Lithium-ion battery silicon-carbon anode material and preparation method thereof

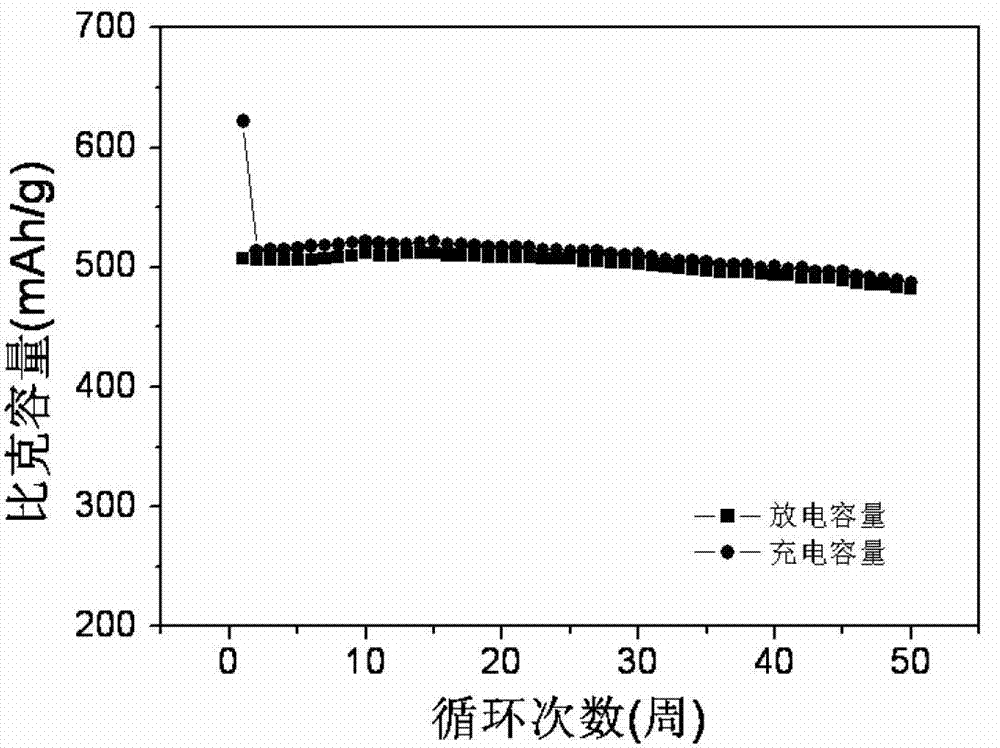

A technology for lithium ion batteries and negative electrode materials, which is applied to battery electrodes, circuits, electrical components, etc., can solve the problems of affecting battery cycle performance and low Coulomb efficiency, and achieve good cycle stability, simple preparation process, and high specific capacity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] The preparation method of silicon carbon negative electrode material for lithium ion battery of the present invention comprises the following steps:

