Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

43results about How to "Reduced likelihood of stripping" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

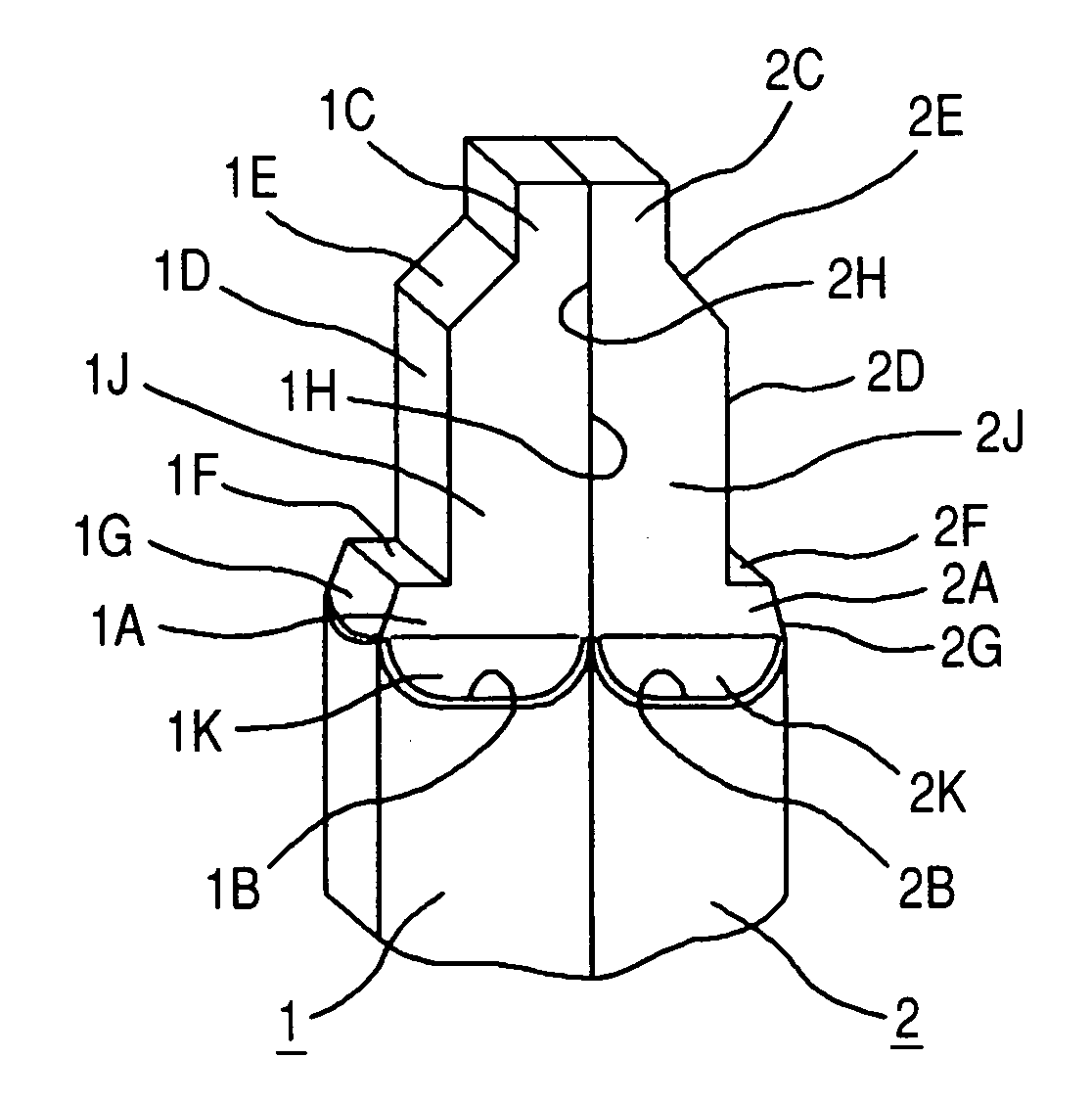

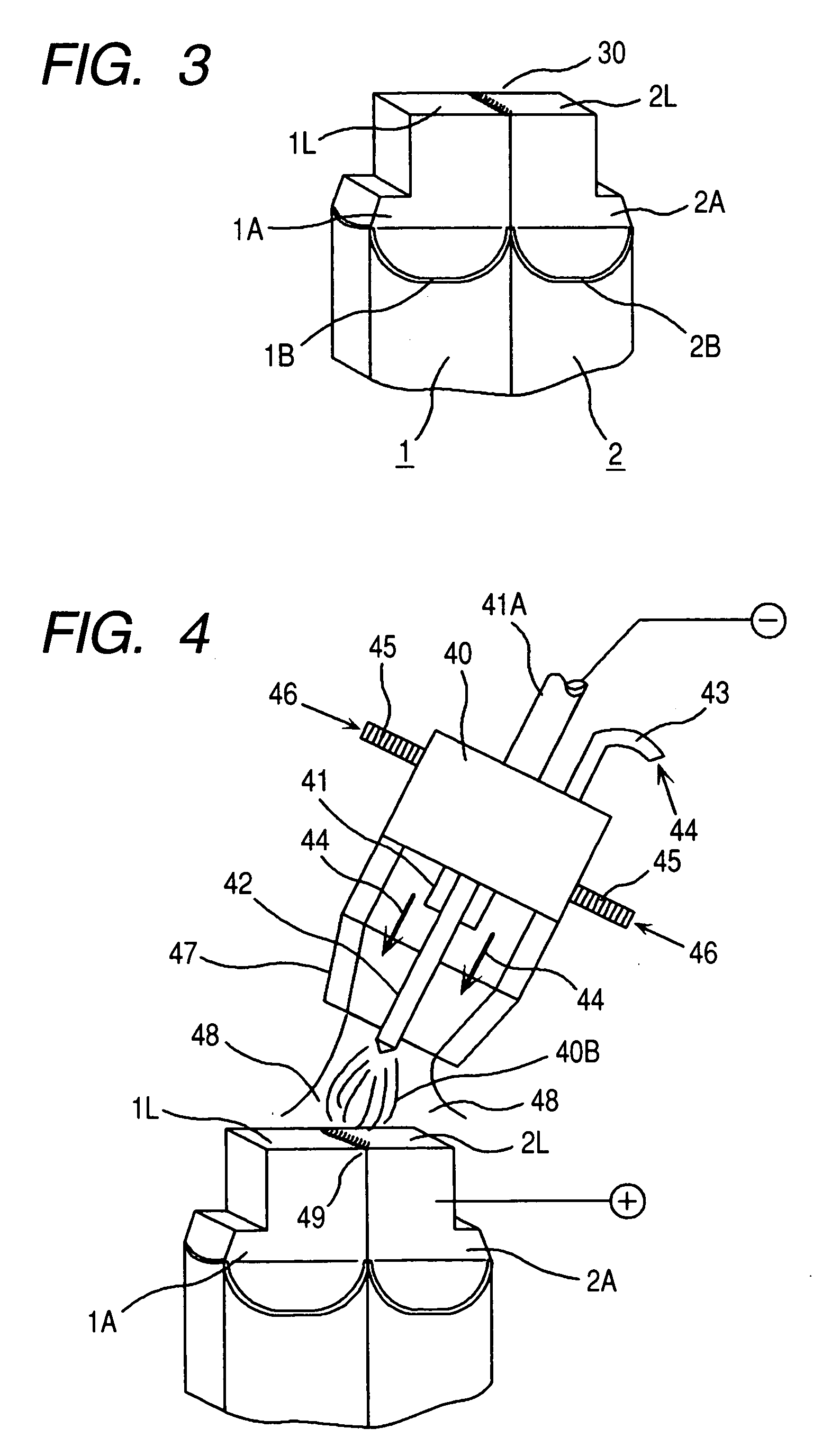

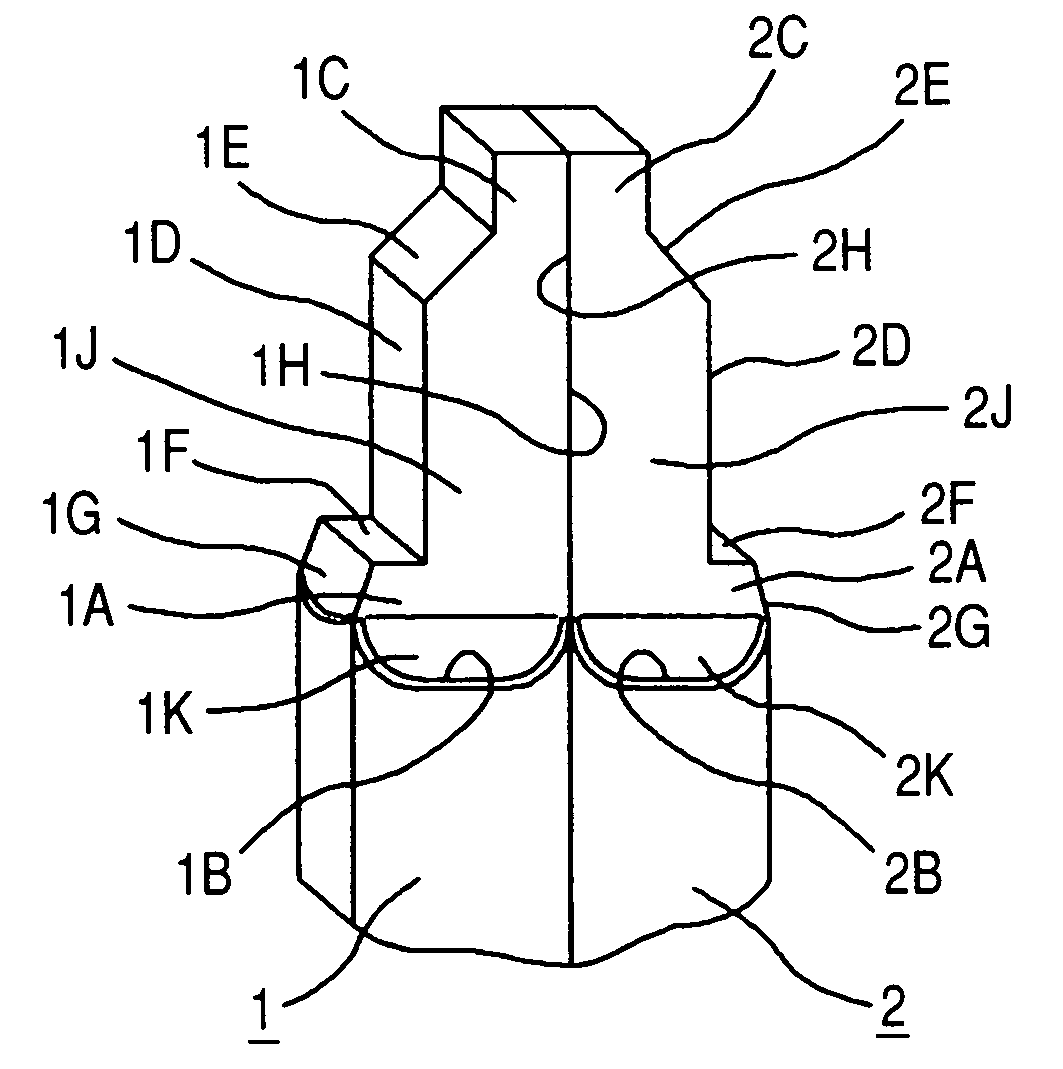

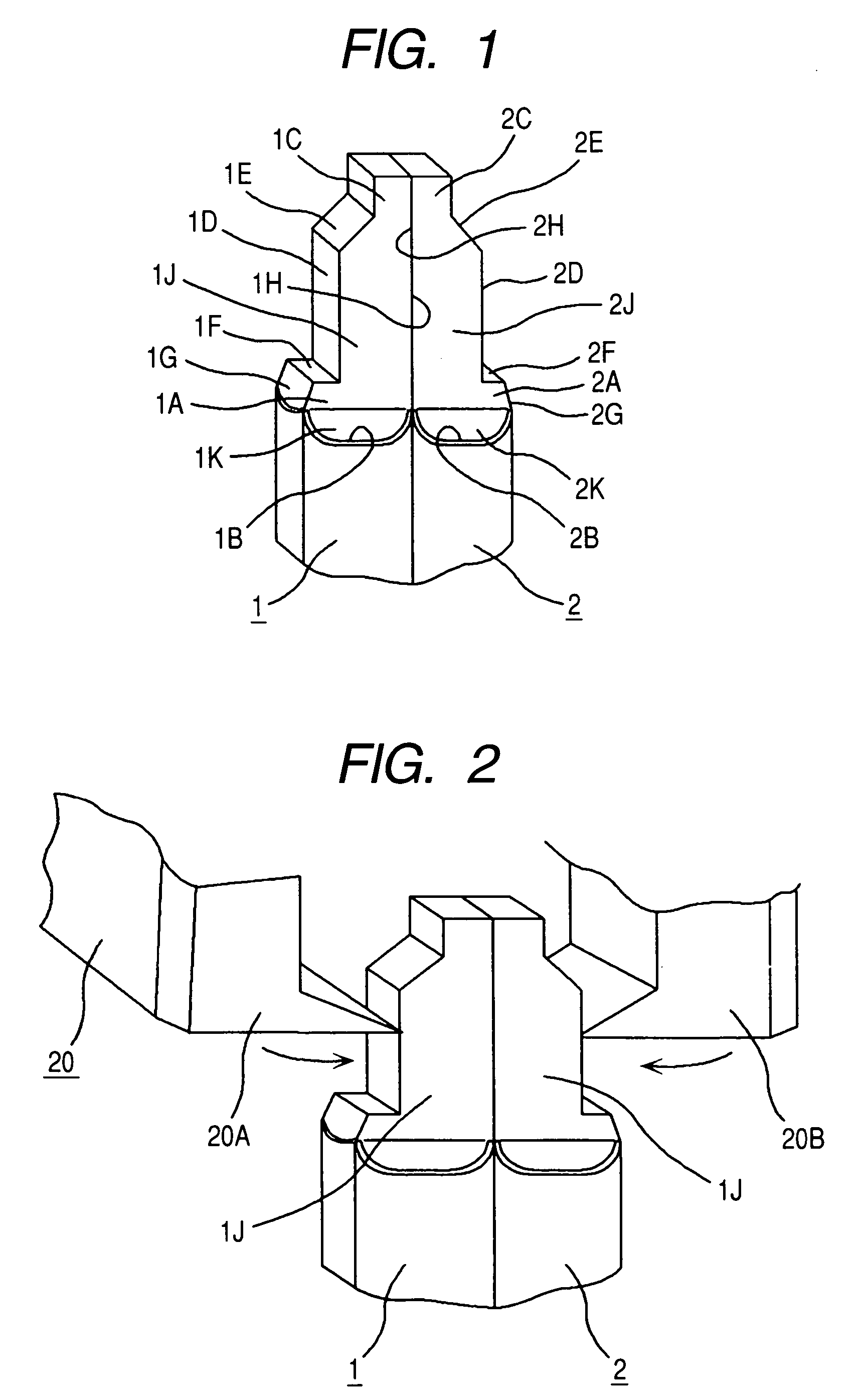

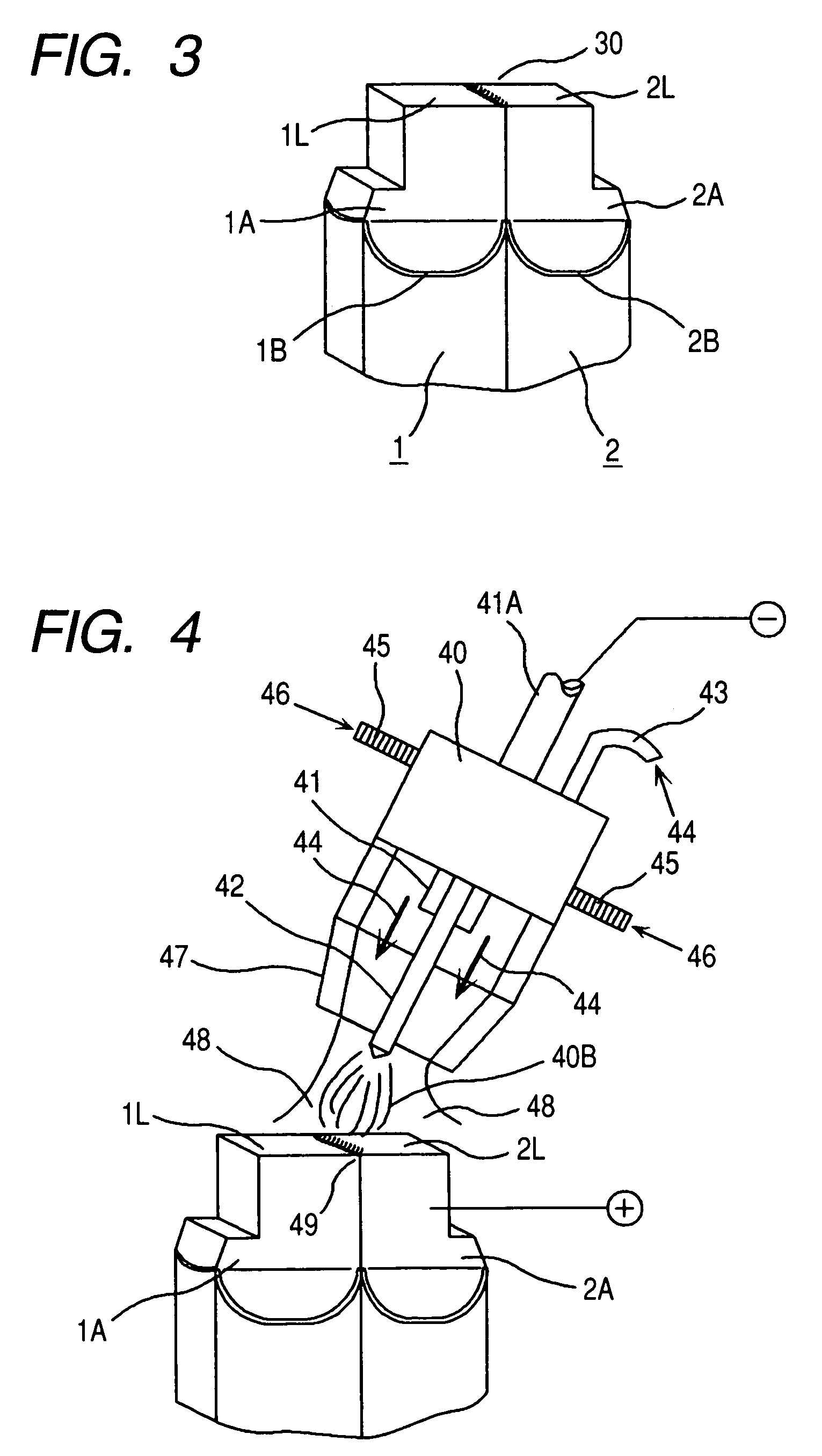

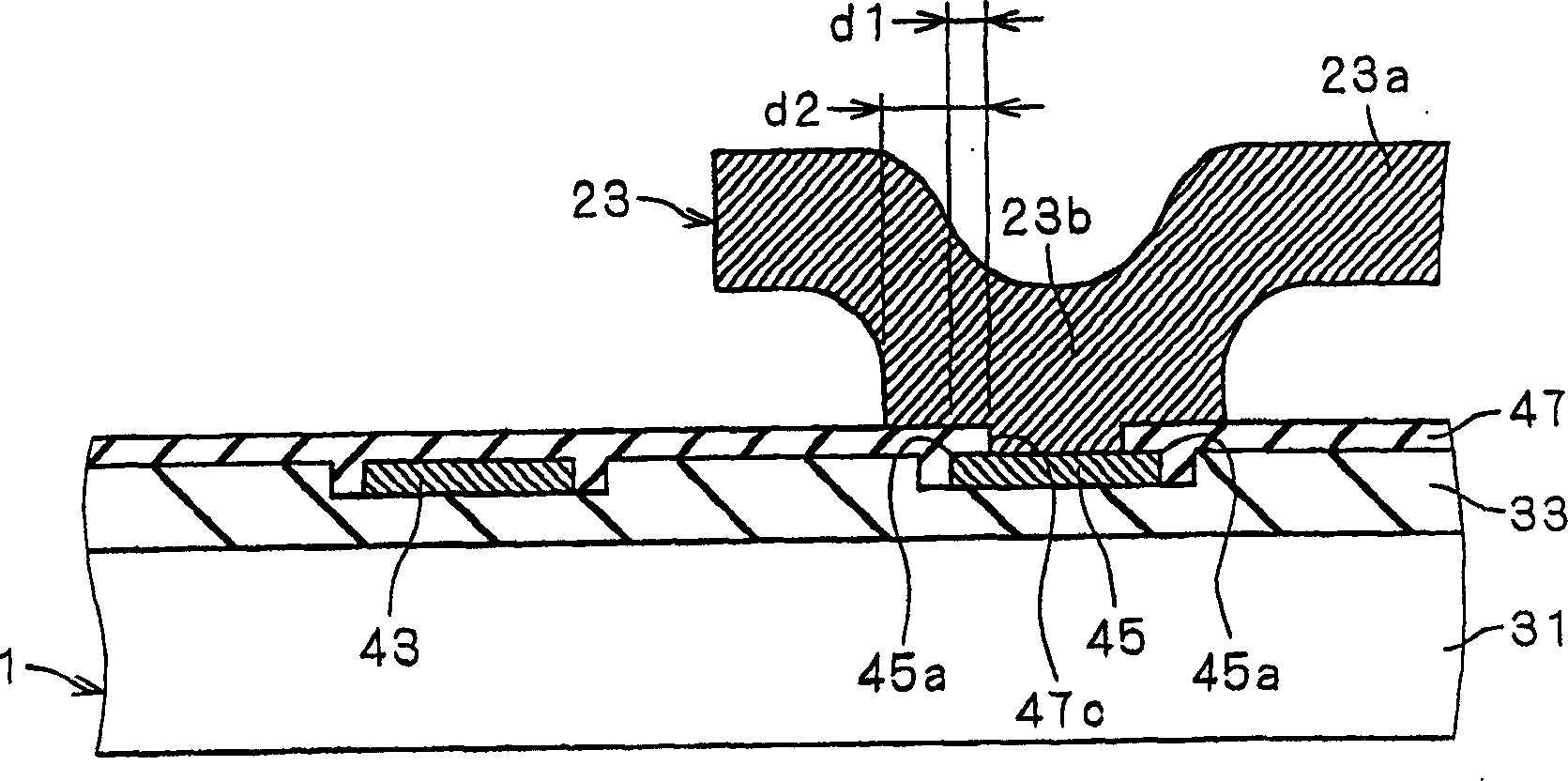

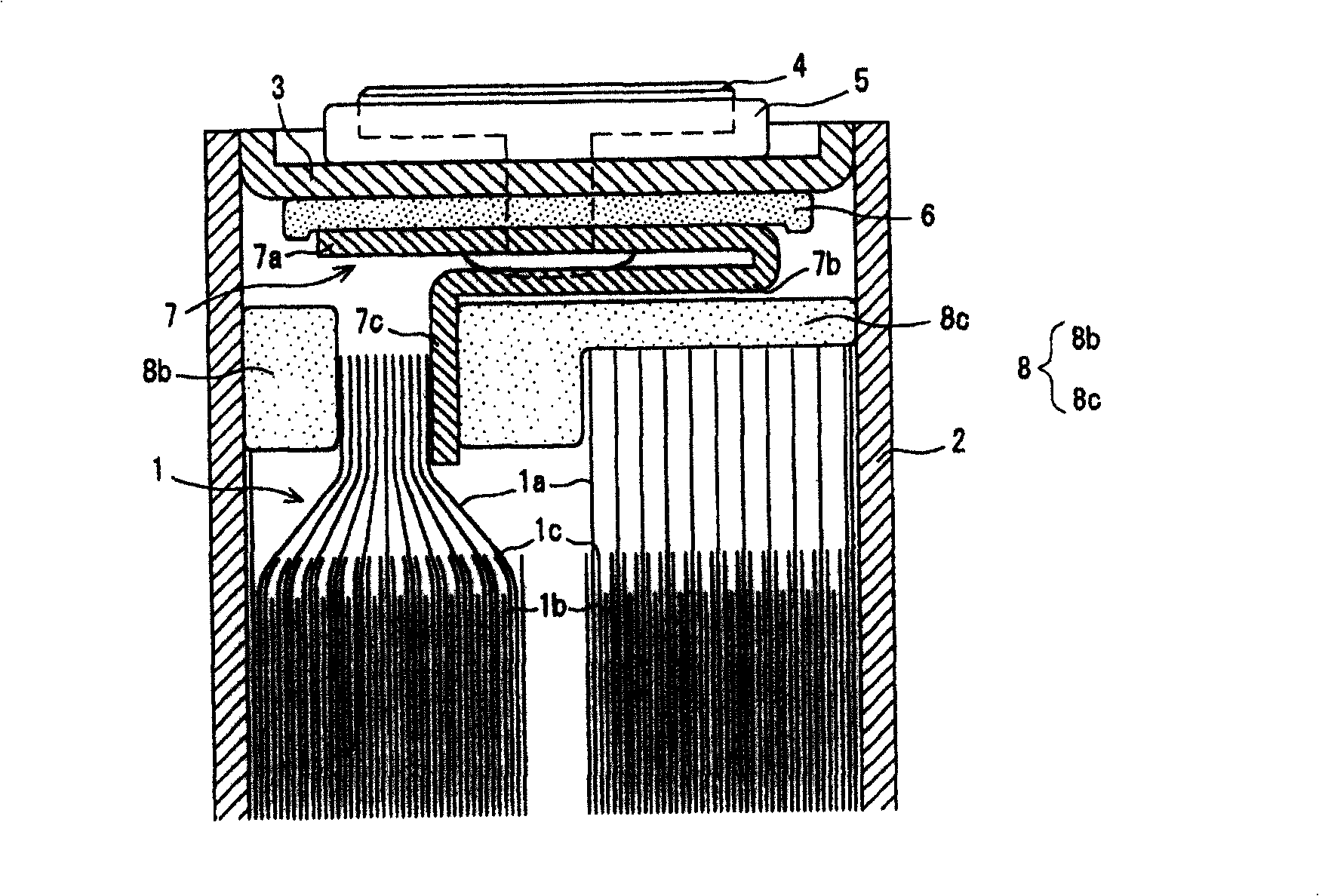

Joint structure of electric wire, stator of rotary electric machine, method for manufacturing the same

ActiveUS20060267440A1Reduced likelihood of strippingRationalization of joining workSynchronous generatorsLine/current collector detailsProduction rateElectrical conductor

When electric wires (joint conductors) are disposed adjacent each other in a peeled state of coatings, a gap corresponding to the total thickness of both conductors' insulating films as skin layers is formed between end joined face portions of the conductors. The gap becomes larger because the conductors are tapered. Therefore, the adhesion between both conductors is impaired, with a consequent fear of occurrence of joining imperfection. In opposed joined face portions of electric wires (joint conductors), the conductors are deformed from the tips of their axes to the joined face side in such a manner that exposed portions at the tips of the conductors and insulating film faces located in the vicinity thereof are flush with each other or the exposed portions are projected. The gap formed between the electric wires (joint conductors) can be diminished, whereby the reliability of connection is improved and it becomes easier to perform the work of joint conductors, with the result that the productivity of a stator of a rotary electric machine such as an AC generator for a vehicle could be improved.

