Sn-based sulfide and/or nitride modified tin oxide thin-film lithium battery negative electrode and preparation and application thereof

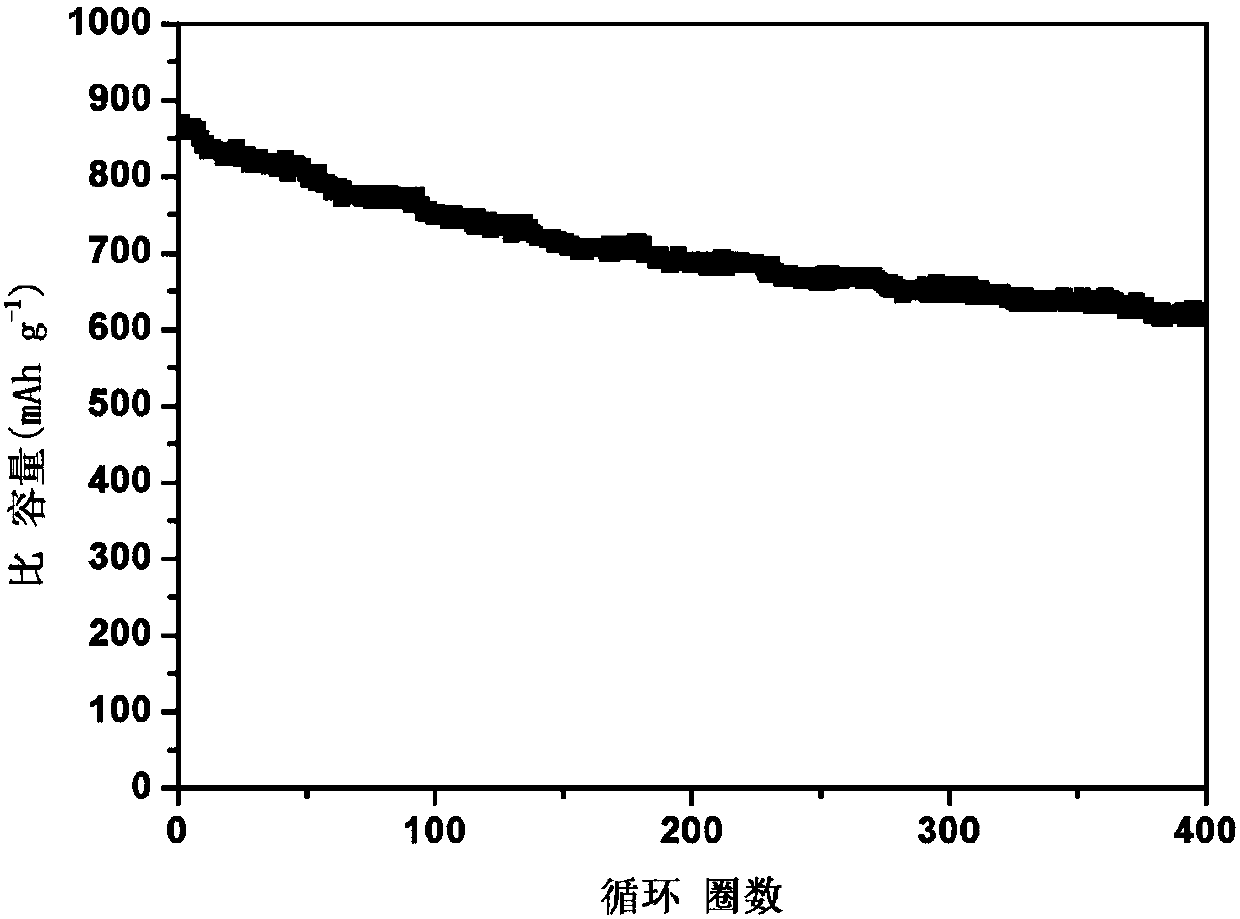

A sulfide, lithium battery technology, applied in battery electrodes, non-aqueous electrolyte battery electrodes, circuits, etc., can solve the problems of decreased electrode volume energy density, difficult control of structure and thickness of active material quality, and inability to play, to provide storage capacity. Lithium capacity, the effect of improving capacity and cycle performance, and improving energy density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0094] Soak the copper foil in 15wt% sulfuric acid for 12h, dry it with alcohol after cleaning and cut it into small pieces of 2cm×2cm. Fix the copper foil on the target stage, select Cr as the target material, and use Ar gas as the atmosphere, remove the baffle after pre-sputtering for 10mins, adjust the power to 80W, and sputter for 5mins. At this time, the thickness of the sputtered Cr layer is 40 nm.

