Preparation method of lithium-sulfur battery applicable to industrialized production

A lithium-sulfur battery and conductive agent technology, applied in the field of electrochemical batteries, can solve the problems of cumbersome and difficult preparation of lithium-sulfur battery positive electrodes, achieve significant commercial value, and inhibit dissolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A preparation of a lithium-sulfur battery suitable for industrialized production, comprising the following steps:

[0033] Pretreatment of graphene:

[0034] Graphene (with a sheet diameter of 10-20 microns, a thickness of 5-20 nanometers, and a specific surface area of 34.193m 2 / g) spread evenly on a clean glass plate, and put it into a plasma cleaner to clean it. During the cleaning process, the working voltage was set to 600V, the oxygen flow rate was set to 500mL / min, and the cleaning time was 5 minutes. After cleaning, the graphene was put into a vacuum drying oven and stored at 50°C for future use.

[0035] Pretreatment of carbon cloth collector:

[0036] Carbon cloth (thickness 0.32 ~ 0.36mm, density 150 ~ 175g / cm 3 ) on a clean glass plate, and put it into an oxygen plasma cleaning machine to clean it. During the cleaning process, the working voltage was set to 600V, the oxygen flow rate was set to 500mL / min, and the cleaning time was 5 minutes. After cle...

Embodiment 2

[0057] Pretreatment of graphene:

[0058] Graphene (with a sheet diameter of 10-20 microns, a thickness of 5-20 nanometers, and a specific surface area of 34.193m 2 / g) spread evenly on a clean glass plate, and put it into a plasma cleaner to clean it. During the cleaning process, the working voltage was set to 600V, the oxygen flow rate was set to 500mL / min, and the cleaning time was 5 minutes. After cleaning, the graphene was put into a vacuum drying oven and stored at 50°C for future use.

[0059] Positive pole piece preparation:

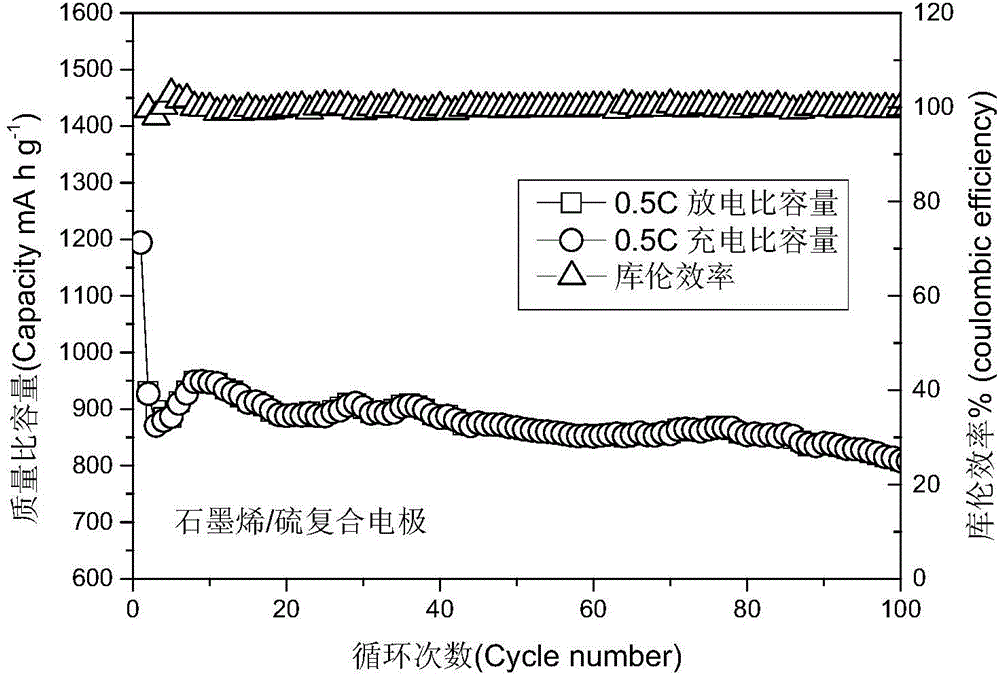

[0060] Mix graphene and elemental sulfur with a mass ratio of 3:7, then put the mixture in a high-speed ball mill with ethanol as a solvent, set 500 cycles per minute, and run for 24 hours. Take the mixed solution out of the ball mill, put it upside down in a clean glass watch glass, and dry it in vacuum at 50°C for 24 hours to obtain the graphene / sulfur composite powder; place the composite powder in a tube furnace, Under the protection of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com