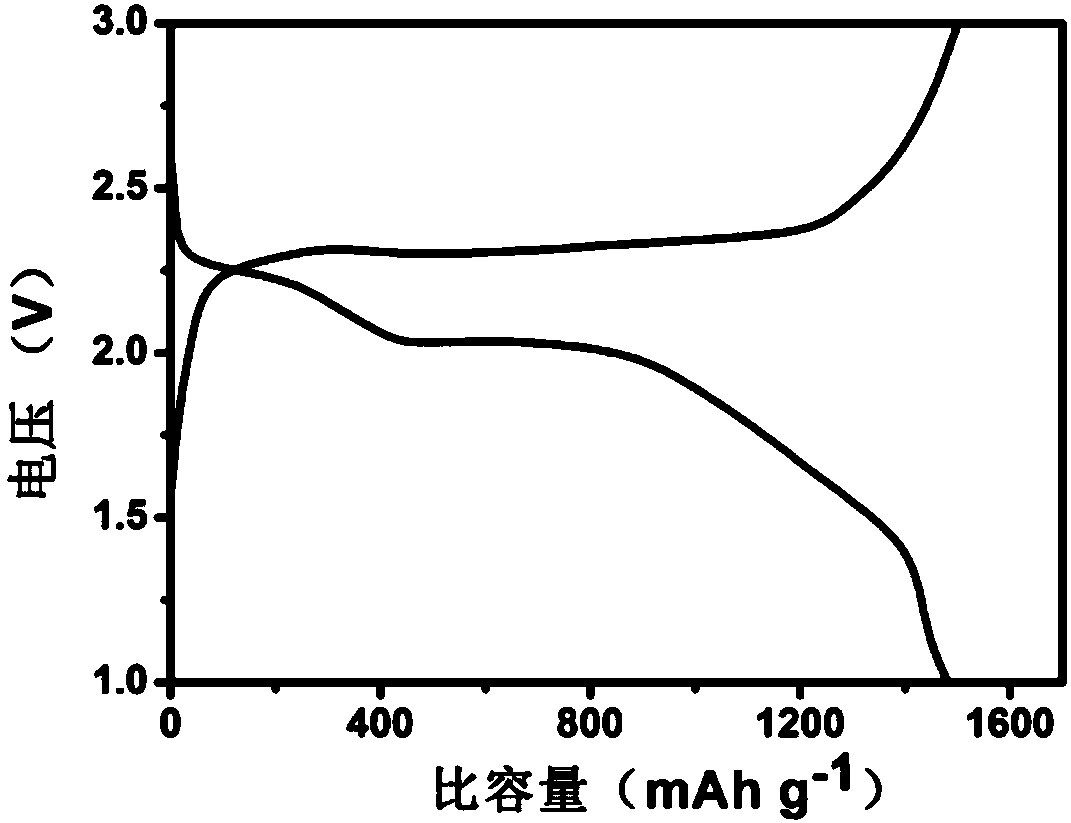

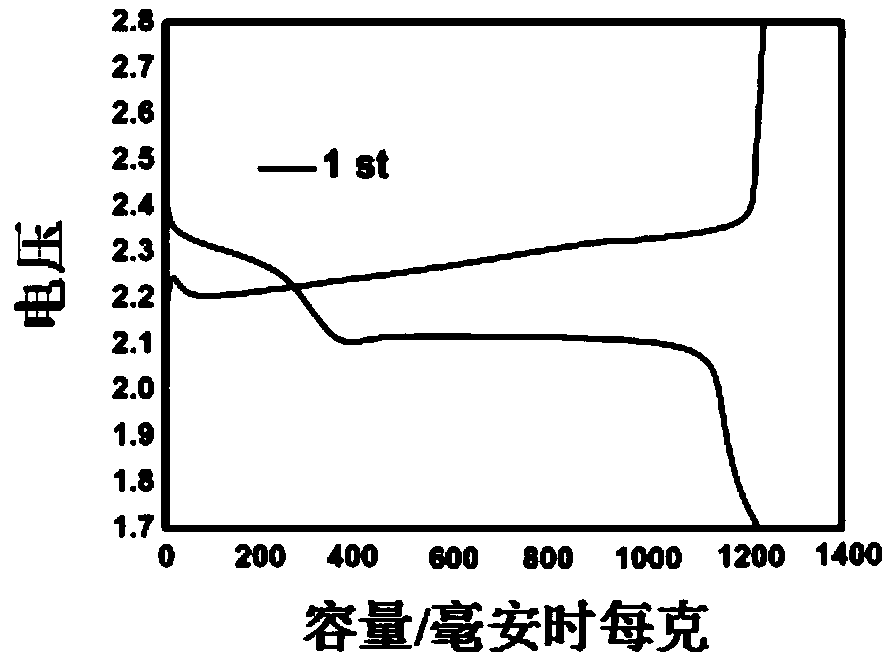

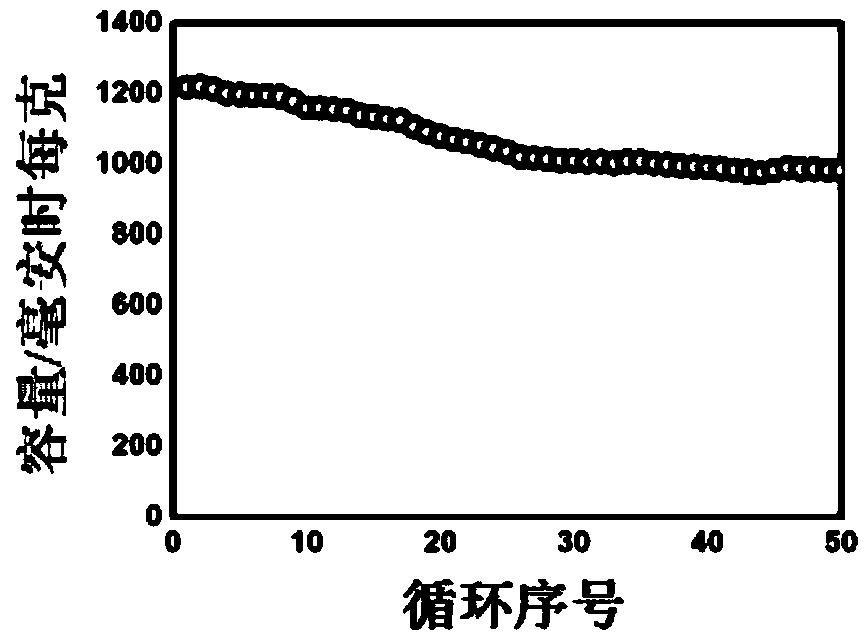

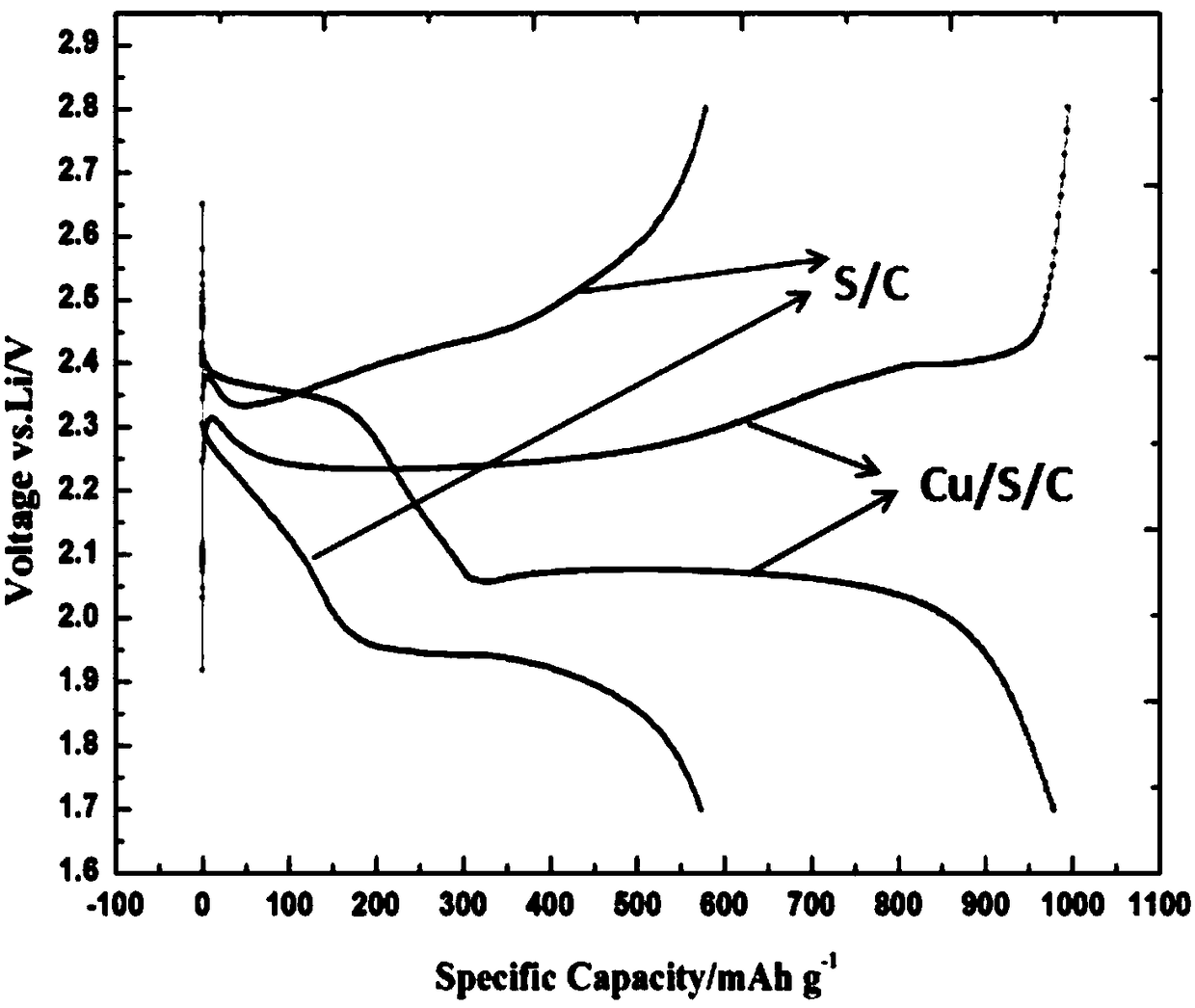

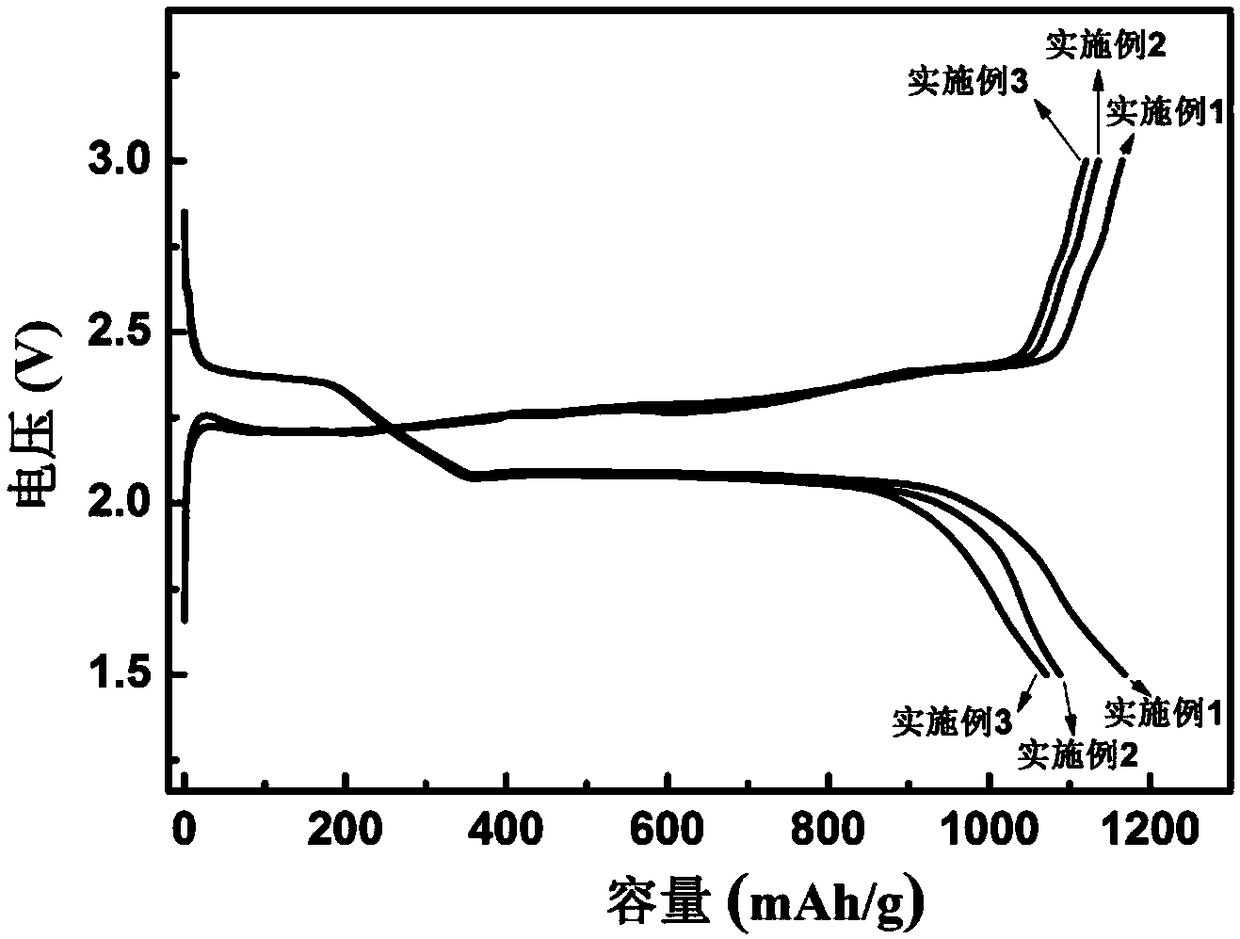

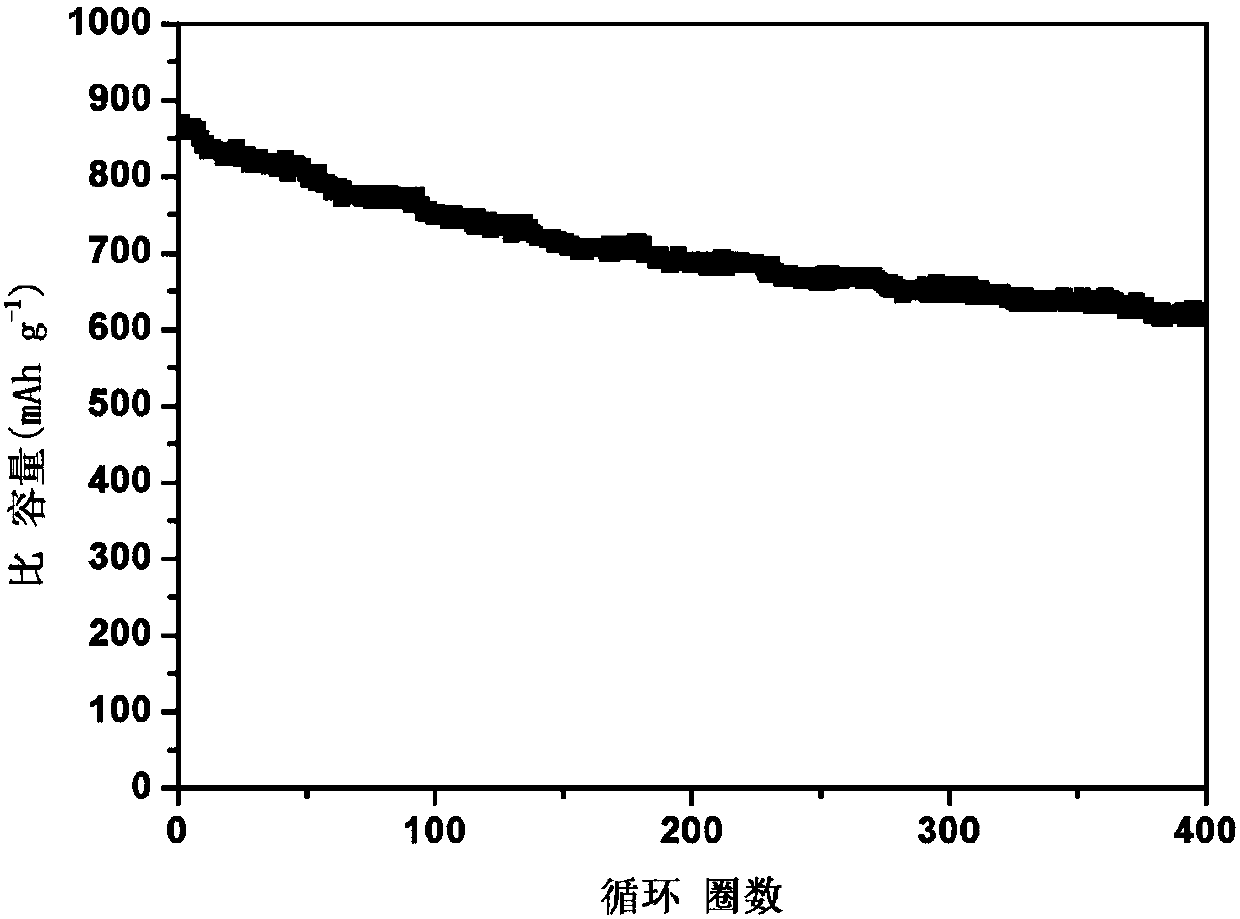

Preparation method of lithium-sulfur battery applicable to industrialized production