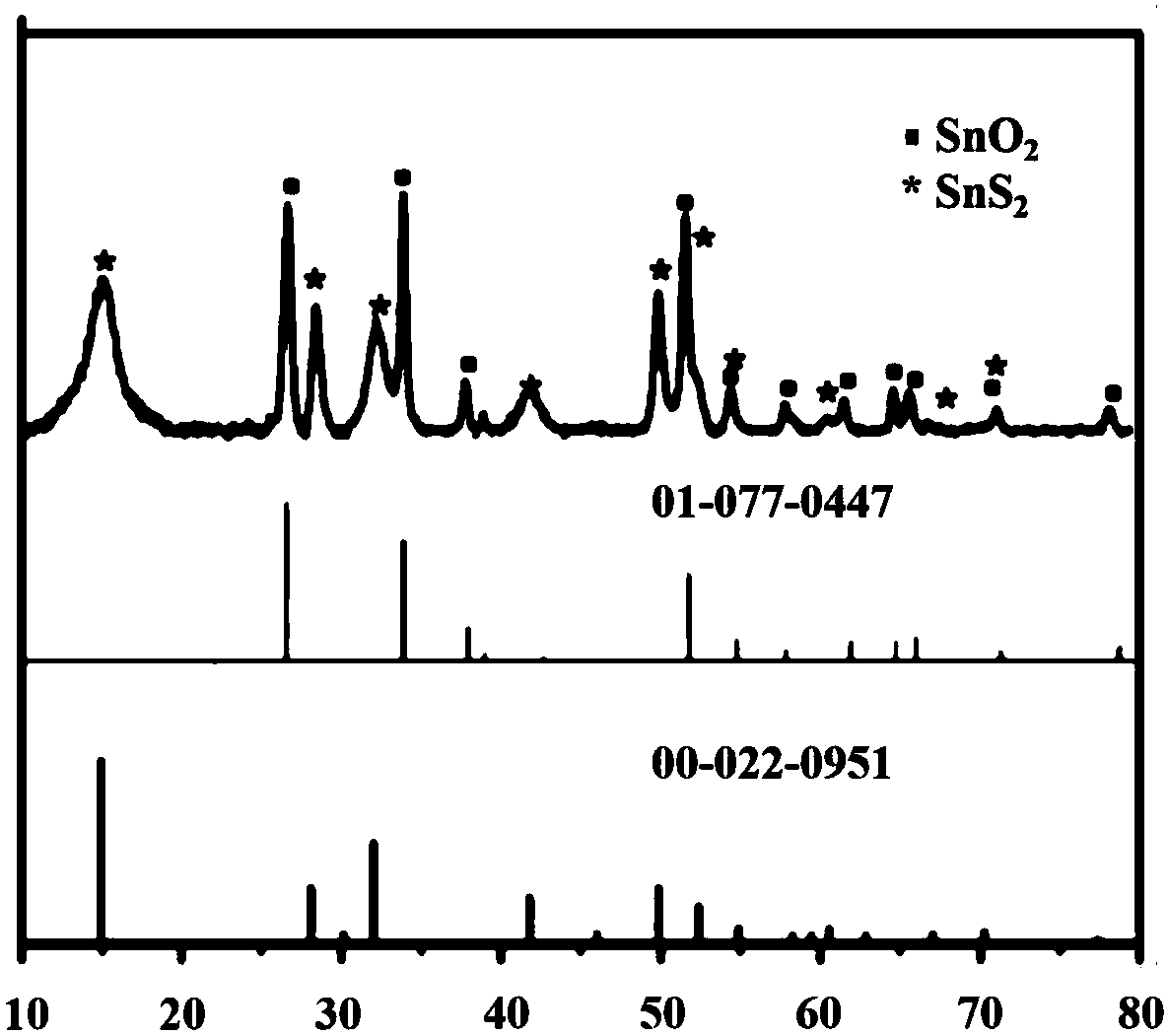

[0095] After the first sputtering, replace the target with Sn target, and adjust the atmosphere to Ar / O 2 (1:6), remove the baffle after pre-sputtering for 10mins, adjust the power to 60W, and sputter for 20mins to obtain 2 thin film copper foil. At this point sputtering SnO 2 The layer thickness is 200 nm. Continue to place the thin film electrode in the magnetron sputtering chamber, change the sputtering atmosphere to Ar / N 2 (1:1), remove the baffle after pre-sputtering for 10mins, adjust the power to 20W, and sputter for 15mins. Sputtering SnN at this time 0.8 The ...

Embodiment 2

[0100] Soak the copper foil in 10wt% sulfuric acid for 12h, dry it with alcohol after cleaning and cut it into small pieces of 2cm×2cm. Fix the copper foil on the target platform, use Ti as the target material, and Ar gas as the atmosphere, remove the baffle after pre-sputtering for 10mins, adjust the power to 50W, and sputter for 10mins. At this time, the sputtered Ti layer has a thickness of 18 nm.

[0101] After the first sputtering, replace the target with Sn target, and adjust the atmosphere to Ar / O 2 (1:2), remove the baffle after pre-sputtering for 10mins, adjust the power to 80W, and sputter for 10mins to obtain 2 thin film copper foil. At this point sputtering SnO 2 The layer thickness was 270 nm. Continue to place the thin film electrode in the magnetron sputtering chamber, change the sputtering atmosphere to Ar / N 2 (1:10), remove the baffle after pre-sputtering for 10mins, adjust the power to 30W, and sputter for 15mins. At this time, the thickness of the sput...