Owner:HITACHI LTD

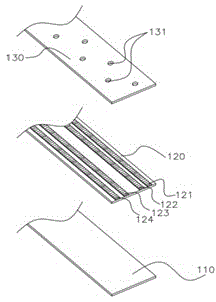

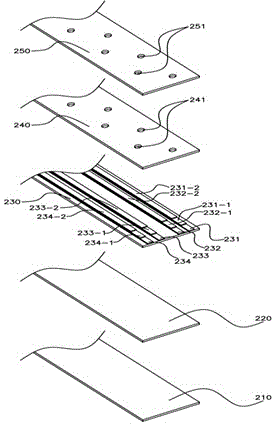

Leakage liquid detection sensor of circuit formed by utilizing ion sputtering coating and manufacturing process of leakage liquid detection sensor

ActiveCN104913881AImprove corrosion resistanceAvoid corrosionDetection of fluid at leakage pointMaterial analysis by electric/magnetic meansWhole bodyEngineering

The invention relates to a manufacturing process of a leakage liquid detection sensor of a circuit formed by utilizing ion sputtering coating. A heat-resistant and corrosion-resistant material is adopted to be taken as a substrate film, an insulating substance coating is formed on the upper surface of the substrate film by utilizing ion sputtering coating process, and two double-conduction lines are fabricated on the insulating coating through adoption of an ion sputtering coating manner; the upper surface of insulating coating is provided with a bonding layer and a protective film layer which are attached to each other; if a uniform conductive film is formed on a surface of the whole body of the substrate film or the insulating coating, film coating is performed after further coverage of a shielding adhesive tape, the shielding adhesive tape is removed after the ion sputtering coating process, and then a conduction line is formed; and a liquid leakage detection device is fabricated. The manufacturing process is advantageous in that various liquids or moisture can be prevented from resulting in corrosion occurring in the conduction line, leakage of a conductive liquid can be accurately detected, and occurrence of false alarms is minimized; reliability of the liquid leakage detection device is improved; and improvement of a bonding force between the film layers is facilitated, the stripping possibility of the upper-layer protective film layer is reduced, and the reject ratio of products is reduced.

Owner:DOGO TECH CO LTD

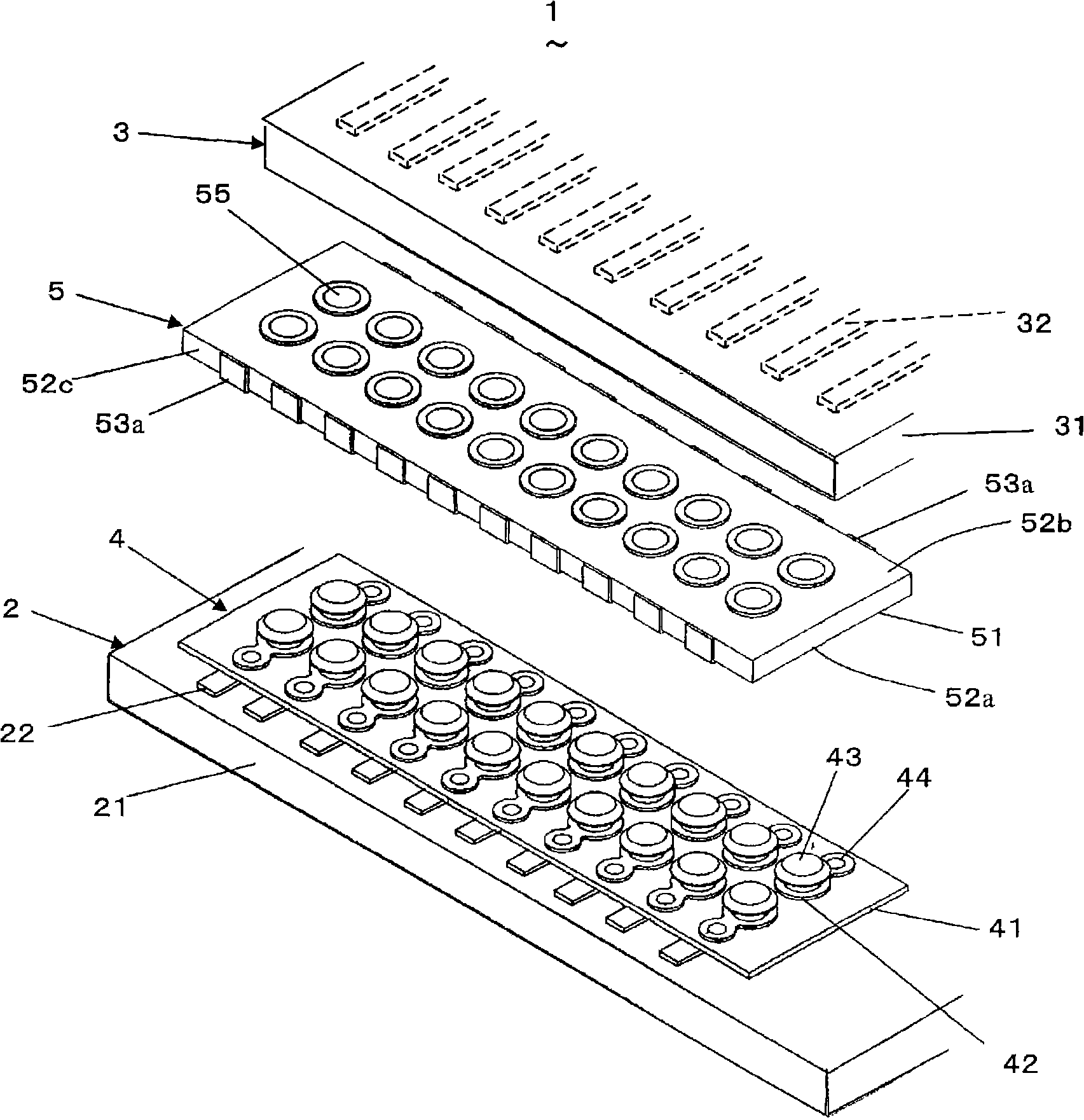

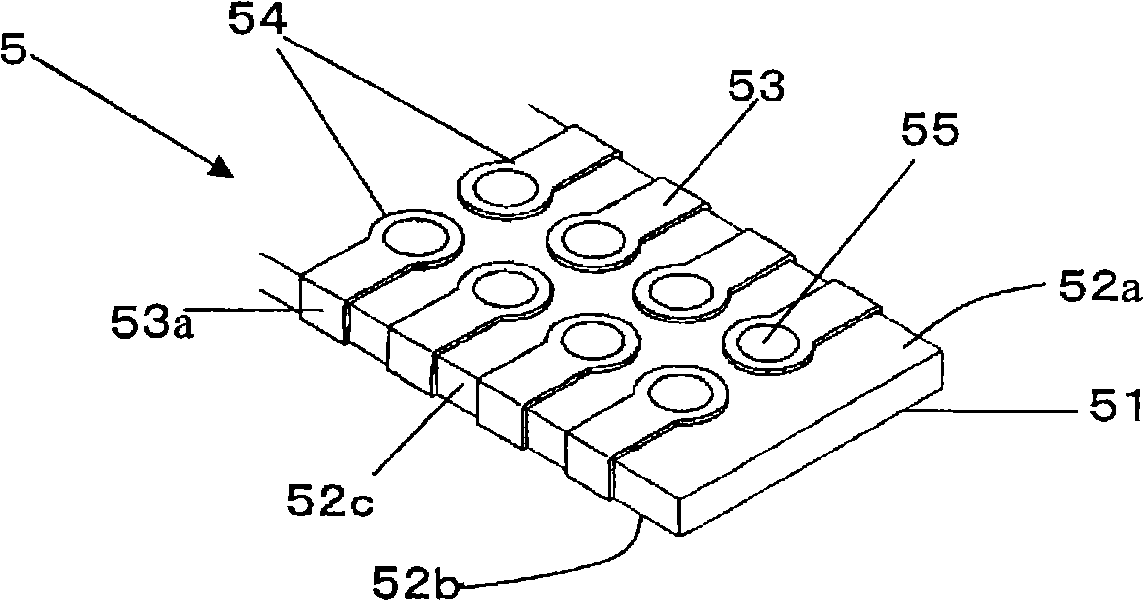

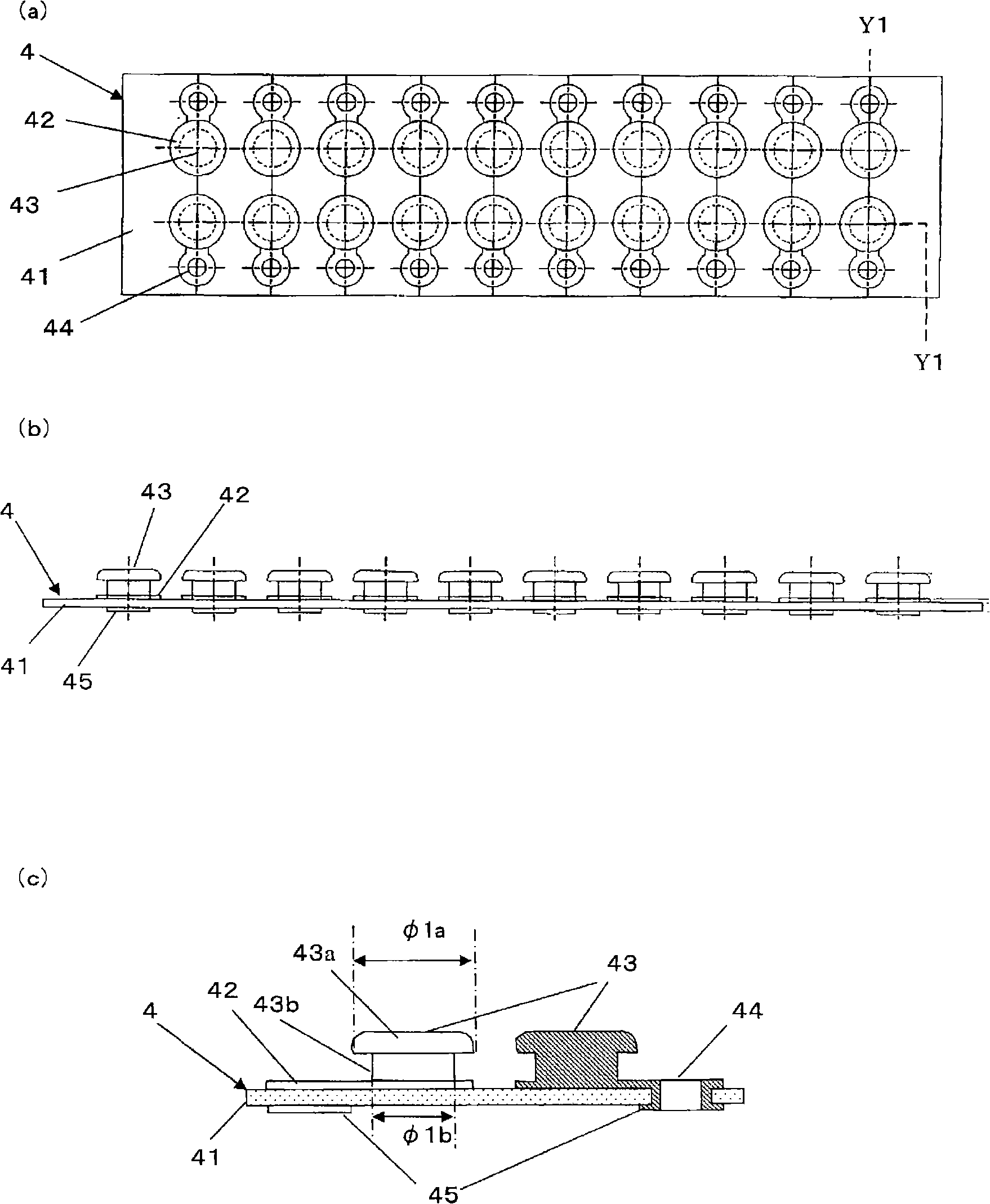

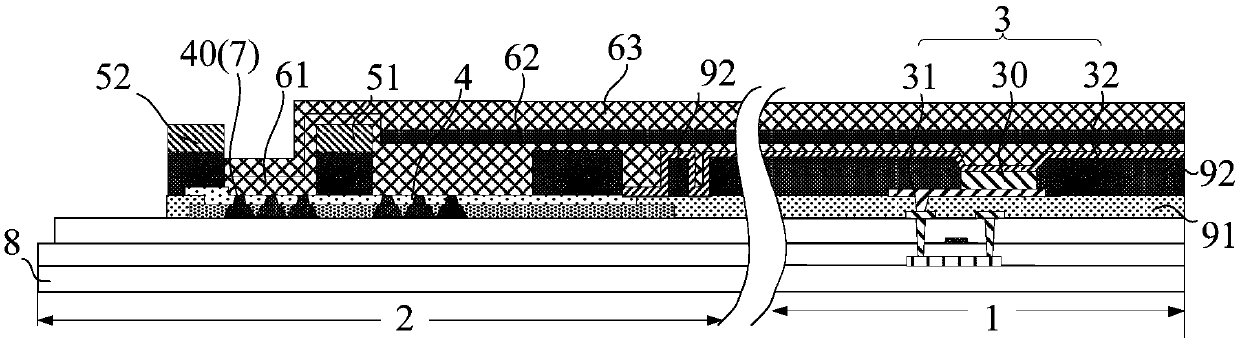

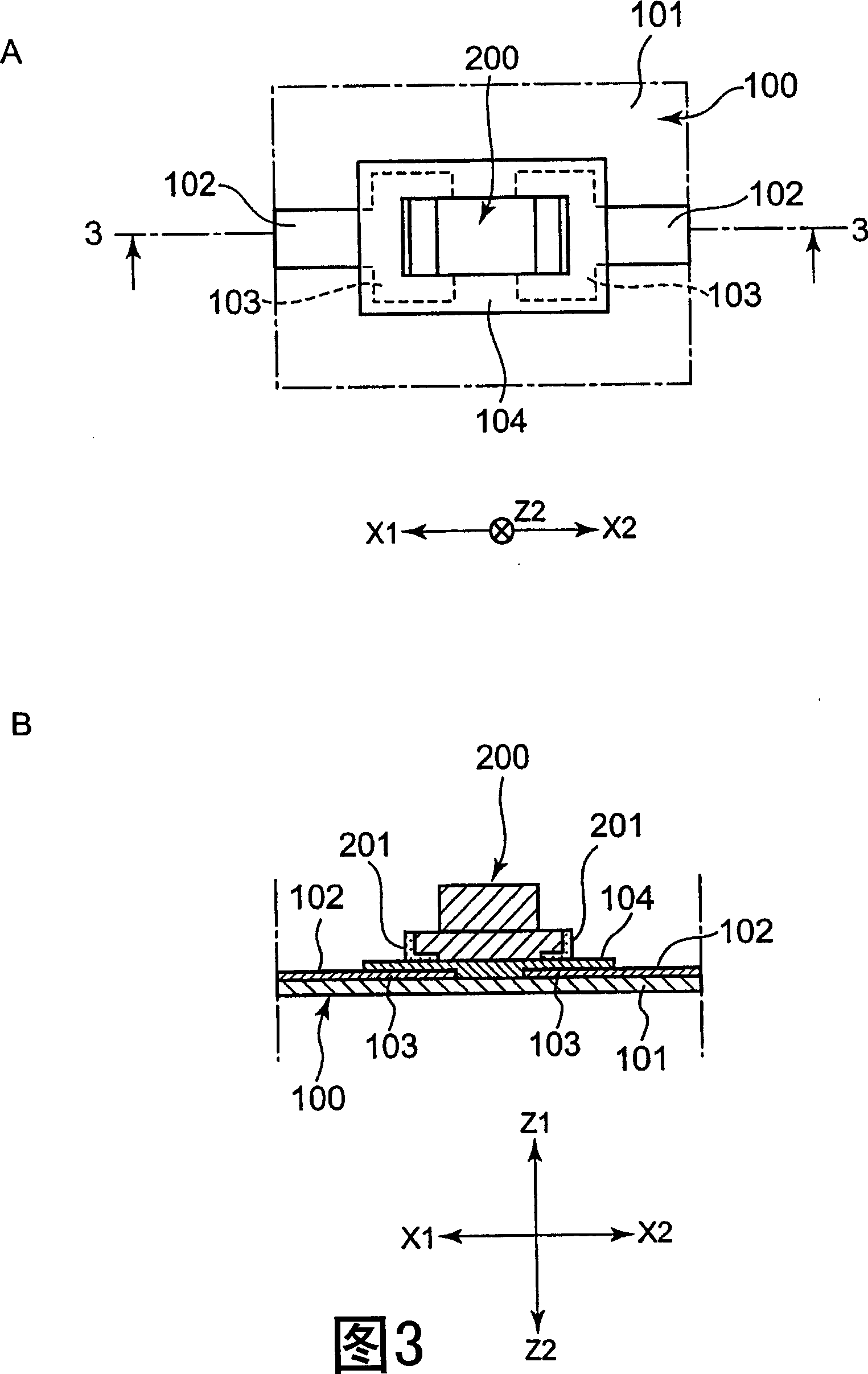

Board-to-board connector

InactiveCN101310416AReduce thicknessReduce breakageCoupling device connectionsPrinted circuits structural associationsHigh densityBoard-to-board connector

A thin board-to-board connector with high density in which there is no connection between three-dimensional complex metal springs. The board-to-board connector (1) comprises a connector (4) having a bump (43) for electrical connection having an umbrella shape on a board (41) and connected to a circuit board (2) electrically connected to the bump (43) and a connector (5) having an elastic electrically conductive section (54) having a through hole (55) made in a conductive pattern (53) on an elastic insulating board (51) and connected to a circuit board (3) electrically connected to the elastic conductive section (54). When a bump (43) is inserted into the through hole (55), the elastic conductive section (54) is electrically connected to the bump (43), and the side surface of the through hole (55) is pressed against to the bump (43) and elastically deformed and dented. Consequently, the bump (43) is press-fit into the through hole (55). With this, the bump (43) can be inserted into the elastic conductive section (54) and engaged with it, and thereby electrical and mechanical connection between circuit boards can be simultaneously achieved in a two-dimensional manner, realizing a low-height connector.

Owner:PANASONIC ELECTRIC WORKS CO LTD

Joint structure of electric wire, stator of rotary electric machine, method for manufacturing the same

ActiveUS7615906B2Reduced likelihood of strippingRationalization of the joining workSynchronous generatorsLine/current collector detailsProduction rateElectrical conductor

When electric wires (joint conductors) are disposed adjacent each other in a peeled state of coatings, a gap corresponding to the total thickness of both conductors' insulating films as skin layers is formed between end joined face portions of the conductors. The gap becomes larger because the conductors are tapered. Therefore, the adhesion between both conductors is impaired, with a consequent fear of occurrence of joining imperfection. In opposed joined face portions of electric wires (joint conductors), the conductors are deformed from the tips of their axes to the joined face side in such a manner that exposed portions at the tips of the conductors and insulating film faces located in the vicinity thereof are flush with each other or the exposed portions are projected. The gap formed between the electric wires (joint conductors) can be diminished, whereby the reliability of connection is improved and it becomes easier to perform the work of joint conductors, with the result that the productivity of a stator of a rotary electric machine such as an AC generator for a vehicle could be improved.