InactiveCN104953102AInhibition of volume expansion effectIncrease capacityFinal product manufactureCell electrodesVolume variationHigh volume manufacturing

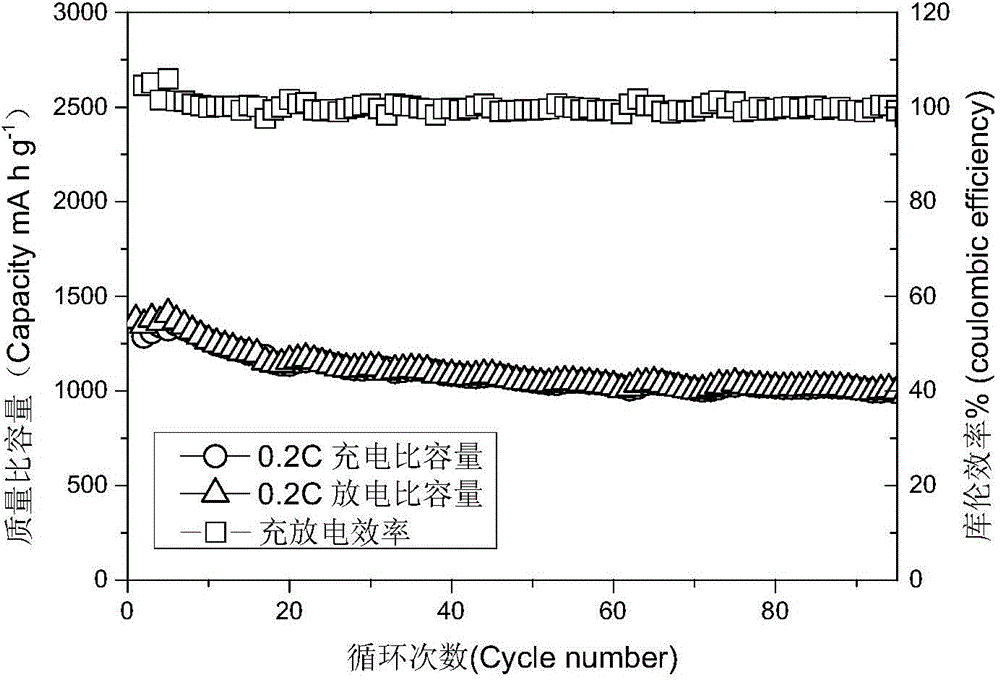

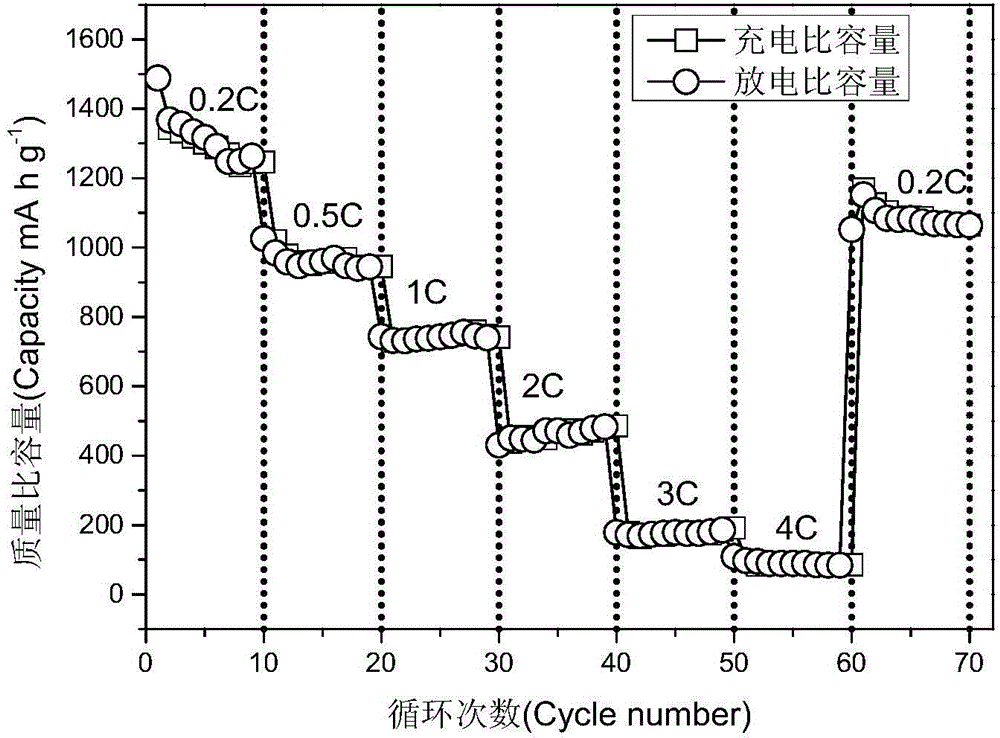

The invention relates to a preparation method of a lithium-sulfur battery applicable to the industrialized production, and belongs to the field of an electrochemical battery. A battery positive electrode adopts a mixture obtained by simply processing a graphene material capable of being commercialized and realizing mass production and elemental sulfur. The graphene plays a role in mechanical isolation on one aspect, so that the volume variation of sulfur in the charging-discharging process can be inhibited; on the other aspect, the pass-through effect of polysulfide in electrolyte as well as corrosion of polysulfide on a lithium cathode can be prevented to a certain extent by virtue of good space structure, so that the specific discharge capacity of the charging and discharging of the lithium-sulfur battery can be improved. Under the 0.2C current density, the primary discharging capacity can reach 1370mAh.g<-1> or more. After the battery is cycled for 95 times, the capacity still can be maintained about 1000mAh.g<-1>. After the battery is cycled for 30 times, the capacity tends to be stable, and the capacity is maintained at 90 percent or more.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Carbon-coated ferroferric oxide and preparation method and application of carbon-coated ferroferric oxide in lithium battery

InactiveCN103117388AAvoid direct contactImprove lithium storage characteristicsCell electrodesSecondary cellsCarbon coatingChemistry

The invention discloses a carbon-coated ferroferric oxide. The carbon coating quantity is 5-40%, and the carbon-coated ferroferric oxide is prepared by introducing an acetylene gas into Fe2O3 under Ar atmosphere at 500-700 DEG C so as to carry out reduction and carbon coating of Fe2O3, wherein the flow velocity ratio of Ar to acetylene is 100:(1-10), thereby obtaining a carbon-coated Fe3O4 composite material. The invention aims at overcoming the defect of FexOy and conducting carbon coating on FexOy. Due to the carbon coating, not only the direct contact of the active material FexOy and electrolyte overcome can be prevented and the conductivity of FexOy is improved, but also defects of volume expansion effects, the agglomeration easiness and the like of FexOy and the electrolyte are suppressed, so that the lithium storage characteristic of FexOy is improved, and the height ratio capacity characteristic of FexOy is fully exerted.

Owner:XIAN INTAIN NEW ENERGY MATERIALS SCI & TECH

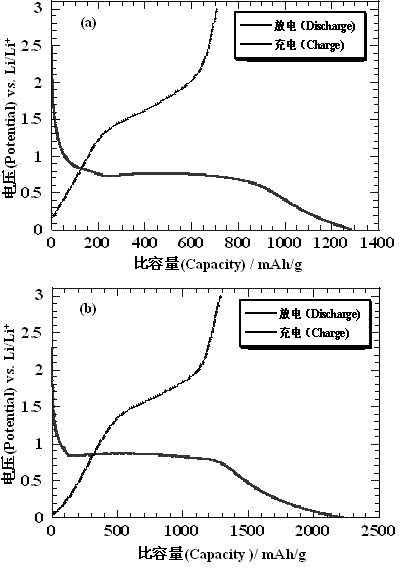

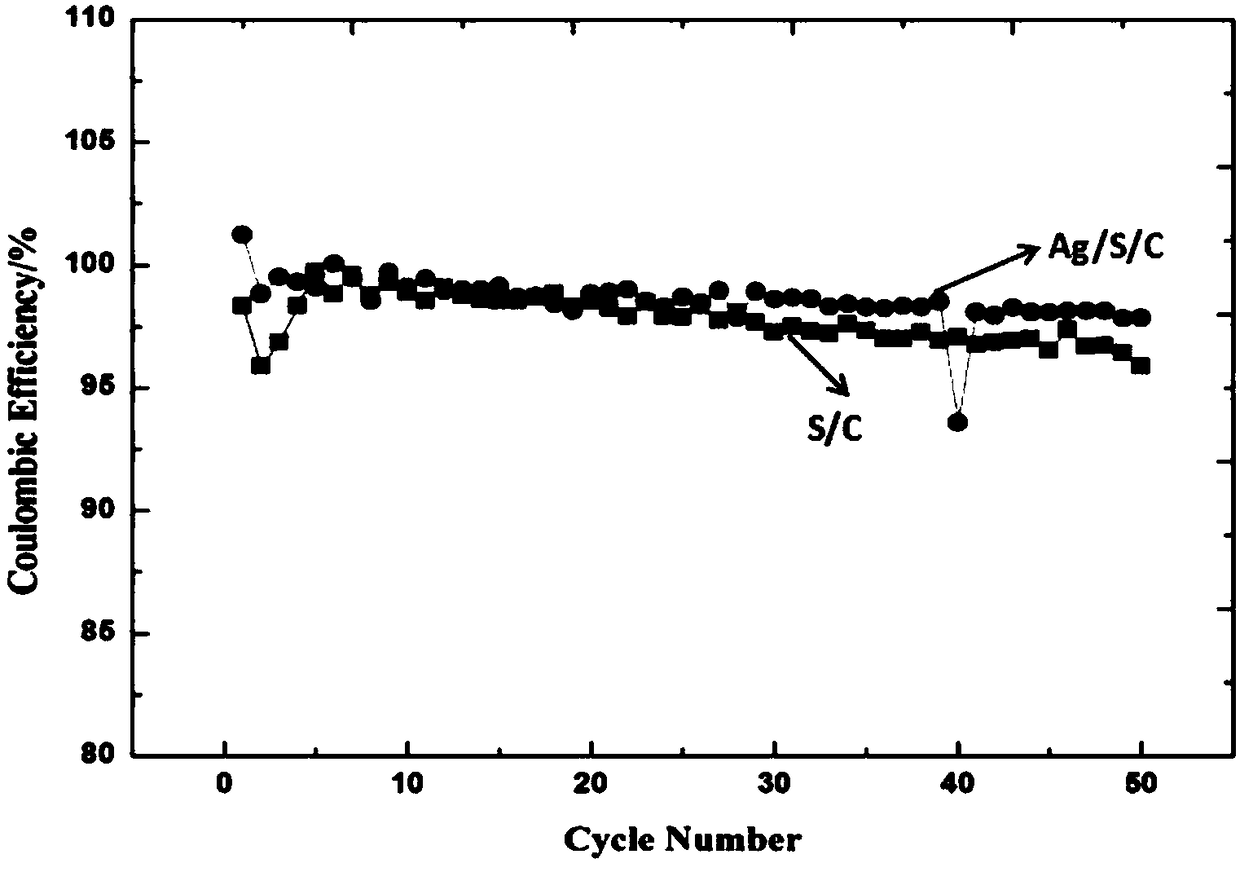

Preparation method of anode material of lithium-sulphur battery

InactiveCN108258212AImprove cycle performanceInhibition of volume expansion effectPositive electrodesLi-accumulatorsCarbon compositesLithium–sulfur battery

The invention provides a preparation method of an anode material of a lithium-sulphur battery. The preparation method comprises the steps of preparing a sulfur-carbon composite, loading a conductive metal on the surface of the sulfur-carbon composite to form a composite composited by the conductive metal, a sulfur material and a carbon material. The method can inhibit a shuttle effect of polysulfide and a volume expansion effect of the anode material, and the cycle performance of the battery is effectively improved.

Owner:ZHEJIANG FOREVER NEW ENERGY TECH CO LTD +1

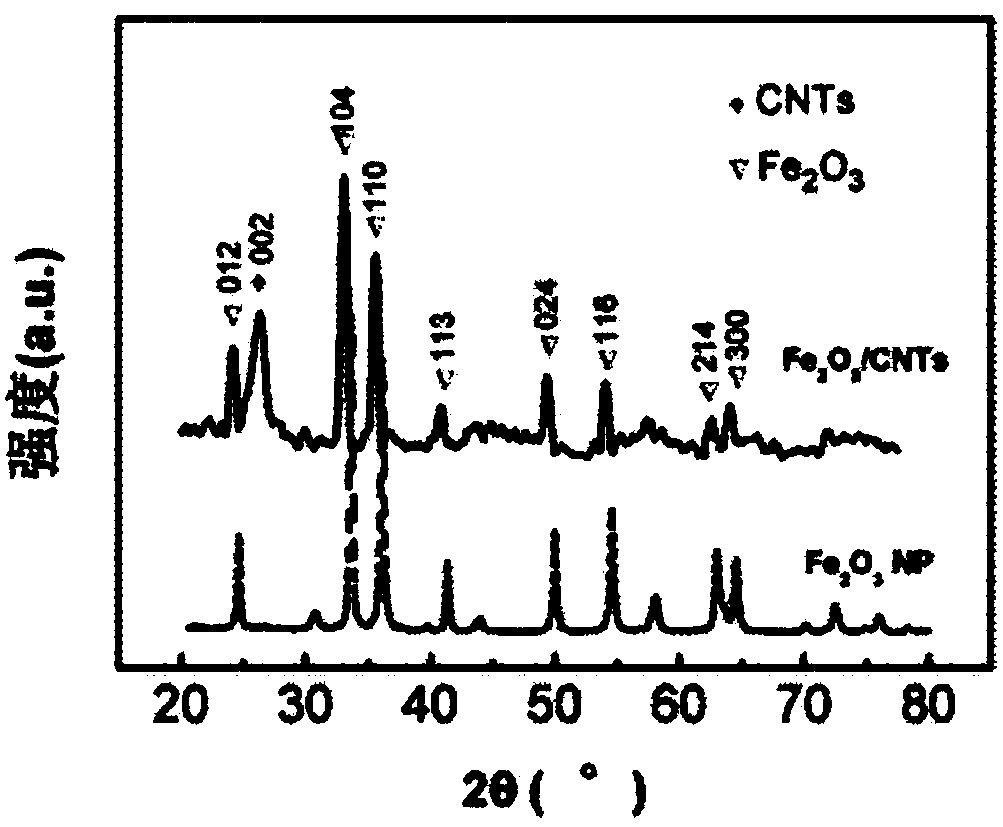

Preparation method of ferric oxide/carbon/carbon nanotube lithium-ion battery negative electrode material

ActiveCN108183213AHigh purityGood dispersionCell electrodesSecondary cellsActivated carbonNanoparticle

The invention provides a preparation method of a ferric oxide / carbon / carbon nanotube (CNT) lithium-ion battery negative electrode material. The preparation method comprises the following steps: step 1, after mixing carbon nanotubes and KOH powder, adding a mixture into distilled water; after stirring, drying and roasting to obtain activated carbon nanotubes; step 2, mixing a mixed solution of Fe(NO3)9 and C6H12O6 with an activated carbon nanotube dispersion solution, and reacting to obtain Fe2O3 / C / CNT. According to the preparation method provided by the invention, carbon cladded ferric oxide nanoparticles and the carbon nanotubes are combined together, so that the disadvantages that the electric conductivity is low, the specific capacity is low and the coulombic efficiency is relatively low and the like when the carbon cladded ferric oxide nanoparticles are used as a lithium-ion battery negative electrode can be improved.

