Preparation method for foam graphene compound indium zinc sulfide material

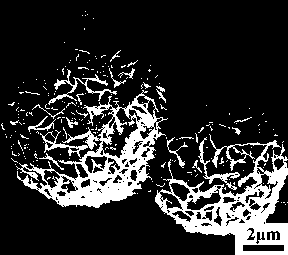

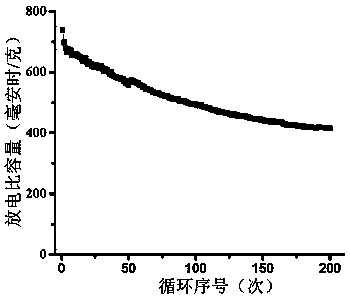

A technology of foamed graphene and indium zinc sulfide, applied in the field of material chemistry, can solve the problems of slow diffusion capacity, low theoretical specific capacity, limiting battery energy and power density, etc., achieve obvious structure, strong adsorption, and inhibit volume expansion effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] (1) Preparation of graphene oxide

[0024] Place graphene oxide in deionized water to prepare a graphene oxide aqueous solution with a concentration of 10 mg / mL, and disperse it ultrasonically for 10 minutes;

[0025] (2) Preparation of foamed graphene

[0026] Cut the nickel foam with a thickness of 1 mm into a square with a side length of 2 cm, immerse it in 10 mL of the graphene oxide aqueous solution prepared in step (1), and disperse it ultrasonically for 30 minutes so that the graphene oxide is fully immersed in the porous structure of the nickel foam. The completed nickel foam is taken out, then immersed in a 20 mg / ml sodium ascorbate solution, and soaked for 24 hours to fully reduce the graphene oxide to obtain a precursor, and then immerse the prepared precursor in polydimethylsiloxane, After soaking for 60 minutes, place it in an oven and dry at 80°C for 24 hours to obtain a graphene-nickel foam composite, then place the graphene-nickel foam composite in 98% ...

Embodiment 2

[0032] (1) Preparation of graphene oxide

[0033] Graphene oxide was placed in deionized water, configured into a graphene oxide aqueous solution with a concentration of 5 mg / mL, and ultrasonically dispersed for 5 minutes;

[0034] (2) Preparation of foamed graphene

[0035] Cut the nickel foam with a thickness of 1 mm into a square with a side length of 2 cm, immerse it in 5 mL of the graphene oxide aqueous solution prepared in step (1), and disperse it ultrasonically for 20 minutes so that the graphene oxide is fully immersed in the porous structure of the nickel foam. The completed nickel foam is taken out, then immersed in a 10 mg / ml sodium ascorbate solution, and soaked for 12 hours to fully reduce the graphene oxide to obtain a precursor, and then immerse the prepared precursor in polydimethylsiloxane, After soaking for 30 minutes, place in an oven and dry at 50°C for 12 hours to obtain a graphene-nickel foam composite, then place the graphene-nickel foam composite in 98%...

Embodiment 3

[0039] (1) Preparation of graphene oxide

[0040] Graphene oxide was placed in deionized water, configured into a graphene oxide aqueous solution with a concentration of 8 mg / mL, and ultrasonically dispersed for 10 minutes;

[0041] (2) Preparation of foamed graphene

[0042] Cut the nickel foam with a thickness of 1 mm into a square with a side length of 2 cm, immerse it in 8 mL of the graphene oxide aqueous solution prepared in step (1), and disperse it ultrasonically for 25 minutes to fully immerse the graphene oxide in the porous structure of the nickel foam. The completed nickel foam is taken out, then immersed in a 15 mg / ml sodium ascorbate solution, and soaked for 18 hours to fully reduce the graphene oxide to obtain a precursor, and then immerse the prepared precursor in polydimethylsiloxane, After soaking for 30 minutes, put it in an oven and dry at 70°C for 18 hours to obtain a graphene-nickel foam composite, then place the graphene-nickel foam composite in 98% conc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com