Owner:HITACHI LTD

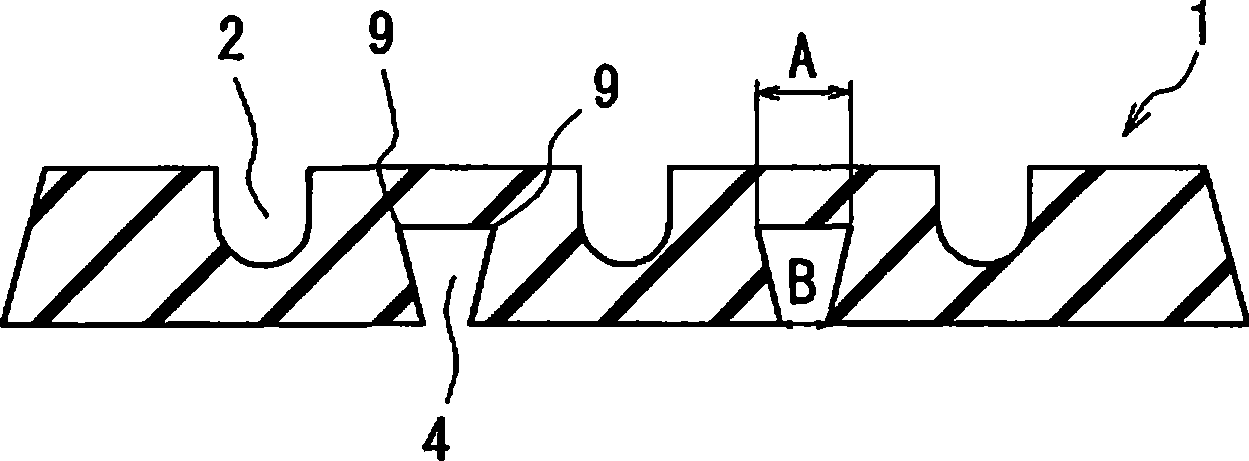

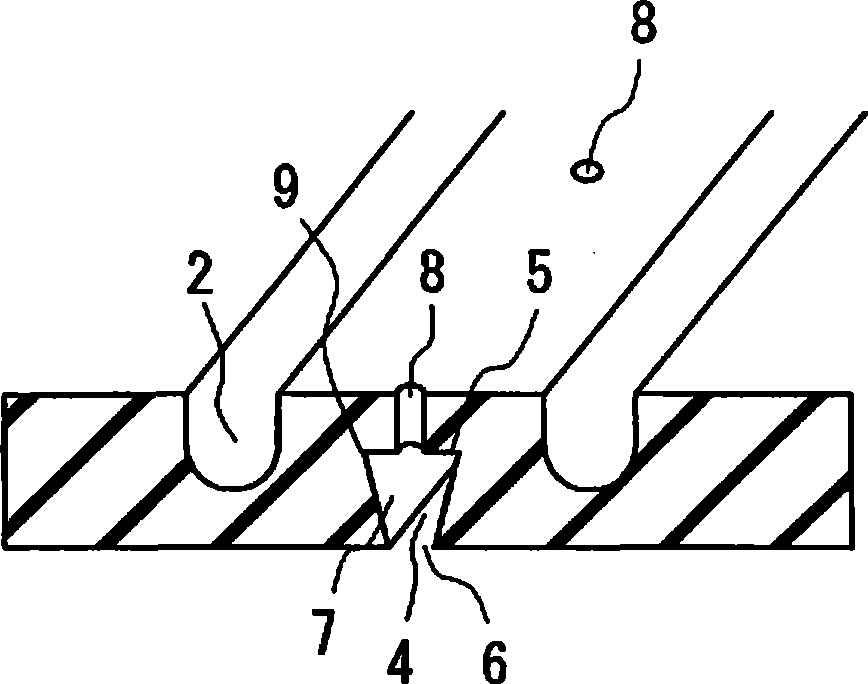

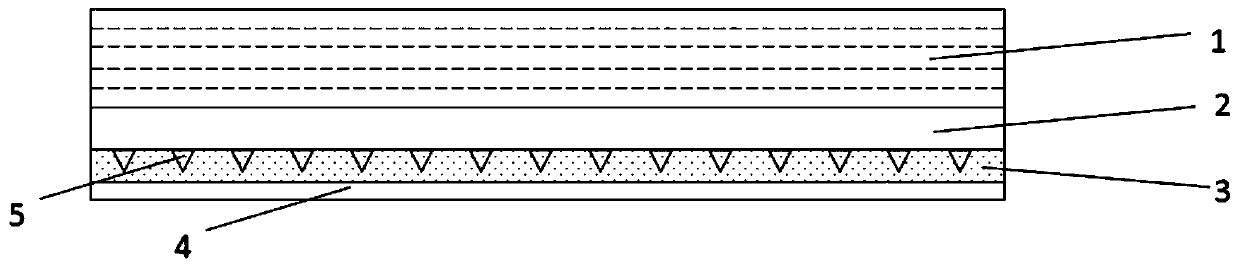

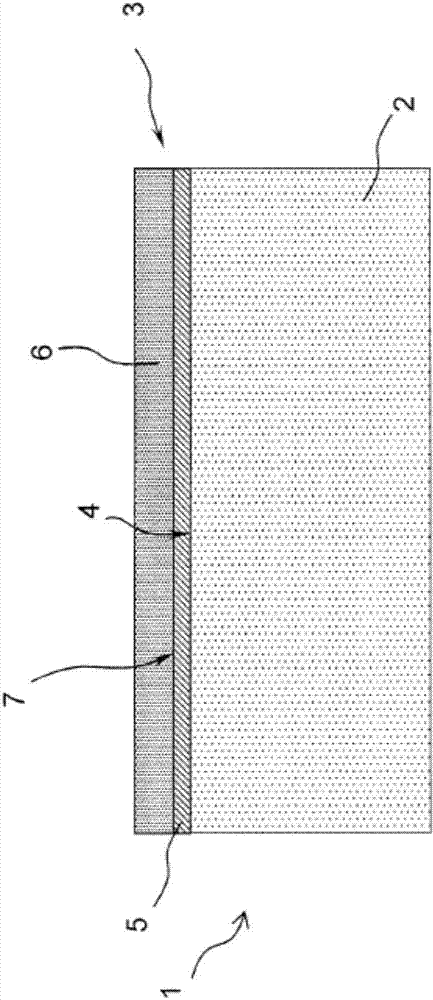

Prevulcanized tread and recapped tire using the same

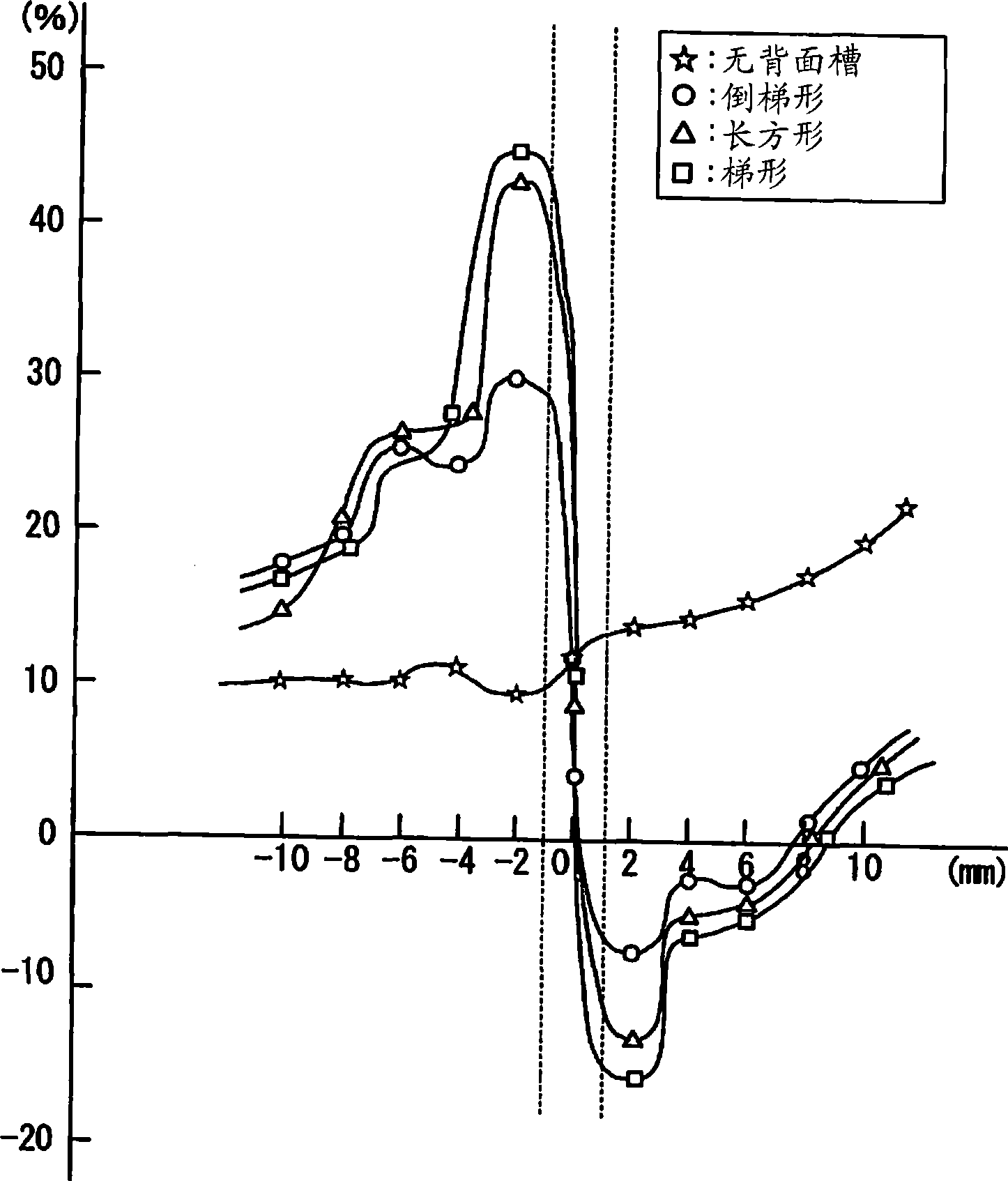

InactiveCN101466558AReduced likelihood of strippingReduce the possibilityTyresTyre tread bands/patternsGround contactEngineering

A precured tread exhibiting excellent wet performance from the beginning to the end of wear of the tread. To achieve this, the cross sectional shape of back side grooves formed in the back side of the procured tread is appropriately set to increase the rigidity of the land part of the tread, making the tread far less possible to separate from the base tire. A retreaded tire using the precured tread is also provided. The precured tread (1) has circumferential grooves (2) formed in that front side of the procured tread that is on the ground contact surface side and extending in the tire circumferential direction and also has the back side grooves (4) formed in that back side of the procured tread that is on the side bonded to the base tire (3), extending in the tire circumferential direction, and exposed to the tread surface of the tire as the tread surface wears. The back side grooves (4) have a generally trapezoidal cross section in the lateral direction of the tire, and the width of each groove (4) is constant or gradually reduced from the bottom (5) of the groove toward its opening (6). The retreaded tire is constructed by using the precured tread.

Owner:BRIDGESTONE CORP

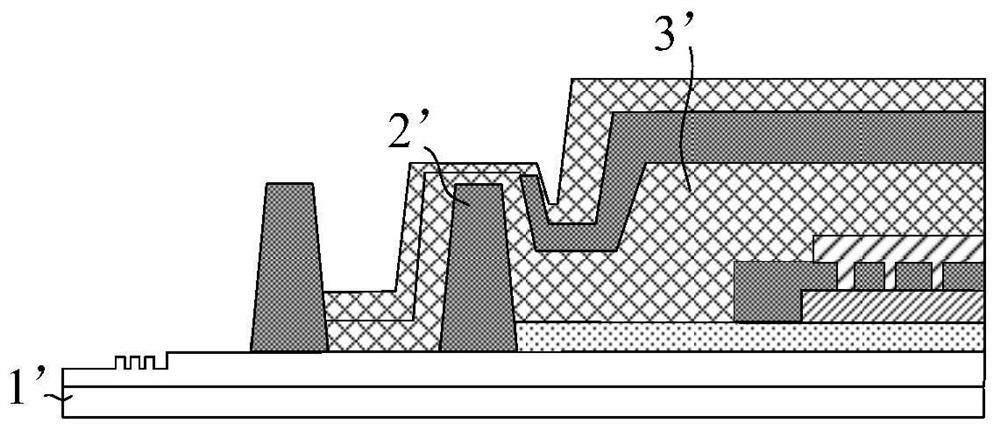

Display panel and display device

ActiveCN109585690AImprove bindingReduced likelihood of cracksSolid-state devicesSemiconductor/solid-state device manufacturingConvex structureSurface plate

The embodiment of the invention provides a display panel and a display device, and relates to the technical field of display for solving the problem that in the prior art, a packaging layer and a blocking part are easy to peel off. The display panel comprises a substrate, a blocking part and a packaging layer, wherein the blocking part surrounds a display area of the display panel; and the blocking part is located on one side of the substrate; and the packaging layer is located on one side, away from the substrate, of the blocking part, wherein the surface of the blocking part in contact withthe packaging layer comprises a concave-convex structure.

Owner:XIAMEN TIANMA MICRO ELECTRONICS

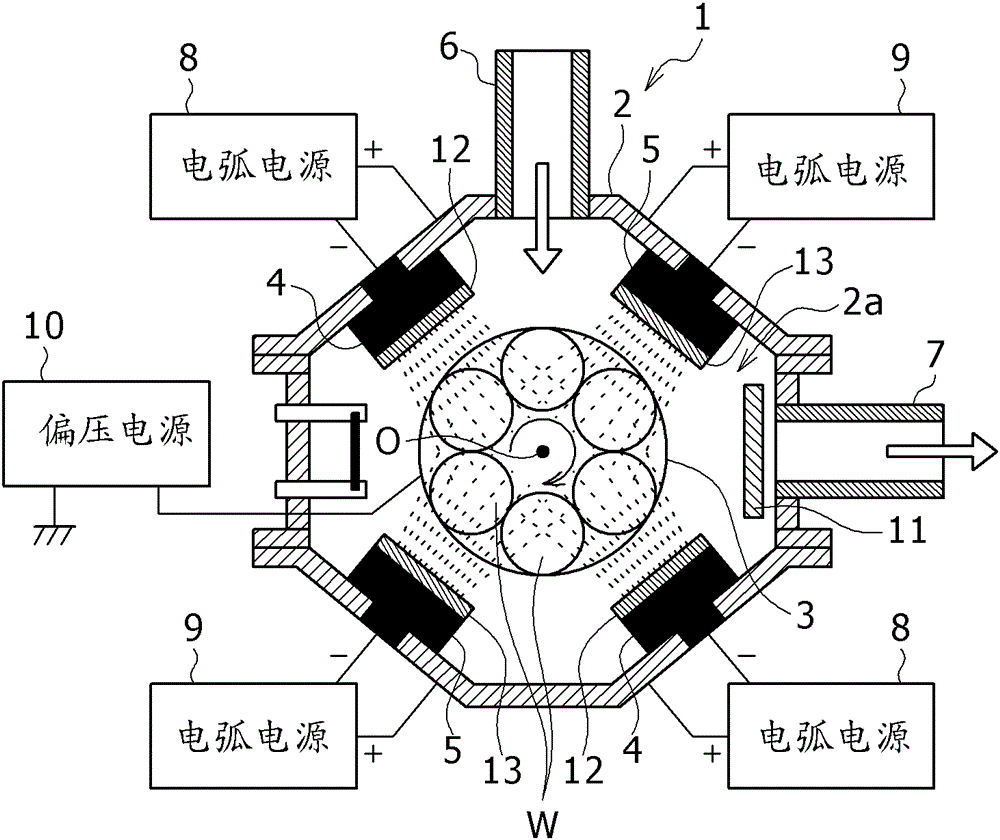

Herstellungsverfahren FooR Hartes Gleitelement

InactiveCN105420670AReduced likelihood of strippingFit closelyVacuum evaporation coatingSputtering coatingCarbon filmSurface layer

A manufacturing method of a hard sliding member of the present invention includes a surface treatment step of surface-treating a surface of a substrate, and a carbon film formation step of forming a carbon film on the surface of the substrate by performing arc ion plating with using a target containing carbon. In the carbon film formation step, formation of the carbon film is started by performing the arc ion plating while introducing a hydrocarbon gas, then an introduction amount of the hydrocarbon gas is reduced and the arc ion plating is continued so as to form an intermediate layer, and a surface layer made of ta-C is formed on a surface.

Owner:KOBE STEEL LTD

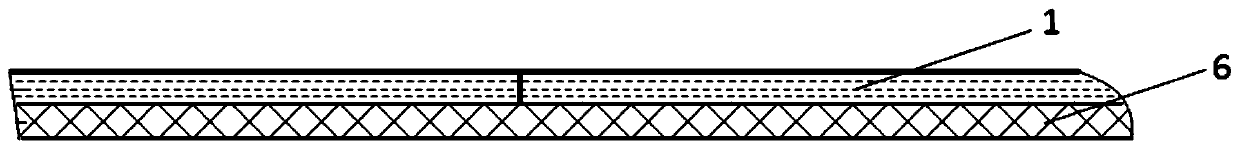

Paint prefabricated film, protection structure and preparation method of protection structure

PendingCN111173675AUniform thicknessReduce internal defectsLamination ancillary operationsSynthetic resin layered productsFilm baseEngineering

The invention provides a paint prefabricated film, a protection structure and a preparation method of the protection structure. The surface, deviated from a back glue layer, of a substrate base material layer is a smooth plane, the smooth plane has the relatively low surface tension, and a paint coating formed on the surface of the smooth plane can be more uniform in thickness and fewer in insidedefects, so that the quality is higher; a plurality of bulge parts are arranged on the surface, facing the back glue layer, of the substrate base material layer, so that the binding force of the substrate base material layer and the paint coating is smaller than that of the substrate base material layer and the back glue layer, separation of the paint coating from a paint prefabricated film base body can be realized by the aid of the external force, and the paint coating is used for protecting the outer surface of a wind turbine blade base body. The paint prefabricated film is applied to preparation of the wind turbine blade protection structure, and the large-area damage to the paint coating due to sand erosion and rain erosion of the area having the low thickness of the paint coating dueto the non-uniform thickness of the paint coating can be avoided, so that the protection effect of the protection structure can be improved.

Owner:SINOMATECH WIND POWER BLADE

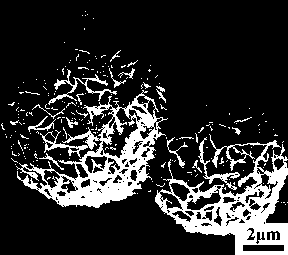

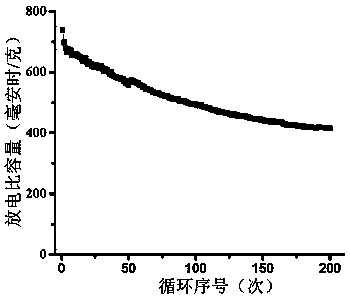

Preparation method for foam graphene compound indium zinc sulfide material

InactiveCN108899501AImprove electrochemical performanceInhibition of volume expansion effectNegative electrodesSecondary cellsIndiumCharge discharge

The invention belongs to the field of material chemistry and relates to a preparation method for a cathode material of a lithium ion battery. The method comprises three steps: preparing graphene oxide, preparing foam graphene and preparing a foam graphene compound indium zinc sulfide material. The cathode material with higher charge-discharge specific capacity and better cycle performance is acquired by introducing graphene foams and indium zinc sulfide as cathode active materials; the initial charge-discharge capacity can reach up to 742.17mAh / g; after 200 times of circulation, the cathode material still has a reversible capacity of 415.23mAh / g.

Owner:INT ACAD OF OPTOELECTRONICS AT ZHAOQING SOUTH CHINA NORMAL UNIV

Electrode structure, and method for manufacturing thin-film structure

InactiveCN1466775AReduce the possibility of corrosionPrevent infiltrationSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringFilm structure

An electrode structure where a sacrifice film is removed without removing another insulating film and a method for manufacturing a thin-film structure. There are formed anchor holes for opening the surface of a wiring line which is covered with a sacrifice film and a nitride film. The anchor hole is formed of a hole portion of the nitride film and an opening of the sacrifice film. The diameter ofthe hole portion is smaller than the width of the wiring line by a first predetermined distance from the edge of the surface of the wiring. The diameter distance from the hole portion. Because of thepresence of the first and second predetermined distances, the distance by which the etchant for removing the sacrifice film penetrate into an oxide film.

Owner:MITSUBISHI ELECTRIC CORP

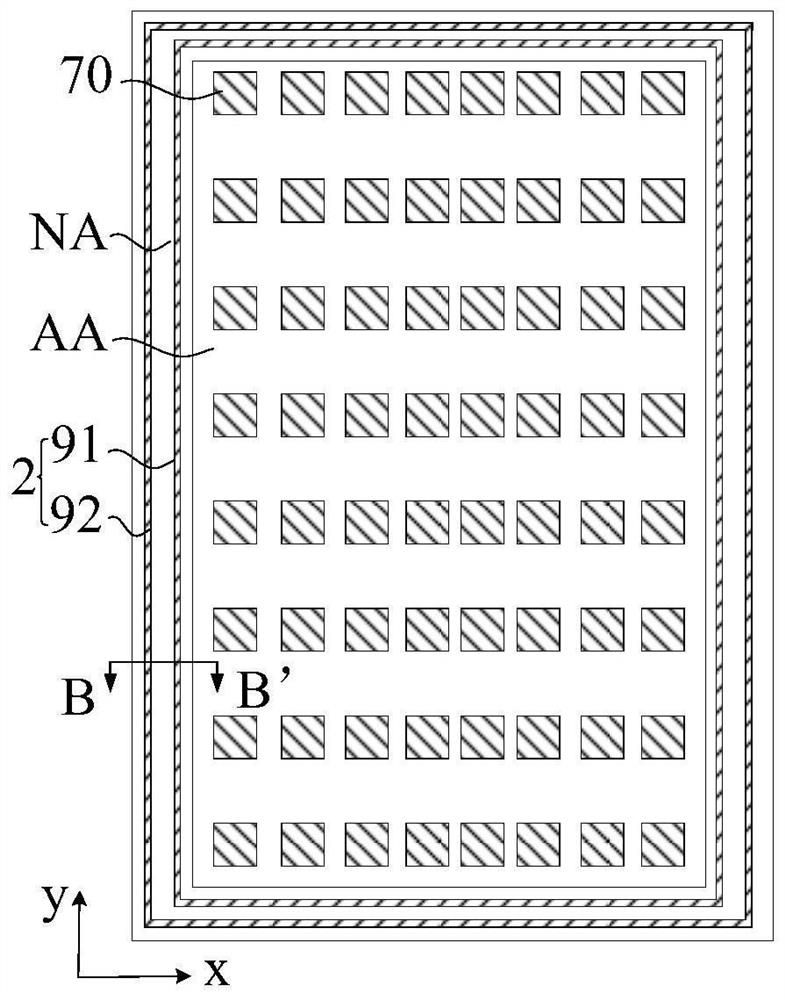

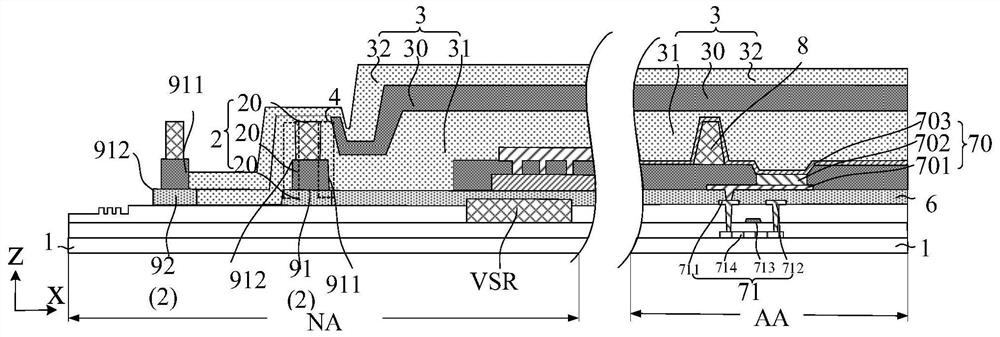

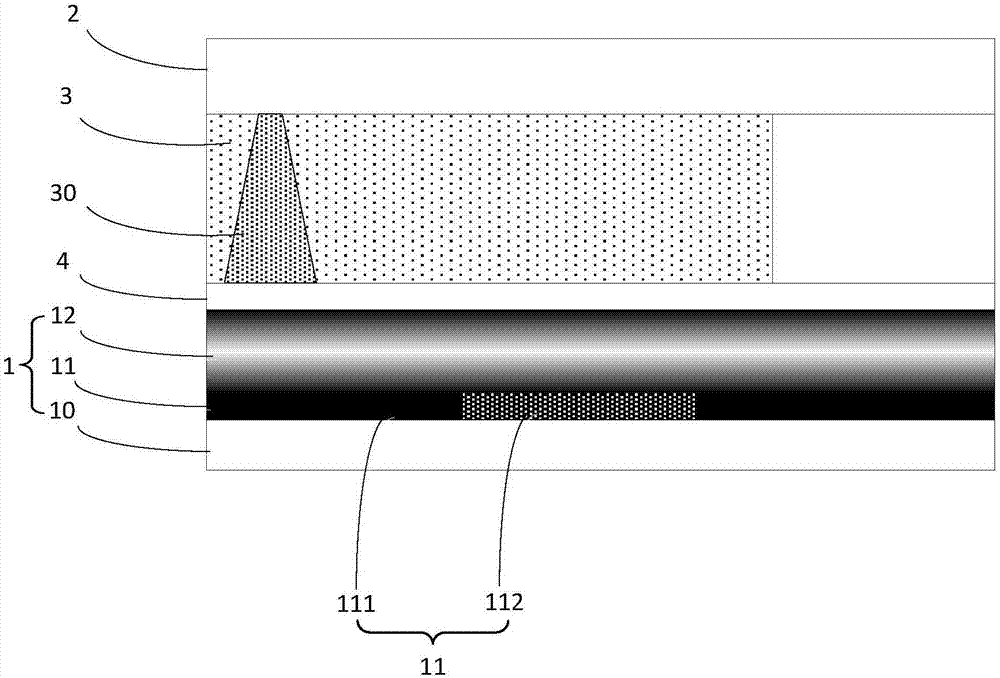

Display panel and manufacturing method thereof, and display device

ActiveCN109638057AEnsuring Package ReliabilityAvoid enteringSolid-state devicesSemiconductor/solid-state device manufacturingElectricityDisplay device

The embodiment of the invention provides a display panel and a manufacturing method thereof, and a display device, and related to the field of display technology, which are used to solve the problem that the encapsulation layer in the display panel in the prior art is easy to peel off. The display panel includes a display area and a non-display area surrounding the display area; the display area includes a plurality of light emitting units; each of the light emitting units includes a first electrode, a light emitting layer and a second electrode which are arranged in a stack; the non-display area includes a metal layer and an inorganic layer, which contact each other, wherein the metal layer is electrically connected to the second electrodes located in the display region, and the metal layer includes an opening, the opening is filled with an organic layer, and the organic layer is in contact with the metal layer and the inorganic layer.