Owner:INT ACAD OF OPTOELECTRONICS AT ZHAOQING SOUTH CHINA NORMAL UNIV

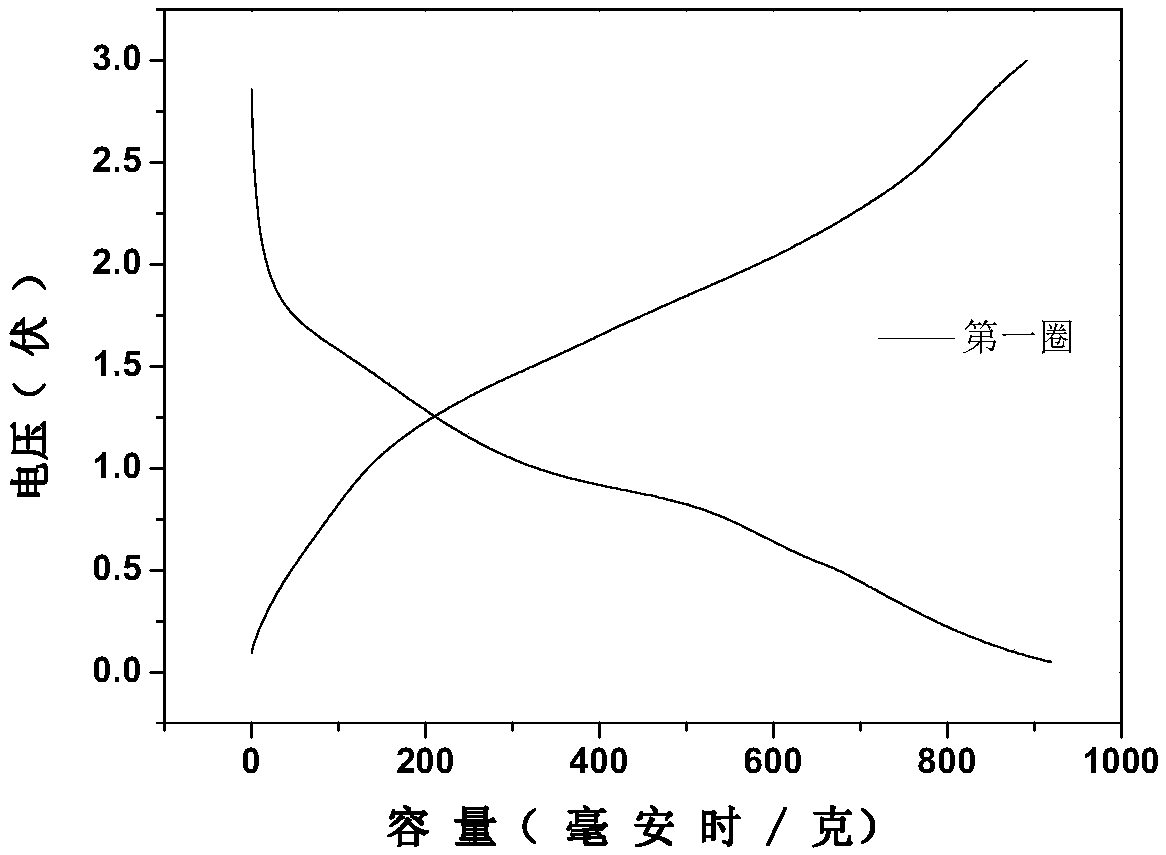

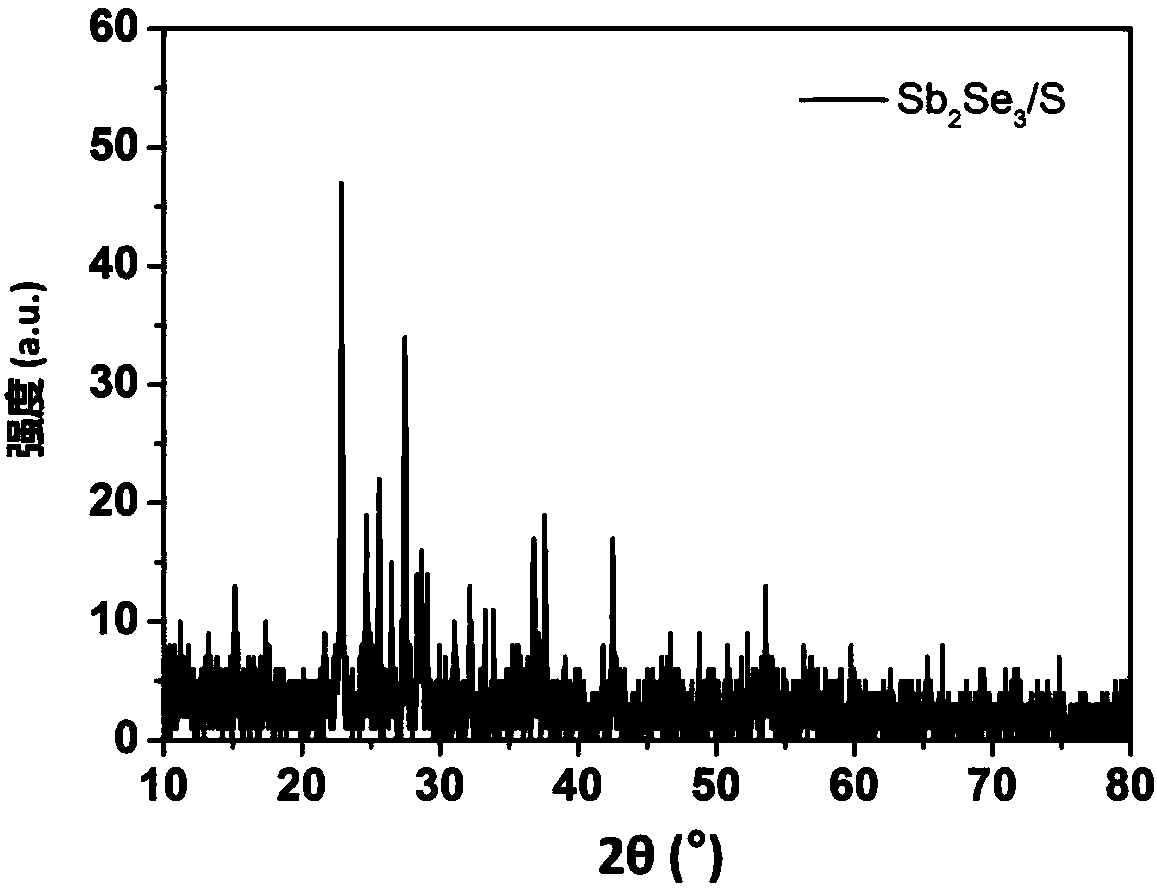

Lithium-sulfur battery anode material and application thereof

ActiveCN108550818AHighlight substantiveInhibition of volume expansion effectCell electrodesSecondary cellsElectrical batterySulfur

The invention relates to a lithium-sulfur battery anode material and an application thereof. The material is prepared by the following method, which comprises the following steps: first step, dissolving antimony trichloride in triethylene glycol, and stirring to obtain a cationic solution; dissolving selenium powder in a first mixed solution, and stirring to obtain a selenium precursor solution; pouring the selenium precursor solution into a second mixed solution, stirring under a nitrogen atmosphere at 180-250 DEG C, then adding the cationic solution, continuing to stir the solution, coolingthe same to the room temperature to obtain a pure Sb2Se3 selenium telluride nanorod; and second step, placing the selenium telluride nanorod prepared in the previous step and sulfur powder in a mortarto separate sulfur, and performing a reaction at 150-160 DEG C for 10-16h to prepare the lithium-sulfur battery anode material. The lithium-sulfur battery anode material provided by the invention isused as a positive electrode pole piece of a battery and has excellent electrochemical performance.

Owner:SYNERGY INNOVATION INST OF GDUT HEYUAN

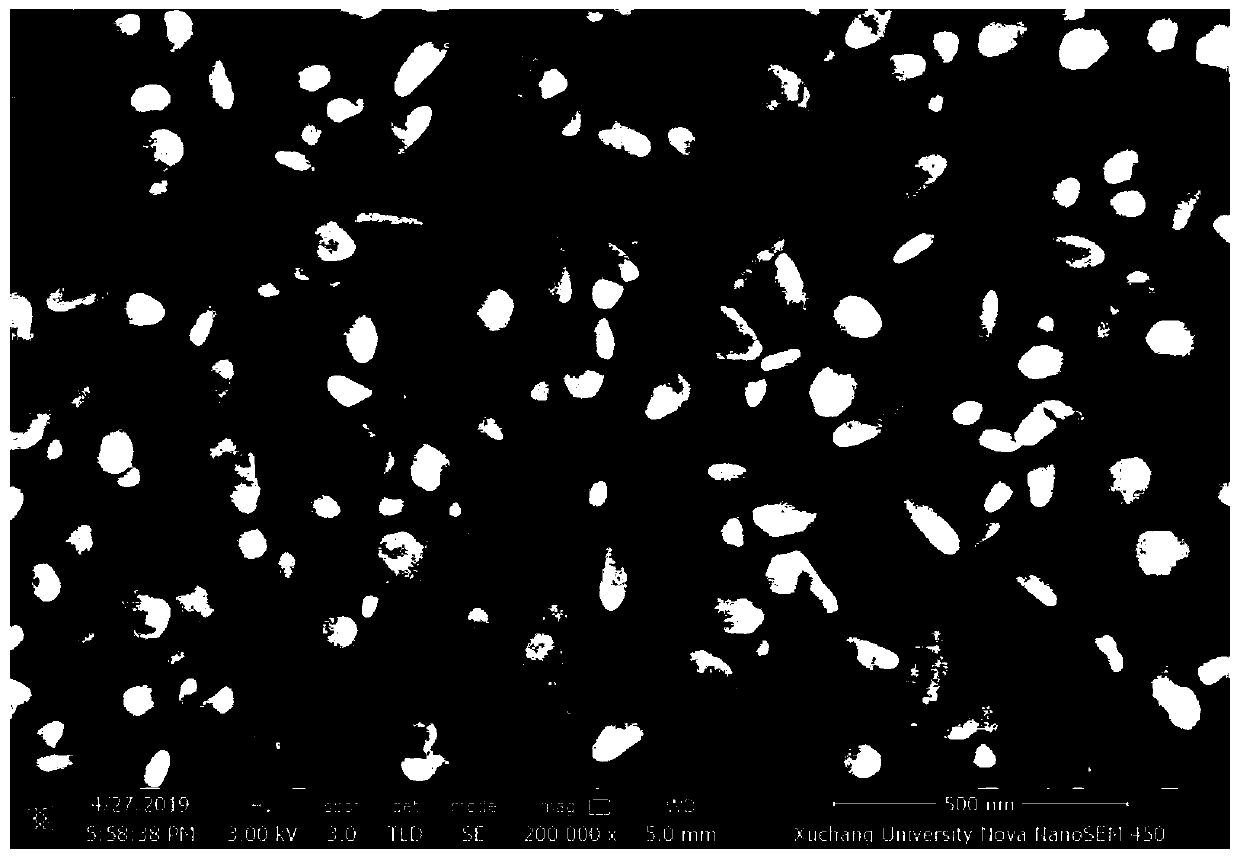

Fe2O3 porous nanowire electrode material, and preparation method and application thereof

ActiveCN110371924AImprove bindingImprove cycle stabilityMaterial nanotechnologySecondary cellsNanowireSeed crystal

The invention discloses a Fe2O3 porous nanowire electrode material, and a preparation method and application thereof. The preparation method comprises the following steps of ZnO seed crystal preparation, ZnO nano array preparation and Fe2O3 porous nanowire preparation. A metal current collector or a carbon material current collector is taken as a substrate, firstly, a ZnO nano array is prepared through a hydrothermal method, the Fe2O3 porous nanowire electrode material is prepared through a second hydrothermal method, the length of the prepared Fe2O3 nanowire electrode material is about 1 [mu]m, the diameter of the Fe2O3 nanowire electrode material is within 20 nm to 80 nm, and the Fe2O3 porous nanowire electrode material is of a porous structure and is bonded firmly with a matrix. The prepared Fe2O3 porous nanowire electrode material has the characteristics of high cyclic stability and excellent rate performance, and has wide application prospects.

Owner:XUCHANG UNIV

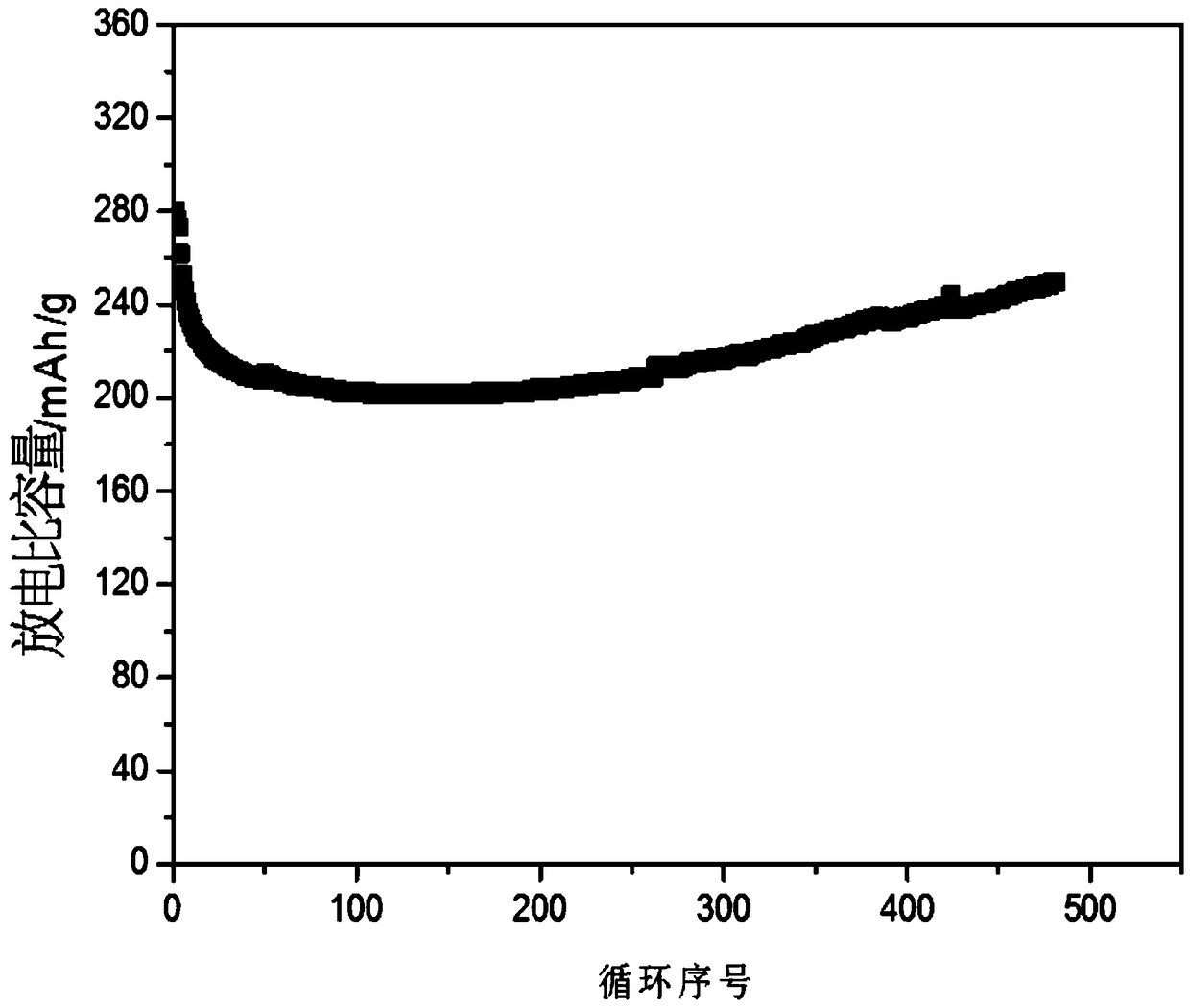

Method for preparing lithium battery SiO negative electrode material with high cycle performance

ActiveCN111653739AAvoid self reunionInhibition of volume expansion effectSilicaGraphiteKneader reactorGraphite

The invention relates to the technical field of lithium battery electrode materials. Aiming at the problems of large volume expansion and reduced cycle performance of an SiO material applied to a lithium battery negative electrode material, the invention discloses a method for preparing a lithium battery SiO negative electrode material with high cycle performance, which comprises the following steps: adding SiO and a low-viscosity carbon source into a kneading machine, heating, stirring and kneading to obtain a compound A; transferring the compound A, graphite and a high-viscosity carbon source into granulation equipment through vacuum equipment for inert atmosphere granulation to obtain a material B; and putting the material B into a calcining furnace, calcining at high temperature in aninert atmosphere, and naturally cooling to room temperature to obtain the SiO negative electrode material of the lithium battery. The dispersion performance of SiO and graphite in a high-viscosity carbon source is improved through the low-viscosity carbon source, so that SiO and graphite form a uniform dispersion effect, SiO is firmly bonded to the surface of graphite through residual carbon of the low-viscosity carbon source and residual carbon of the high-viscosity carbon source, the volume expansion effect is effectively inhibited, and the specific capacity and the cycle performance are improved.

Owner:WANXIANG 123 CO LTD

Silicon-carbon composite material water-based composite slurry and preparation method thereof, and lithium ion battery

ActiveCN110190258AEasy to prepareEasy to operate and controlCell electrodesSecondary cellsWater basedCarbon composites

The invention discloses silicon-carbon composite material water-based composite slurry a preparation method thereof, and a lithium ion battery. The preparation method comprises the steps of: (1) performing dry power stirring of a silicon-carbon composite material and SP to obtain a material A; (2) performing infiltrating and stirring of the material A, water and CMC colloid to obtain slurry, wherein the solid content of the slurry is 40-45%; (3) performing stirring of the slurry, an SBR emulsion and a PAA emulsion at an intermediate speed, and performing defoaming and standing; and (4) regulating the viscosity to be 2000-3000 mPa.s. The water-based composite binder slurry takes water as a solvent, is uniformly dispersed, shortens the time of secondary stirring in the preparation process, can effectively improve the distribution uniformity of the binder on the pole piece, effectively inhibits the decomposition of electrolyte in the circulation process, and forms a more uniform SEI film,so that the prepared lithium ion battery has high first coulombic efficiency and a good circulation performance.

Owner:SHANGHAI ELECTRICGROUP CORP

Electrolyte suitable for silicon-carbon negative electrode and lithium ion battery

PendingCN111834671AReduce interface impedanceInhibition of reductive decompositionSecondary cells servicing/maintenanceOrganic electrolytesElectrolytic agentDisilane

The invention discloses an electrolyte suitable for a silicon-carbon negative electrode and a lithium ion battery. The electrolyte comprises an electrolyte lithium salt, a non-aqueous organic solventand an additive. The additive comprises a negative electrode film-forming additive, a fluorinated phenyl boron compound and a disilyl sulfate compound. Through the synergistic effect of the fluorophenyl boron compound additive, the disilane alkyl sulfate compound additive, the negative electrode film-forming additive and the novel lithium salt type additive, the electrolyte has excellent film-forming performance on the surface of the silicon-carbon negative electrode, and the formed SEI film is relatively small in impedance and relatively stable in component and structure. By using the electrolyte, the discharge capacity, the cycling stability and the high-temperature storage performance of the silicon-carbon negative electrode lithium ion battery can be effectively improved, gas production can be inhibited, the problems of volume expansion, particle breakage and the like in the battery cycling process can be effectively solved, and meanwhile, the electrolyte has good high-temperatureand low-temperature performance.

