Tin-phosphide composite material and preparation method and application thereof

A composite material and tin phosphide technology, applied in electrochemical generators, electrical components, battery electrodes, etc., can solve problems such as poor conductivity and large volume expansion, and meet low equipment requirements, inhibit volume expansion, and good conductivity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] Specifically, the preparation method of the tin phosphide composite material at least includes the following steps:

[0035] Mixing tin source materials and carbon source materials and maintaining them under alkaline conditions for hydrothermal reaction to obtain hollow tin dioxide balls with carbon sources attached to the surface;

[0036] Under an inert atmosphere, carbonize the obtained hollow tin dioxide balls to obtain hollow tin dioxide balls with a carbon layer on the surface;

[0037] Mixing the hollow tin dioxide balls covered with carbon layer and the phosphorus source material, and heating in an inert atmosphere to make the two react to obtain the tin phosphide composite material;

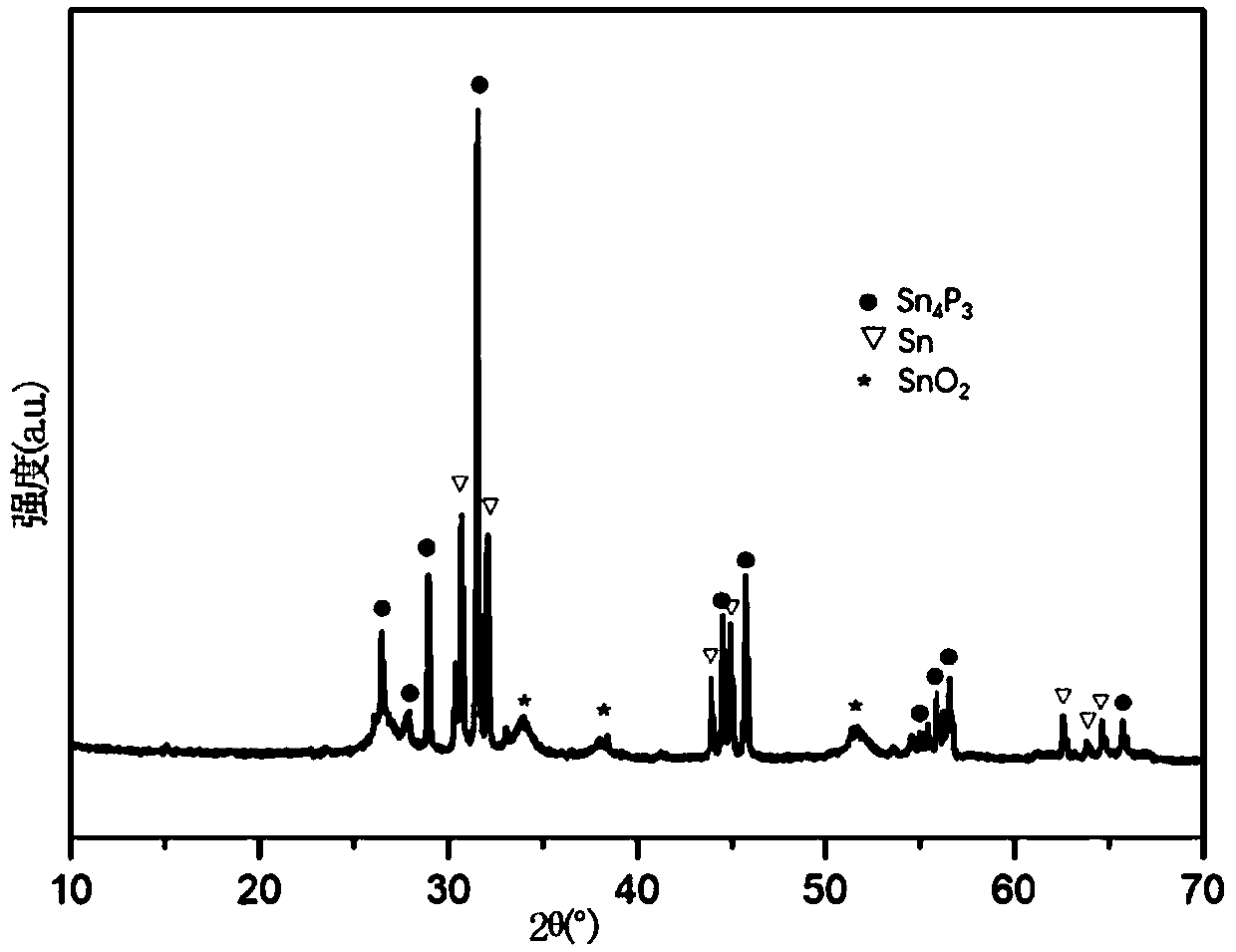

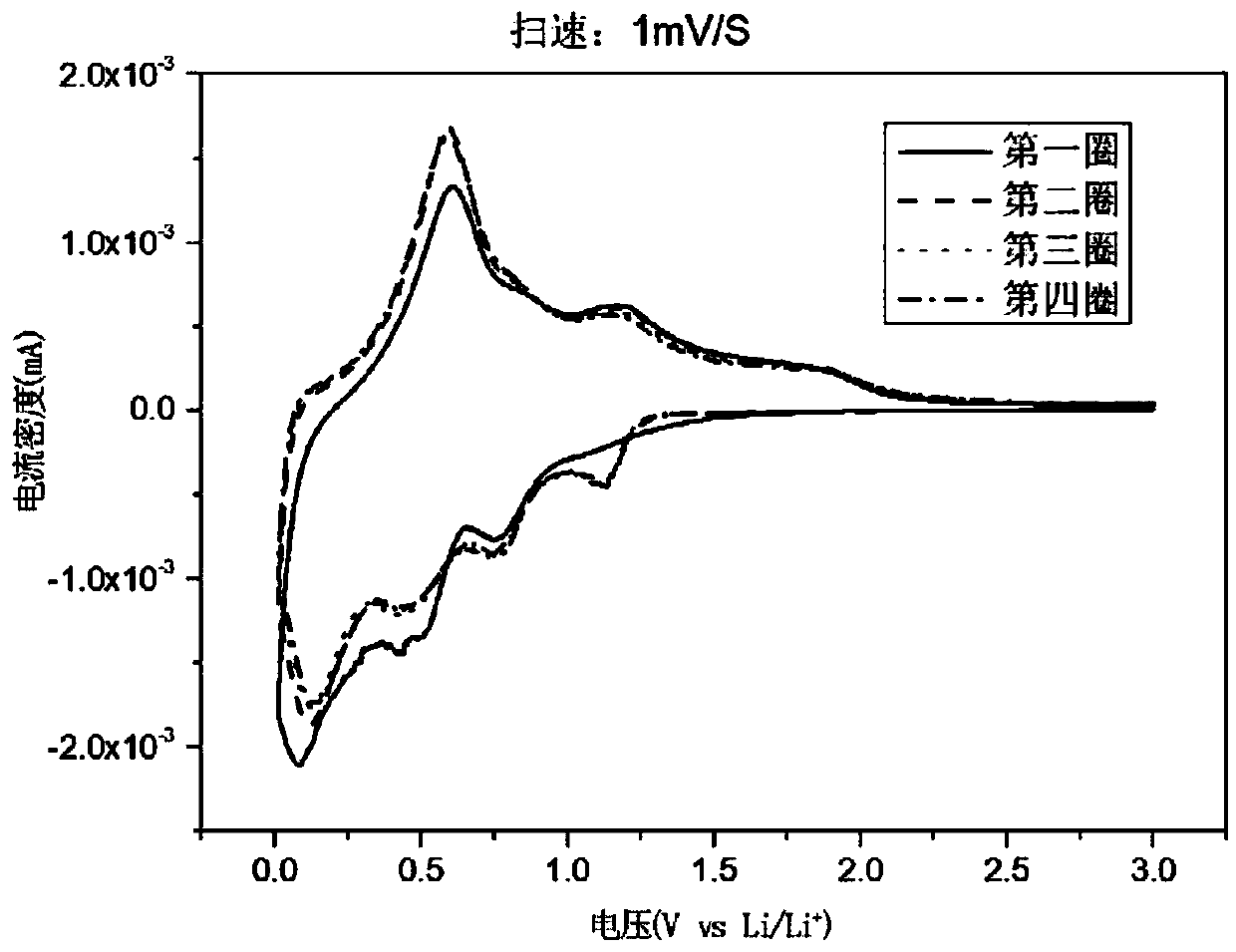

[0038] The tin phosphide composite material at least contains tin phosphide, hollow tin dioxide and carbon, and the carbon is coated on the surface of the tin phosphide and hollow tin dioxide.

[0039] The preparation method of the above-mentioned tin phosphide composite material...

Embodiment 1

[0062] A preparation method of a tin phosphide composite material, specifically comprising the following steps:

[0063] (1) Weigh 1.5g of K 2 SnO 3 ·3H 2 O (potassium stannate), 1.2g urea, 1.2g polyvinyl alcohol (alcoholysis degree is 87%), prepare deionized water 180mL, absolute ethanol 120mL simultaneously;