Owner:SHANGHAI TIANMA MICRO ELECTRONICS CO LTD

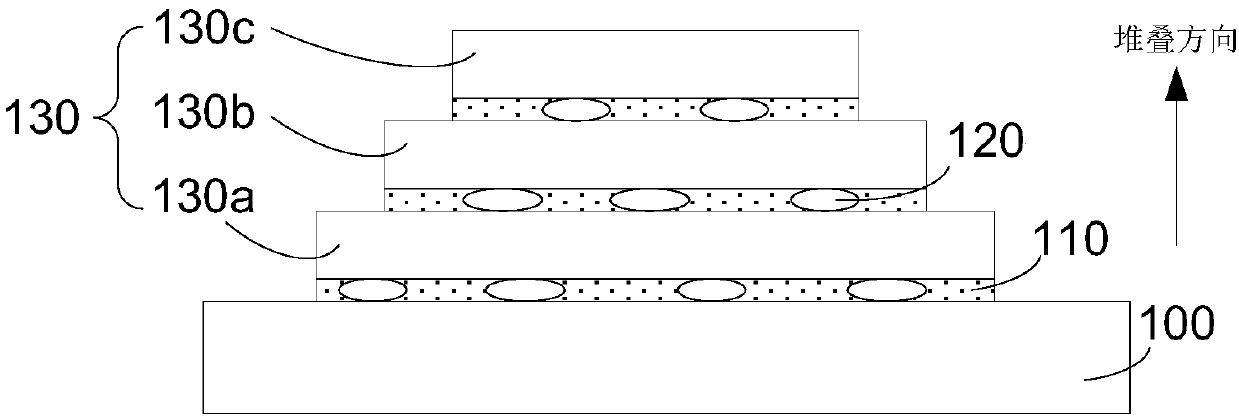

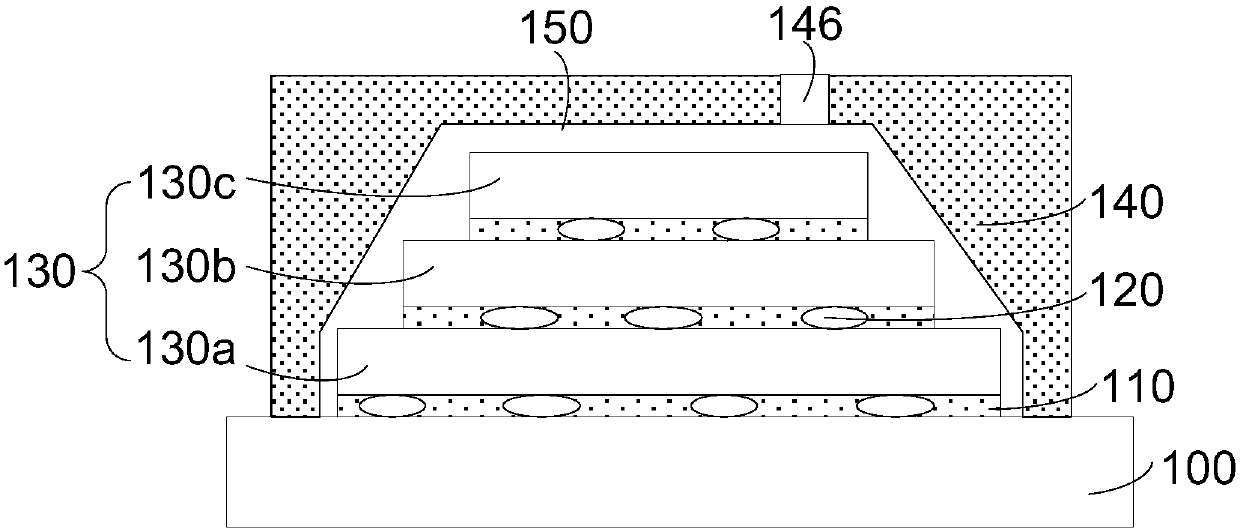

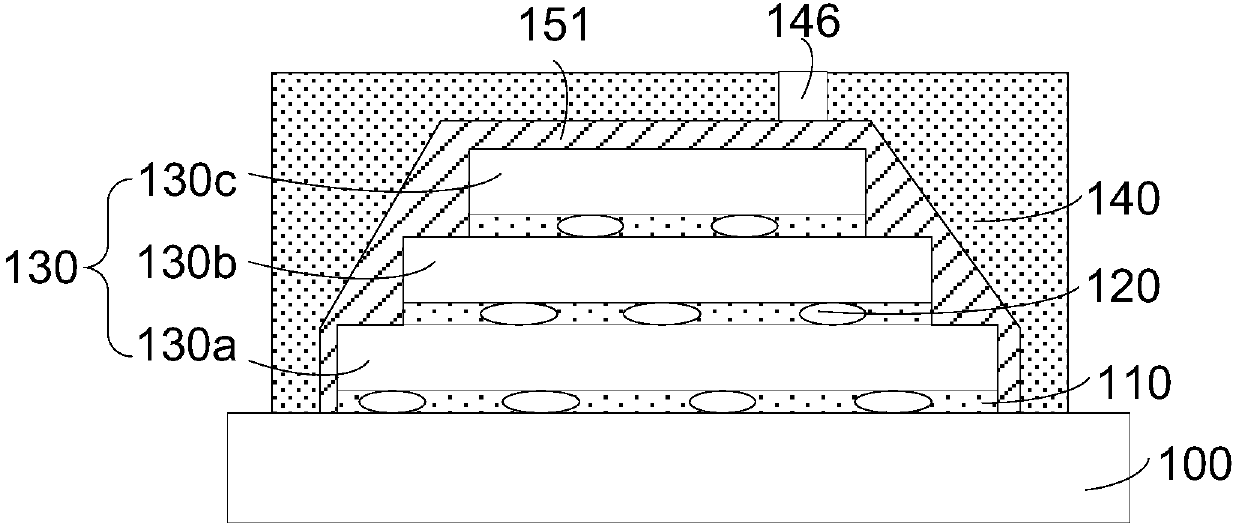

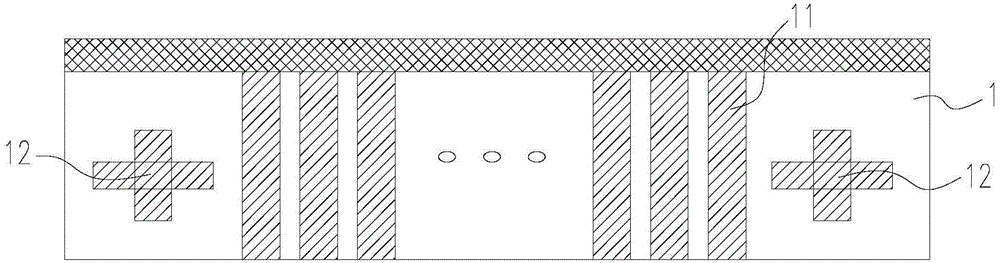

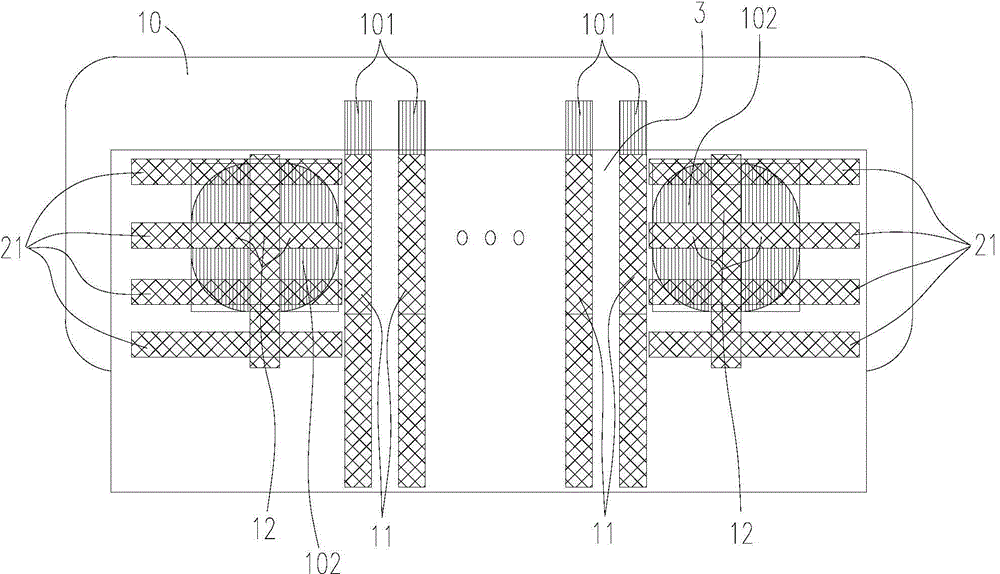

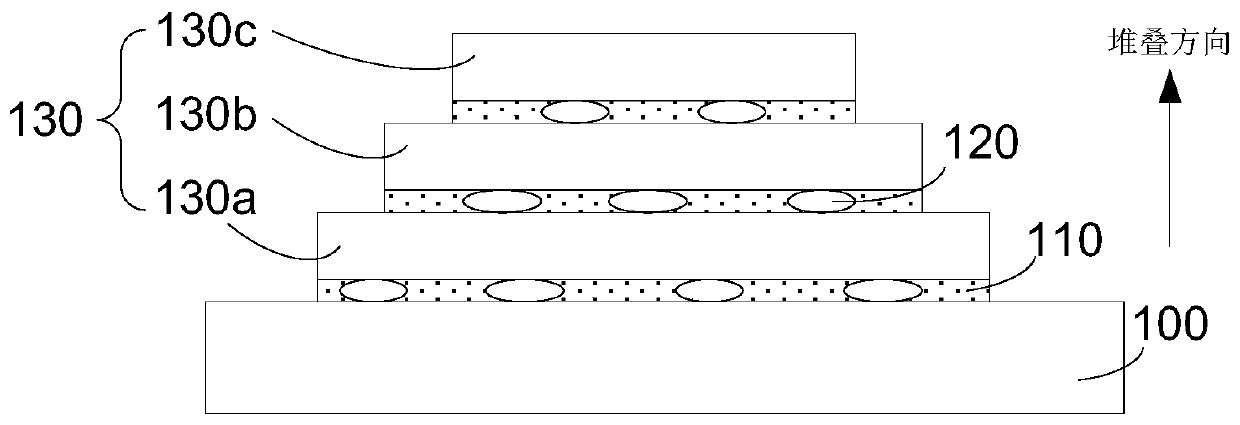

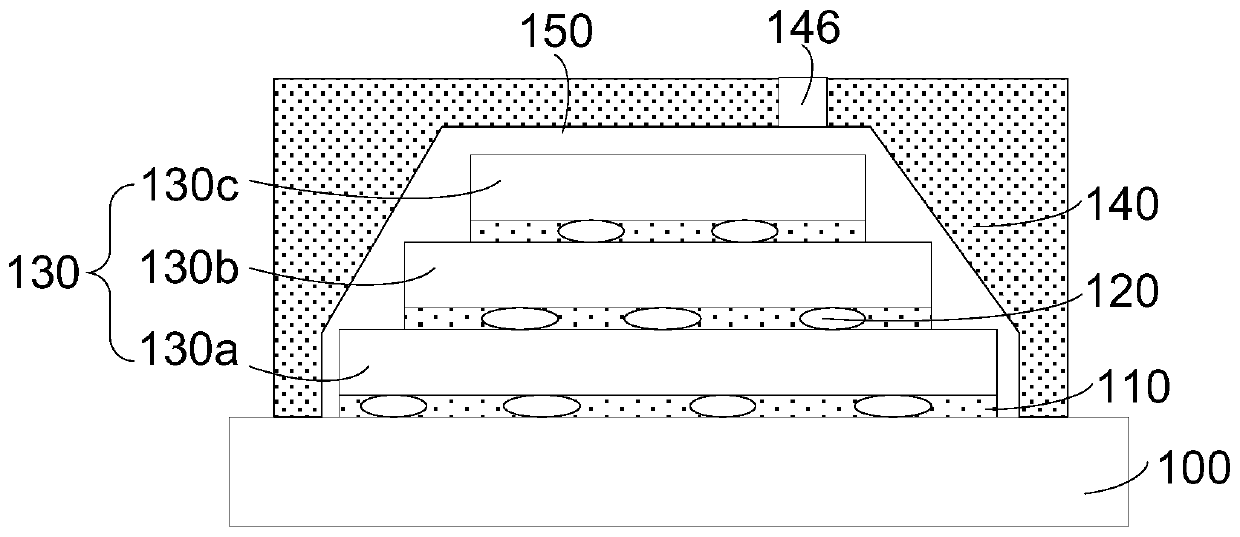

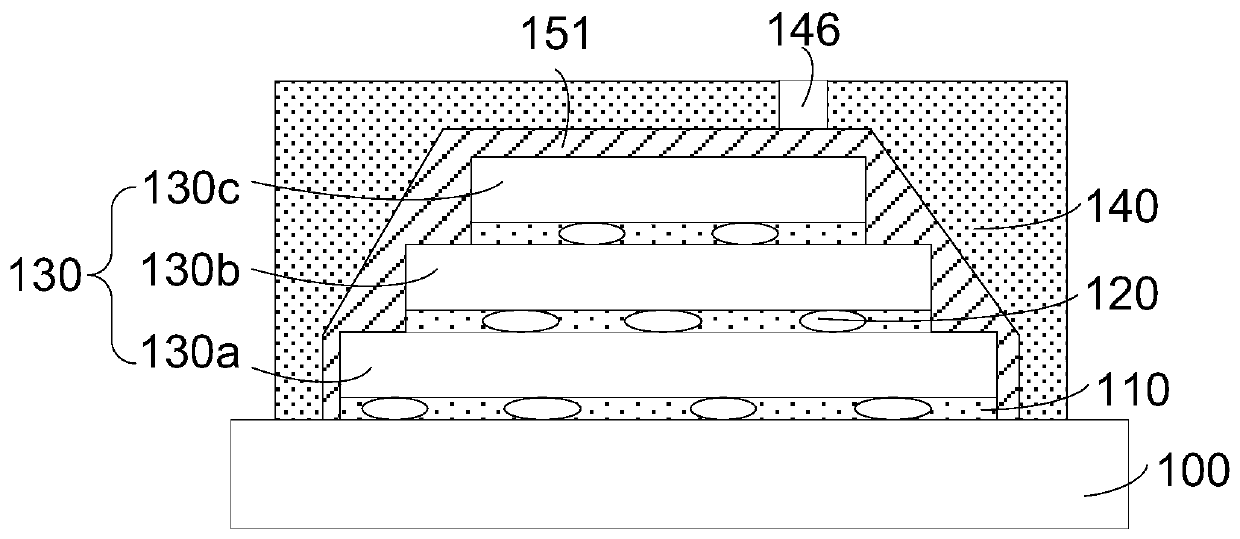

Semiconductor packaging mould, semiconductor device and packaging method of semiconductor device

ActiveCN109637939AReduce thicknessReduced likelihood of strippingSemiconductor/solid-state device detailsSolid-state devicesSemiconductor packageEngineering

The invention discloses a semiconductor packaging mould, a semiconductor device and a packaging method of the semiconductor device. The semiconductor packaging method comprises the steps that a packaging substrate is provided, and a plurality of chips are stacked on the packaging substrate; the chips are covered with the packaging mould, thus a chip accommodating cavity accommodates all the chips,and the contour surface shape of the chip accommodating cavity is matched with the contour surface shapes of the stacked chips; and a packaging material is injected into the chip accommodating cavitythrough an injection hole. The outer contour surface of the chip accommodating cavity is matched with the outer contour surfaces of the stacked chips, so that the thickness of the subsequently formedpackaging material is small and uniform, and the chips and the packaging material are prevented from warping.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