Owner:香河昆仑新能源材料股份有限公司

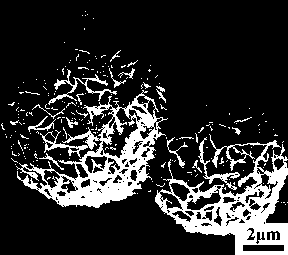

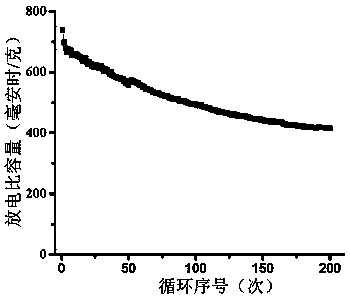

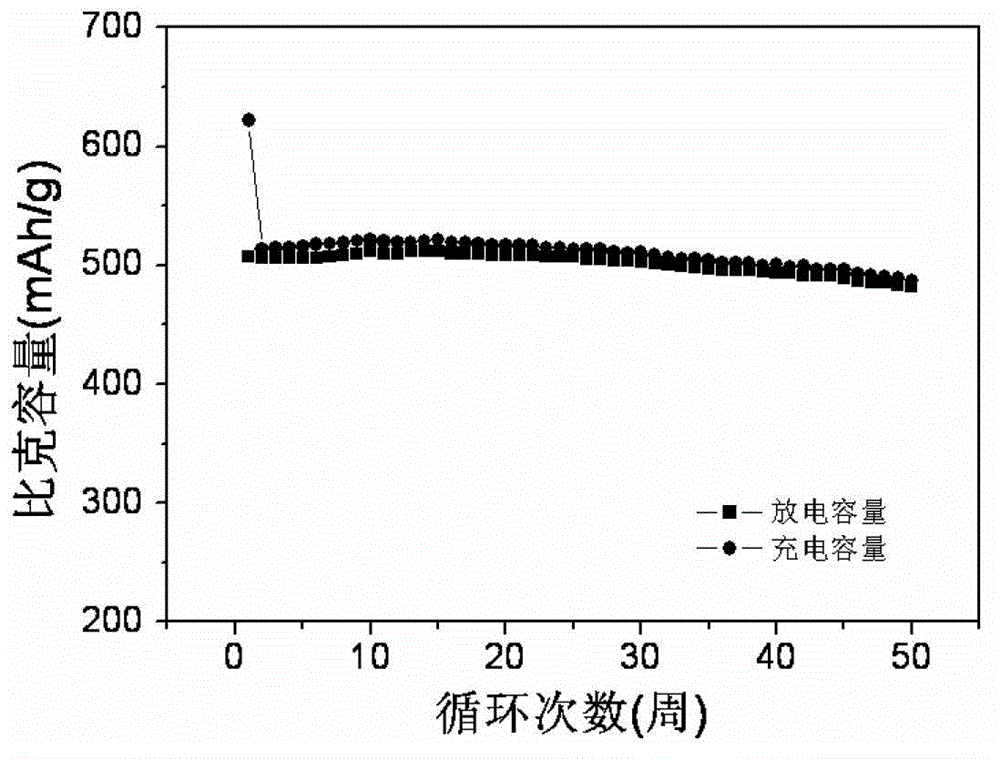

Preparation method for foam graphene compound indium zinc sulfide material

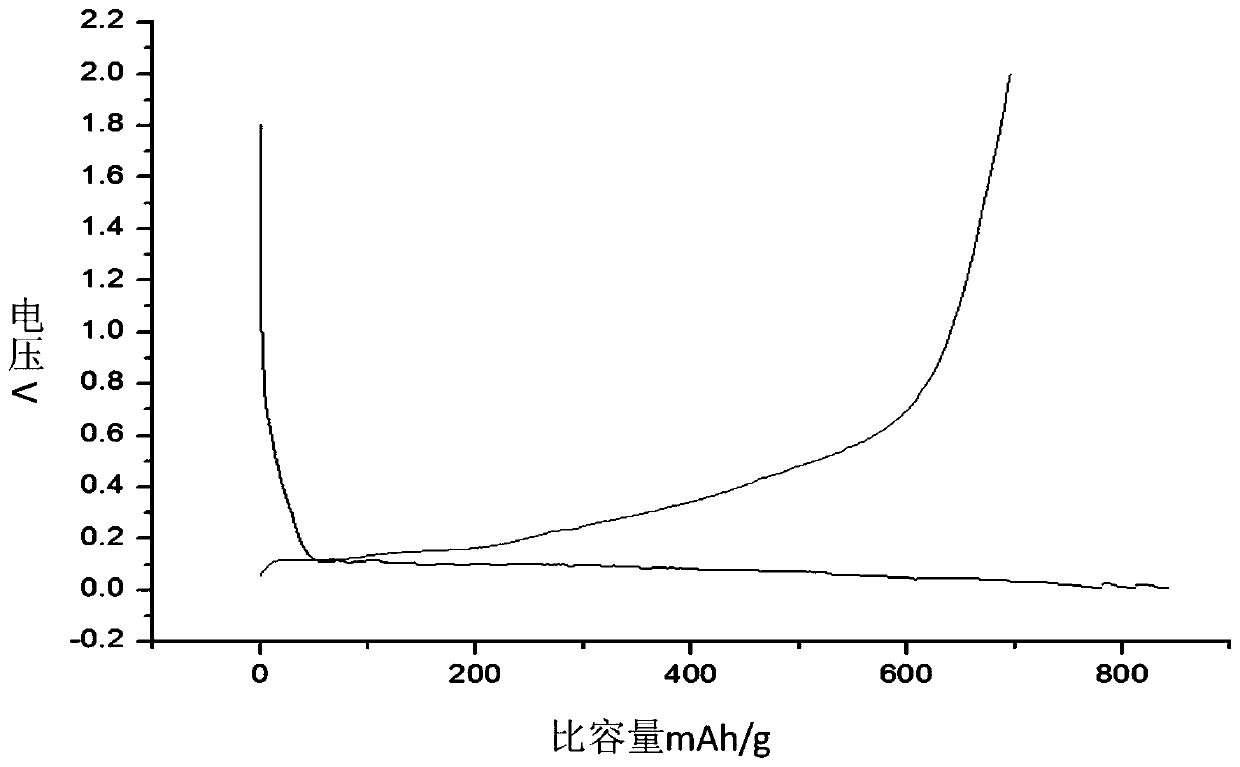

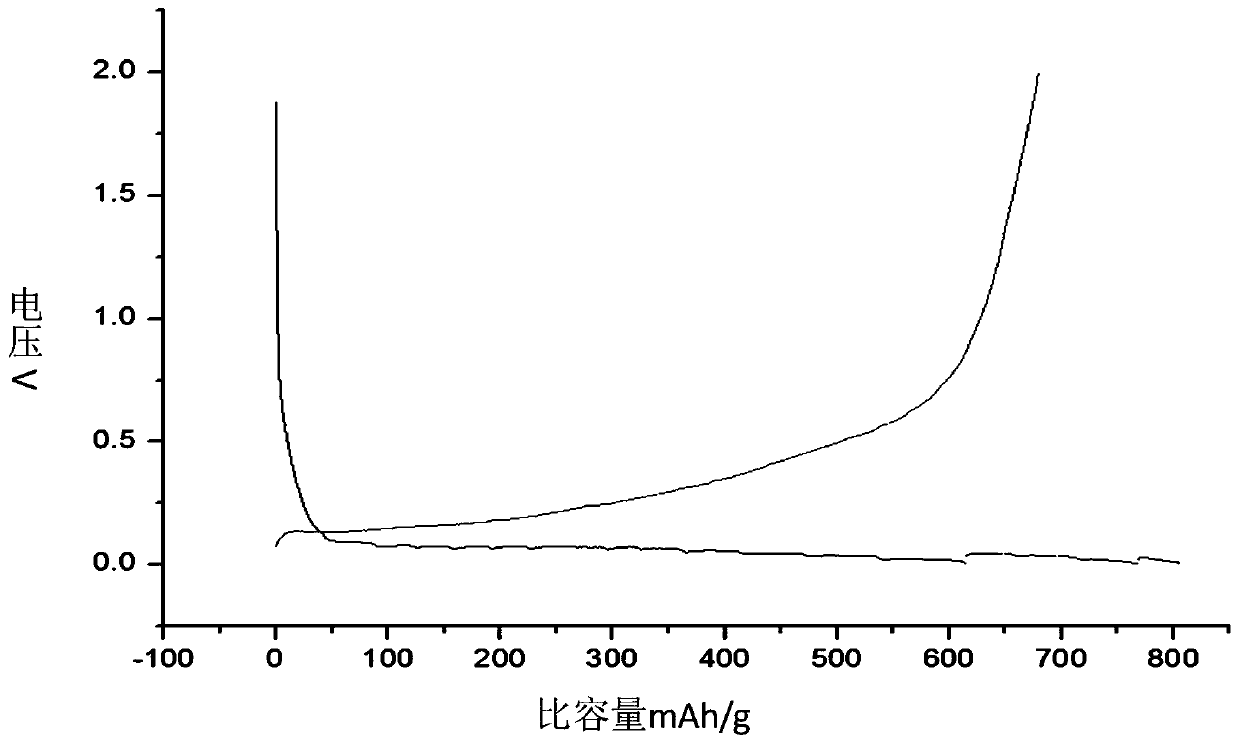

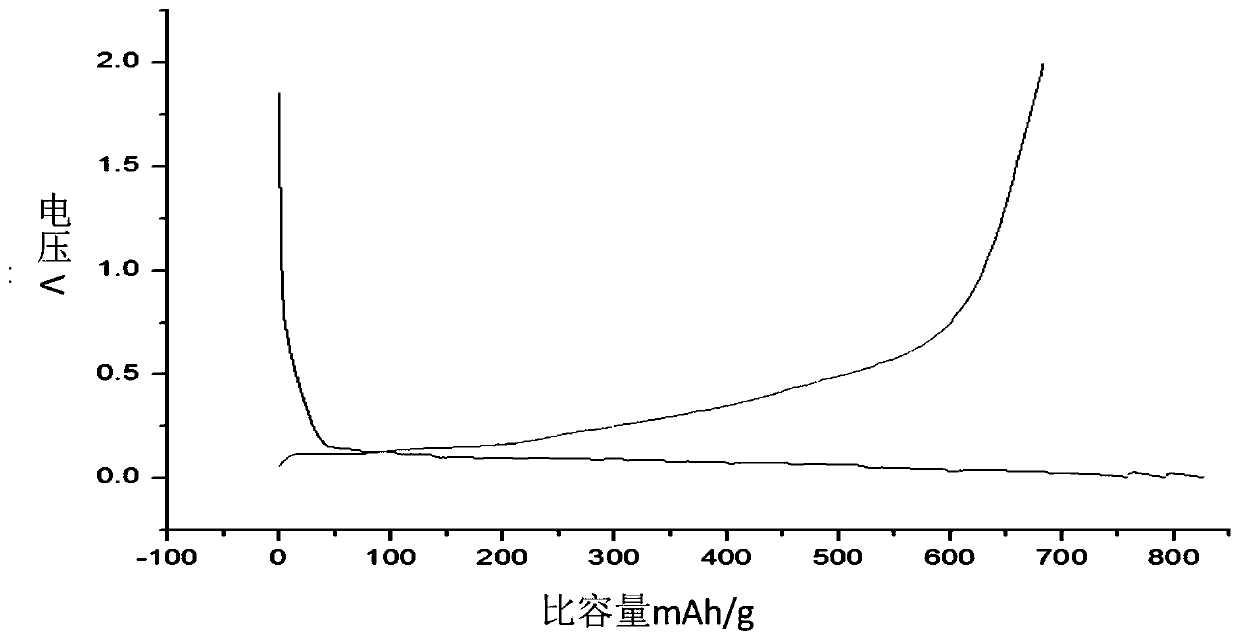

InactiveCN108899501AImprove electrochemical performanceInhibition of volume expansion effectNegative electrodesSecondary cellsIndiumCharge discharge

The invention belongs to the field of material chemistry and relates to a preparation method for a cathode material of a lithium ion battery. The method comprises three steps: preparing graphene oxide, preparing foam graphene and preparing a foam graphene compound indium zinc sulfide material. The cathode material with higher charge-discharge specific capacity and better cycle performance is acquired by introducing graphene foams and indium zinc sulfide as cathode active materials; the initial charge-discharge capacity can reach up to 742.17mAh / g; after 200 times of circulation, the cathode material still has a reversible capacity of 415.23mAh / g.