Embodiment 3

[0104] Soak the copper foil in 10wt% hydrochloric acid for 12 hours, dry it with alcohol after cleaning and cut it into small pieces of 2cm×2cm. Fix the copper foil on the target stage, select Pt as the target material, and use Ar gas as the atmosphere, remove the baffle after pre-sputtering for 10mins, adjust the power to 50W, and sputter for 7mins. At this time, the thickness of the sputtered Pt layer was 15 nm.

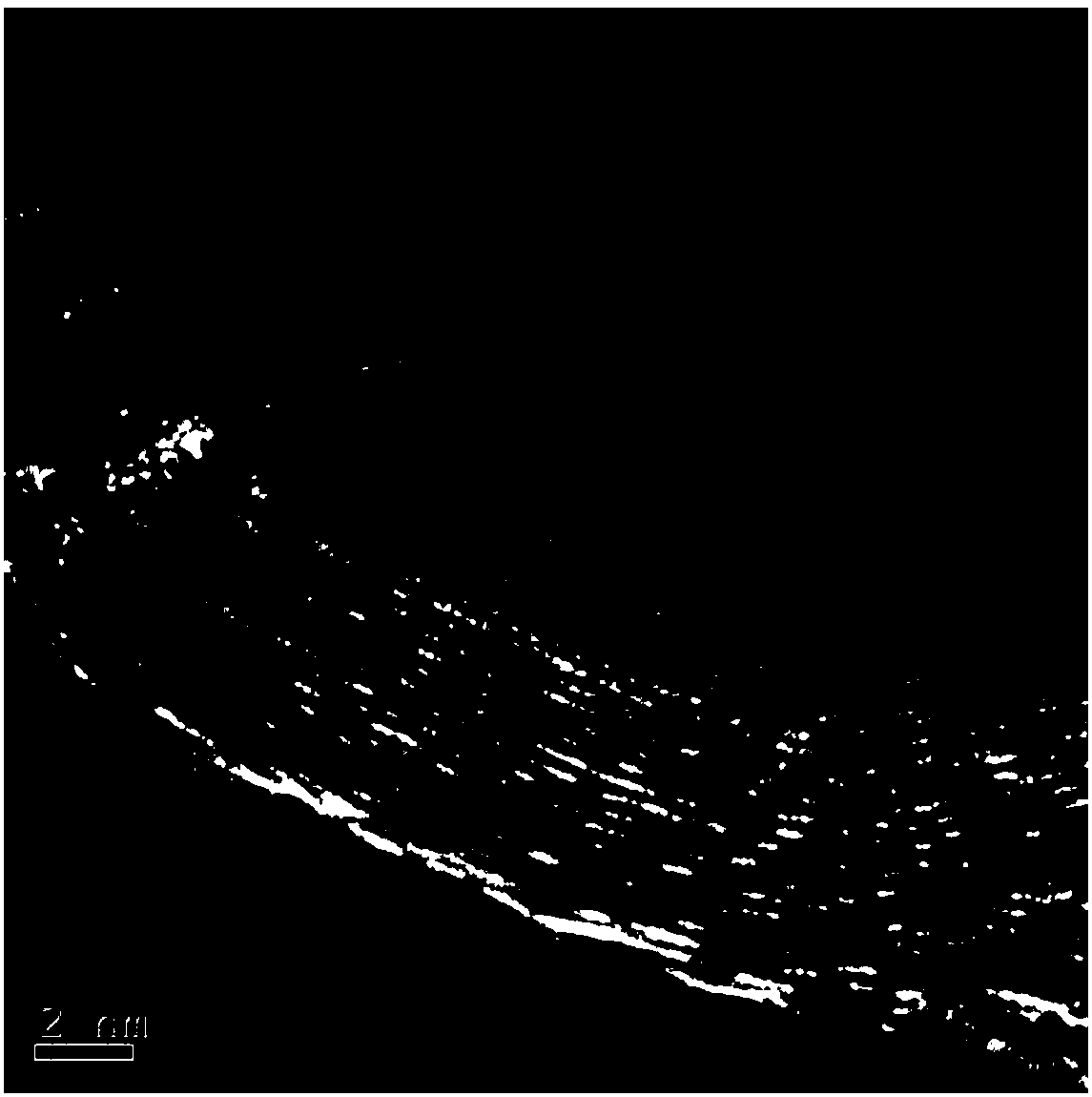

[0105] After the first sputtering, replace the target with Sn target, and adjust the atmosphere to Ar / O 2 (1:1), remove the baffle after pre-sputtering for 10mins, adjust the power to 40W, and sputter for 30mins to obtain 2 thin film copper foil. At this point sputtering SnO 2 The layer thickness was 350 nm. Continue to place the thin film electrode in the magnetron sputtering chamber, change the sputtering atmosphere to Ar / H 2 S (1:4), remove the baffle after pre-sputtering for 10mins, adjust the power to 40W, and sputter for 12mins. At this point the sputte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com