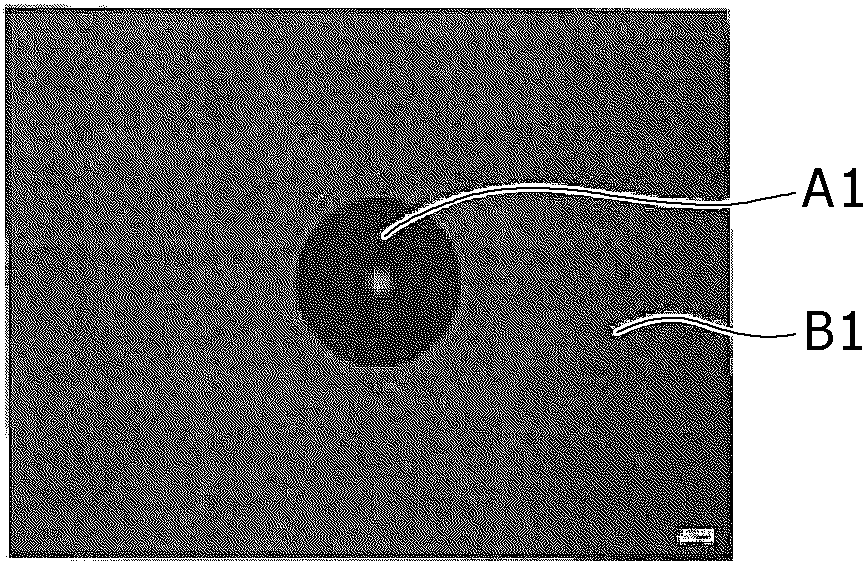

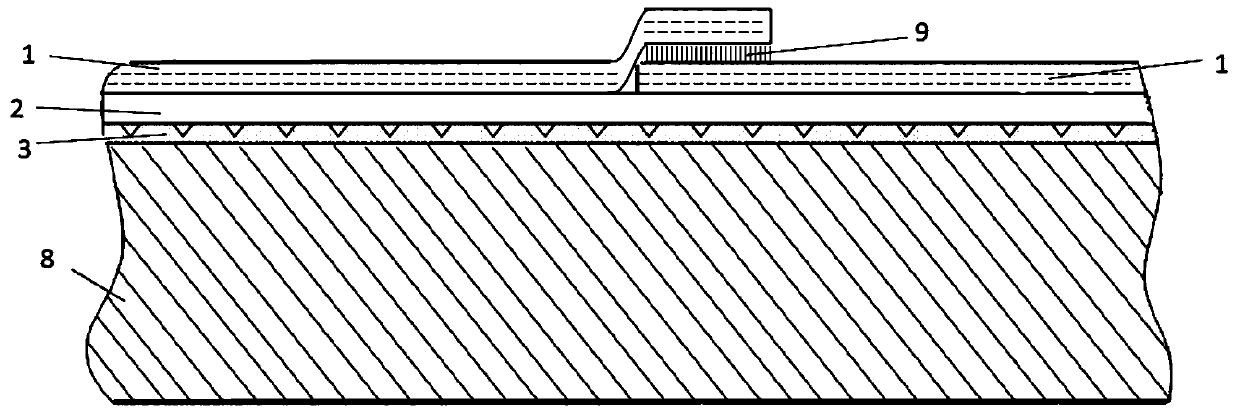

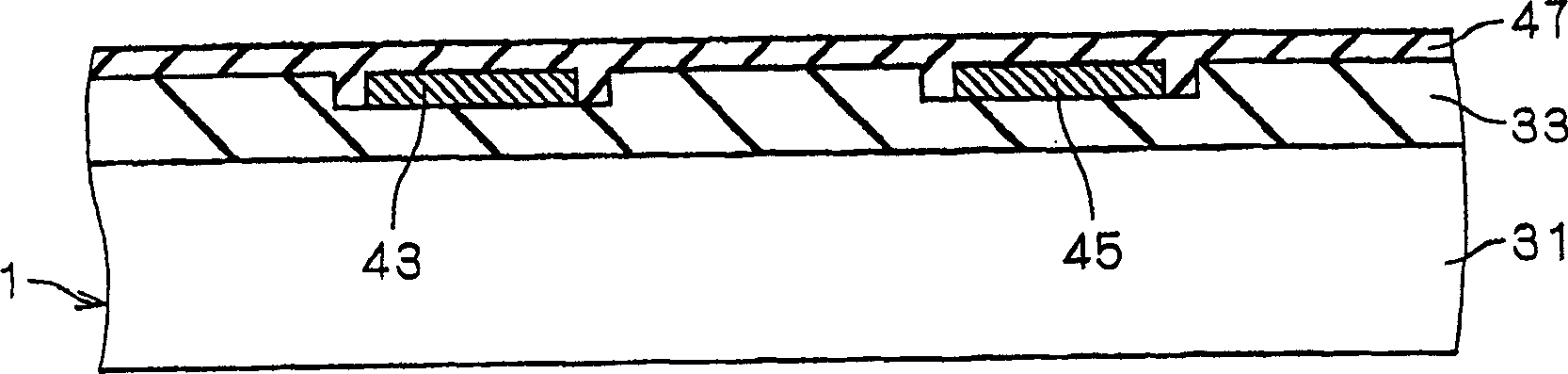

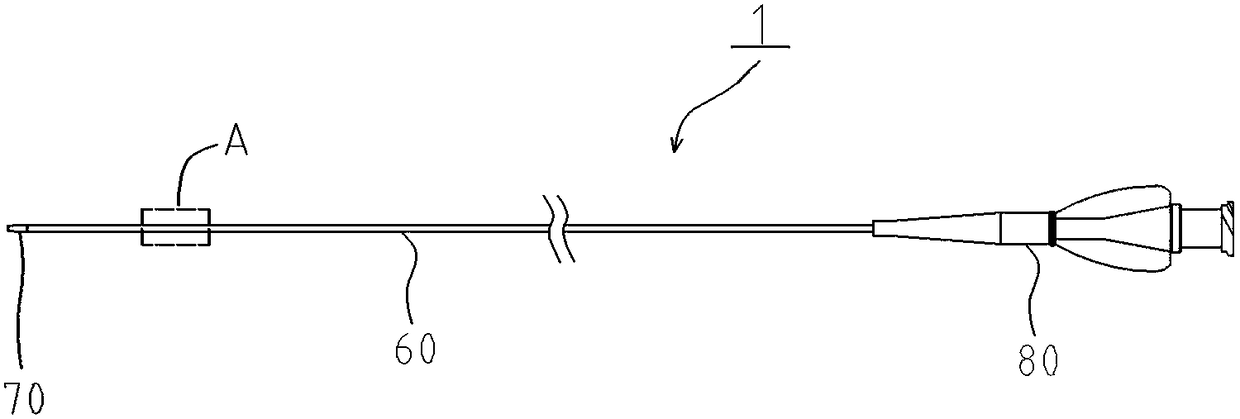

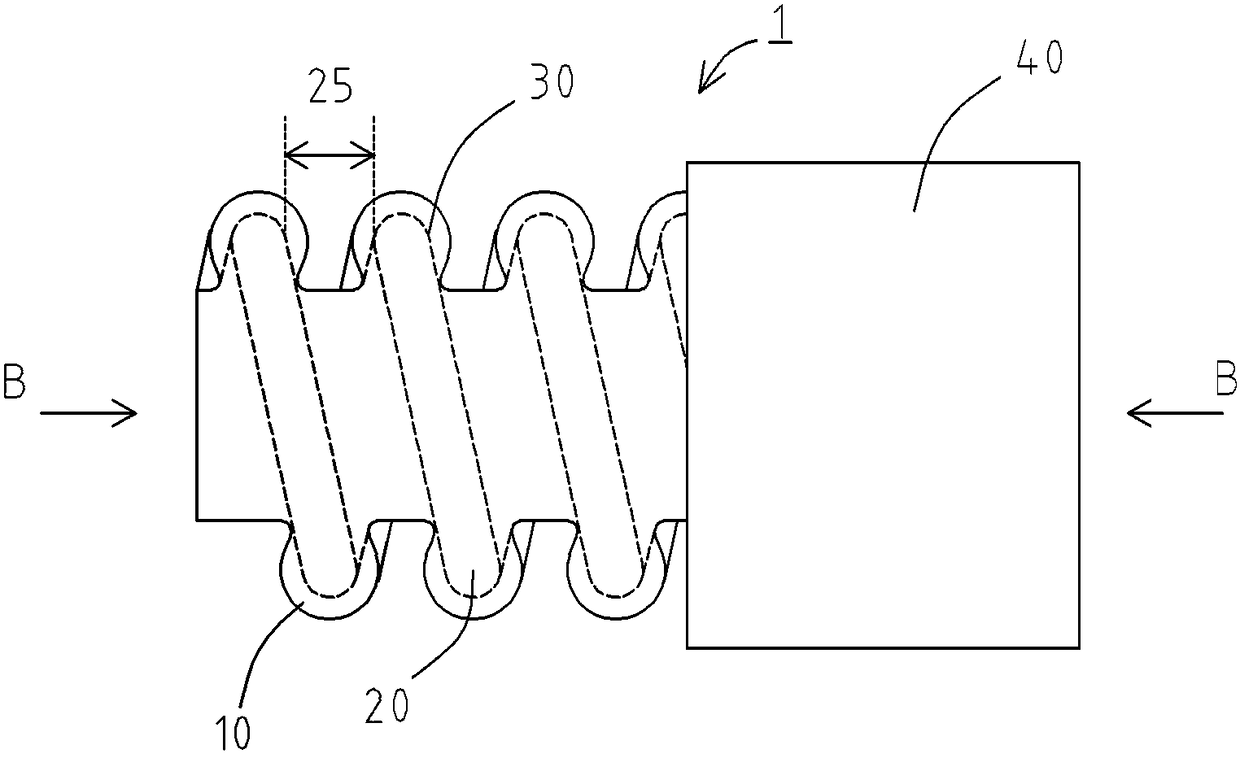

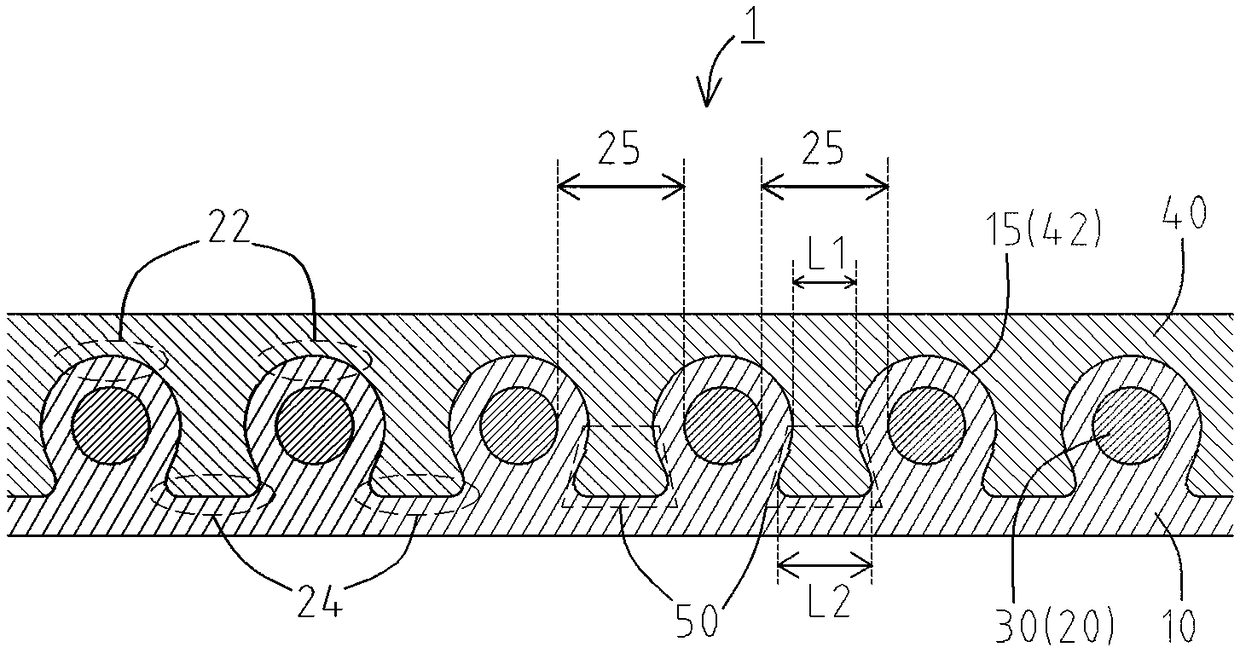

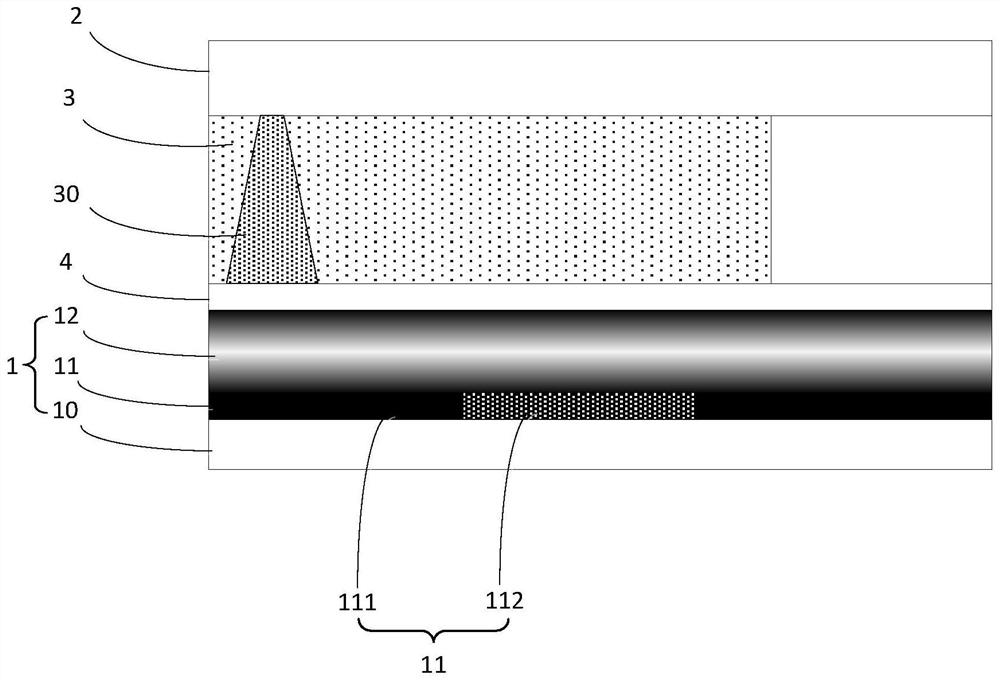

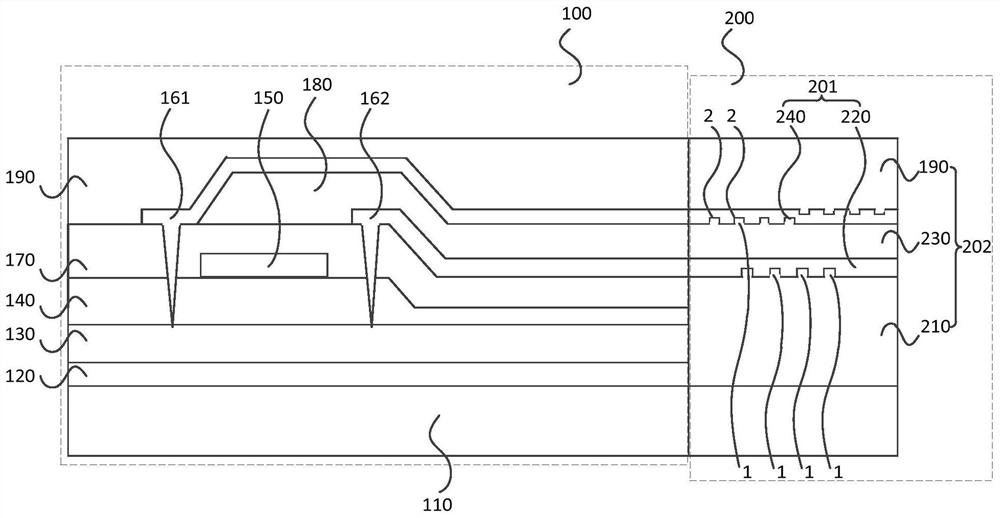

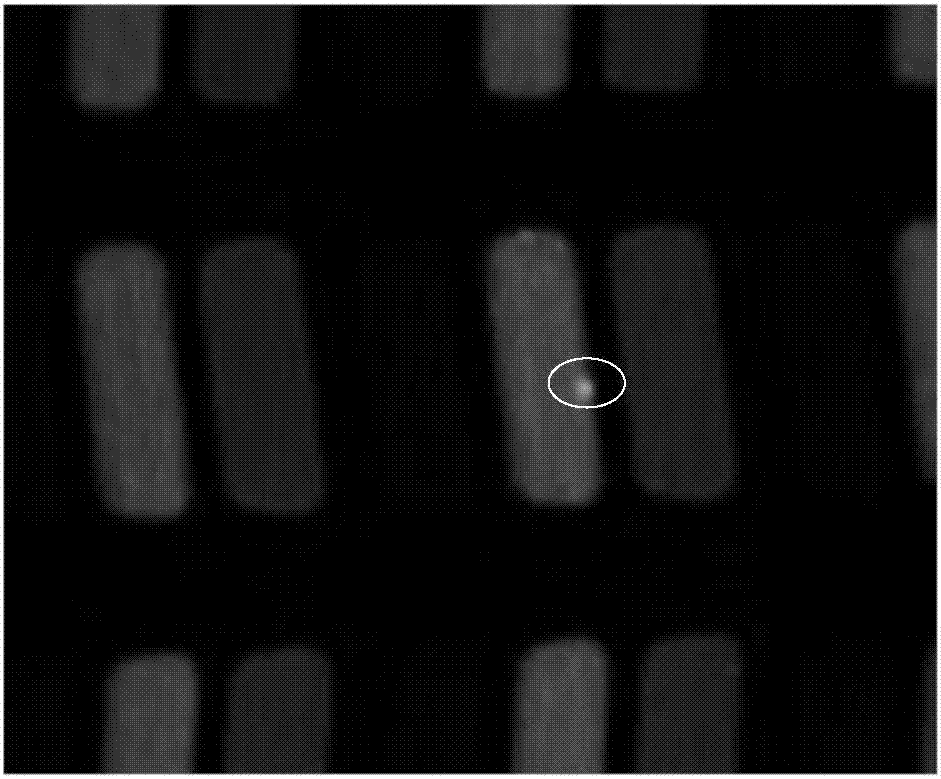

Catheter and balloon catheter

ActiveCN108156808AImprove joint strengthGuaranteed joint strengthBalloon catheterCoatingsBlood vesselBile duct

To provide a catheter wherein, even if an outer layer is pulled in the axial direction (front end direction and rear end direction), the outer layer is unlikely to be separated from an inner layer; and a balloon catheter. Provided is a catheter 1 wherein an outer layer 40 has a protrusion 50 provided at the location of a recess 24 in the inner layer 10, the protrusion 50 extending through a gap 25to a deeper position than a reinforcement layer (coil body) 30 and also extending axially. As a result of this configuration, the joint strength between the inner layer 10 and the outer layer 40 is increased, and an anchor effect by which the protrusion 50 of the outer layer 40 engages with the reinforcement layer 30 (coil body) 30 reduces the possibility of separation of the outer layer 40 fromthe inner layer 10 occurring when the outer layer 40 is pulled axially (front end direction and rear end direction) at a narrowed section or a closed section during the insertion of the catheter 1 into a blood vessel, a bile duct, a pancreas duct, etc.

Owner:ASAHI INTECC CO LTD

Battery and method of producing the same

InactiveCN100440587CReduced likelihood of strippingGood effectCell seperators/membranes/diaphragms/spacersFinal product manufactureEngineeringElectrical and Electronics engineering

A battery including: a power generating element having a positive electrode, a negative electrode, and a separator; a battery case for housing the power generating element; a battery cover for closing the battery case; and a lead for electrically connecting a terminal provided for the battery cover and the positive electrode or the negative electrode, wherein a part in which the lead and the positive electrode or the negative electrode are electrically connected to each other is sandwiched by an insulating member.

Owner:GS YUASA INT LTD

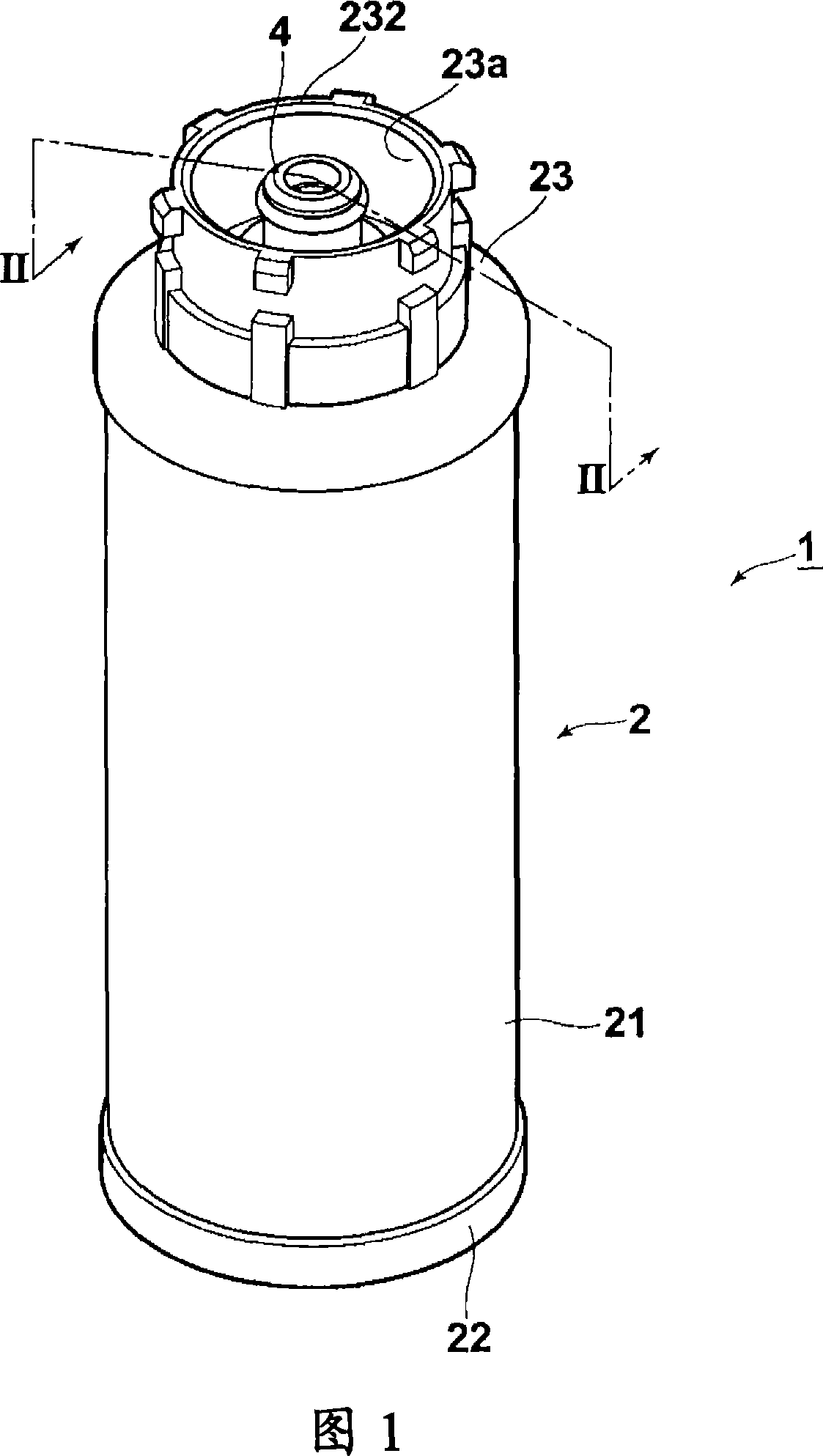

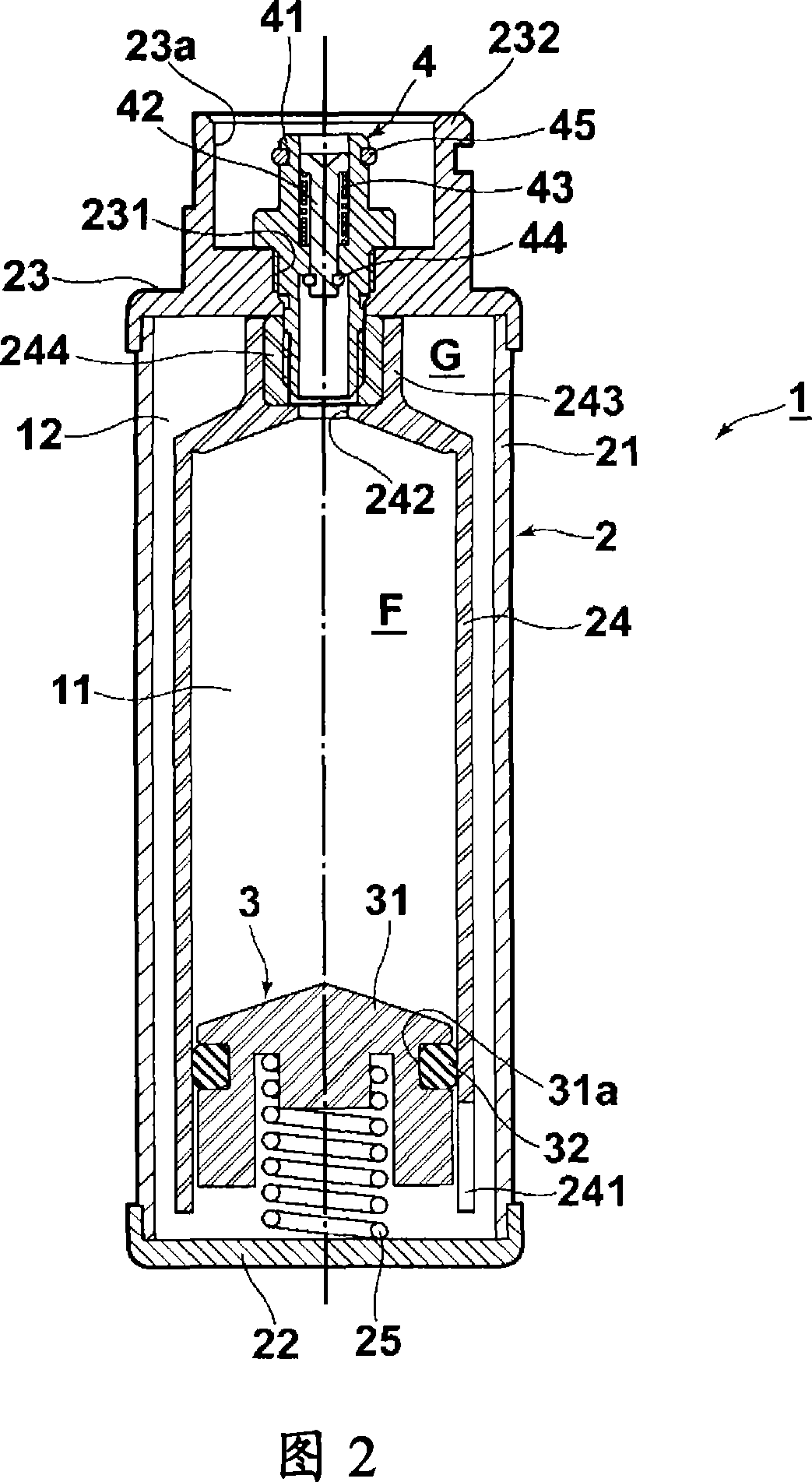

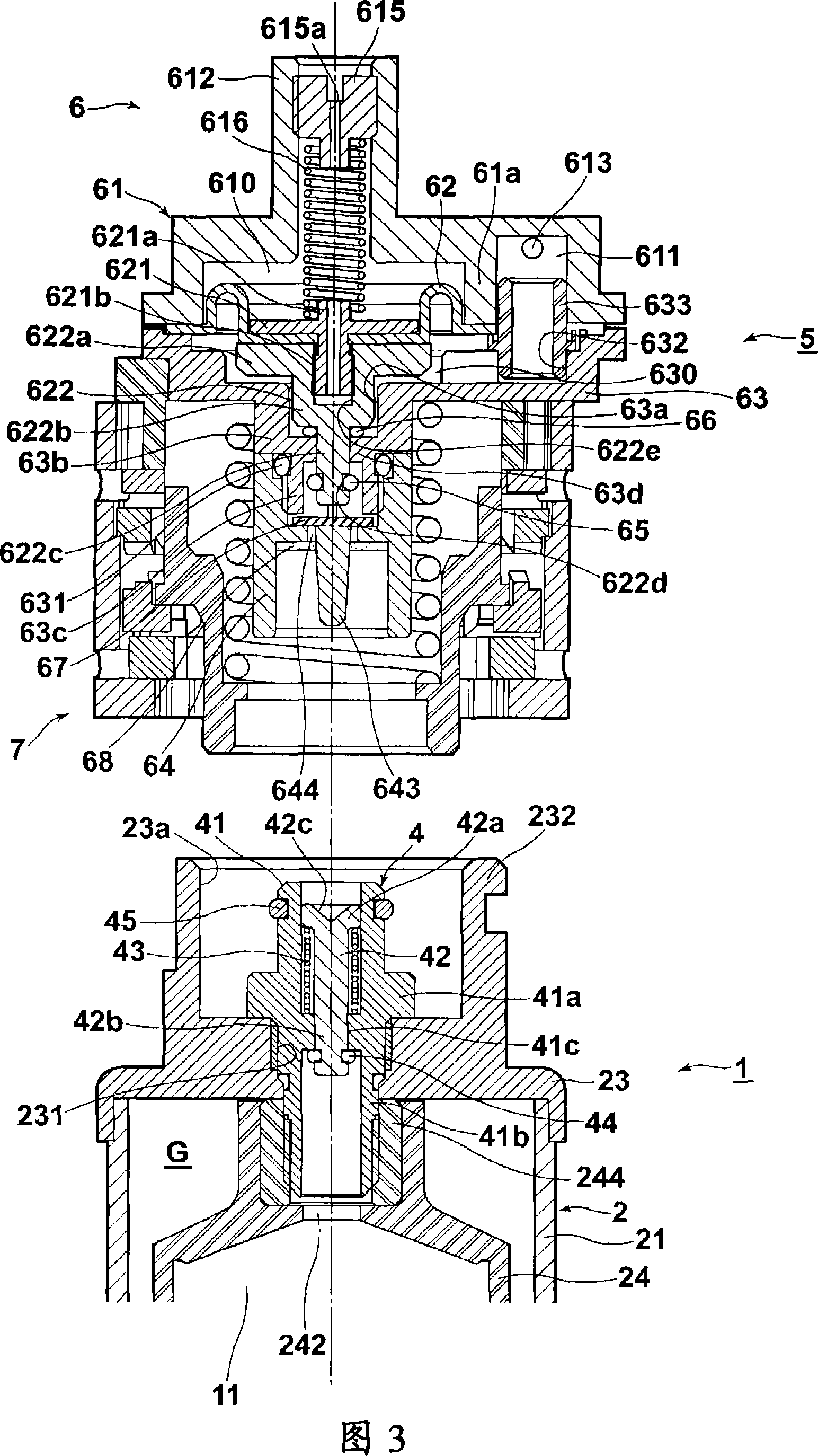

Fuel container for fuel cell

InactiveCN101218703AVolume will not decreaseIncreasing the thicknessReactant parameters controlSolid electrolyte fuel cellsFailure rateFuel cells

The present invention provides a fuel container for fuel cell in which failure rate is lowered while increasing the number of times of repeated use and the bulk ratio of the fuel by securing positive slidability, sufficient durability and adhesion of a partition wall member. A fuel container (1) for fuel cell comprises a container body (2) having a connection opening (23a) to be connected with a fuel cell or a pressure regulator and containing liquid fuel F to be supplied to the fuel cell and an extrusion means G for pushing out the liquid fuel F. A partition wall member (3) for sectioning the interior of the container body (2) into a fuel storage chamber (11) for containing the liquid fuel F, and a chamber (12) for containing the extrusion means G is arranged slidably in the container body (2). Furthermore, a valve (4) for releasing or interrupting conduction of the liquid fuel F is provided at the supply opening (23a). Sliding frictional force occurring on the sliding surface of the container body (2) and the partition wall member (3) is 10 N or less.