Owner:INT ACAD OF OPTOELECTRONICS AT ZHAOQING SOUTH CHINA NORMAL UNIV

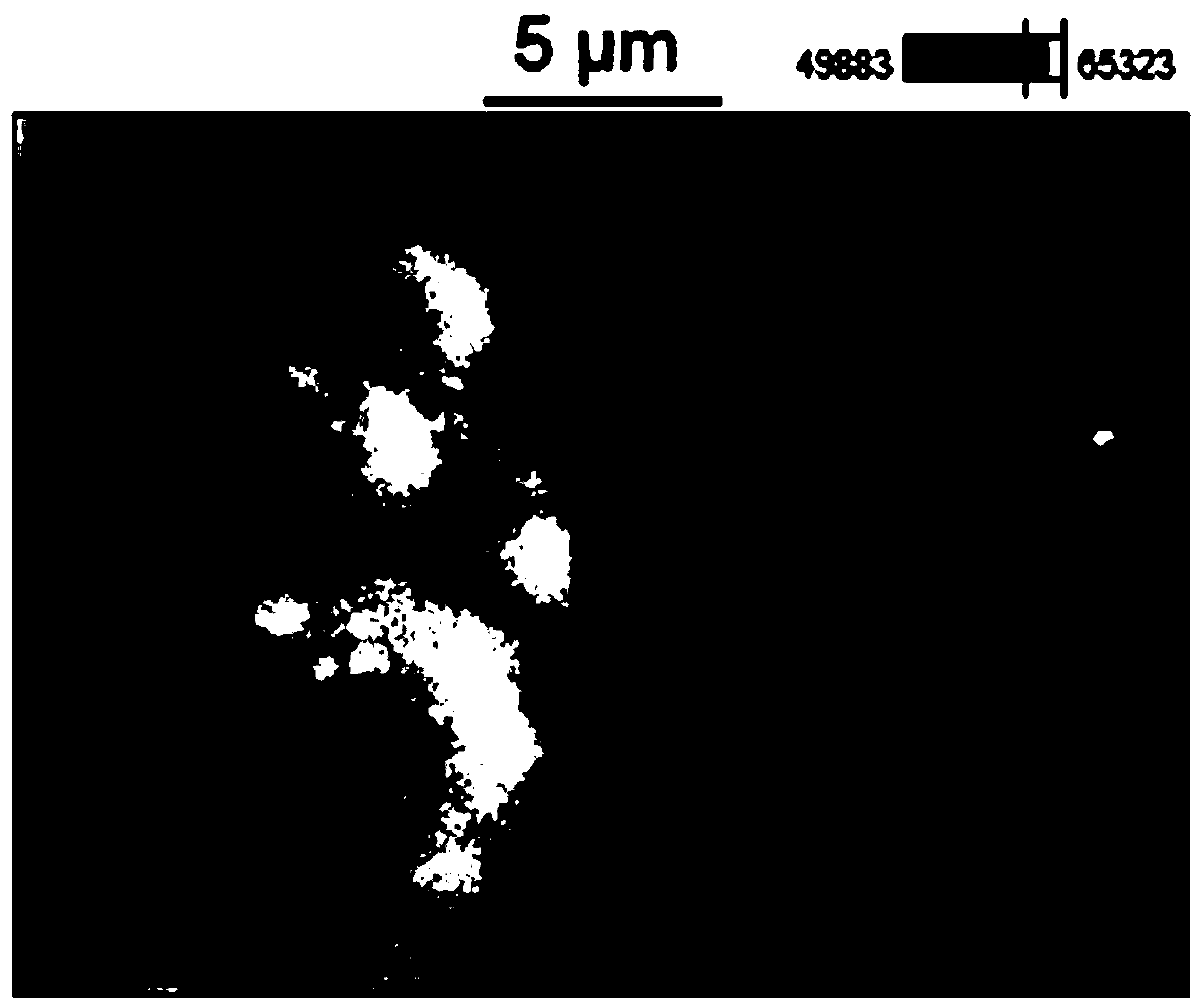

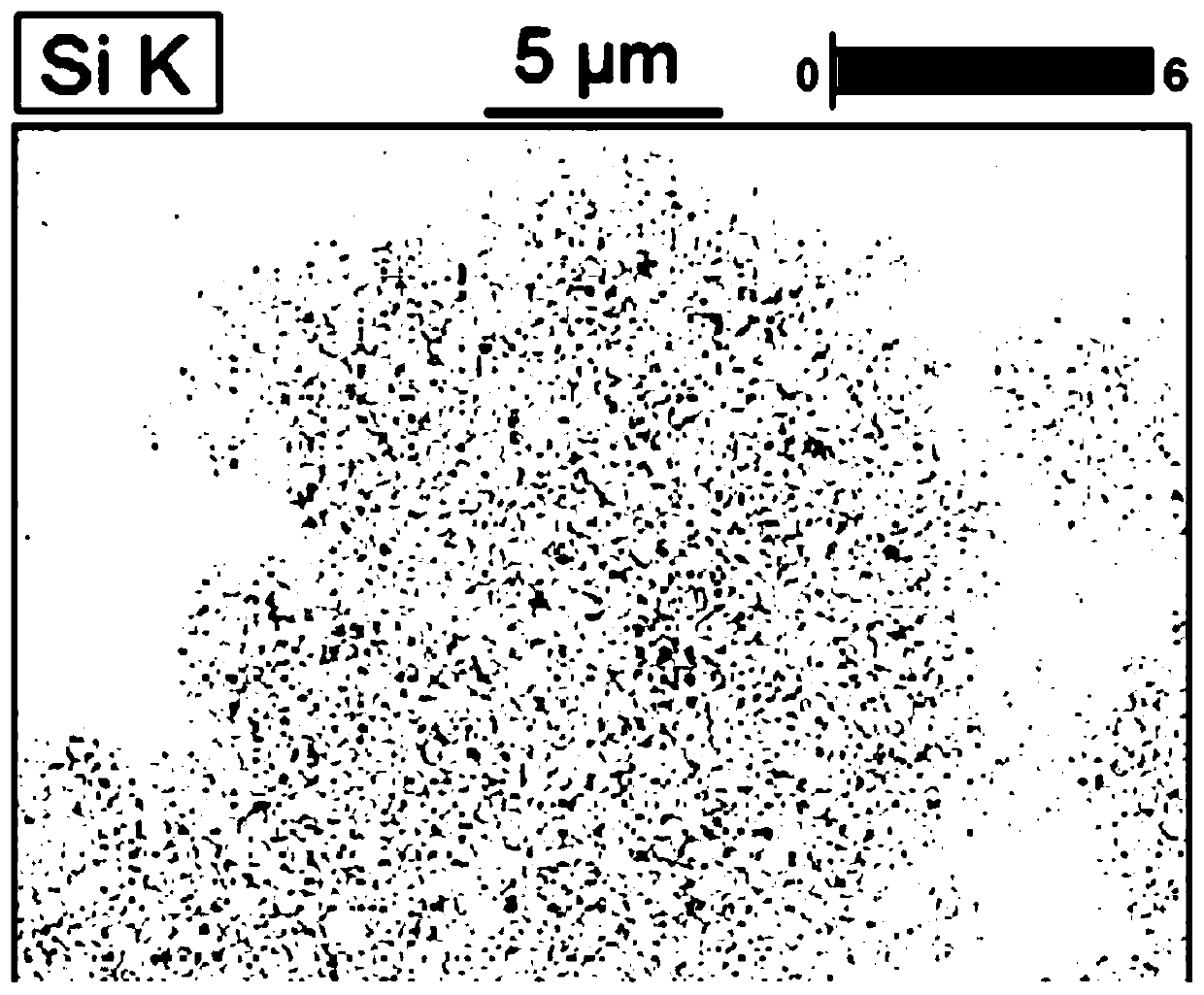

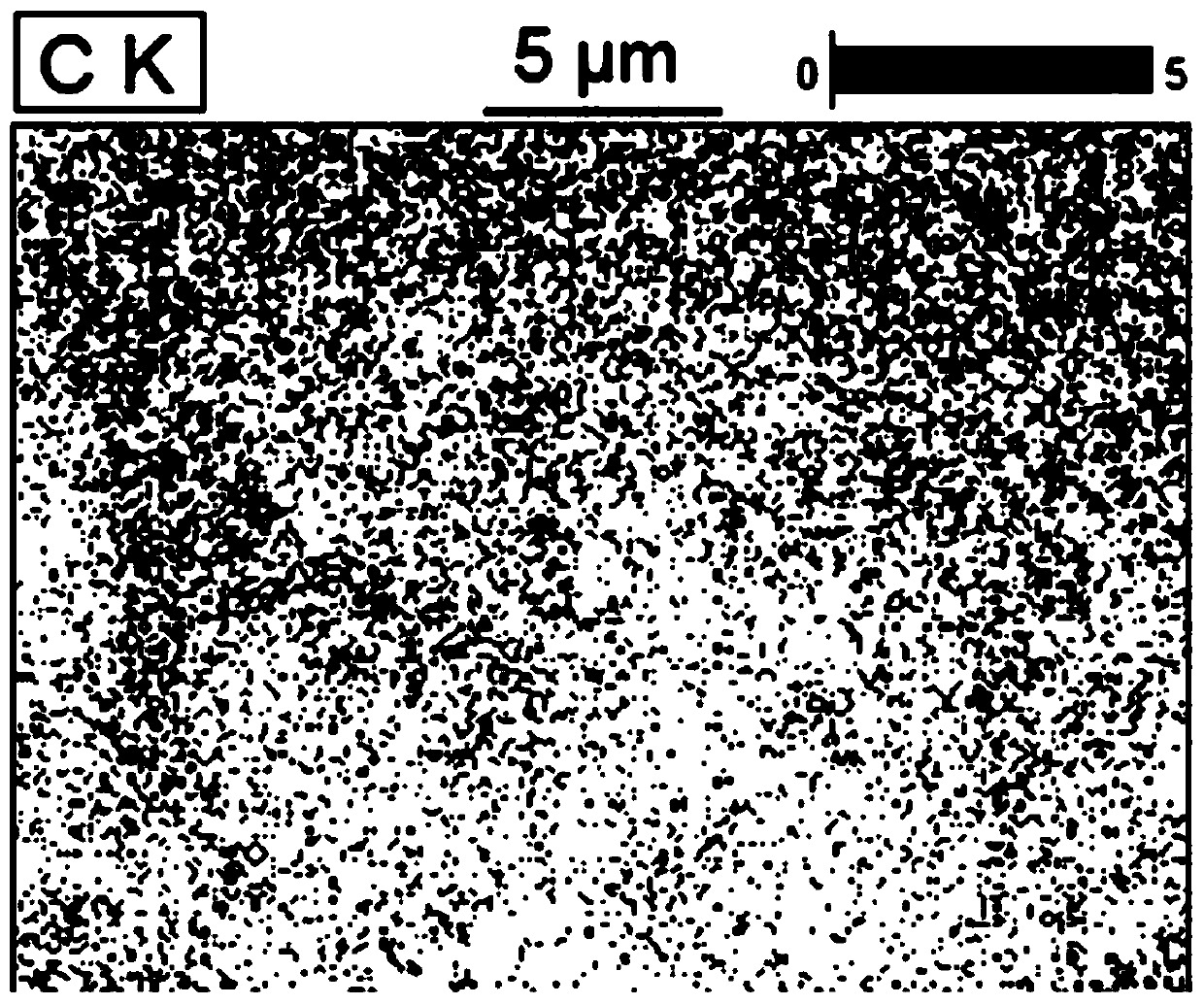

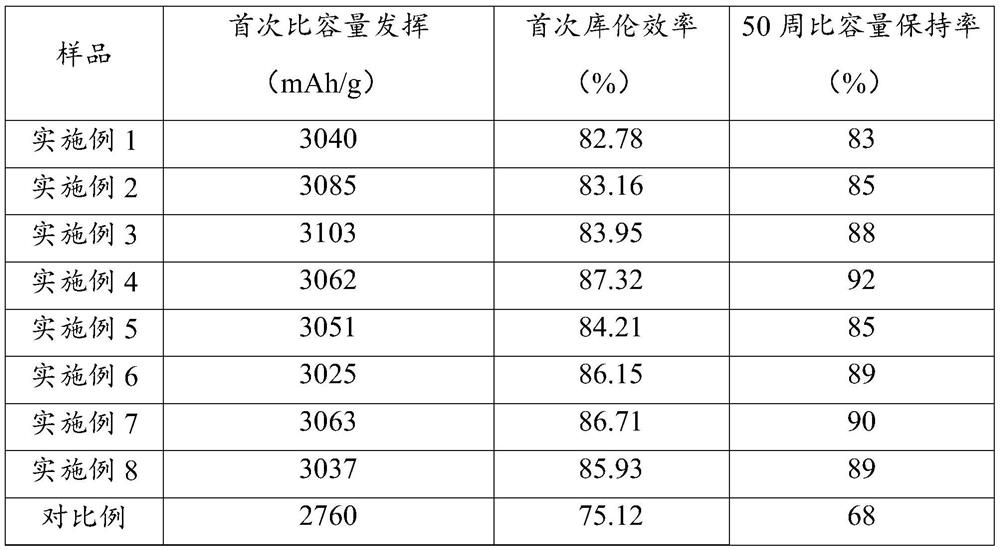

Silicon carbon negative electrode material for lithium ion battery and preparation method thereof

ActiveCN103199252BInhibition of volume expansion effectLow costCell electrodesCarbon compositesSodium-ion battery

The present invention discloses a lithium-ion battery silicon-carbon anode material and a preparation method thereof, and is to improve specific capacity and cycling performance. The material disclosed by the present invention is composed of an oxygen-containing silicon-carbon composite material and a graphite powder, wherein the oxygen-containing silicon-carbon composite material is formed by dispersing an oxygen-containing silicon-based material in a graphite powder and organic cracking carbon. Comparing the present invention with the prior art, the oxygen-containing silicon-based material is constituted by uniformly dispersing silicon particles in SiOx and a first buffer layer is formed, the oxygen-containing silicon-based material is uniformly dispersed in the organic cracking carbon and the graphite powder to form a second expansion buffer layer, thus the volume expansion effect of the silicon during charging and discharging can be effectively inhibited and cycle stability is improved. The lithium-ion battery silicon-carbon anode material is simple in preparation process, low in raw material costs, and easy for mass production.

Owner:BTR NEW MATERIAL GRP CO LTD

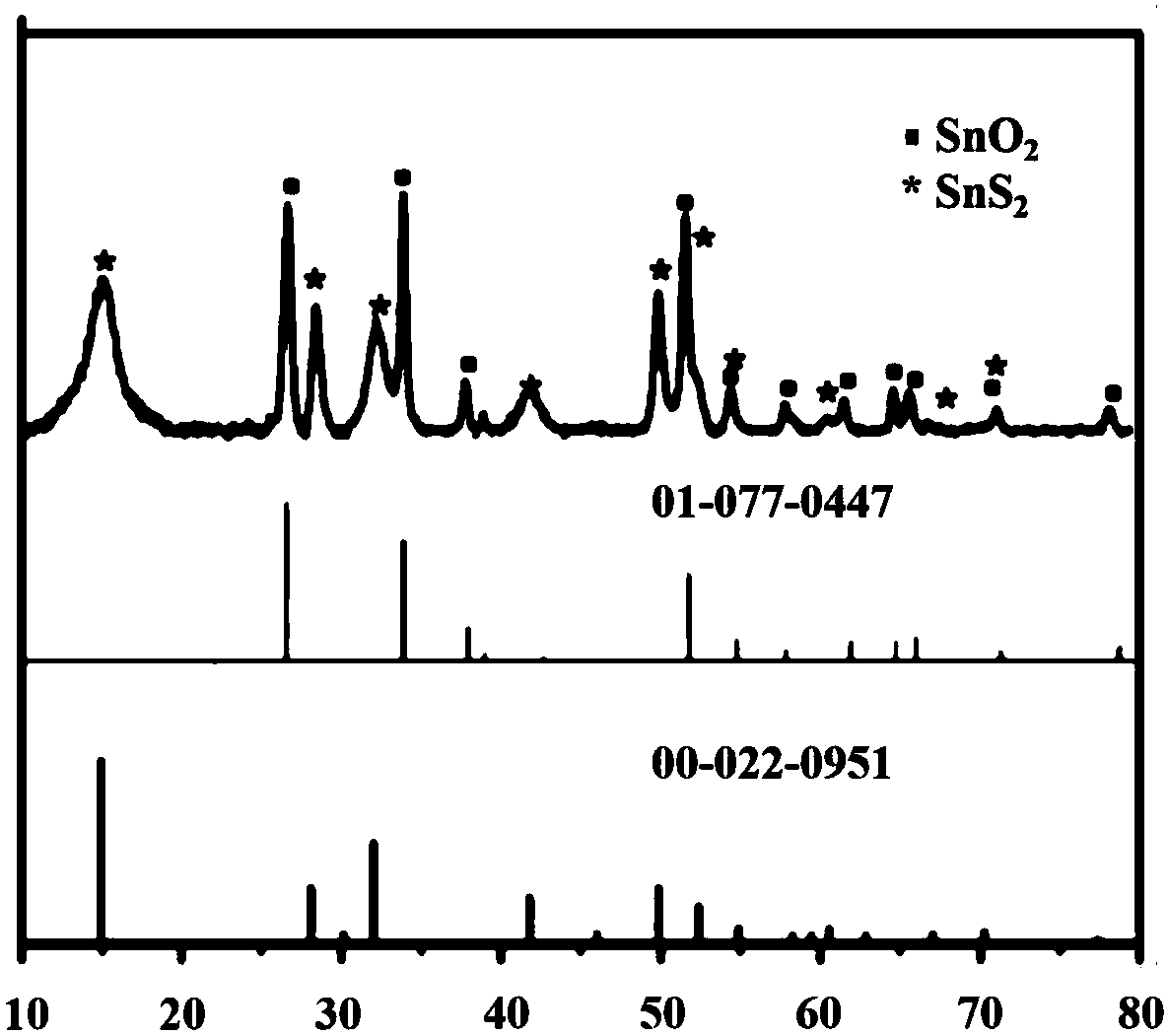

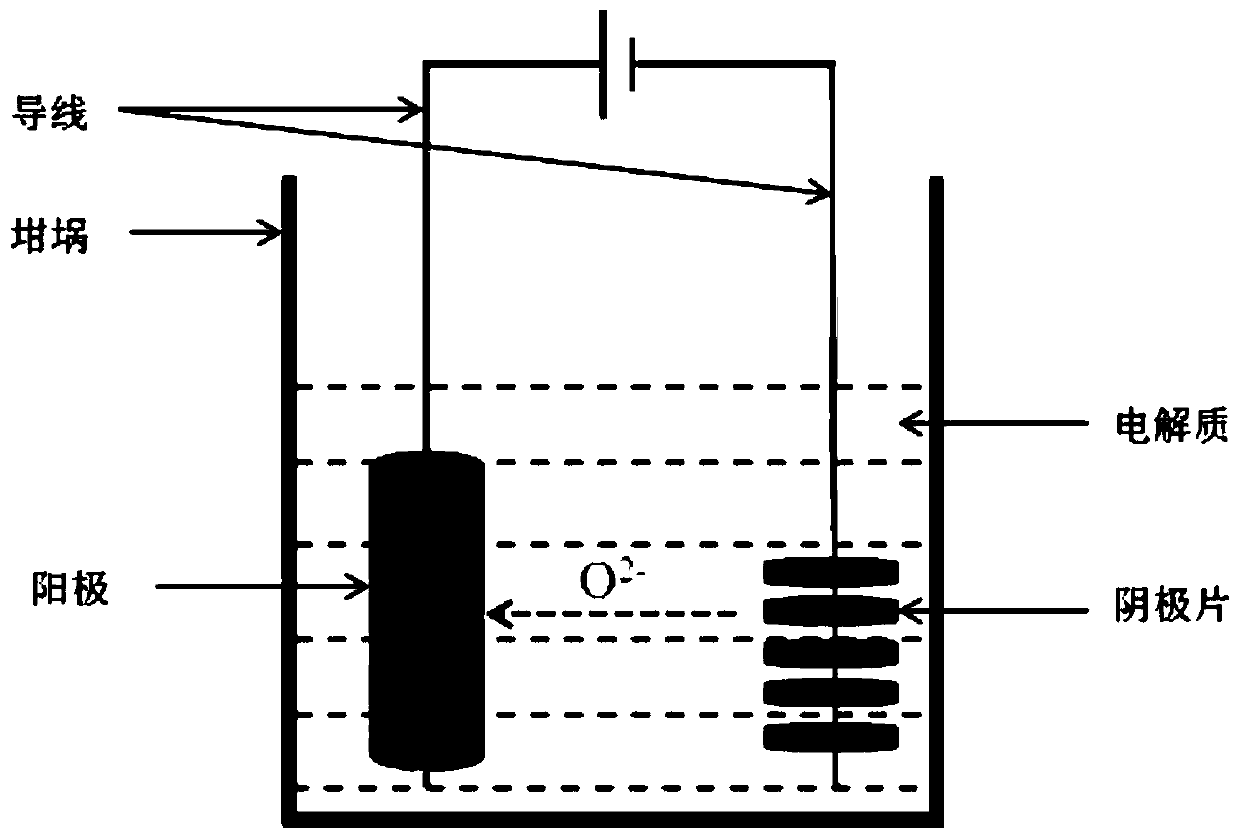

Sn-based sulfide and/or nitride modified tin oxide thin-film lithium battery negative electrode and preparation and application thereof

ActiveCN110034273AIncrease capacityImprove cycle performanceNon-aqueous electrolyte accumulator electrodesLattice constantNitride

The invention discloses a Sn-based sulfide and / or nitride modified SnO2 thin-film lithium battery negative electrode, and the negative electrode is characterized in that the negative electrode comprises a current collector, a metal buffer layer compounded on the current collector, an active substance layer compounded on the metal buffer layer and a modification layer compounded on the active substance layer; the material of the metal buffer layer is a conductive metal with the lattice constant being within the range of 3.6-4.7; the material of the active substance layer is SnO2; the material of the modification layer is SnS2 and / or SnNx, wherein x is 0.7 to 1.2. The invention also provides a preparation method and application of the negative electrode. According to the present invention, with the existence of the metal buffer layer, the active material layer having the dominant crystal face structure and the modification layer can be stably compounded without the existence of the adhesive phase; for example, SnO2 can be tightly compounded; in addition, the volume effect of the active substance in the charging and discharging process is buffered to a certain extent.