[0064] (2) After mixing the above-mentioned potassium stannate, polyvinyl alcohol, urea, deionized water, and absolute ethanol until uniform, the first mixed material is obtained, and then the first mixed material is placed in the polytetrafluoroethylene liner React at 150° C. for 15 h in a reaction kettle, centrifuge and wash with ethanol and deionized water, and vacuum-dry at 60° C. for 12 h.

[0065] (3) The dried sample was placed in a tube furnace, fed with argon, reacted at 400° C. for 4 hours, and cooled to obtain a hollow spherical tin dioxide material coated with amorphous carbon on the surface.

[0066] (4) Mix 1.5 g of the hollow spherical tin dioxide ma...

Embodiment 2

[0076] A preparation method of a tin phosphide composite material, specifically comprising the following steps:

[0077] (1) Weigh 1.5g of K 2 SnO 3 ·3H 2 O (potassium stannate), 1.2g urea, 1.2g polyvinyl alcohol (87% degree of alcoholysis), and prepare 300mL of deionized water;

[0078] (2) After mixing the above-mentioned potassium stannate, polyvinyl alcohol, urea, and deionized water until uniform, the first mixed material is obtained, and then the first mixed material is placed in a reaction kettle with a polytetrafluoroethylene liner, React at 150°C for 15h, centrifuge and wash with ethanol and deionized water, and vacuum dry at 60°C for 12h.

[0079] (3) The dried sample was placed in a tube furnace, fed with argon, reacted at 400° C. for 4 hours, and cooled to obtain a hollow spherical tin dioxide material coated with amorphous carbon on the surface.

[0080](4) Get 1.5 g of the hollow spherical tin dioxide material obtained in step (3) and mix it with 8 g of sodiu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com