Owner:TOKAI

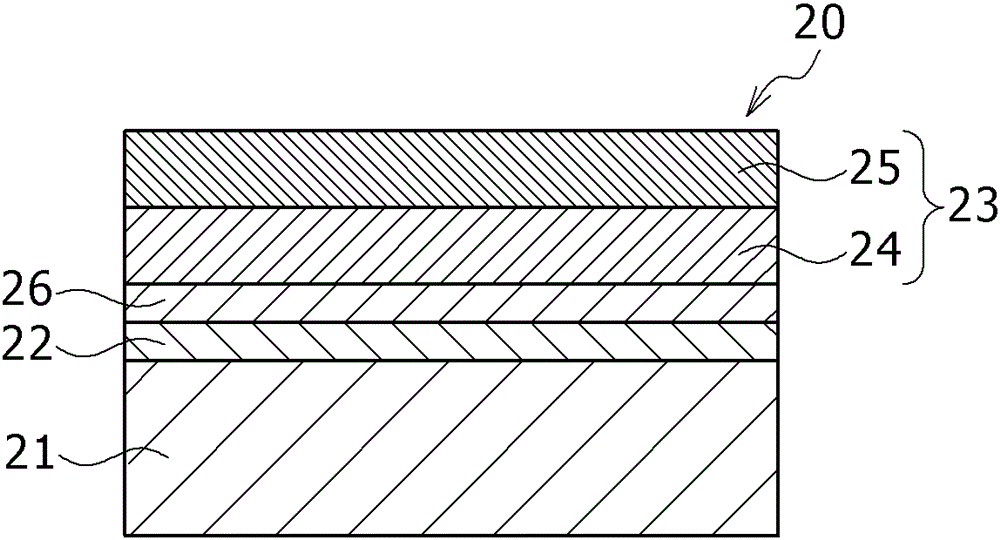

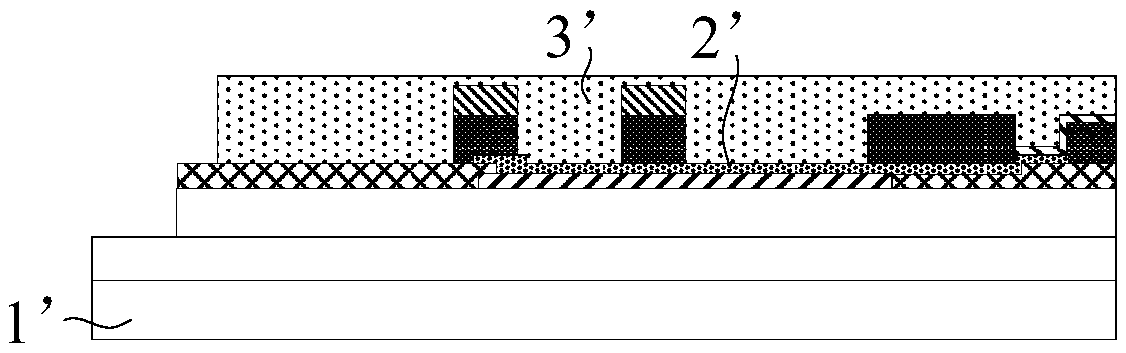

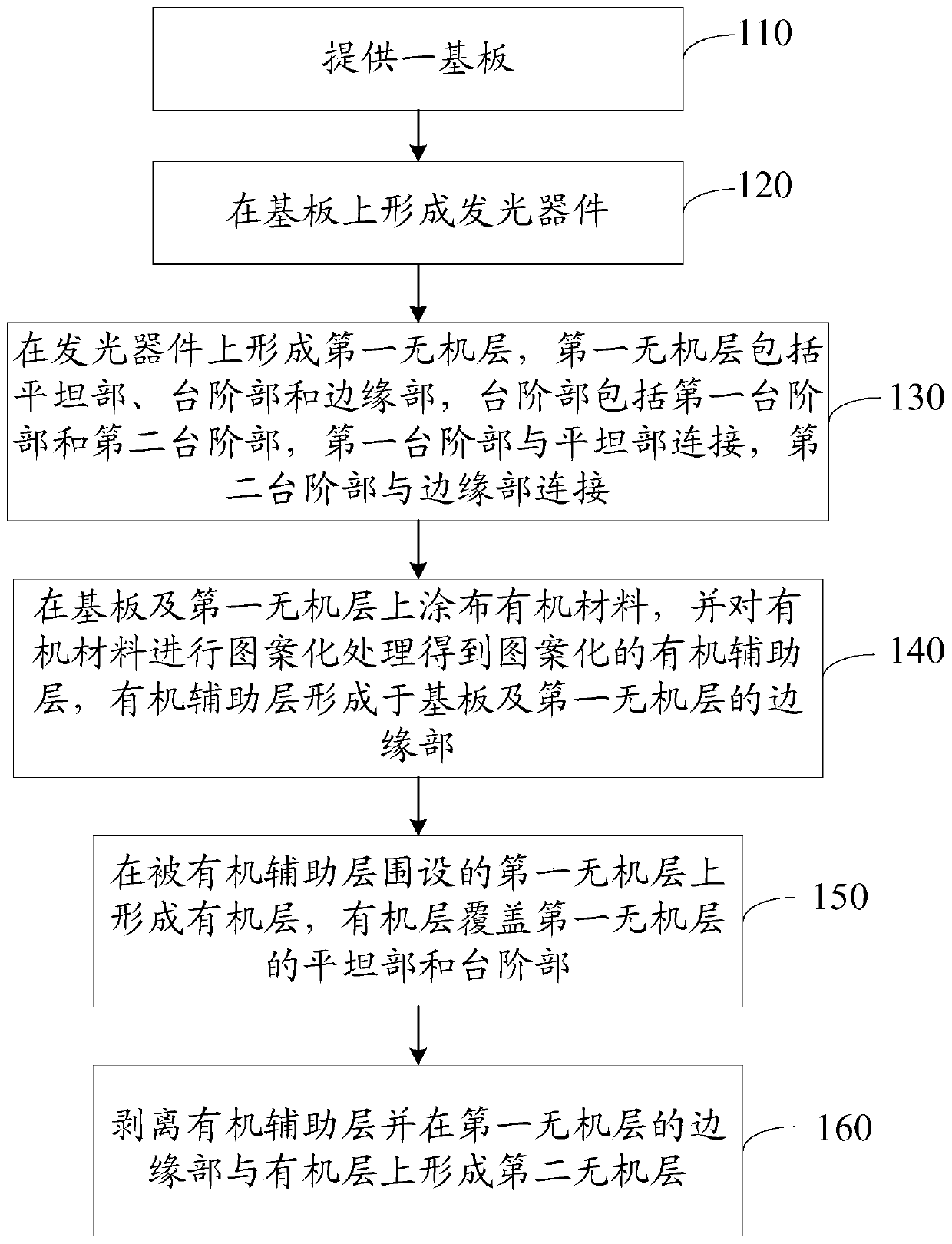

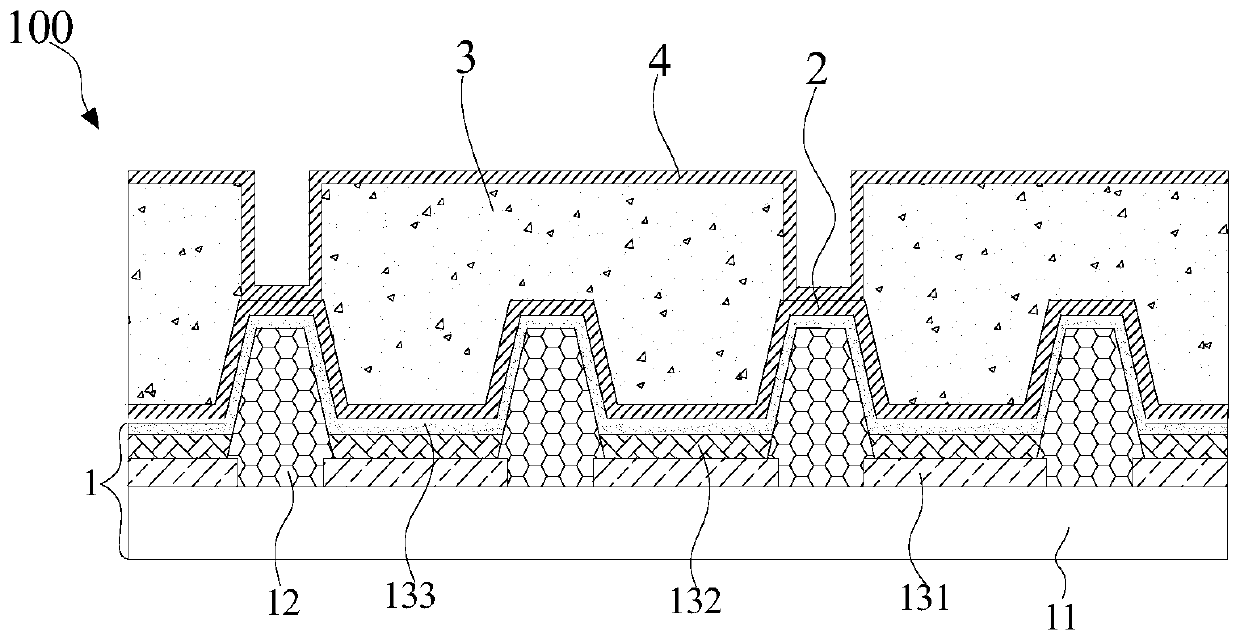

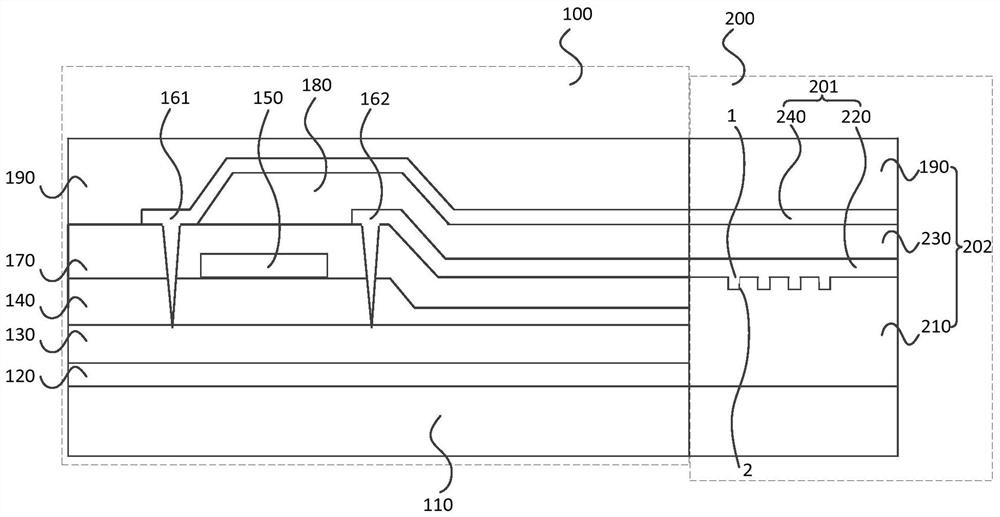

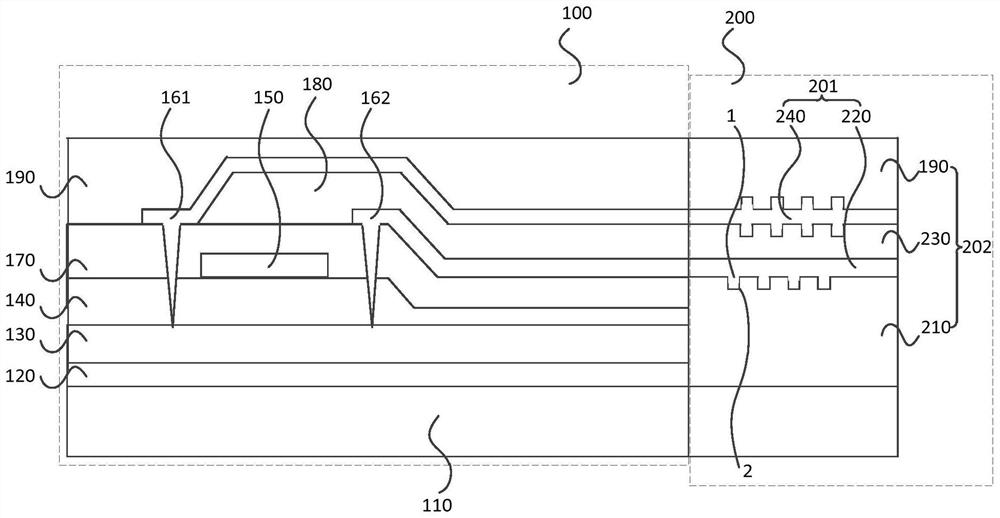

Preparation method of light-emitting panel, light-emitting panel and display device

InactiveCN109873016AAvoid settingReduced likelihood of strippingSolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceComputer science

The invention discloses a preparation method of a light-emitting panel, the light-emitting panel and a display device; the preparation method comprises the steps that a substrate is provided; a light-emitting device is formed on the substrate; a first inorganic layer is formed on the light-emitting device, wherein the first inorganic layer comprises a flat part, a step part and an edge part; the step part comprises a first step part and a second step part; the first step part is connected with the flat part, and the second step part is connected with the edge part; the substrate and the firstinorganic layer are coated with organic materials, and patterning is carried out on the organic materials to obtain the patterned organic auxiliary layer, wherein the organic auxiliary layer is formedon the edge parts of the substrate and the first inorganic layer; an organic layer is formed on the first inorganic layer which is surrounded by the organic auxiliary layer, and the organic layer covers the flat part and the step part of the first inorganic layer; and the organic auxiliary layer is stripped off, and a second inorganic layer is formed on the edge parts of the first inorganic layerand the organic layer, so that the arrangement of a retaining wall is avoided, thereby lowering the possibility of stripping between the film layers.

Owner:WUHAN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

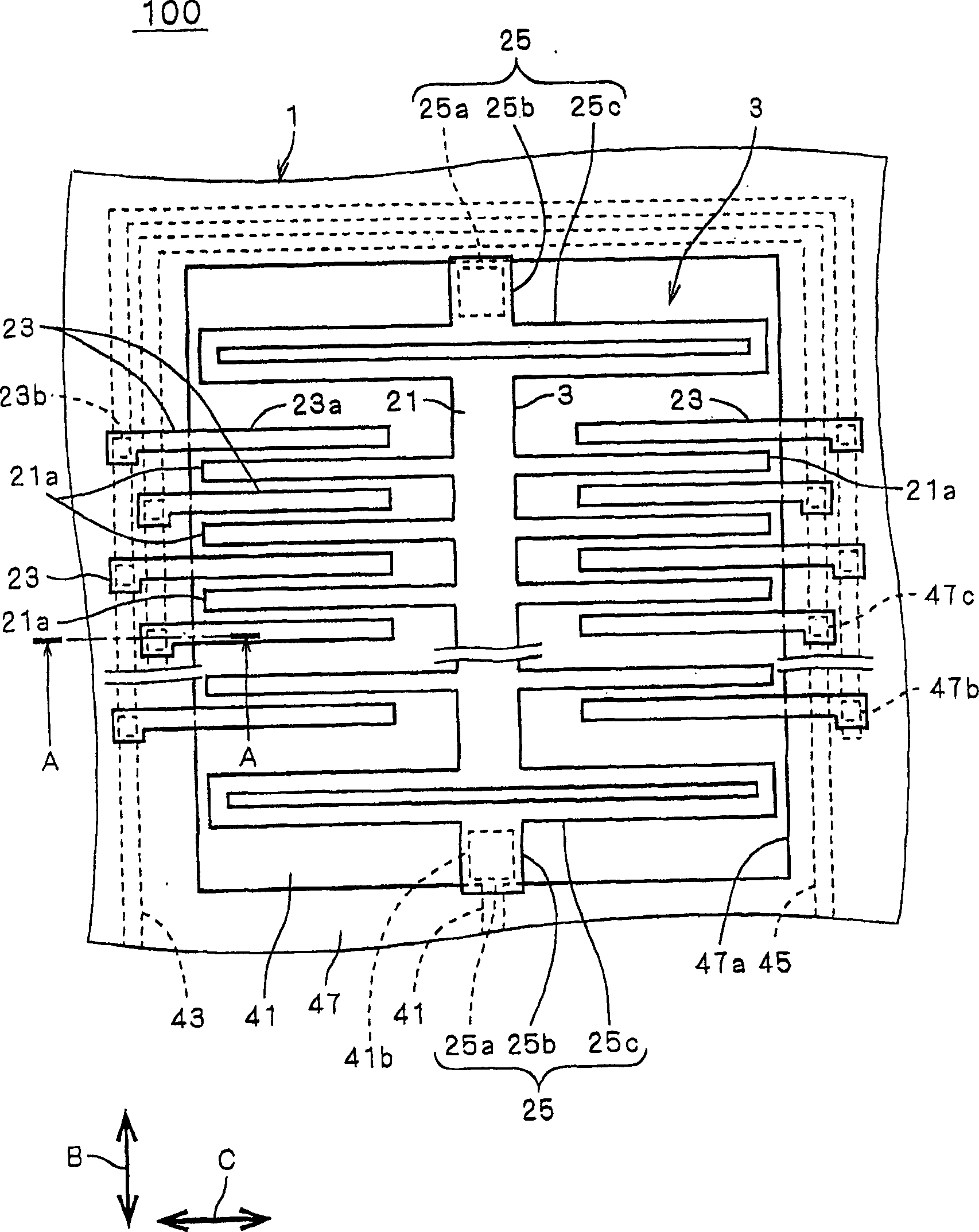

Coil wiring element and method for manufacturing coil wiring element

InactiveCN103827686AImprove reliabilitySuppress stressMagnetic field measurement using flux-gate principleInductances/transformers/magnets manufactureEngineeringElectrical and Electronics engineering

Owner:THE FUJIKURA CABLE WORKS LTD

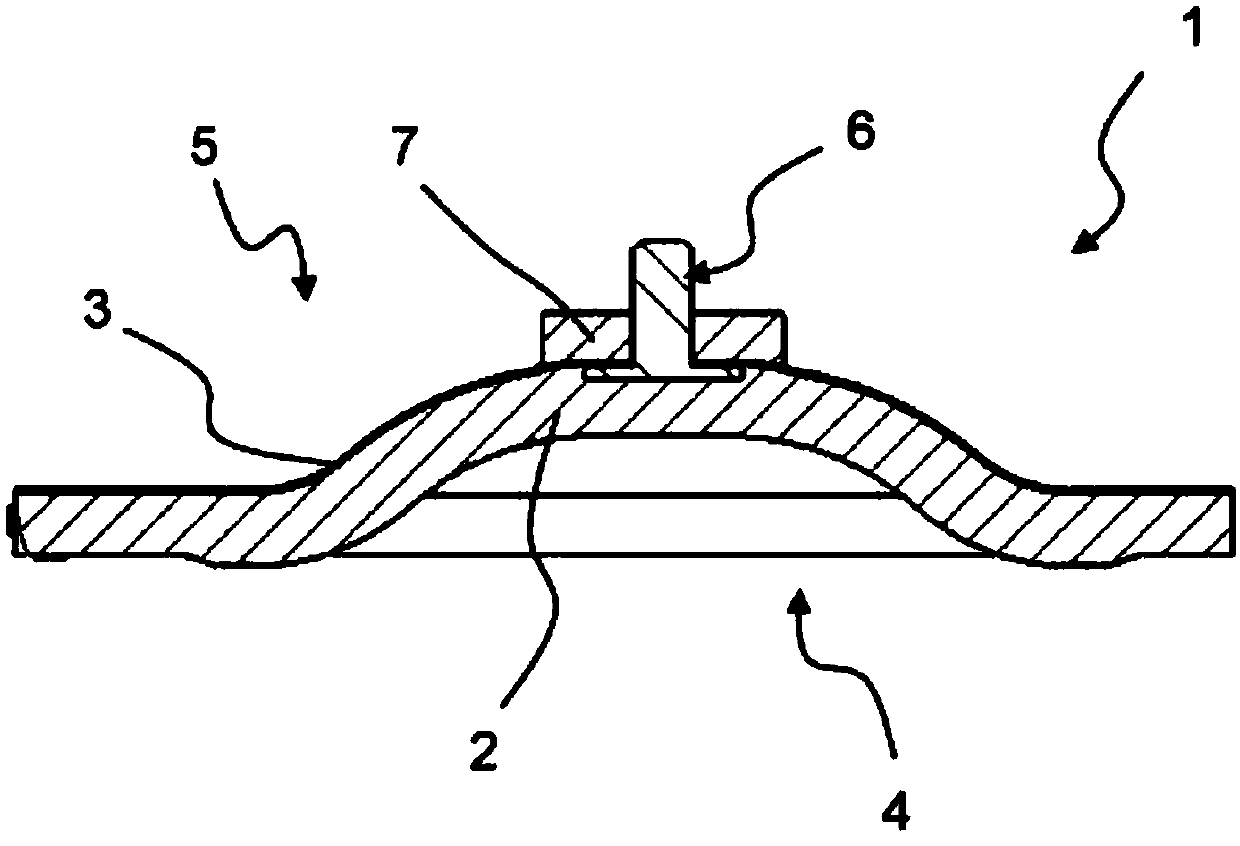

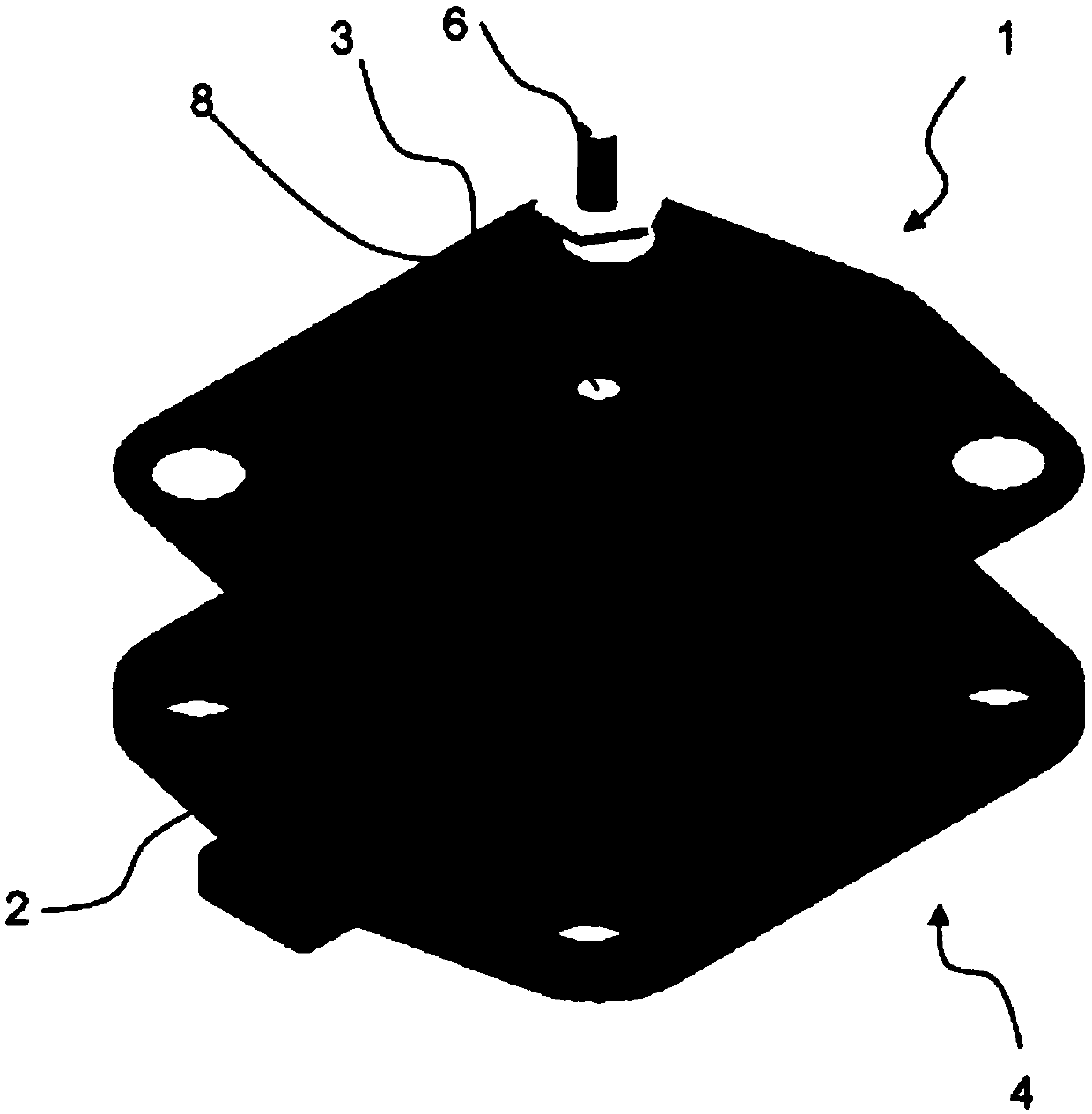

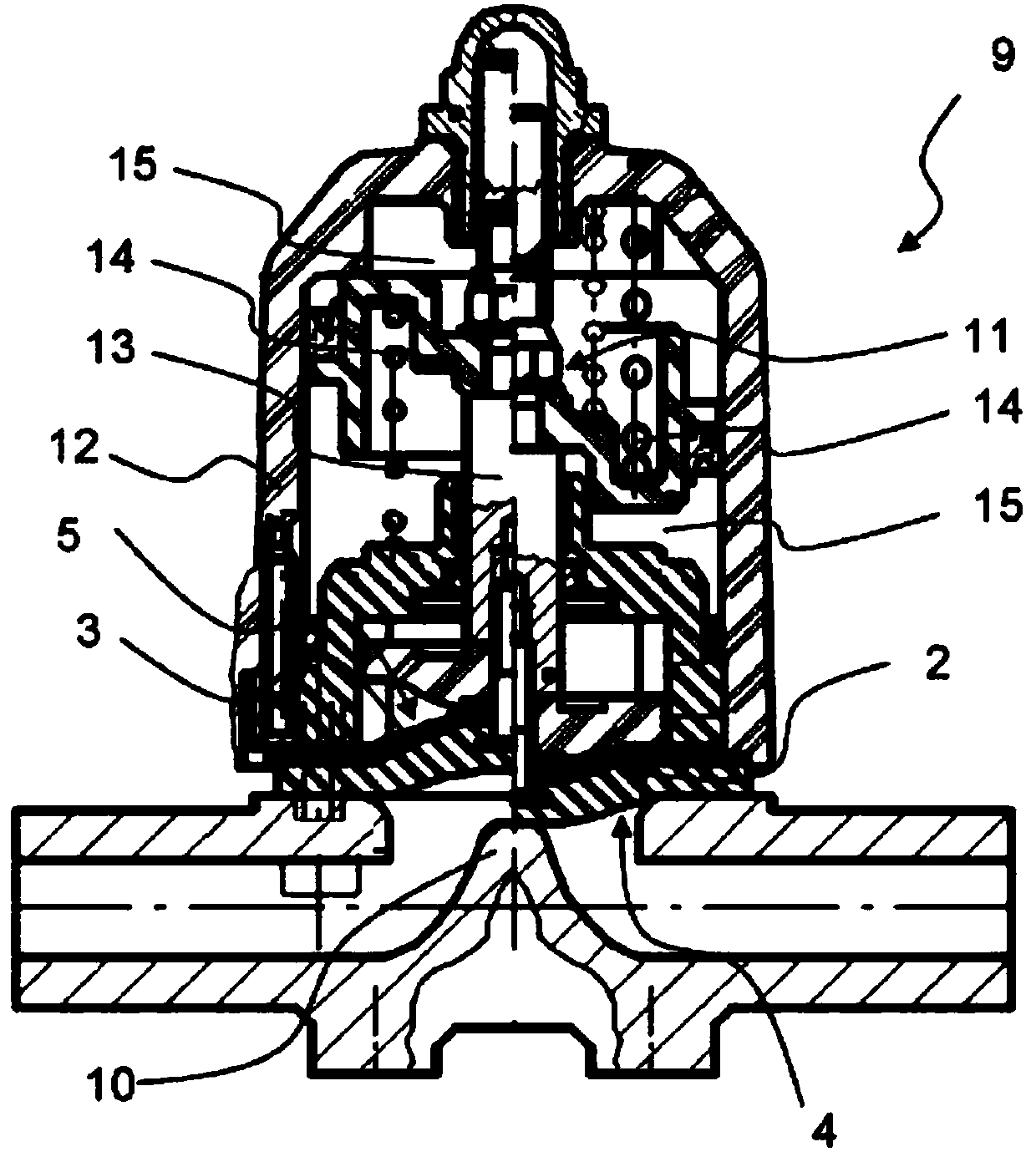

Diaphragm for diaphragm valve and manufacturing method thereof

InactiveCN109927299AContact area halvedReduced likelihood of strippingDiaphragm valvesEngine diaphragmsElastomerDiaphragm valve

The invention relates to a diaphragm (1) used for a diaphragm valve (9) and comprising a body (2) formed by an elastomer. The body (2) has a side (4) facing a medium and a side (5) far away from the medium. A force transmission member (6) for fixing a valve stem driver (11) of the diaphragm valve (9) is arranged on the side (5), far away from the medium, of the body (2). The body (2) is also provided with a reinforcement region (3), wherein the reinforcement region (3) is arranged on the outer side of the body (2) and is arranged on the side (5), far away from the medium, of the body.