Owner:CENT SOUTH UNIV

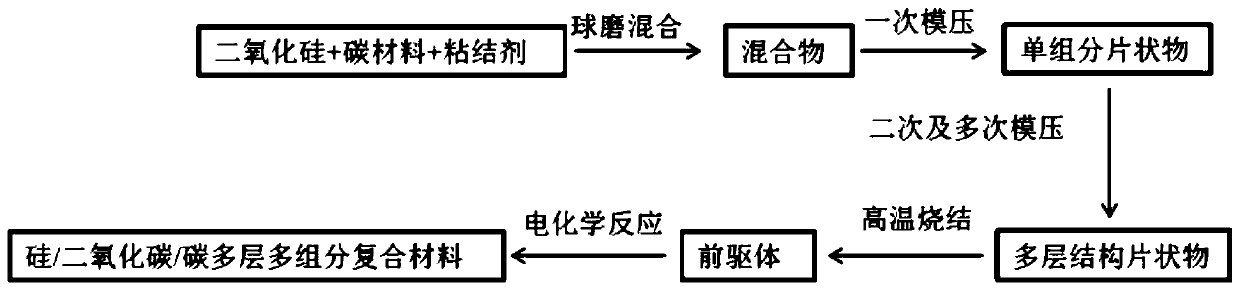

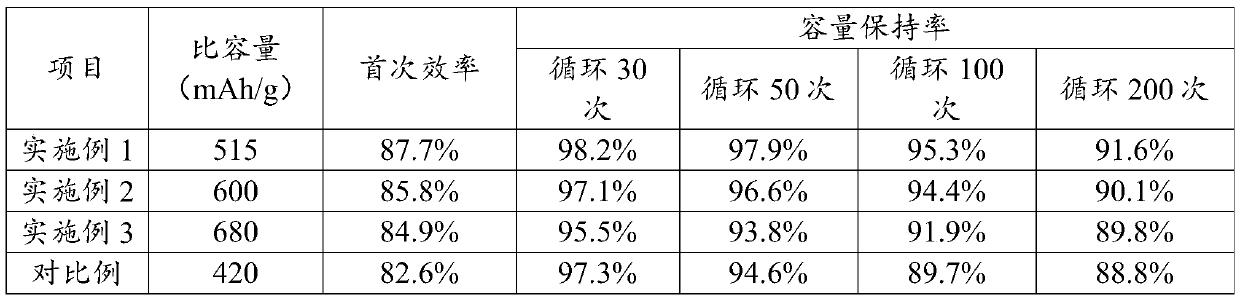

Multilayer composite negative electrode material, preparation method thereof, negative electrode sheet and lithium battery

ActiveCN110112364AImprove efficiencyIncrease the specific capacity of the negative electrodeNegative electrodesSecondary cellsCarbon layerLithium-ion battery

The invention provides a multilayer composite negative electrode material, a preparation method thereof, a negative electrode sheet and a lithium battery. The preparation method of the multilayer composite negative electrode material comprises the steps that silicon, silicon dioxide and carbon are used as raw materials to prepare a multilayer precursor; a silicon material is mixed with a binder toacquire a first precursor layer mixture; silicon dioxide, a carbon material and the binder are mixed to acquire a second precursor layer mixture; the carbon material is mixed with the binder to acquire a third precursor layer mixture; the first, second and third precursor layer mixtures are molded in the order of a silicon layer, a silicon dioxide / carbon mixed layer and a carbon layer, and then are sintered to acquire a multilayer precursor; and silicon dioxide in the multilayer precursor is reduced to monatomic silicon to acquire the multilayer composite negative electrode material. According to the invention, a denser solid electrolyte interface film can be generated during the first charge and discharge process; the volume expansion effect of the silicon material during the charge anddischarge process is suppressed; and the first efficiency of the battery, the specific capacity of the negative electrode and the cycle performance of the battery are improved.

Owner:ZHUHAI COSMX BATTERY CO LTD

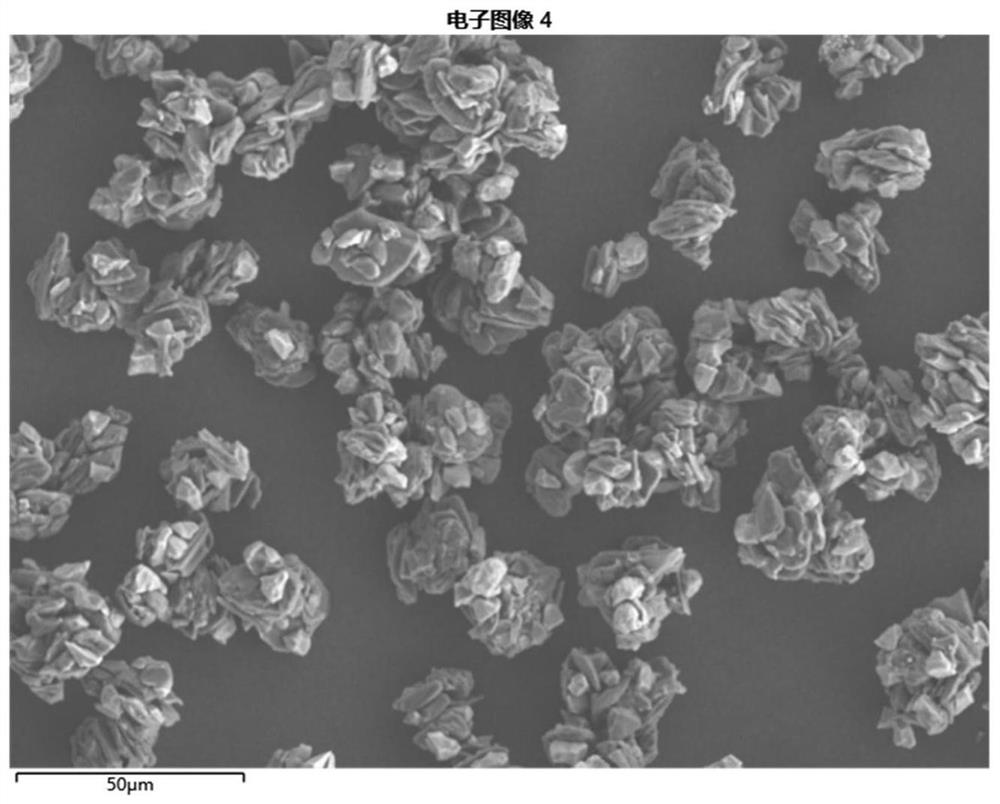

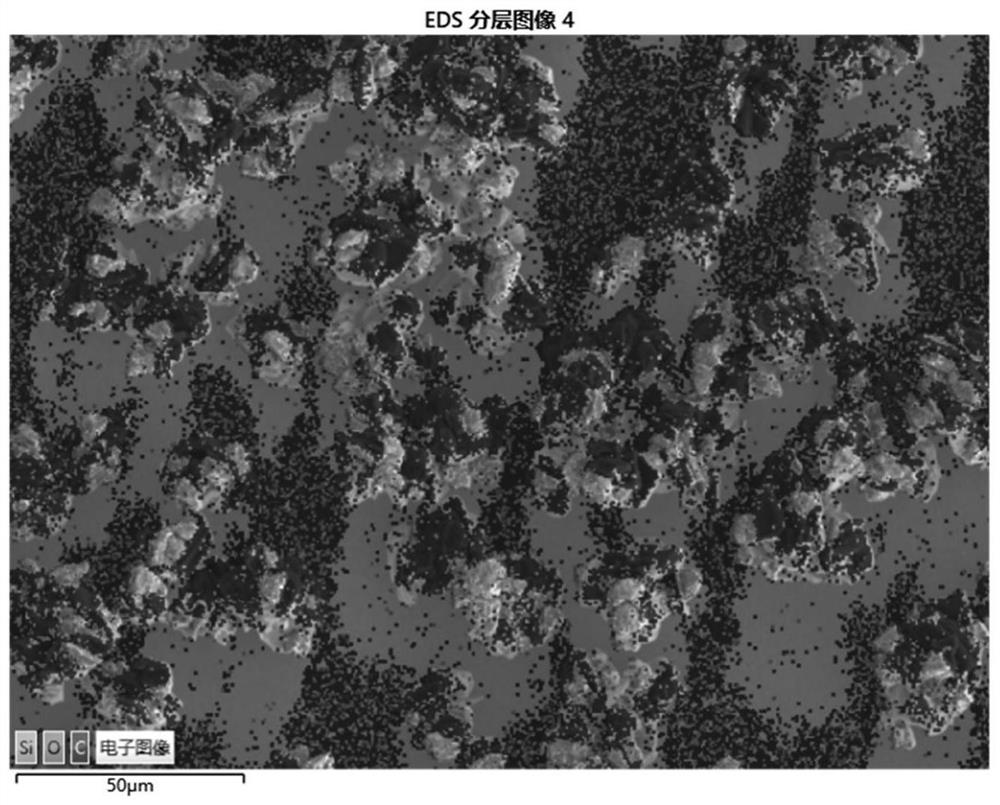

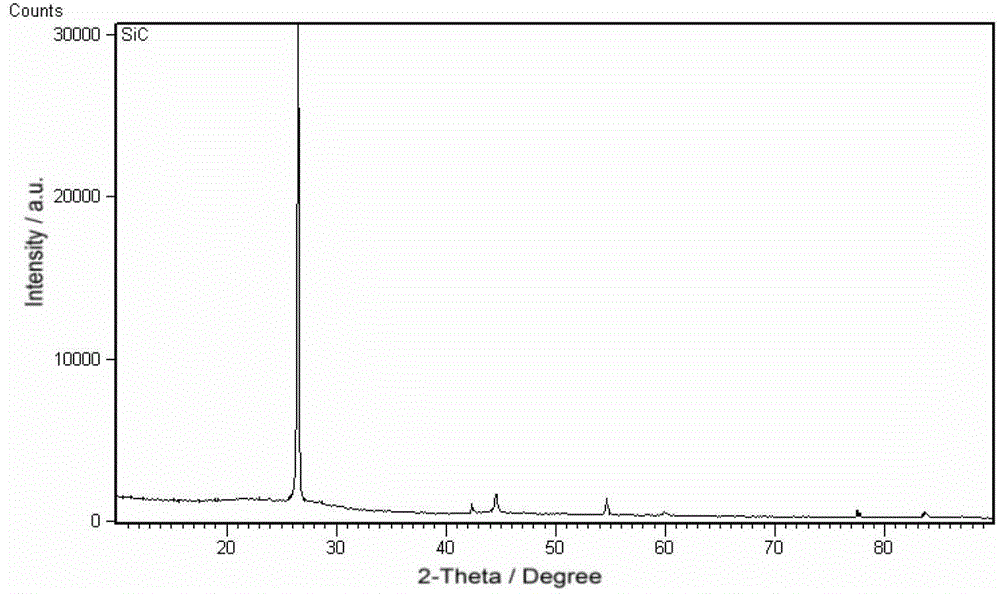

Method for synthesizing silicon/graphite/amorphous carbon/conductive carbon black quaternary composite material by using industrial metallurgical silicon

ActiveCN110571420AInhibition of volume expansion effectEvenly dispersedCell electrodesSecondary cellsCarbon compositesCarbon layer

The invention discloses a method for synthesizing a silicon / graphite / amorphous carbon / conductive carbon black quaternary composite material by using industrial metallurgical silicon, and belongs to the technical field of lithium ion battery materials. According to the silicon / graphite / amorphous carbon / conductive carbon black quaternary composite material prepared by the invention, silicon particles are uniformly dispersed in a carbon matrix, the conductivity of the silicon particles is improved, the binding force between silicon-carbon layers and the binding force between carbon-carbon layersare enhanced through secondary high-energy ball milling, the stability of the silicon-carbon composite structure is remarkably improved, the volume expansion effect of silicon is effectively inhibited, and the charge-discharge cycle life is prolonged.

Owner:ZHEJIANG NORMAL UNIVERSITY

Modified organic silicon polymer, preparation method thereof and lithium secondary battery

ActiveCN112592477AImprove adhesionImprove self-healing abilityCell electrodesSecondary cellsElastomerPtru catalyst

The invention belongs to the technical field of materials, and particularly relates to a modified organic silicon polymer, a preparation method thereof and a lithium secondary battery. The preparationmethod comprises the following steps: carrying out a hydrosilylation reaction on side-chain hydrogen-containing silicone oil and a modifier under the action of a catalyst, and grafting amino, alkoxyor carboxyl functional groups on the modifier onto the hydrogen-containing silicone oil through the reaction to obtain the modified organosilicon polymer. The obtained modified organic silicon polymeris an elastomer containing amino, alkoxy or carboxyl functional groups on a side chain, not only has good bonding performance and self-healing performance, but also can interact with functional groups such as hydroxyl on the surface of a silicon-based negative electrode to form a self-healing three-dimensional cross-linked network, effectively inhibits the volume expansion effect of the silicon-based negative electrode active material, and maintains the integrity of the silicon-based negative electrode structure in the charging and discharging process, so that the cycling stability of the obtained lithium secondary battery is improved.