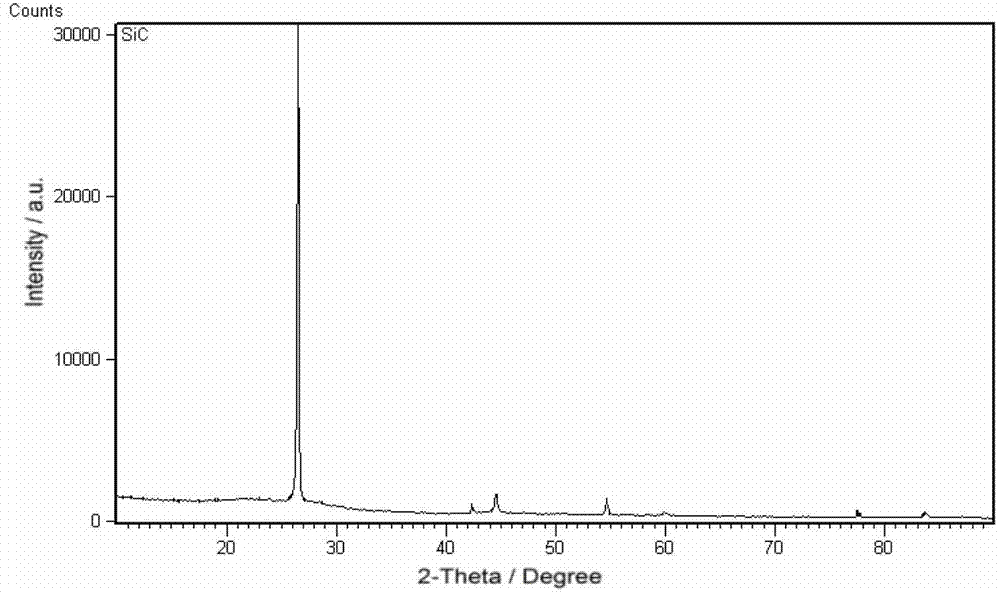

[0028] 1. Heat treatment: SiO with a particle size of 1-1000 μm Y , where 0.5≤Y≤1.5, the temperature is raised to 700-1300 °C at a heating rate of 1-2 °C / min, kept for 1-12 hours, and naturally cooled to room temperature. During the heat preservation process, SiO Y A disproportionation reaction will occur at high temperature, and a single silicon phase will be formed, so that the single particle Si is evenly dispersed in the SiO x , forming a mixture, SiO x It is crystalline and / or amorphous, 0.5<x≤2.0, Si is 0.5-50nm single crystal silicon and / or polycrystalline silicon.

[0029] During the process from the beginning of heating to the end of cooling, one or more protective gases such as nitrogen, argon or reducing gas are introduced, and the flow rate is 0.1-0.5m 3 / h.

[0030] The microstructure and shape of the mi...

Embodiment 1

[0043] 1. SiO with a particle size of 1-300 μm 1.0 Carry out heat treatment, pass into high-purity nitrogen protection, the flow rate is 0.2m 3 / h, the heating rate is 1°C / min, the temperature is raised to 1300°C, kept for 6h, and naturally cooled to room temperature. Uniform dispersion of Si particles in SiO x in, because SiO 1.0 Partially differentiated at high temperature to form silicon oxide with x between 1.0 and 2.0, then 1.0figure 1 As shown, Si is in the state of single crystal silicon and polycrystalline silicon of 0.5-50nm, dispersed in SiO x middle.

[0044] 2. Ball milling the mixture to obtain an oxygen-containing silicon-based material with a particle size of 100-300 nm.

[0045] 3. According to the mass percentage, mix and disperse 40% oxygen-containing silicon-based materials, 40% artificial graphite and alcohol to form a slurry evenly, control the solid content of the slurry at 40%, and dry the slurry to obtain a dried product. Then mix and disperse 20% ...

Embodiment 2

[0050] 1. SiO with a particle size of 20-500 μm 0.5 Carry out heat treatment, pass into high-purity nitrogen protection, the flow rate is 0.1m 3 / h, the heating rate is 2°C / min, the temperature is raised to 700°C, kept for 12h, and naturally cooled to room temperature. Uniform dispersion of Si particles in SiO x , forming a mixture, SiO x It is amorphous, 0.5<x≤2.0, Si is 0.5~50nm single crystal silicon and polycrystalline silicon.

[0051] 2. Grinding the mixture to obtain an oxygen-containing silicon-based material with a particle size of 50-250 nm.

[0052] 3. According to mass percentage, mix and disperse 85% oxygen-containing silicon-based materials, 5% mesophase carbon microspheres and alcohol to form a slurry evenly, control the solid content of the slurry at 5%, and dry the slurry to obtain dry matter, and then mix and disperse 10% polyacrylonitrile, dry matter and alcohol to form a slurry, control the solid content of the slurry at 45%, and dry the slurry to obtai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com