Owner:塞德流量控制有限责任公司

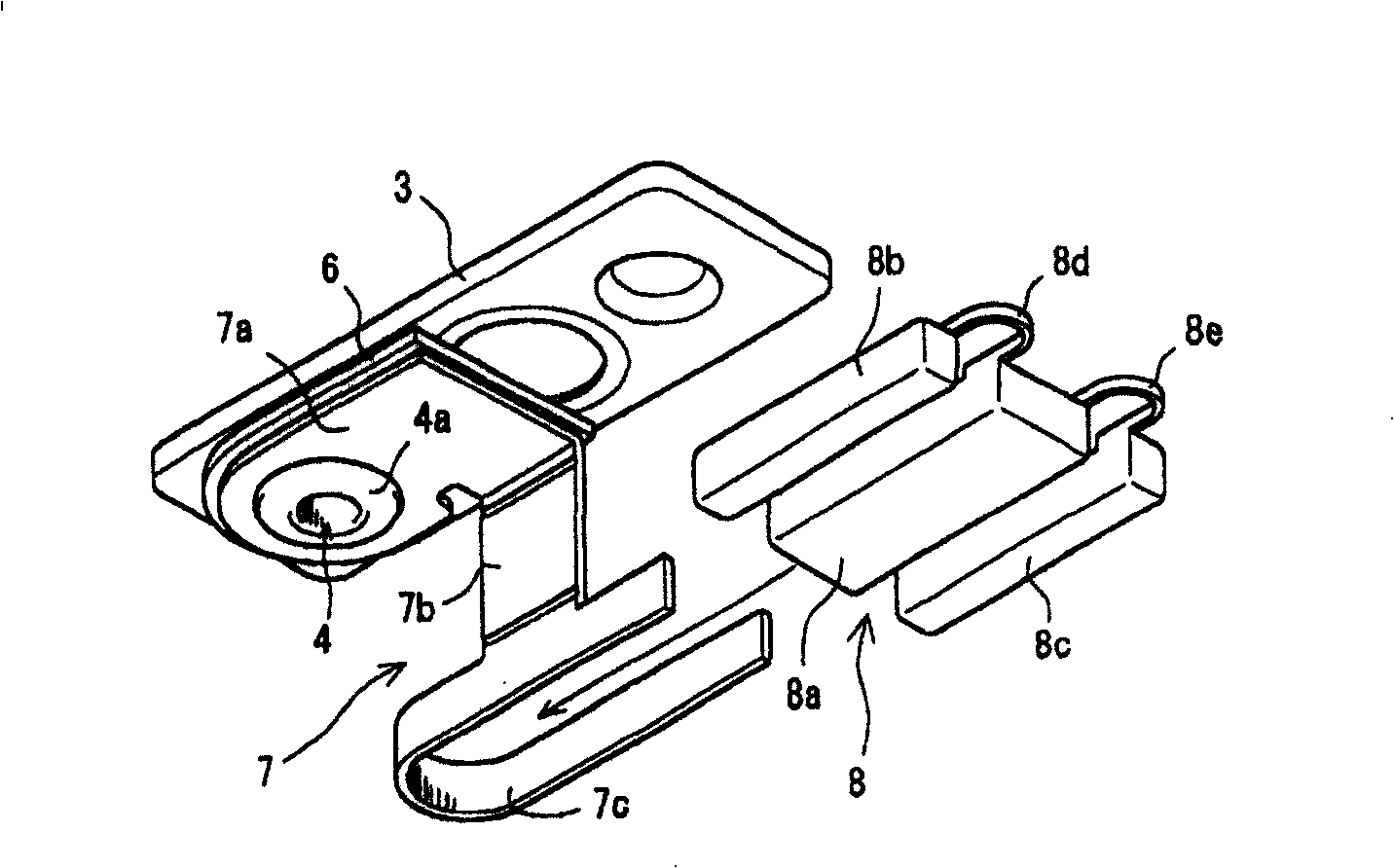

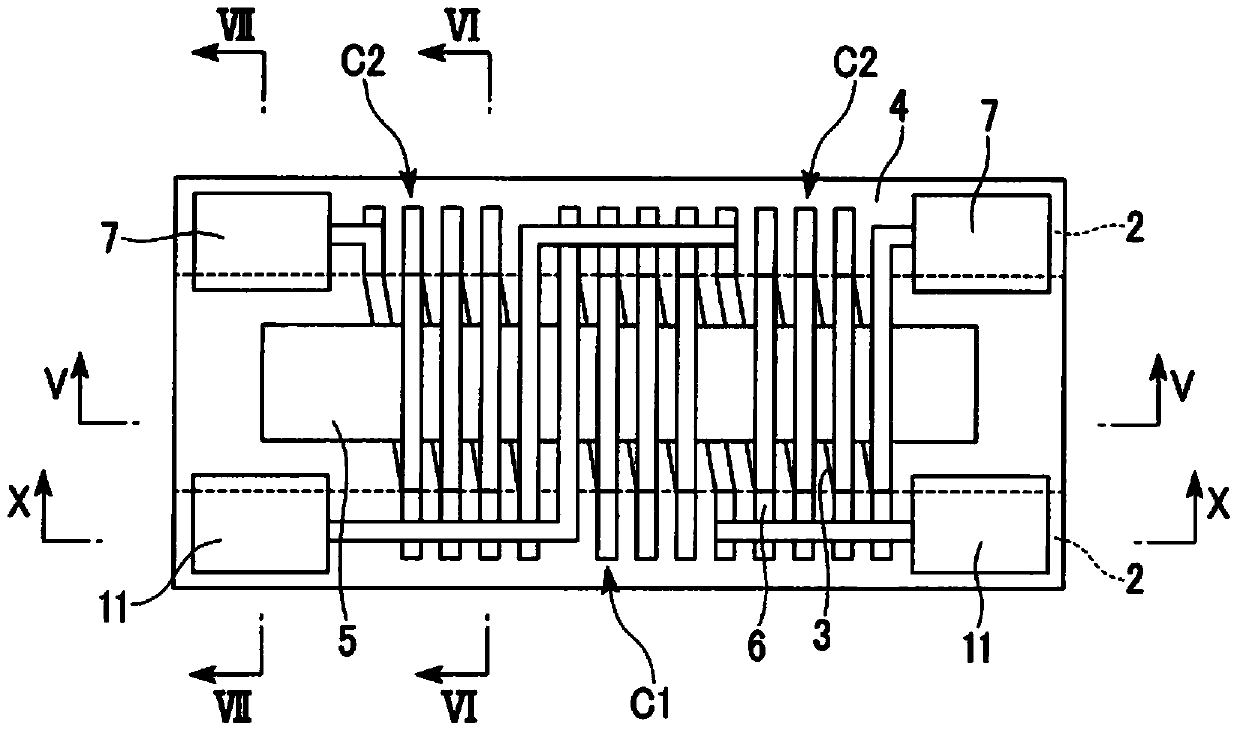

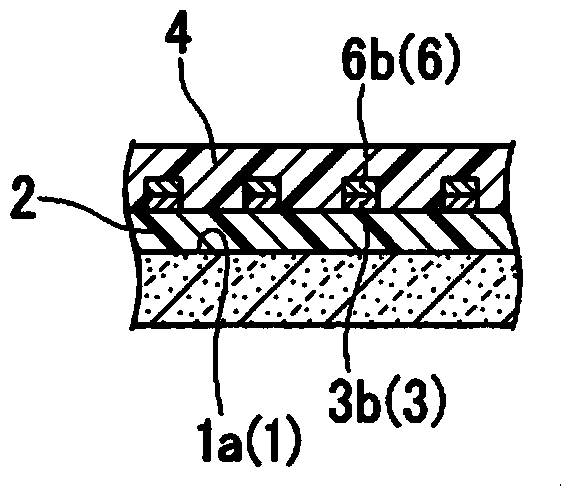

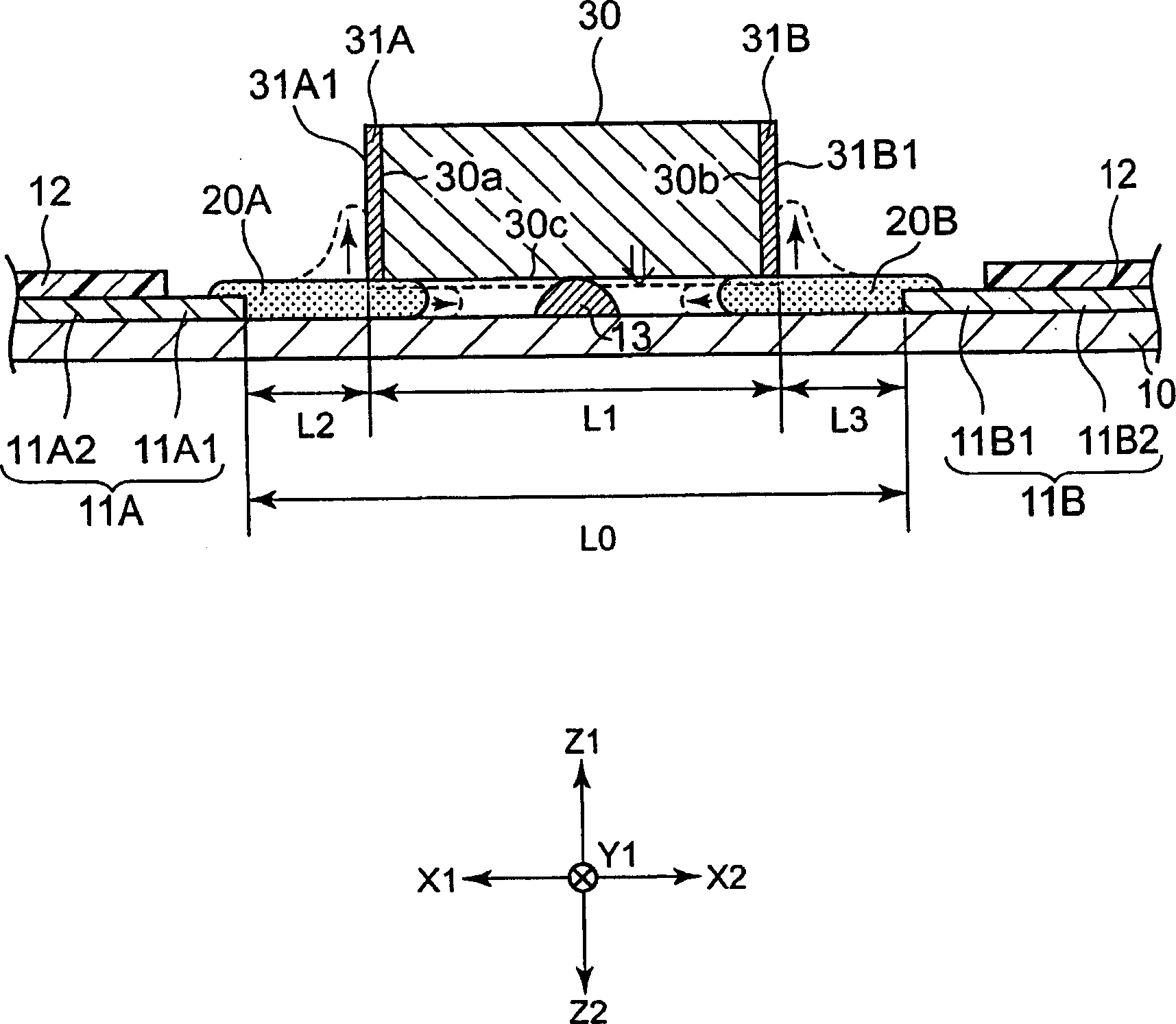

Electronic components packaging substrate

InactiveCN1816250AImprove the fixing strengthReduced likelihood of strippingPrinted circuit assemblingElectrical connection printed elementsEngineeringElectrical and Electronics engineering

To provide an electronic component mounting substrate which ensures higher fixing intensity of an electronic component to an insulating substrate. An electronic component 30 is connected to conductive patterns 11A, 11B via conductive bonding agent layers 20A, 20B by providing an interval L2 between a side end surface 31A1 of an electrode 31A and an end of a connector 11A1 of a conductive pattern 11A, and also providing an interval L3 between a side surface 31B1 of an electrode 31B and end of a connector 11B1 of a conductive pattern 11B. Accordingly, when a peeling force is applied to the electronic component 30, the peeling force is not transferred directly to the conductive patterns 11A, 11B, and the conductive patterns 11A, 11B are not easily peeled. The electronic component 30 is rigidly fixed to the surface of the insulating substrate 10 with conductive bonding agent layers 20A, 20B.

Owner:ALPS ALPINE CO LTD

Ceramic tile for combustion chambers lining, in particular of gas turbines, and manufacturing method thereof

ActiveCN103782102AReduce porosityImprove uniformityContinuous combustion chamberCasings/liningsBrickInter layer

A ceramic tile (1) for combustion chambers lining, in particular of gas turbines, comprises a base body (2) made of ceramic material, for example in alumina or in alumina-mullite, and a coating (3) applied to at least one face (4) of the base body (2). The coating (3) is a multilayer ceramic coating, comprising at least one outer layer (6) made of alumina or ceramic material comprising alumina, and at least one intermediate layer (5), arranged between the outer layer (6) and the base body (2) and made of ceramic material comprising mullite and preferably in mullite or in alumina-mullite.

Owner:ANSALDO ENERGIA SPA

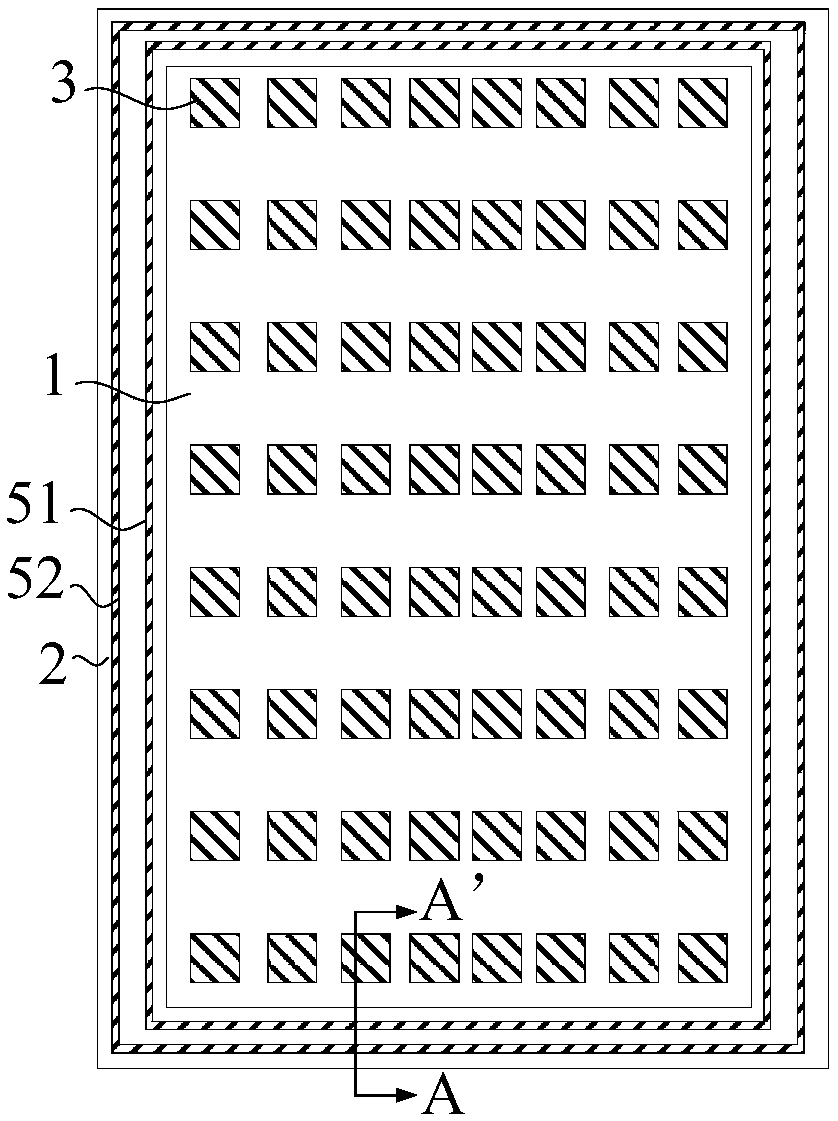

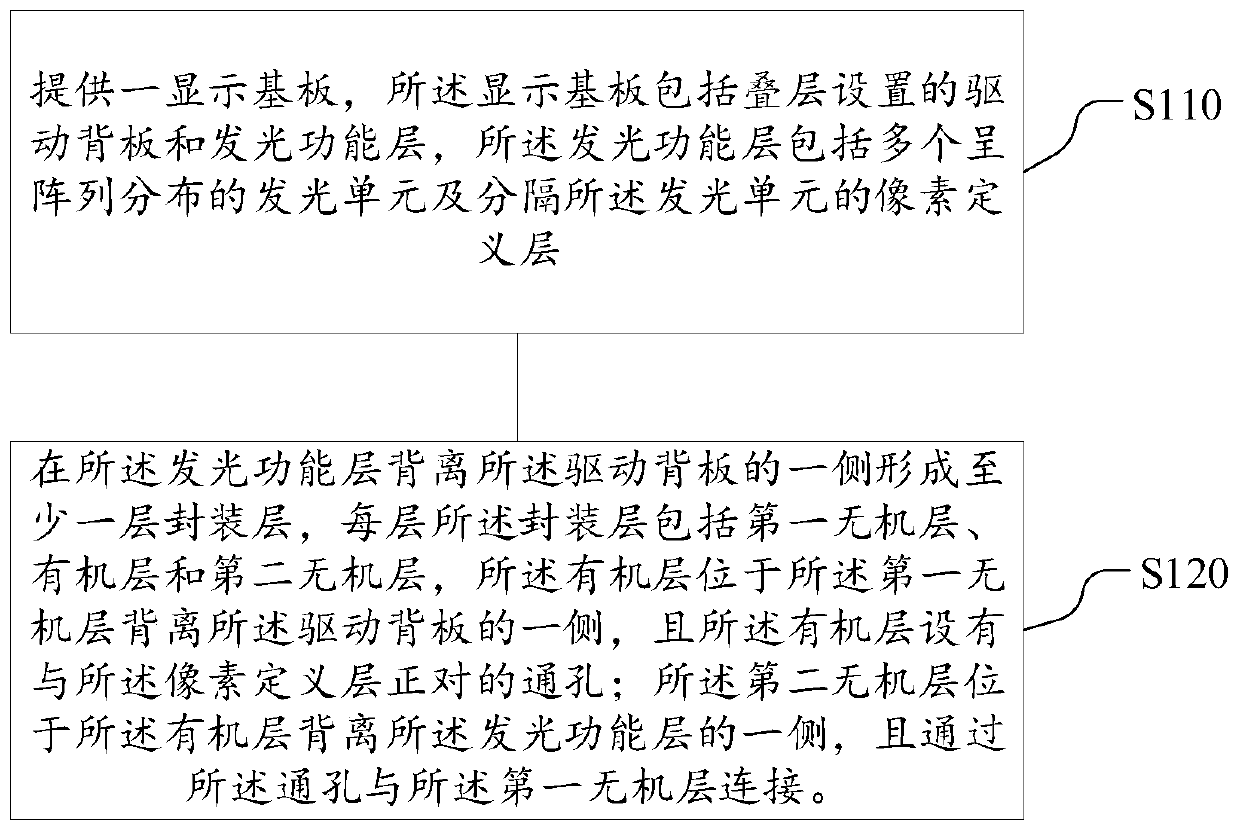

Display device, display panel and packaging method of display substrate

ActiveCN111326677APrevent peelingIncrease contact areaSolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceEngineering

The invention provides a display device, a display panel and a packaging method of a display substrate, and relates to the technical field of display. The packaging method comprises that: a display substrate is provided, the display substrate comprises a driving backboard and a light-emitting function layer which are arranged in a laminated mode, and the light-emitting function layer comprises a plurality of light-emitting units distributed in an array mode and a pixel definition layer for separating the light-emitting units; at least one packaging layer is formed on the side, deviating from the driving backboard, of the light-emitting function layer, each packaging layer comprises a first inorganic layer, an organic layer and a second inorganic layer, the organic layer is located on the side, deviating from the driving backboard, of the first inorganic layer, and the organic layer is provided with a through hole right opposite to the pixel definition layer; and the second inorganic layer is located on the side, away from the light-emitting function layer, of the organic layer and connected with the first inorganic layer through the through hole. According to the display device, the display panel and the packaging method of the display substrate, stripping of the packaging layer can be avoided, and the packaging effect is improved.

Owner:BOE TECH GRP CO LTD

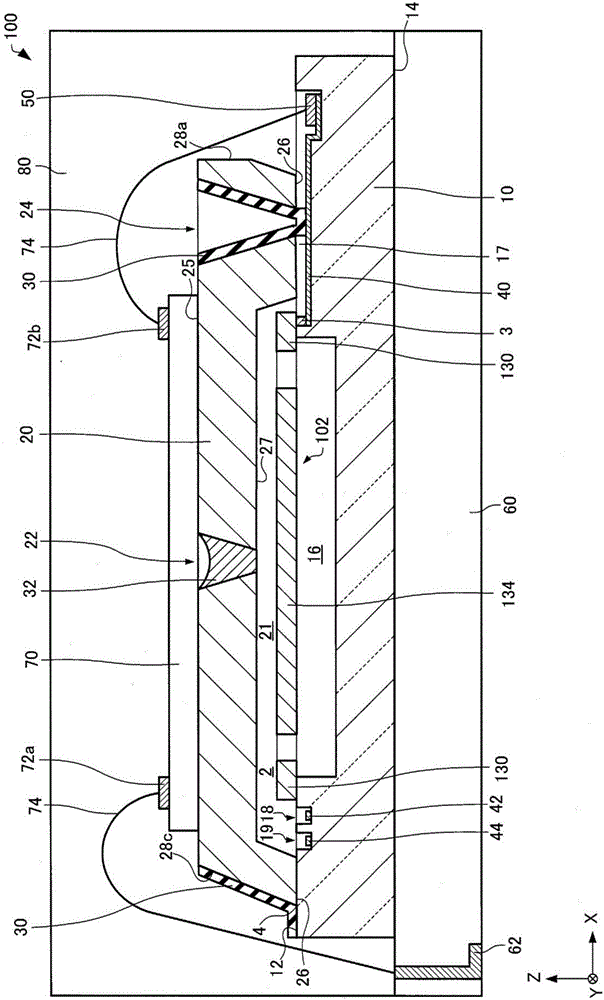

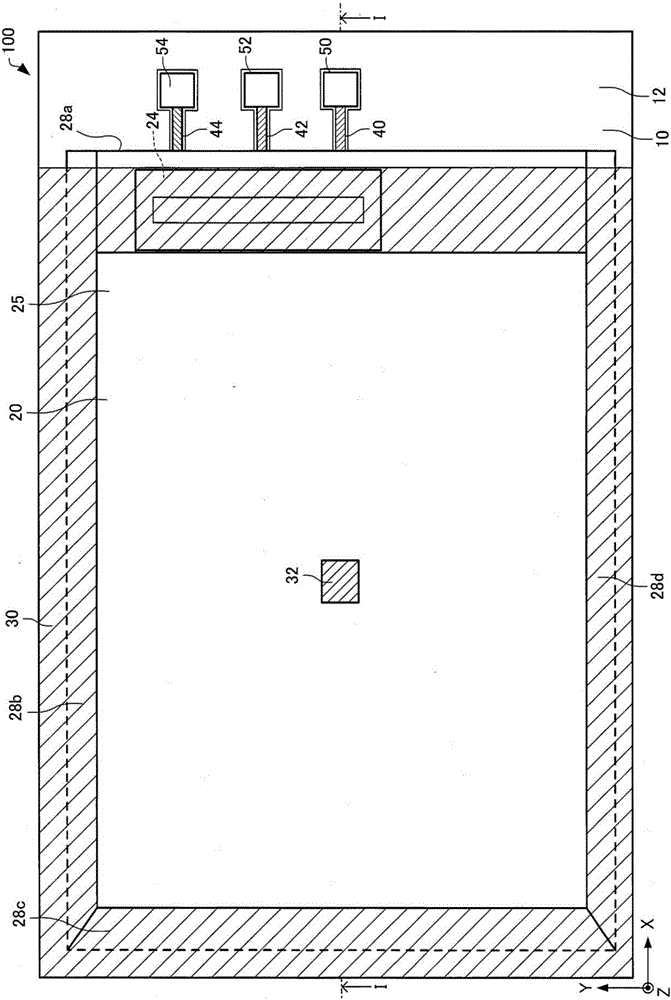

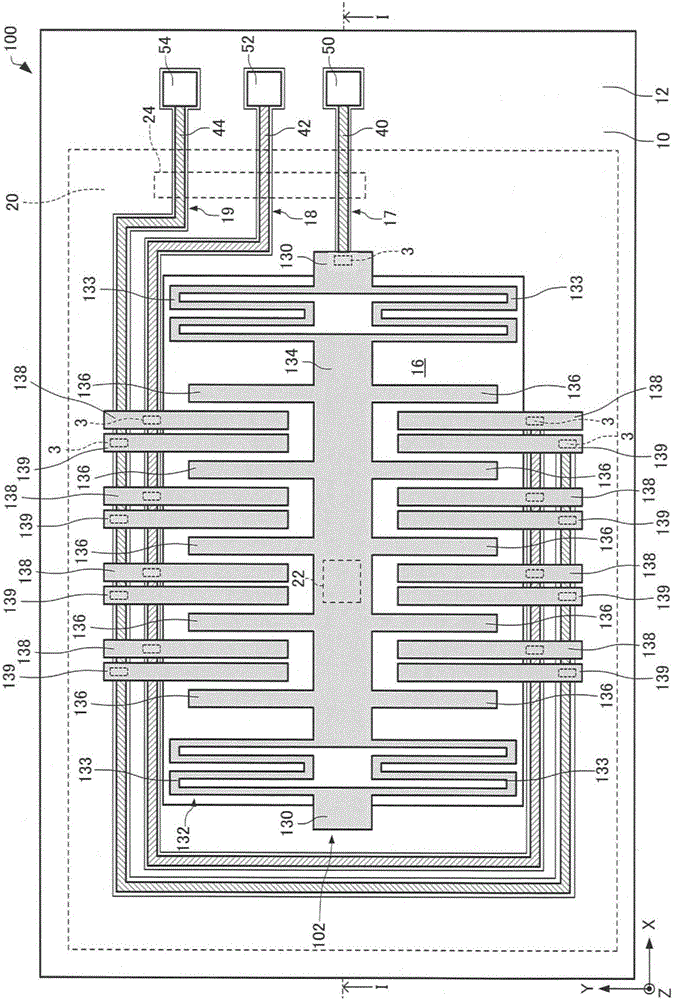

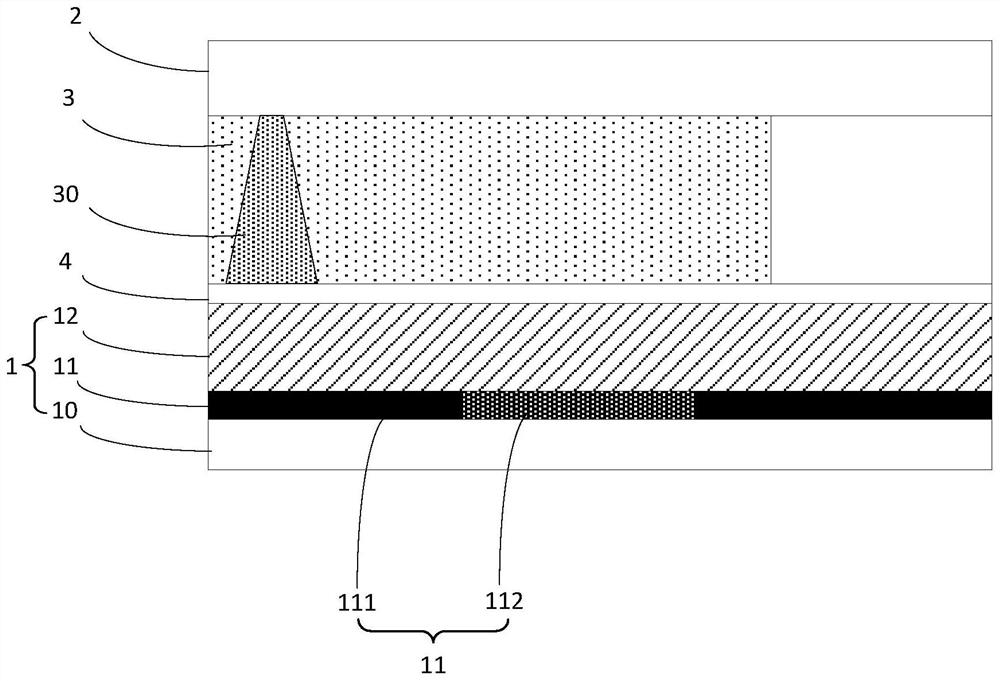

Physical quantity sensor, manufacturing method thereof, electronic equipment, and movable body