Owner:SHENZHEN EUBO NEW MATERIAL TECH

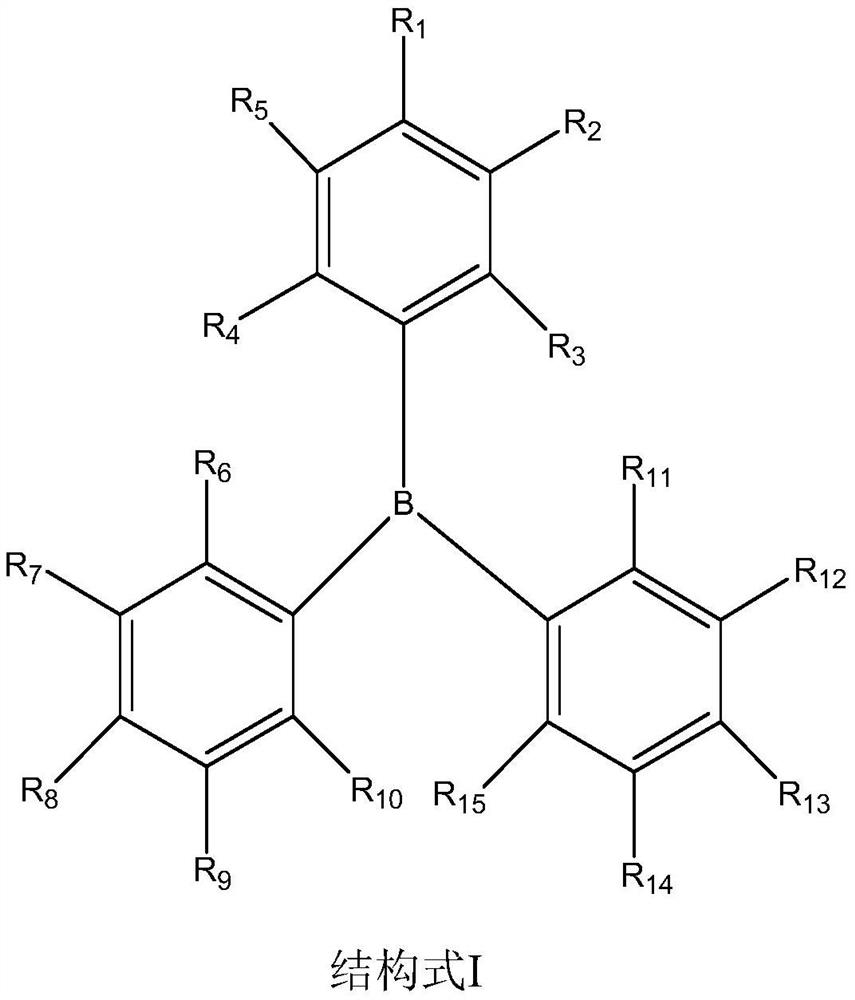

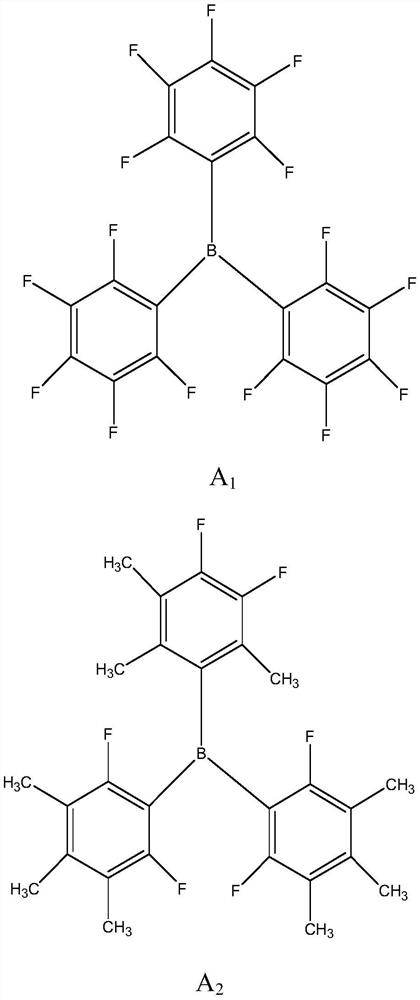

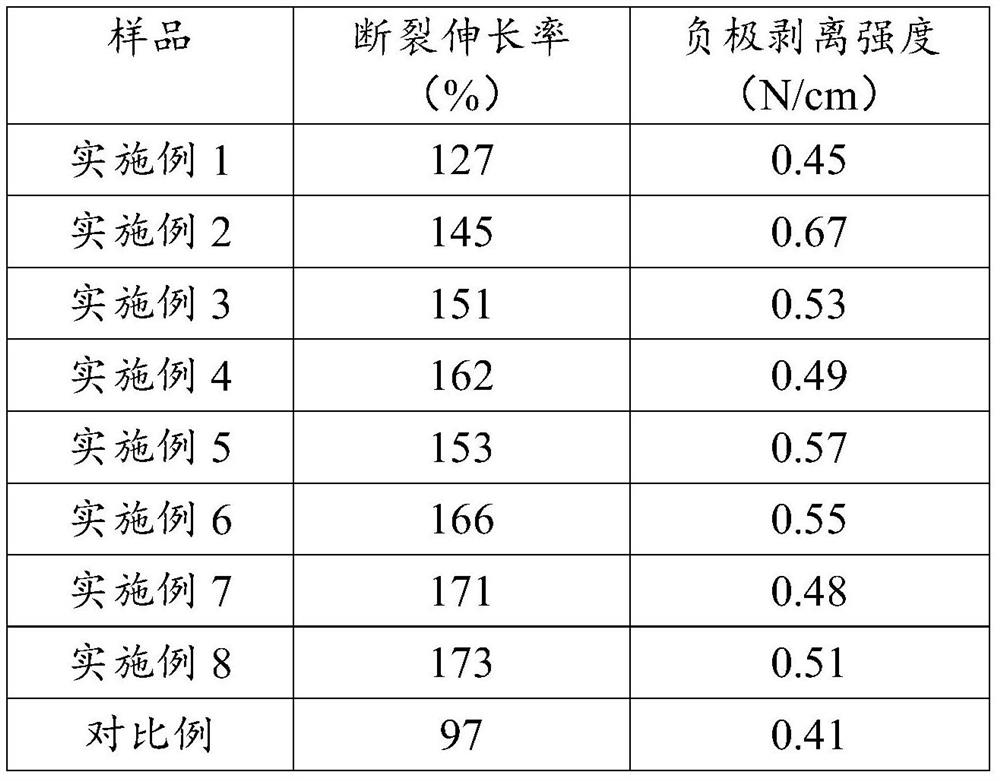

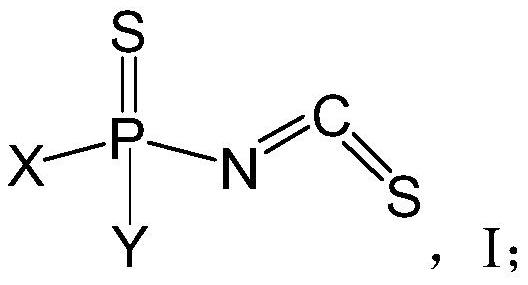

Electrolyte additive, electrolyte, and secondary battery

ActiveCN113506916AImprove cycle lifeImprove securityFinal product manufactureSecondary cells servicing/maintenanceElectrolytic agentElectrical battery

The invention belongs to the technical field of batteries, and particularly relates to an electrolyte additive, an electrolyte and a secondary battery. The structural general formula of the electrolyte additive is shown in a following formula I, and x and Y in the formula I are respectively and independently selected from one of isothiocyano group, cyclohexyl group, alkoxy group, phenyl group and halogen. According to the electrolyte additive provided by the invention, side reactions on the surface of a positive electrode can be reduced, flame-retardant phosphorus free radicals are generated, and the cycling stability and the safety performance of a pole piece are improved; and an SEI film can be polymerized on the surfaces of a positive electrode and a negative electrode, so that the elasticity of the SEI film is improved, the SEI film can better adapt to the huge volume expansion and shrinkage stress of electrode materials, such as a silicon substrate, etc., in a lithium intercalation and deintercalation process, and the cycling stability and safety of the battery are improved.

Owner:EVERGRANDE NEW ENERGY TECH SHENZHEN CO LTD

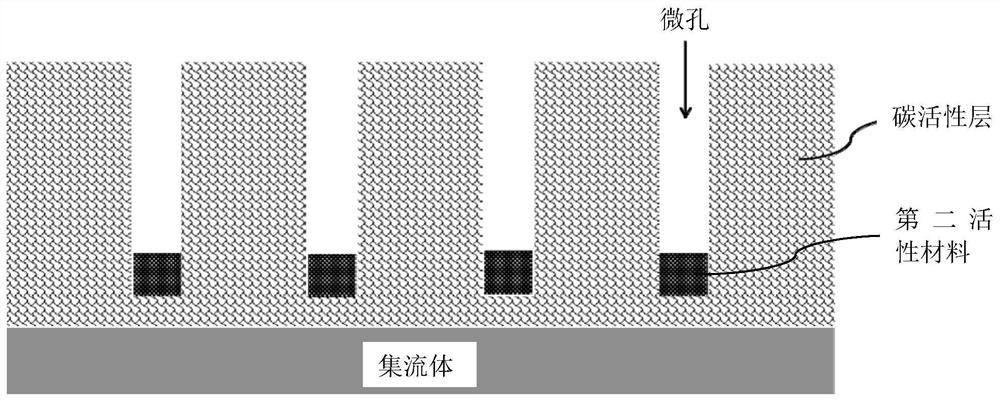

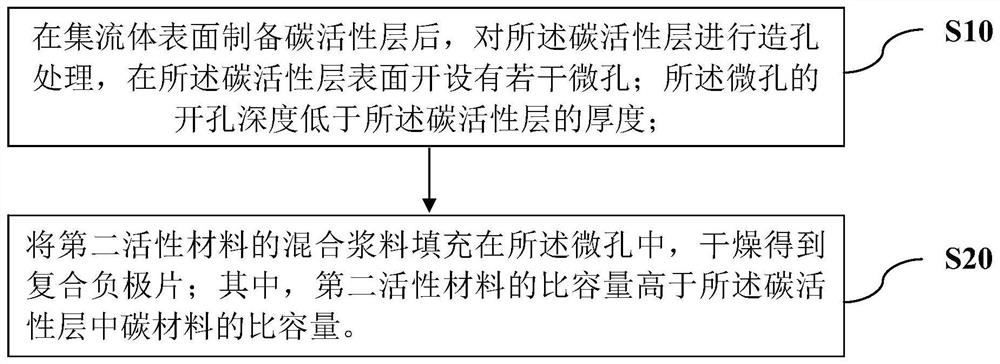

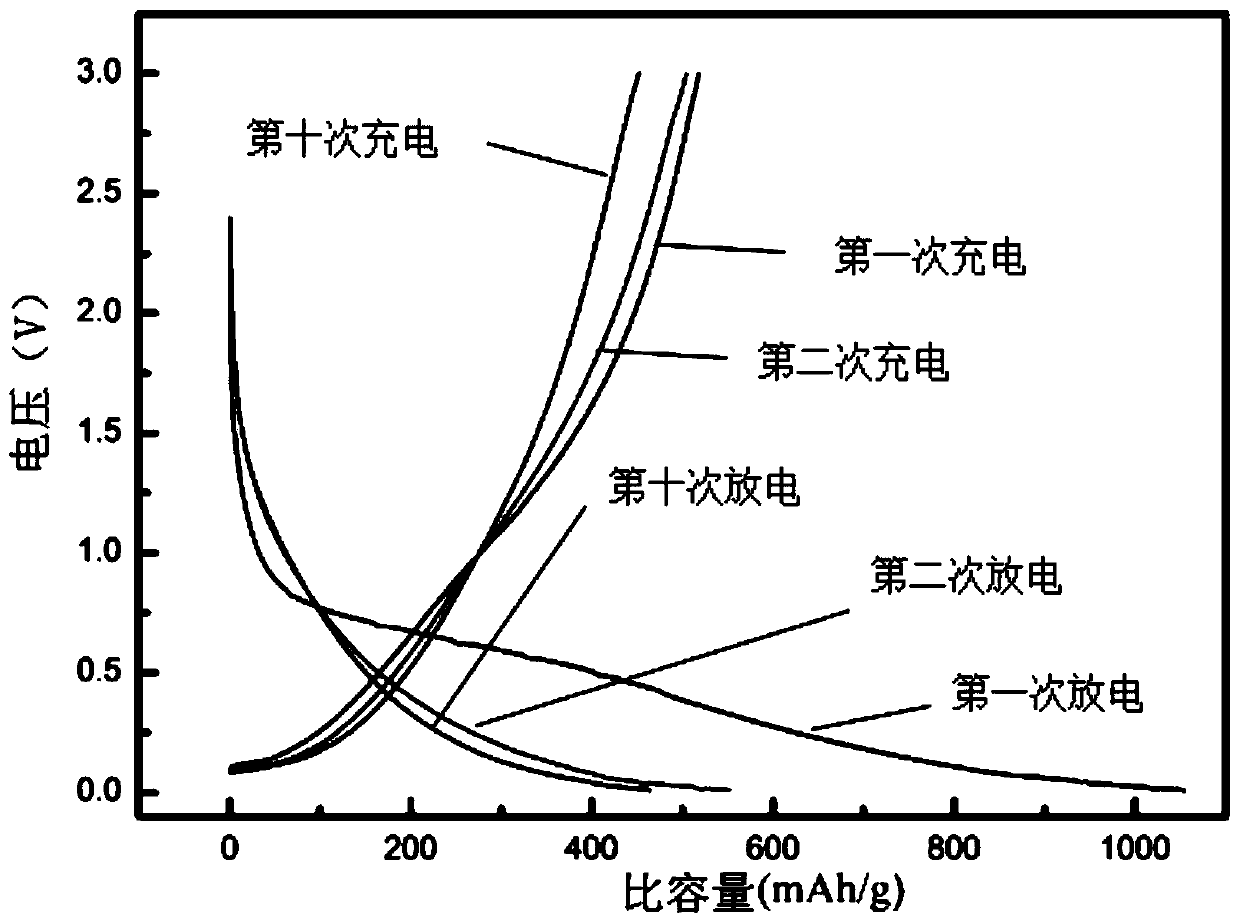

Composite negative plate and preparation method thereof, and secondary battery

PendingCN113644231AInhibition of volume expansion effectIncrease capacitySecondary cellsNegative electrodesCurrent collectorOpen cell

The invention belongs to the technical field of batteries, and particularly relates to a composite negative plate and a preparation method thereof, and a secondary battery. The composite negative plate comprises a current collector and a carbon active layer combined on the surface of the current collector, a plurality of micropores are formed in the surface, deviating from the current collector, of the carbon active layer, the micropores are filled with a second active material, and the specific capacity of the second active material is higher than that of a carbon material in the carbon active layer; and the opening depth of the micropores is lower than the thickness of the carbon active layer. According to the composite negative plate disclosed by the invention, through the synergistic effect of the carbon active layer and the second active material which is filled in the micropores and has higher a specific capacity, the capacity of the composite negative plate can be improved so that the capacity density of the battery is improved, and the volume expansion effect of the active material can be relieved or even inhibited through the carbon active layer; and the microporous structure is also beneficial to improving the ion migration transmission efficiency, improving the electrolyte retention capacity of the pole piece and improving the electrochemical performance of the composite pole piece.

Owner:EVERGRANDE NEW ENERGY TECH SHENZHEN CO LTD

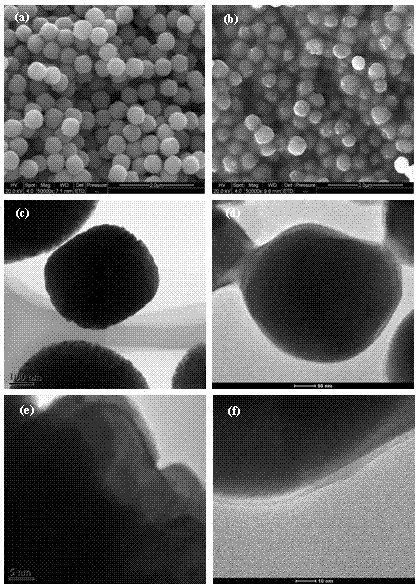

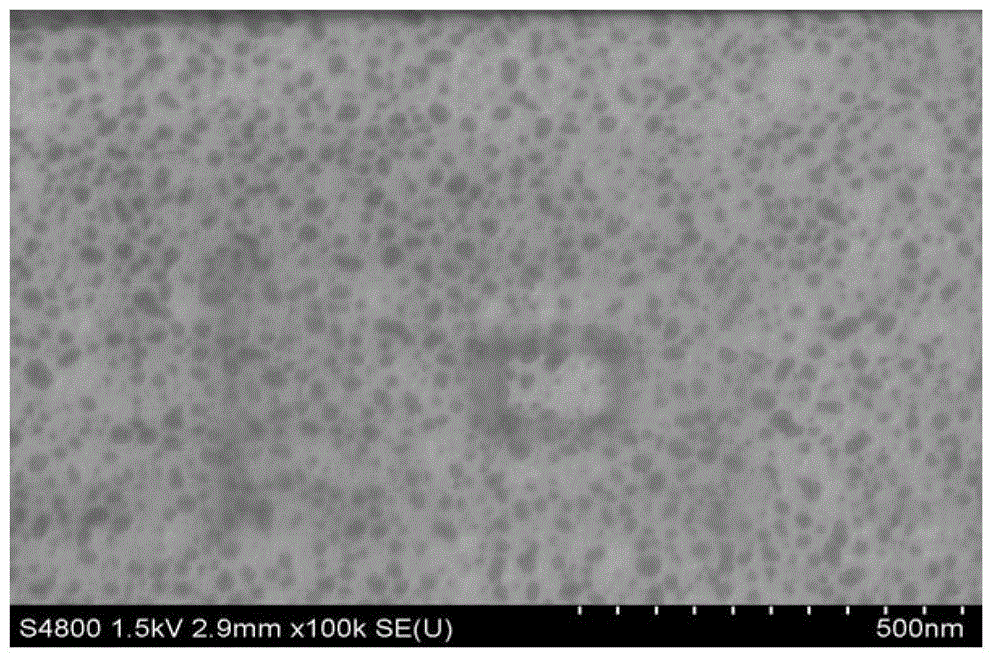

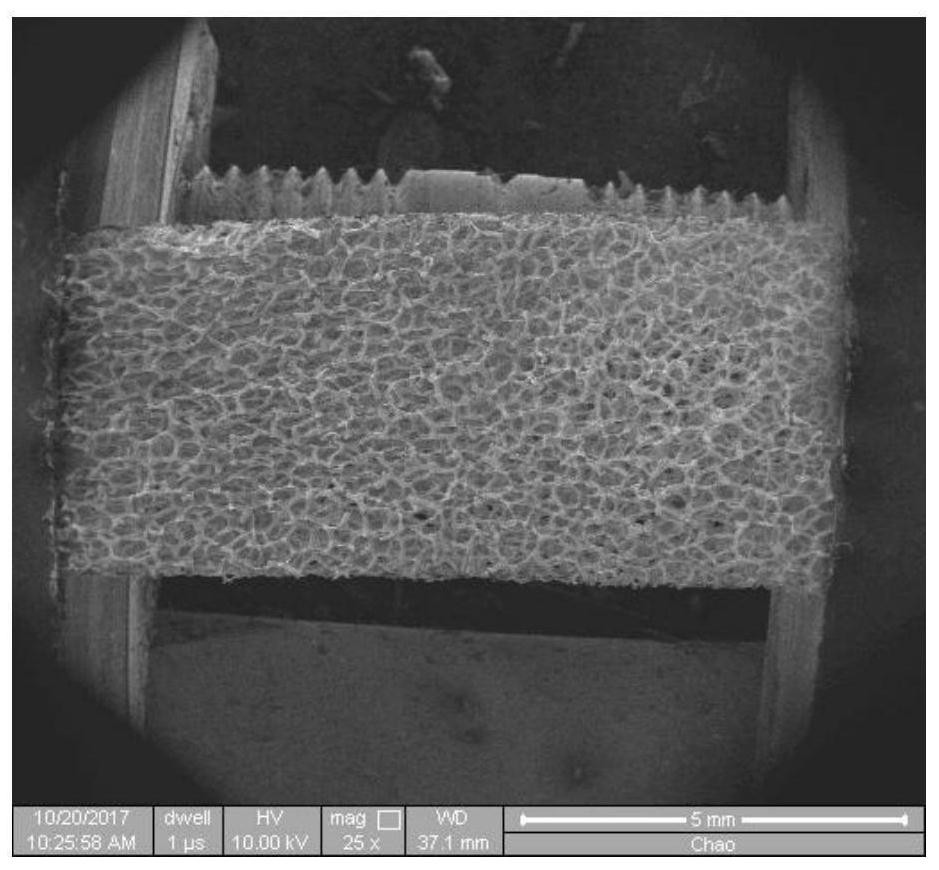

Preparation method and application of transition metal oxide/graphitized mesocarbon microbead composite material

InactiveCN109728290AImprove conductivityInhibition of volume expansion effectCell electrodesSecondary cellsMicrosphereFiltration

The invention provides a preparation method and an application of a transition metal oxide / graphitized mesocarbon microbead composite material. The preparation method comprises the steps of firstly preparing surface oxidized graphitized mesocarbon microbeads, then adding the surface oxidized graphitized mesocarbon microbeads into an aqueous solution of transition metal chloride, slowing drippinga precipitating agent, stirring, carrying out pumping filtration, drying, and carrying out calcining heat treatment in an inert atmosphere. The material can directly serve as an anode material for lithium ion batteries, and has excellent rate performance and cycle performance. The whole preparation process of the composite material is simple to operate, and the reaction conditions are easy to control.

Owner:安徽益佳通电池有限公司

Silicon-carbon composite material as well as preparation method and application thereof

ActiveCN113611844AImprove activity stabilityImprove cycle stabilityNegative electrodesSecondary cellsCarbon compositesSolid state electrolyte

The invention discloses a silicon-carbon composite material and a preparation method and application thereof. A chemical vapor deposition method is adopted for preparing a graphene foam body which is subjected to in-situ toughening through a carbon nano toughening agent and has carbon nano tubes growing on the surface of the graphene foam body, and then the Si powder or SiOx powder with the carbon nano tubes or carbon nano sheets growing on the surface of the Si powder or SiOx powder is loaded in the graphene foam body, so that a flexible electrode based on the silicon-carbon composite material with a novel structure is prepared and is used as a negative electrode of a semi-solid, quasi-solid or all-solid-state battery. The silicon-carbon composite material prepared by the invention has the characteristics of high capacity and high cycle stability, has excellent interface wettability, stability and ion / electron conductivity with solid electrolyte, does not need a current collector, and remarkably improves the energy density and power density of the solid-state battery.

Owner:重庆锦添翼新能源科技有限公司 +1

Pole sheet preparation method for improving performance of silicon-based negative electrode lithium ion battery

PendingCN113948679AQuality improvementImprove efficiencyCell electrodesElectrolytic agentCopper foil

The invention discloses a preparation method of a pole sheet for improving the performance of a silicon-based negative electrode lithium ion battery. The method comprises the following steps: dissolving a modified additive into deionized water / absolute ethyl alcohol in a certain proportion to obtain a modified additive solution, and fully mixing a silicon-based negative electrode material, a conductive agent, a binder and the modified additive solution in a certain mass ratio to form a slurry-like substance, wherein the modified additive is a plurality of aromatic organic matters and must contain one of aromatic acid or aromatic aldehyde and one of aromatic alcohol or aromatic amine; and then uniformly coating the surface of a copper foil with the slurry-like substance, and respectively carrying out drying at 50-80 DEG C for 30-60 minutes and vacuum drying at 100-150 DEG C for 10-20 hours to obtain the silicon-based negative pole sheet. According to the invention, the poor contact property caused in the silicon particle expansion process is effectively improved, the problems of lattice volume expansion, silicon particle pulverization, repeated growth of SEI films on the surfaces of silicon particles, electrolytic solution consumption and the like after the silicon-based material is charged and discharged are solved, and the first efficiency, rate discharge and cycle performance of the prepared battery are improved.

Owner:NANCHANG UNIV

Preparation method of CZTSSe thin film and application of CZTSSe thin film in lithium ion battery

ActiveCN110029317AGuaranteed electrical conductivityAvoid complex processesCell electrodesVacuum evaporation coatingHigh energyCopper foil

The invention discloses a preparation method of a copper-zinc-tin sulfide-selenide (CZTSSe) thin film and application of the thin film in a lithium ion battery. By means of a magnetron sputtering method, by means of copper foil treated with Se, the atmosphere with Se and S plasma is created in a sputtering cavity, and a Cu-Zn-Sn-S-Se precursor is synthesized through reactive sputtering. The thin film is arranged in the protective atmosphere, and after high-temperature annealing, the CZTSSe thin film is obtained. The preparation method is simple and effective, the uniformity and the stability of the preparation material are guaranteed, meanwhile, the material integrates the advantages of metal sulfide-selenide and has high energy density and circulating stability, and the discharge performance of the battery is effectively improved.

Owner:CENT SOUTH UNIV

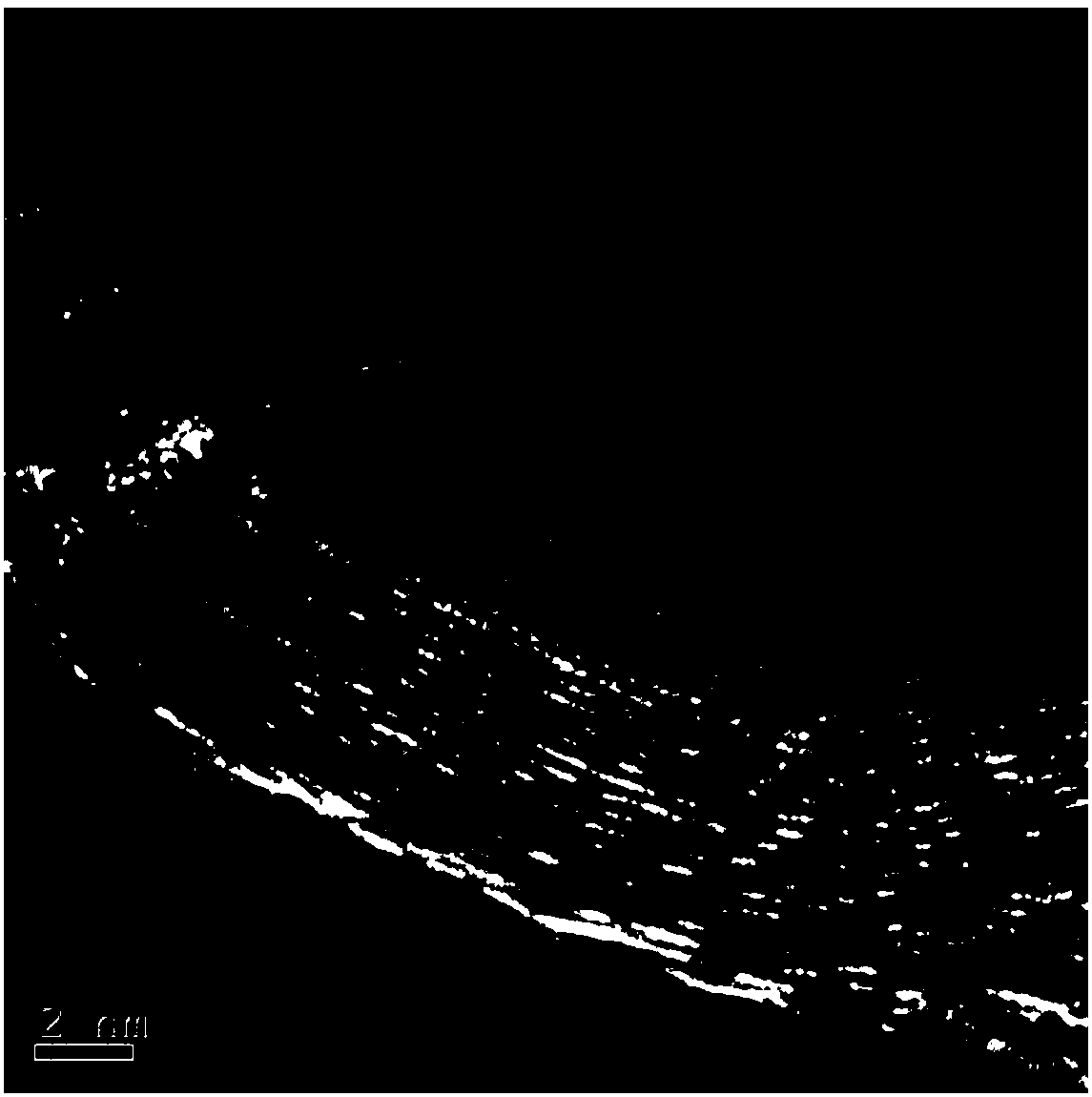

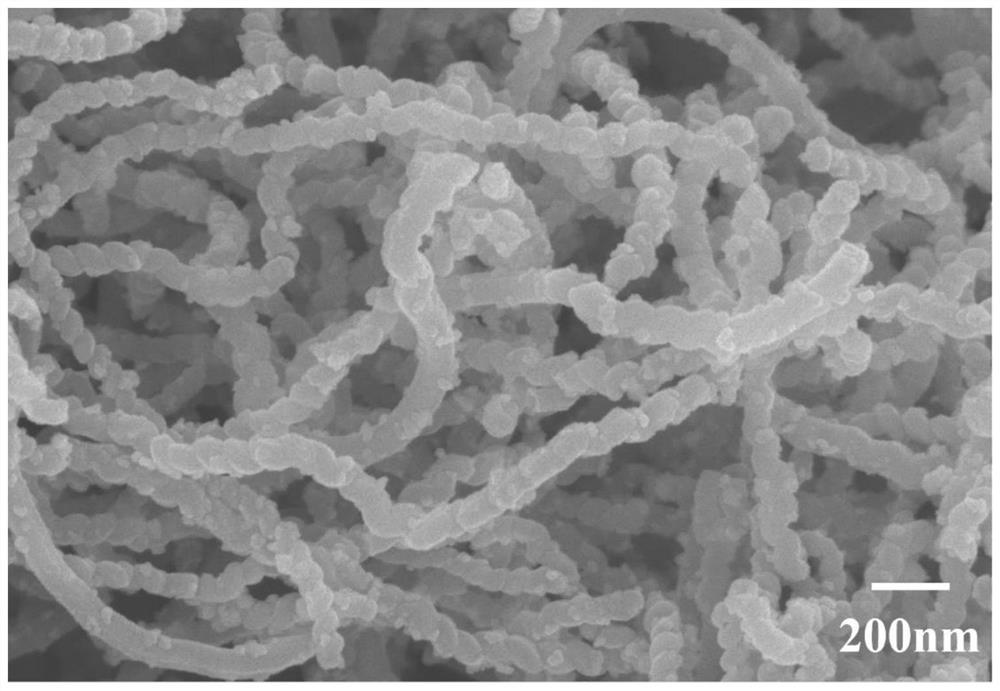

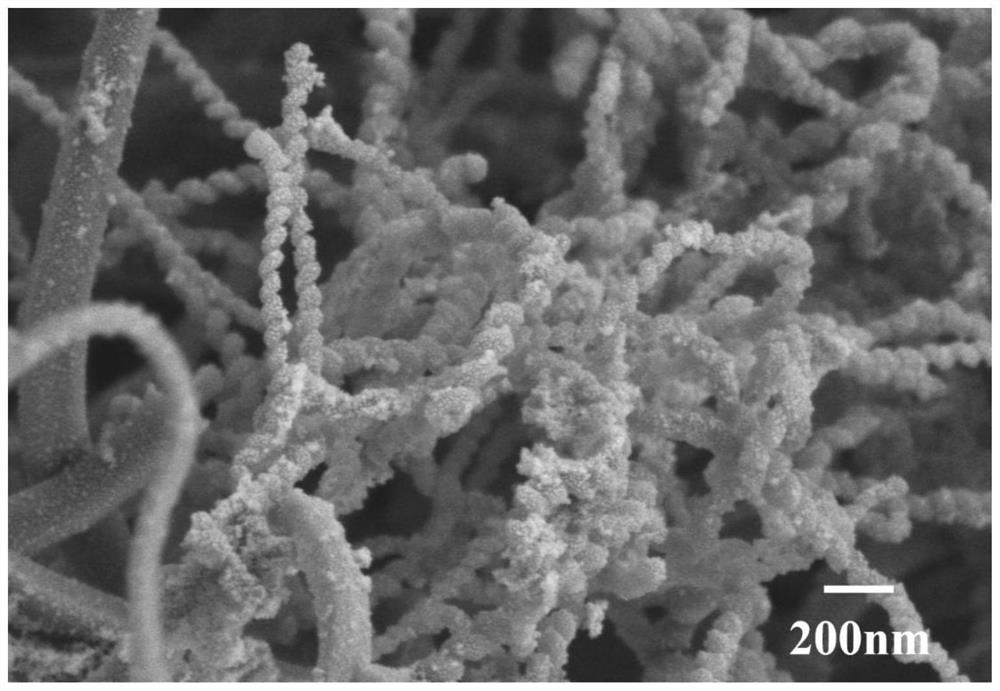

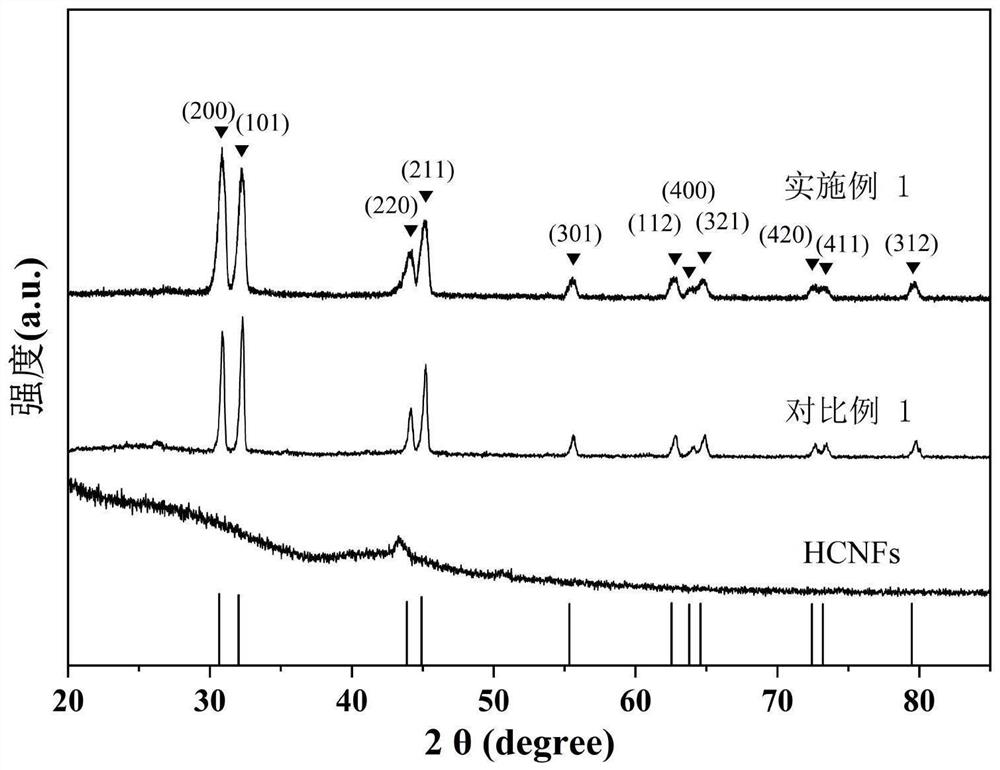

Carbon-tin nano composite material as well as preparation method and application thereof

ActiveCN114597369AImprove conductivityInhibition of volume expansion effectCell electrodesFiberCarbon coating

According to the carbon tin nano composite material and the preparation method and application thereof, the conductivity of the composite material is improved by utilizing a three-dimensional network structure formed by spiral nano carbon fibers, and network gaps of the structure provide a buffer space for expansion of tin nano particles grafted on the surfaces of the fibers, so that the conductivity of the carbon tin nano composite material is improved. The volume expansion effect of tin is inhibited, tin nanoparticles with small particle size and uniform distribution are generated by utilizing a sol-gel method and a reduction reaction and are uniformly grafted to the surface of the fiber, the volume expansion effect of tin is reduced by nanocrystallization of tin, the cycling stability of the composite material is improved, and a carbon coating layer is formed by a vapor deposition method, so that the composite material is prepared. According to the invention, tin nanoparticles are used as an intermediate layer and cooperate with HCNFs and a carbon coating layer to form a sandwich structure, so that the volume expansion effect of tin is effectively inhibited, the cycling stability and the capacity rate are improved, and the specific capacity can reach 503.9 mAh / g under the current density of 200mA / g and the cycle index is 200.

Owner:SICHUAN UNIVERSITY OF SCIENCE AND ENGINEERING

Polyacrylonitrile-Li3VO4 lithium-ion battery anode material and preparation method thereof

PendingCN110600717ALoss of electrochemical performanceImprove practicalityCell electrodesSecondary cellsCross-linkElectrolysis

The invention relates to the technical field of Li3VO4 lithium-ion battery anode materials, and discloses a polyacrylonitrile-Li3VO4 lithium-ion battery anode material, which includes the following formula materials: ammonium metavanadate, polyvinylpyrrolidone, lithium carbonate, polyacrylonitrile, an adhesive, and a conductive agent. In the polyacrylonitrile-Li3VO4 lithium-ion battery anode material, the polar polymer material polyacrylonitrile is added to generate a self-cyclization reaction to generate a cyclic polytetrahydropyridine derivative, of which a large amount of sp2 hybridizationcarbon can effectively promote the electron transfer rate and the rate performance of the electrode in an electrolytic reaction; and during the cyclization reaction, the polytetrahydropyridine derivative and the Li3VO4 are closely cross-linked together. Further, the flexible polymer chain of the polytetrahydropyridine derivative can suppress the volume expansion effect of the Li3VO4 during the delithiation and lithiation process of the electrode material, improve the cycle stability performance, and prevents the matrix structure of the anode material from collapsing and losing electrochemicalperformance.

Owner:刘怀金

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com