InactiveCN105937919AReduced likelihood of strippingSolid-state devicesAcceleration measurementTectorial membraneEngineering

The invention provides a physical quantity sensor, a manufacturing method thereof, electronic equipment, and a movable body. The physical quantity sensor can decrease the possibility that a cover might come off from a base. The physical quantity sensor (100) includes: a base (10); a cover (20); a function element (102) provided inside a cavity (2) formed by the base (10) and the cover (20); and a protection film (30) with which a principal surface (12) of the base (10), a bonding boundary portion (4) between the principal surface (12) of the base (10) and the cover (20), and the cover (20) are coated continuously, wherein the protection film (30) is an inorganic material film or an organic semiconductor film.

Owner:SEIKO EPSON CORP

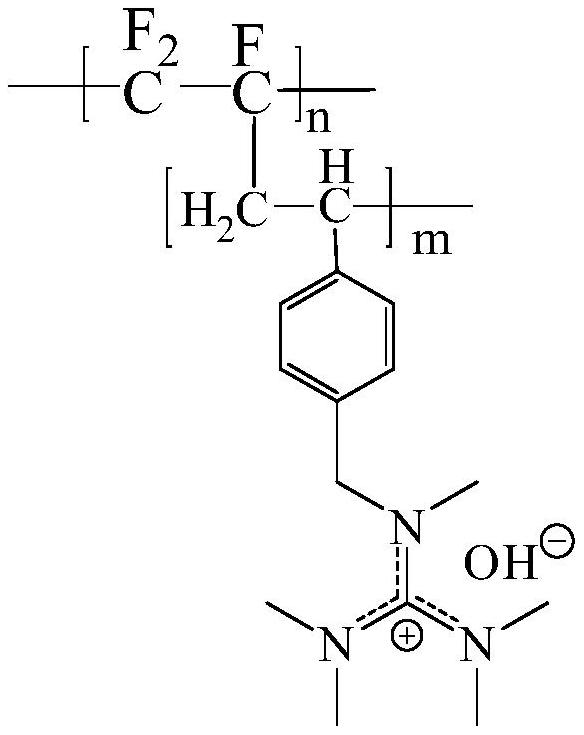

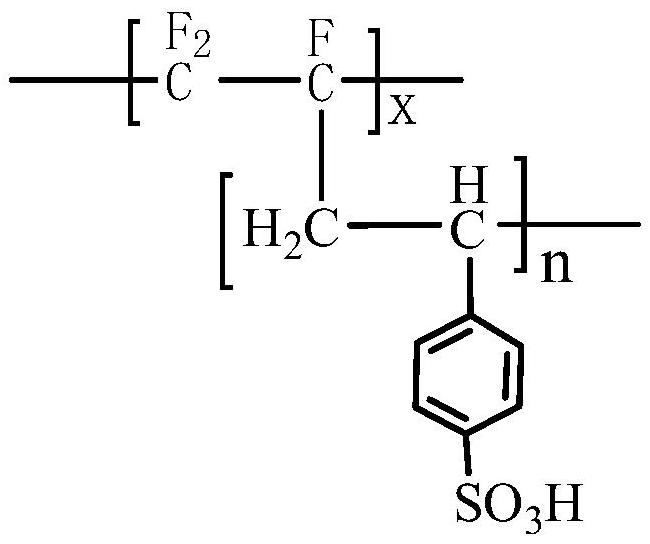

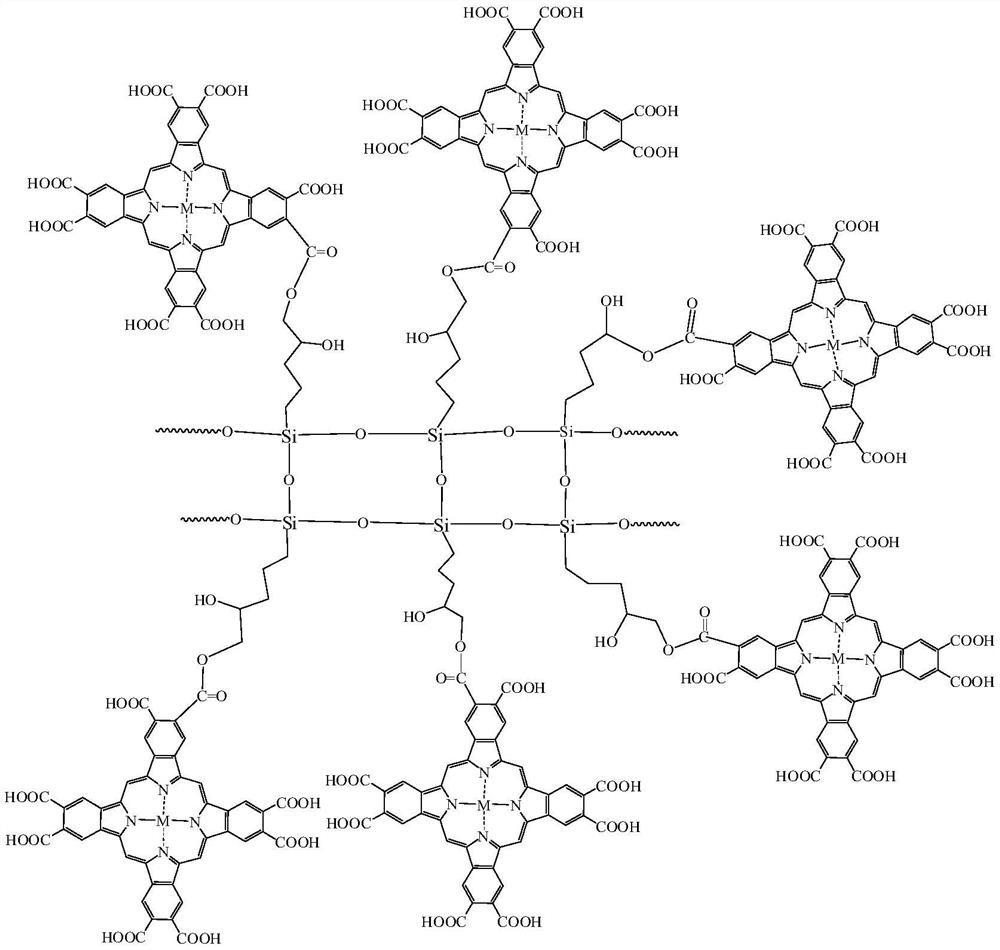

Main chain fluorocarbon alkali-resistant bipolar membrane and preparation method thereof

ActiveCN114506139AIncrease resistance to strong alkali concentrationOvercome the defect that it is easy to be degraded by hydroxide attackLamination ancillary operationsSynthetic resin layered productsChemical physicsPhysical chemistry

The invention discloses a preparation method of a main chain fluorocarbon alkali-resistant bipolar membrane, and belongs to the field of electrically driven membranes. Both an anion exchange membrane layer and a cation exchange membrane layer in the prepared bipolar membrane take fluorocarbon chains as main chains, so that the defect that hydroxyl attacks carbon-oxygen bonds in a common main chain is overcome; meanwhile, the anion exchange membrane layer and the cation exchange membrane layer have similar physicochemical properties, so that the stripping possibility in the use process is reduced, and the service life is prolonged.

Owner:FUJIAN NORMAL UNIV

Touch panel comprising flexible printed circuit board with dummy patterns and manufacturing method

InactiveCN106293190AReduced likelihood of strippingIncrease the occupied spaceInput/output processes for data processingPrinted circuit boardTouch panel

The invention discloses a flexible printed circuit board used for a touch panel. The flexible printed circuit board comprises flexible printed circuit board alignment marks arranged on the flexible printed circuit board and provided with outer sides, and dummy patterns arranged on the flexible printed circuit board and abutted to the outer sides of the flexible printed circuit board alignment marks.

Owner:HENGHAO TECH CO LTD +1

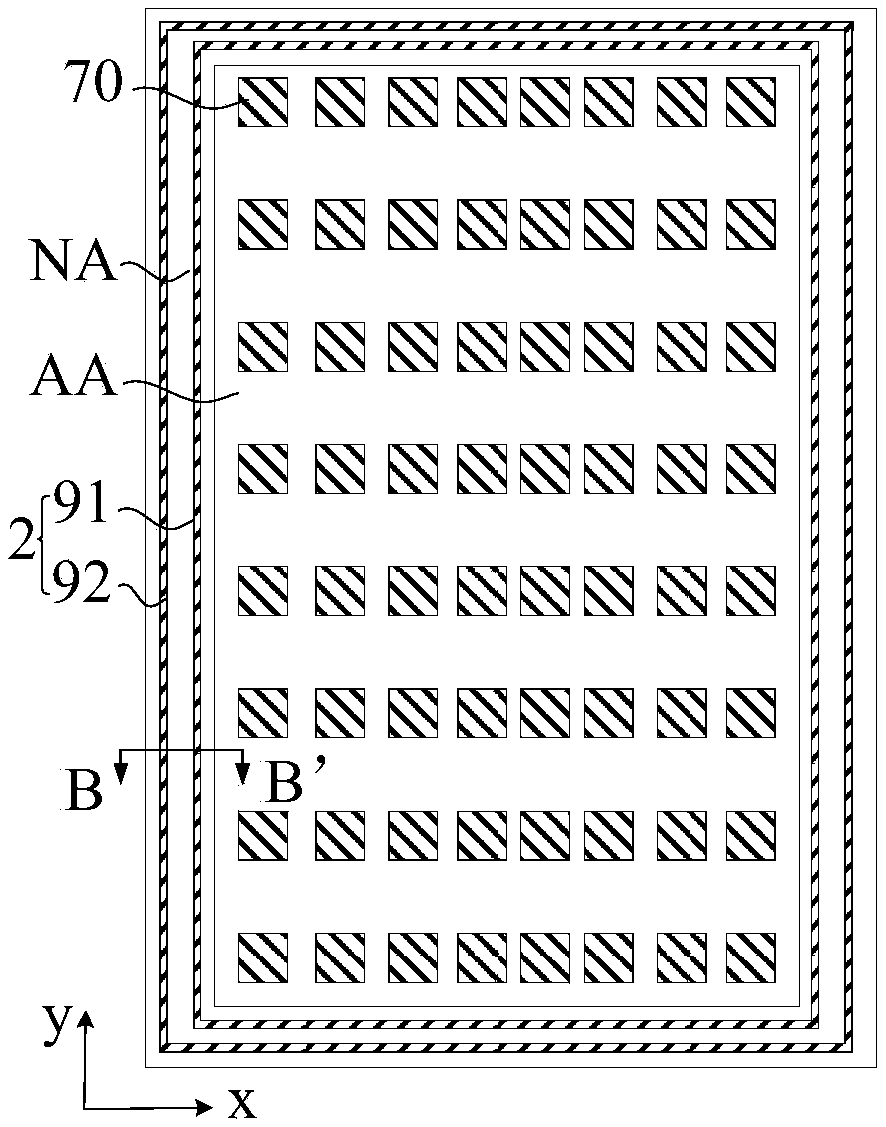

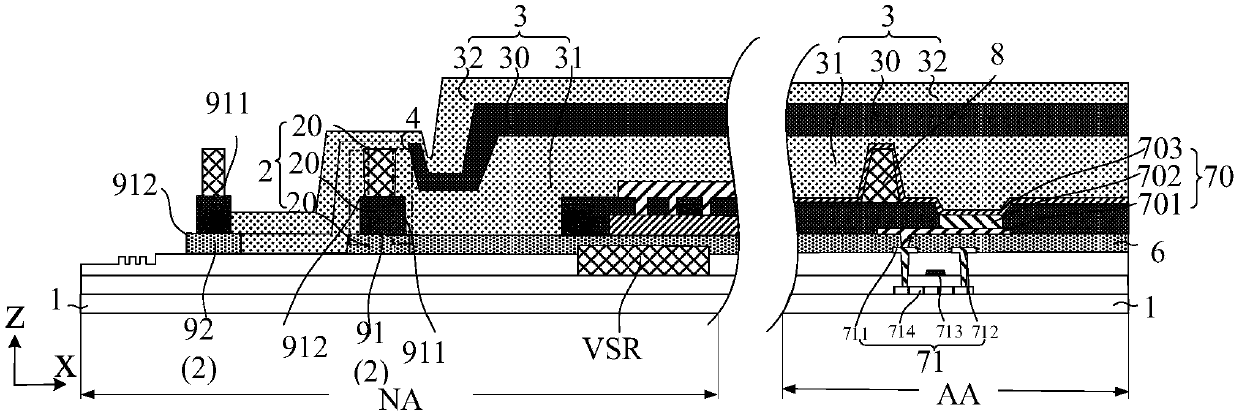

Display panel and display device

ActiveCN109585690BEnsuring Package ReliabilityReduced likelihood of strippingSolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceEngineering

Examples of the present invention provide a display panel and display device, which involves the field of display technology to solve the problem of being easy to peel off in the existing technology and the prudent block.The display panel includes substrate substrates, blocking parts, and packaging layers; of which, the blocking parts surround the display area of the display panel; and the blocking part is located on the side of the substrate substrate;Among them, the surface of the blocking part of the block and the packaging layer includes the uneven structure.

Owner:XIAMEN TIANMA MICRO ELECTRONICS

A color filter substrate, a display panel and a display device

ActiveCN107367782BReduce contentReduced likelihood of strippingOptical filtersNon-linear opticsLiquid crystallinePhysical chemistry

Owner:BOE TECH GRP CO LTD +1

Array substrate and flexible display device

ActiveCN109449163BImprove stabilityImprove the situation of uneven forceSolid-state devicesSemiconductor devicesEngineeringFlexible display

Owner:GUANGZHOU GOVISIONOX TECH CO LTD

Color film substrate, display panel and display device

ActiveCN107367782AGood physical parameter matchingReduced likelihood of strippingOptical filtersNon-linear opticsLiquid crystalDisplay device

The invention discloses a color film substrate, a display panel and a display device, and relates to the technical field of display. Small molecule organic color resistance materials are stopped from diffusing to liquid crystals, and good adhesion between a protective layer and a color filter layer is reduced. The color film substrate comprises a substrate base plate and the color filter layer formed on the surface of the substrate base plate, the protective layer is arranged on the surface of the color filter layer back to the substrate base plate and contains organic materials and inorganic materials, and the content of the inorganic materials in the protective layer is gradually increased and then gradually reduced along the direction far away from the surface of the color filter layer back to the substrate base plate. The display panel comprises the color film substrate. The color film substrate is used for the display device.

Owner:BOE TECH GRP CO LTD +1

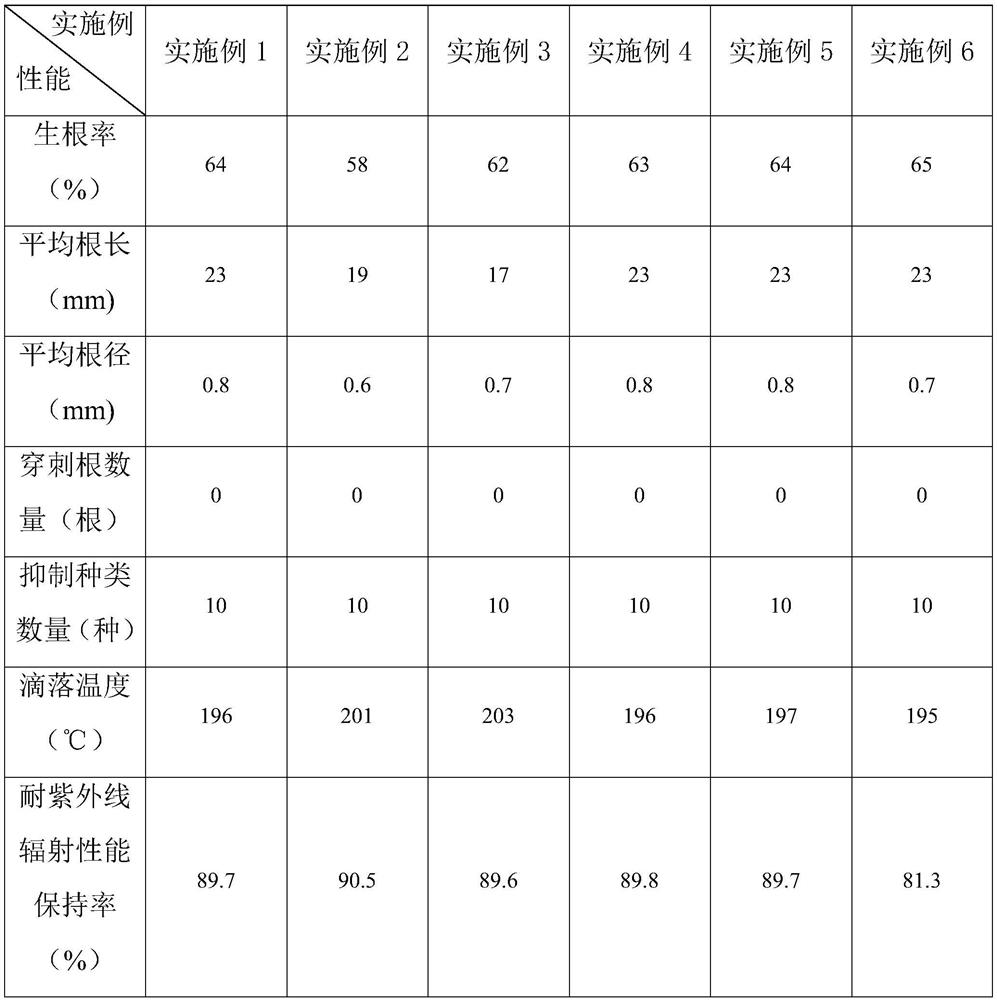

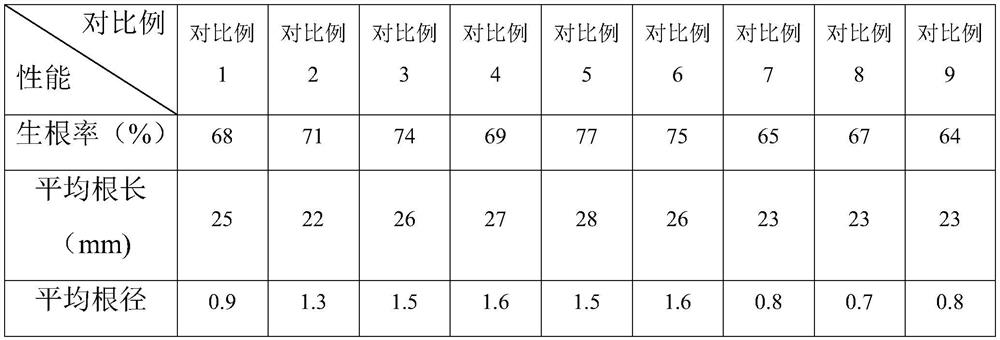

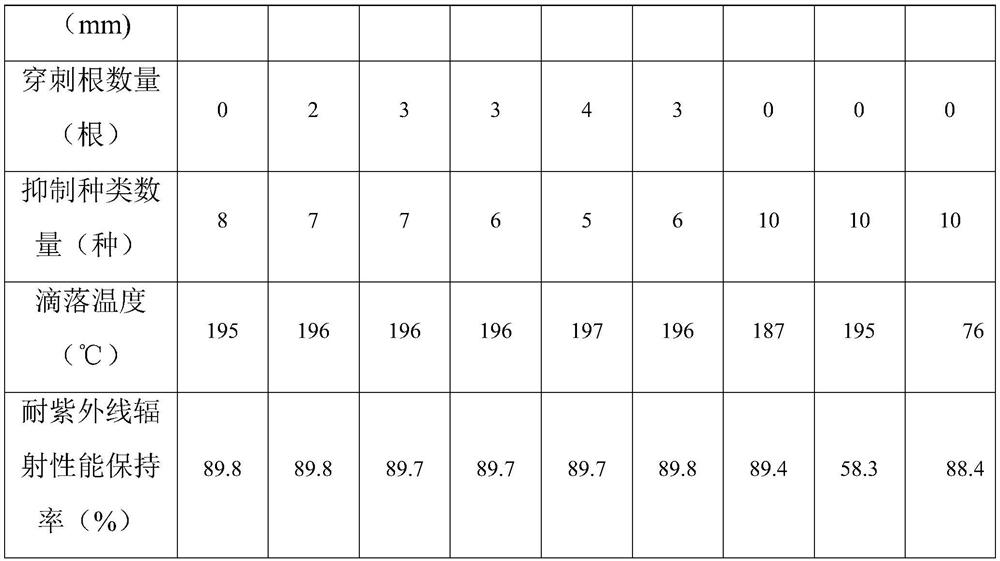

Modified asphalt waterproof membrane and preparation method thereof

ActiveCN112026294BImprove heat resistanceImprove corrosion resistanceSynthetic resin layered productsLaminationPolymer sciencePlant roots

The invention discloses a modified bitumen waterproof coiled material and a preparation method thereof. The film layer contains the following components by weight: 200-230 parts of PVC resin, 7-8 parts of light stabilizer, 10-12 parts of heat stabilizer, 65-80 parts of plant root inhibitor; the modified asphalt waterproof roll of the present invention The material has the advantages of being able to inhibit the growth of plant roots, reduce the possibility of being penetrated by plant roots, and have a longer service life.

Owner:上海建材集团防水材料有限公司

Semiconductor packaging mold, semiconductor device and packaging method for semiconductor device

ActiveCN109637939BReduce thicknessReduced likelihood of strippingSemiconductor/solid-state device detailsSolid-state devicesDevice materialSemiconductor package

The invention discloses a semiconductor packaging mold, a semiconductor device and a packaging method for the semiconductor device. The semiconductor packaging method includes providing a packaging substrate on which a plurality of chips are stacked; covering the chip with a packaging mold so that the chip accommodation cavity accommodates all the chips, and the outline surface shape of the chip accommodation cavity is adapted to the outline surface shape of the stacked chips; The encapsulation material is injected into the chip accommodation cavity through the injection hole. The fit of the chip accommodation chamber to the outer contour surface of the stacked chips makes the subsequently formed packaging material thinner and uniform in thickness, avoiding warping of the chip and the packaging material.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com